Green smelting method based on rhodochrosite leaching-purification

A smelting method and rhodochrosite technology, applied in the field of manganese metallurgy, can solve the problems of long leaching and purification process, low technical and economic indicators, large consumption of chemicals, etc., and achieve high impurity removal depth, good technical and economic indicators, and raw materials. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

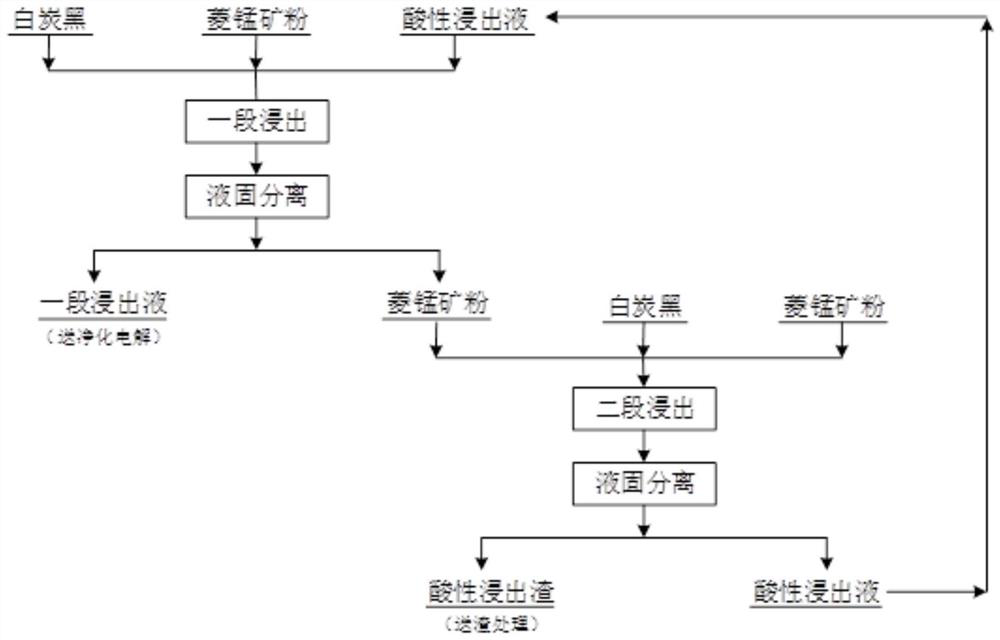

Method used

Image

Examples

Embodiment 1

[0031] One-stage leaching: add 1.05t rhodochrosite powder (Mn:27.69%, Fe:1.32%, Al:1.87%, SiO2:.10.76%), 3.5 kg white carbon black (-500 mesh) and 1.5m3 water, then start stirring, and add 6.1m3 of acidic leaching solution with a pH of 1.1 into the reactor at a feed rate of 5 m3 / h, and control the end point pH to 5.1. After the addition was complete, the stirring reaction was continued for 60 min, and then a section of leachate and a section of leach residue were obtained by filtration. Sampling and detection of the leach solution of the first stage showed that the concentrations of iron, aluminum and silicon in the leach solution of the first stage were 1.1, 36.6, and 22.7mg / L respectively, and the Mn content in the leaching residue of the first stage was 15.77%.

[0032] Second-stage leaching: Add 3.25 t of first-stage leaching residue (H2O:38%) and 1.5kg of white carbon black (-500 mesh) as seeds in the reactor, then start stirring, and put 6.5 m3 sulfuric acid acidity of 7...

Embodiment 2

[0034] One-stage leaching: add 0.96t rhodochrosite powder (Mn:27.69%, Fe:1.32%, Al:1.87%, SiO2:.10.76%), 1.8 kg white carbon black (-800 mesh) and 1.2m3 water, then start stirring, and add 7.2m3 of acidic leaching solution with a pH of 1.3 into the reactor at a feed rate of 8 m3 / h, and control the final pH to 4.8. After the addition was completed, the stirring reaction was continued for 45 min, and then a section of leachate and a section of leach residue were obtained by filtration. Sampling and testing of the first-stage leachate showed that the iron, aluminum, and silicon concentrations in the first-stage leachate were 1.1, 41.4, and 25.4 mg / L, respectively, and the Mn content in the first-stage leach residue was 13.88%.

[0035] Second-stage leaching: Add 2.86 t of first-stage leaching residue (H2O:38%) and 0.9kg of white carbon black (-800 mesh) as seed crystals in the reactor, then start stirring, and put 6.1 m3 of sulfuric acid acidity 75g / L anode The mixture of liquid...

Embodiment 3

[0037]One-stage leaching: add 1.15t rhodochrosite powder (Mn:27.69%, Fe:1.32%, Al:1.87%, SiO2:.10.76%), 4.2 kg white carbon black (-500 mesh) and 1.8m3 water, then start stirring, and add 5.5m3 of acidic leaching solution with a pH of 1.3 into the reactor at a feed rate of 5m3 / h, and control the end point pH to 5.5. After the addition was complete, the stirring reaction was continued for 75 min, and then a section of leaching solution and a section of leaching residue were obtained by filtration. Sampling and detection of the leach solution of the first stage showed that the concentrations of iron, aluminum and silicon in the leach solution of the first stage were 0.2, 7.6, and 3.2 mg / L respectively, and the Mn content in the leaching residue of the first stage was 18.21%.

[0038] Second-stage leaching: Add 3.04 t of first-stage leaching residue (H2O:39%) and 2.4kg of white carbon black (-800 mesh) as seed crystals in the reactor, then start stirring, and put 8.1 m3 of sulfur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com