Getter for krypton and xenon gas purification and preparation method thereof

A getter and high-purity technology, applied in chemical instruments and methods, inert gas compounds, inorganic chemistry, etc., can solve the problems of small fluctuation range of oxygen and nitrogen compounds, failure to meet purity requirements, insufficient processing capacity, etc., and reach the fluctuation range The effect of large size, long service life and high utilization rate of zirconium

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example

[0030] The experimental device is a reaction tube with a heater, the getter is filled in the reaction tube, the filling thickness is 61mm, the inner diameter of the reaction tube is Φ25, and the air intake volume is 500ml / min

[0031] The experimental method is: before the experimental device is put into normal operation, the getter is activated first. The activation operation method is to heat up to 980°C in a vacuum state and maintain it for 6-8 hours to activate.

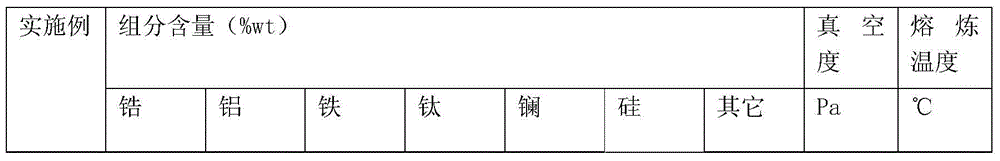

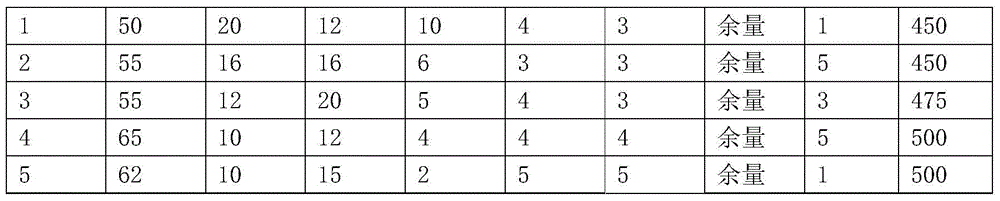

[0032] The experimental results are shown in Table 1 and Table 2:

[0033] Table 1 Content unit: 1×10 -6 mol / mol

[0034]

[0035] Table one is the multi-element alloy getter of the embodiment 1-5 of the present application and the traditional ZrAl as comparative example 16 Comparison of main impurity content in krypton gas after purification of getter (zirconium 84 ± 2%, aluminum: 16 ± 2%), other impurity content is negligible, wherein, fluorocarbon content in krypton gas is 150-220ppm (volume percentage )...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com