Metal-modified 13X molecular sieve desulphurization adsorbent and its preparation method and use

A technology of metal modification and molecular sieve, applied in separation methods, non-metallic elements, chemical instruments and methods, etc., can solve the problems of harsh operating conditions, insufficient desulfurization depth, high operating costs, etc., achieve high activity at room temperature, reduce equipment investment, Effect of reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The preparation method of metal-modified 13X molecular sieve desulfurization adsorbent adopts the following steps:

[0037] (1) preparation concentration is that the cerium nitrate solution of 0.1mol / L is standby as active component ion exchange salt solution;

[0038] (2) Take 13X molecular sieve, add step (1) to obtain cerium nitrate solution, the mass ratio of 13X molecular sieve and cerium nitrate solution is 1:10, carry out ion exchange reaction, the reaction temperature of ion exchange is 20 ℃, ion exchange time is 48h , followed by filtration, washing, and drying at 100° C. for 12 h;

[0039] (3) Place the product obtained in step (2) in a tube furnace, and activate it by roasting under a nitrogen atmosphere. The roasting temperature rise rate is 2°C / min, the roasting temperature is 300°C, and the roasting time is 5h. After cooling in the furnace, That is, a metal ion-exchanged molecular sieve desulfurization adsorbent is obtained.

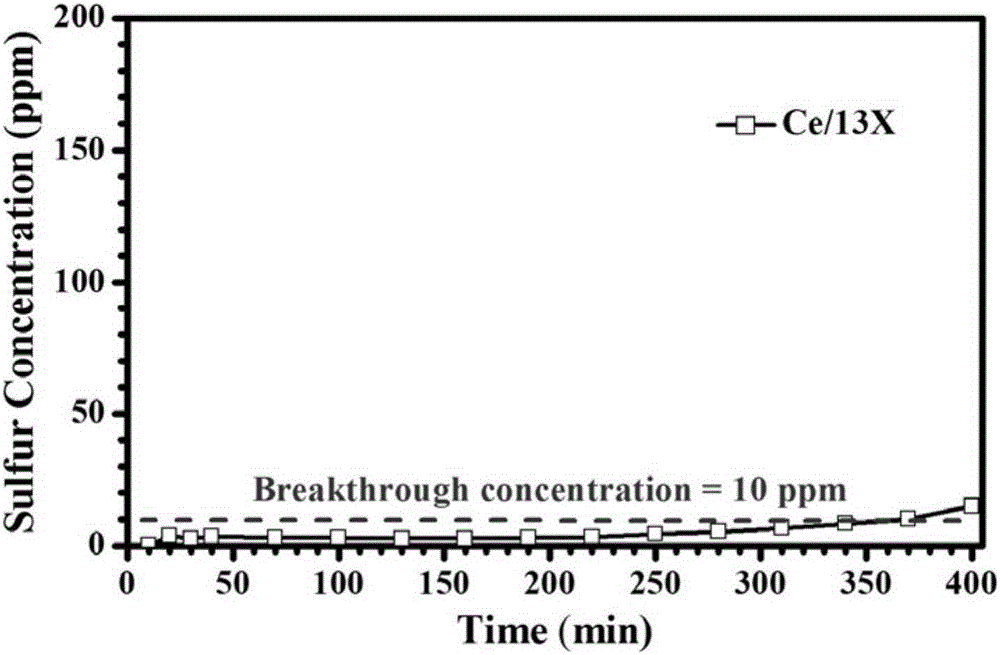

[0040] The prepared metal-m...

Embodiment 2

[0043] The preparation method of metal-modified 13X molecular sieve desulfurization adsorbent adopts the following steps:

[0044] (1) preparation concentration is that the cerium nitrate solution of 0.025mol / L is standby as active component ion exchange salt solution;

[0045] (2) Get 13X molecular sieve, add step (1) to obtain cerium nitrate solution, the mass ratio of 13X molecular sieve and cerium nitrate solution is 1:50, carry out ion exchange reaction, the reaction temperature of ion exchange is 90 ℃, ion exchange time is 2h , followed by filtration, washing, and drying at 120° C. for 6 h;

[0046] (3) Place the product obtained in step (2) in a tube furnace, and activate it by roasting under a nitrogen atmosphere. The heating rate of the roasting is 1°C / min, the roasting temperature is 700°C, and the roasting time is 1h. After cooling in the furnace, That is, a metal ion-exchanged molecular sieve desulfurization adsorbent is obtained.

[0047] The prepared metal-modi...

Embodiment 3

[0049] The preparation method of metal-modified 13X molecular sieve desulfurization adsorbent adopts the following steps:

[0050] (1) preparation concentration is that the cobalt nitrate solution of 0.2mol / L is standby as active component ion exchange salt solution;

[0051] (2) Take 13X molecular sieve, add step (1) to obtain cobalt nitrate solution, the mass ratio of 13X molecular sieve and cobalt nitrate solution is 1:30, carry out ion exchange reaction, the reaction temperature of ion exchange is 80 ℃, ion exchange time is 24h , followed by filtration, washing, and drying at 100° C. for 10 h;

[0052] (3) Place the product obtained in step (2) in a tube furnace and activate it by roasting under a nitrogen atmosphere. The roasting temperature rise rate is 5°C / min, the roasting temperature is 400°C, and the roasting time is 8h. After cooling in the furnace, That is, a metal ion-exchanged molecular sieve desulfurization adsorbent is obtained.

[0053] The prepared metal-mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com