Residual oil conversion combined process method

A combined process and residual oil technology, applied in the petroleum industry, hydrotreating process, processing hydrocarbon oil, etc., can solve the problems of complex equipment, low conversion rate of fixed bed, poor equipment stability, etc., to reduce the difficulty of reaction and harsh processing. The effect of improving the flow distribution and mass transfer, and improving the depth of impurity removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

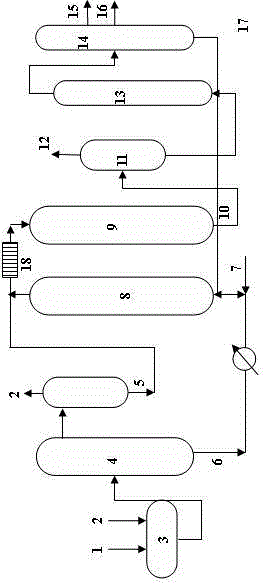

[0038] In this example, a combined process of solvent deasphalting, ebullating bed, fixed bed, and catalytic cracking is used to carry out hydroconversion of residual oil. First, the residual oil raw material and pentane solvent are uniformly mixed in a static mixer, and then enter a two-stage solvent deasphalting device to obtain deasphalted oil and deoiled asphalt. After preheating, the deoiled asphalt is mixed with hydrogen and enters the fluidized bed for hydrotreating The device performs hydrogenation reaction under the prepared fluidized bed hydrogenation catalyst and process conditions, removes sulfur, nitrogen, metal and other heteroatoms in the raw material, and at the same time converts asphaltenes into colloids or smaller molecules, reducing product viscosity , The hydrogenation product is separated to obtain a liquid-phase modified product oil, which is mixed with the deasphalted oil into a fixed-bed hydrogenation unit for reaction, and the product oil is obtained u...

Embodiment 2

[0053] Compared with Example 1, the ebullated bed reactor uses a mixed catalyst. The long-term stability of the fixed bed is good, see Table 4 for details, and the temperature of the fixed bed reactor was increased by 3°C at 5000, 8000 and 12000 hours.

[0054] Table 5 Stability results of the fixed bed hydrogenation reaction system.

[0055] Example Example 1 Example 2 Operating time, hours Final oil metal content (μg / g) / total pressure drop of fixed bed reaction system (MPa) Final oil metal content (μg / g) / total pressure drop of fixed bed reaction system (MPa) 500 13.1 / 0.08 11.0 / 0.08 5000 13.0 / 0.12 10.9 / 0.11 8000 12.7 / 0.13 11.5 / 0.12 12000 13.5 / 0.14 11.2 / 0.12

[0056] As can be seen from the stability experiment results of the above-mentioned fixed bed reaction system, the method of the present invention can realize the long-term stable operation of the fixed bed hydrotreating unit, and it can be predicted according to the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com