Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

46results about How to "High accuracy of shape and size" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Heat forming method for aluminum alloy sheet metal part after solid solution and water quenching

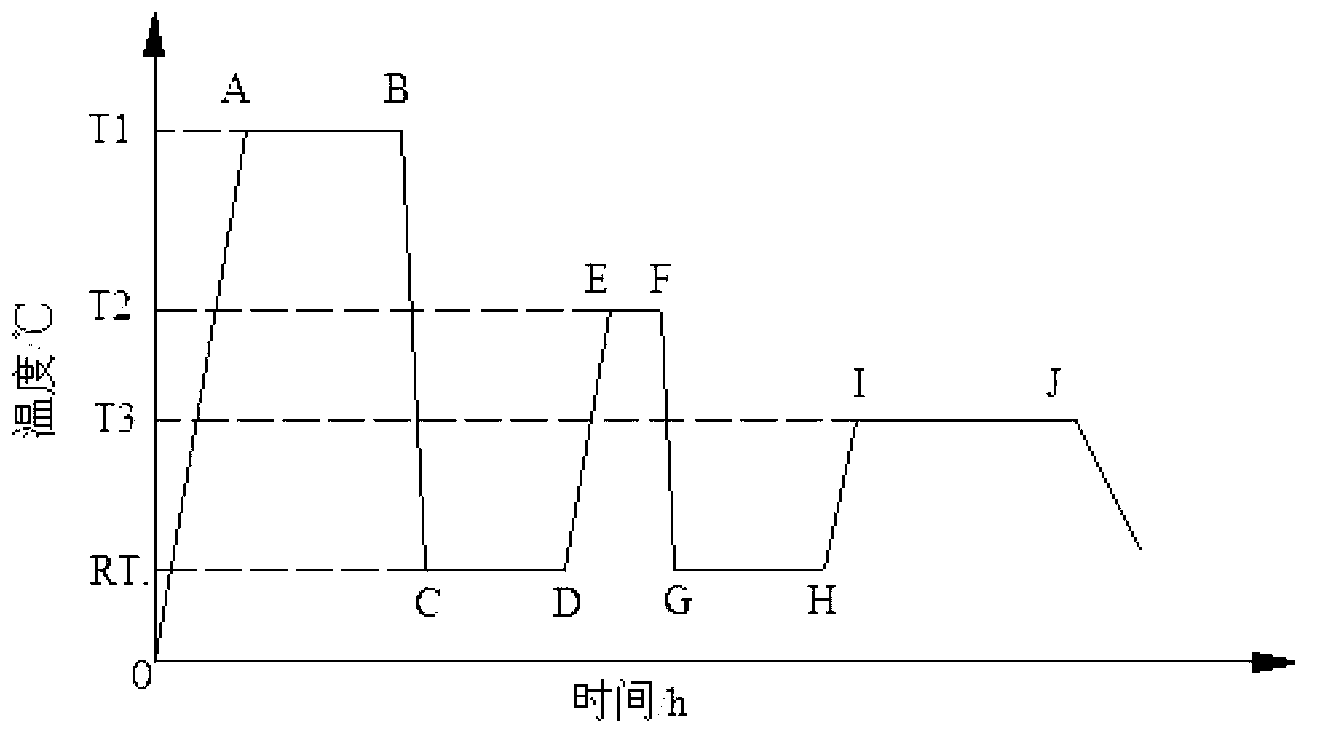

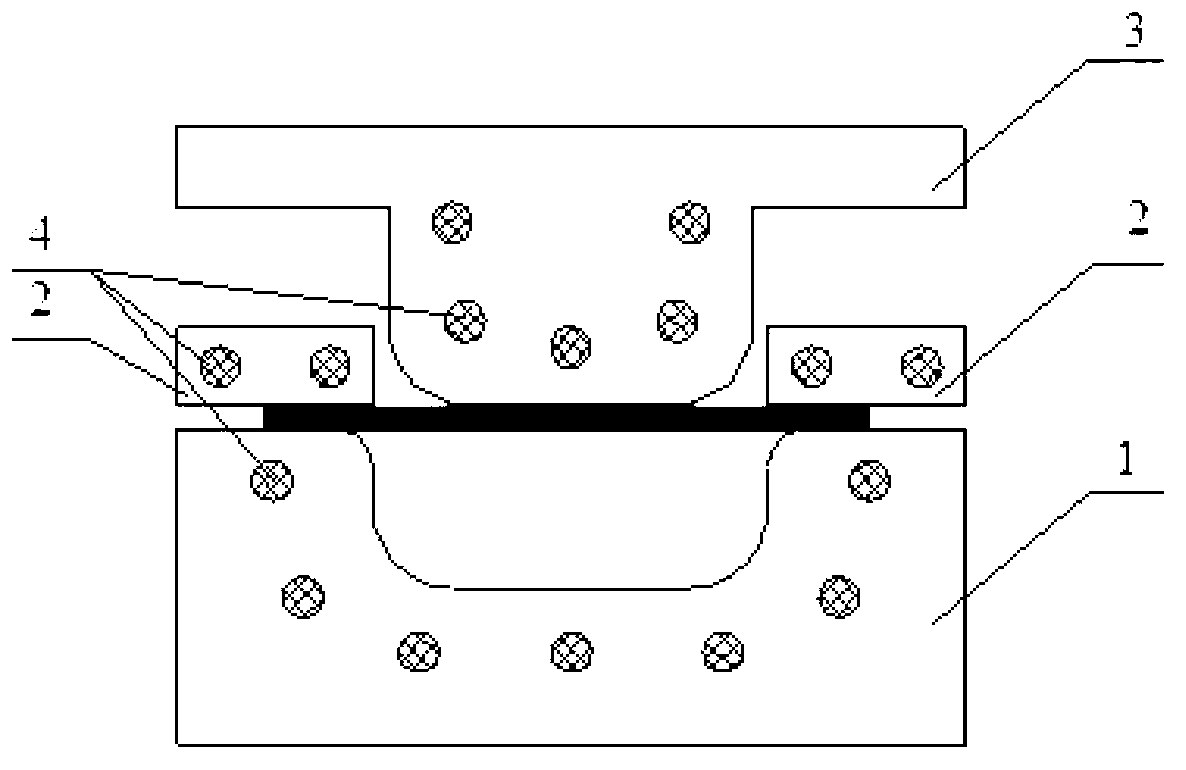

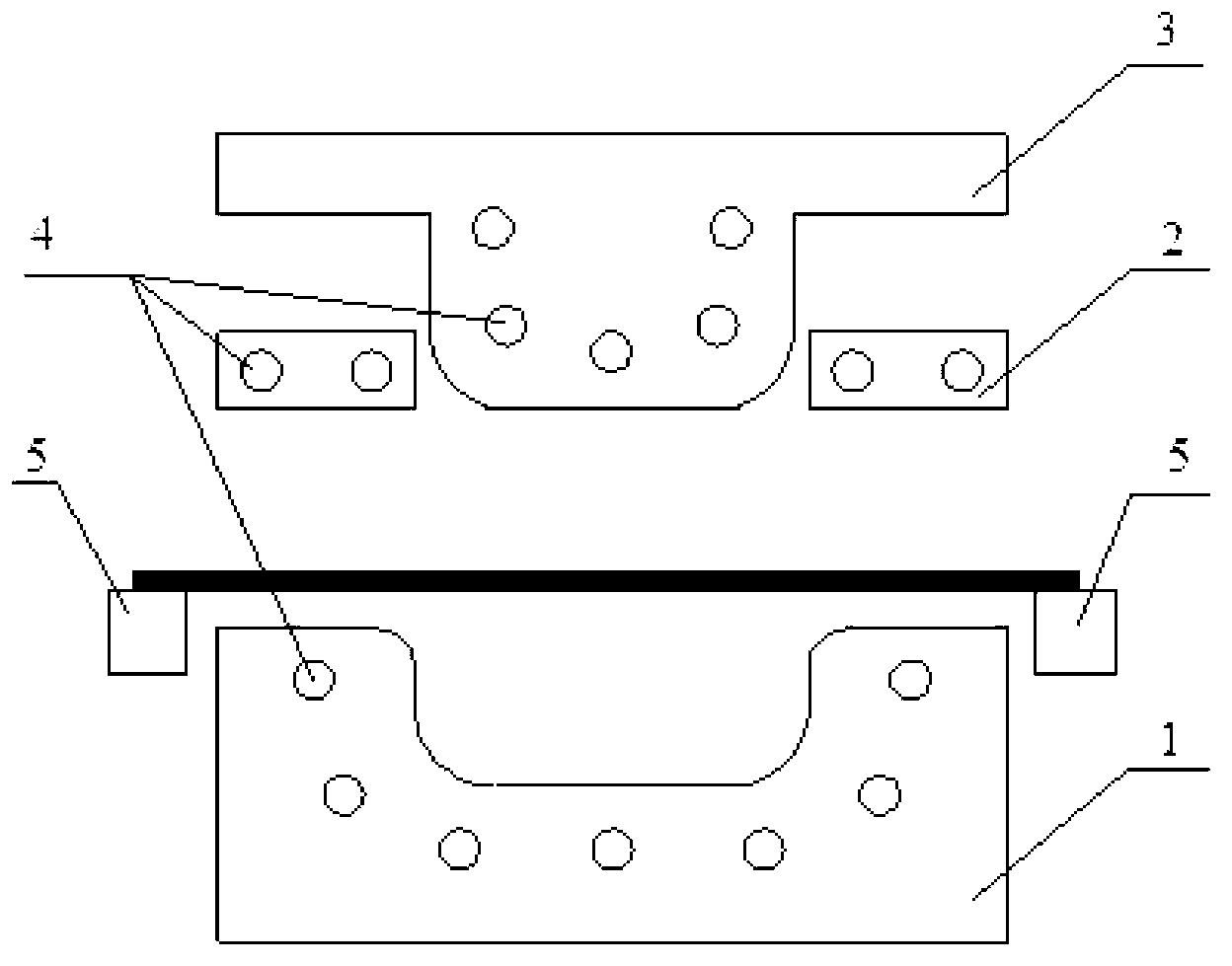

InactiveCN102974675AGuaranteed shape and size accuracyAvoid quick transfersShaping toolsSize changeSupersaturated solid solution

The invention discloses a heat forming method for an aluminum alloy sheet metal part after solid solution and water quenching, relates to a heat forming method for a heat-treatable strengthening aluminum alloy sheet metal part and aims at solving the technical problems that existing heat-treatable strengthening aluminum alloy is large in shape and size change in the process of heat treatment after the heat-treatable strengthening aluminum alloy is formed first, heat melting forming and cold mold quenching technique requires transfer locating and forming to be fast, in an aluminum alloy sheet metal part cold-hot compound mold forming method, control on temperature of an aluminum alloy slab is difficult, in-mold cooling and quenching speed after forming is slow and not beneficial for obtaining a supersaturated solid solution, requirements for forming equipment are high, and the like. The forming method includes the flowing steps: carrying out the solid solution and the water quenching to the aluminum alloy slab, then, placing the aluminum alloy slab in a hot-state mold to carry out secondary heating, and carrying out aging treatment after pressing forming. According to the heat forming method for the aluminum alloy sheet metal part after the solid solution and the water quenching, the requirements for the forming equipment are not high, precision of shape and size of the aluminum alloy sheet metal part is high, strength is greatly improved, and the heat forming method for the aluminum alloy sheet metal part after the solid solution and the water quenching is suitable for the heat-treatable strengthening aluminum alloy such as 2000 series aluminum alloy, 6000 series aluminum alloy and 7000 series aluminum alloy.

Owner:HARBIN INST OF TECH

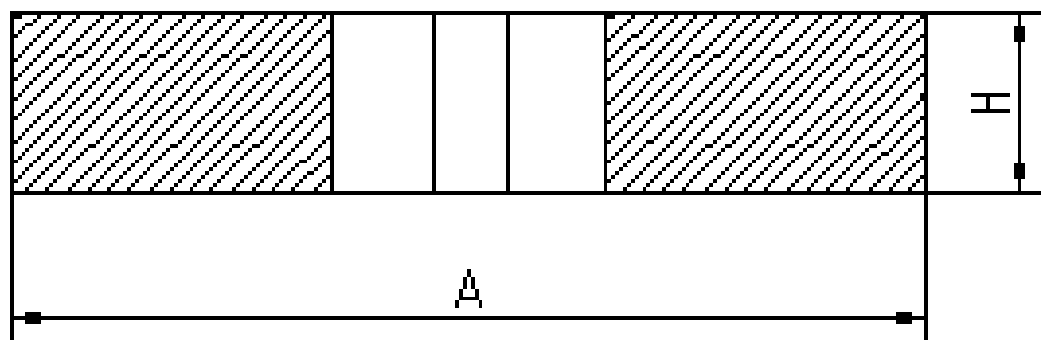

Hot rolled steel plate with yield strength being 700MPa and preparation method thereof

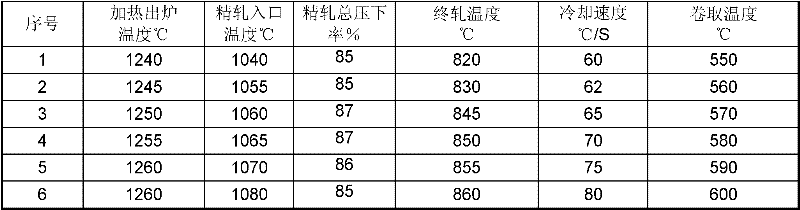

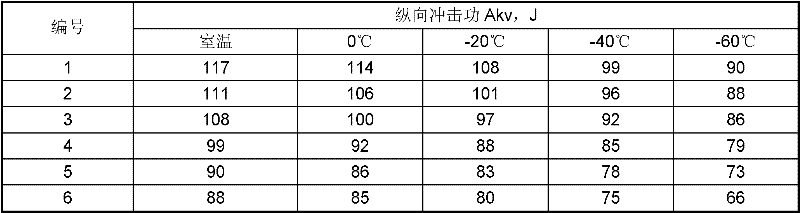

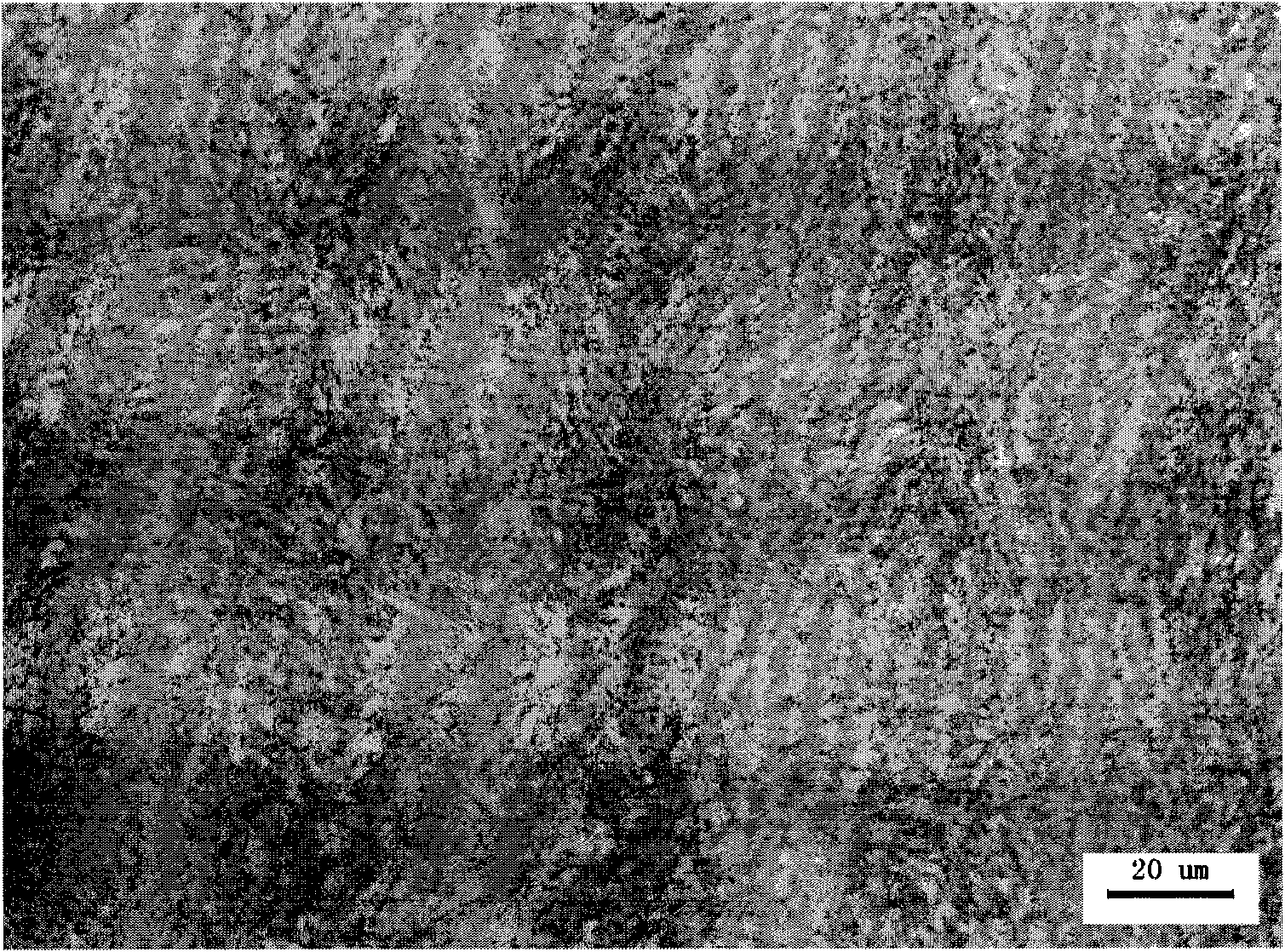

The invention discloses a high-strength hot rolled steel plate with yield strength being 700MPa. The steel plate comprises the following chemical components by weight: 0.04-0.08% of C, 0.15-0.3% of Si, 1.20-1.90% of Mn, 0.020-0.060% of Al, not more than 0.015% of P, not more than 0.0009% of S, 0.06-0.08% of Nb, 0.09-0.12% of Ti, 0.0008-0.005% of B, not more than 0.002% of O and not more than 0.004% of N. A preparation method is characterized in that the heating temperature is 1240-1260 DEG C; the rough rolling temperature is 1230-1100 DEG C; the finish rolling inlet temperature is 1080-1040 DEG C; the final rolling temperature is 820-860 DEG C; the total finish rolling reduction ratio is not less than 85%; the laminar flow is cooled at a speed being not less than 60 DEG C / s after finish rolling; and the coiling temperature is controlled between 550 DEG C and 600 DEG C.

Owner:MAANSHAN IRON & STEEL CO LTD

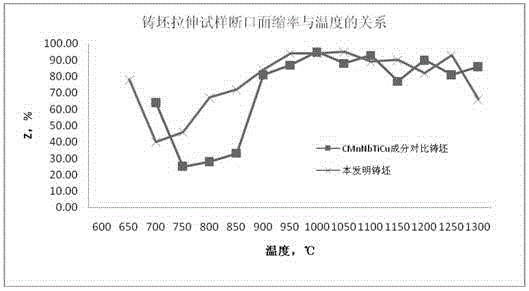

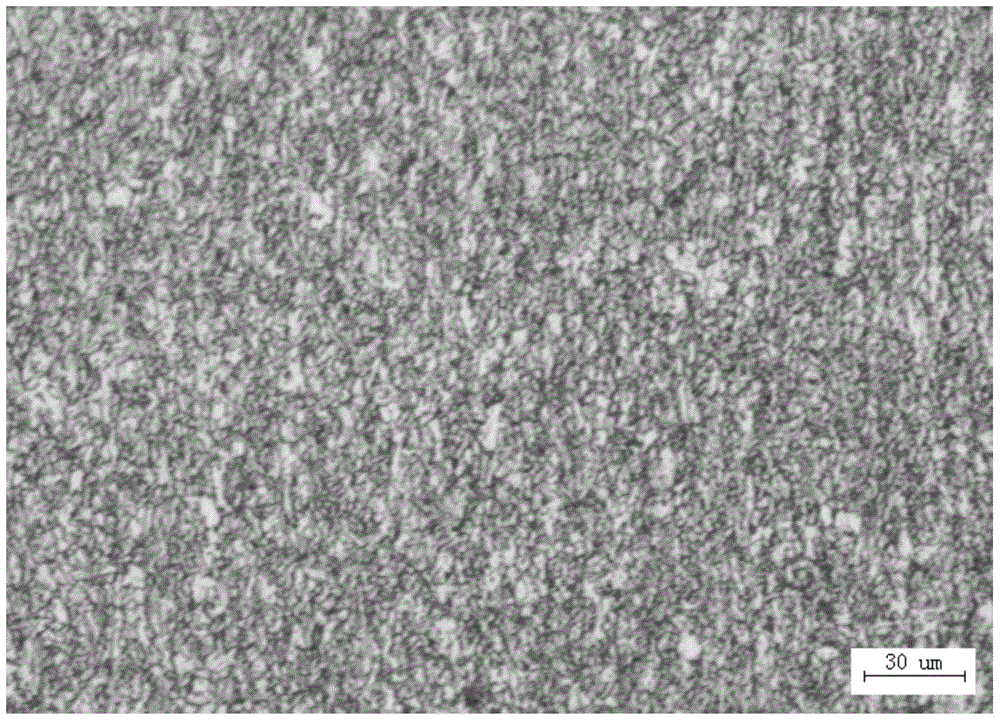

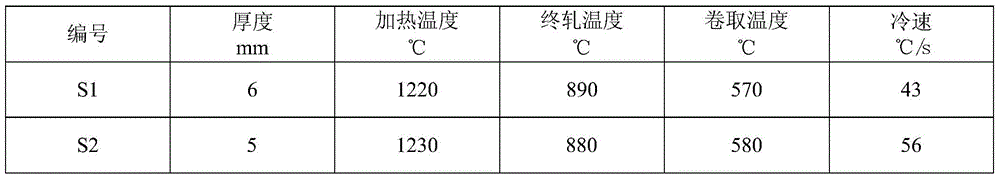

High-strength hot rolled steel plate with excellent cold forming property and preparation method thereof

InactiveCN102226249AHigh accuracy of shape and sizeHigh dimensional accuracyRoll mill control devicesMetal rolling arrangementsSheet steelChemical composition

The invention discloses a high-strength hot rolled steel plate with excellent cold forming property. The steel plate comprises the following chemical components by weight: 0.04-0.08% of C, 0.15-0.3% of Si, 1.20-1.90% of Mn, 0.020-0.060% of Al, not more than 0.015% of P, not more than 0.0009% of S, 0.06-0.08% of Nb, 0.09-0.12% of Ti, 0.05-0.1% of Mo, not more than 0.002% of O and not more than 0.004% of N. A preparation method is characterized in that the heating temperature is 1240-1260 DEG C; the rough rolling temperature is 1230-1100 DEG C; the finish rolling inlet temperature is 1080-1040 DEG C; the final rolling temperature is 820-860 DEG C; the total finish rolling reduction ratio is not less than 85%; the laminar flow is cooled at a speed being not less than 60 DEG C / s after finish rolling; and the coiling temperature is controlled between 550 DEG C and 600 DEG C.

Owner:MAANSHAN IRON & STEEL CO LTD

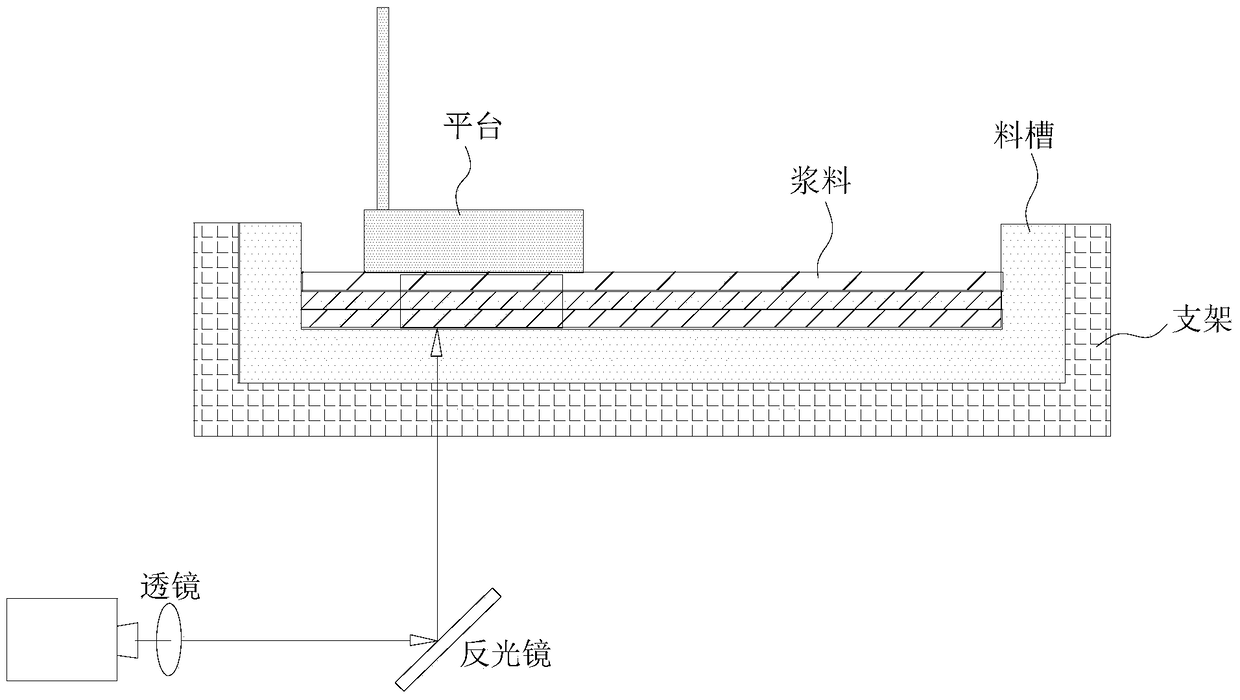

Ceramic material as well as preparation method and application thereof

ActiveCN109020605AHas a complex shapeWith strengthAdditive manufacturing apparatusCeramicwareSlurryUltimate tensile strength

The invention belongs to the technical field of 3D printing materials, and particularly relates to a ceramic material as well as a preparation method and application thereof. The preparation method ofthe ceramic material provided byin the invention comprises the following steps: (a) performing photocuring molding for on slurry comprising ceramic powder, and to obtaining a green body; and (b) successively degreasing, immersing and sintering the green body,and to obtaining the ceramic material. The green body is prepared by virtue of the photocuring molding method, so that the molding efficiency is high, and the shape and dimension precision of the green body is high; and by virtue of degreasing, the non-deformable and non-fracturing porous green body can be obtained, and by virtue of immersion, the ceramic material with a complicated shape and high strength and toughness can be obtained.

Owner:广东工大资产经营有限公司 +1

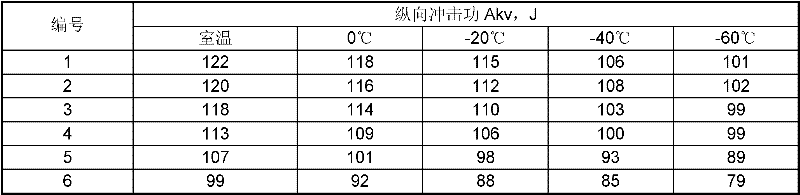

Method for manufacturing section steel with high strength and high toughness by using hot-rolling steel plate

ActiveCN101602078AHigh strengthImprove impact toughnessShaping toolsIncreasing energy efficiencySheet steelInduction heater

The invention relates to a method for manufacturing section steel with high strength and high toughness by using a hot-rolling steel plate. In the method, the hot-rolling steel plate is adopted, cut by a fixed size, heated to 1050DEG C to 1100DEG C by an induction heater under the clamping of a horizontal roller and an upright roller and then bent and manufactured into section steel by using a roller type forming machine set, the section steel is sent into the induction heater, water-cooling quenching is carried out on the section steel after being heated to 930DEG C to 960DEG C within the time of 60 to 150 seconds, the quenching and cooling speed of the section steel is greater than or equal to 8DEG C / S, the section steel after quenching is heated to 630DEG C to 660DEG C by a tempering induction heater to carry out tempering, the tempering time is 80 to 200 seconds, and straightening, flaw detection, surface inspection and sampling inspection are carried out after refining so as to manufacture the section steel with high strength and high toughness. The invention has the characteristics of small internal stress, high strength, high impact toughness, high shape and size precision, good straightness degree and the like. The section steel can be applied to the production of important structural parts, such as the manufacture of components comprising semilunar plates used for the connection of ocean platform racks, crossbeams of heavy-duty transport trucks and the like.

Owner:武汉钢实机电设备有限公司

Manufacturing method of laminated ceramics

The invention relates to the technical field of ceramic manufacturing, in particular to a manufacturing method of laminated ceramics. Slurry can be applicable to a DLP photo-curing face forming method to manufacture laminated ceramic bodies by optimizing the composition and proportioning of the slurry, the forming efficiency is high, ceramic particles in the bodies can be dispersed evenly, and the shape and size accuracy of the bodies is high; then the bodies cannot deform and crack in the manufacturing process by controlling process parameters in degreasing and sintering steps, the laminated ceramics with micron-scale thickness can be manufactured and are uniform in compactness, good in surface smoothness, high in accuracy and excellent in performance, and manufactured ceramic products are high in reliability. The manufacturing method adopts a two-step degreasing method integrating vacuum / atmosphere protection degreasing and air degreasing, can remarkably improve the degreasing efficiency, enables the degreasing time to be shortened from 48-60 hours required by an existing method to 8-20 hours and can also decrease the defects including deformation, cracking, blistering and the like of the bodies due to the too high one-step degreasing and heating rate or the too high pyrolysis rate of organic matter in the bodies.

Owner:广东金瓷三维技术有限公司

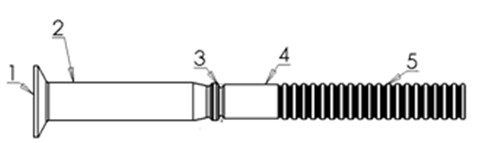

Processing process of titanium alloy ring groove rivet with big length-to-diameter ratio

The invention relates to a processing process of a ring groove rivet, and in particular relates to the processing process of a titanium alloy ring groove rivet with a big length-to-diameter ratio. The processing process belongs to the technical field of a ring groove rivet processing process. The processing process of the titanium alloy ring groove rivet with the big length-to-diameter ratio is characterized in that process ring grooves, a broken neck groove, a work rod part and a head of a blank after grinding are sequentially formed by disposable lathing molding by adopting a numerically controlled lathe. In the processing process, the high precision of ring groove processing is realized by utilizing the high precision of the lathe, the efficient processing is realized by utilizing the numerically controlled automatic fast feeding, the excircle precision of the ring groove rivet with the big length-to-diameter ratio, processed by the process, is high, and the surface roughness and the batch product size consistency are superior to a product processed by the conventional process, and therefore, the size and the mechanical property stability of the entire product is improved, and final batch product testing indicators are superior to the conventional product.

Owner:东方蓝天钛金科技有限公司

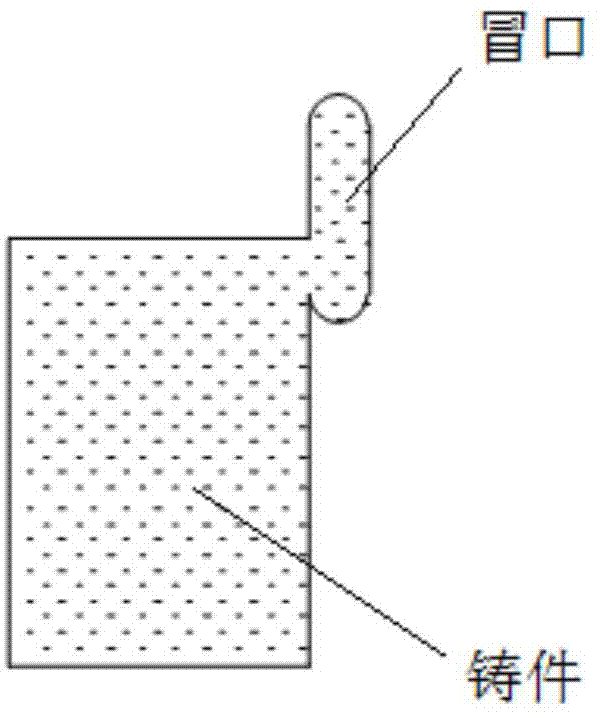

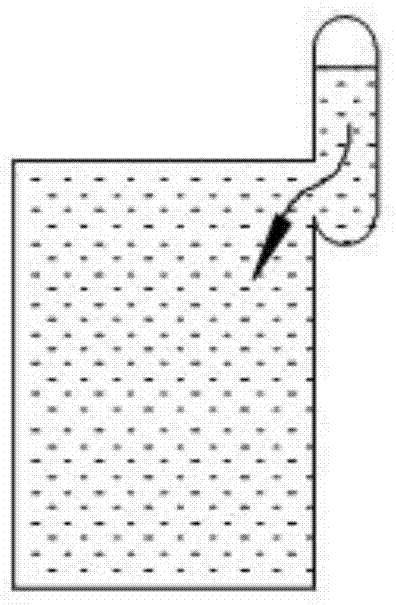

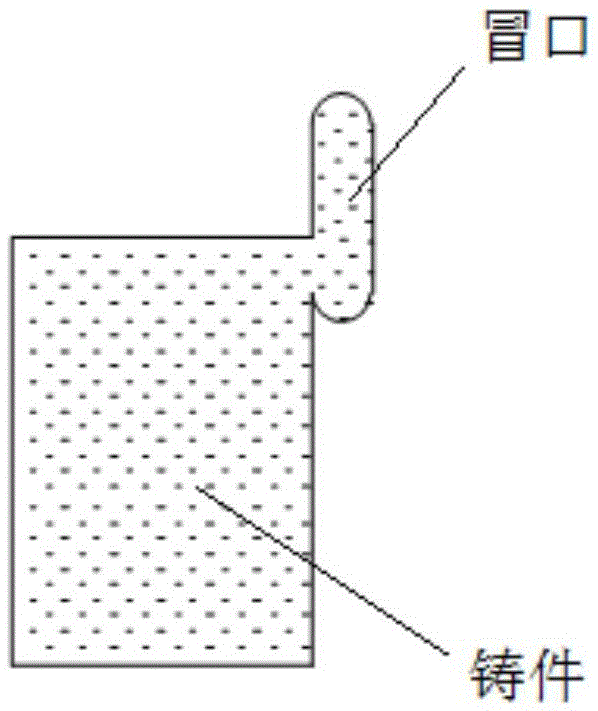

Method for setting riser on casting of ship diesel engine body

ActiveCN103658541APrevent concentrated shrinkageImprove self-feeding capabilityFoundry mouldsFoundry coresSelf compensationEngineering

The invention provides a method for setting a riser on a casting of a ship diesel engine body. The riser is arranged at a central line part between a bottom plate of the casting and a crankshaft, the riser and a riser neck are previously solidified on the casting, and the diameter of the riser and the diameter of the riser neck are calculated according to the modulus of the riser and the modulus of the riser neck. The method solves the problems that as a traditional technology adopts a casting method for compensating contraction by the riser and the riser neck, excessive molten iron is squeezed back to the riser when the casting enters a graphitization expansion period, and although the casting is prevented from a concentrated contracted hole under the gravity action of the molten metal column of the riser when secondary contraction occurs in a solidifying later period, micro contracted loosening among eutectic colonies cannot be overcome. According to the application, the riser and the riser neck are previously solidified on the casting, and pressure is built in the casting through the utilization of all or part of eutectic expansion quantity. The contraction self-compensation capability is improved, and contracted loosening flaws are reduced.

Owner:CSIC NO 12 RES INST

Technological process for performing continuous casting-rolling formation on 42CrMo steel ring piece

The invention discloses a technological process for performing a continuous casting-rolling formation on 42CrMo steel ring piece, and belongs to the technical field of batch production of medium-small scale ring pieces. The technological process is characterized by comprising the following steps of: alloy melting, refining of steel liquid, centrifugal casting of ring blanks, hot rolling, heat treatment and refining, wherein the step of refining of steel liquid is to melt the steel liquid in a basic electric arc furnace at 1680-1700 DEG C; and the step of centrifugal casting of ring blanks is to perform centrifugal pouring on the refined steel water to form ring blanks at 1550-1560 DEG C, demould the ring blanks at 1200-1250 DEG C after the pouring is finished, convey the ring blanks to a radial-axial rolling machine by a conveying system and directly roll and form the ring blanks at 1050 DEG C by utilizing blank casting afterheat. The process has the advantages that the utilization ratio of the material is improved, the technological process is shortened, the production cost is reduced, the quality and the accuracy of the ring piece are improved, the energy source and manpower resources are saved, and the production efficiency is improved.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

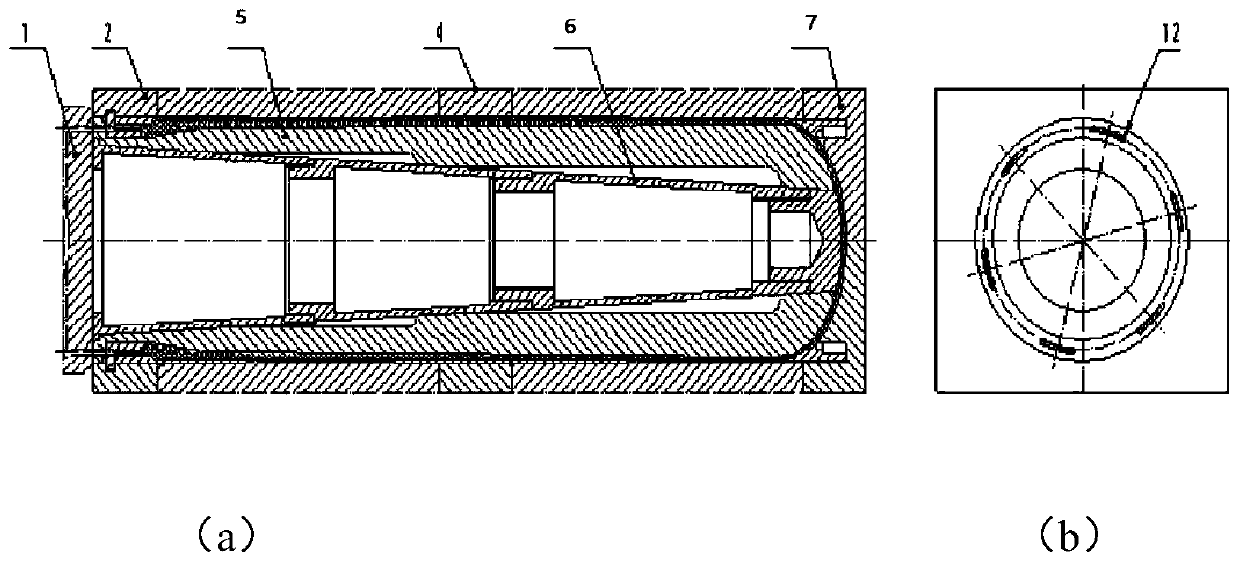

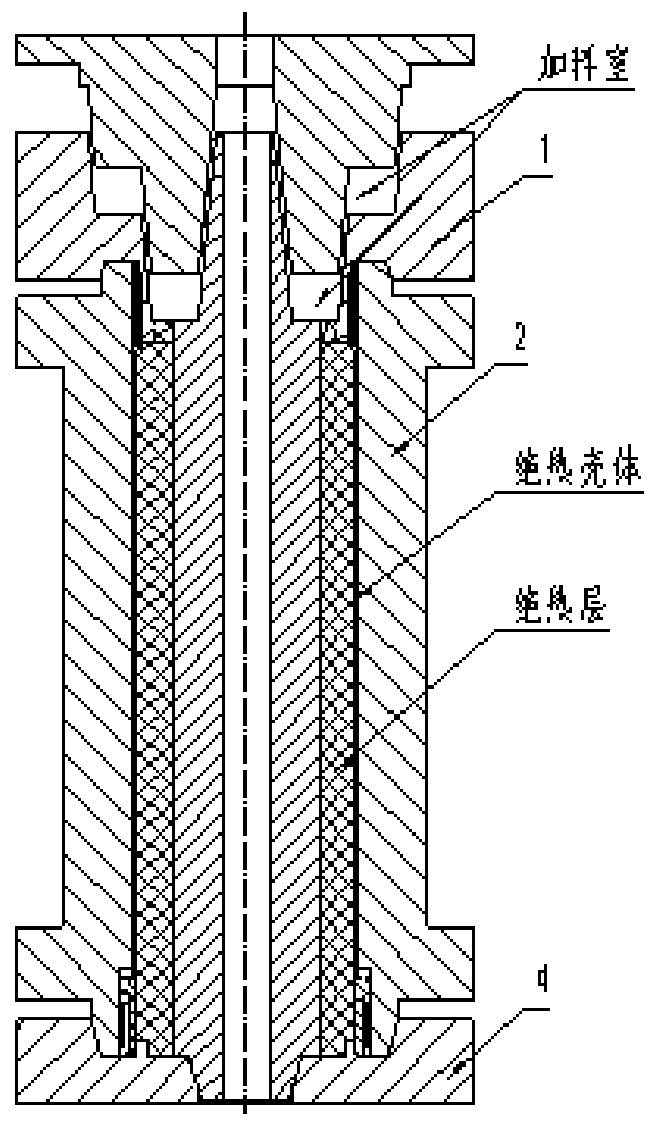

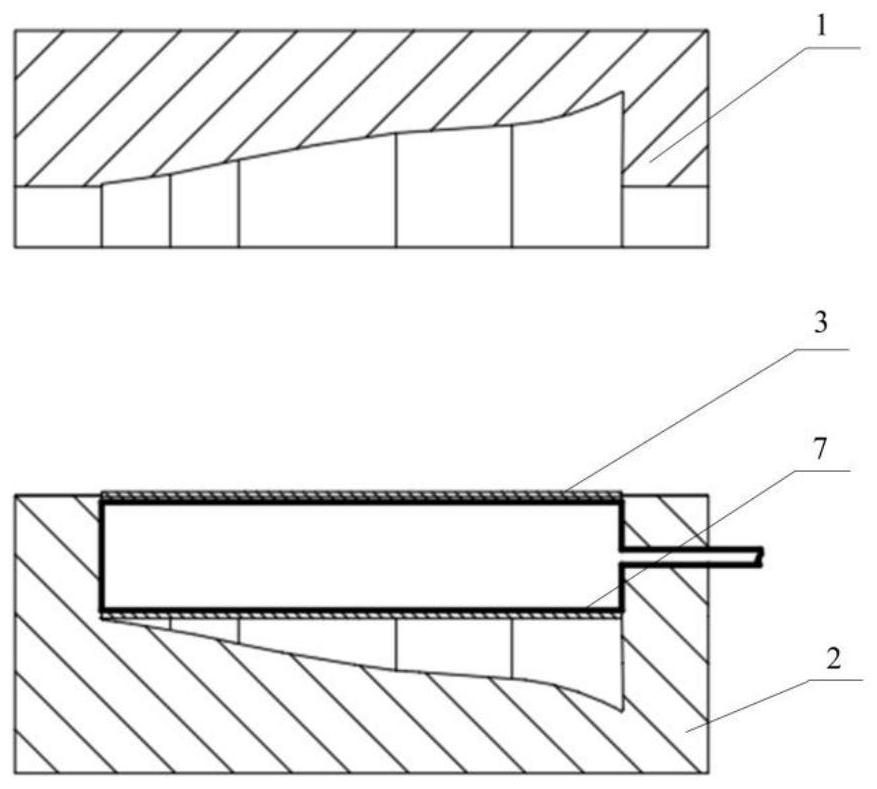

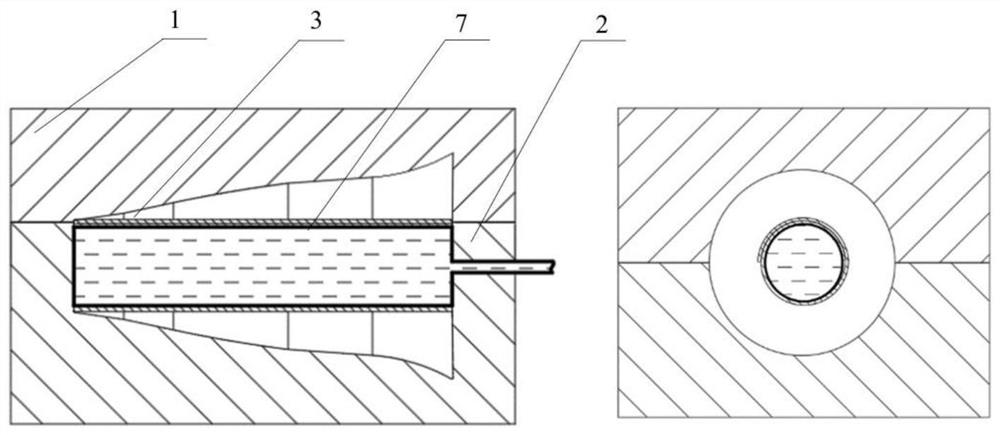

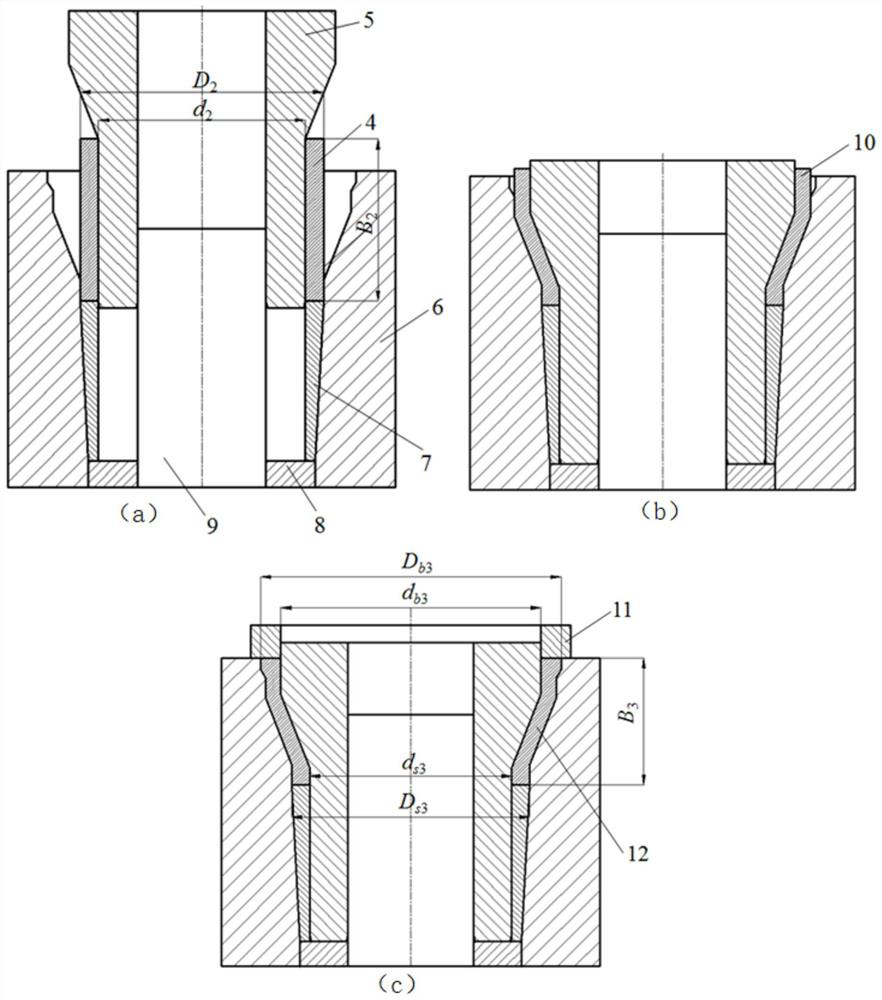

Injection or injection-compression molding tool and process for thermal insulation layer of combustion chamber of solid rocket engine

ActiveCN111070560AImprove skillsHigh molding shape and dimension accuracyCoatingsCompression moldingCombustion chamber

The invention belongs to the technical field of manufacturing of thermal insulation layers in thermal protection structures of solid rocket engines, and provides an injection or injection-compressionmolding tool for a thermal insulation layer of a combustion chamber of a solid rocket engine. The injection or injection-compression molding tool comprises a pouring integrated plate (1), a thermal insulation shell pressure-bearing limiting assembly, a split-type combined mold core (5), a limiting cone (6) and a thermal insulation shell; the thermal insulation shell pressure-bearing limiting assembly is used for providing pressure-bearing support for the outer side of the thermal insulation shell in the process of injection or injection-compression of a thermal insulation material into the thermal insulation shell; the split-type combined mold core (5) and the limiting cone (6) are matched to be placed in the thermal insulation shell and form a cavity with the thermal insulation shell, andthe cavity is consistent with the thermal insulation layer to be subjected to injection or injection-compression molding in shape and size so as to allow the thermal insulation material to be injected in a pressurized mode at the high pressure; and a thermal insulation material injecting channel is formed in the pouring integrated plate (1), so that the thermal insulation material enters the cavity among the thermal insulation shell, the split-type combined mold core and the limiting cone through the pouring integrated plate (1).

Owner:HUBEI INST OF AEROSPACE CHEMOTECHNOLOGY

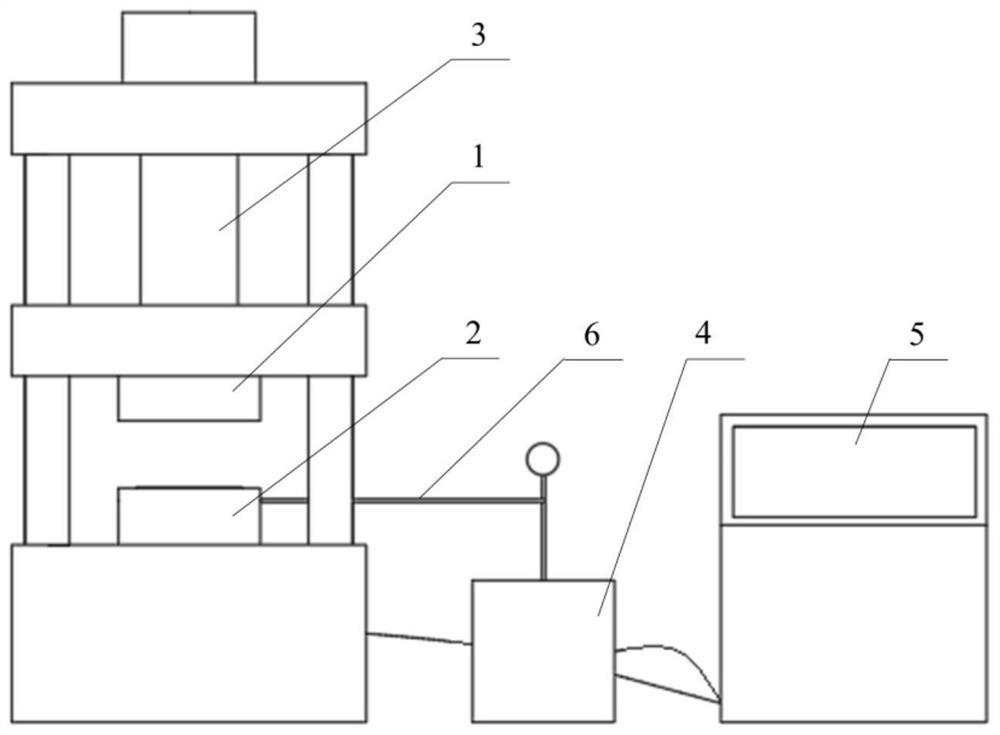

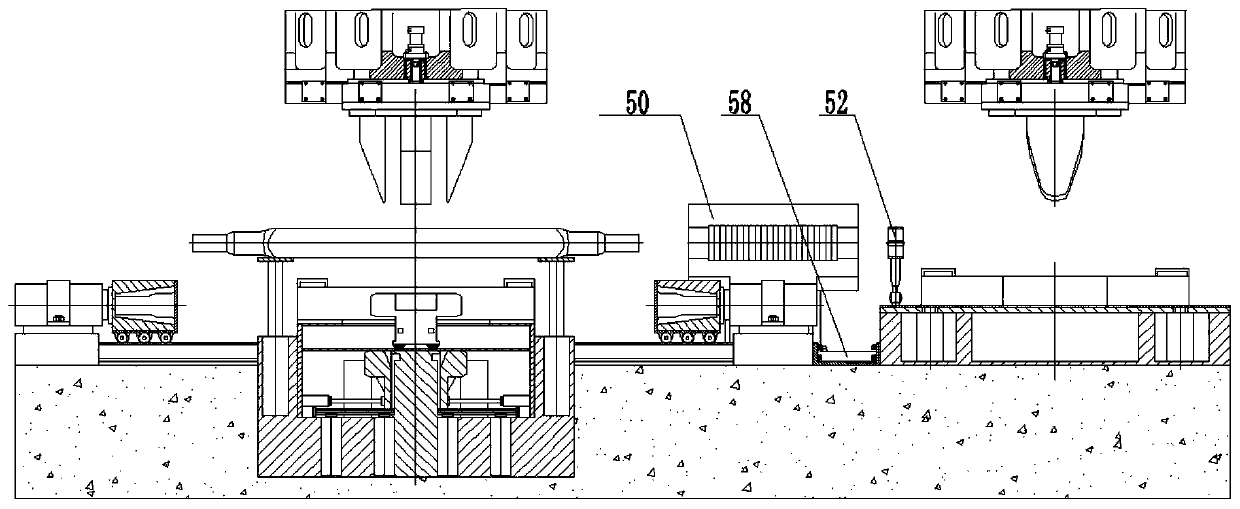

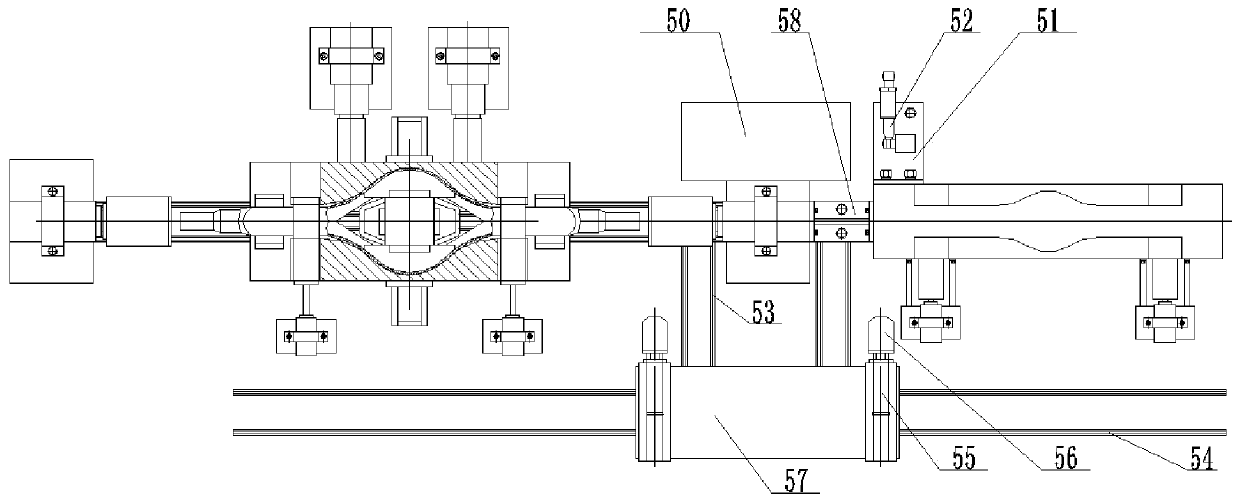

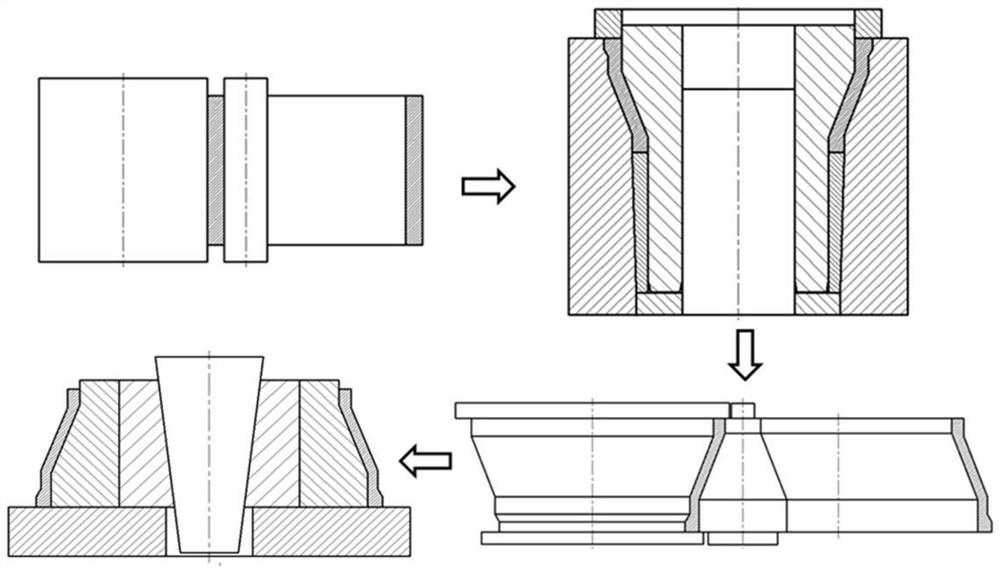

Special-shaped component ultra-low pressure liquid filling forming system and method

ActiveCN112024692AImprove performanceHigh forming precisionSoldering apparatusControl systemStructural engineering

The invention discloses a special-shaped component ultra-low-pressure liquid filling forming system which comprises a control system, a supercharger, a driving device, a pre-forming unit and a final forming unit. The invention further provides a special-shaped component ultra-low-pressure liquid filling forming method based on the special-shaped component ultra-low-pressure liquid filling formingsystem. The special-shaped component ultra-low-pressure liquid filling forming method comprises the following steps that S1, a slab is adopted to make an equal-diameter cylinder-shaped roll blank witha lap joint part in the longitudinal direction; S2, the equal-diameter cylinder-shaped roll blank is bulged into a variable-diameter cylinder-shaped prefabricated roll blank; S3, the lap joint part reserved on the variable-diameter cylinder-shaped prefabricated roll blank is cut and welded in the axis direction to obtain a variable-diameter prefabricated pipe blank; and S4, the variable-diameterprefabricated pipe blank is subjected to fluid filling shape pressing, so that the variable-diameter prefabricated pipe blank is subjected to compression deformation, and a special-shaped component isformed. According to the special-shaped component ultra-low-pressure liquid filling forming system and method, the performance, forming precision and forming efficiency of the special-shaped component are improved.

Owner:HARBIN INST OF TECH

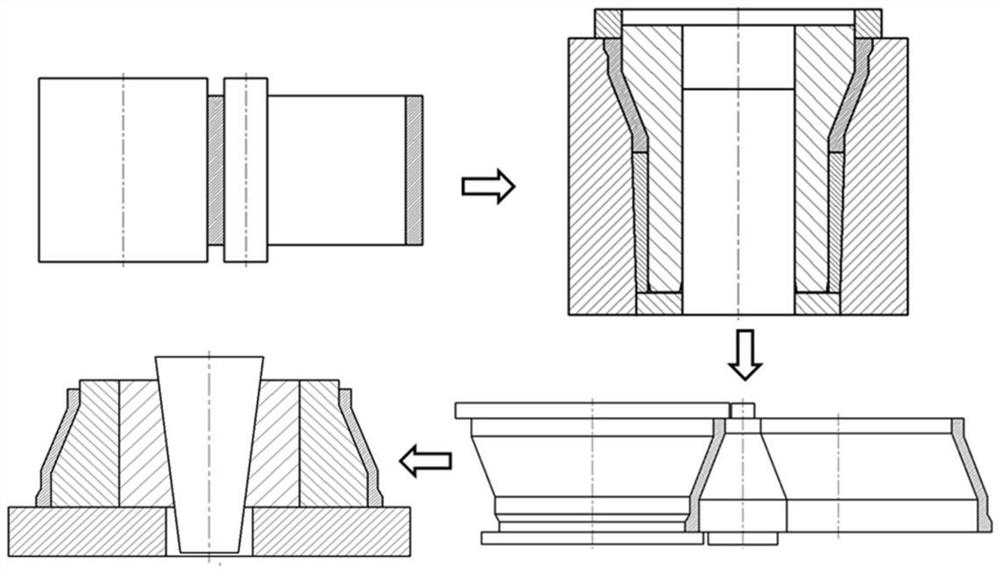

Near-net composite forming method for large wall thickness sudden change ring part

ActiveCN113059100AReduce forging forceHigh accuracy of shape and sizeMetal rollingRolling millWaste heat

The invention discloses a near-net composite forming method for a large wall thickness sudden change ring part. The method comprises the steps of: carrying out heating and heat preservation on a forged and punched small-diameter rectangular-section ring blank, taking out the small-diameter rectangular-section ring blank, and placing the small-diameter rectangular-section ring blank on a hot ring rolling mill for rolling, stopping rolling when the outer diameter is increased to a target size to obtain a large-diameter rectangular-section ring blank, taking out the large-diameter rectangular-section ring blank, and carrying out heating and heat preservation; placing the large-diameter rectangular-section ring blank in a forming die for hot forming, obtaining a special-shaped-section ring blank in the required shape, taking out the special-shaped-section ring blank, and carrying out heating and heat preservation; finish ring rolling and near-net forming, specifically, placing the special-shaped-section ring blank on the ring rolling mill for finish ring rolling, carrying out near-net forming through a special-shaped roller to obtain the section contour of the ring part, and stopping rolling when the outer diameter grows to the target size to obtain the wall thickness sudden change ring part; and rapidly placing the wall thickness sudden change ring part on a bulging machine, carrying out thermal bulging through waste heat to improve the dimensional accuracy and the roundness and to improve residual stress distribution, continuing to maintain pressure after bulging is carried out to the target size, cooling the ring part to room temperature and then taking out the ring part to obtain a the target ring part. According to the method, the forming accuracy is high.

Owner:WUHAN UNIV OF TECH

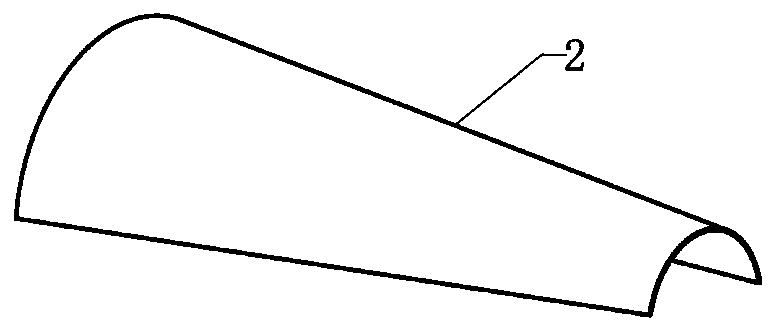

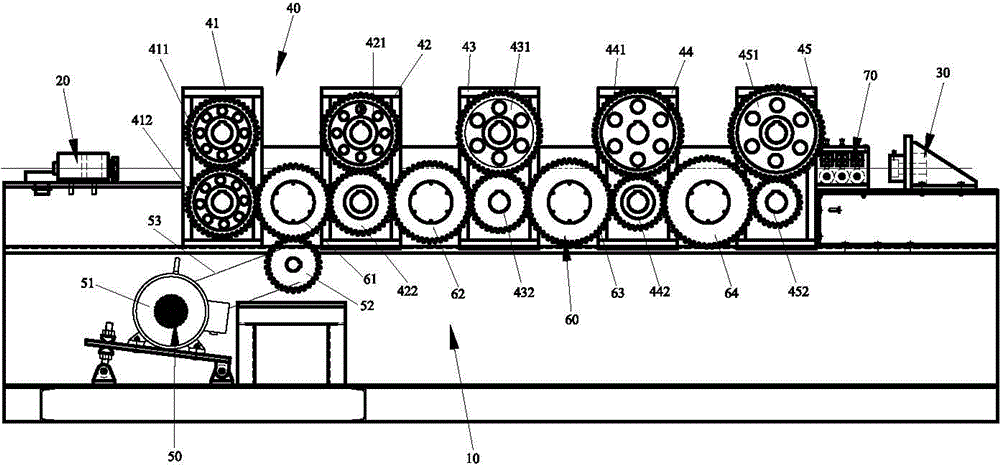

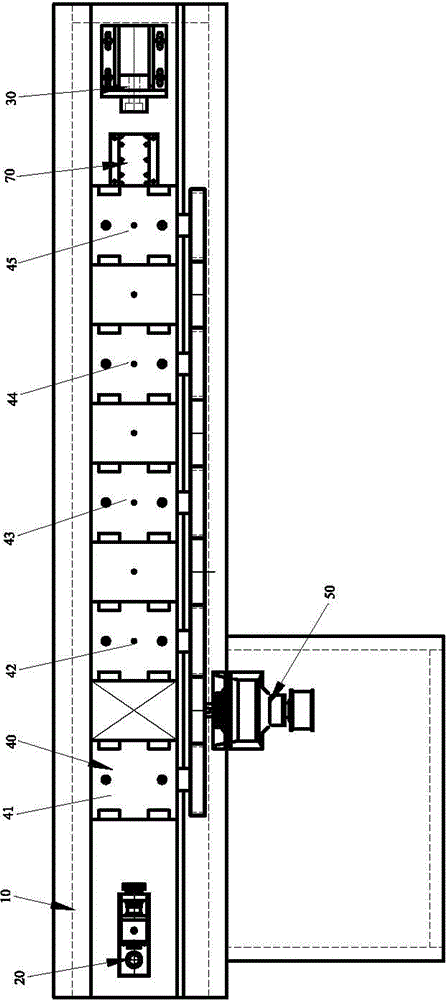

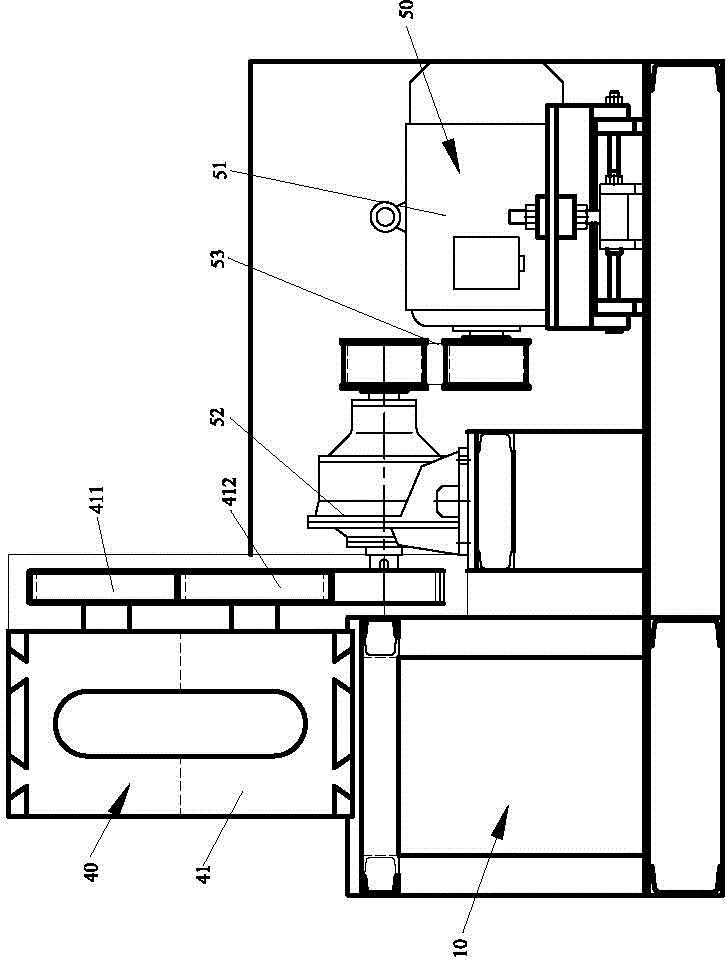

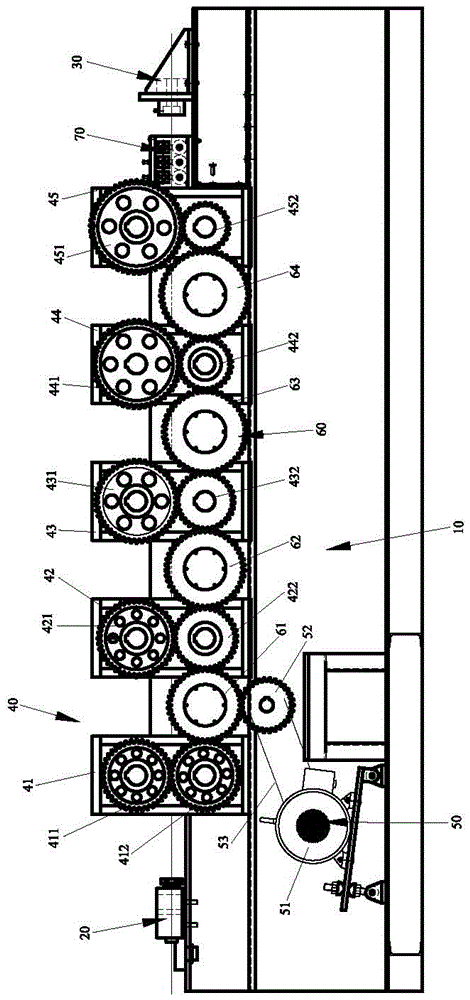

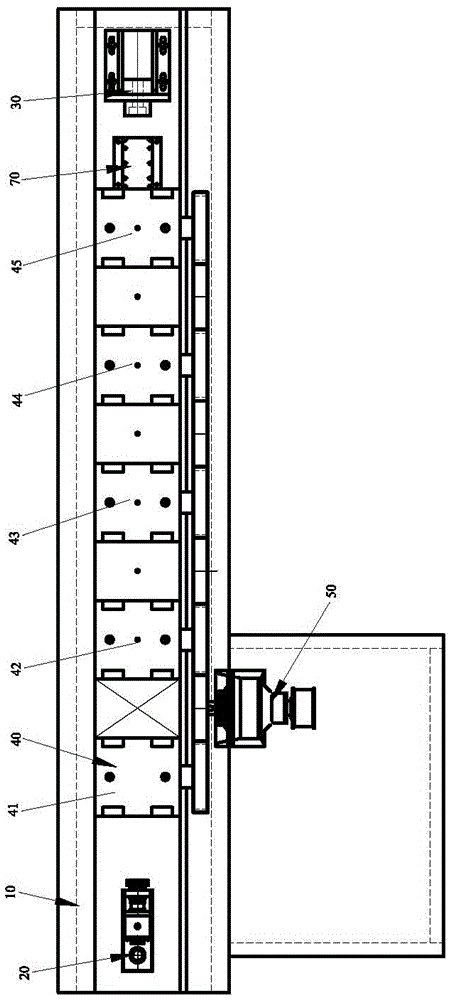

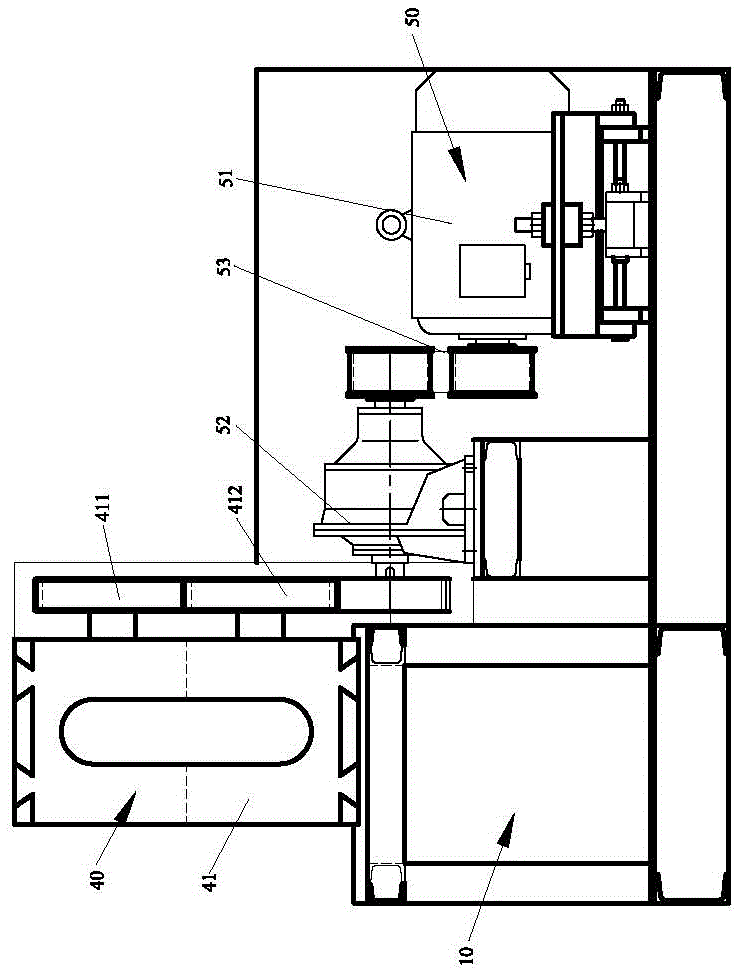

Forming equipment of medium-thick-wall integral automobile drive axle shell axle arch

PendingCN110038969AReasonable structureSmooth connectionShaping toolsMetal working apparatusEngineeringThick wall

The invention discloses a forming equipment of a medium-thick-wall integral automobile drive axle shell axle arch. The forming equipment comprises a wedge pre-expanding forming mechanism, a core moldexpanding forming mechanism, a semi-closed heating furnace, an industrial robot mechanism and a transportation mechanism, the core mold expanding forming mechanism is positioned on the left side of the wedge pre-expanding forming mechanism, the core mold expanding forming mechanism is connected with the wedge pre-expanding forming mechanism through a connecting seat, the side, close to the wedge pre-expanding forming mechanism, of the core mold expanding forming mechanism is provided with the semi-closed heating furnace through a semi-closed heating furnace support, the side, close to the wedge pre-expanding forming mechanism, of the semi-closed heating furnace is provided with the industrial robot mechanism, and the transportation mechanism is arranged on the other side of the core mold expanding and forming mechanism and the other side of the wedge pre-expanding forming mechanism. The forming equipment can obviously improve the stress state of the expanding region, so that the bending transition position of the medium-thick-wall axle shell axle arch and the straight arm is better formed, and the shape and size precision of the axle arch is greatly improved.

Owner:NORTH CHINA INST OF SCI & TECH

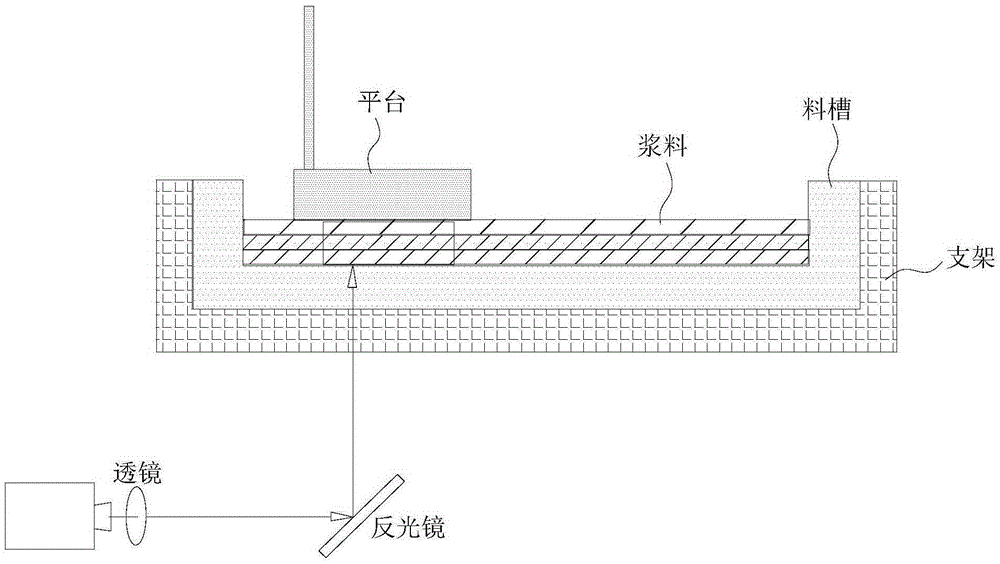

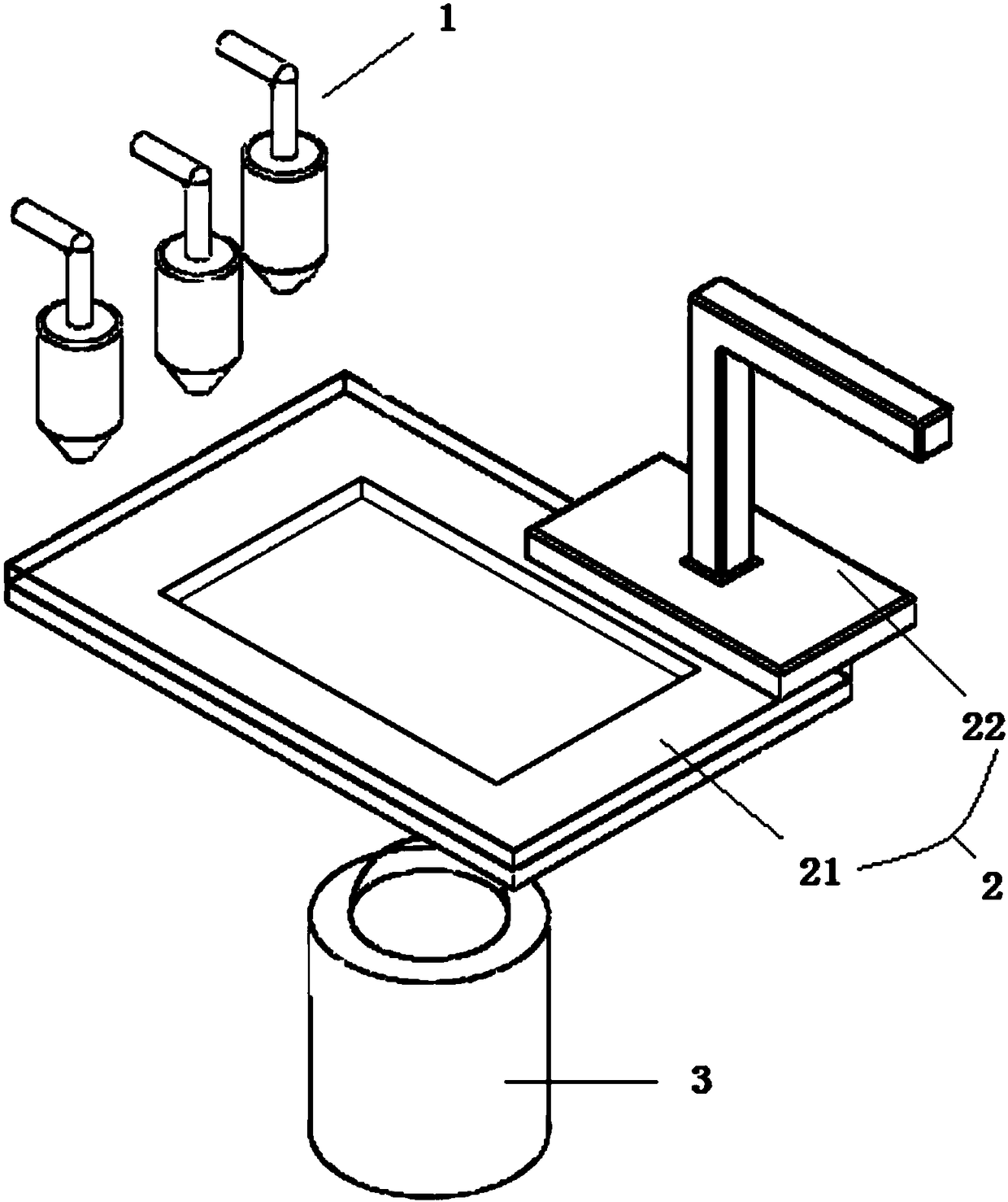

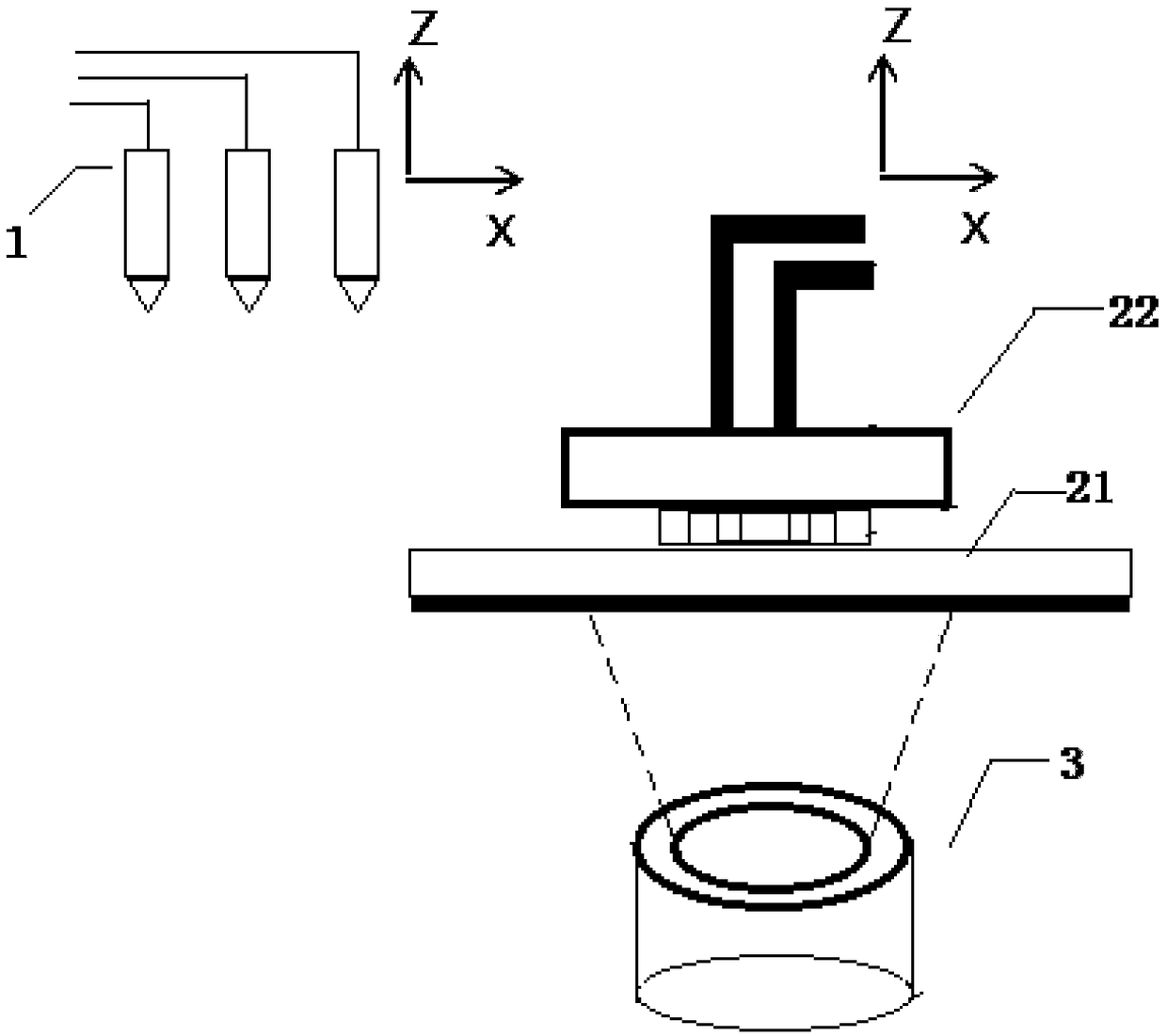

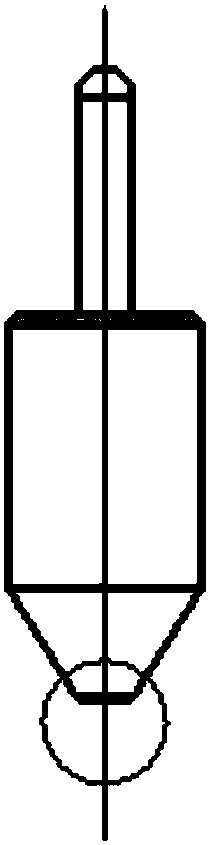

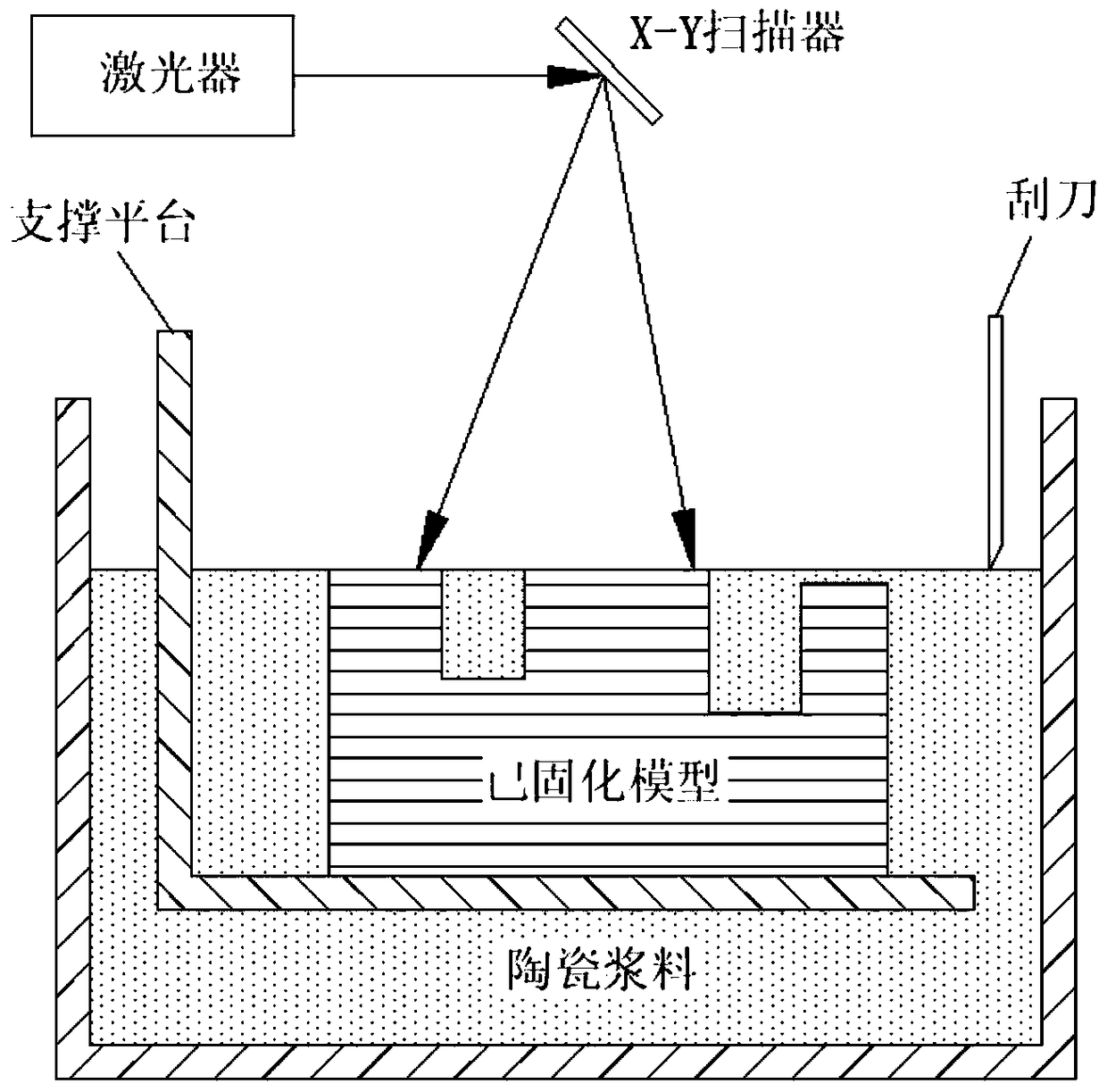

Additional material manufacturing platform based on photocuring formation

PendingCN108274582AHigh accuracy of shape and sizeEasy to prepareAdditive manufacturing apparatusCeramic shaping apparatusData informationEngineering

The invention discloses an additional material manufacturing platform based on photocuring formation. The additional material manufacturing platform based on the photocuring formation comprises a material conveying device for supplying materials at the set position, a bearing and sucking device for bearing the materials and sucking a formed blank, an ultraviolet irradiation device for achieving photocuring formation of the materials, and a control chip for controlling running of the material conveying device, the bearing and sucking device and the ultraviolet irradiation device according to data information of a to-be-formed model. The additional material manufacturing platform provided by the invention can achieve a high degree of automatic operation, achieves preparation of the complicated model simply, and is high in forming efficiency, and the shape and dimension precision of the blank is high.

Owner:GUANGDONG UNIV OF TECH

A kind of preparation method of layered ceramic

Owner:广东金瓷三维技术有限公司

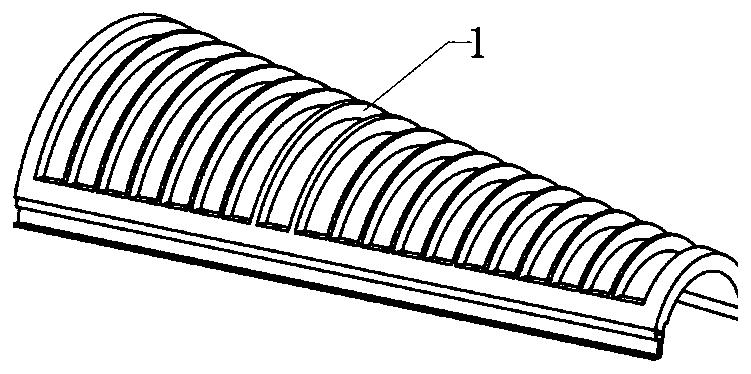

Forming method of large-size curved surface thin-wall metal skin

ActiveCN110883239AFirmly connectedHigh accuracy of shape and sizeAircraft componentsShaping toolsEngineeringMaterials science

The invention provides a forming method of a large-size curved surface thin-wall metal skin. The forming method comprises the steps that the position and size characteristics of reinforcing ribs on acurved surface wall plate are extracted aiming at the assembly relationship between the curved surface wall plate and the thin-wall skin; the thickness of the assembled curved surface wall plate and thin-wall skin is assumed to be M, the size of a forming male die is determined by taking the inner surface of the curved surface wall plate as a reference, and the forming surface of the male die is offset by the thickness M along the outer side of a normal line to obtain the inner surface characteristics of a female die; the thickness dimensions of discrete support dies are consistent with the thickness dimension of the curved surface wall plate, and the forming surfaces of the discrete support dies are determined by taking the inner surface of the formed thin-wall skin as a reference; according to the size and distribution of the reinforcing ribs on the curved surface wall plate, the number of the discrete support dies is set to be consistent with the number N of the reinforcing ribs, and the positions of the discrete support dies on the male die are consistent with the positions of the reinforcing ribs on the curved surface wall plate; and the curved surface thin-wall plate blank isstamped and formed by utilizing the male die and female die combining the discrete support dies to obtain a required thin-wall skin member.

Owner:DALIAN UNIV OF TECH +1

Thrust composite power device and method applying same for producing specially-shaped wire materials

The invention discloses a thrust composite power device and method applying the same for producing specially-shaped wire materials. The device comprises a rack, a drawing die, a forming die, a plurality of roll wire-pushing mechanisms and a drive mechanism, wherein the plurality of roll wire-pushing mechanisms are transversally arranged in parallel; the plurality of roll wire-pushing mechanisms are located between the drawing die and the forming die, and a transmission gear disc is connected between the adjacent roll wire-pushing mechanisms; the drive mechanism drives one transmission gear disc to rotate. According to the device disclosed by the invention, a wire feeding mode of roll wire-pushing is adopted, and moreover, the wire materials are pushed in the forming die, and a tension device does not need to be configured at the outlet of the forming die, and thus simplifying the overall device; working procedures are reduced in a manner of combining rolling with die drawing, and thus increasing the working efficiency, and reducing the working intensity and labour amount of working personnel; meanwhile, specially-shaped steel wires with great width-thickness ratios and complex shapes can be produced through reasonable collocation of multi-pass rolling, so that the varieties of the producible specially-shaped steel wires are increased, and the shape and dimension accuracies of the products are high.

Owner:DONGGUAN KELEE STEEL WIRE

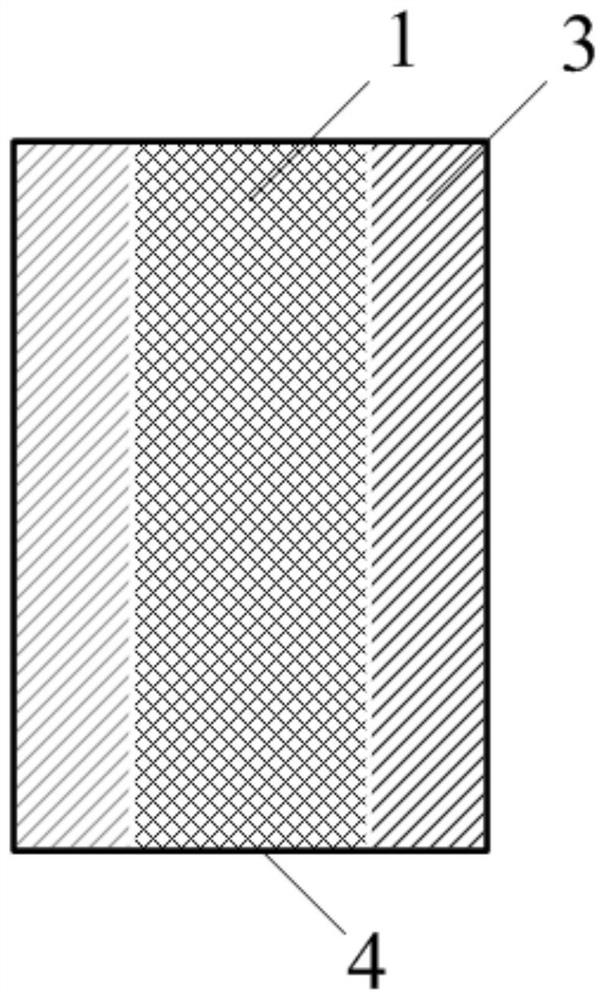

Composite manufacturing technique for isothermal forward and reverse combined extrusion and vacuum diffusion welding of blanket first wall

ActiveCN104690418AHigh accuracy of shape and sizeImprove streamline distributionNuclear energy generationThermonuclear fusion reactorWeld microstructureEngineering

The invention discloses a composite manufacturing technique for isothermal forward and reverse combined extrusion and vacuum diffusion welding of a blanket first wall. The technique is characterized in that preformed U-shaped parts are firstly formed by slabs with rectangular initial cross sections through bending; U-shaped parts, which are provided with openings in two ends and H-shaped cross sections, are then formed through forward and reverse combined extrusion of the isothermal precise plastic forming technique, and serve as first components; U-shaped parts, which are provided with one-way openings and U-shaped cross sections, are then formed through one-way extrusion of the isothermal precise plastic forming technique, and serve as second components; pairwise butt welding of the first components is finally carried out through vacuum diffusion welding in such a manner that the openings of every two butt welded first components are opposite to each other; packaging welding of the second components and the first components at the two ends is carried out in such a manner that the openings of the second components are opposite to the openings of the corresponding first components, so as to form the blanket first wall. The blanket first wall formed through the technique achieves high shape and dimension precisions, uniform wall thicknesses, distortion-free runner sections, and good runner and weld microstructure performances; the material utilization rate and the production efficiency are high, and the technique is stable.

Owner:HEFEI UNIV OF TECH

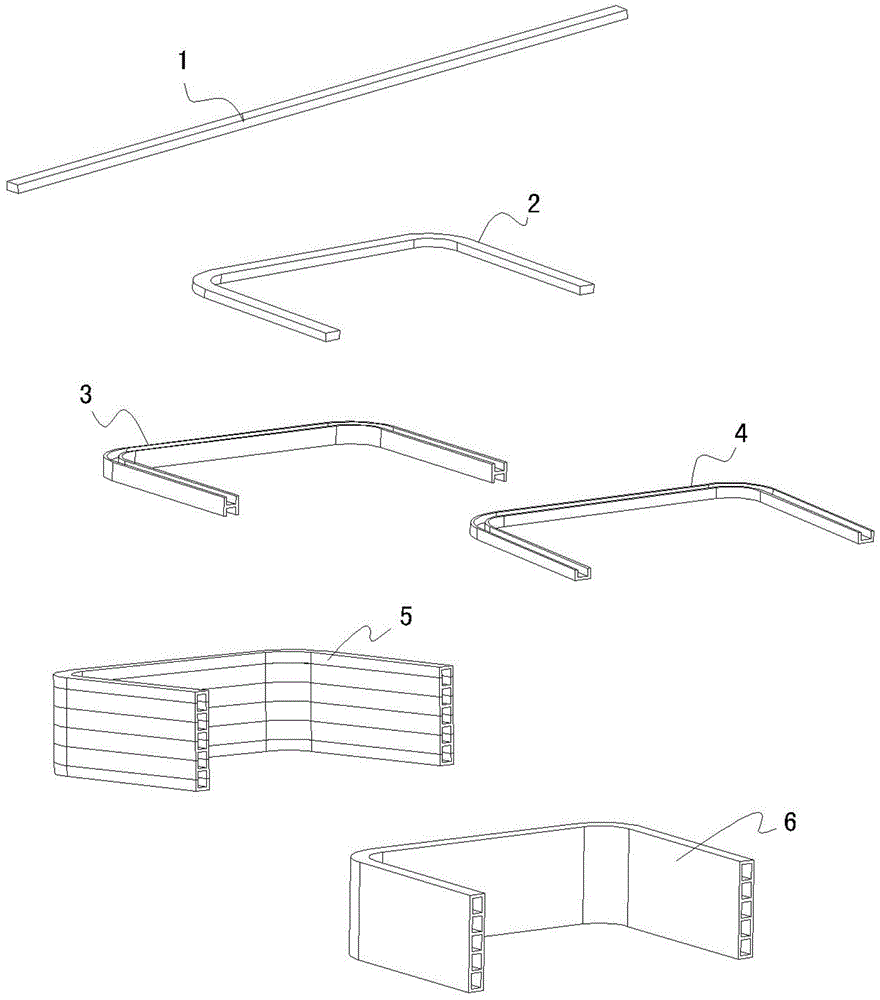

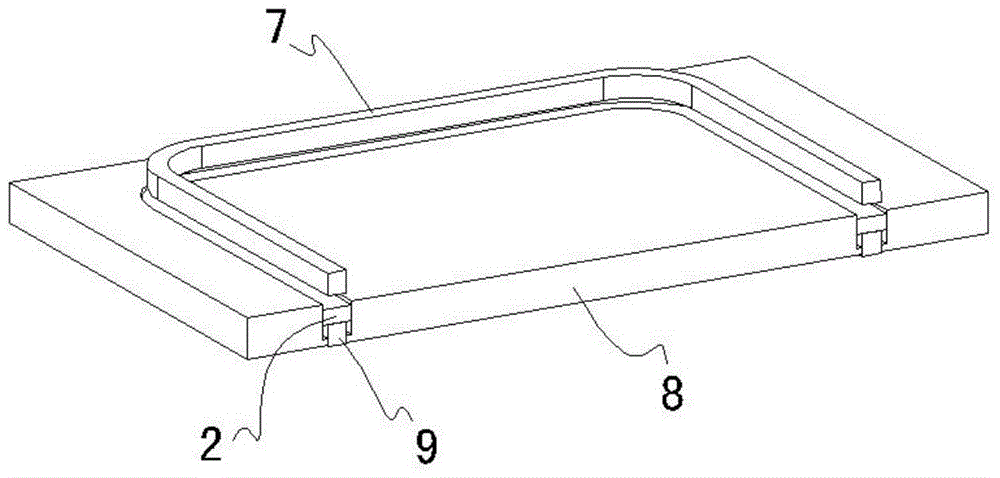

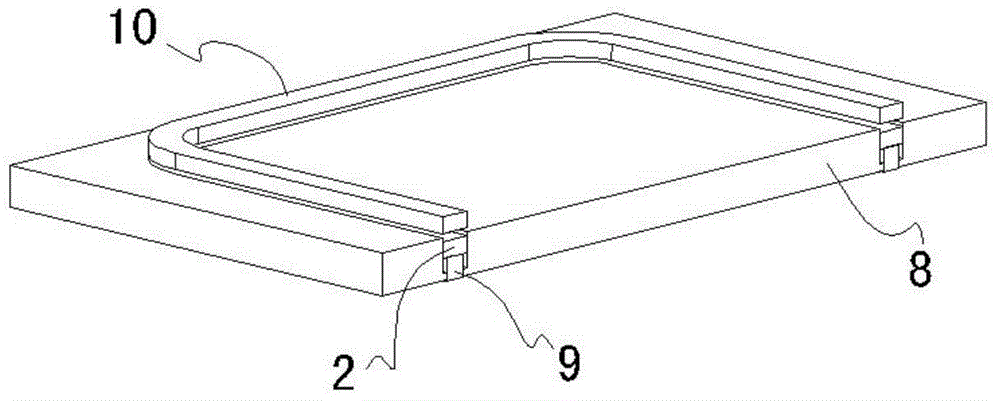

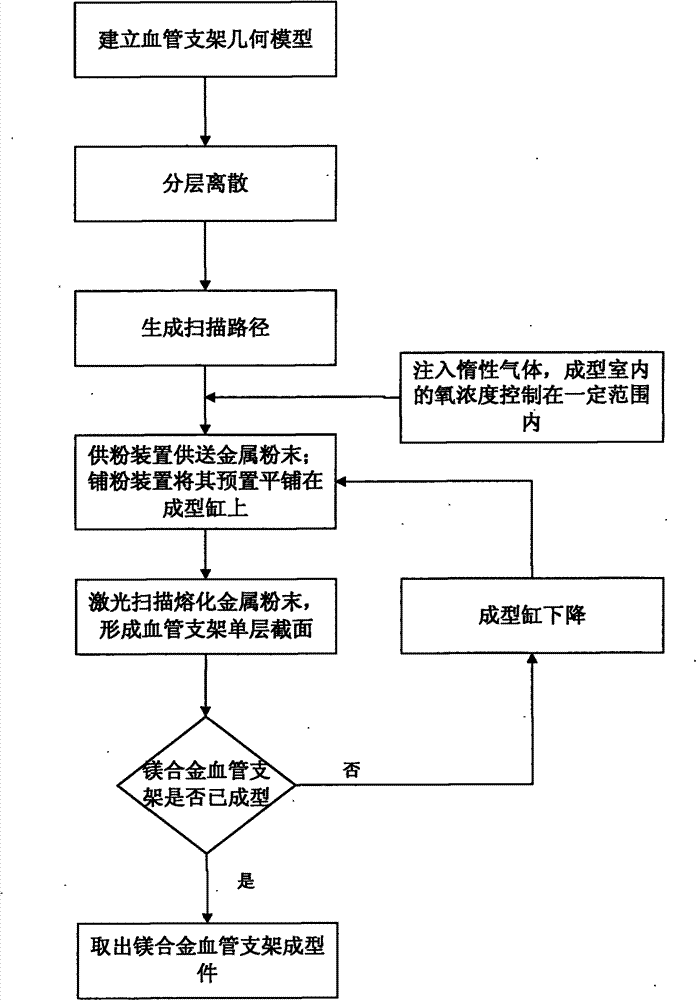

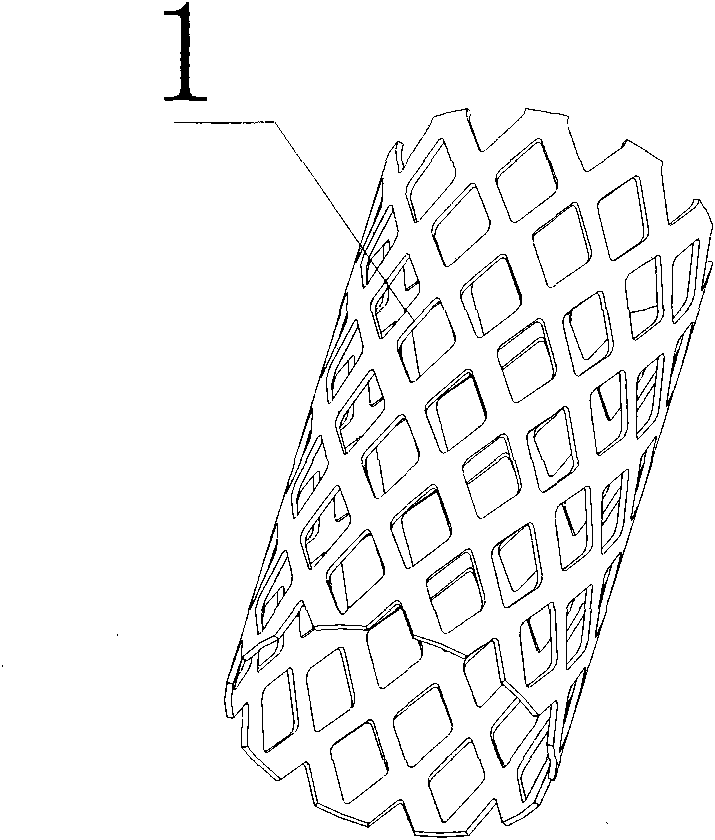

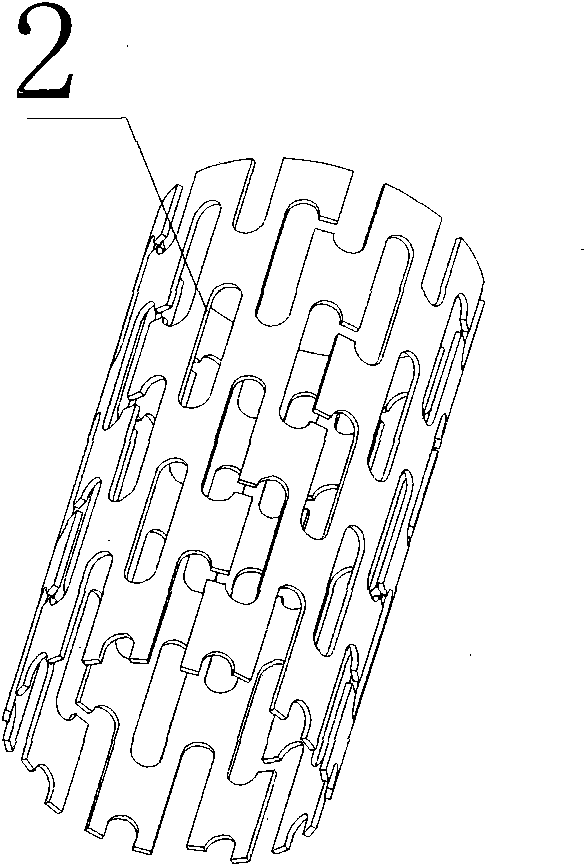

Selective laser melting (SLM) molding method for magnesium alloy stent

ActiveCN101856723BHigh forming precisionImprove mechanical propertiesIncreasing energy efficiencySelective laser meltingSelective laser sintering

The invention provides a selective laser melting (SLM) molding method for a magnesium alloy stent, comprising the following steps: (1) constructing a stent geometrical model in an upper computer, layering and dispersing the geometrical model, and generating a scanning path based on the geometrical model; (2) injecting inert gas in a molding chamber and controlling the oxygen concentration in the molding chamber within a certain concentration range; (3) supplying metal powder to a molding cylinder in the molding chamber by a powder supplier and spreading the metal powder on the molding cylinder by a powder spreading device; (4) adopting laser to scan the metal powder; (5) judging whether the stent is molded or not, if so, taking a stent molding piece out, and otherwise, executing the next steps; and (6) descending the molding cylinder by one layer, repeating the steps of (3), (4) and (5), and melting the metal powder layer by layer until deposition molding to obtain the molded magnesium alloy stent. The invention can mold stents with grids in arbitrary shapes and has the advantages of high manufacture precision and the like.

Owner:SOUTH CHINA UNIV OF TECH

A kind of ceramic material and its preparation method and application

ActiveCN109020605BHas a complex shapeWith strengthAdditive manufacturing apparatusCeramicwareSlurryGreen body

The invention belongs to the technical field of 3D printing materials, and in particular relates to a ceramic material and its preparation method and application. The invention provides a method for preparing a ceramic material, comprising the following steps: a) photocuring a slurry containing ceramic powder to obtain a green body; b) sequentially degreasing, impregnating and sintering the green body , to obtain ceramic materials. The invention prepares the green body through the light-curing molding method, which has high molding efficiency and high accuracy of the shape and size of the green body; through degreasing, the green body forms a porous green body without deformation and cracking, and after impregnation, it can be prepared to have Ceramic material with complex shape, high strength and toughness.

Owner:广东工大资产经营有限公司 +1

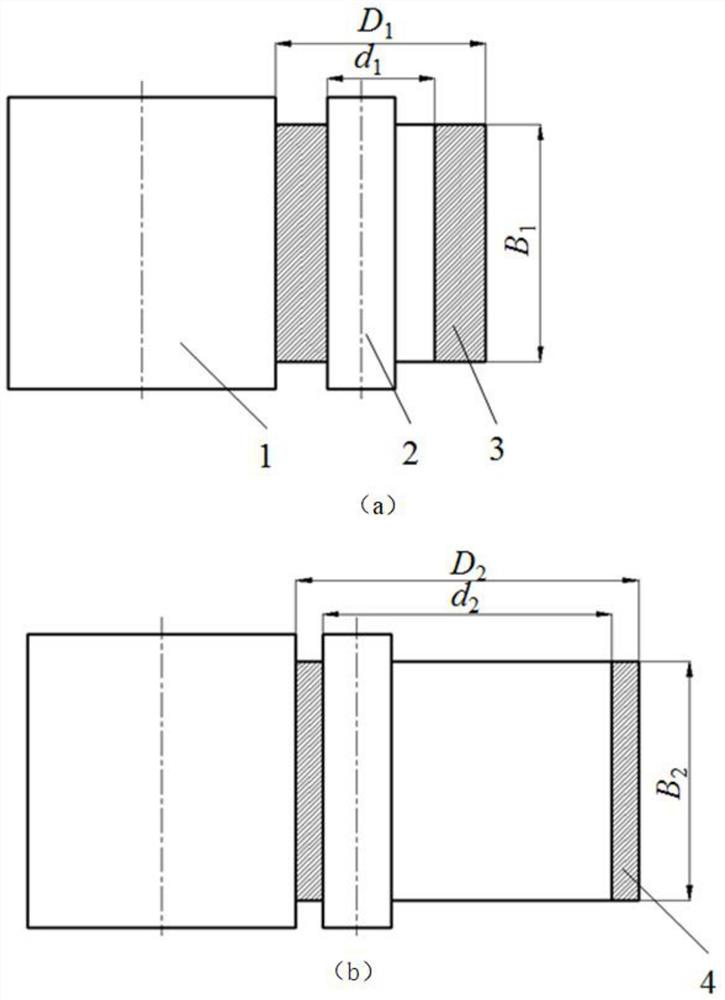

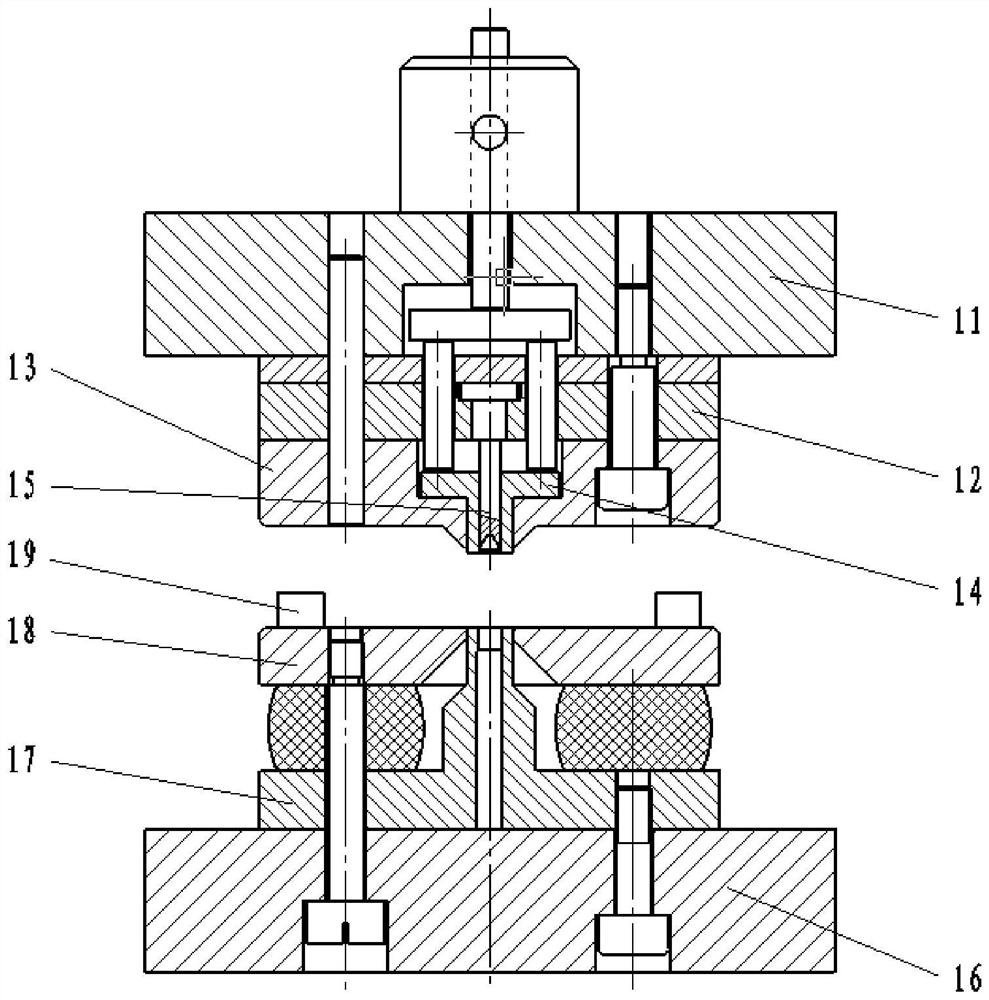

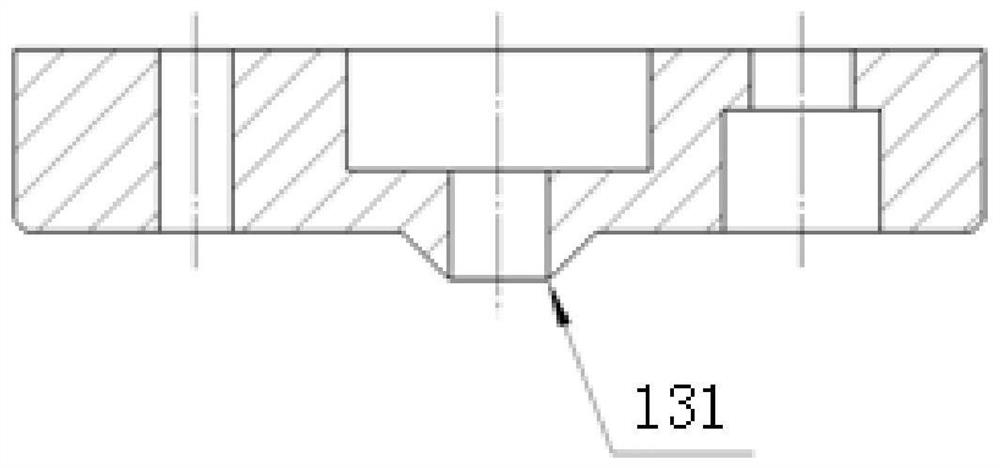

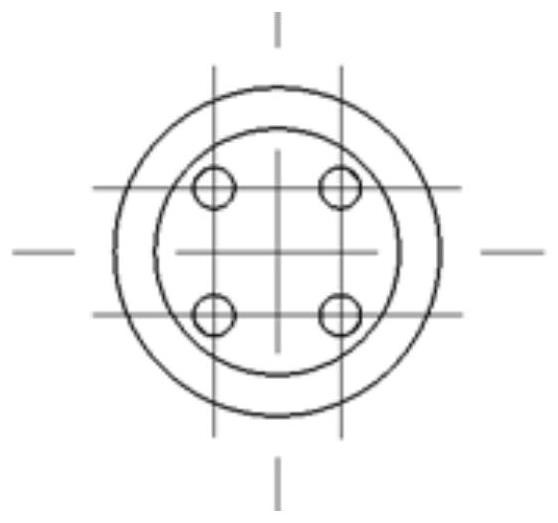

Manufacturing method and device of felt sealing ring for aviation and stamping die

The invention relates to a manufacturing method and device of a sealing ring, in particular to a manufacturing method and device of a felt sealing ring for aviation and a stamping die, and solves the problems that an inner hole of the felt sealing ring machined by an existing method is prone to hair slip and unstable in shape and size. The method comprises the following steps: punching felt into an annular blank by using a punching die according to a part drawing, loading the annular blank into a roasting clamp, roasting, inspecting and infiltrating. The device comprises a stamping die and a roasting clamp. The male die and the female die in the punching die are both provided with inclined cutting edges, so that the punched section of the felt is straight, deformation is small, high size precision can be obtained, meanwhile, the male die, the female die and the supporting block are coaxial and provided with radial fit clearances, and the punched end face of the annular blank is straight. The annular blank is roasted through the roasting clamp, redundant broken filaments in the inner hole are removed, shaping is achieved, and therefore the sealing ring manufactured through the method is free of protruding broken filaments in the inner hole, free of hair falling and stable in shape and size.

Owner:XIAN AERO ENGINE CONTROLS

Process Flow of Continuous Forming of 42crmo Steel Ring by Casting and Rolling

The invention discloses a technological process for performing a continuous casting-rolling formation on 42CrMo steel ring piece, and belongs to the technical field of batch production of medium-small scale ring pieces. The technological process is characterized by comprising the following steps of: alloy melting, refining of steel liquid, centrifugal casting of ring blanks, hot rolling, heat treatment and refining, wherein the step of refining of steel liquid is to melt the steel liquid in a basic electric arc furnace at 1680-1700 DEG C; and the step of centrifugal casting of ring blanks is to perform centrifugal pouring on the refined steel water to form ring blanks at 1550-1560 DEG C, demould the ring blanks at 1200-1250 DEG C after the pouring is finished, convey the ring blanks to a radial-axial rolling machine by a conveying system and directly roll and form the ring blanks at 1050 DEG C by utilizing blank casting afterheat. The process has the advantages that the utilization ratio of the material is improved, the technological process is shortened, the production cost is reduced, the quality and the accuracy of the ring piece are improved, the energy source and manpower resources are saved, and the production efficiency is improved.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Setting Method of Riser of Marine Diesel Engine Fuselage Casting

ActiveCN103658541BPrevent concentrated shrinkageImprove self-feeding capabilityFoundry mouldsFoundry coresSelf compensationEngineering

The invention provides a method for setting a riser on a casting of a ship diesel engine body. The riser is arranged at a central line part between a bottom plate of the casting and a crankshaft, the riser and a riser neck are previously solidified on the casting, and the diameter of the riser and the diameter of the riser neck are calculated according to the modulus of the riser and the modulus of the riser neck. The method solves the problems that as a traditional technology adopts a casting method for compensating contraction by the riser and the riser neck, excessive molten iron is squeezed back to the riser when the casting enters a graphitization expansion period, and although the casting is prevented from a concentrated contracted hole under the gravity action of the molten metal column of the riser when secondary contraction occurs in a solidifying later period, micro contracted loosening among eutectic colonies cannot be overcome. According to the application, the riser and the riser neck are previously solidified on the casting, and pressure is built in the casting through the utilization of all or part of eutectic expansion quantity. The contraction self-compensation capability is improved, and contracted loosening flaws are reduced.

Owner:CSIC NO 12 RES INST

Ultrasonic-assisted permeation and homogenization forming device and method for frozen printing liquid drops

ActiveCN114558990AImprove penetrationHigh accuracy of shape and sizeAdditive manufacturing apparatusFoundry mouldsUltrasonic generatorLow frequency ultrasound

The invention discloses an ultrasonic-assisted permeation and homogenization forming device and method for frozen printing liquid drops, the ultrasonic-assisted permeation and homogenization forming device comprises an ultrasonic generator, a transducer and an amplitude-change pole, the ultrasonic generator selects 20 KHz low-frequency ultrasonic waves, and a flange plate is arranged on the section surface of the amplitude-change pole and is in threaded connection with the outer cavity wall of a low-temperature forming chamber. According to the ultrasonic-assisted permeation and homogenization forming method for the frozen printing liquid drops, in the sand paving process, pre-paved molding sand particles are subjected to ultrasonic vibration to be homogenized and distributed by adjusting the frequency of an ultrasonic generator; when the pure water binder is sprayed, liquid drops are sprayed to the surface of the pre-mixed molding sand and permeate to the bottom of the pre-cooled molding sand under the assistance of low-frequency ultrasonic waves to be frozen, solidified and formed. The sand mold freezing 3D printing method is adopted for sand mold freezing 3D printing, sand paving is compact and uniform, liquid drop permeation is sufficient, and the sand mold freezing printing forming precision is precise and controllable.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

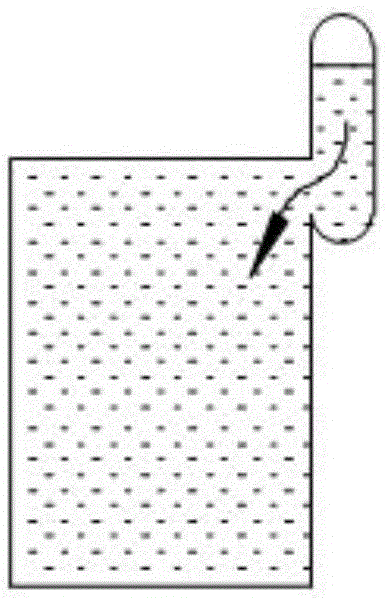

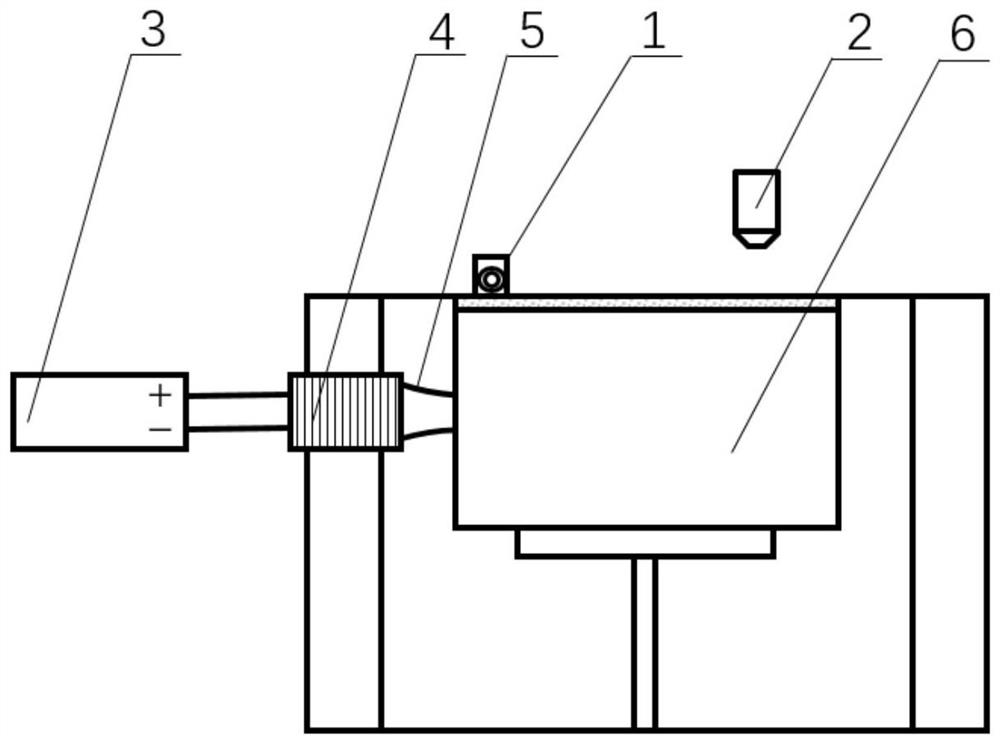

Gradient material electrode and preparation method thereof

ActiveCN110814449BInhibitionHigh accuracy of shape and sizeElectrical-based machining electrodesConductive materialsElectrical discharge machining

The invention discloses a gradient material electrode and a manufacturing method thereof. At least one layer of low-loss-rate conductive materials, which are in gradient diffusion from outside to inside, is arranged on a preset surface of an electrosparking processing tool electrode. A layer of materials with a processing loss rate lower than that of an electrode base body is prepared on the preset surface (all surface or side wall area surface) of the electrode, material component change gradient is formed from outside to inside, and matrix material components are finally equivalent, so thatthe loss rate is gradually transited to be the same with the loss rate of the matrix material from low to high, and therefore, generation or expansion of a fillet on the sharp corner position of the electrode is restrained, and shape dimension precision of the processed workpiece is improved; material components of the gradient material of the electrode matrix surface are gradually transited and are firmly combined with the matrix material, so that the defect that a purely prepared layer of low-loss-rate materials is liable to collapse in an electro-spark processing process is avoided.

Owner:SHENZHEN UNIV

Thrust compound power device and method for producing special-shaped wire using the device

The invention discloses a thrust composite power device and method applying the same for producing specially-shaped wire materials. The device comprises a rack, a drawing die, a forming die, a plurality of roll wire-pushing mechanisms and a drive mechanism, wherein the plurality of roll wire-pushing mechanisms are transversally arranged in parallel; the plurality of roll wire-pushing mechanisms are located between the drawing die and the forming die, and a transmission gear disc is connected between the adjacent roll wire-pushing mechanisms; the drive mechanism drives one transmission gear disc to rotate. According to the device disclosed by the invention, a wire feeding mode of roll wire-pushing is adopted, and moreover, the wire materials are pushed in the forming die, and a tension device does not need to be configured at the outlet of the forming die, and thus simplifying the overall device; working procedures are reduced in a manner of combining rolling with die drawing, and thus increasing the working efficiency, and reducing the working intensity and labour amount of working personnel; meanwhile, specially-shaped steel wires with great width-thickness ratios and complex shapes can be produced through reasonable collocation of multi-pass rolling, so that the varieties of the producible specially-shaped steel wires are increased, and the shape and dimension accuracies of the products are high.

Owner:DONGGUAN KELEE STEEL WIRE

Near-net compound forming method for large ring with sudden change in wall thickness

ActiveCN113059100BReduce forging forceHigh accuracy of shape and sizeMetal rollingThermodynamicsPunching

The invention discloses a near-net composite forming method for a large-scale sudden change in wall thickness ring. The small-diameter rectangular cross-section ring billet after forging and punching is heated and kept warm, taken out and put on a hot-rolled ring machine for rolling. When the outer diameter grows to Stop rolling when the target size is reached to obtain a large-diameter rectangular cross-section ring billet, take it out and heat it for heat preservation; put the large-diameter rectangular cross-section ring billet into the forming mold for thermoforming, obtain the desired shape of the special-shaped cross-section ring billet, take it out and heat it for heat preservation; Ring rolling near-net shape—put the special-shaped cross-section ring billet on the ring rolling machine for fine ring rolling, and use special-shaped rolls to form the ring section profile, and stop rolling when the outer diameter grows to the target size to obtain rings with abrupt wall thickness ; Put the ring with sudden change in wall thickness on the bulging machine quickly, and use the waste heat to perform thermal bulging to improve the dimensional accuracy and roundness and improve the distribution of residual stress. After bulging to the target size, continue to hold the pressure, and take it out after cooling to room temperature. Get the target ring. This method has high forming precision.

Owner:WUHAN UNIV OF TECH

A 750mpa grade high-strength steel plate, its use and its manufacturing method

ActiveCN104018092BImprove the uniformity of mechanical propertiesEasy to shapeUltimate tensile strengthMechanical property

The invention relates to a 750MPa-level high-strength steel plate, and application and a manufacturing method thereof. The 750MPa-level high-strength steel plate contains the following components in percentage by weight: 0.14-0.18% of C, 0.20-0.40% of Si, 1.30-1.70% of Mn, at most 0.015% of P, at most 0.005% of S, 0.030-0.060% of Nb, 0.030-0.060% of V, 0.20-0.50% of Cr, 0.05-0.20% of Mo, 0.015-0.040% of Al, and the balance of Fe and inevitable impurities. The steel plate produced according to the chemical components, technique and specific method has the following parameters: the yield strength is 650-700 MPa, the tensile strength is 800-850 MPa, the elongation percentage is 16-20%, the hardness HV10 is 250-300, the -60 DEG C Charpy V-notch impact energy is greater than 40J (the size of the impact specimen is 4*10*55mm), the transverse, longitudinal and 45-degree strength difference is less than 20 MPa, and the mechanical property uniformity is high.

Owner:MAGANG (GROUP) HOLDING CO LTD +1

A kind of preparation method of tooth-shaped special-shaped ceramics

The invention relates to the technical field of ceramic preparation, in particular to a preparation method of tooth-like special-shaped ceramics. Slurry is applicable to a photo-curing forming method to prepare tooth-like ceramic bodies by optimizing the composition and proportioning of the slurry, the forming efficiency is high, ceramic particles in the bodies can be also dispersed evenly, and the shape and size accuracy of the bodies is high; the bodies cannot deform and crack in the producing process by controlling process parameters in degreasing and sintering steps, the sintered compactness is higher, tooth-like ceramic products are more uniform in structure, higher in accuracy and better in surface smoothness, the thickness of the tooth-like ceramic products can be greater than 8 mm, and accordingly the reliability of the ceramic products is improved.

Owner:GUANGDONG UNIV OF TECH

Casting and rolling continuous forming technological process for 42CrMo steel ring piece

The invention discloses a technological process for continuous forming of 42CrMo steel casting and rolling, which belongs to the technical field of batch production of medium and small ring parts. The feature is that the technological process is alloy melting → molten steel refining → centrifugal casting ring billet → hot rolling → heat treatment → finishing, the molten steel refining is smelted by alkaline electric arc furnace oxidation method, and the smelting temperature is 1680 ° C ~ 1700 ° C; Centrifugal ring billet casting refers to the centrifugal casting of refined molten steel into a ring billet. The pouring temperature is 1550°C~1560°C. After the pouring is completed, the mold is released at 1200°C~1250°C. It is transferred to radial-axial rolling through the conveying system. On the machine, the waste heat of the cast slab is directly rolled and expanded at 1050°C. The advantage is that the utilization rate of materials is improved, the technological process is shortened, the production cost is reduced, the quality and precision of ring parts are improved, energy and human resources are saved, and production efficiency is improved.

Owner:赵敏

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com