Manufacturing method of laminated ceramics

A ceramic and layered technology, applied in the field of layered ceramics preparation, can solve the problems of high cost and complicated preparation process, and achieve the effect of high molding efficiency, excellent performance and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

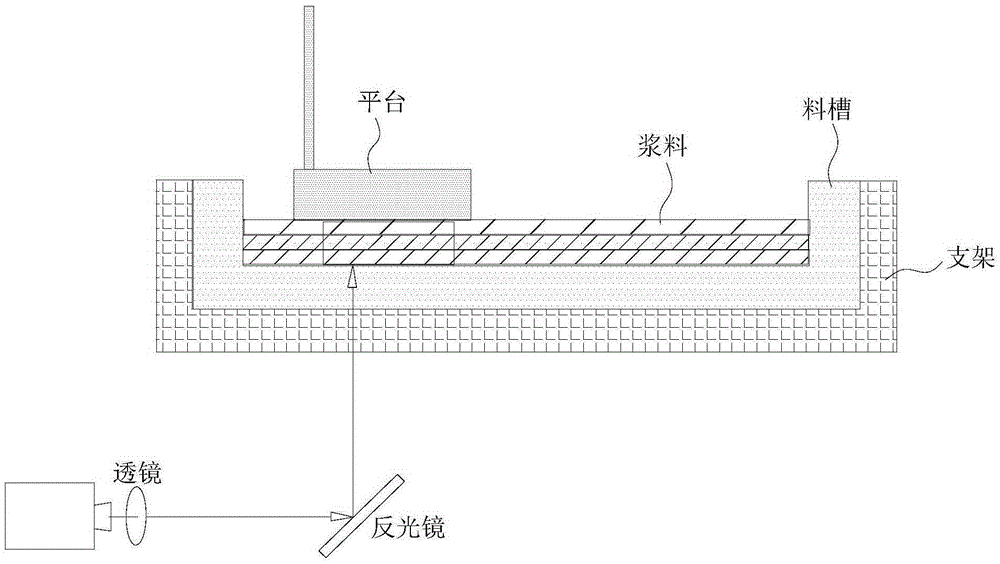

Method used

Image

Examples

Embodiment 1

[0030] This embodiment provides a method for preparing a layered ceramic with a three-layer structure, and the specific steps are as follows:

[0031] (1) Preparation of slurry

[0032] The first slurry, the second slurry, and the third slurry were prepared respectively as follows: firstly, the ceramic powder, dispersant and ethanol were ball milled in a planetary ball mill (or a roller ball mill in other embodiments) for 8 hours , so that the components are mixed uniformly; then the obtained mixture is dried at 60° C. to obtain a dispersed powder. Then, the dispersed powder, resin and surfactant were ball-milled in a ball mill for 16 hours to mix the components uniformly to obtain the primary slurry. Next, the initial slurry was placed in a negative pressure environment and stirred for 30 minutes to remove air bubbles to obtain a slurry. (The ball milling medium used in the ball milling is alumina, the shape of the ball milling medium is spherical, the diameter of the ball ...

Embodiment 2

[0048] This embodiment provides a method for preparing a layered ceramic with a three-layer structure, and the specific steps are as follows:

[0049] (1) Preparation of slurry

[0050] The first slurry, the second slurry, and the third slurry were prepared respectively as follows: firstly, the ceramic powder, dispersant and ethanol were ball-milled in a planetary ball mill for 8 hours to mix the components evenly; then the obtained mixture was placed in Dry at 60°C to obtain a dispersed powder. Then put the dispersed powder, resin and surfactant in a ball mill for 16 hours to make the components evenly mixed to obtain the primary slurry. Next, the initial slurry was placed under a negative pressure environment and stirred for 60 minutes to remove air bubbles to obtain a slurry. (The ball milling medium used in the ball mill is zirconia, the shape of the ball milling medium is columnar, the diameter of the ball milling medium is 5mm, and the ratio of material to ball is 2:1....

Embodiment 3

[0066] This embodiment provides a method for preparing a layered ceramic with a three-layer structure, and the specific steps are as follows:

[0067] (1) Preparation of slurry

[0068] The first slurry, the second slurry, and the third slurry were prepared respectively as follows: firstly, the ceramic powder, dispersant and ethanol were ball-milled in a roller ball mill for 8 hours to mix the components uniformly; then the obtained mixture was Dry at 60°C to obtain a dispersed powder. Then put the dispersed powder, resin and surfactant in a ball mill for 24 hours to make the components evenly mixed to obtain the primary slurry. Next, the initial slurry was placed in a negative pressure environment and stirred for 20 minutes to remove air bubbles to obtain a slurry. (The ball milling medium used in the ball milling is zirconia, the shape of the ball milling medium is columnar, the diameter of the ball milling medium is 10mm, and the ratio of material to ball is 6:1.)

[006...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com