Forming equipment of medium-thick-wall integral automobile drive axle shell axle arch

A forming equipment and integral technology, applied in metal processing equipment, forming tools, manufacturing tools, etc., can solve the problems that restrict the development of the integral drive axle housing of heavy vehicles, the difficulty of processing the contour of the large arc surface, and the difficulty of the contour of the large arc surface. Large and other problems, to achieve the effect of rich and diverse movement mechanisms, avoiding the problem of cracking defects, and improving the appearance and comprehensive mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

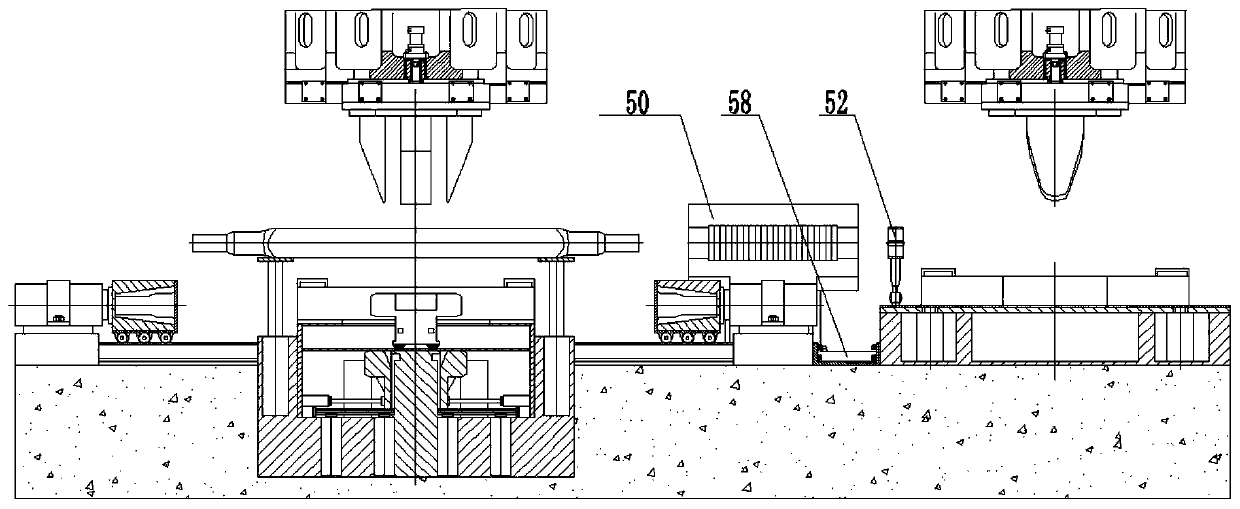

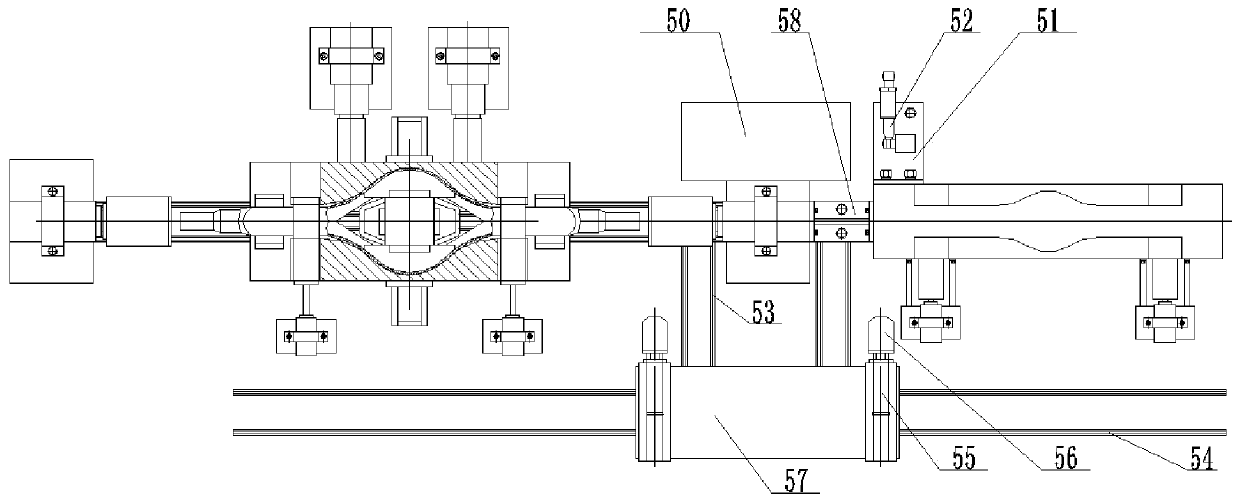

[0050] like Figure 1-Figure 17 As shown, the forming equipment for the medium-thick-wall integrated automobile drive axle housing bridge arch includes a wedge pre-expansion forming mechanism, a mandrel expansion forming mechanism, a semi-closed heating furnace 50, an industrial robot mechanism and a transportation mechanism. The core mold expansion forming mechanism is located on the left side of the wedge pre-expansion forming mechanism, and the core mold expansion forming mechanism is connected with the wedge pre-expansion forming mechanism through a connecting seat 58, and the core mold expansion forming mechanism is close to the wedge A semi-closed heating furnace 50 is installed on the cylinder block 35 on one side of the pre-expansion forming mechanism through a semi-closed heating furnace bracket, and an industrial robot mechanism is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com