Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

43results about How to "Has a promoting effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Infant formula milk powder for improving health of intestinal tract and preparation method thereof

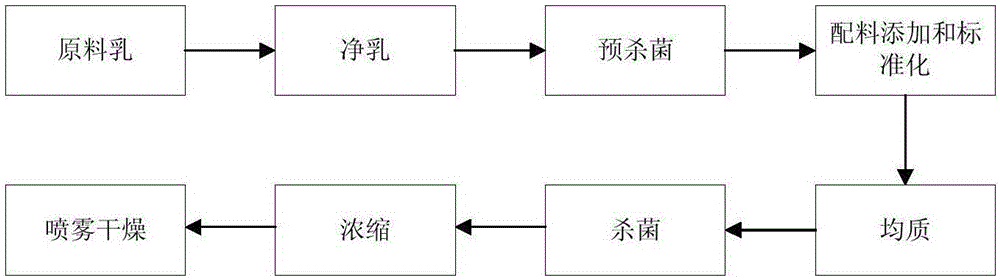

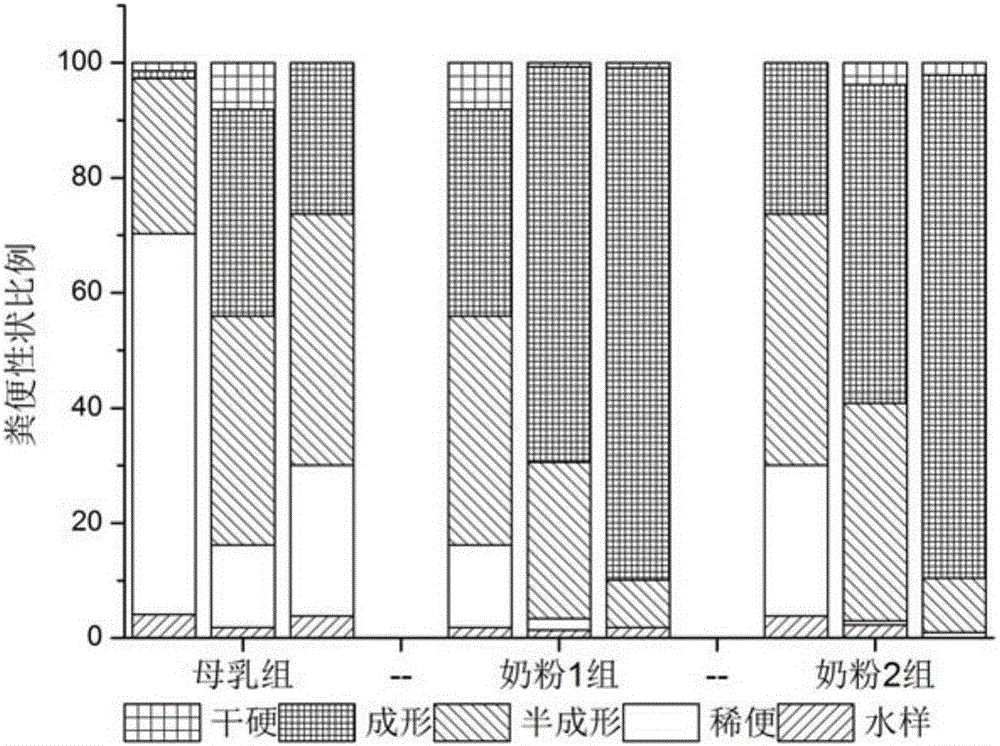

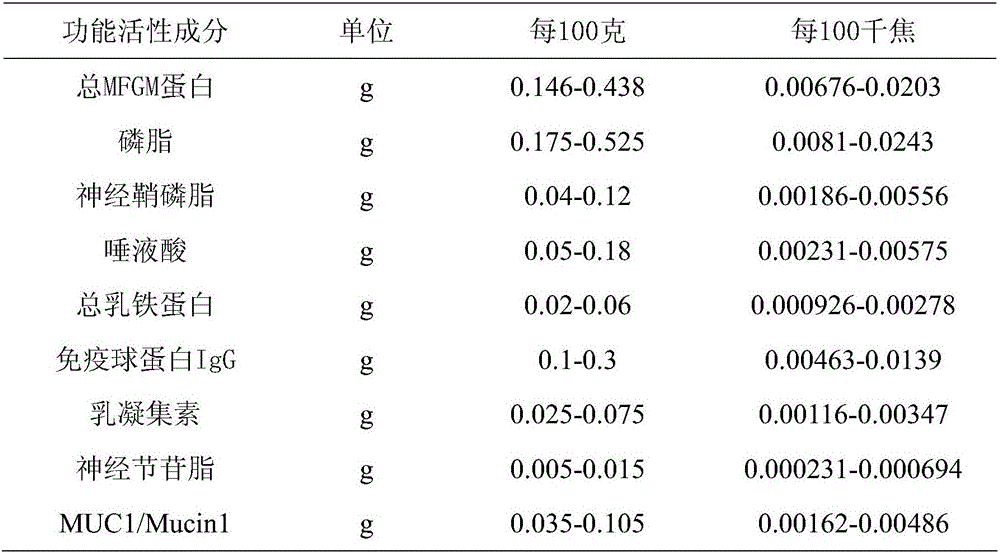

The invention provides infant formula milk powder for improving health of intestinal tracts, which is prepared with raw milk as a main raw material with addition of whey protein powder being rich in MFGM and other materials. By means of the novel whey protein powder being rich in MFGM as the raw material, contents of bio-active substances having special functional components, such as MFGM protein, lactoferrin, phospholipid, gangliosides, sphingomyelin, sialic acid and the like, are increased by regulation of the formula, so that the milk powder can promote colonization of probiotics in intestinal flora of infants and improves the content of immune factors in intestinal tracts and reduces intestinal disease incidence. The formula is suitable for researching on formula milk powder for infants and follow-up infants.

Owner:BEIJING SANYUAN FOOD

Preparation method and application of pelodiscus sinensis collagen peptide

InactiveCN105063140AShorten the enzymatic digestion timeImprove peptide content and purityCosmetic preparationsHydrolysed protein ingredientsEnzymatic hydrolysisFreeze dry

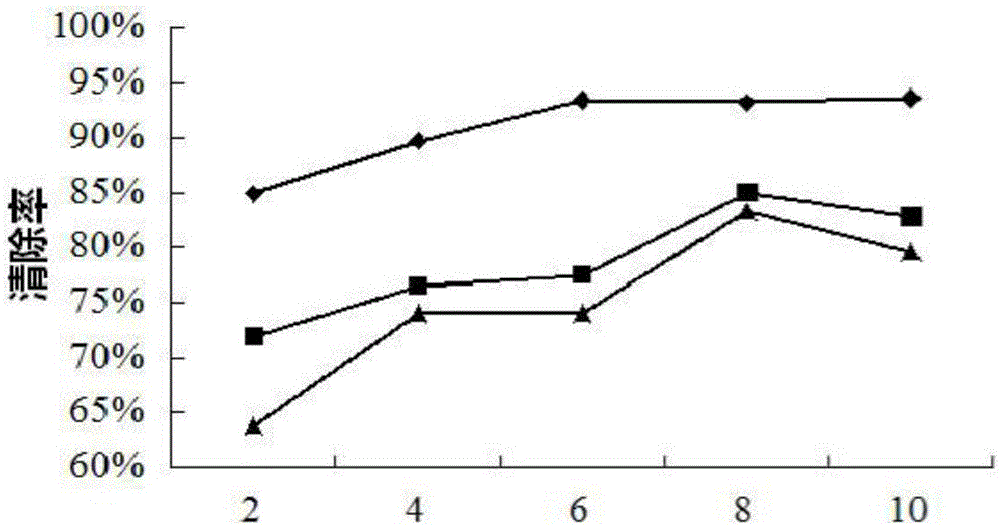

The invention relates to a preparation method of pelodiscus sinensis collagen peptide. The preparation method is characterized by comprising the following steps: (1) preprocessing; (2) enzymatic hydrolysis: adding papain to a collagen solution obtained from the step (1) for enzymatic hydrolysis so as to convert collagen into collagen peptide; (3) enzyme inactivation; (4) centrifugation: centrifuging enzymatic hydrolysate obtained from the step (3) and reserving supernatant liquid; (5) membrane separation: intercepting a collagen peptide component which is less than 10000Da in molecular weight from the supernatant liquid through membrane separation; (6) concentration; and (7) freeze-drying. Meanwhile, the invention also provides application of the collagen peptide in the preparation of drugs, health care products as well as skin care and beauty products having an immune enhancing function. Compared with the prior art, the preparation method disclosed by the invention has the advantages that the pelodiscus sinensis collagen peptide is extracted within 2-4h only by combining a one-time enzymic method and membrane separation technology, so that enzymatic hydrolysis time is effectively reduced compared with general researches which require 5-6; and in addition, the collagen peptide which is less than 10000Da is obtained through separation, so that peptide content and purity of a finished collagen peptide product are significantly improved.

Owner:ZHEJIANG WANLI UNIV

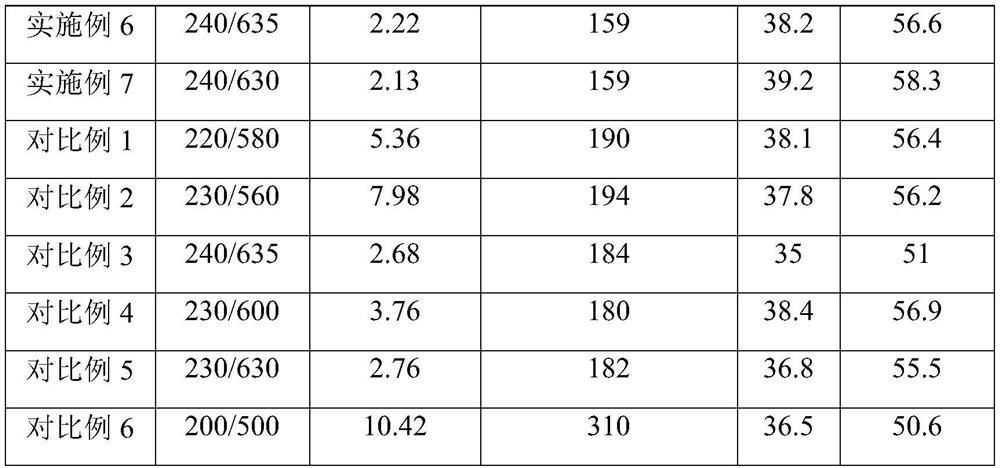

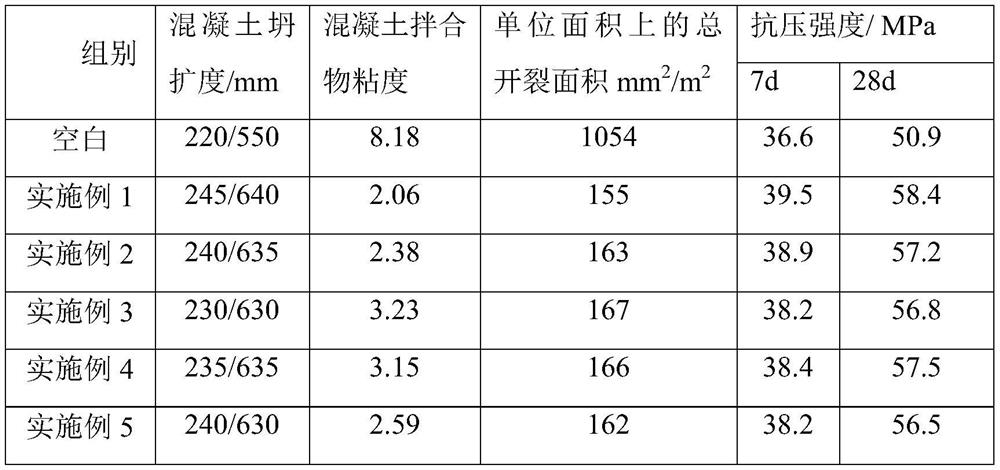

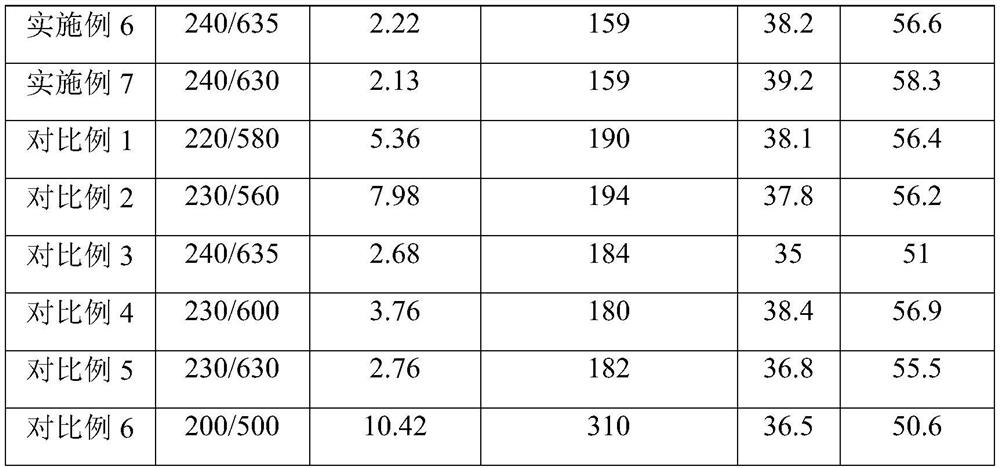

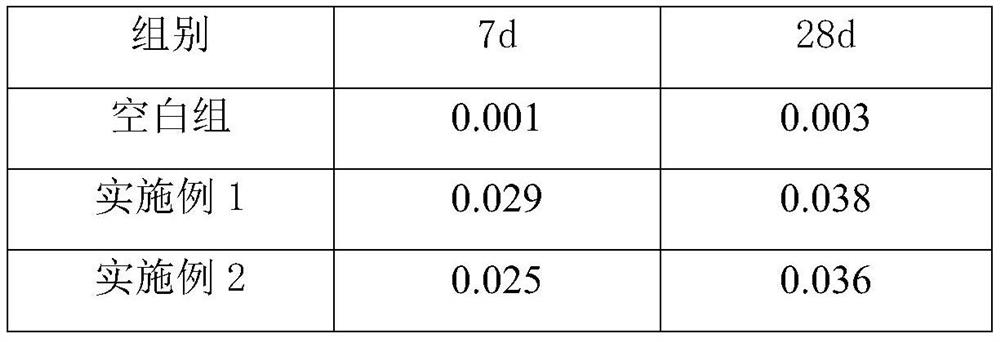

Viscosity-reducing enhanced anti-cracking agent and preparation method thereof

ActiveCN113387612AOvercoming the problem of increased viscosityLow viscosityCelluloseSilicon dioxide

The invention discloses a viscosity-reducing enhanced anti-cracking agent and a preparation method thereof. The viscosity-reducing enhanced anti-cracking agent is prepared from the following raw materials in percentage by mass: 30-60% of a modified magnesium oxide expanding agent, 5-20% of synthetic fiber, 10-40% of a viscosity-reducing component and 20-50% of an enhancing component, wherein the viscosity-reducing component comprises microbead powder, cellulose ether, a powder water reducing agent and sepiolite, and the enhancing component comprises a superfine mineral admixture, silica fume, nano silicon dioxide, sodium gluconate and urea. According to the invention, a viscosity-reducing component and an enhancing component are compounded on the basis of shrinkage compensation of an expanding agent and early crack resistance of fibers, the components have a synergistic effect under a proper ratio so as to effectively reduce the viscosity of concrete and improve the strength of the concrete, and the viscosity-reducing component and the enhancing component have a promoting effect on the expanding agent so as to synergistically improve the expansion effect of the expanding agent.

Owner:武汉三源特种建材有限责任公司

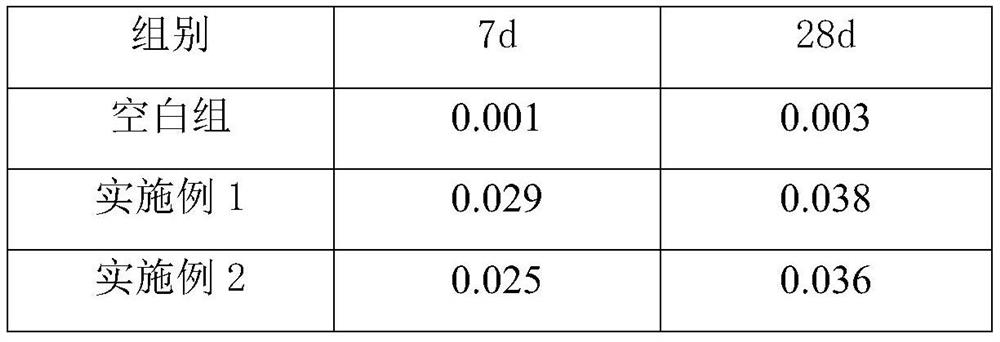

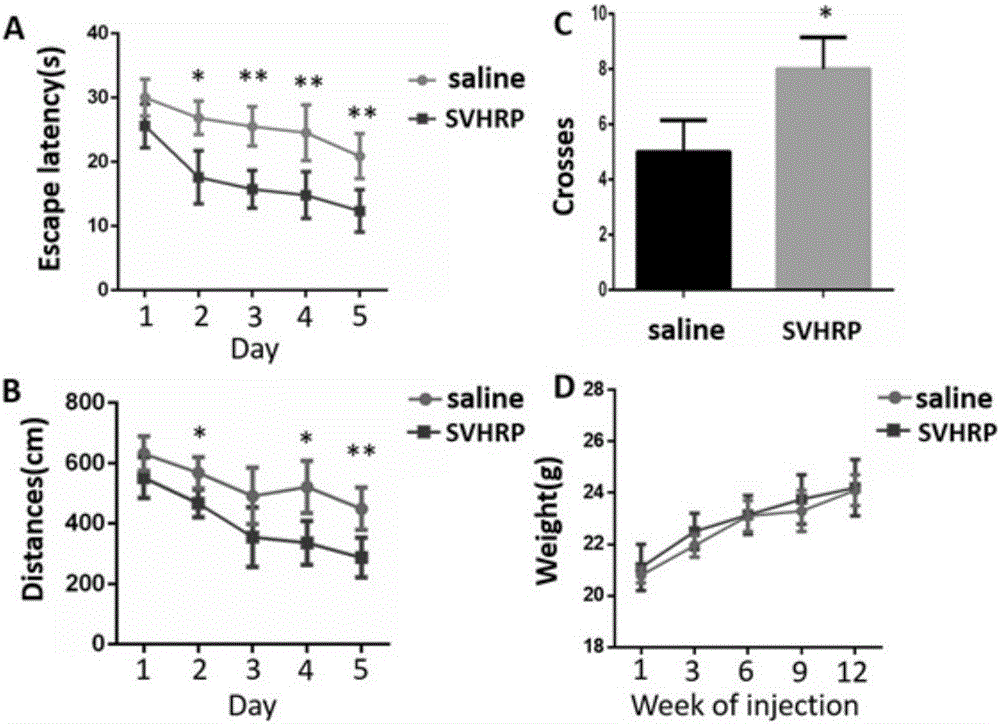

Scorpion venom heat-resistant synthetic peptide and application thereof

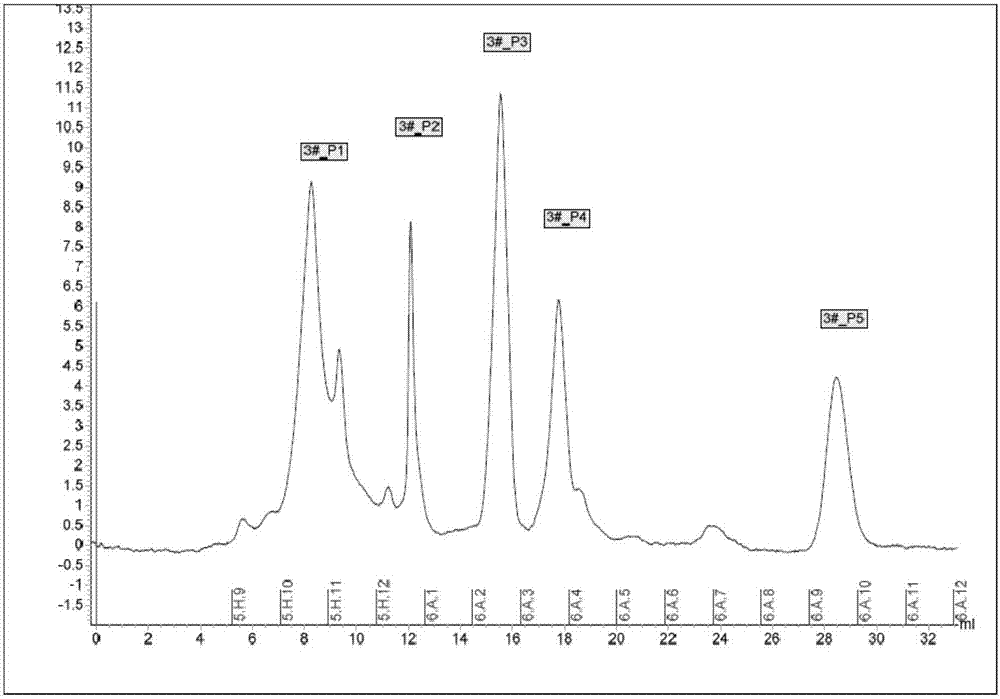

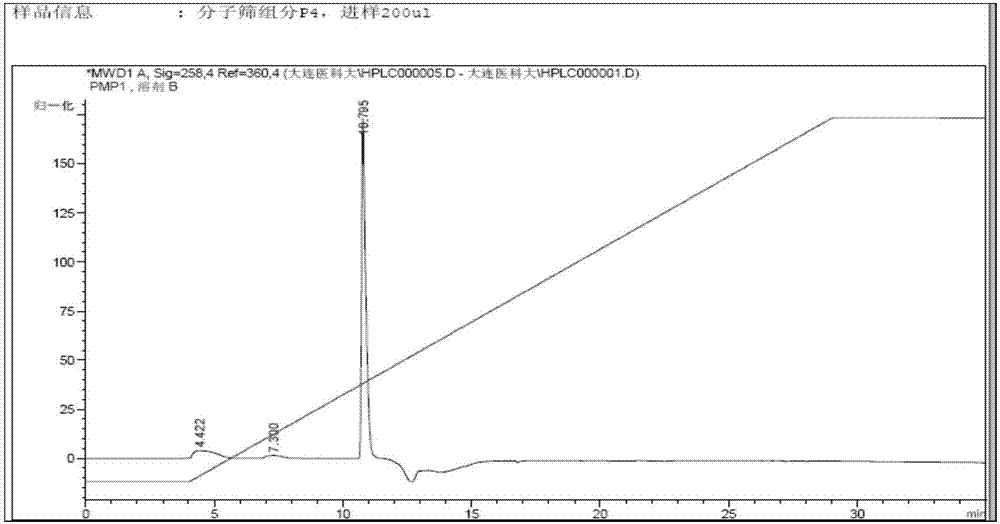

ActiveCN106220713AHas a promoting effectImprove chemotaxis abnormalitiesNervous disorderPeptide/protein ingredientsDiseaseChemical synthesis

The invention belongs to the field of research and development of polypeptide medicines and discloses a scorpion venom heat-resistant synthetic peptide and application thereof. An amino acid sequence of an SVHRP (scorpion venom heat-resistant peptide) is detected out from BmK (Buthus martensii Karsch) which is a traditional Chinese medicine; according to animal experiment verification, a scorpion venom heat-resistant peptide extract liquid sample has pharmacological activity in prevention and treatment of intractable epilepsy, Parkinson's disease and Alzheimer's disease, the sample is subjected to LaGm composite and repeated fast magnetic separation prior to nanoLC-ESI-MS (nano-liter reversed-phase chromatography and electrospray ionization mass spectrometry) integrated mass spectrometry parallel experiment to detect out a polypeptide sequence formed by 15 amino acid residues. The scorpion venom heat-resistant synthetic peptide is prepared by solid-phase chemical synthesis, chromatography purification and mass spectrometry identification. An amino acid sequence of the scorpion venom heat-resistant synthetic peptide is as shown in SEQ ID NO.1 and keeps pharmacological activity and safety of the scorpion venom heat-resistant peptide, and the scorpion venom heat-resistant peptide also has a characteristic of biological activity in promotion of reverse differentiation of neuroglial cells into neural stem cells.

Owner:上海万锦医药科技有限公司

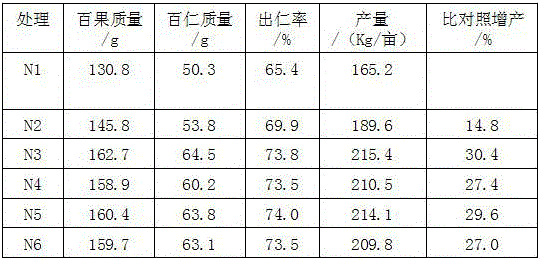

Total nutrient and loosed soil type multifunctional fertilizer specially used for peanuts and production method thereof

InactiveCN106699475APromote expansionIncrease productionCalcareous fertilisersAlkali orthophosphate fertiliserPhosphatePotassium

The invention discloses a total nutrient and loosed soil type multifunctional fertilizer specially used for peanuts. The fertilizer is characterized by being prepared from the following raw materials in parts by weight: 23-26 parts of urea, 25-27 parts of monoammonium phosphate, 23-27 parts of potassium chloride, 3-5 parts of a silicon calcium magnesium fertilizer, 11-16 parts of clay, 1-2 parts of humic acid, 1-2 parts of polyacrylamide and 1-2 parts of a microelement auxiliary. The fertilizer product pays attention to a peanut growth soil environment, is beneficial to acicula formation and ovary enlargement of peanuts, and effectively improves the peanut yield.

Owner:STANLEY AGRI GRP CO LTD

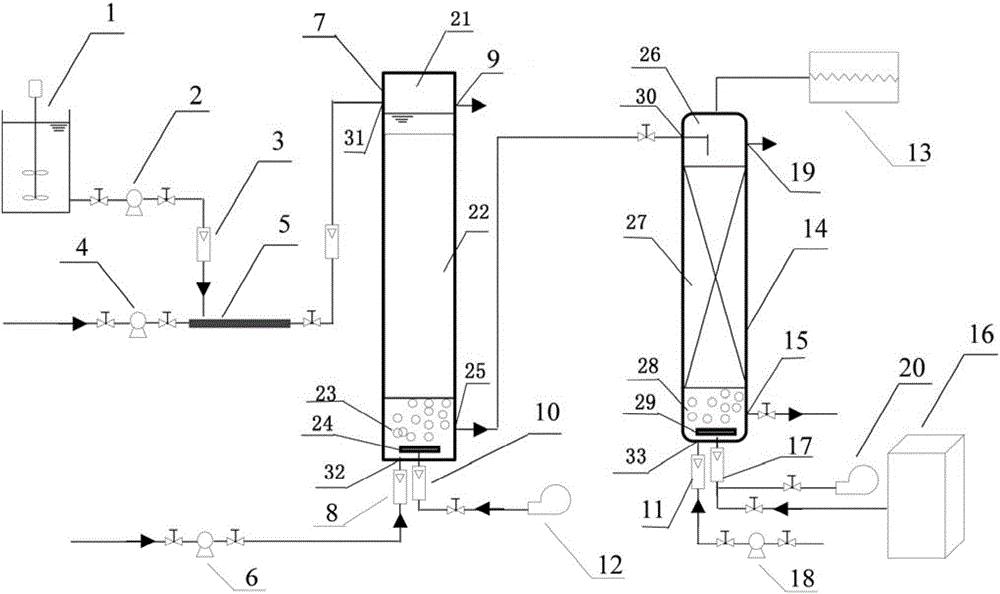

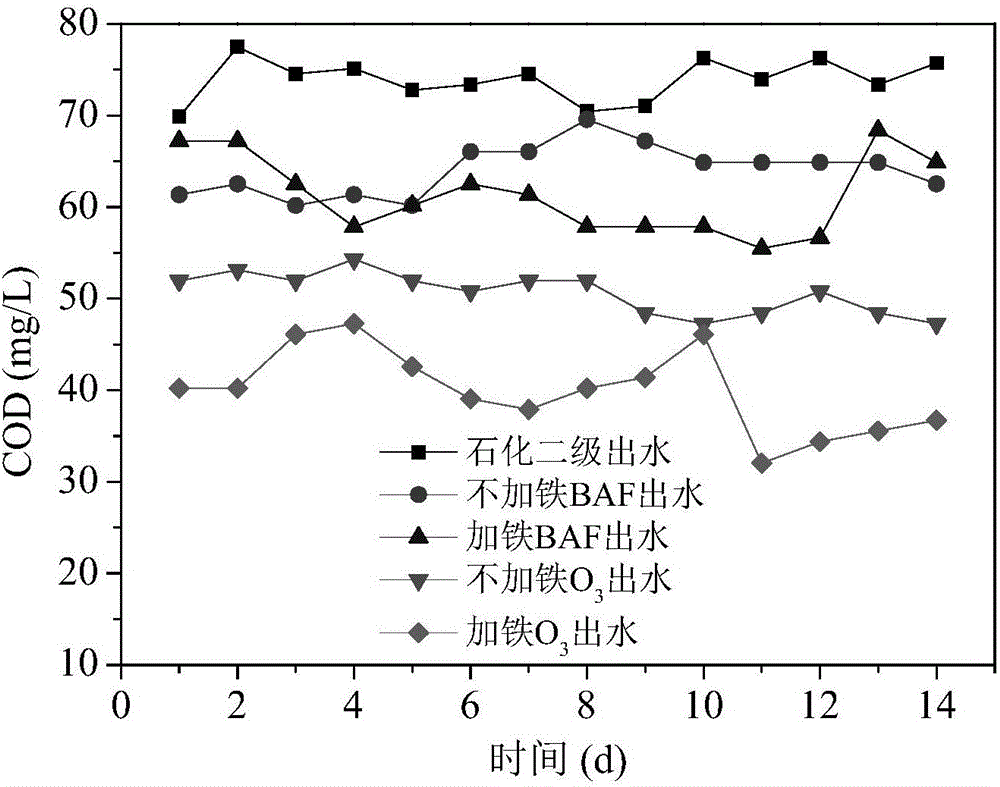

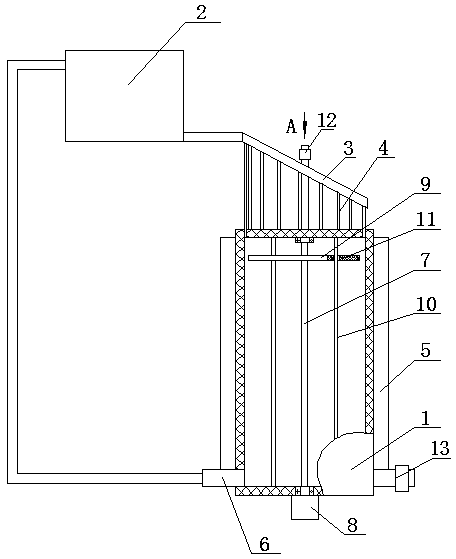

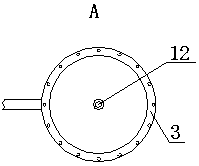

Coupled type waste water treatment device and treatment method of petrochemical secondary effluent

ActiveCN105819629AHigh removal rateSave volumeTreatment using aerobic processesWater treatment compoundsPetrochemicalOrganic matter

The invention discloses a coupled type waste water treatment device which comprises a biological aerated filter (7) and a catalytic ozonation tower (14) .The biological aerated filter (7) is in a downward flow mode, and sequentially comprises a first water inlet area (21), a first filler area (22) and a first water outlet area (23) from top to bottom .The catalytic ozonation tower (14) is a sealed tower, and sequentially comprises a second water inlet area (26), a second filler area (27) and a second water outlet area (28) from top to bottom .The sewage deep treatment technology is provided aiming at the urgent technical demand of petrochemical sewage plants in China for upgrading and reconstruction, phosphorus and organic matter can be removed at the same time, and the two units can be coupled.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

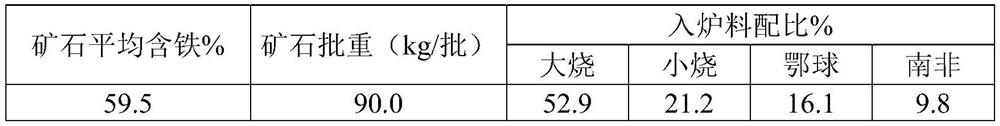

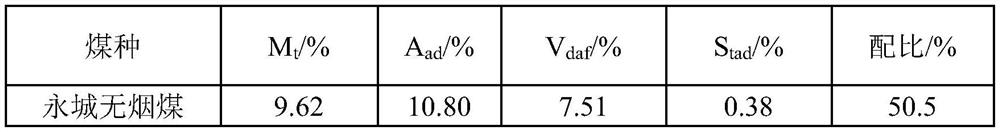

Method for smelting scrap steel through blast furnace oxygen-enriched large-proportion bituminous coal injection

ActiveCN114686626ALarge storage capacityRaise the ratioBlast furnace detailsProcess efficiency improvementAir volumeCoke

The invention discloses a method for smelting waste steel by blast furnace oxygen-enriched large-proportion bituminous coal injection, which comprises the following steps: charging: all charging materials of a blast furnace comprise sintered ore, pellet ore, lump ore, coke and waste steel, adding the waste steel at the edge ring belt of the blast furnace according to the mass ratio of the waste steel consumption to the ore batch weight in each batch of charging materials of (3-5): 22, and charging into the furnace for smelting; material distribution: the ore-coke ratio at the edge of a furnace wall is 4: 3 or 3: 2, and the mass percent of the central coke adding amount is 29.4-33.3% of that of a coke batch; blowing: blowing coal is mixed coal of anthracite and bituminous coal, and the mass percentage of the bituminous coal is 42-45%; air blowing: the adopted air blowing oxygen enrichment rate is 8-12%, and the standard air speed (standard air volume / air inlet area) is 252-272 m / s; by improving the blast oxygen enrichment rate of the blast furnace, using high-volatile bituminous coal for injection in a large proportion, adding waste steel into the furnace, adjusting the material distribution system, strengthening the central gas flow of the blast furnace and inhibiting the edge gas flow, the stable furnace condition, low consumption and high yield of the blast furnace are realized.

Owner:武汉钢铁有限公司

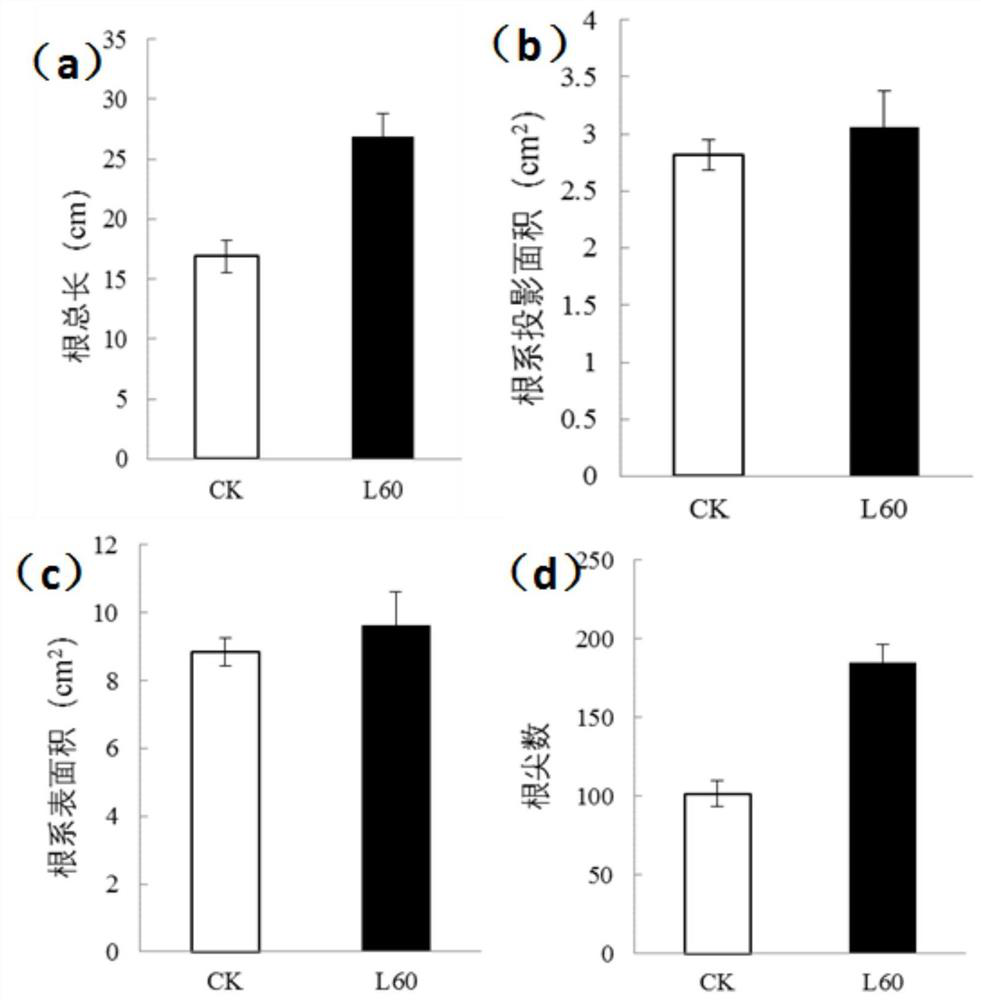

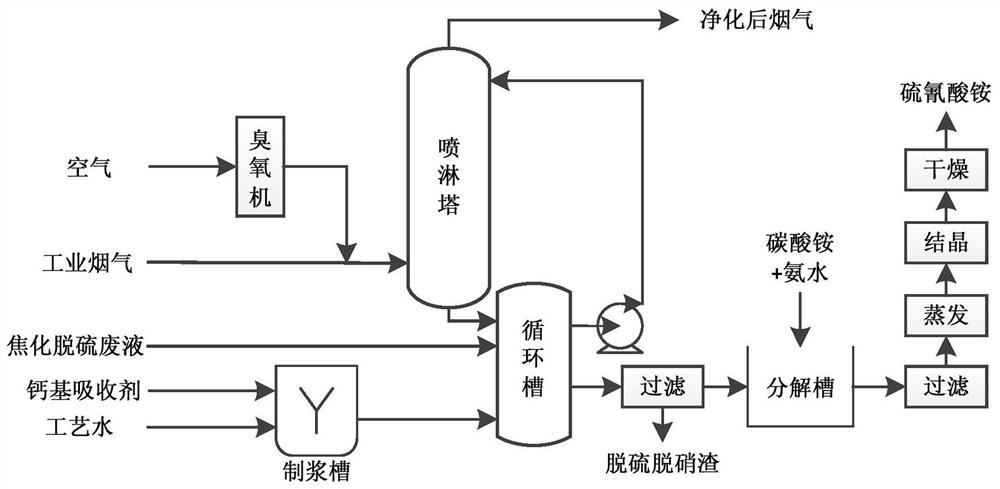

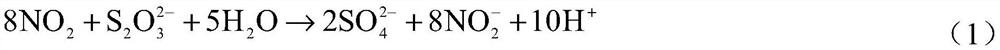

Method for cooperative treatment of coking desulfurizing waste liquid, calcium-based solid waste and pollutants in industrial smoke

ActiveCN108211761AEfficient removalIncrease added valueGas treatmentDispersed particle separationDecompositionCo-processing

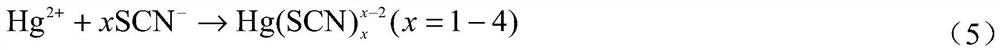

The invention relates to a method for cooperative treatment of coking desulfurizing waste liquid, calcium-based solid waste and pollutants in industrial smoke. The method comprises the following steps: absorbing the oxidized industrial smoke by using absorbent slurry while controlling the pH of the slurry to 6 or higher during the absorption, wherein the absorbent slurry is a mixture of the calcium-based solid waste and the coking desulfurizing waste liquid; after the absorption, discharging the purified smoke, and performing solid-liquid separation on the absorbent slurry; performing impurityremoval and pH regulation on the obtained liquid phase, and heating for decomposition; performing solid-liquid separation to obtain an ammonium thiocyanate product. The method provided by the invention can realize efficient removal of sulfur dioxide, nitrogen oxide and mercury in smoke while recycling an ammonium thiocyanate product with high added value. The method provided by the invention canbe used for performing cooperative treatment on the waste gas, wastewater and waste residue generated in an industrial production process, has the advantages of simple process, low raw material cost and no wastewater discharge in the whole process, realizes cyclic economy of dealing with waste by waste, is suitable for industrial application and creates good economic benefits.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

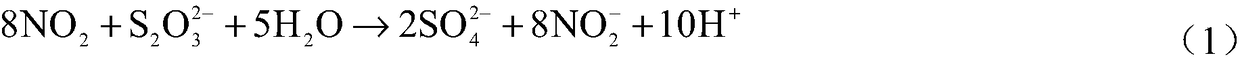

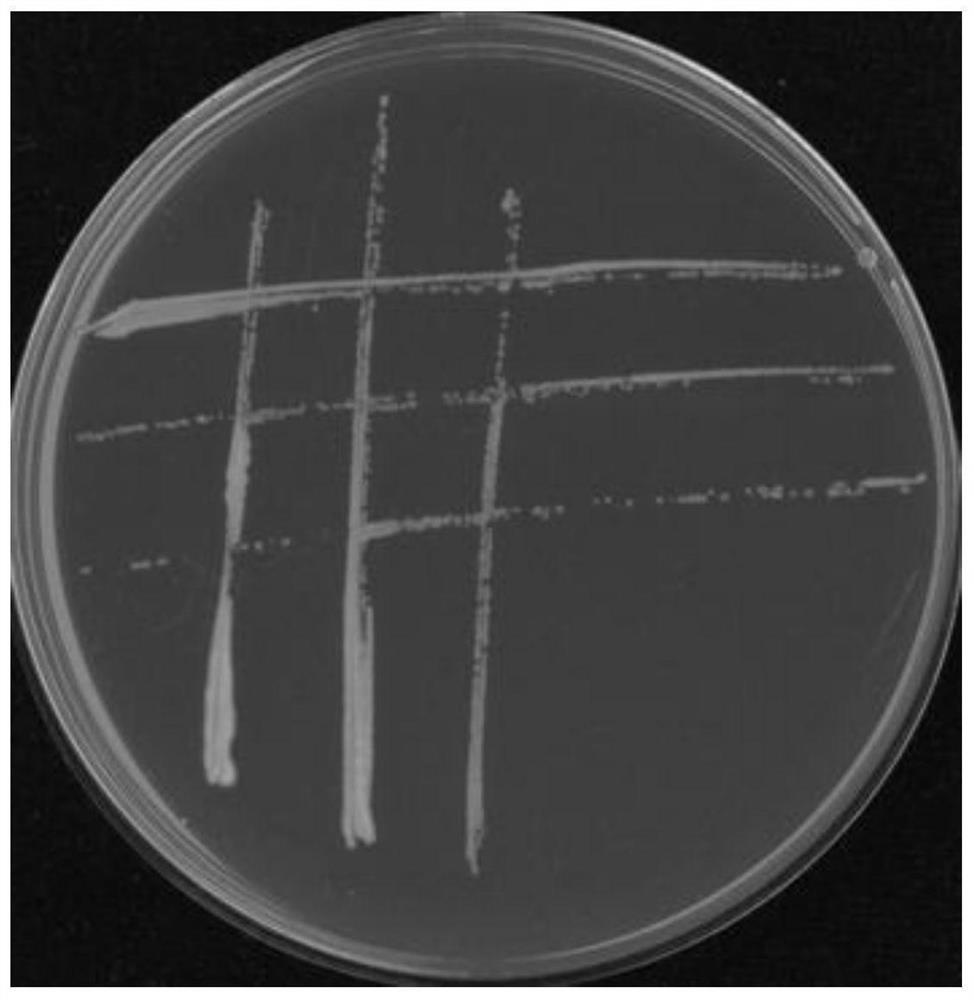

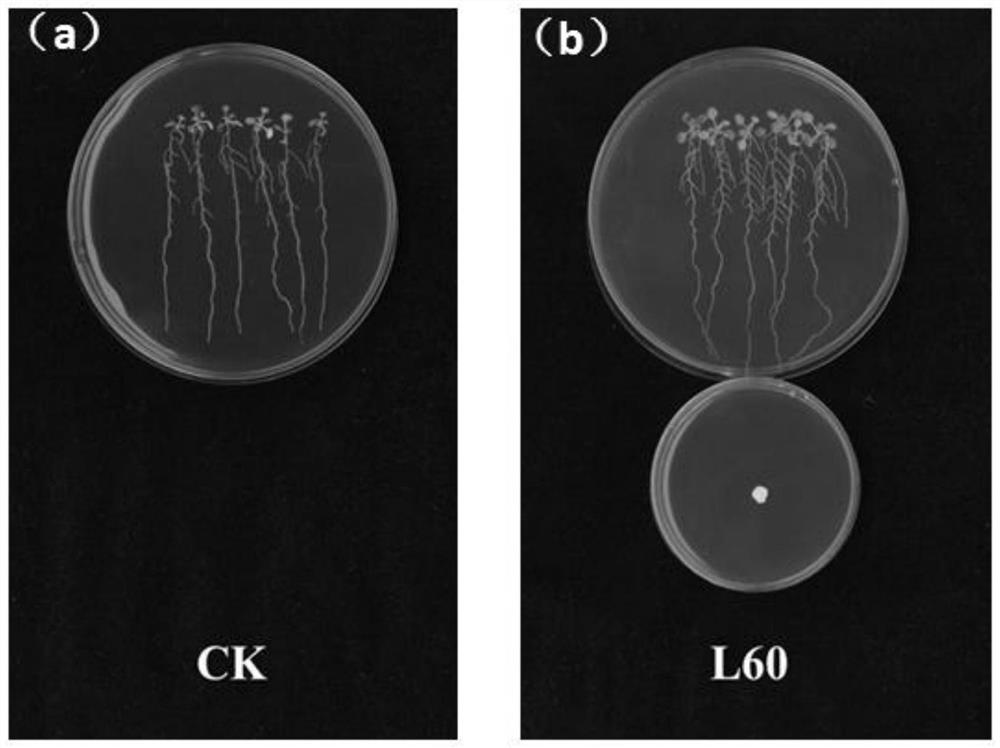

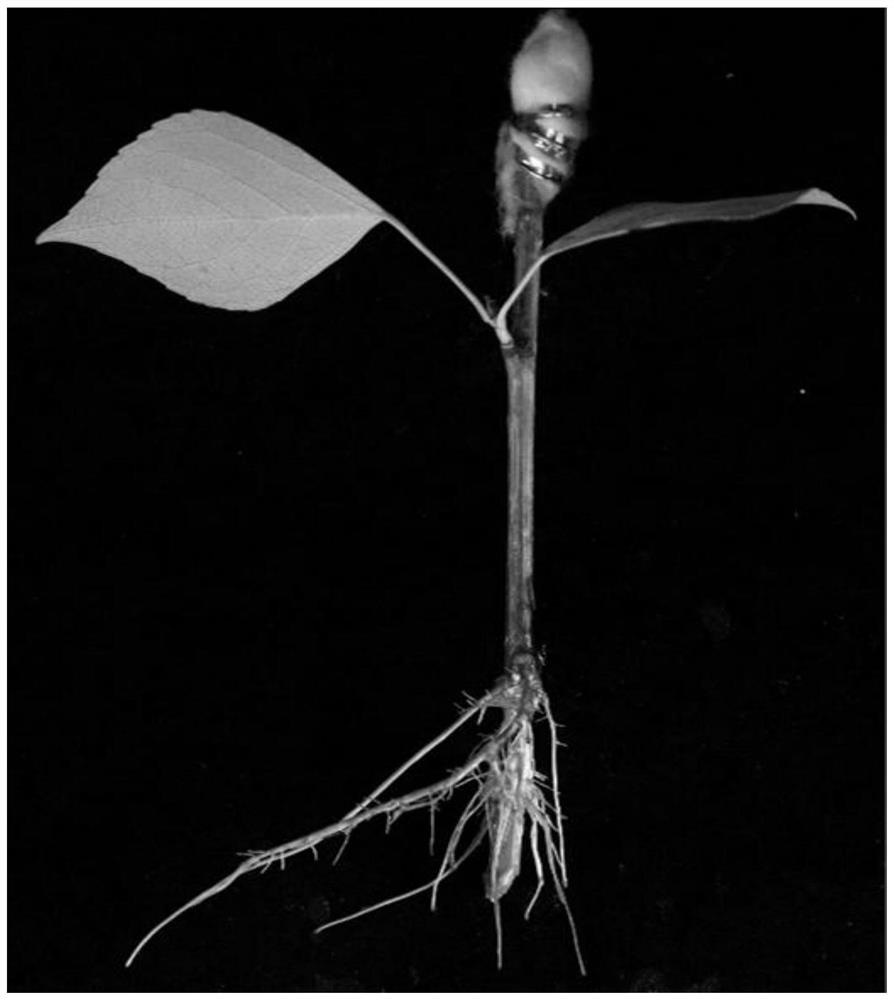

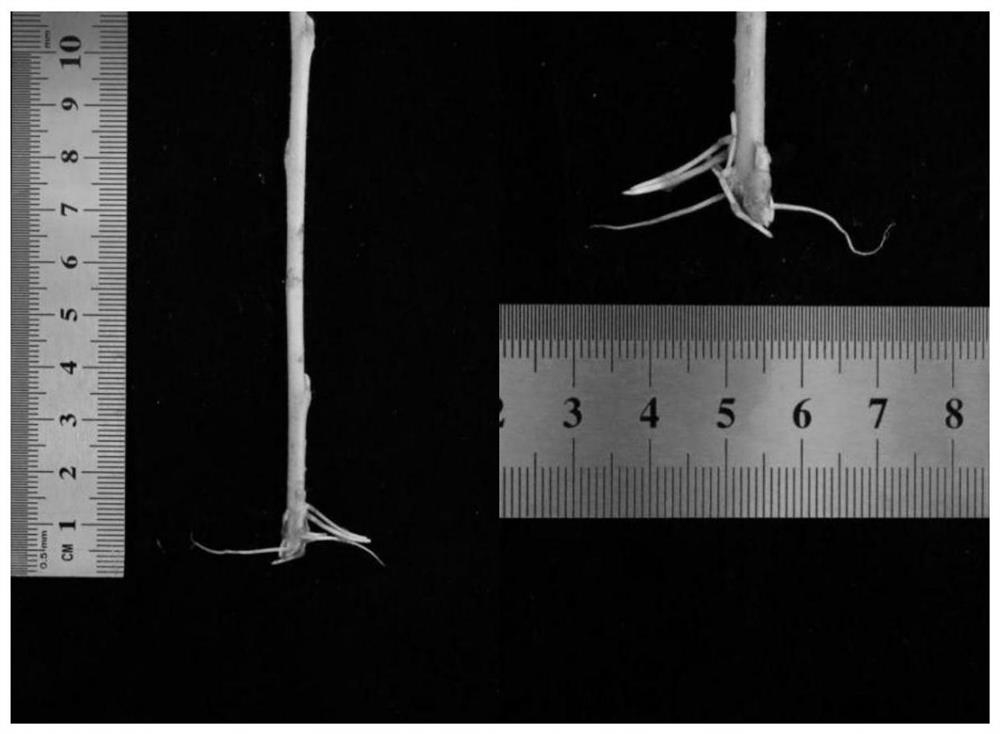

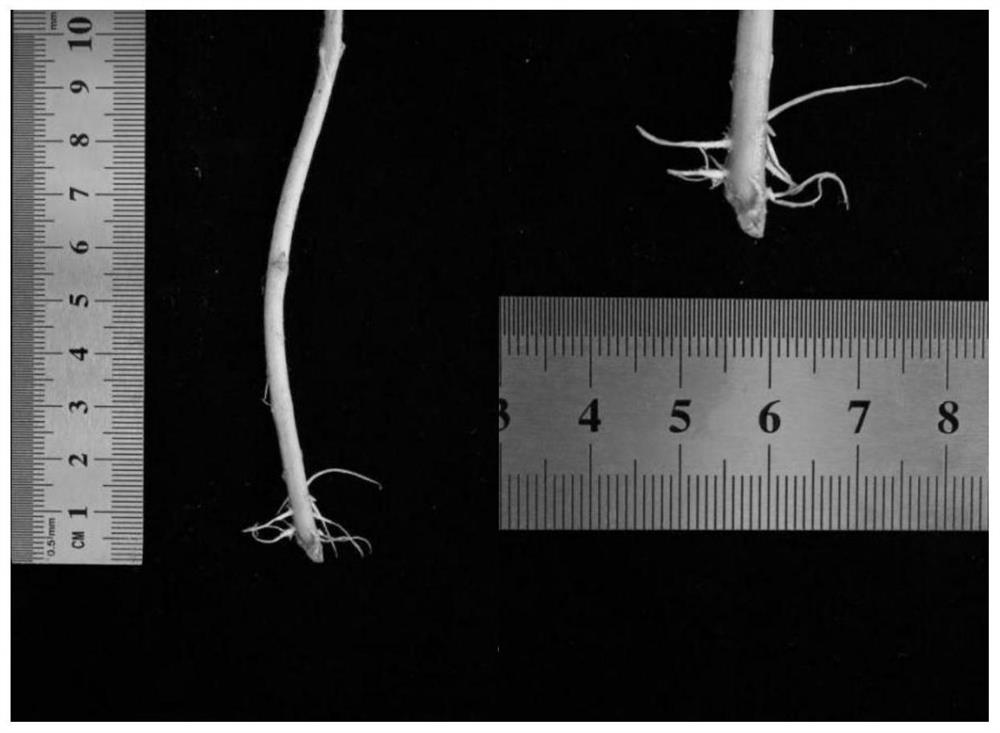

Applications of corn growth promoting rhizobacteria in promoting growth of plants

ActiveCN112680386APromote growthIncrease the projected areaBiocidePlant growth regulatorsBiotechnologyMicroorganism

The invention relates to the technical field of microbial application, and specifically discloses applications of corn rhizosphere growth promoting bacteria in promoting growth of plants. The corn rhizosphere growth promoting bacteria are staphylococcus haemolyticus and can be used for promoting the growth of corns and arabidopis thaliana. Volatile substances produced by the strains can promote the growth of the corns and arabidopis thaliana, especially have efficient promotion effects on the roots of the corns and arabidopis thaliana.

Owner:HENAN UNIVERSITY

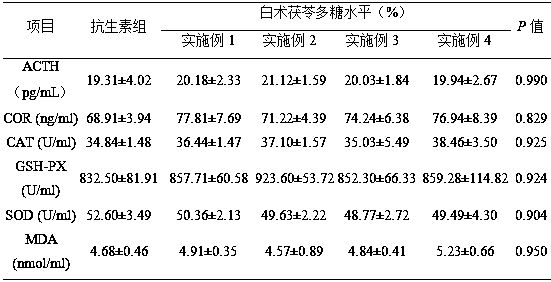

Application of atractylodes macrocephala polysaccharide and pachymaran as feed additive for improving weaning stress of piglets

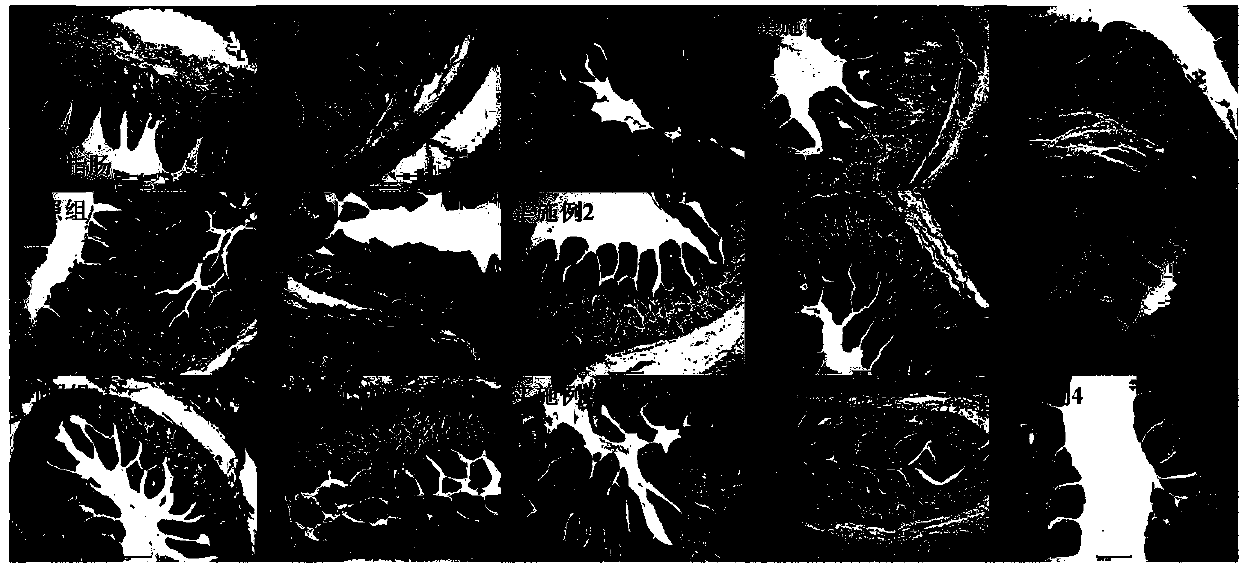

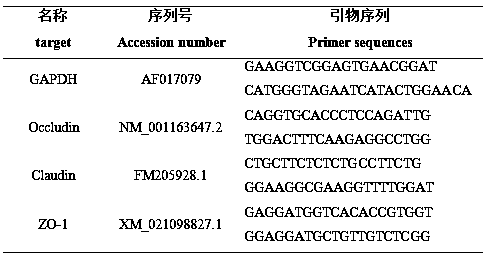

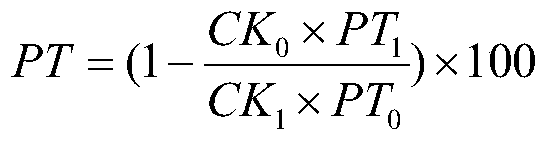

InactiveCN109527249AAlleviate early weaning stressImprove intestinal barrier functionAccessory food factorsFood additiveAnimal science

The invention discloses an application of atractylodes macrocephala polysaccharide and pachymaran as a feed additive for improving weaning stress of piglets, which belongs to the field of the feed additive. The application of atractylodes macrocephala polysaccharide and pachymaran as feed additive for improving weaning stress of the piglets is characterized in that the appropriate addition amountaccounts for 0.02%-0.08% of mass of a basic feed, the overhigh addition amount affect the growth performance, immunity and feed-to-weight ratio of the piglets, and the excessive low addition amount cannot achieve the effect; the atractylodes macrocephala polysaccharide and pachymaran is composed of atractylodes macrocephala polysaccharide and pachymaran according to a mass ratio of 1-2:1-2, and the content of polysaccharides in atractylodes macrocephala polysaccharide and pachymaran is 37.5%; and the application of atractylodes macrocephala polysaccharide and pachymaran as the feed additive for improving weaning stress of the piglets can effectively alleviate the early weaned stress of the piglets, improves the growth performance of the weaned piglets, and is a very good antibiotic substitute.

Owner:JIANGXI AGRICULTURAL UNIVERSITY

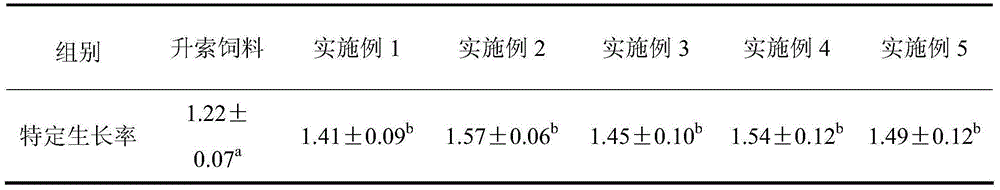

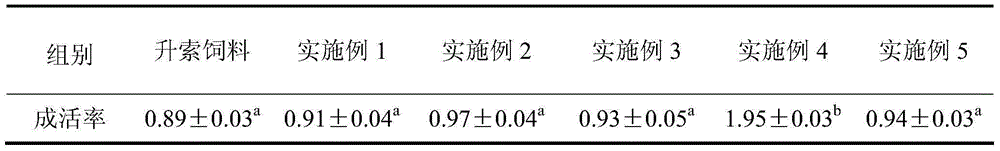

Siganus oramin fry mixed feed and preparation method thereof

InactiveCN105053621AMeeting nutritional needsEliminate dependenciesAnimal feeding stuffFish oilCiliate

The invention relates to a fish feed, and especially relates to a siganus oramin fry mixed feed. The invention further relates to a preparation method of the siganus oramin fry mixed feed. The mixed feed comprises the following components in parts by weight: 18 to 27 parts of squid powder, 7 to 15 parts of bean cake, 6 to 13 parts of bone meal, 5 to 12 parts of locust tree leaf powder, 3 to 8 parts of ajuga ciliate, 2 to 7 parts of sophora flavescens, 2 to 6 parts of ginger, 3 to 7 parts of purslane, 2 to 5 parts of tsaoko fruit, 2 to 6 parts of ligusticum wallichii, 1 to 4 parts of licorice, 1 to 5 parts of peanut vine, 2 to 6 parts of fish oil, 1 to 4 parts of honey, 1 to 4 parts of olive oil, and 1 to 4 parts of composite vitamins. The provided siganus oramin fry mixed feed is developed on the basis of energy metabolism mode and nutritional requirements of siganus oramin fry, can completely replace the fish meal, and has the advantages of high living rate of siganus oramin fry, low feed coefficient, and high specific growth rate.

Owner:QINGDAO HAIZHIXING BIOLOGICAL SCI & TECH

Stable rooting method for poplar cuttage

ActiveCN113575151AUse low concentrationShort cycleClimate change adaptationGrowth substratesHorticultureAgronomy

The invention discloses a stable rooting method for poplar cuttage, and belongs to the technical field of tree seed propagation. The stable rooting method for the polar cuttage comprises the following steps of wrapping the top end of an explant with leaves with a water absorbing material, girdling a base part, soaking in water for culture, dropwise adding auxin on the water absorbing material during culture to obtain an explant with adventitious roots, and then performing cuttage. According to the stable rooting method for cuttage, the use concentration of exogenous auxin is effectively reduced, the bacterium breeding phenomenon caused by a traditional culture method is avoided, the purposes of enabling poplar cuttage branches to stably root and improving the transplanting survival rate are achieved, and a new working method is provided for asexual propagation of the poplar and rapid rooting of the cuttage branches.

Owner:NORTHEAST FORESTRY UNIVERSITY

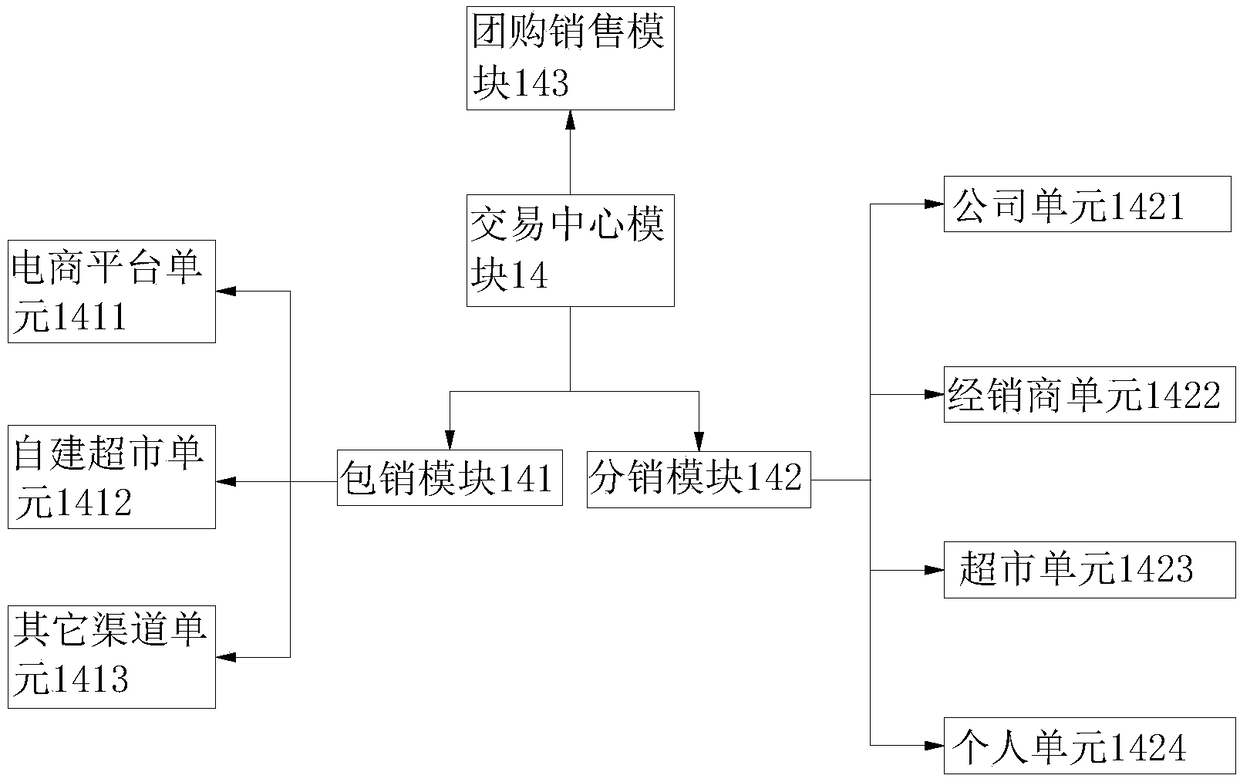

Agricultural and sideline product transaction management system

InactiveCN108921615AExpand sales channelsIncrease incomeFinanceBuying/selling/leasing transactionsThird-Party PaymentsComputer science

The invention discloses an agricultural and sideline product transaction management system. The system comprises a transaction management module and a planting member module; the transaction management module internally comprises a transaction management center module, a product release module, a marketing center module, a transaction center module, a settlement center module and a customer service center module; the transaction center module comprises an exclusive sales module, a distribution module and a group purchase module; and the settlement center module comprises a bank / third-party payment module and a cash payment module. When the agricultural and sideline product transaction management system is used, planters of the exclusive sales module and the planting member module sign exclusive sales contracts, so that the sale problem of agricultural and sideline products of a part of farmers is solved, the planting enthusiasm of the farmers is improved, and a plurality of sale modesare achieved; and moreover, the sale channels of the agricultural and sideline products are integrally added, the incomes of the farmers are increased, and the arrears of purchase and sale money of the farmers are reduced.

Owner:芜湖市联网汇通电子科技有限公司

Application of atractylodes macrocephala polysaccharide and pachymaran as feed additive for improving intestinal health of piglets

InactiveCN109527250AImprove intestinal barrier functionImprove performanceAccessory food factorsEarly weaningWeaned piglets

The invention discloses an application of atractylodes macrocephala polysaccharide and pachymaran as a feed additive for improving intestinal health of piglets, which belongs to the field of the feedadditive. The application of atractylodes macrocephala polysaccharide and pachymaran as feed additive for improving intestinal health of piglets is characterized in that the appropriate addition amount accounts for 0.02%-0.08% of mass of a basic feed, the overhigh addition amount affect the growth performance, immunity and feed-to-weight ratio of the piglets, and the excessive low addition amountcannot achieve the effect; the atractylodes macrocephala polysaccharide and pachymaran is composed of atractylodes macrocephala polysaccharide and pachymaran according to a mass ratio of 1-2:1-2, thecontent of polysaccharides in atractylodes macrocephala polysaccharide and pachymaran is 37.5%; and the application of atractylodes macrocephala polysaccharide and pachymaran as the feed additive forimproving intestinal health of the piglets can effectively improve the intestinal barrier function of the early weaned piglets, improves the intestinal health of piglets, and can replace the antibiotics in promoting the growth performance of the piglets.

Owner:JIANGXI AGRICULTURAL UNIVERSITY

Sugar-free apple vinegar beverage and production method thereof

InactiveCN107164198ASimple processing technologyProtect orangeMicroorganism based processesVinegar preparationPreservativeSugar free

The invention discloses a sugar-free apple cider vinegar beverage and a production method thereof. The production method comprises color protection, beating in circulation, enzyme addition, static clarification, blending, inoculation, anaerobic fermentation, sterilization and canning. The produced sugar-free apple cider vinegar beverage is orange-yellow. The beverage of the present invention adopts fresh apples as raw materials for production, does not contain any preservatives and other pigment additives, is sweet and sour, has rich nutrition, and is suitable for drinking by consumers including fat-phobic people, obesity patients and diabetic patients; and the production method is simple , low production cost, suitable for large-scale industrial production.

Owner:启东市惠鹤蔬果农地股份专业合作社

Method for preventing and controlling tomato whiteflies in greenhouse by using photosynthetic high-fat film agent

The invention provides a method for preventing and controlling greenhouse tomato whiteflies in a greenhouse by using a photosynthetic high-fat film agent. The method is characterized by adopting the photosynthetic high-fat film agent, wherein the photosynthetic high-fat film agent is prepared from, by weight, the following components: 200 parts of dodecanol, 50 parts of hexadecanol, 8 parts of anemulsifier, 5 parts of a co-emulsifier, 40 parts of a thickener and 800 parts of water. After the photosynthetic high-fat film agent is diluted by adding water, greenhouse tomato crops are sprayed. The method for preventing and controlling tomato whiteflies in the greenhouse by using the photosynthetic high-fat film agent has the advantages of being simple, high in efficiency, environmentally friendly and free of pollution, and has the promotion effects of improving the quality of tomatoes and guaranteeing the quality of tomatoes and selling the tomatoes in advance.

Owner:ZHUHAI RUNNONG SCI & TECH CO LTD

Sugar-free purple sweet potato lactic acid drink and production method thereof

ActiveCN104719480AHigh nutritional valueSimple production processMilk preparationPreservativePurplish red

The invention discloses a sugar-free purple sweet potato lactic acid drink and a production method thereof. The production method comprises the steps of circulating beating, addition of an enzyme, standing, clarification, blending, inoculation, anaerobic fermentation, sterilization and canning. The produced purple sweet potato lactic acid drink is purple red. The drink disclosed by the invention adopts fresh purple sweet potatoes with peels as production raw materials, does not contain any preservatives and other pigment additives and is sour, sweet, delicious and rich in nutrients and applicable to the majority of consumers, including people afraid of obesity and patients with obesity and diabetes; and furthermore, the production method is simple, the production cost is relatively low, and the production method is applicable to large-scale industrial production.

Owner:谭强

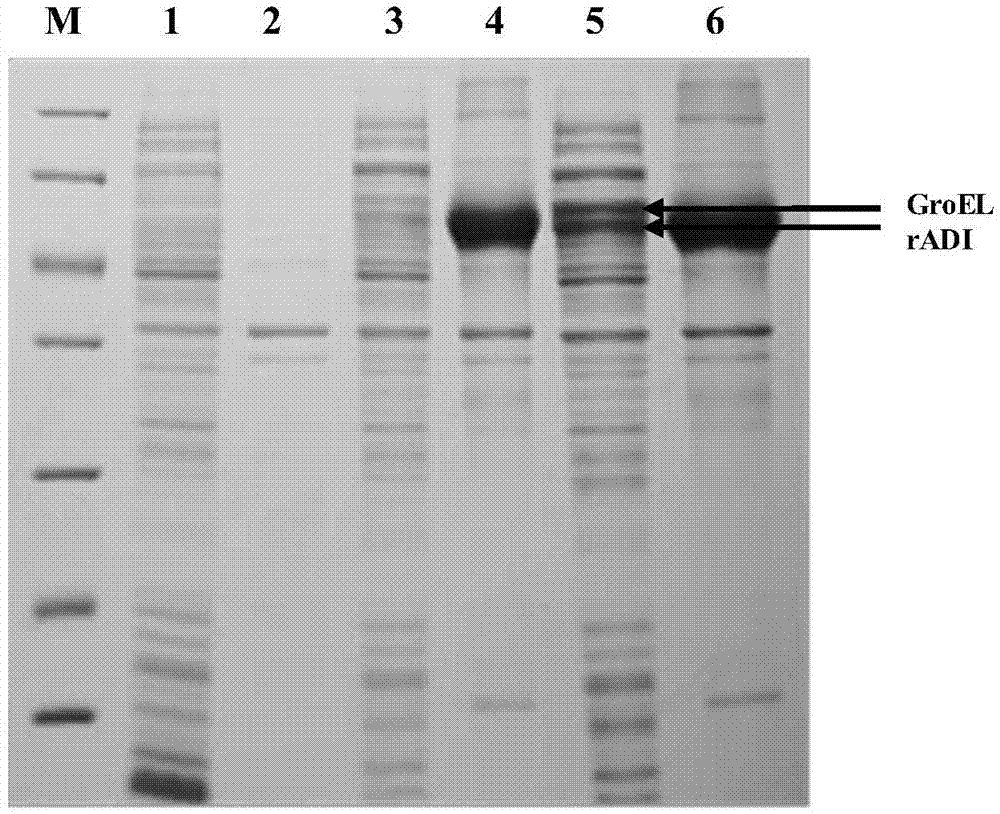

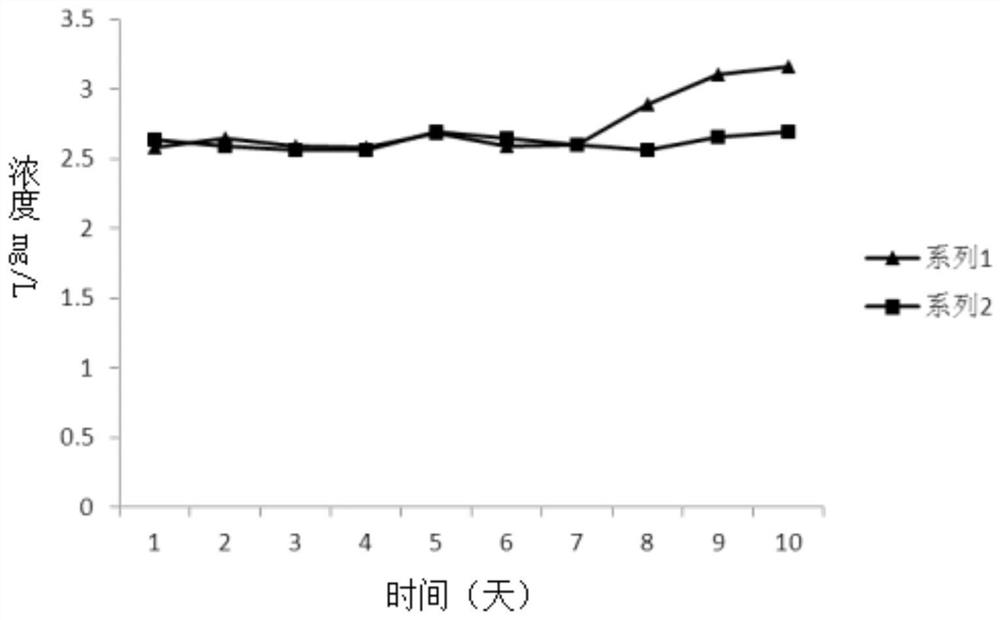

Method for promoting efficient water-soluble expression of arginine deiminase

ActiveCN103468664BPromote efficient water-soluble expressionOvercoming the drawbacks of poorly soluble expressionHydrolasesMicroorganism based processesPseudomonas putidaCitrulline

The invention discloses a method for promoting efficient water-soluble expression of arginine deiminase (ADI). The method comprises the following steps: connecting ADI gene derived from Pseudomonas putida with a pET-30a-c(+) carrier to construct a recombinant expression plasmid pET30a-ADI, and cotransforming the pET30a-ADI and pGro7 plasmid into E.coliBL21(DE3) to obtain double-plasmid-containing engineering bacteria; inoculating the engineering bacteria into an LB (Langmuir-Blodgett) culture medium containing 1-10 g / L D-glucose, adding L-arabinose, and culturing; and when the bacteria are cultured to a logarithmic phase, adding 1-10 g / L L-arginine and 0.1 mM IPTG (isopropyl-beta-D-thiogalactopyranoside), and carrying out induced culture at 16 DEG C under the condition of 180 rpm. The method disclosed by the invention can obviously enhance the water-soluble yield of the recombinant ADI protein, enhances the activity of the crude enzyme solution by 15 times, effectively overcomes the defect of difficulty in soluble expression of the recombinant ADI, provides technical support for application of industrialized large-scale production of citrulline and the like, and also provides a new idea for expression of other recombinant proteins.

Owner:SHANDONG UNIV

Boron-zinc-magnesium-rich full-water-soluble banana special purpose fruit-swelling fertilizer and preparation method thereof

InactiveCN106916015AFollow the law of nutrient utilizationImprove stress resistanceMagnesium fertilisersAlkali orthophosphate fertiliserPhosphateWater soluble

The invention discloses boron-zinc-magnesium-rich full-water-soluble banana special purpose fruit-swelling fertilizer and a preparation method thereof and belongs to the technical field of agricultural fertilizer. In order to solve the problem that improper selection of the banana fertilizer causes nutrient imbalance and seriously influences banana quality and yield. The boron-zinc-magnesium-rich full-water-soluble banana special purpose fruit-swelling fertilizer comprises 250 to 450 parts of urea, 40 to 150 parts of monoammonium phosphate, 450 to 650 parts of potassium sulfate, 2 to 10 parts of a boron element, 0.5 to 5 parts of a zinc element, 0.5 to 5 parts of a magnesium component and 0.2 to 1 part of a fruit-swelling aid. The fertilizer is prepared according to the actual demand of the nutrients in the growth period of the banana. The components are mutually promoted and none is dispensable. The components produce synergism and satisfy nutrient demands in a banana growth period so that the quality and yield of the banana are greatly increased.

Owner:STANLEY AGRI GRP CO LTD

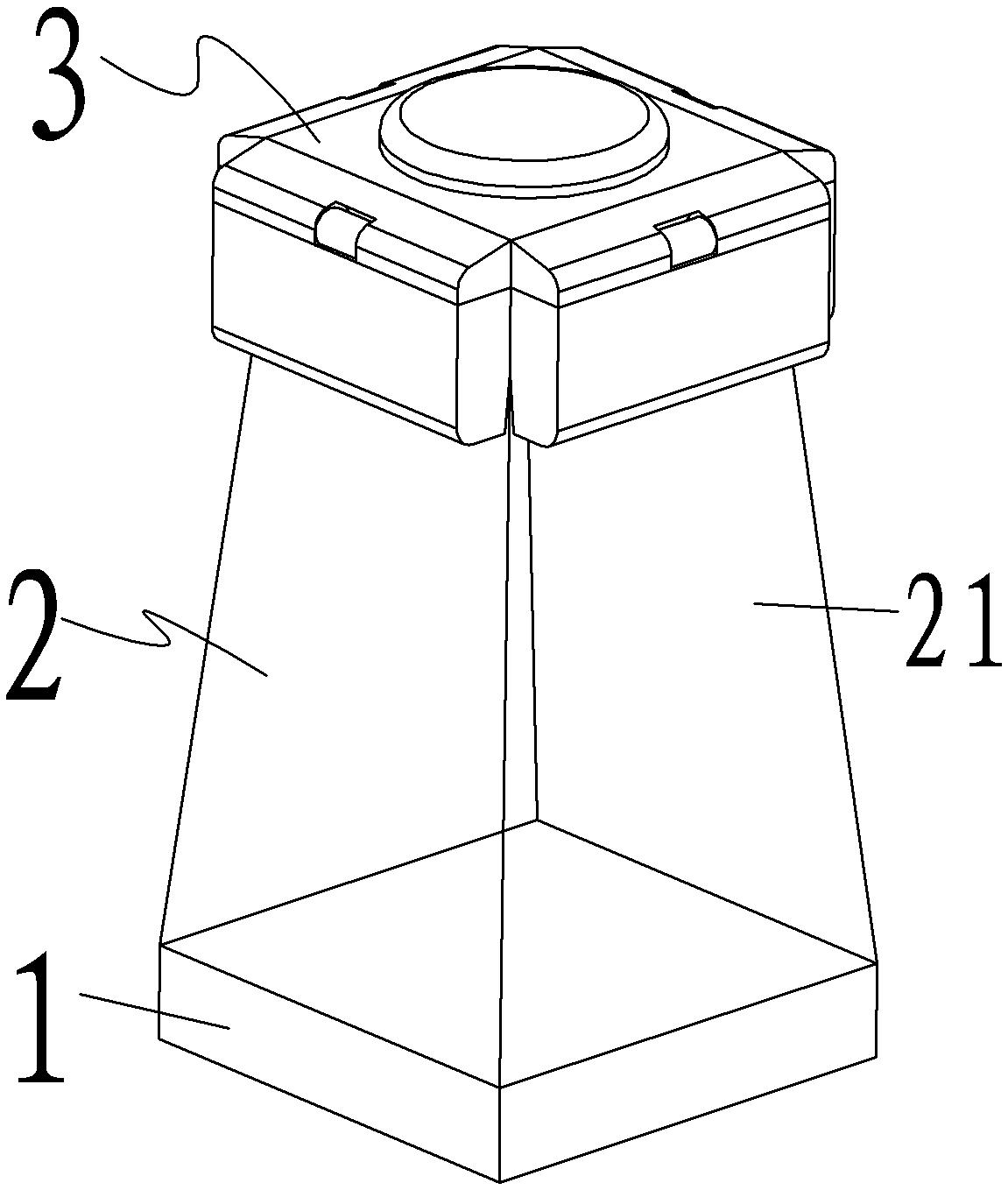

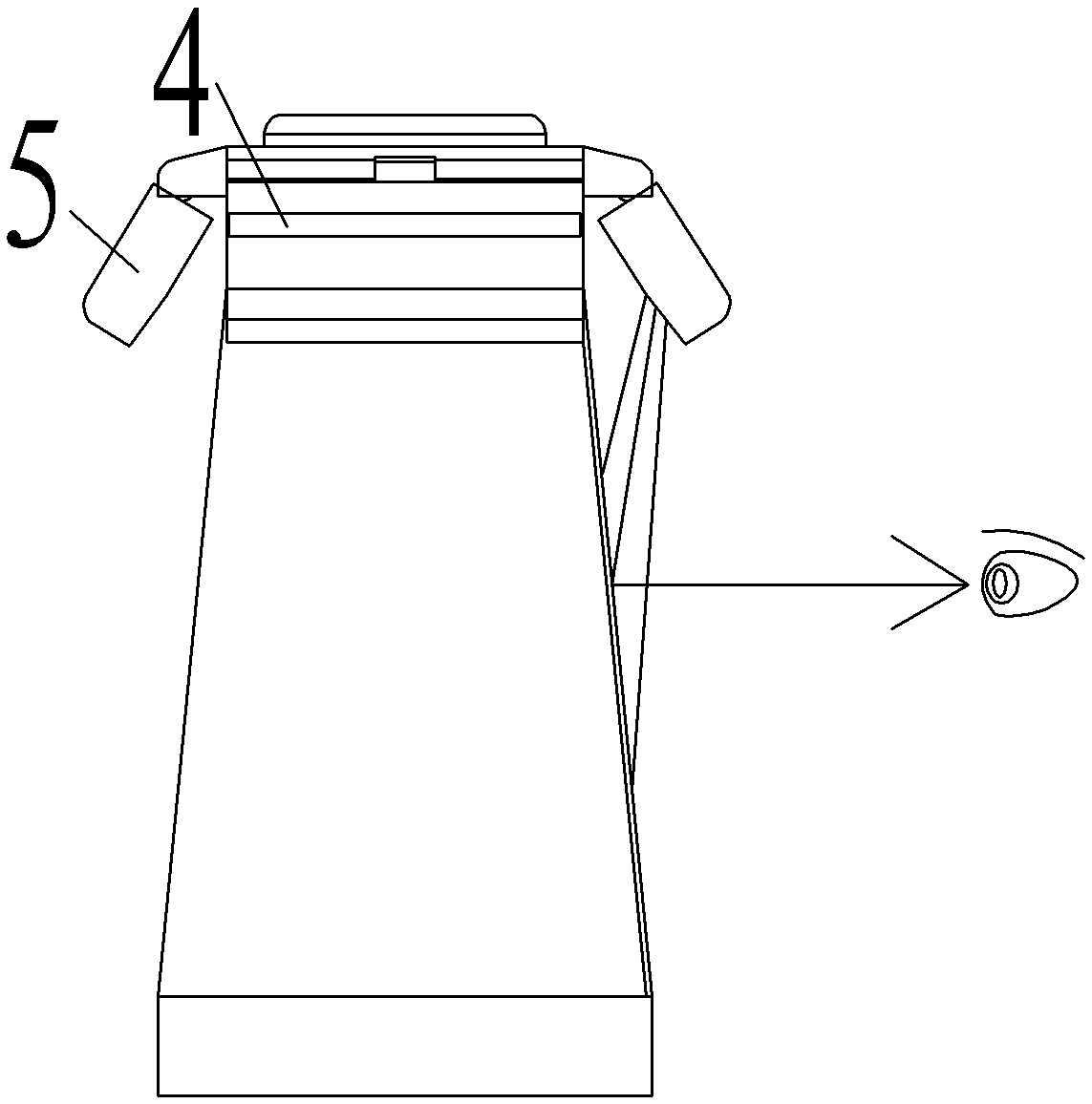

Medical pseudo holographic imager

PendingCN108053888AEasy to explainEfficient communicationMedical communicationDiagnostic recording/measuringGraphicsTouchscreen

A medical pseudo holographic imager comprises a main body; the main body comprises a rectangular pedestal, a developing table arranged above the rectangular pedestal, and a host; a development board is arranged in the host; projectors connected with the development board and matched in number with transparent boards are arranged in the host, and arranged in a projection reversal plate with the rotation angle controlled by the development board; a wifi module and a software operation platform are arranged in the development board; 3D figure browsing software is arranged in the software operation platform, and figures are respectively outputted to the 4 projectors through a video output module; at least one transparent board is covered by a touch screen; the input end of the touch screen isconnected with the development board. The medical pseudo holographic imager can directly demonstrate images, and doctors can conveniently explain conditions for patients, thus directly promoting validcommunications between doctors and patients, enabling patients and patient family members to understand conditions, making correct selections for the treatments, improving the medical teaching quality, allowing medical learners to directly understand the focus principles, and promoting the medical education for certain level.

Owner:余军辉

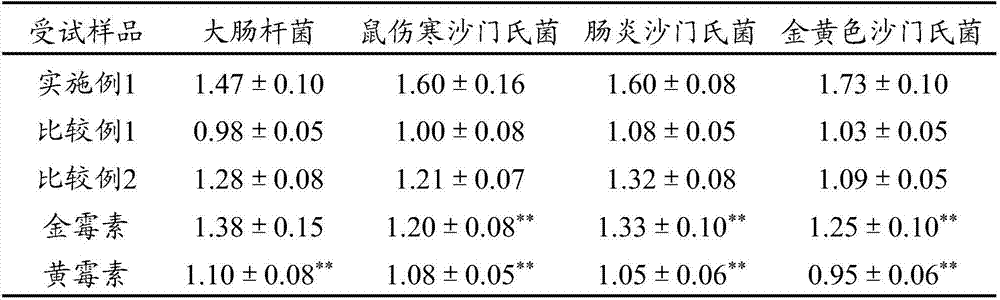

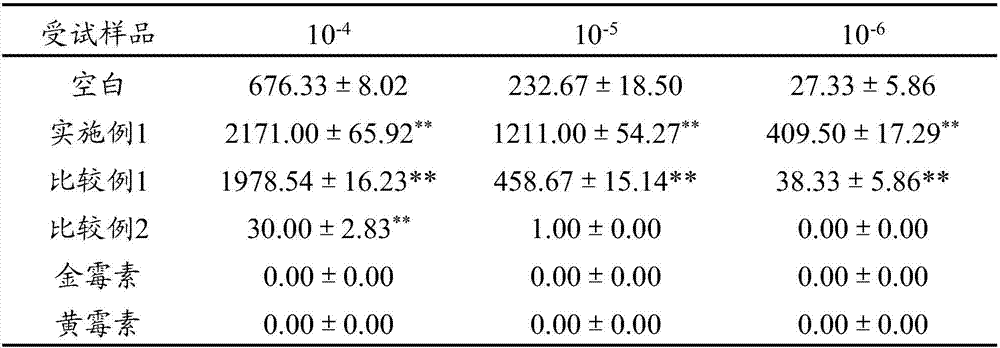

Traditional Chinese medicine composition and application and feed thereof

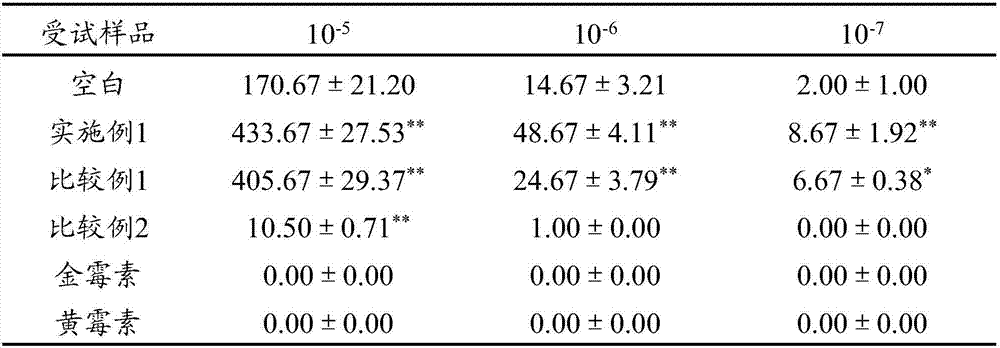

PendingCN106954753AInhibit pathogenic bacteriaIncreased probioticsAntibacterial agentsAnimal feeding stuffMedicineFlos chrysanthemi

The invention provides a traditional Chinese medicine composition which is prepared from the following raw materials in percentage by weight: 25-35% of fructus mume, 25-35% of folium isatidis, 15-25% of Chinese mosla herb, 10-15% of flos chrysanthemi indici and 5-10% of radix bupleuri. In the invention, the fructus mume, folium isatidis, Chinese mosla herb, flos chrysanthemi indici and radix bupleuri are compounded and added instead of feed antibiotics into the drinking water of chicken so as to realize functions of inhibiting pathogenic bacteria and promoting probiotics and an effect of promoting the growth and development of broilers to enhance the broiler immunity, improve the intestinal flora of broilers and improve the chicken quality.

Owner:HEBEI AGRICULTURAL UNIV.

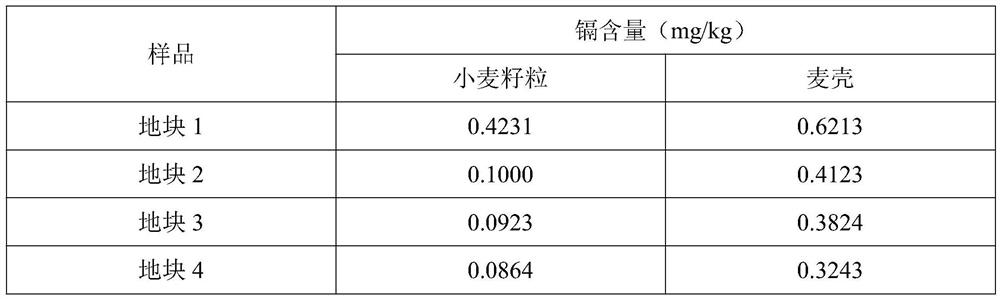

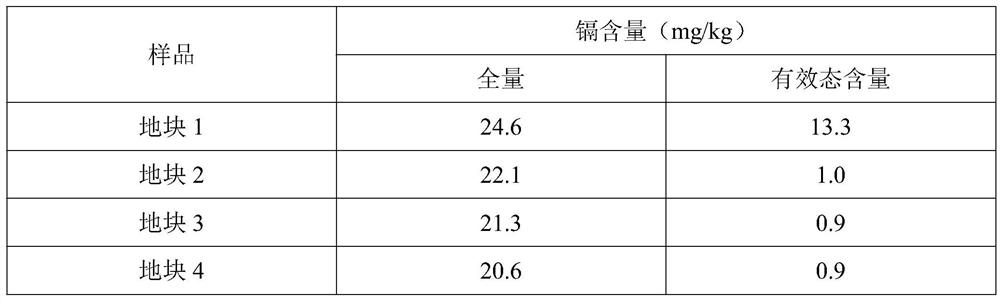

A heavy metal polluted soil remediation agent suitable for acidic farmland soil

ActiveCN110586645BIncrease profitPromote growthContaminated soil reclamationClay mineralsMetal contamination

The invention discloses a remediation agent suitable for heavy metal polluted soil in acidic farmland soil, which uses the crop seeds to be sown as the core, and the heavy metal polluted soil remediation agent as the seed coat, and the seed coat layer of the heavy metal polluted soil remediation agent includes crop waste material fermentation layer, clay mineral layer and water-absorbing polymer layer, wherein, the crop waste fermentation layer is in contact with the seed coat, and the repair agent coating layer is coated on the outside of the crop seeds in the form of layer-by-layer coating, and is in contact with the crop seeds when they are sown. At the same time, it is applied to the soil, which simplifies the application process of the restoration agent. The restoration agent exists around the roots of the crops to improve the utilization efficiency of the restoration agent; the wheat coated with the restoration agent is planted in the soil polluted by heavy metal cadmium, and the heavy metal in the harvested wheat The content of cadmium is lower than the limit standard of pollutants in food, the reduction rate of cadmium in wheat has reached more than 76%, and the passivation rate of available cadmium in soil has reached more than 92%.

Owner:DEZHOU MICROP BIO TECH CO LTD

A kind of surfactant composition applied to in vitro diagnostic reagent

ActiveCN109596834BImprove surface activityImprove bindingBiological testingSucroseSodium perfluorooctanoate

Owner:WHITMAN BIOTECH NANJING

A kind of viscosity-reducing enhanced anti-cracking agent and preparation method thereof

The invention discloses a viscosity-reducing enhanced anti-cracking agent and a preparation method thereof. The raw materials include the following components in mass percentage: 30-60% of modified magnesium oxide expansion agent, 5-20% of synthetic fiber, and viscosity-reducing component 10-40%, reinforcement component 20-50%; the viscosity-reducing component includes microbead powder, cellulose ether, powder water reducer, sepiolite; the reinforcement component includes ultra-fine mineral admixture, silica fume , Nano silicon dioxide, sodium gluconate, urea. The present invention combines the viscosity-reducing component and the strengthening component on the basis of the expansion agent compensating for shrinkage and early crack resistance of the fiber. Each component has a synergistic effect under a suitable ratio, effectively reducing the viscosity of the concrete and improving the strength of the concrete. At the same time, the viscosity-reducing component and the strengthening component have a promoting effect on the expansion agent, and can synergistically improve the expansion effect of the expansion agent.

Owner:武汉三源特种建材有限责任公司

A kind of deactivated Raney nickel catalyst green recovery treatment device and recovery method

InactiveCN106807403BReduce pollutionReduce dosageCatalyst regeneration/reactivationRaney catalystsAcetic acidRecovery method

A green recovery treatment device and recovery method for deactivated Raney nickel catalyst, including a vertical cylinder body and a liquid distribution kettle, an annular pipe is installed on the upper part of the cylinder body, the annular pipe is installed obliquely, and several connecting pipes are connected to the lower part of the annular pipe The connecting pipe is connected to the upper end of the cylinder, and the connecting pipe extends into the cylinder to cooperate with the inner wall of the cylinder. Several electromagnets are evenly installed on the outer circumference of the cylinder, and the liquid outlet of the liquid mixing kettle is connected to the upper inlet of the annular pipe. The bottom of the body is installed with a pump, the pump is connected to the liquid inlet of the liquid distribution kettle, the upper part of the body is equipped with a CO inlet with a valve, and the bottom of the body is equipped with a discharge pipe with a valve. In the present invention, in the recycling process of the deactivated Raney nickel catalyst, CO and acidic acetic acid which is good for the environment are used for treatment, so as to avoid the use of strong acid and have the advantages of environmental protection.

Owner:BOHAI UNIV

A coupled wastewater treatment device and a treatment method for petrochemical secondary effluent

ActiveCN105819629BImprove phosphorus removal effectSave volumeTreatment using aerobic processesWater treatment compoundsPetrochemicalSewage

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

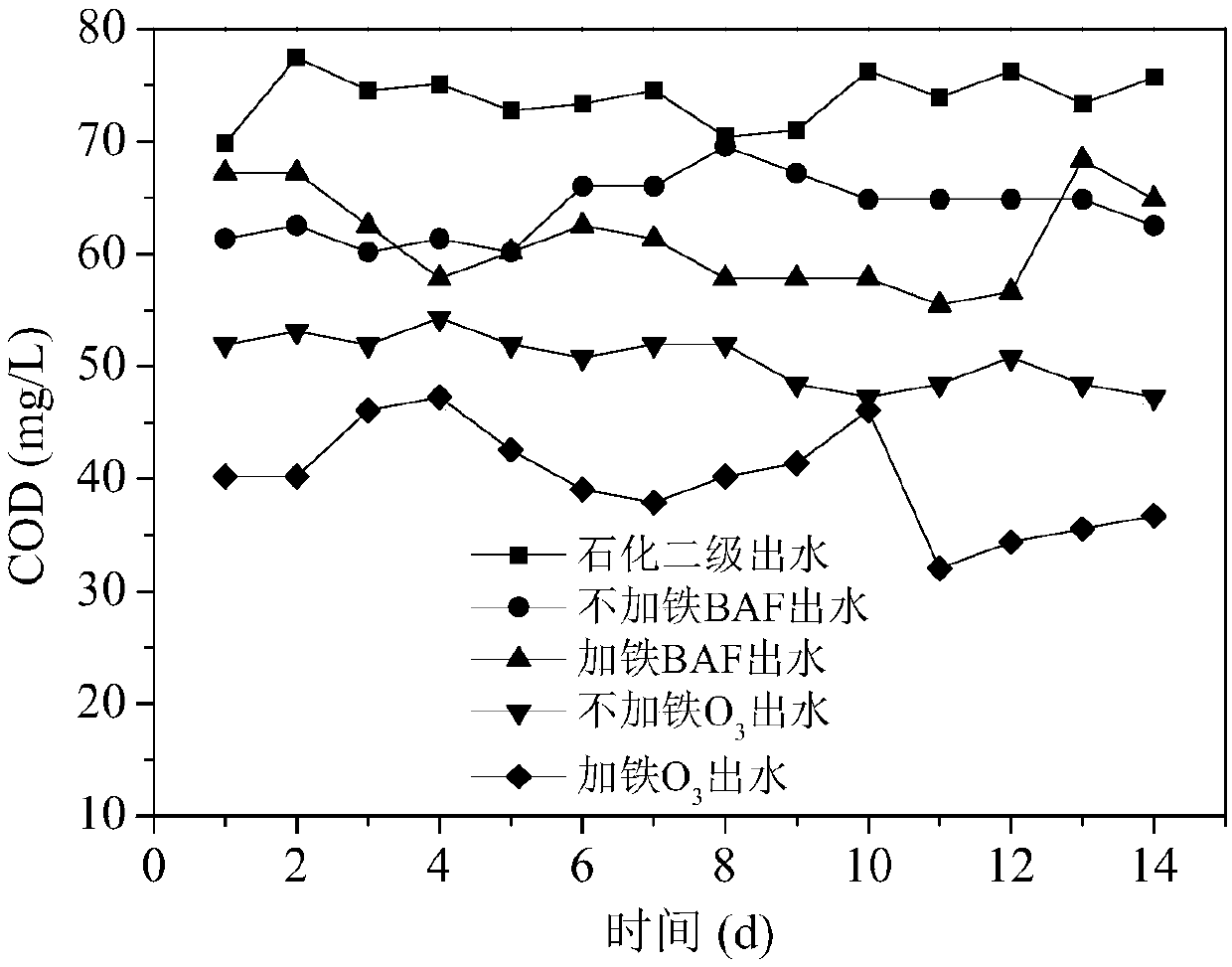

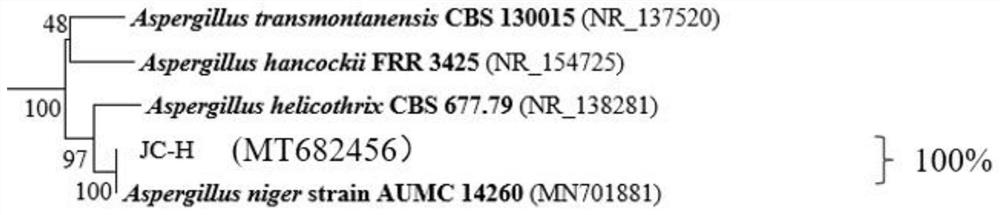

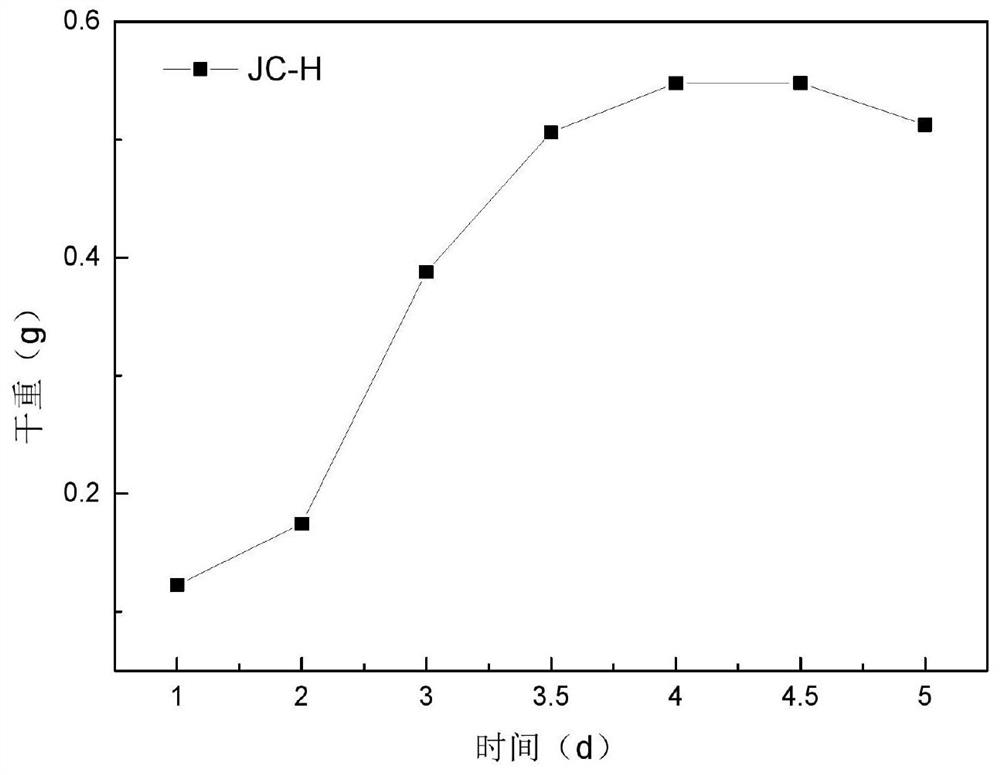

Acid-producing bacterium JC-H and application thereof as well as culture and identification method of acid-producing bacterium JC-H

PendingCN114032178ADecreased acid production capacityHas a promoting effectFungiChemical analysis using titrationMicroorganismMicrobiology

The invention discloses an acid-producing bacterium JC-H, which is named as Aspergillus niger JC-H, is preserved in China General Microbiological Culture Collection Center (CGMCC) on January 4, 2021, and has a preservation number of CGMCC NO: 21424. The strain can be applied to acid production, and the acid production efficiency is the highest when a fermentation medium is used for constant-temperature shake culture under the conditions that the temperature is 30 DEG C, the pH is 6 and the rotating speed is 160rpm. The acid-producing bacterium provided by the invention can provide a strain resource for biological acid production.

Owner:XIAN UNVERSITY OF ARTS & SCI

A method for co-processing coking desulfurization waste liquid, calcium-based solid waste and pollutants in industrial flue gas

ActiveCN108211761BEfficient removalIncrease added valueGas treatmentDispersed particle separationFluid phaseFlue gas

The invention relates to a method for cooperative treatment of coking desulfurizing waste liquid, calcium-based solid waste and pollutants in industrial smoke. The method comprises the following steps: absorbing the oxidized industrial smoke by using absorbent slurry while controlling the pH of the slurry to 6 or higher during the absorption, wherein the absorbent slurry is a mixture of the calcium-based solid waste and the coking desulfurizing waste liquid; after the absorption, discharging the purified smoke, and performing solid-liquid separation on the absorbent slurry; performing impurityremoval and pH regulation on the obtained liquid phase, and heating for decomposition; performing solid-liquid separation to obtain an ammonium thiocyanate product. The method provided by the invention can realize efficient removal of sulfur dioxide, nitrogen oxide and mercury in smoke while recycling an ammonium thiocyanate product with high added value. The method provided by the invention canbe used for performing cooperative treatment on the waste gas, wastewater and waste residue generated in an industrial production process, has the advantages of simple process, low raw material cost and no wastewater discharge in the whole process, realizes cyclic economy of dealing with waste by waste, is suitable for industrial application and creates good economic benefits.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

A kind of scorpion venom heat-resistant synthetic peptide and use thereof

ActiveCN106220713BHas a promoting effectImprove chemotaxis abnormalitiesNervous disorderPeptide/protein ingredientsChemical synthesisScorpion Venoms

The invention discloses a scorpion venom heat-resistant synthetic peptide and its application, belonging to the field of polypeptide drug research and development. The polypeptide of the present invention is the amino acid sequence of the scorpion venom heat-resistant peptide (SVHRP) detected from the venom of the traditional Chinese medicine East Asian scorpion scorpion (BmK). A sample of the heat-resistant peptide extract from scorpion venom with pharmacodynamic activity of Alzheimer's disease (premature Alzheimer's disease) was separated by LaGM composite material and repeated rapid magnetic separation, and then performed parallel mass spectrometry using nanoliter reversed-phase chromatography-electrospray mass spectrometry (nanoLC-ESI-MS). A polypeptide sequence consisting of 15 amino acid residues was detected in the experiment; a heat-resistant synthetic peptide of scorpion venom was prepared through solid-phase chemical synthesis, chromatographic purification and mass spectrometry identification. Its amino acid sequence is shown in SEQIDNo 1, which maintains the The pharmacodynamic activity and safety of the scorpion venom heat-resistant peptide, and the bioactivity of the scorpion venom heat-resistant peptide also promotes the reverse differentiation of glial cells into neural stem cells.

Owner:上海万锦医药科技有限公司

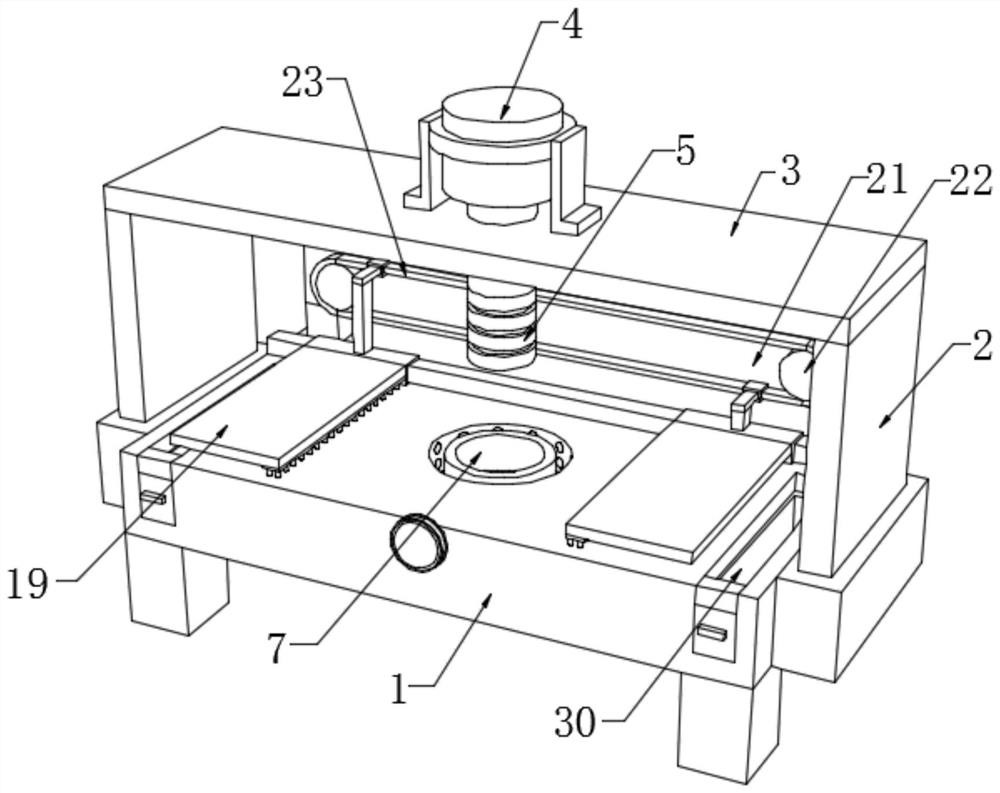

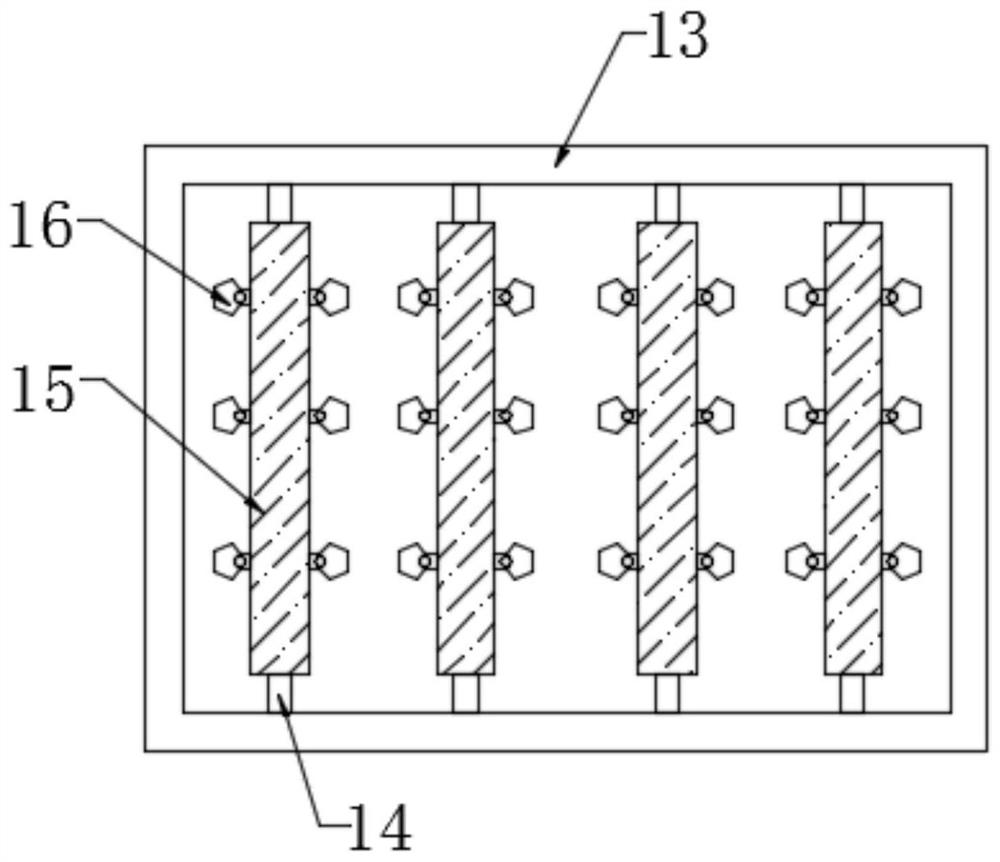

Tipped fixed seat threading die with heat dissipation holes

ActiveCN114473056AEven heat dissipationPlay a cooling roleMaintainance and safety accessoriesEngineeringFan blade

The invention relates to the technical field of cutting-edge-embedded fixed seat screw dies, in particular to a cutting-edge-embedded fixed seat screw die with heat dissipation holes, and discloses a cutting-edge-embedded fixed seat screw die with the heat dissipation holes. Comprising a working table, mounting frames, top frames, a blade embedding device body, a blade, a placement groove, a fixed seat threading die body, a heat dissipation hole body, an operation groove, a fan, a flow guide pipe, a flow dividing pipe, a wind power flow guide plate, a rotating shaft, a connecting cylinder, dispersing fan blades and a sliding rod, the mounting frames are fixedly mounted on the two sides of the working table, and the top frames are fixedly mounted at the top ends of the two mounting frames; an inlaying device body is fixedly installed in the middle of the top end of the top frame. The fan runs to generate wind power, the wind power enters the operation groove through diversion and dispersion of the diversion pipe and the diversion pipe, a certain heat dissipation effect can be achieved on the fixed seat screw die body through penetration of the formed heat dissipation hole body, and therefore the fixed seat screw die body can dissipate heat in real time during running; and the problem of damage caused by too high heat is avoided.

Owner:东台市双厦工具有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com