Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

52results about How to "High emulsifying activity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of emulsified stable type soy isolate protein

InactiveCN102578365AImprove emulsion stabilityHigh activityVegetable proteins working-upProtein solutionFreeze-drying

The invention relates to a preparation method of emulsified stable type soy isolate protein and belongs to the field of process technology of soy protein. The preparation method comprises the main steps as follows: preparing a soy isolate protein solution with the ratio of deionized water to soy isolate protein used as a raw material being (5-25):1 w / w; fully hydrating, and then stirring and preheating at 40-60 DEG C; regulating pH to be 6.5-7.5; adding papain for enzymolysis to obtain a sample of different hydrolysis degrees; then killing enzyme for 5 min at 90 DEG C; cooling to room temperature; regulating pH to be neutral; centrifuging; taking supernate to carry out freeze drying or spray drying; preparing a sample solution with the ratio of deionized water to the sample of different hydrolysis degrees being (5-25):1 w / w; preheating at 30-50 DEG C; regulating pH to be 7.0; adding transglutaminase to start crosslinking; after 1h, heating for 5 min at 80 DEG C to inactivate the enzyme; cooling to room temperature; then regulating pH to be neutral; centrifuging; taking supernate; and performing freeze drying or spray drying to obtain the highly emulsified stable type soy isolate protein. The preparation method for the emulsified stable type soy isolate protein is economic and effective; and the emulsion stability of the soy protein is remarkably improved.

Owner:JIANGNAN UNIV

Active thermophilic bacteria mutant strain and application thereof in oil displacement

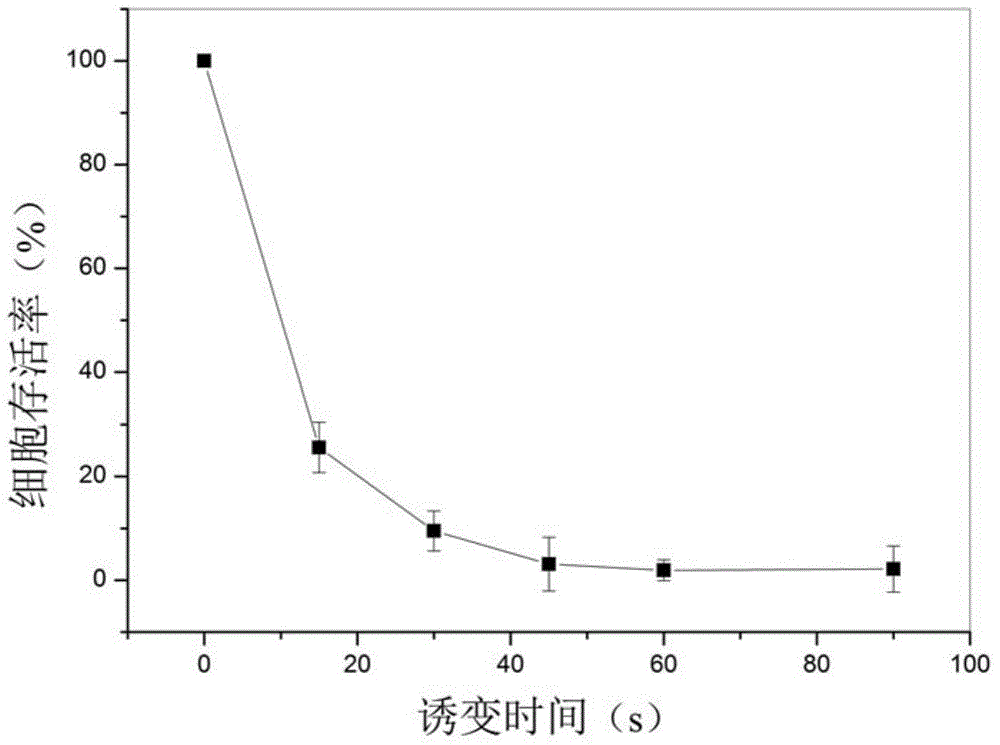

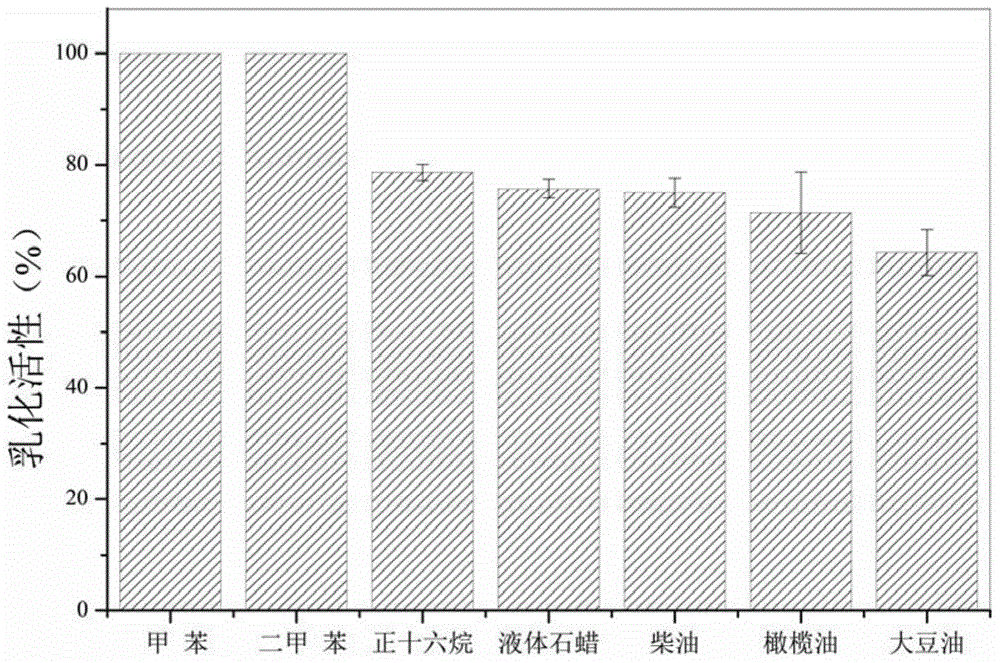

ActiveCN104152388AHigh emulsifying activityGood emulsification stabilityBacteriaMutant preparationWater contentMutagenic Process

The invention aims to provide an active thermophilic bacteria mutant strain and an application thereof in oil displacement. The invention provides an XS2-450 (Geobacillus sp.) which is obtained through normal-pressure room-temperature plasma mutagenesis to an original strain Geobacillus sp.XS2, wherein the Geobacillus sp.XS2 is assigned the accession number CGMCC No.9430. By means of the normal-pressure room-temperature plasma mutagenesis method to obtain the Geobacillus sp. XS2-450, emulsification activity of an emulsifying agent can be greatly increased and the emulsification activity on methylbenzene and dimethylbenzene can reach 100%. Emulsification stability is good. 70%-100% of the emulsification activity can be maintained after 30-day standing. The emulsification activity is not obviously reduced after serial passages of a strain being carried out for 20 times. The mutant strain Geobacillus sp. XS2-450 is subjected to industrially amplifying production in the invention and is applied in a pilot-scale experiment of a single well in an oil field. Oil production amount in Liu 55-4 oil well in Changqing oil field is increased by 12 times and water content in a produced liquid is reduced by more than 70%. The mutant strain has a great economic value and a potential in large-scale application.

Owner:TIANJIN INST OF IND BIOTECH CHINESE ACADEMY OF SCI

Fermented vegetable grease cosmetic composition having antioxidant effect

ActiveCN106420404AHigh emulsifying activityImprove emulsion stabilityCosmetic preparationsBody powdersSunflower seedChemistry

The present invention relates to a fermented vegetable grease cosmetic composition having an anti-oxidation effect, particularly to an anti-oxidation function cosmetic composition, which comprises fermented olive oil, jojoba oil, sunflower seed oil, rosehip oil, camellia oil, grape seed oil, green tea oil, macadamia oil and hazel nut oil. According to the present invention, the anti-oxidation function cosmetic composition with effects of prominent anti-oxidation ability, excellent emulsifying activity, excellent emulsifying stability, significantly-increased free fatty acid content, excellent use experience, and excellent moisturizing.

Owner:COSMAX CHINA INC +1

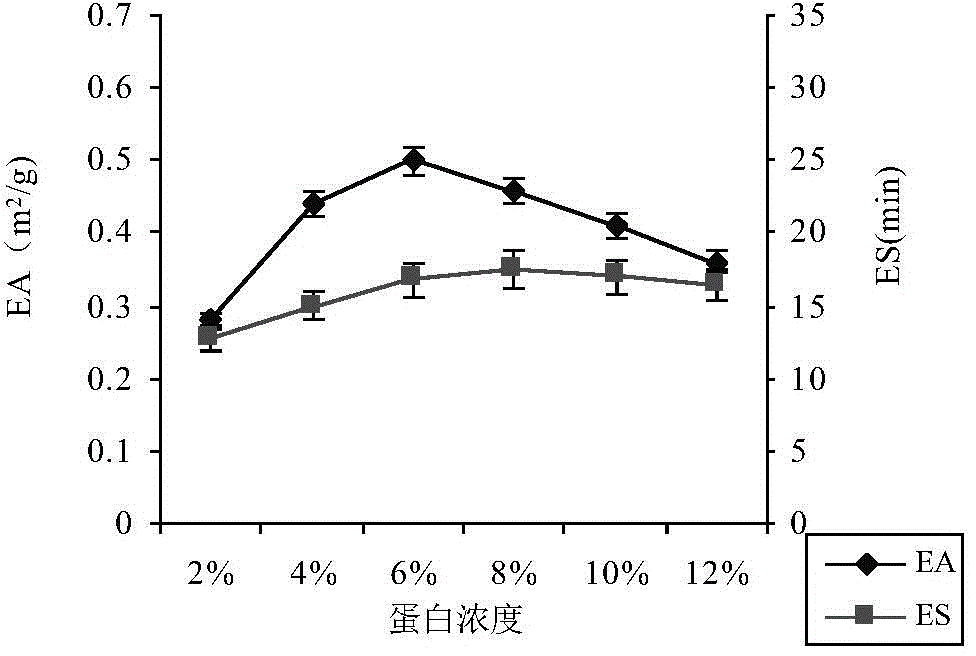

Method for improving emulsifying property of isolated soybean protein under acidic condition, and products of isolated soybean protein

InactiveCN104351463AHigh emulsifying activityGood emulsifying effectVegetable proteins working-upProteinase activityEmulsion

The invention discloses a method for improving the emulsifying property of isolated soybean protein under the acidic condition, and products of the isolated soybean protein, belonging to the field of modification of the isolated soybean protein. The method comprises the steps of (1) carrying out pretreatment on the isolated soybean protein by extrusion; (2) drying and crushing the product obtained by the treatment in the step (1), and then dissolving the product with water to obtain isolated soybean protein water solution; (3) feeding protease into the isolated soybean protein water solution, and carrying out an enzymolysis reaction; (4) carrying out enzyme deactivation, cooling, concentrating and drying to obtain the modified isolated soybean protein. The modified isolated soybean protein obtained by the modification method has the emulsifying property of 0.49m<2> / g when the pH value is 4, so that the emulsifying property of the modified isolated soybean protein is improved by 172% compared with the common isolated soybean protein; the emulsion stability of the modified isolated soybean protein is 16.2 minutes and is improved by 20% compared with the common isolated soybean protein; the modified isolated soybean protein prepared by the method can be applied to preparing dairy products, drink products, flour products, meat products, or the like.

Owner:SOYBEAN TECH DEV RES CENT HEILONGJIANG PROV

Feed for promoting intestinal development of meat chickens in fattening period

InactiveCN106509471AImprove developmentPromote peristalsisFood processingAnimal feeding stuffBiotechnologyRapeseed

The present invention discloses a feed for promoting intestinal development of meat chickens in a fattening period. The feed comprises the following raw materials in parts by weight: 3-7 parts of microcrystalline cellulose, 3-5 parts of modified soybean proteins, 4-6 parts of salted duck egg yolk, 3-7 parts of puffed soybeans, 4-10 parts of soybean cake, 12-20 parts of rapeseed meal, 12-18 parts of rapeseed cake, 4-8 parts of lard, 25-55 parts of corn, 10-16 parts of wheat, 3-9 parts of malt powder, 4-12 parts of corn stalks, 1.5-2.5 parts of vital gluten, 1.5-2.5 parts of coix chinensis, 1.5-2.5 parts of haw powder, 0.5-1.5 parts of unprocessed rehmannia roots, 1.5-2.5 parts of grape leaves, 0.6-1 part of barley malt, 0.4-1 part of red date, 1.5-2.5 parts of honey, 1.5-3.5 parts of spirulina platensis powder, 1.5-2.5 parts of soybean lecithin, 1-3 parts of malt selenium, 0.2-0.8 part of red chili powder, 0.4-0.8 part of vitamin, 1.5-2.5 parts of calcium hydrogen phosphate and 2-4 parts of stone powder.

Owner:岳从军

Method of covalent compound modification of potato protein and polysaccharide

InactiveCN104788686AReduce waste of resourcesEasy to expandVegetable proteins working-upSolubilityProtein solution

The invention discloses a method of covalent compound modification of potato protein and polysaccharide. The method comprises the following steps: a, mixing the potato protein and distilled water, preparing a 0.02-0.06g / ml potato protein solution, regulating pH (potential of hydrogen) of the potato protein solution to 7.5-8.5 with a NaOH solution, b, adding polysaccharide into the potato protein solution after pH regulation in Step a at a mass ratio of the potato protein to polysaccharide as 4:1-2:1, regulating pH (potential of hydrogen) to 7.5-8.5 with the NaOH solution, c, carrying out ultrasonic treatment on a mixed solution obtained in Step b, and d, drying the mixed solution after the ultrasonic treatment in Step c after vacuum freeze drying, transferring into a drier, putting a saturated KBr or KI solution at the bottom of the drier, putting the drier in an incubator for reaction to form a potato protein-polysaccharide covalent compound. The solubility, emulsification activity, stability and the like of the potato protein-polysaccharide covalent compound obtained by modification by the method are greatly improved.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

Method for reducing allergenicity of special soybean isolation protein of soy-based infant formula powder

ActiveCN102488075AAllergenicity reductionUnaffected or minimally affected by natural flavorProtein foodstuffs working-upWater bathsProtein solution

The invention discloses a method for reducing allergenicity of special soybean isolation protein of soy-based infant formula powder, belonging to the field of food safety. Soybean isolation protein prepared from non-transgenic and non-radiation soybean is used as the raw material; the special soybean isolation protein is subjected to compound modification by adopting an ultra-high static pressurenon-thermal physical method cooperatively with a compound enzyme method, therefore, the allergenicity of the special soybean isolation protein is obviously reduced; meanwhile, functionalities, such as an nitrogen soluble index, emulsifying activity, viscosity, thixotropy, in-vitro digestibility coefficient and the like, and nutritional quality are improved. Detailed parameters of the ultra-high static pressure and compound enzyme enzymatic treatment are as follows: weighing a certain amount of the soybean isolation protein, mixing and modulating the soybean isolation protein into 1-1.65% of uniform slurry, then, transferring the slurry into an aluminium foil bag, sealing, and vaccumizing; pre-heating an ultra-high static pressure water bath circulation device to 20-25 DEG C, then, puttingthe soybean isolation protein in an ultra-high static pressure processing cavity, increasing pressure to 315-385 MPa with the pressure increasing rate of 250 MPa / min, and keeping the pressure for 15-20 min with the pressure relieving rate of 300 MPa / min; and concentrating a soybean isolation protein solution in vacuum to 5-15%, then, transferring the soybean isolation protein solution into an enzymatic tank, adjusting the temperature of enzymatic liquid to 48-55 DEG C, adjusting a pH value of the enzymatic liquid to 6-7.5, wherein the use amount of special compound enzyme (preparing neutral protease and flavourzyme according to the mass ratio of 1:1 in a mixed and compound manner) is 1.5-2.5%; and the enzymatic time is 1.2-2.5 h; and then, obtaining a finished product by enzyme inactivating the enzymatic liquid, desalting, concentrating, atomizing and drying. When the product obtained by using the method disclosed by the invention is detected by ELISA (Enzyme-Linked Immuno Sorbent Assay), the allergen content is reduced by 87.49-90.75%.

Owner:兆隆康源(山西)生物科技有限公司

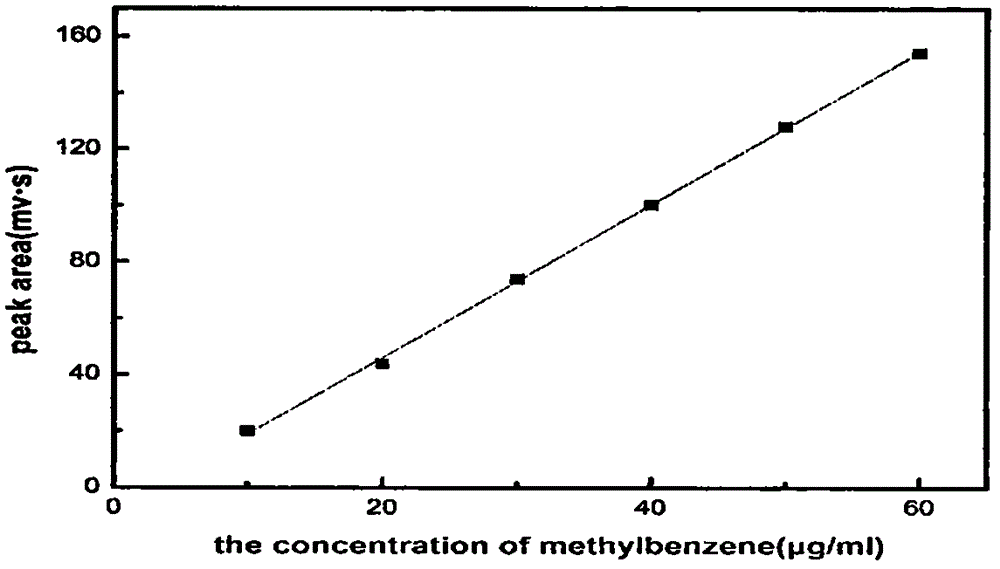

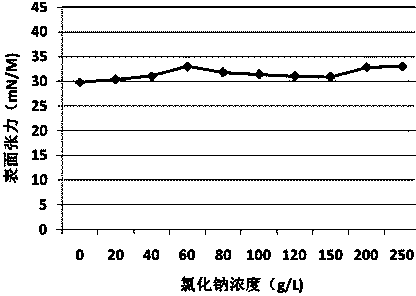

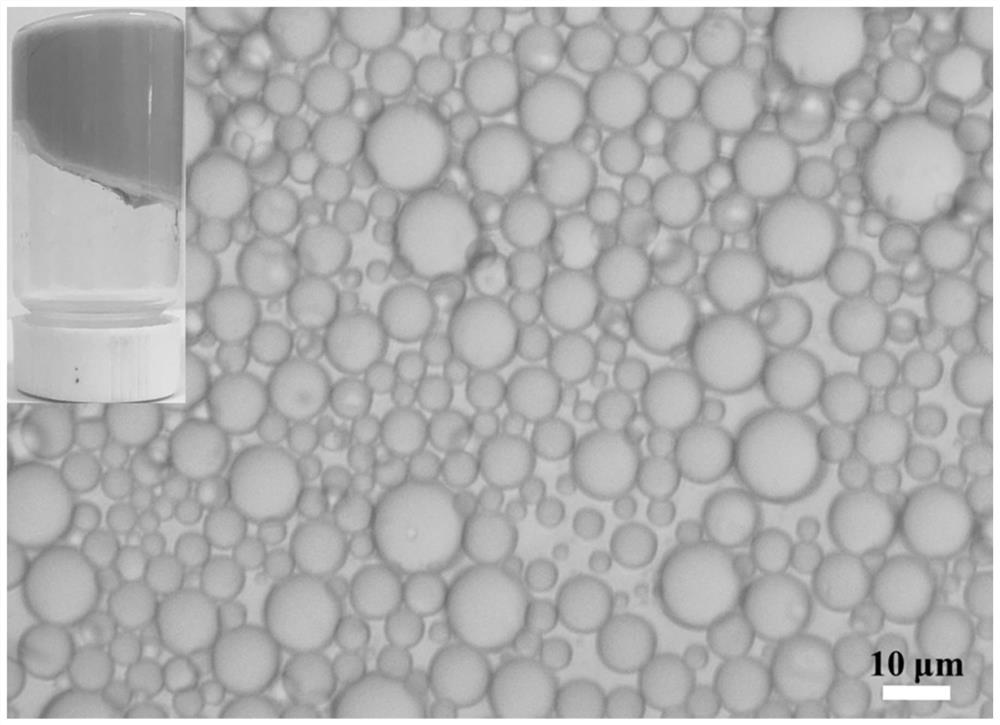

New Timone massilia strain and application thereof

InactiveCN106244499AReduce surface tensionGood ability to produce biosurfactantsBacteriaMicroorganism based processesPetroleum wastewaterPetroleum Pollution

The invention discloses a new strain-Timone massilia J42 and application thereof serving as a petroleum degrading strain in degrading petroleum wastewater. The new strain is obtained by separating from bottom sediment of a Xiang River sand excavating ship area. The strain has high bio-surfactant generating capability, emulsifying activity and liquid surface tension lowering capability. In addition, J42 methylbenzene degrading experiments show that the strain has quite high capability of degrading aromatic hydrocarbon methylbenzene. The strain also presents high COD removing efficiency in petroleum wastewater degrading experiments. The strain has good application prospect in the field of petroleum pollution bioremediation.

Owner:CECEP L&T ENVIRONMENTAL TECH

High-stability potato peptide emulsion and preparation method thereof

InactiveCN106962942AHigh emulsifying activityImprove emulsion stabilityFood ingredient as antioxidantFood homogenisationEmulsionVegetable oil

The invention discloses a high-stability potato peptide emulsion and a preparation method thereof. The preparation method of the potato peptide emulsion comprises the following steps that (1) a potato peptide water solution and vegetable oil are mixed, and a fresh emulsion is obtained after homogenizing; (2) the fresh emulsion is processed with a high pressure homogenizing cooperated with high static pressure method, and the high-stability potato peptide emulsion is obtained. The provided potato peptide emulsion has high emulsification stability and oxidation stability, can be taken as the raw material for preparing functional food, can improve the potato processed product added value and has a wide application prospect in the fields of foods, cosmetics and the like. The provided preparation technology is simple, and the high-stability potato peptide emulsion is easy for industrialization production.

Owner:INST OF AGRO FOOD SCI & TECH CHINESE ACADEMY OF AGRI SCI

Method for improving emulsifying activity of rapeseed protein

InactiveCN108441536AImprove emulsifying activitySimple production processPeptide preparation methodsFermentationWater contentChemistry

The invention discloses a method for improving emulsifying activity of rapeseed protein, and belongs to the technical field of rapeseed protein modification. The method comprises the following steps:1) adjusting the water content of rapeseed meal, and performing extrusion pretreatment after adjustment of the water content; 2) crushing and sieving the rapeseed meal after extrusion pretreatment, adding water and performing mixing to prepare a 5%-15% mixed liquor, adjusting pH and temperature, adding protease for enzymolysis, cooling a product to room temperature after enzymolysis, and adjustingpH to neutrality; 3) performing ultrafiltration treatment on an enzymatic hydrolysate to obtain rapeseed protein with molecular weight cutoff of 10-50 kDa, and performing concentrating and spray drying on the rapeseed protein with molecular weight cutoff of 10-50 kDa to obtain rapeseed protein with high emulsifying activity. The method has the characteristics of simple production process, low enzyme consumption, short enzymolysis time and low production cost.

Owner:SHAANXI UNIV OF SCI & TECH

Amino acid nanometer facial cleanser rich in soybean polysaccharides and preparation method thereof

ActiveCN110025558AReduce the amount of applicationReduce stimulationCosmetic preparationsToilet preparationsBetaineIrritation

The invention relates to an amino acid nanometer facial cleanser rich in soybean polysaccharides and a preparation method thereof. The amino acid facial cleanser comprises the following compositions:water, leucine, glycine, valine, serine, threonine, histidine, alanine, arginine, sericin, sodium methyl cocoyl taurate, cocoamidopropyl betaine, soybean polysaccharides, honey extract, tocopherol, ginger, phenoxyethanol and essence. The facial cleanser has the advantages that: a plurality of amino acids are used as raw materials, soybean polysaccharides are added after the amino acids are compounded, and the prepared amino acid nanometer facial cleanser rich in soybean polysaccharides not only can realize high-efficiency cleaning effect, but also can reduce the application amount of a surfactant and reduce skin irritation, has high safety, and can be used by children and for sensitive skins. The compounded amino acids are matched with the soybean polysaccharides so as to have better moisturizing and anti-sensitization effects. The facial cleanser has mild performance, good stability, and no irritation to skin.

Owner:BOHAI UNIV

Stable microemulsion based on modified perilla seed protein and preparation method of microemulsion

PendingCN111631297AImprove emulsifying activityGood stabilityVegetable proteins working-upProtein composition from waste materialsSucroseProtease

The invention discloses a stable microemulsion based on modified perilla seed protein and a preparation method of the microemulsion, and belongs to the technical field of protein modification. The method comprises the following steps: adjusting the moisture of perilla seed meal, performing extrusion pretreatment, then performing crushing and sieving, adding water, performing mixing to prepare a perilla seed meal mixed solution, adjusting the pH value and temperature, adding protease, carrying out enzymolysis, performing cooling to room temperature, adjusting the pH value to neutrality, carrying out ultrafiltration treatment to obtain perilla seed protein with the molecular weight cutoff of 30-100kDa, and performing concentrating and drying to obtain the perilla seed protein with emulsifying activity; and uniformly mixing perilla seed protein, sucrose ester, flaxseed gum and polyglycerol ester, then adding flaxseed oil and a preservative, and finally, performing high-speed shearing emulsification and high-pressure homogenization to obtain the stable microemulsion. The preparation method is simple in production process, small in required enzyme dosage and low in production cost, andthe prepared microemulsion is good in stability.

Owner:SHAANXI UNIV OF SCI & TECH

Pseudomonas for producing lipopeptide surfactant and purpose

ActiveCN103865819AGood emulsifying activityAbility to reduce surface tensionBacteriaMicroorganism based processesChemistryLipopeptide

The invention provides pseudomonas for producing a lipopeptide surfactant and a biosurfactant by using the bacterial strain. The provided biosurfactant can be used for oil extraction industrial, environmental biology restoration field and / or food industry.

Owner:WILMAR SHANGHAI BIOTECH RES & DEV CENT

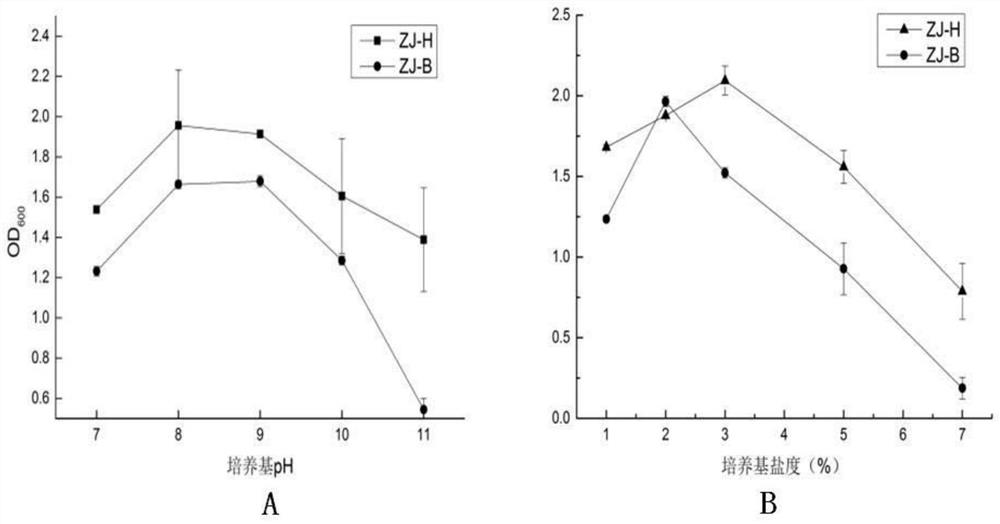

Arthrobacter strain ZJ-H and application thereof

ActiveCN110551662AImprove degradation rateHigh emulsifying activityBacteriaWater contaminantsAlkaneMetabolite

The invention provides an arthrobacter strain ZJ-H and an application of the arthrobacter strain ZJ-H to the degradation of petroleum hydrocarbons in a high-saline-alkali environment. The strain ZJ-His selected from oil-based drilling cutting samples of the Bohai sea oilfield, which are provided by a China sea petroleum Bihai environmental protection technology service company. The strain ZJ-H isstrong in tolerance to the high-saline-alkali environment and can normally survive in the environment with the salinity of 1-5% and the pH value of 7-11; the strain ZJ-H has relatively high petroleumdegradation rate in the saline-alkali environment, which reaches 74.45%; a metabolic product of the strain ZJ-H has relatively high emulsifying activity, has a good emulsifying effect on petroleum ether, and is beneficial to further decomposition and utilization of the petroleum ether by the strain; and the strain ZJ-H has a good degradation capability for n-alkanes (including long-chain alkanesof C20-C30) in raw petroleum, the degradation rate exceeds 83%, and especially, the degradation rate of C25-C30 reaches about 95%.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Green preparation method of food-grade multifunctional lignin/silicon dioxide nanoparticle emulsifier

PendingCN113367323AGreat application potentialHigh emulsifying activityCosmetic preparationsToilet preparationsFreeze-dryingSio2 nanoparticle

The invention discloses a green preparation method of a food-grade multifunctional lignin / silicon dioxide nanoparticle emulsifier. The green preparation method comprises the following steps of dissolving enzymatic hydrolysis lignin in a sodium hydroxide aqueous solution, centrifuging to remove insoluble impurities, then adjusting the pH value to be neutral, centrifuging again to remove water-insoluble lignin, dialyzing, and freeze-drying to obtain water-soluble lignin for later use; weighing SiO2 nanoparticles, dispersing the SiO2 nanoparticles in water, adding a chitosan solution, stirring for a period of time, centrifuging to remove supernatant liquid, cleaning residual solids with ultrapure water, dispersing the particles in water again, adding the water-soluble lignin, stirring, centrifuging to remove supernatant liquid, cleaning residual solids with ultrapure water, and obtaining the final sample through freezing and drying. A new method is provided for green preparation of the multifunctional food-grade emulsifier, and the application potential of lignin and SiO2 in the field of food is expanded.

Owner:ZHEJIANG SCI-TECH UNIV

Food-grade temperature-sensitive Pickering emulsion and preparation method thereof

InactiveCN112741299AChange stabilitySensitive to temperatureFood shapingFood ingredient as emulsifierControlled releaseFood grade

The invention provides a food-grade temperature-sensitive Pickering emulsion and a construction method thereof, and belongs to the technical field of emulsion preparation. The temperature-sensitive Pickering emulsion comprises edible wax modified starch nanocrystals, flavor components and water. The preparation method comprises the following steps of mixing the edible wax modified starch nanocrystals with the flavor components and the water so as to obtain mixed liquor, then performing high-speed dispersion, and dispersing the mixed liquor through combination of high-pressure homogenizing or high-pressure microjet so as to obtain the temperature-sensitive Pickering emulsion. The Pickering emulsion prepared by the preparation method disclosed by the invention can be used as a safe and effective flavor component slow and controlled release system.

Owner:JIANGNAN UNIV

Method for preparing high-emulsibility egg white emulsion

ActiveCN110122655ALow viscosityImprove liquidityProteins working-up by texturisingAnimal proteins working-upOrganic acidAnimal science

The invention discloses a method for preparing a high-emulsibility egg white emulsion. The method includes: preprocessing egg white, performing Co-60 gamma ray processing, adding organic acid, preparing the egg white emulsion and the like. The method has the advantages that the problems that a traditional method is complex in egg white emulsion processing process, poor in emulsifying stability andthe like are solved, and a new method which is simple, efficient, green and environmentally friendly, safe, reliable and high in additional value is established.

Owner:HUAZHONG AGRI UNIV

Cable sheath material of thermocouple for methanation device

InactiveCN107312207AHigh emulsifying activityHigh bonding strengthRubber insulatorsMethanationPolyethylene glycol

The invention discloses a cable sheath material of a thermocouple for a methanation device. The cable sheath material comprises the following raw materials in parts by weight: 70-80 parts of a main material, 1-2 parts of a sulfurizing agent, 0.1-0.6 part of di(dioctyl pyrophosphate) oxotitanate, 2-4 parts of vinyl triethoxysilane, 50-60 parts of a filling and reinforcing material, 1-2 parts of polyethylene glycol, 1-2 parts of chlorinated paraffin and 1-3 parts of a stabilizer, wherein the filling and reinforcing material comprises the following components in parts by weight: 16-22 parts of a Tara gum compound, 2-8 parts of carbon nanotube, 2-4 parts of graphene, 6-10 parts of nanometer titanium dioxide, 2-5 parts of glass fiber, 2-8 parts of nanometer silicon dioxide. The cable sheath material is excellent in high temperature resistance and aging resistance and extremely good in oil resistance and ozone resistance and has extremely strong impact resistance and balanced toughness and hardness.

Owner:安徽吉安特种线缆制造有限公司

Special emulsifier for rosin emulsion

The invention discloses a special emulsifier for rosin emulsion and belongs to the technical field of rosin deep processing. The emulsifier is prepared from, by weight, 5-8 parts of cardanol, 1-2 parts of polyethylether modified trisiloxane, 6-10 parts of ethyl alcohol, 0.1-0.2 part of lignin sulfonate, 15-25 parts of sodium lauryl sulfate and 10-15 parts of deionized water with the electric conductivity smaller than 5 microseconds per centimeter. The emulsifier is prepared with cardanol, polyethylether modified trisiloxane, ethyl alcohol, lignin sulfonate, sodium lauryl sulfate and deionized water with the electric conductivity smaller than 5 microseconds per centimeter as the raw materials. The emulsifier is used for preparing the rosin emulsion and has the advantages of being high in activity and high in stability.

Owner:GUANGXI RONGSHUI MINXING RESIN CO LTD

High-performance degradable polypropylene composite material for water horse

The invention discloses a high-performance degradable polypropylene composite material for a water horse. The high-performance degradable polypropylene composite material is prepared from the following raw materials in parts by weight: 80-120 parts of polypropylene, 1-2 parts of a nucleating agent, 3-5 parts of a plasticizer, 2-8 parts of glass fibers, 4-10 parts of wool fibers, 2-6 parts of coconut fibers, 1-6 parts of roasted kaolin, 2-4 parts of diatomite, 1-2 parts of tetrabutyl titanate, 1-2 parts of a stabilizer, 1-2 parts of a lubricating agent and 1-2 parts of an anti-ageing agent. Theplasticizer is prepared from the following components in parts by weight: 1-2 parts of castor oil compound, 1-2 parts of epoxy fatty acid methyl ester and 0.5-1 part of disproportionated rosin. The castor oil compound is prepared from the following process: mixing castor oil, hydrogen peroxide and formic acid, heating up and stirring, adding cocoalkanoylamido propyl betaine and a neutral phosphate buffer solution to uniformly stir, and adding soybean proteins to homogenize, thereby obtaining the caster oil compound.

Owner:芜湖盈奇塑业有限公司

Preparation method of modified phosphatide-soybean protein composite emulsion

ActiveCN105146052AImprove synergyHigh emulsifying activityVegetable proteins working-upPhosphatide foodstuff compositionsPhosphoric acidEmulsion

The invention relates to a preparation method of modified phosphatide-soybean protein composite emulsion, and belongs to the field of fine and deep processing of soybean protein. The method comprises the following steps: (1) dissolving soybean lecithin in distilled water so as to obtain a phosphatide solution, preheating the phosphatide solution, performing pulsed electric field treatment on the preheated phosphatide solution, carrying out vacuum freeze-drying, and dissolving the obtained material in a phosphoric acid buffer solution so as to obtain a modified phosphatide solution; (2) dissolving soy protein isolate in the phosphoric acid buffer solution so as to obtain a soybean protein solution; and (3) mixing and stirring the modified phosphatide solution and the soybean protein solution so as to obtain mixed liquor, adding olive oil to the mixed liquor, and performing homogenizing treatment on the mixed liquor and the olive oil so as to obtain the composite emulsion. The method is simple in technology and safe to operate; the soybean lecithin is modified through a pulsed electric field, and then the modified soybean lecithin and the soybean protein are composited, so that the prepared composite emulsion is high in emulsifying activity, high in emulsifying stability, and safe and harmless, and has better application prospects.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

Method for improving perilla seed protein emulsifying activity

ActiveCN109880873AEasy to modifyGood effectPeptide preparation methodsFermentationRoom temperatureProtease

The invention discloses a method for improving the perilla seed protein emulsifying activity, and belongs to the technical field of perilla seed protein modification. The method comprises the following steps that 1, perilla seed meal is subjected to water conditioning, and after water conditioning, ultrahigh-pressure pretreatment is conducted; 2, the perilla seed meal obtained after ultrahigh-pressure pretreatment is smashed, screened and mixed by adding water to prepare a 4-20% mixed liquid, pH and temperature are adjusted, enzymolysis is conducted by adding protease, after enzymolysis, temperature is lowered to the room temperature, and the pH value is adjusted to be neutral; 3, the enzymolysis liquid is subjected to ultrafiltration, perilla seed protein with the molecular weight cut-offof 5-30 kDais obtained, the perilla seed protein is subjected to concentration and spray drying, and the perilla seed protein high in emulsifying activity is prepared. The method has the advantages that the production process is simple, the required enzyme using amount is low, the enzymolysis time is short, and the production cost is low.

Owner:SHAANXI UNIV OF SCI & TECH

Preparation method of low-methoxy hawthorn pectin

ActiveCN112210022AHigh purityHigh Galacturonic Acid (GalA) ContentPreparing sample for investigationFood ingredientsBiotechnologyAmylase

The invention relates to a preparation method of low-methoxy hawthorn pectin, in particular to a method for extracting, separating and purifying hawthorn pectin from hawthorn, namely a method for preparing low-methoxy hawthorn pectin (LMP) by taking amylase and amyloglucosidase as processing aids. Pectin esterase treatment is not used in the implementation process of the method, the pectin prepared through the method is high in purity, high in galacturonic acid content and large in linear polygalacturonic acid area proportion, and the molecular weight of the pectin is remarkably lower than that of hawthorn pectin prepared without the purification treatment process. The method is suitable for preparing the LMP by taking all types of hawthorns and processing byproducts thereof as raw materials, and is not influenced by the varieties, producing areas and maturity of the hawthorns, hawthorn processing byproducts comprise hawthorn waste residues obtained after hawthorn beverage processing,hawthorn waste residues obtained after hawthorn wine processing and the like, waste can be turned into wealth, and social and economic benefits are remarkable.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

Preparation method of special emulsifier for rosin emulsion

ActiveCN105944621BHigh emulsifying activityImprove stabilityTransportation and packagingMixingDiethyl etherSodium sulfate

Owner:GUANGXI RONGSHUI MINXING RESIN CO LTD

Power cable with excellent mechanical performances

InactiveCN106977802AGood antifoulingImprove the bactericidal effectPlastic/resin/waxes insulatorsCyclohexanoneBenzoyl peroxide

The invention discloses a power cable with excellent mechanical performances, the power cable includes a conductor and a sheath layer coating the outer side of the conductor; the sheath layer comprises the following raw materials by weight: 38-48 parts of ethylene-vinyl acetate polymer, 30-40 parts of chlorinated polyethylene, 1.5-2.5 parts of tricresyl phosphate, 1-2 parts of microcrystalline wax, 24-32 parts of diatomite, 6-10 parts of sepiolite powder, 45-65 parts of white carbon black, 13-17 parts of glass bead, 4-10 parts of wollastonite, 20-30 parts of modified bentonite, 3-5 parts of zinc oxide, 0.4-0.8 part of Triallyl isocyanurate, 0.4-1 part of peroxide cyclohexanone, 0.8-1.6 parts of benzoyl peroxide, 0.5-1 part of antioxidant AW and 1.5-2.5 parts of antioxidant NBC. The power cable with excellent mechanical performances has excellent waterproof property, excellent bactericidal and bacteriostatic performances and excellent mechanical performances.

Owner:JINYUAN ELECTRIC GRP

Light-weight high-toughness PVC foamed trough plate for display panel

InactiveCN106674804AGood wear resistanceGood mechanical propertiesBuilding insulationsBenzimidazolePolypropylene

The invention discloses a light-weight high-toughness PVC foamed trough plate for a display panel. The trough plate comprises the following raw materials in parts by weight: 50-70 parts of PVC resin, 4-8 parts of polytetrafluoroethylene, 4-10 parts of polypropylene, 0.8-1.2 parts of dibenzoyl peroxide, 1.5-2.5 parts of 2-thiol benzimidazole, 0.3-0.9 part of pyromellitic dianhydride, 1.5-2.5 parts of coal tar, 0.4-1 part of dibutyl phthalate, 1.5-2.5 parts of stearic acid, 1-2 parts of triphenyl phosphate, 0.4-1 part of disproportionated rosin, 4-8 parts of ceramic microspheres, 4-8 parts of polyamide fibers, 3-7 parts of glass beads, 20-30 parts of zeolite power compound kapok fibers, 4-8 parts of a silane coupling agent KH550, 6-10 parts of white carbon black, 4-8 parts of magnesium hydroxide, 3-7 parts of a foaming agent, 1.5-2.5 parts of an ultraviolet absorbent and 1-2 parts of an anti-aging agent.

Owner:安徽优丽普科技有限公司

Arthrobacter strain zj-h and its application

ActiveCN110551662BStrong toleranceImprove degradation rateBacteriaWater contaminantsAlkaneArthrobacter

The invention provides an Arthrobacter strain ZJ-H and its application in degrading petroleum hydrocarbons in a high-saline environment. Strain ZJ‑H was screened from oil-based drilling cuttings samples from Bohai Oilfield, provided by CNOOC Bihai Environmental Technology Service Company. Strain ZJ‑H has a strong tolerance to high saline-alkali environment, and can survive normally in an environment with a salinity of 1-5% and a pH of 7-11; strain ZJ-H has a high degradation rate of petroleum in a saline-alkali environment , reaching 74.45%; the metabolites of bacterial strain ZJ‑H have better emulsifying activity, and have good emulsifying effect on petroleum ether, which is beneficial to the further decomposition and utilization of bacterial strain to petroleum ether; Long-chain alkanes including C20-C30) have good degradation ability, the degradation rate exceeds 83%, especially the degradation rate of C25-C30 reaches about 95%.

Owner:TIANJIN UNIV OF SCI & TECH

Waterproof polyethylene cable material excellent in mechanical property

InactiveCN106750797AImprove liquidityImprove mechanical propertiesPlastic/resin/waxes insulatorsCyclohexanoneMicrosphere

The invention discloses a waterproof polyethylene cable material excellent in mechanical property. The material is prepared from, by weight, 30-50 parts of polyethylene, 15-25 parts of polystyrene, 8-16 parts of low-density polypropylene, 0.5-1.2 parts of aluminic acid ester coupling agent, 1-2 parts of maleic anhydride grafted polypropylene, 0.5-1.2 parts of trimethylolethane, 2-8 parts of modified activated zeolite powder, 2-4 parts of zinc sulfide, 2-6 parts of ceramic microspheres, 1-3 parts of boric oxide, 1-3 parts of antimony trioxide, 4-8 parts of ethylene propylene terpolymer, 2-4 parts of glycollic amide, 2-3 parts of cyclohexanone peroxide, 1-2 parts of ammonium pyrophosphate, 1-2 parts of silicone batch, 0.5-1.5 parts of dimethyl phthalate, 0.5-1.5 parts of pentaerythritol, 0.5-1.5 parts of diphenylamine and 1-2 parts of di-iso-decylphthalate. The material is excellent in mechanical property, not easy to tear and good in waterproof prevention and acidic salt and alkaline salt resistance.

Owner:安徽新立电缆材料有限公司

A kind of multilayer embedded solid lipid calcium particle

ActiveCN107549801BEvenly distributedImprove bioavailabilityFood shapingLiposomal deliverySodium CaseinateMolecular biology

The invention discloses multi-layer embedded solid lipid calcium particles. The multi-layer embedded solid lipid calcium particles are made from the following raw materials of 0.5-2 parts by weight ofinsoluble or micro-soluble calcium, 0.5-2 parts by weight of fatty acid esters, 0.05-0.3 part by weight of sodium caseinate and 0.5-3 parts by weight of Indian gum. According to the multi-layer embedded solid lipid calcium particles disclosed by the invention, the physical and chemical characteristics of the fatty acid esters, the sodium caseinate and the Indian gum are fully utilized, and the fatty acid esters, the sodium caseinate and the Indian gum are used for embedding a calcium source according to a specific sequence by a specific method, so that the multi-layer embedded solid lipid calcium particles high in biological availability, favorable in mechanical properties and favorable in processing characteristics are obtained.

Owner:FERGUSON WUHAN BIOTECH

A kind of method for preparing highly emulsifying egg white emulsion

ActiveCN110122655BLow viscosityImprove liquidityProteins working-up by texturisingAnimal proteins working-upBiotechnologyOrganic acid

The invention discloses a method for preparing highly emulsifying egg white emulsion, which comprises the steps of egg white pretreatment, Co-60 gamma ray treatment, adding organic acid, preparation of egg white emulsion and the like. The invention solves the problems of cumbersome egg white emulsion treatment process, poor emulsification stability and the like in the traditional method, and establishes a new method which is simple, efficient, green, safe, reliable and has high added value.

Owner:HUAZHONG AGRI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com