Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31results about How to "Guaranteed profile" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

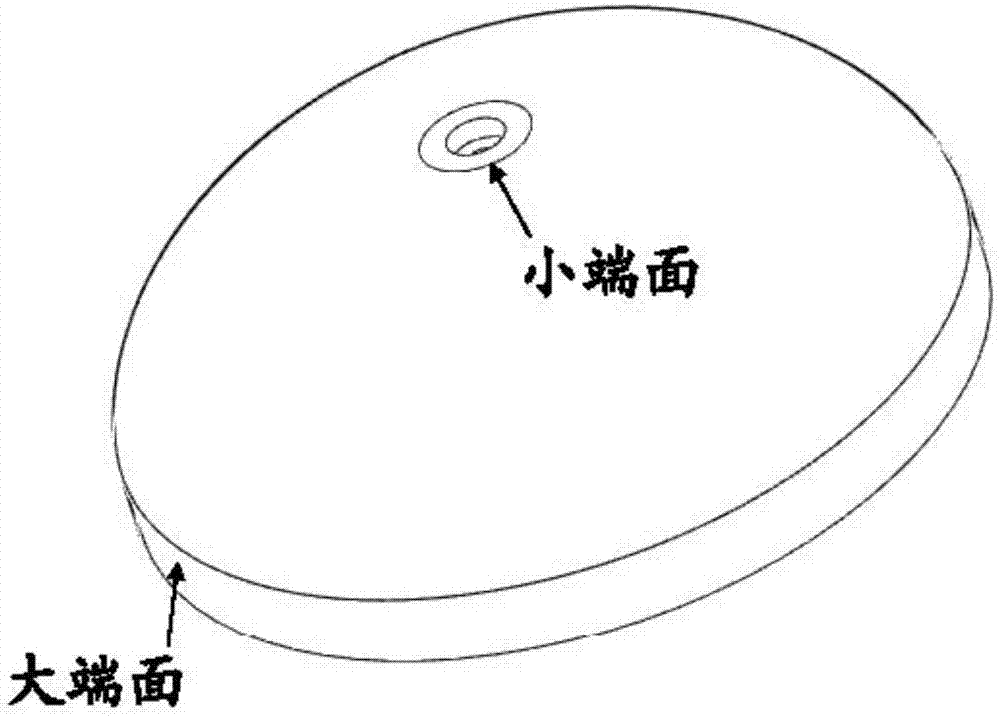

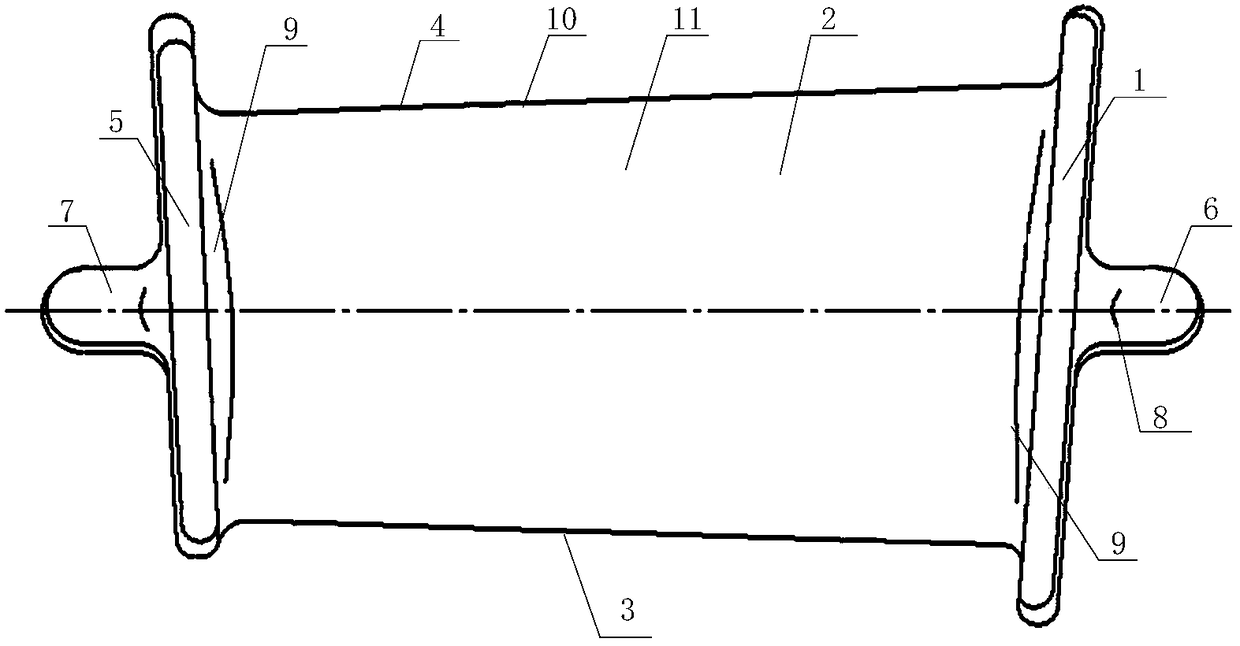

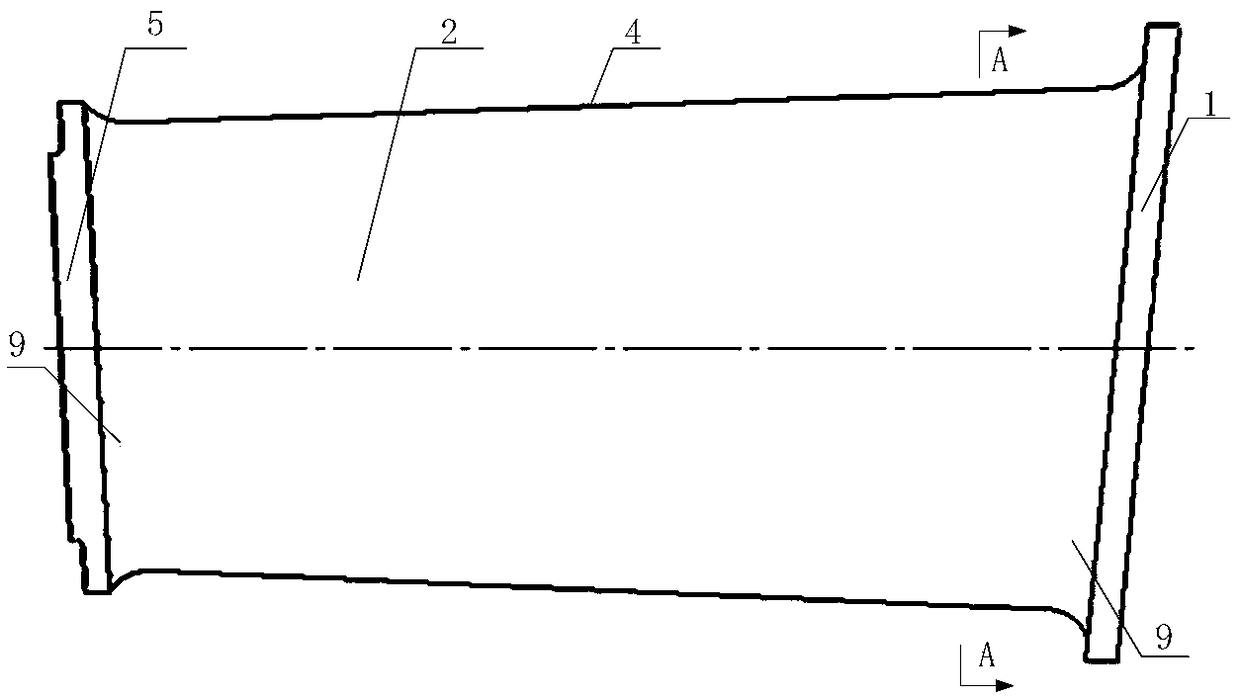

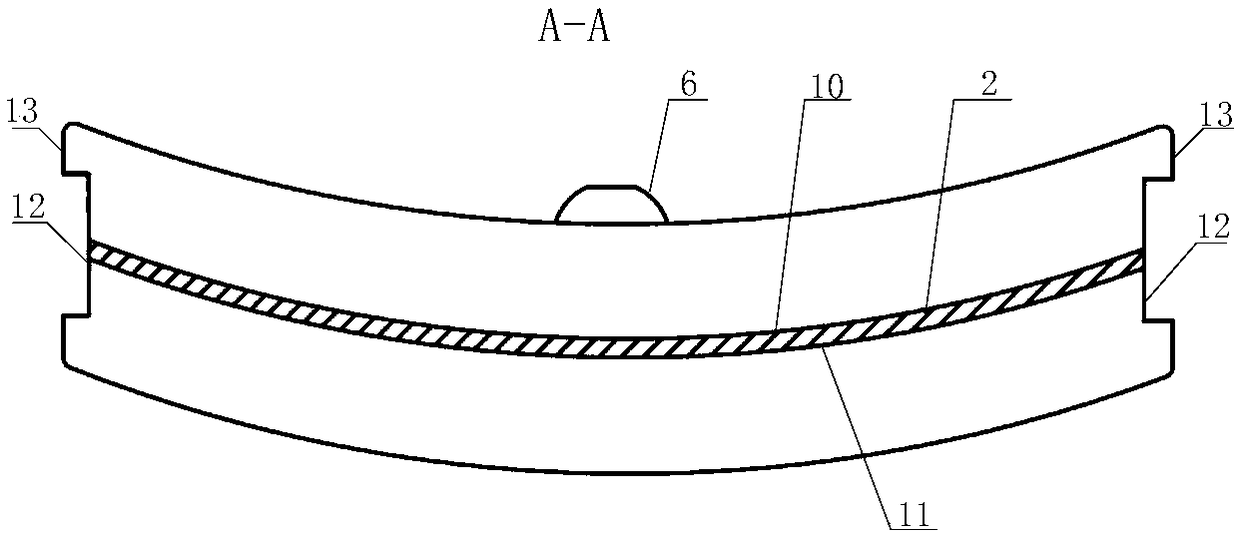

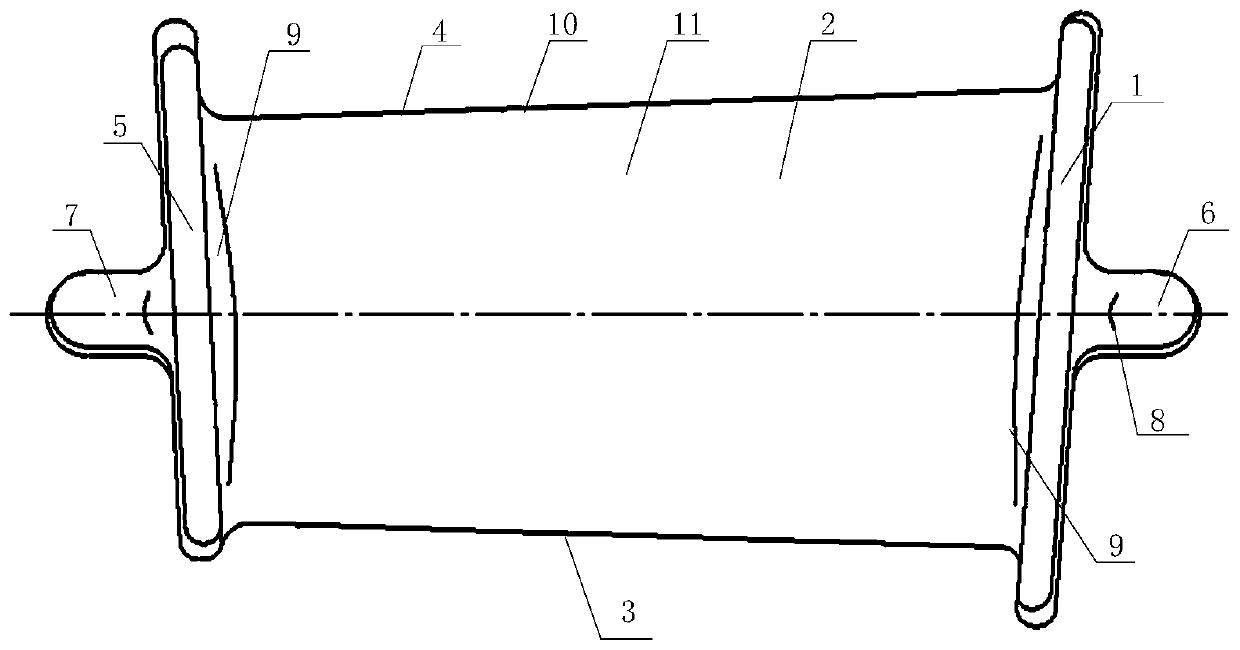

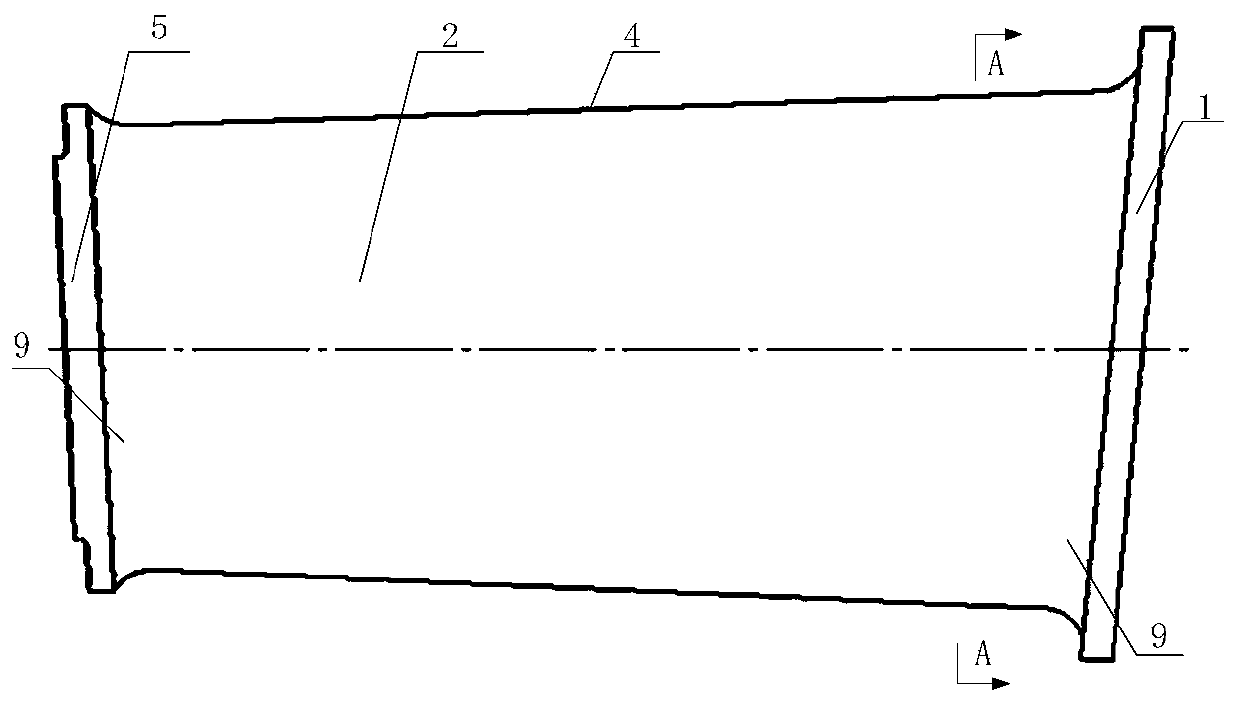

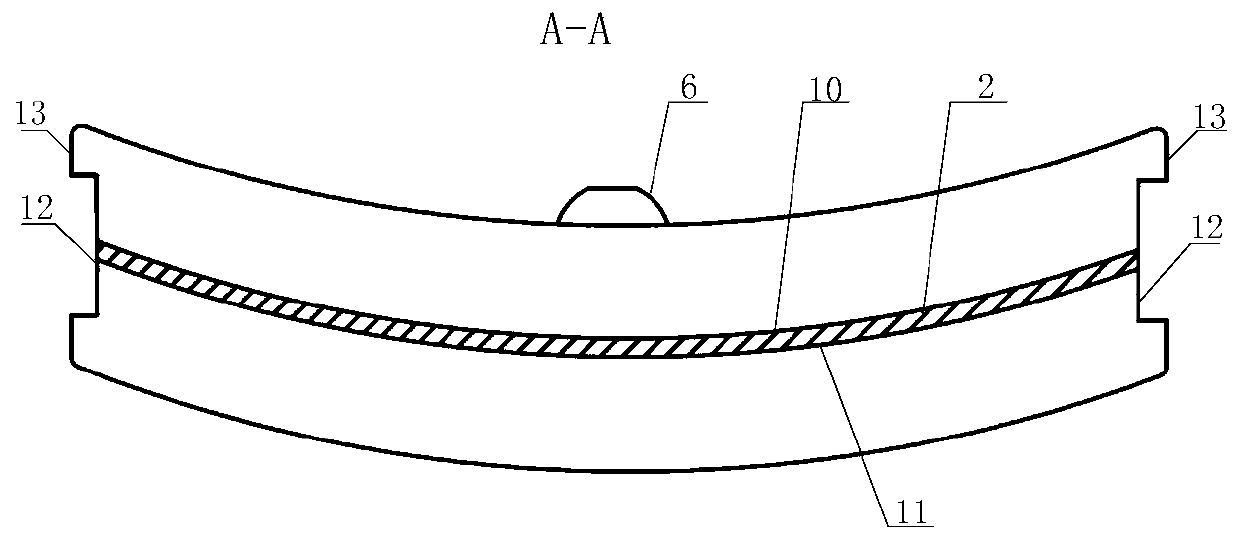

Heat treatment deformation control method for large-diameter and large-modulus elliptical molded surface container semispherical shell

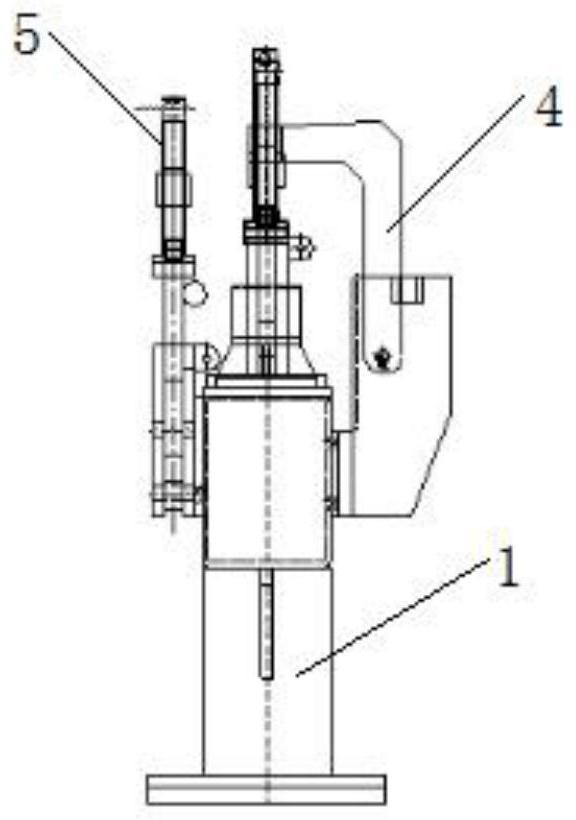

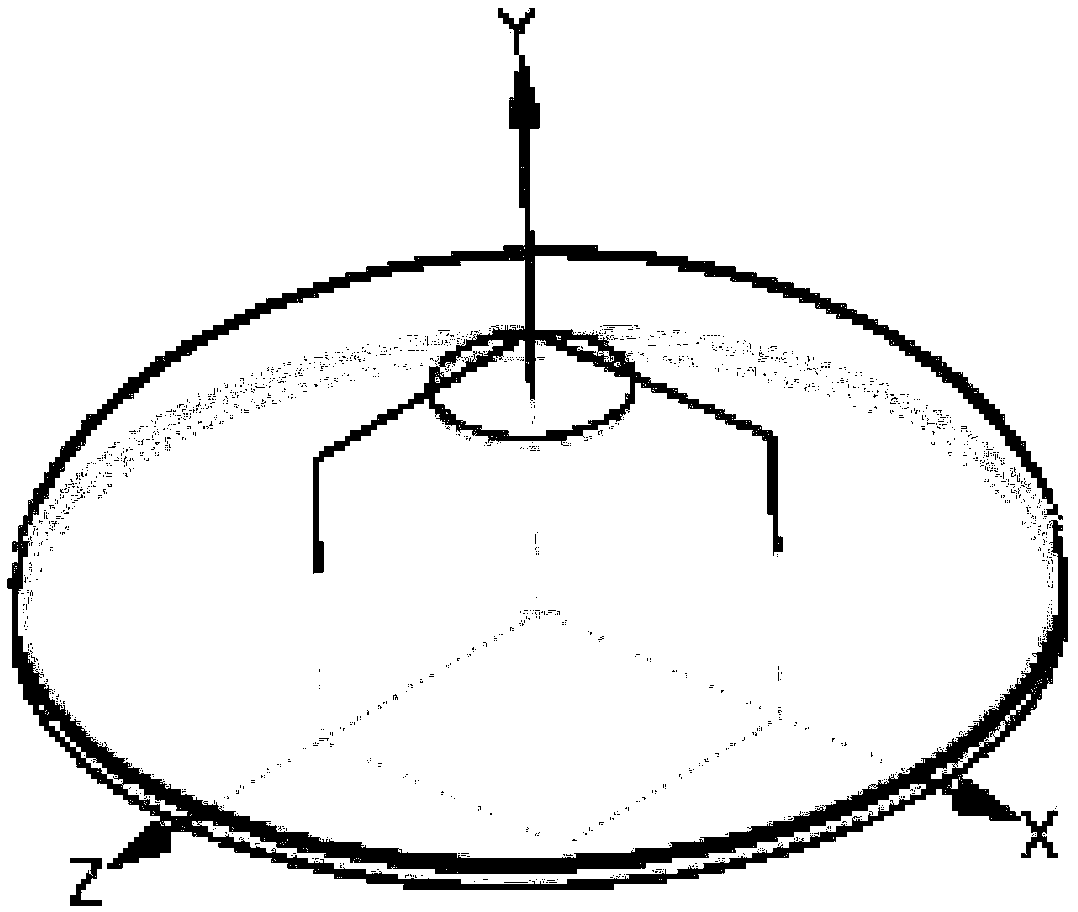

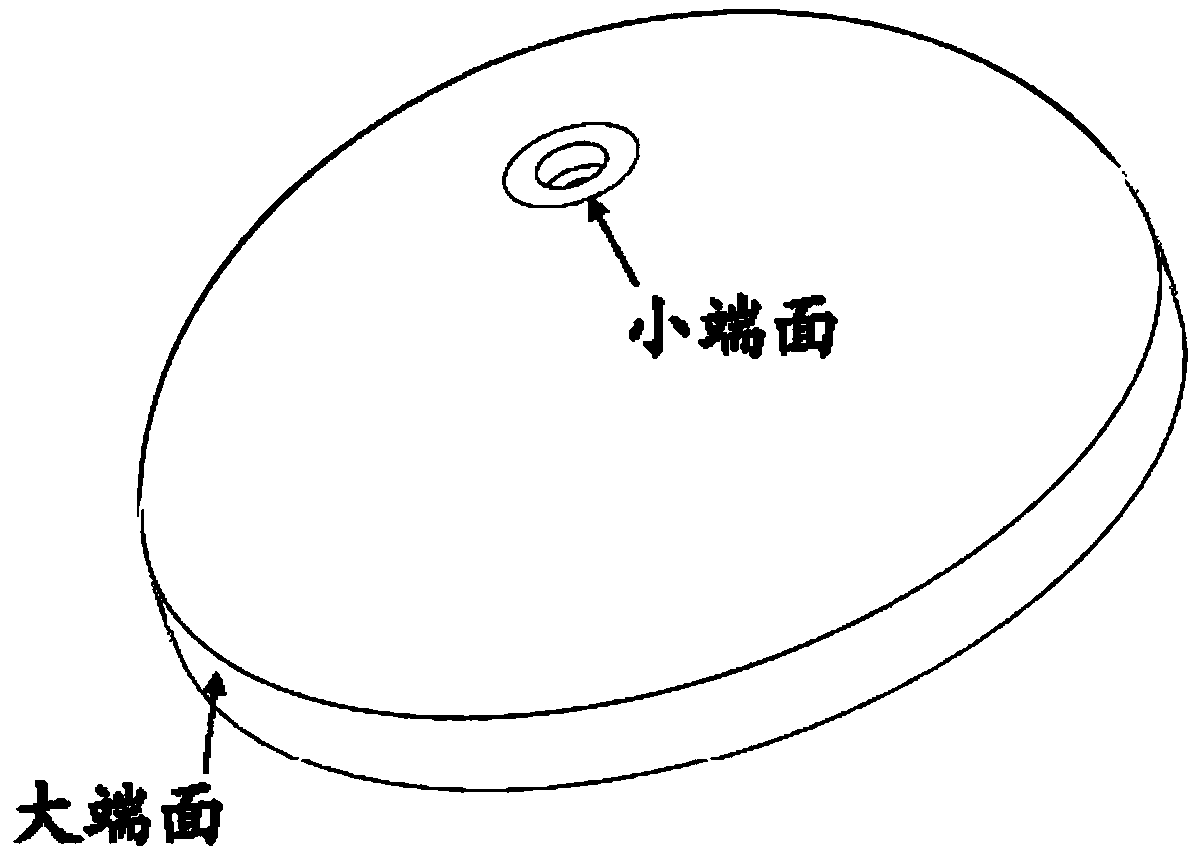

ActiveCN107513677APrevent collapseSmall quenching deformationFurnace typesHeat treatment process controlQuenchingAqueous solution

The invention relates to a heat treatment deformation control method for a large-diameter and large-modulus elliptical molded surface container semispherical shell and belongs to the technical field of container manufacturing. By means of the heat treatment deformation method, due to the fact that an integrated quenching and aging heat treatment tool is designed, the elliptical molded surface container semispherical shell and the heat treatment tool can be tightly matched, the quenching transfer time is shortened, the phenomenon that the top of the shell collapses and pits happen in the circumferential direction of the shell during quenching is avoided, quenching and time aging deformation is reduced, and therefore the heat treatment performance of the elliptical molded surface container semispherical shell can be ensured; and meanwhile, the subsequent machining precision of the shell is also ensured. In addition, a UCON water solution with the concentration ranging from 6% to 10% is adopted in the method to serve as a quenching medium, dynamic flowing of the water solution is maintained, the cooling speed and uniformity of the shell are ensured, meanwhile, quenching deformation is also controlled, and therefore the product precision is ensured.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

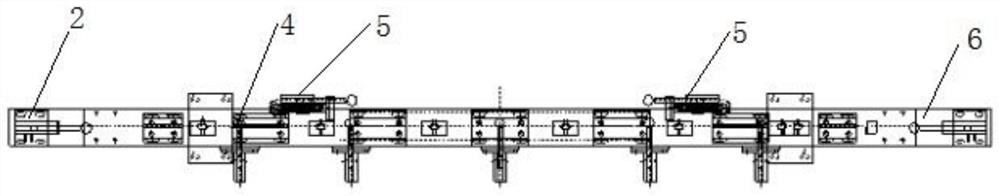

Stator blade finish forging automatic machining method

ActiveCN108747232AImprove machining accuracyUnobstructed walking pathMilling equipment detailsSelf adaptiveMultiple pass

The invention discloses a stator blade finish forging automatic machining method. The method adopts a self-adaption machining technology, and blade deviation, torsion, profile surface tolerance and machining consistency are ensured. The method is simple in machining procedure, computer control and management are adopted, controlled devices completely automatically finish the sequential operation,the degree of automatic operation is improved, multiple devices, multiple passes of procedures, repeated clamping and repeated standard conversion for original stator blade machining are reduced intotwo passes of procedures of machining, two times of clamping and one time of standard conversion on one kind of equipment, labor is saved, the production period of parts is shortened, and the production efficiency is improved.

Owner:AECC AVIATION POWER CO LTD

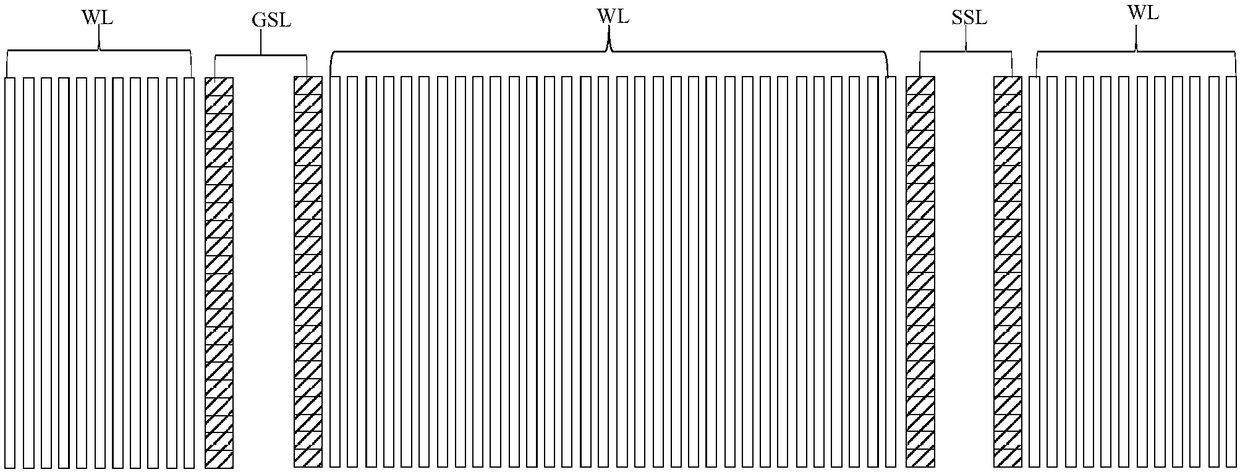

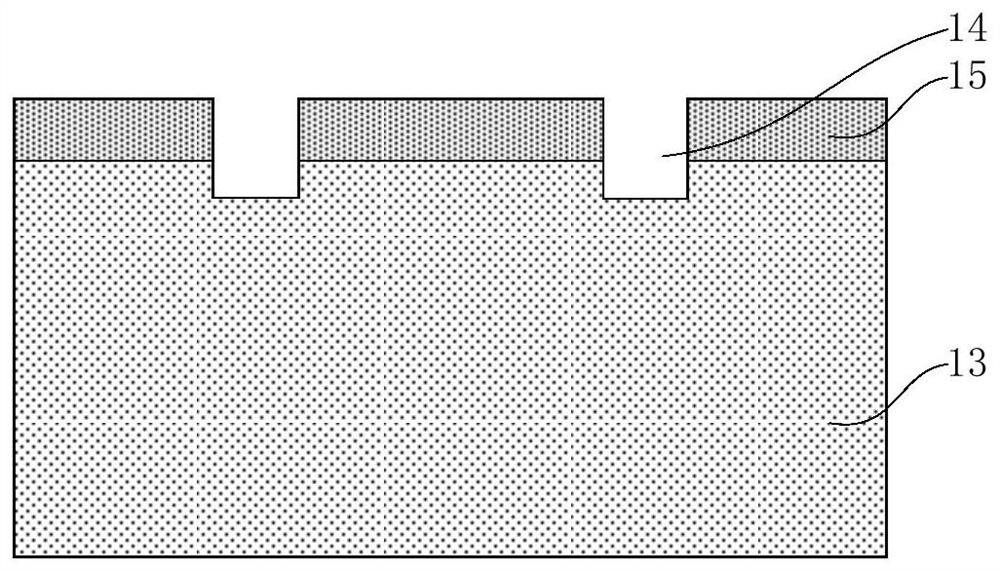

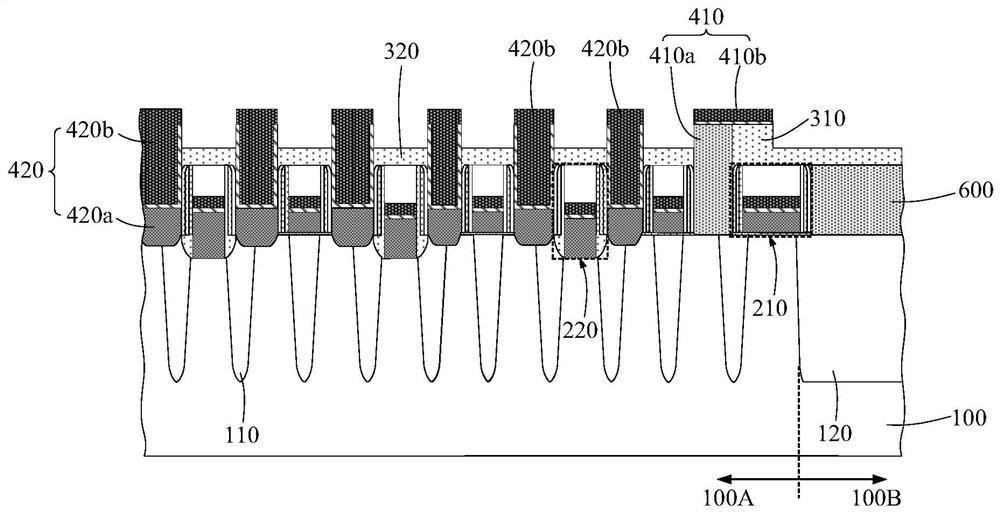

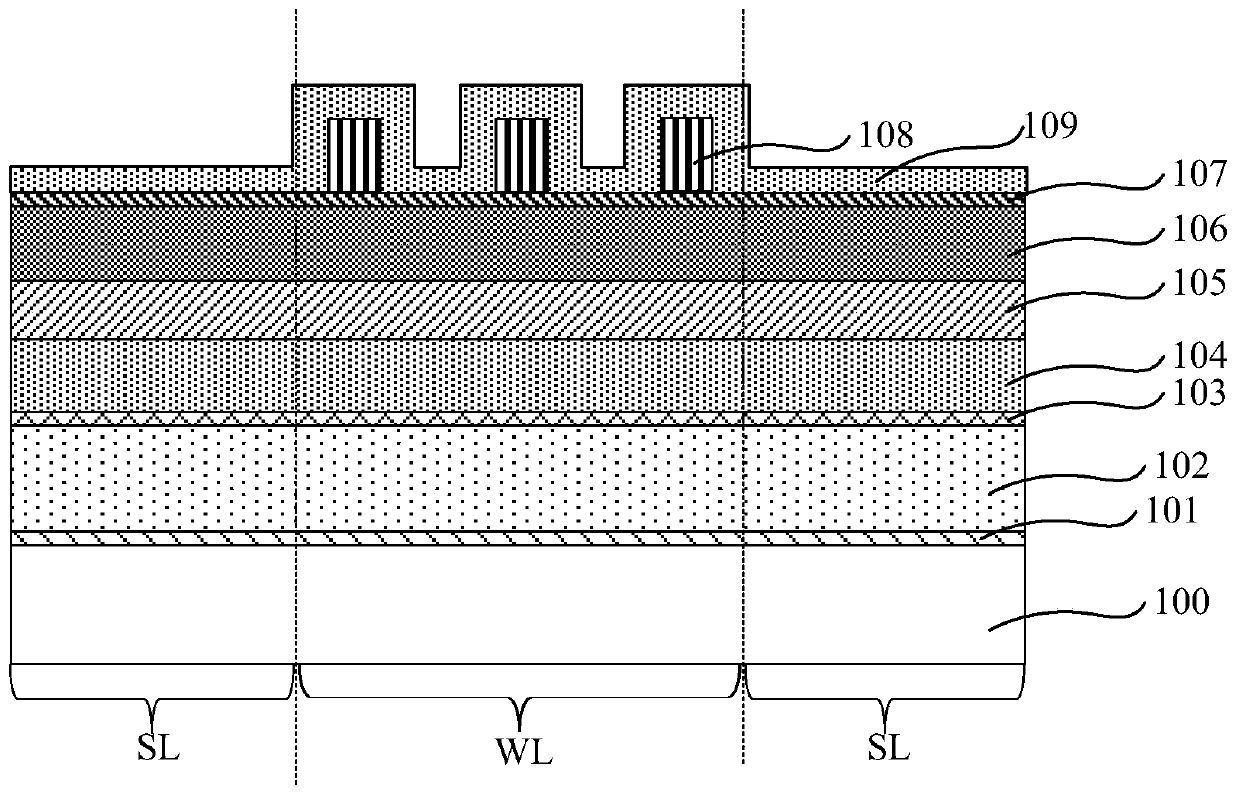

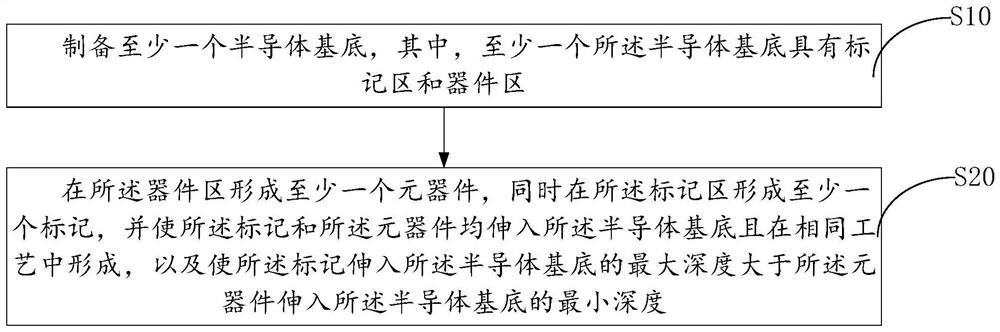

Manufacturing method of semiconductor device

ActiveCN108933140AReduce adverse effectsGuaranteed performanceSolid-state devicesSemiconductor devicesGrid patternEngineering

The invention provides a manufacturing method of a semiconductor device. The method includes steps: depositing a side wall material layer on the surface of a first patterning layer, and forming a second patterning layer corresponding to a first grid electrode on the side wall material layer; and then etching the side wall material layer by regarding the second patterning layer as a mask, and forming a third patterning layer with a first grid pattern and a second grid pattern. The third patterning layer does not have a severe sparse / dense load effect so that there is no etching difference between the first grid electrode and a second grid electrode formed by etching of a grid layer by employing the third patterning layer a mask, the sparse / dense load effect of the grid electrodes is avoided, the appearance of the second grid electrode with abnormal edges is avoided, and the performance of the manufactured semiconductor device is guaranteed.

Owner:SEMICON MFG INT TIANJIN +1

Cosmetic use of an ingredient derived from marrubium vulgare

ActiveUS20190099362A1TightenBeautiful skinCosmetic preparationsOrganic active ingredientsCellular DebrisMedicine

The invention proposes to use a plant material derived from Marrubium vulgare for a non-therapeutic cosmetic treatment for tightening skin pores, said plant material comprising an effective amount of Forsythoside B as the active molecule. The plant material is preferably constituted of a cellular extract of dedifferentiated plant cells freed from cellular debris. This treatment is particularly intended for refining skin grain and / or for treating skin with an oily tendency.

Owner:SEDERMA SA

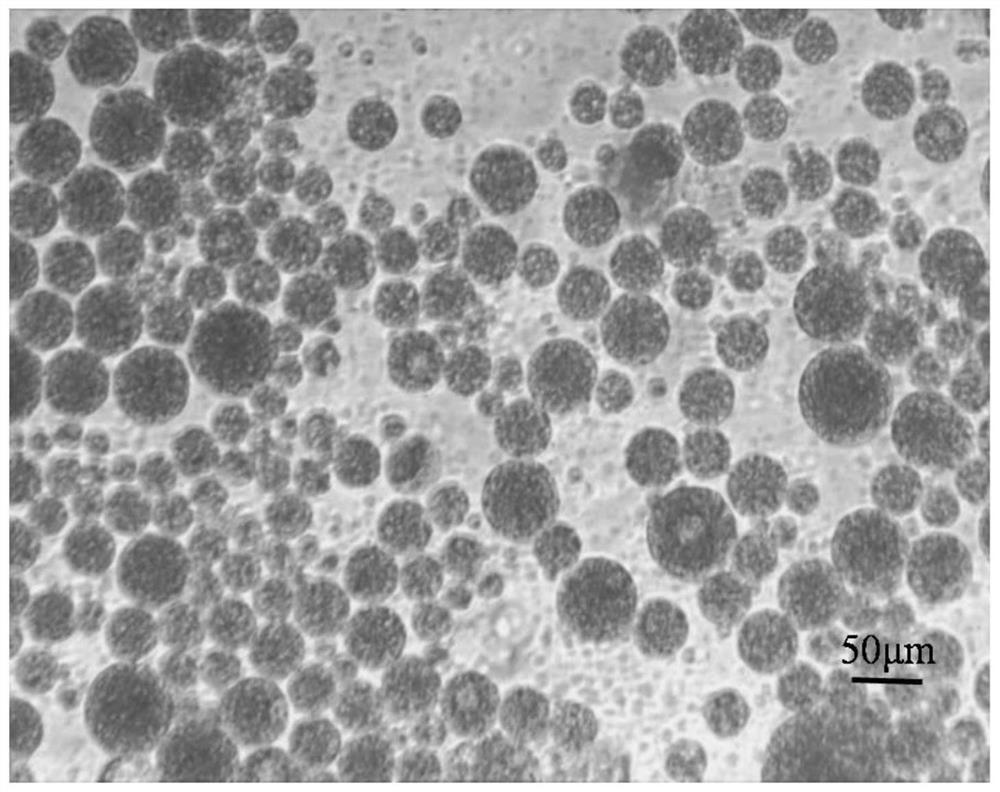

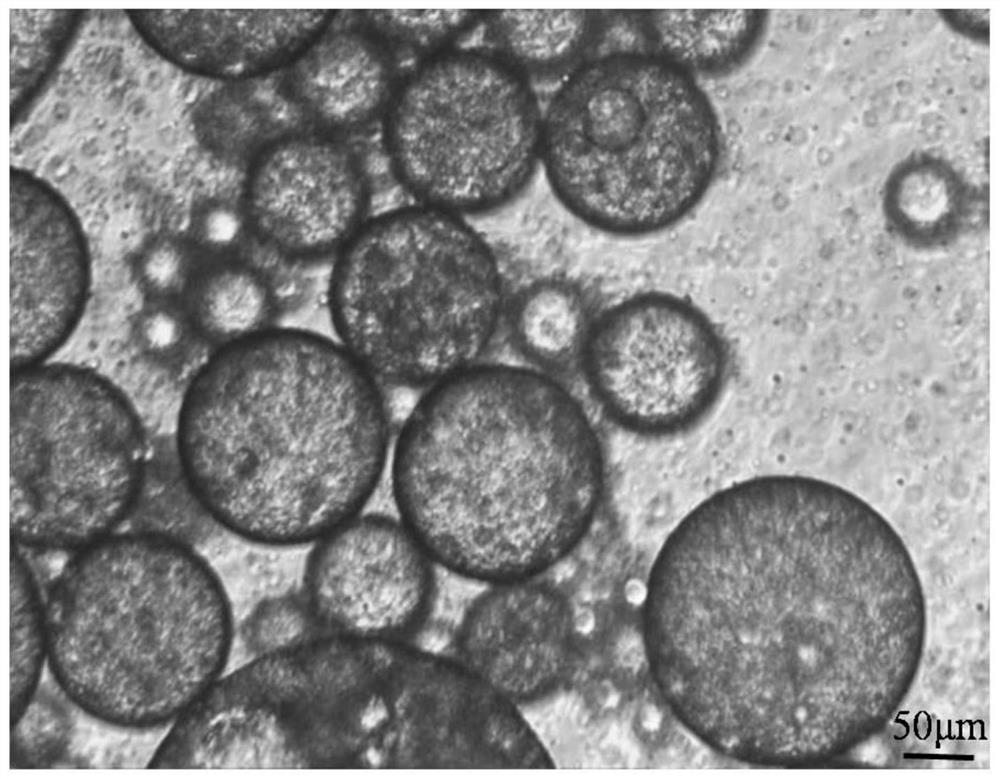

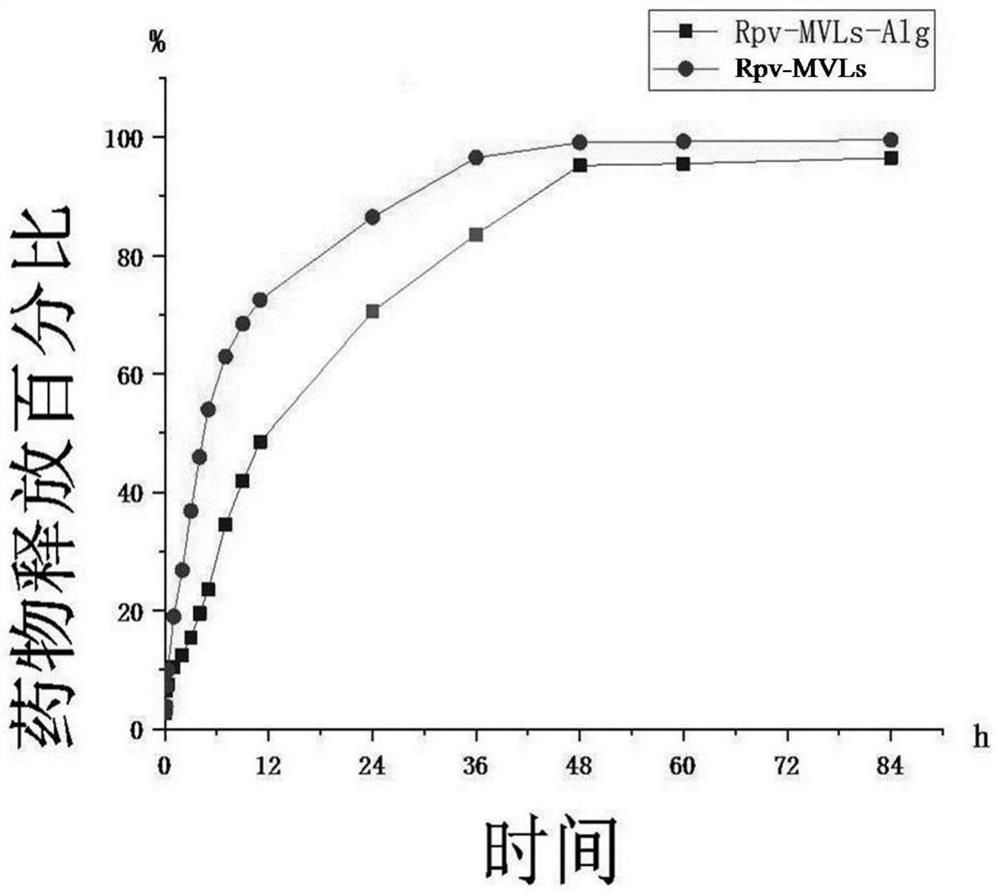

Sodium alginate modified ropivacaine hydrochloride multivesicular liposome microsphere as well as preparation method and application thereof

ActiveCN113171354AGuarantee structureEvenly dispersedAnaestheticsPharmaceutical non-active ingredientsMicrosphereOrganosolv

The invention discloses a sodium alginate modified ropivacaine hydrochloride multivesicular liposome microsphere as well as a preparation method and an application thereof. The preparation method comprises the following steps: firstly, uniformly mixing and dispersing a nano calcium carbonate gel initiator into liquid paraffin, adding multivesicular liposome under the condition of uniform stirring, then adding a sodium alginate solution, and uniformly mixing; and then adjusting the pH value to 3.0-5.8, and rapidly initiating gelation reaction by free calcium ions to form the uniform gel-coated multi-vesicular liposome microspheres with a net-shaped cross-linked structure. The multi-vesicular liposome microsphere has the characteristics of clear structure, uniform particle size, stable state, long slow release time and the like. Compared with an existing preparation method, the preparation method has the advantages that the encapsulation effect of the final multi-vesicular liposome is guaranteed, the surface of the multi-vesicular liposome is uniformly covered with the sodium alginate, the problem that the sodium alginate is connected into a sheet is solved, the stability of the multi-vesicular liposome is enhanced, and therefore the slow release effect is improved. Meanwhile, the use amount of chloroform in the organic solvent can be reduced.

Owner:SOUTH CHINA UNIV OF TECH

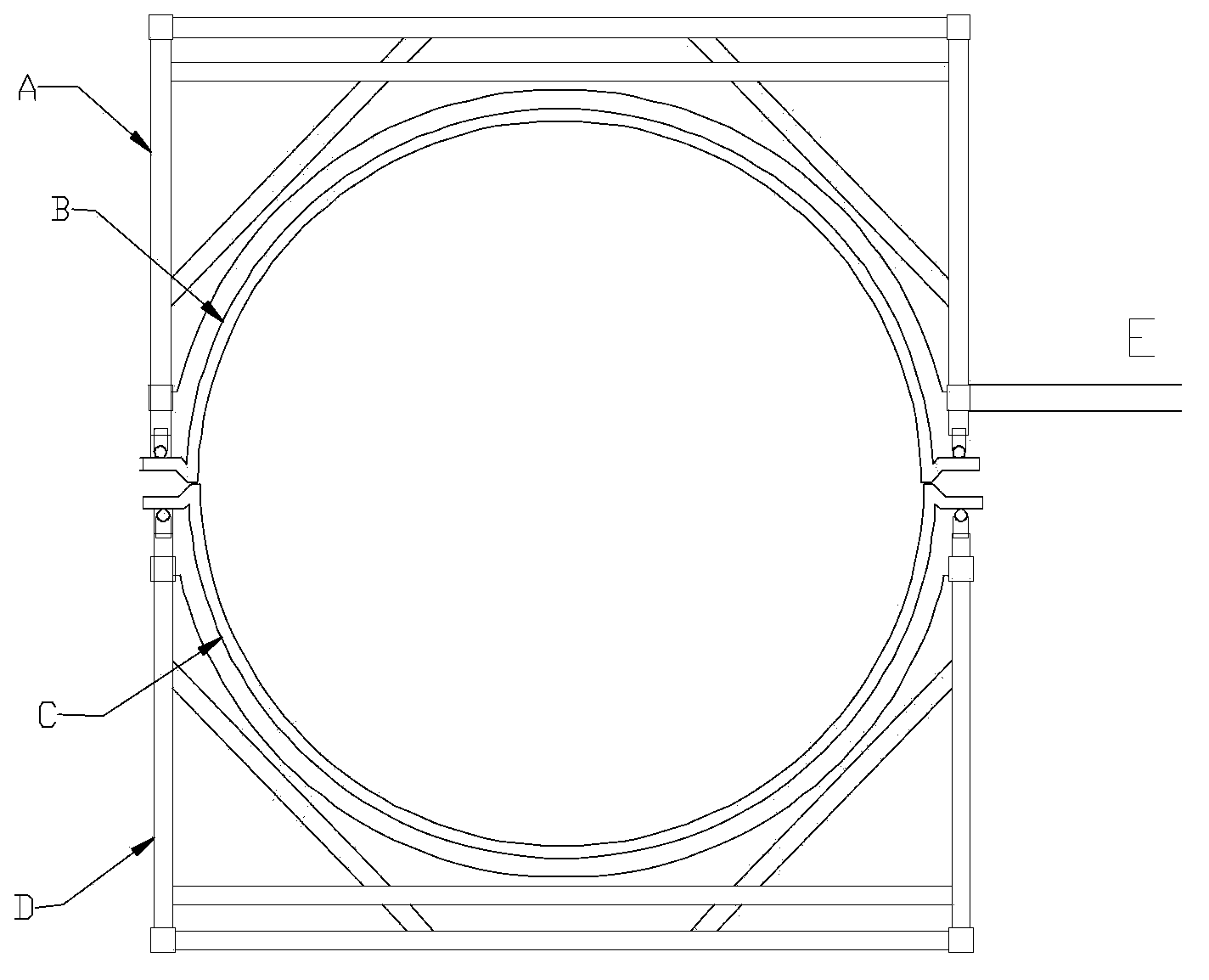

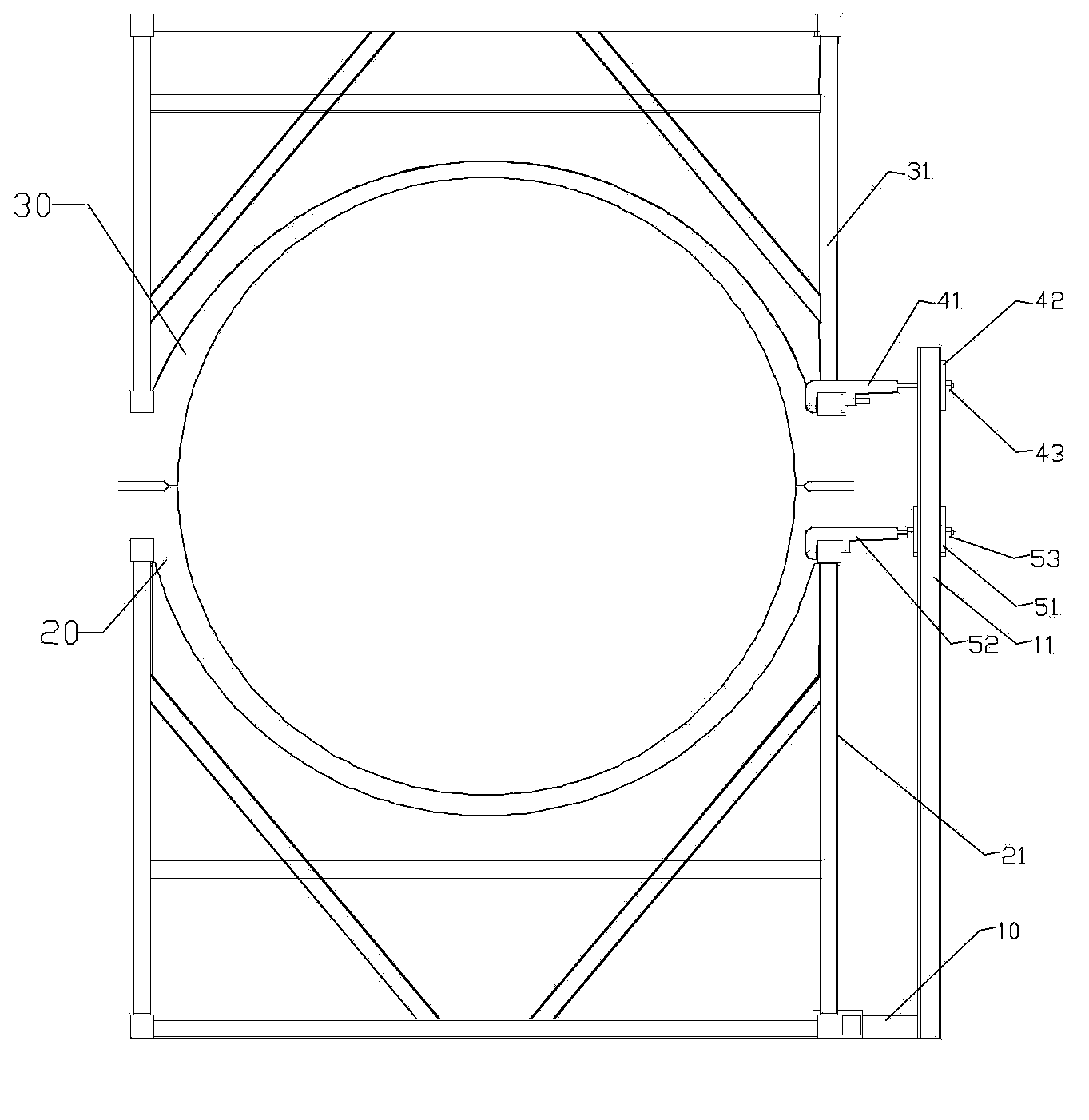

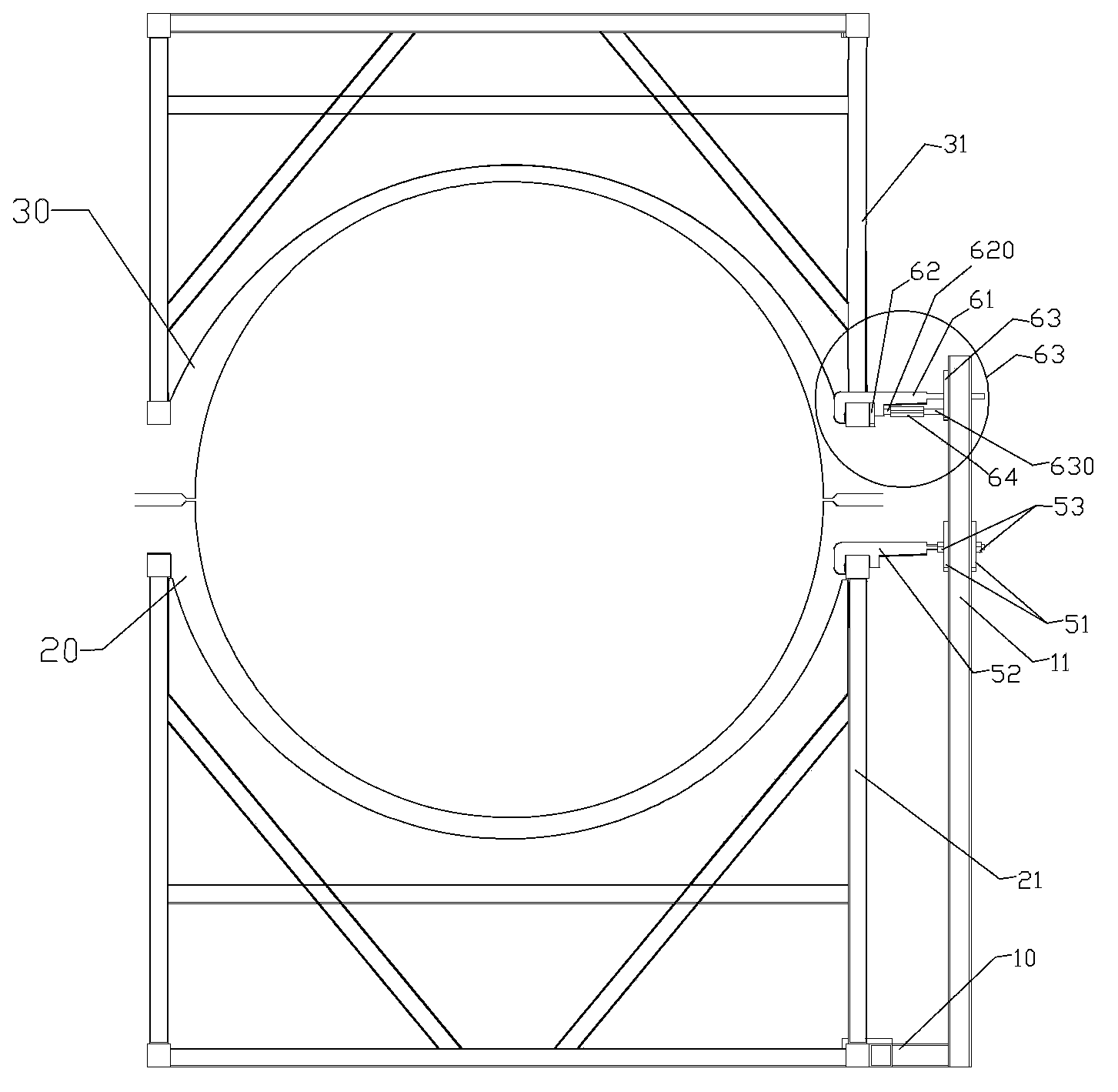

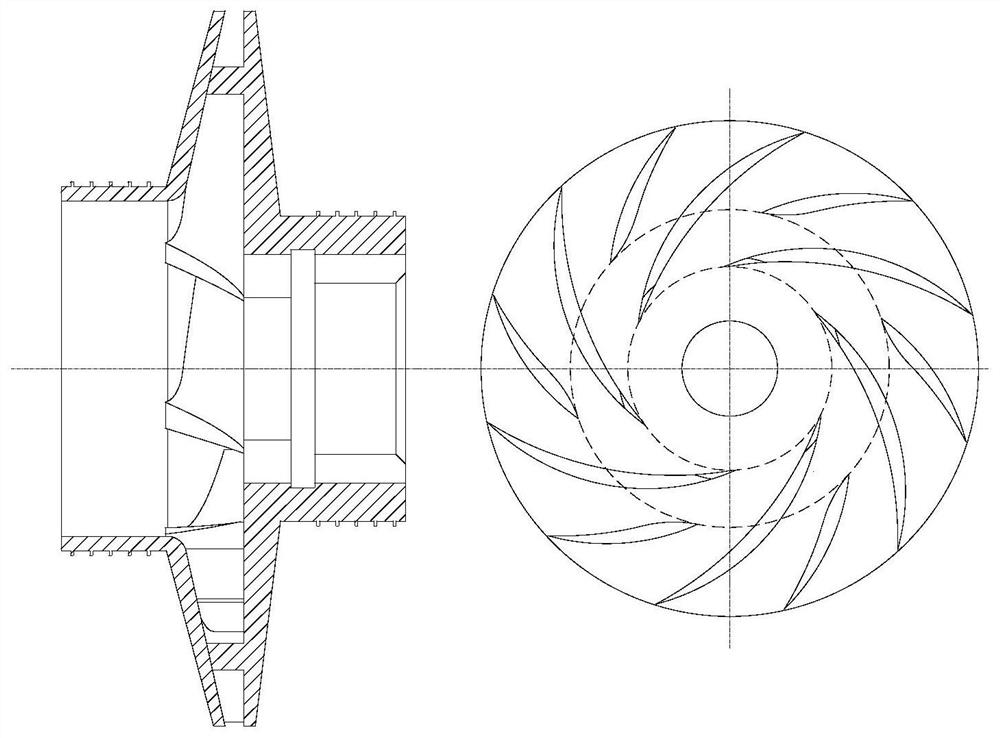

Method and device for adjusting misalignment of shells of mold for fan blade during assembling

ActiveCN103350469AAccurate misalignment adjustmentAccurately achieve misalignment adjustmentSteel frameFan blade

The invention discloses a method for adjusting the misalignment of shells of a mold for fan blades during assembling. The mold comprises an upper shell and a lower shell, wherein the upper shell is fixed on an upper mold steel frame, and the lower shell is fixed on a lower mold steel frame; the upper shell and the upper mold steel frame are put on the lower shell and the lower mold steel frame respectively; the upper shell and the lower shell are abutted together to form a hollow fan-blade mold cavity. The method comprises the following steps of: arranging a detachable adjusting device on the lower mold steel frame, wherein the adjusting device is provided with an adjusting nut; rotating the adjusting nut so that the adjusting nut pulls the upper mold steel frame and the upper shell to move transversely together through a screw rod to align the upper shell to the lower shell; locking and fixing the upper mold steel frame and the lower mold steel frame by a group of mold locking and positioning devices; detaching the adjusting device. The invention aims to provide the method and the device for accurately and conveniently adjusting the misalignment of the shells of the mold for the fan blades during assembling.

Owner:广东明阳新能源材料科技有限公司

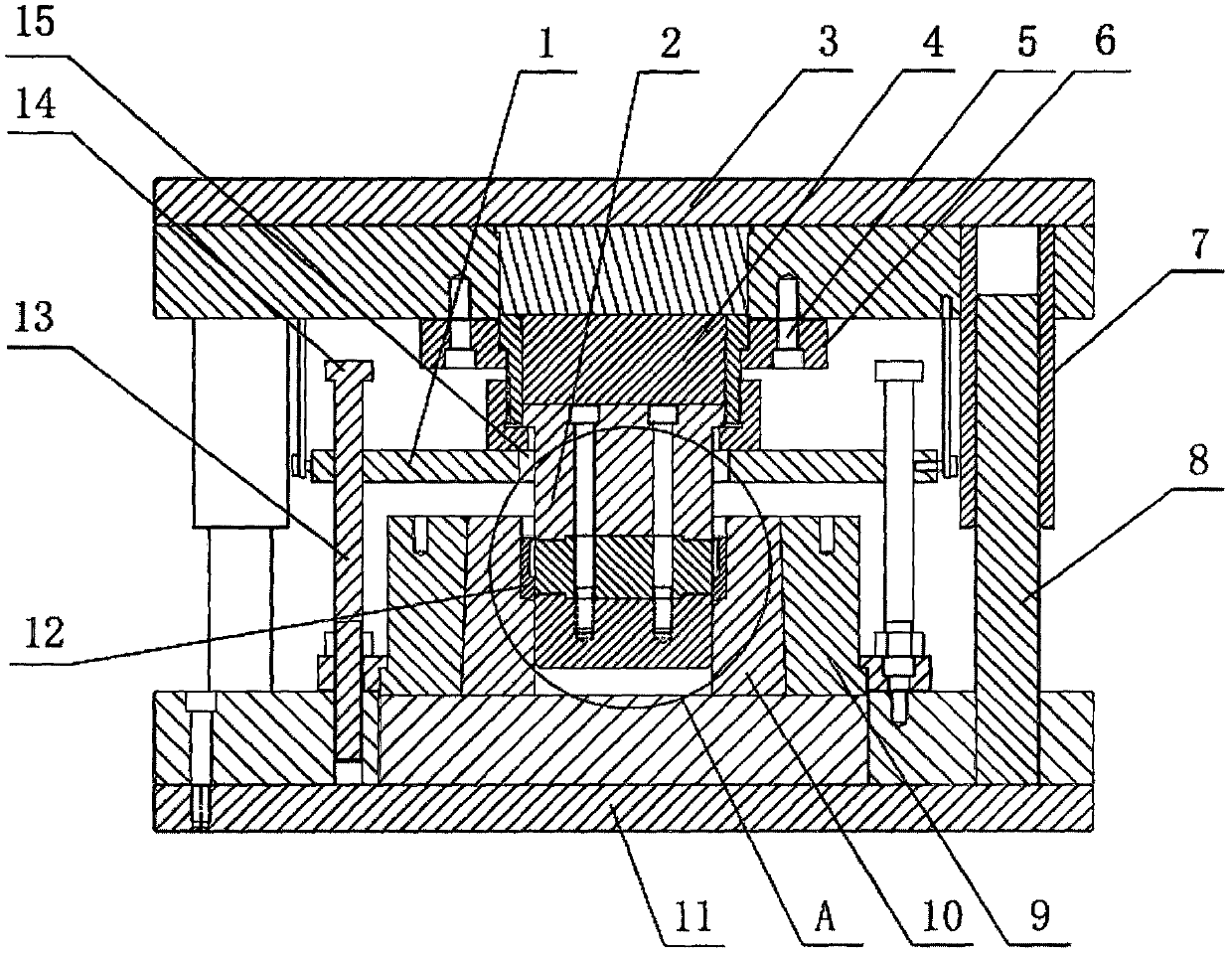

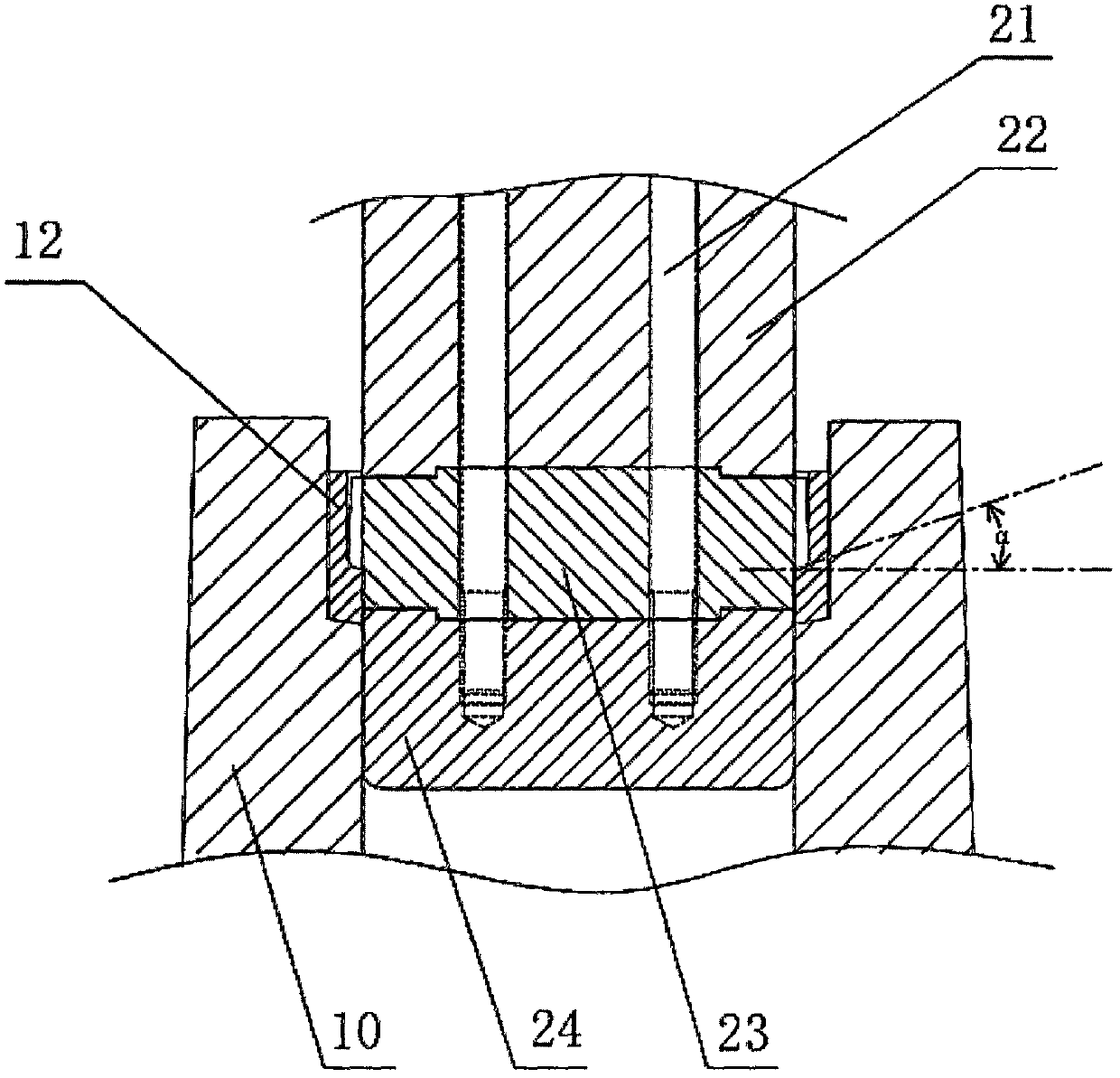

Forming mold and forming method for ring gear

PendingCN107755448AImprove mechanical propertiesIncrease productivityExtrusion diesWheelsEngineeringTooth part

The invention discloses a forming mold and forming method for a ring gear. The forming mold comprises an upper mold base and a lower mold base, wherein a convex mold base is arranged below the upper mold base; a punch mechanism is arranged below and connected with the convex mold base and comprises, from top to bottom, a punch seat, a punch and a guide head; the punch seat, the punch and the guidehead are detachably fixed on the convex mold base via fixed bolts; a detachable concave mold is arranged above the lower mold base; the internal diameter of the upper section of the concave mold is greater than the internal diameter of the lower section of the concave mold; guide pillars and guide sleeves are arranged at two sides of a part located between the upper mold base and the lower mold base; distance between the upper mold base and the lower mold base is adjusted through cooperation of the guide pillars and the guide sleeves; and a material returning mechanism is arranged between theupper mold base and the lower mold bas. The ring gear is molded by using a cold extruding process. The forming mold and the forming method provided by the invention have the advantages of low cost, good tooth form precision uniformity, long mold service life, high production efficiency and good mechanical properties of tooth parts and are applicable to preparation of ring gears with diameters of50 to 500 mm.

Owner:JIAXING DA DAO FORGING TECH CONSULTING LTD

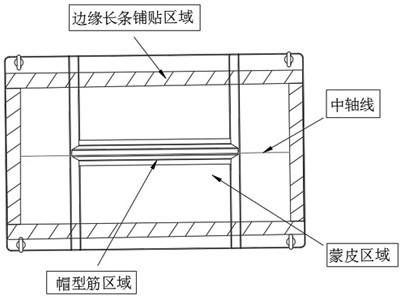

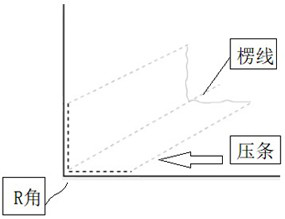

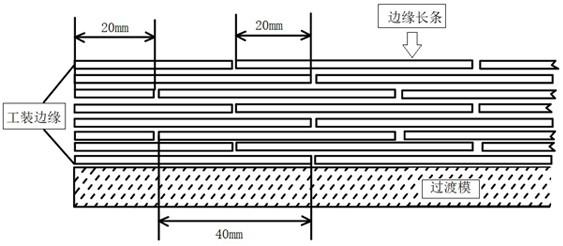

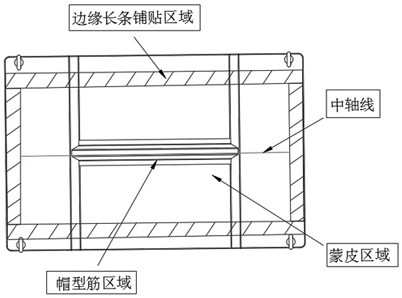

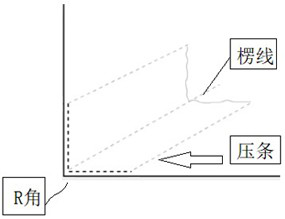

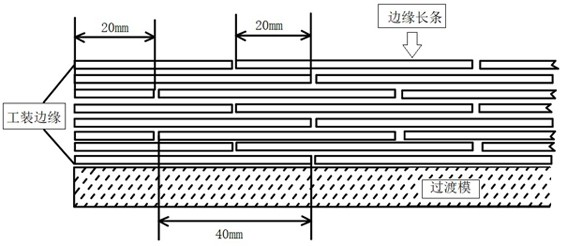

Tool manufacturing method for preventing air leakage of composite material forming tool

ActiveCN112873904AGuarantee internal qualityGuaranteed high temperature airtightnessEngineeringManufacturing engineering

The invention discloses a tool manufacturing method for preventing air leakage of a composite material forming tool. The composite material forming tool is used for forming a composite material part. The composite material forming tool is formed by assembling a composite material paving die and a supporting frame. The composite material paving die is formed by paving and hot-pressing tool prepreg with different thicknesses on the basis of a transition die. In the paving process, pressing strips are paved in the R area and the corner area of the transition die, the tool prepreg is paved in the edge allowance area of the tool in a photo frame mode, and a seam filling long strip is paved in the butt joint area. The photo frame type paving avoids expansion of the edge defect caused by cutting to the interior and cracking during collision or demolding in the carrying process; and the high-temperature air tightness of the tool is further ensured by the pressing strips and the seam filling long strip. The tool manufactured by the method is good in air tightness, the maintenance cost is effectively reduced, the forming quality and the manufacturing period of the composite material part are guaranteed, and good practical and economic values are achieved.

Owner:航天海鹰(镇江)特种材料有限公司

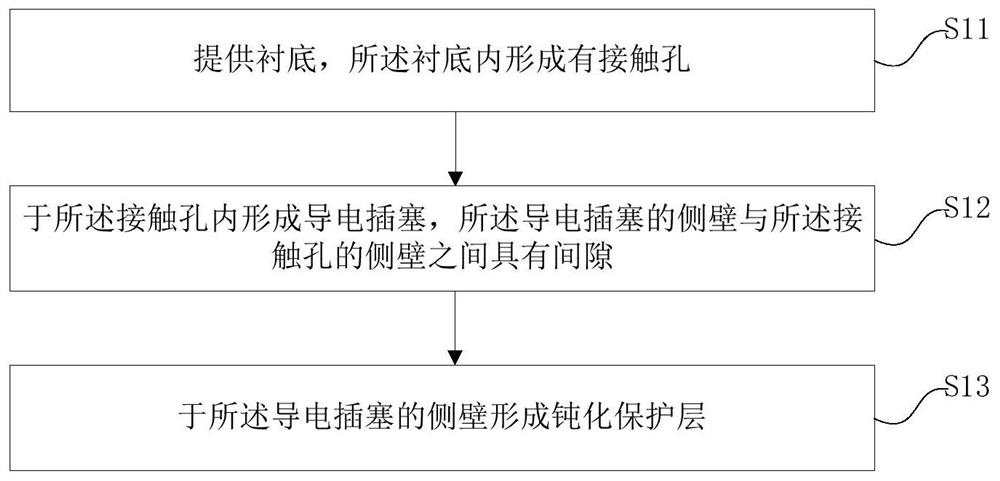

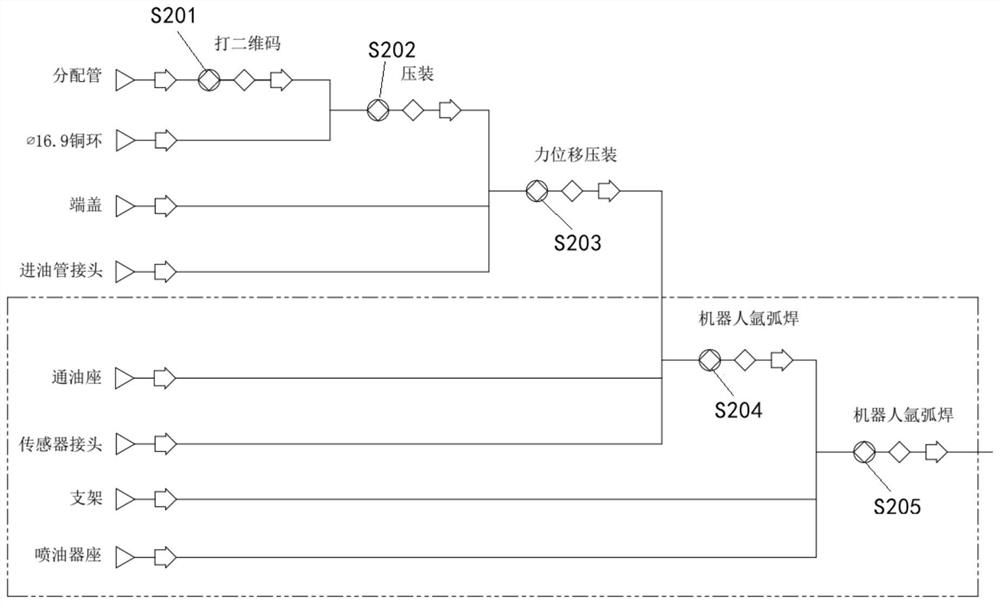

Contact structure, semiconductor device structure and preparation methods of contact structure and semiconductor device structure

PendingCN112652570APrevent oxidationComplete shapeTransistorSemiconductor/solid-state device manufacturingPhysicsElectrically conductive

The invention relates to a contact structure, a semiconductor device structure, and preparation methods of the contact structure and the semiconductor device structure. The contact structure comprises: a conductive plug; and a passivation protection layer which covers the side wall of the conductive plug. According to the contact structure, the passivation protection layer is formed on the side wall of the conductive plug, so that the conductive plug is prevented from being exposed in the air, the surface of the conductive plug is prevented from being oxidized, the passivation protection layer can protect the conductive plug from being removed in an acid pickling process, the complete morphology of the conductive plug is ensured, and the conductive performance of a device is ensured.

Owner:CHANGXIN MEMORY TECH INC

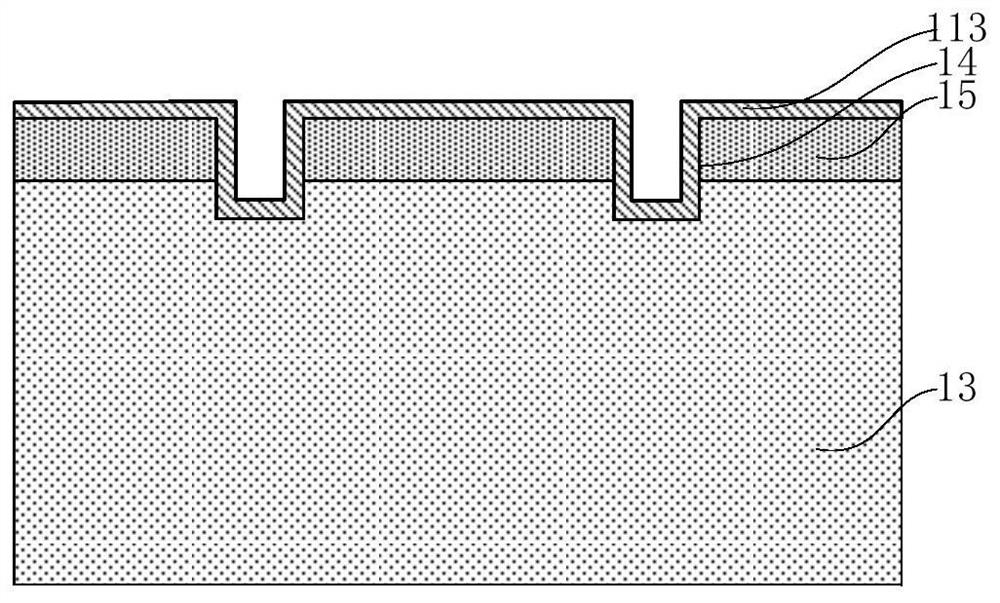

Forming method of L-shaped variable cross-section hollow-structure composite material wave-absorbing component with sawteeth

The invention relates to a forming method of an L-shaped variable cross-section hollow-structure composite material wave-absorbing component with sawteeth. The forming method comprises the following steps of: S1, according to the appearance size of a product, cutting a honeycomb after leaving a margin, and cutting to obtain a honeycomb blank meeting the processing requirement; S2, preparing a soaked material into a wave-absorbing honeycomb blank; S3, machining the wave-absorbing honeycomb blank to prepare a honeycomb part blank; S4, exposing the part where the sawteeth need to be machined; S5, filling low-dielectric pouring sealant in the part, where the sawteeth need to be machined, of the part blank; S6, adopting a forming tool to lay and cure soaked material skin; and S7, adopting a milling tool for sawtooth machining, and thus obtaining the product through preparation. The forming method has the advantages that the size precision control of a part meets the design requirement, the size stability is good, the appearance quality of the formed part is good, the temperature resistance of the part is improved, and the problems that the part is prone to buckling deformation and surface wrinkles are solved; and the sawtooth parts are filled and reinforced by the pouring sealant, so that the sawteeth are not easy to break.

Owner:成都佳驰电子科技股份有限公司

Gear machining process

The invention discloses a gear machining process. The gear machining process is characterized by comprising the following steps of (1), material selection, wherein a gear material is reasonably selected; (2), formation of a gear blank, wherein forging and casting are carried out; (3), rough machining of a gear, wherein gear blank machining, gear form machining and gear end machining are carried out, and redundant materials are cut off; (4), semi-finishing of the gear, wherein gear shaping is carried out on the gear; (5), heat treatment of the gear, wherein preheating, quenching and tempering are carried out; and (6), secondary finishing, wherein standardization is carried out on the gear, and the gear form is subject to finish machining to obtain a final finished product. The gear machining process has the advantages that the working procedures are simple and clear; and rough machining, semi-finishing and secondary finishing are carried out on the gear, so that the gear form is betterguaranteed, the machining efficiency is improved, the cost is saved, and meanwhile the quality of the gear is improved.

Owner:XUZHOU JINCHENG PLANET TRANSMISSION

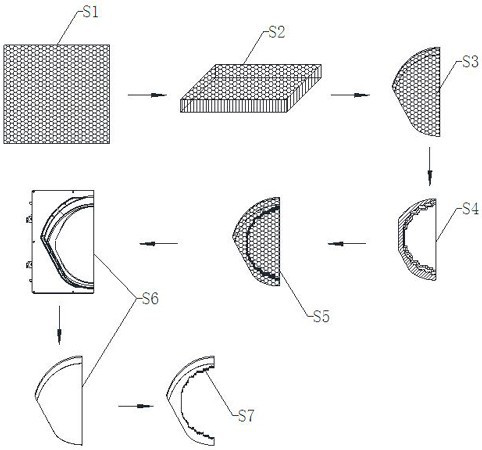

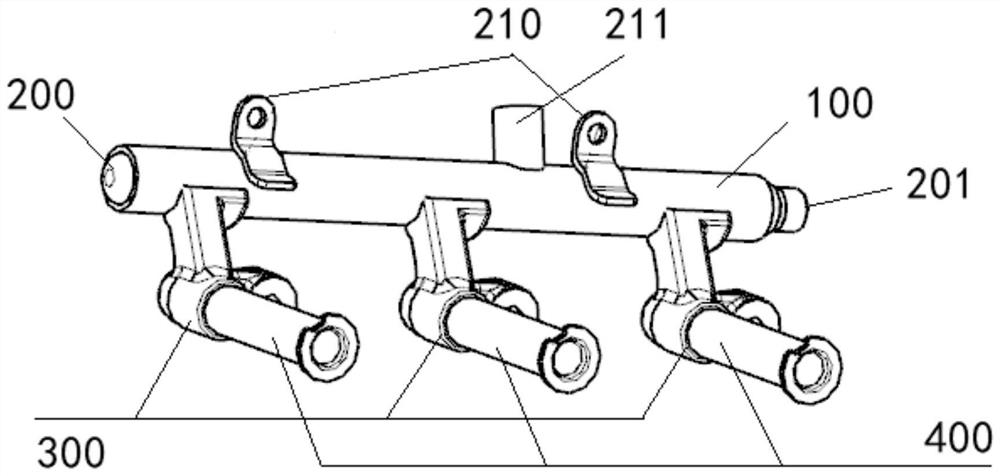

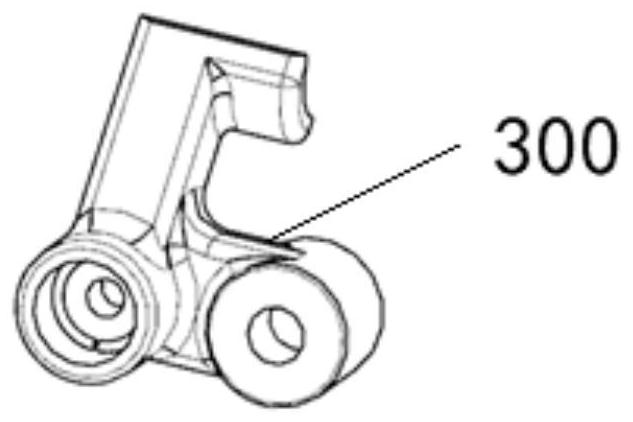

High-pressure oil rail argon arc welding assembly and manufacturing method thereof

ActiveCN114083088AShort process routeIncrease productivityArc welding apparatusFuel injection apparatusAutomotive engineeringManufacturing engineering

The invention relates to the field of automobile high-pressure oil rails, and in particular, relates to a high-pressure oil rail argon arc welding assembly and a manufacturing method thereof. Components of the high-pressure oil rail argon arc welding assembly are divided into a distribution pipe, a first-stage component directly and independently connected to the distribution pipe, a connecting component used for connecting the distribution pipe with other components and a second-stage component connected with the distribution pipe through the connecting component. The manufacturing method comprises the steps that: firstly, a press-fitting component in the first-stage component is connected to the distribution pipe by adopting a press-fitting process; then a first welding component and the connecting component in the first-stage component are connected to the distribution pipe through first-time argon arc welding; and finally, a second welding component and the second-stage component in the first-stage component are connected to the distribution pipe through second argon arc welding. The invention further comprises the high-pressure oil rail argon arc welding assembly. On the premise that the location degree and the outline of a product are guaranteed, the fixed included angle between an oil sprayer seat clamping groove and the distributing pipe in the radial direction is guaranteed, the process route is shortened, and the production efficiency is improved.

Owner:SHANGHAI WINKELMANN LONGCHUAN (SWL) MOTORCOMPONENTS CO LTD

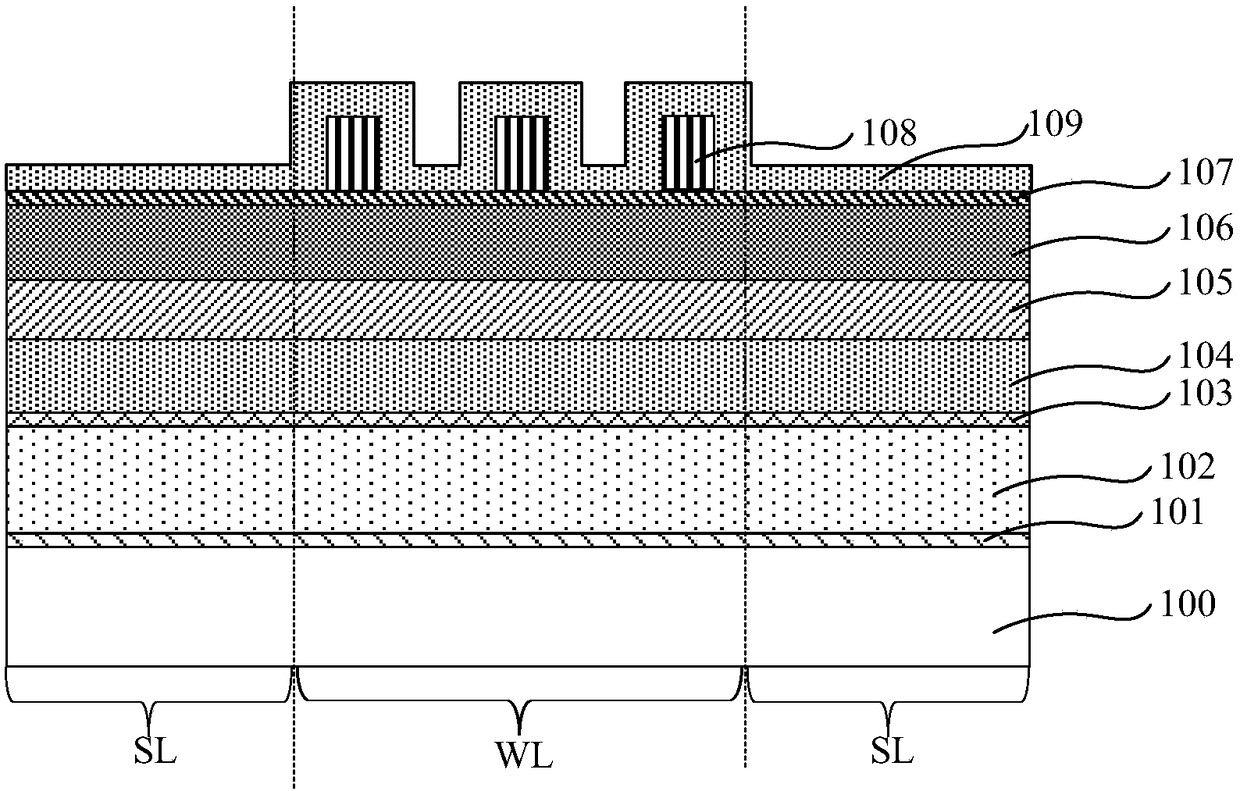

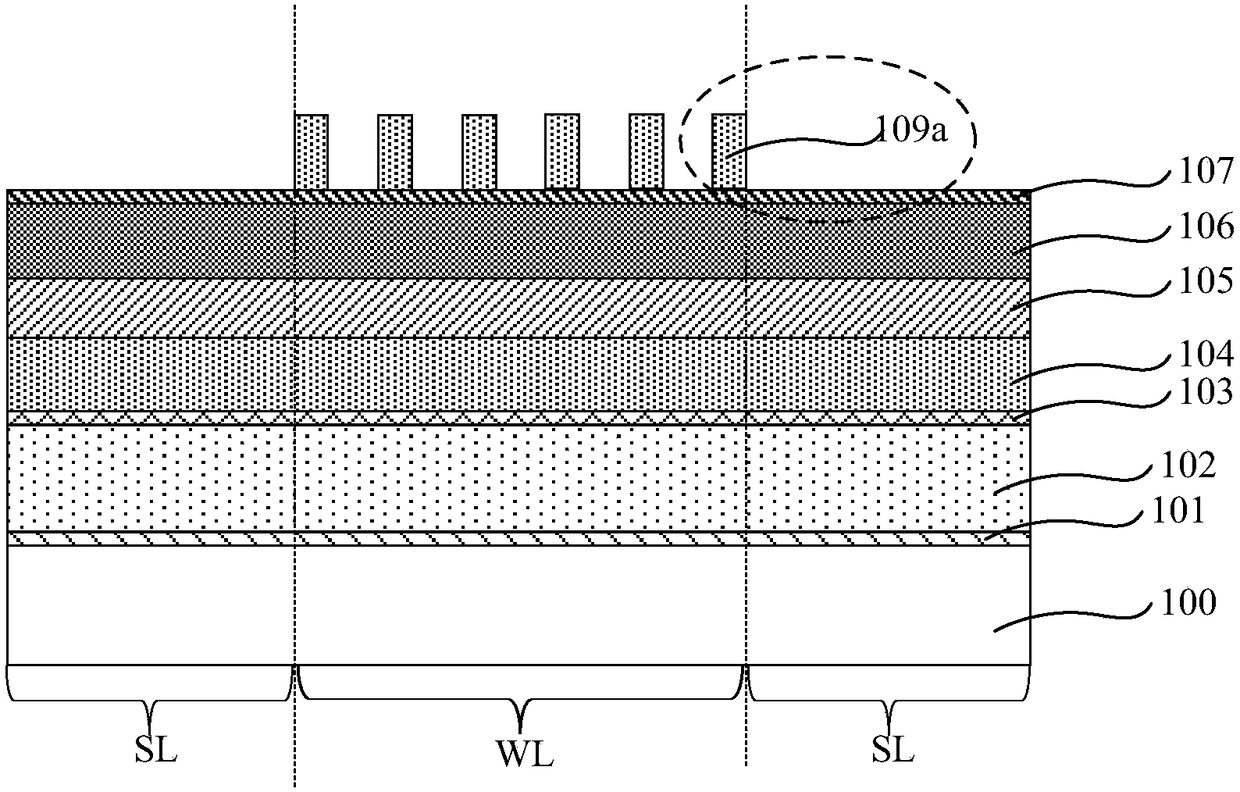

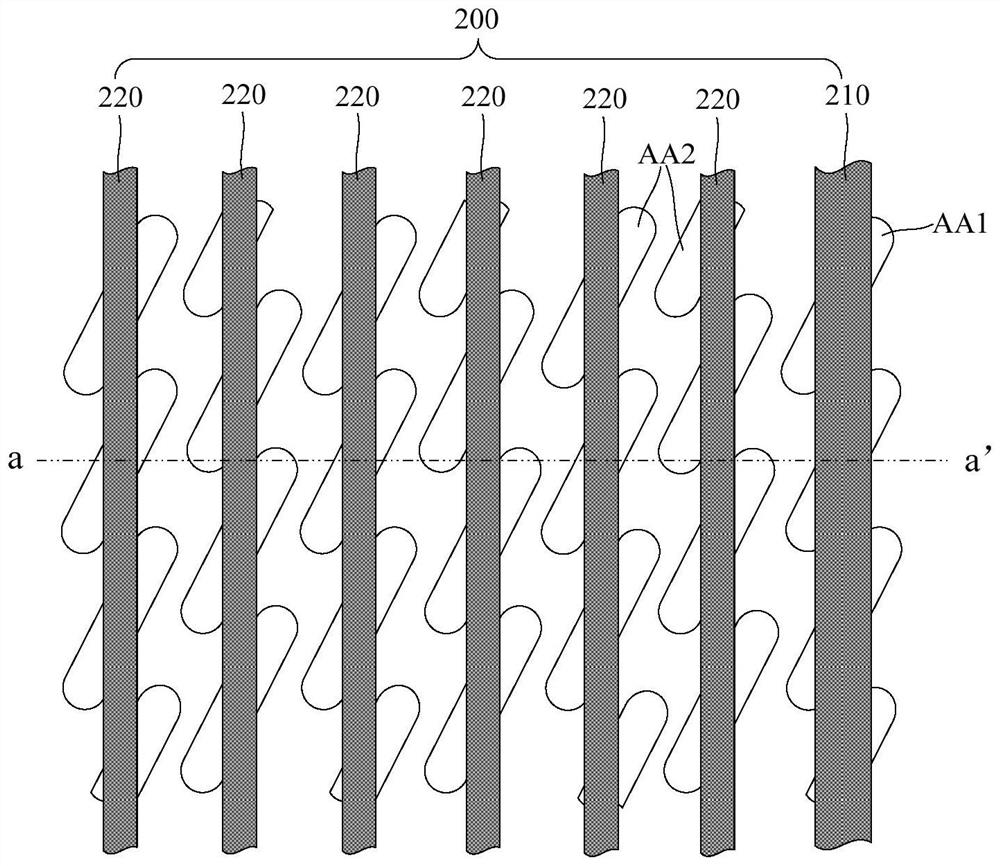

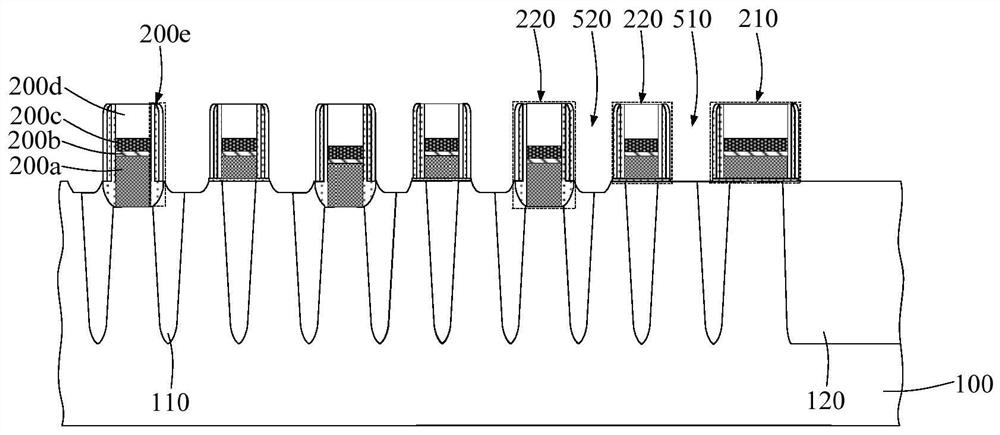

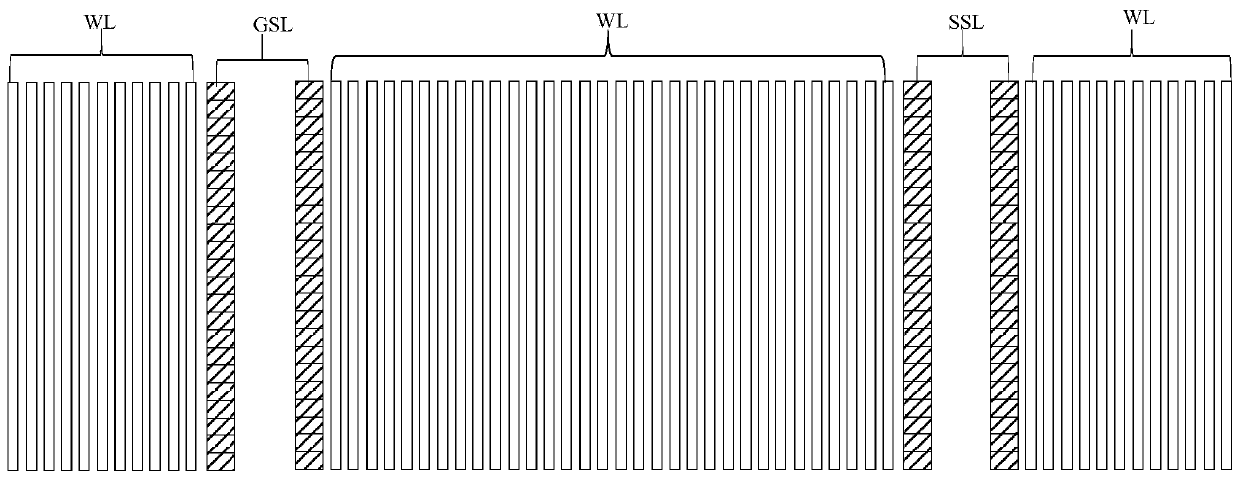

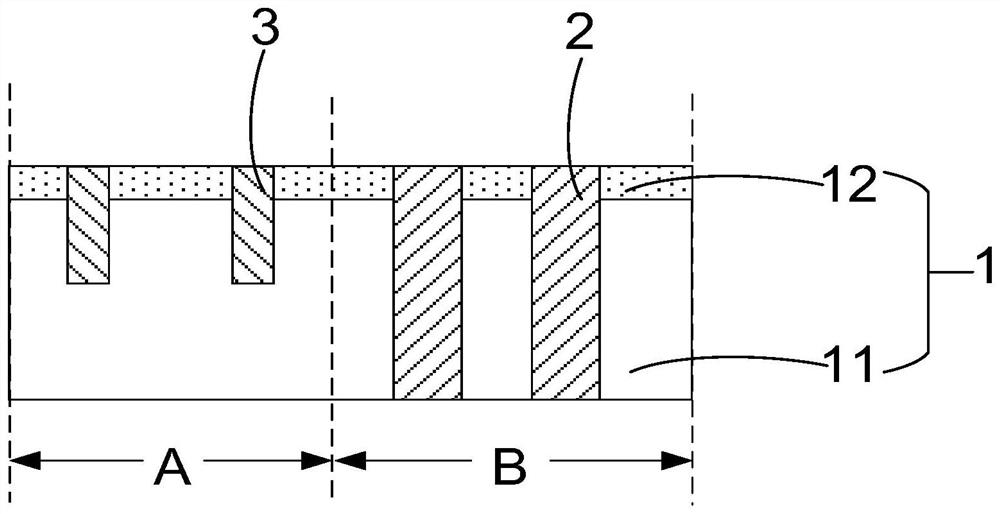

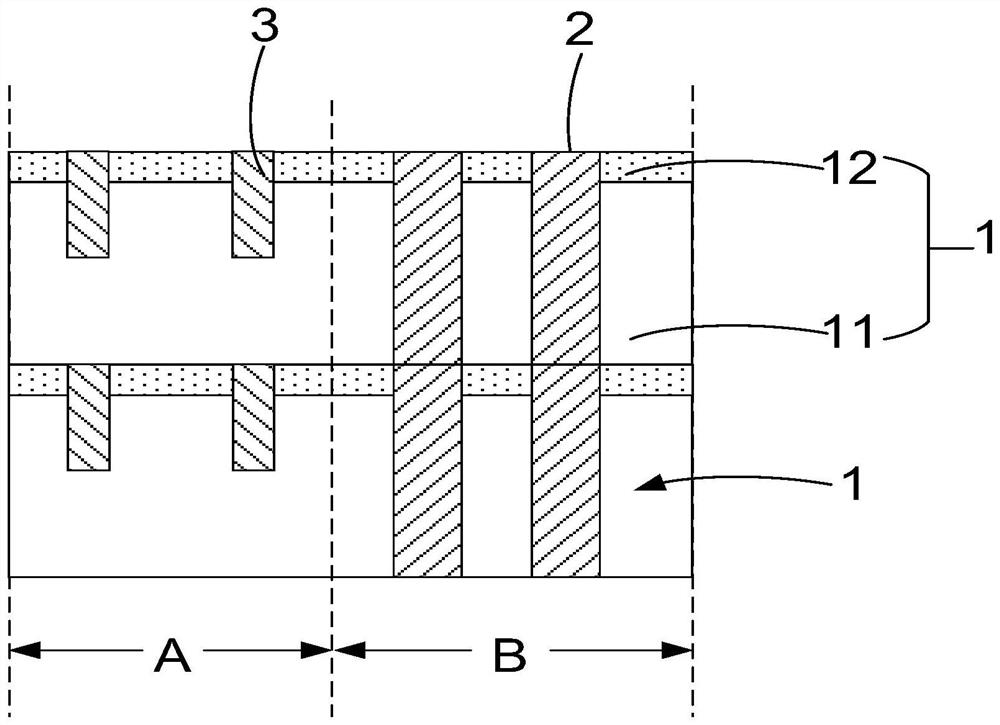

Memory and method of forming the same

ActiveCN111640754BAvoid erosionGuaranteed profileTransistorSemiconductor/solid-state device detailsBit lineComputer science

The present invention provides a memory and a method of forming the same. By making the width dimension of the first bit line located at the edge position in the bit line group larger than the width dimension of the second bit line arranged in the bit line group, when the bit line group is prepared, not only the morphology of the first bit line can be guaranteed, but also the shape of the first bit line can be guaranteed. In addition, under the blocking protection of the first bit line with a larger width, the topography accuracy of the second bit line can also be improved, which is beneficial to improve the device performance of the formed memory. Similarly, since the width dimension of the first contact portion located at the edge position among the plurality of node contact portions is larger than the width dimension of the second contact portion, the topography of the first contact portion can be guaranteed correspondingly, and the pattern of the second contact portion can be improved accordingly. accuracy, further improving the device performance of the formed memory.

Owner:FUJIAN JINHUA INTEGRATED CIRCUIT CO LTD

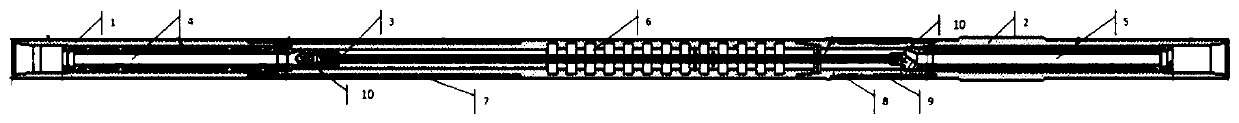

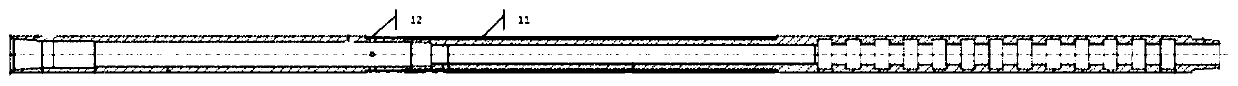

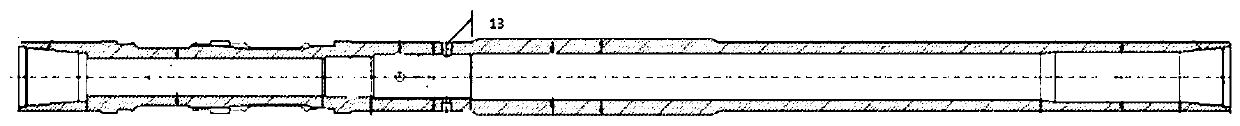

Multipole acoustic wave imaging well logging-while-drilling device

PendingCN111287737AReduce processing difficultyReliable electrical interfaceSurveyDrilling rodsTransducerEngineering

The invention discloses a multipole acoustic wave imaging well logging-while-drilling device. According to the device, one end of a sound receiving system is connected with a sound emitting system through a screw thread to form an integrated structure, a sound insulator is arranged at the lower end of the sound receiving system, the interiors of the sound emitting system, the sound receiving system and the sound insulator communicate with one another to form a central water hole, a central flow guide pipe is arranged in the central water hole, a multipole receiving transducer module and a receiving main control circuit module framework are arranged on the sound receiving system, a four-pole emitting transducer, a single-pole emitting transducer and an emitting excitation circuit module framework are arranged on the sound emitting system, the two ends of the central flow guide pipe are connected with the receiving main control circuit module framework and the emitting excitation circuitmodule framework through sealing pressure-bearing connecting devices correspondingly, a receiving main control circuit module is arranged on the receiving main control circuit module framework, and an emitting excitation circuit module is arranged on the emitting excitation circuit module framework. The device can improve well drilling operation, and improve the well drilling safety coefficient.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Method and device for improving the control level of lateral thickness difference of high-grade non-oriented silicon steel

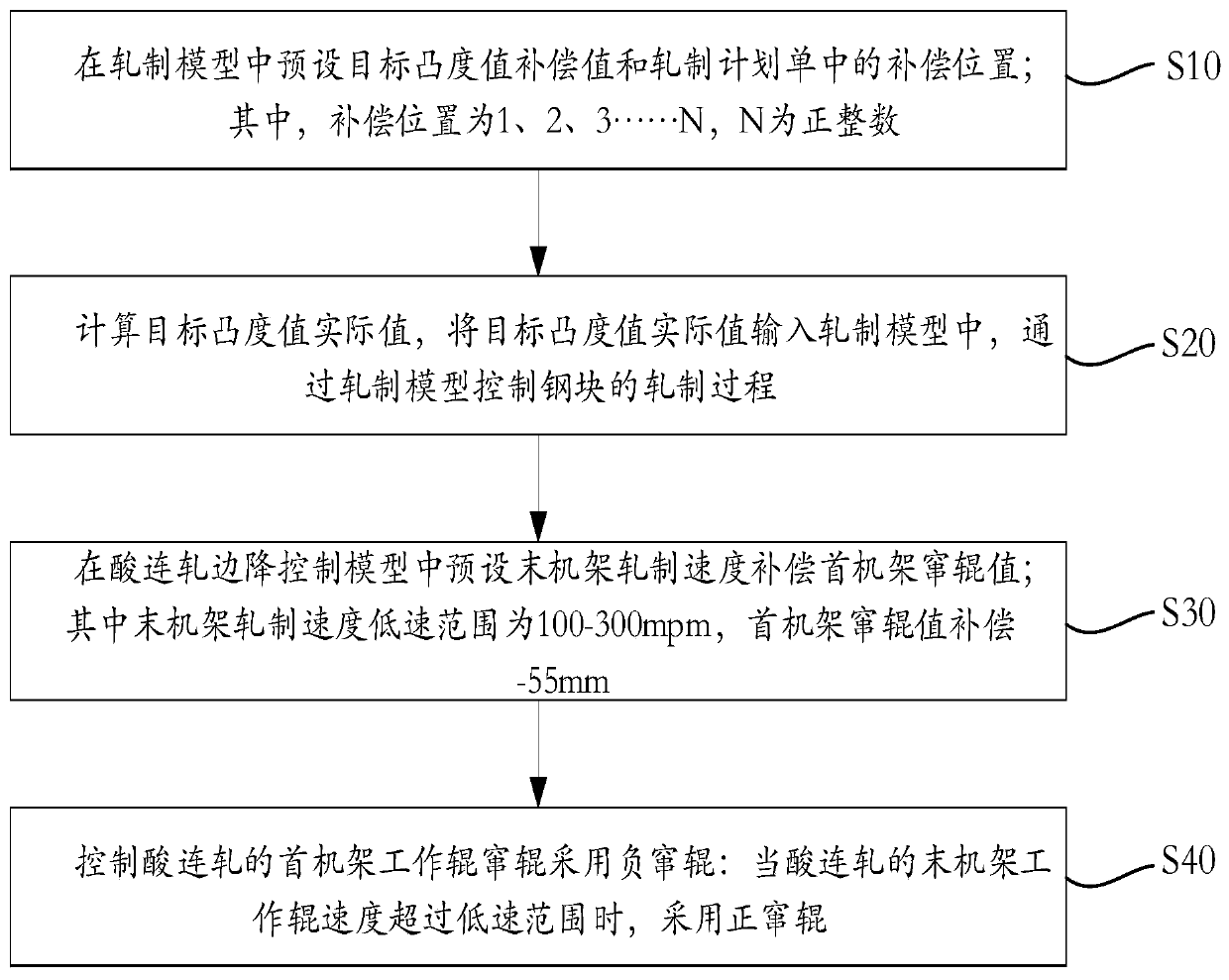

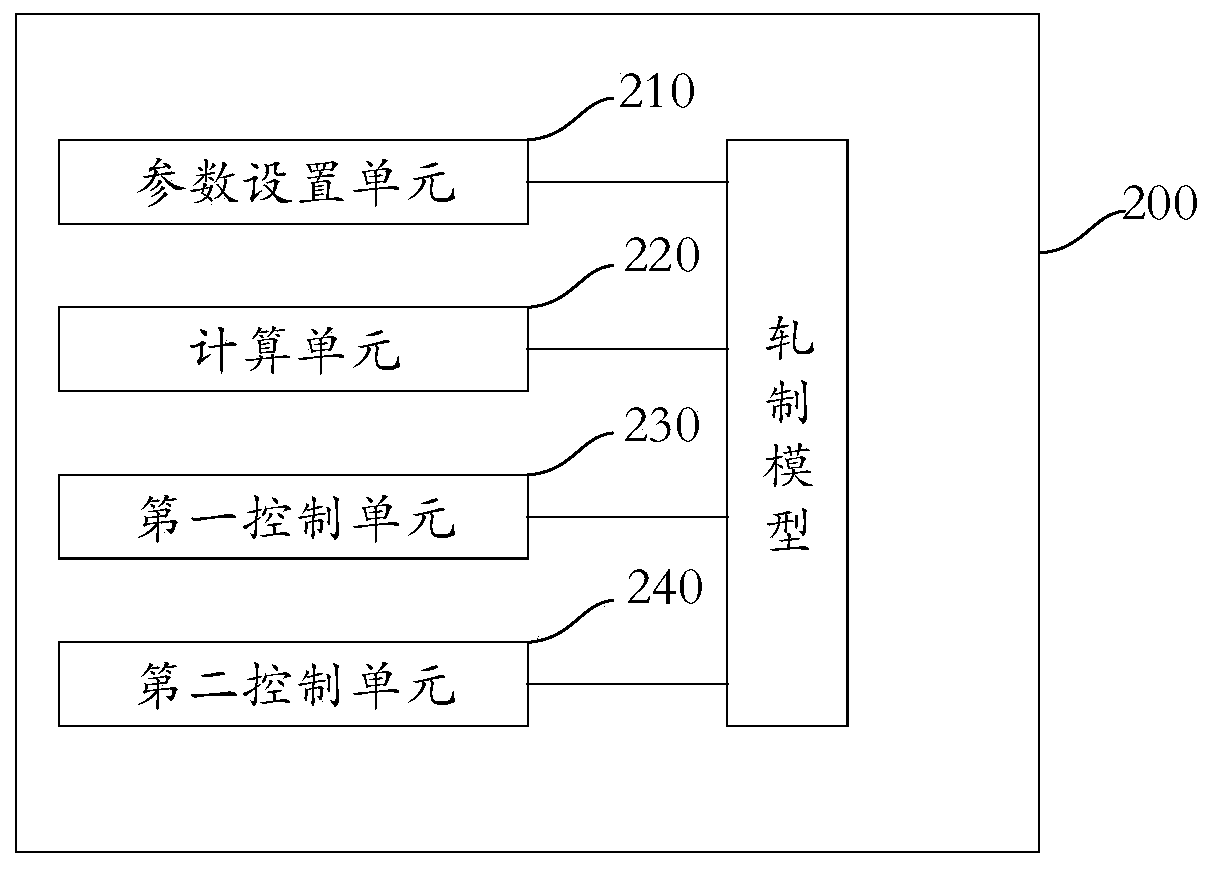

ActiveCN109465297BIncreased level of controlEnsure stabilityRoll mill control devicesDesign optimisation/simulationMetallurgyEngineering

The invention relates to the technical field of steel rolling, in particular to a method for raising the transverse thickness difference of high-grade non-oriented silicon steel, comprising: presetting a target crown value compensation value and a compensation position in a rolling plan sheet in a rolling model, wherein the compensation position is 1, 2, 3... N, and N is a positive integer. The actual value of the target crown value is calculated and input into the rolling model, and the rolling process of the steel block is controlled by the rolling model. The method for raising the transverse thickness difference of the high-grade non-oriented silicon steel provided by the embodiment of the invention improves the control level of the transverse thickness difference of the low-speed whileensuring the rolling stability.

Owner:SHOUGANG ZHIXIN QIAN AN ELECTROMAGNETIC MATERIALS CO LTD

Manufacturing method of semiconductor device

ActiveCN108933140BReduce adverse effectsGuaranteed performanceSolid-state devicesSemiconductor devicesDevice materialMaterials science

The invention provides a method for manufacturing a semiconductor device. After depositing a side wall material layer on the surface of the first patterned layer, firstly form a second patterned layer corresponding to the first grid on the side wall material layer, and then use The second patterned layer is a mask, and the side wall material layer is etched to form a third patterned layer with the first gate pattern and the second gate pattern, because the third patterned layer has no serious sparse / dense load effect, so using the third patterned layer as a mask to etch the gate layer to form the first gate and the second gate have no etching difference, avoiding the sparse / dense loading effect of the gate and avoiding abnormalities The appearance of the edge second gate further ensures the performance of the manufactured semiconductor device.

Owner:SEMICON MFG INT TIANJIN +1

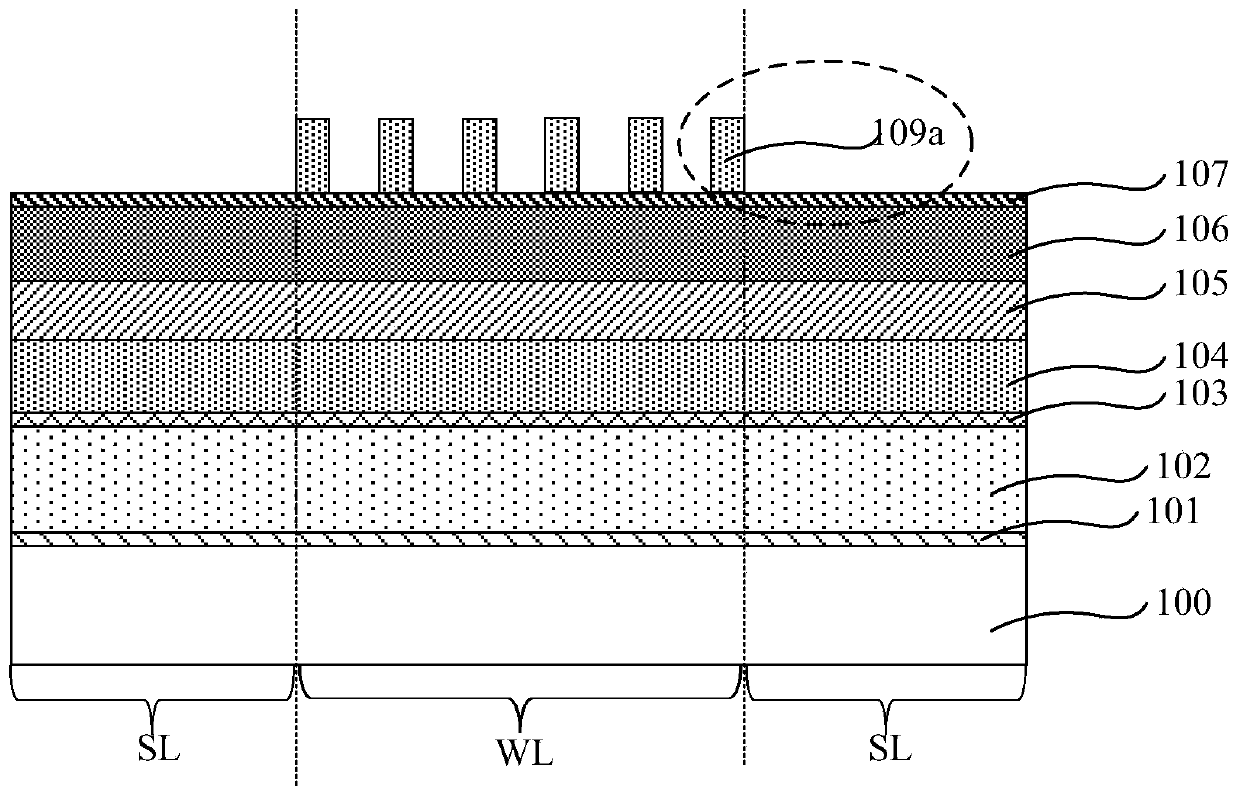

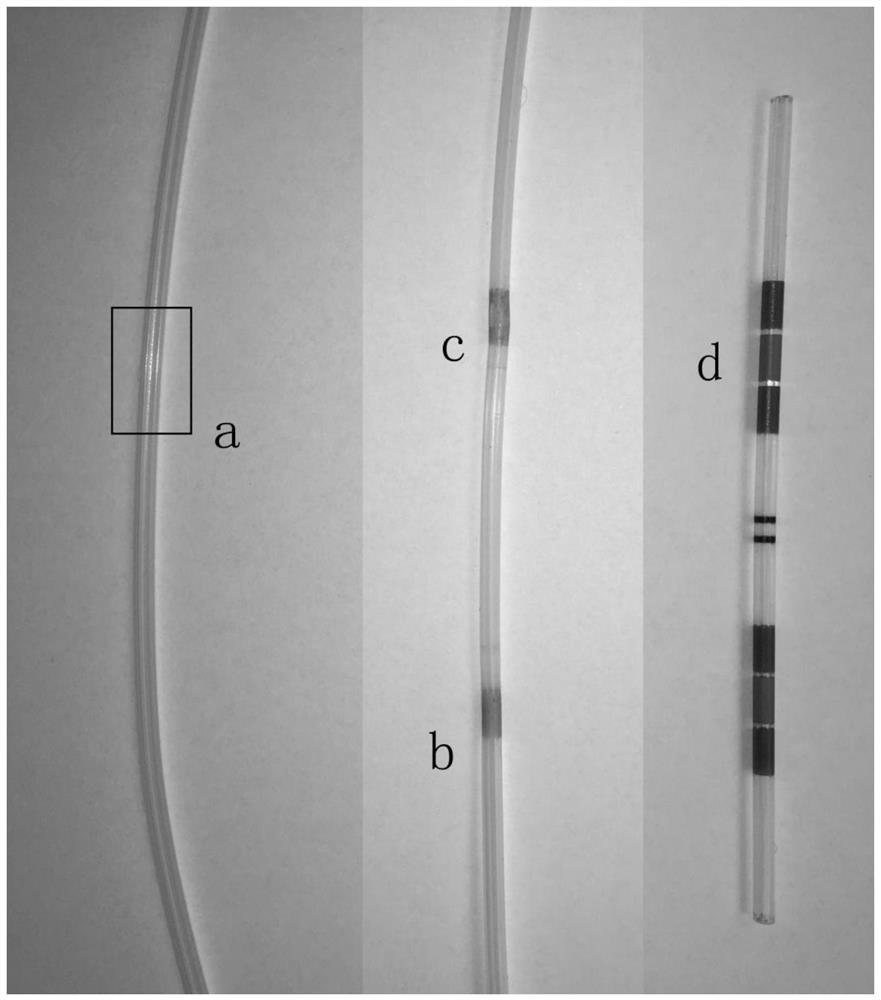

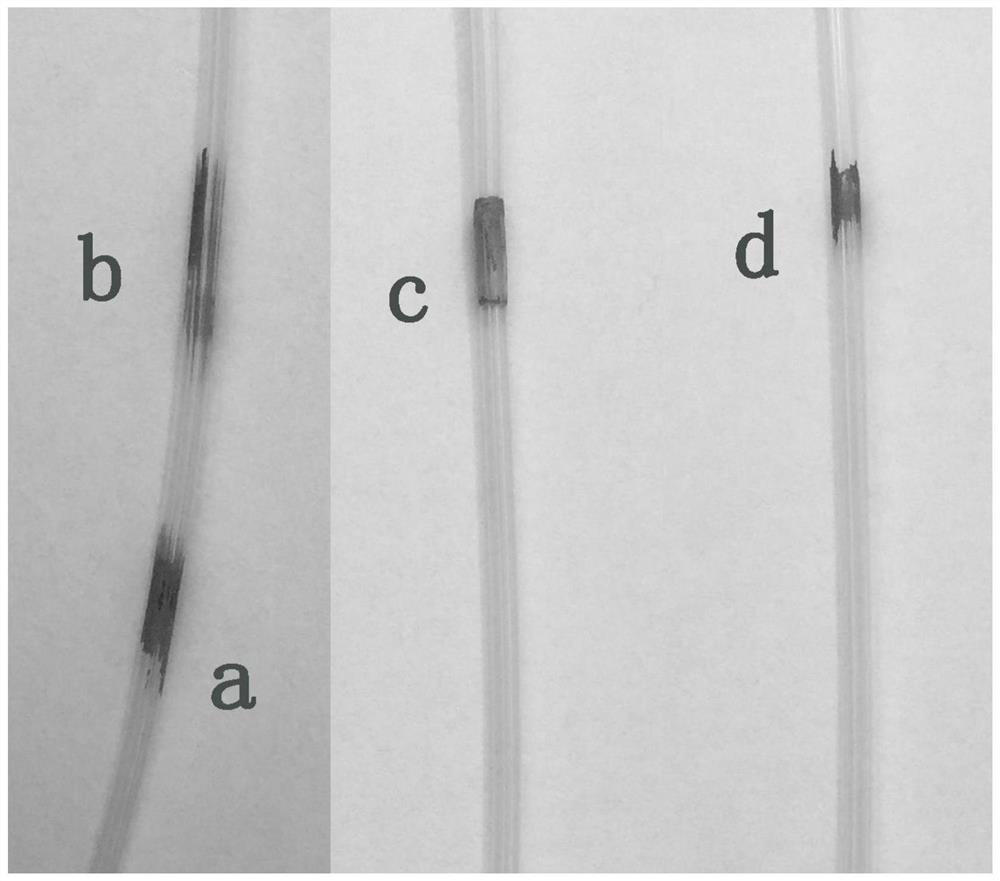

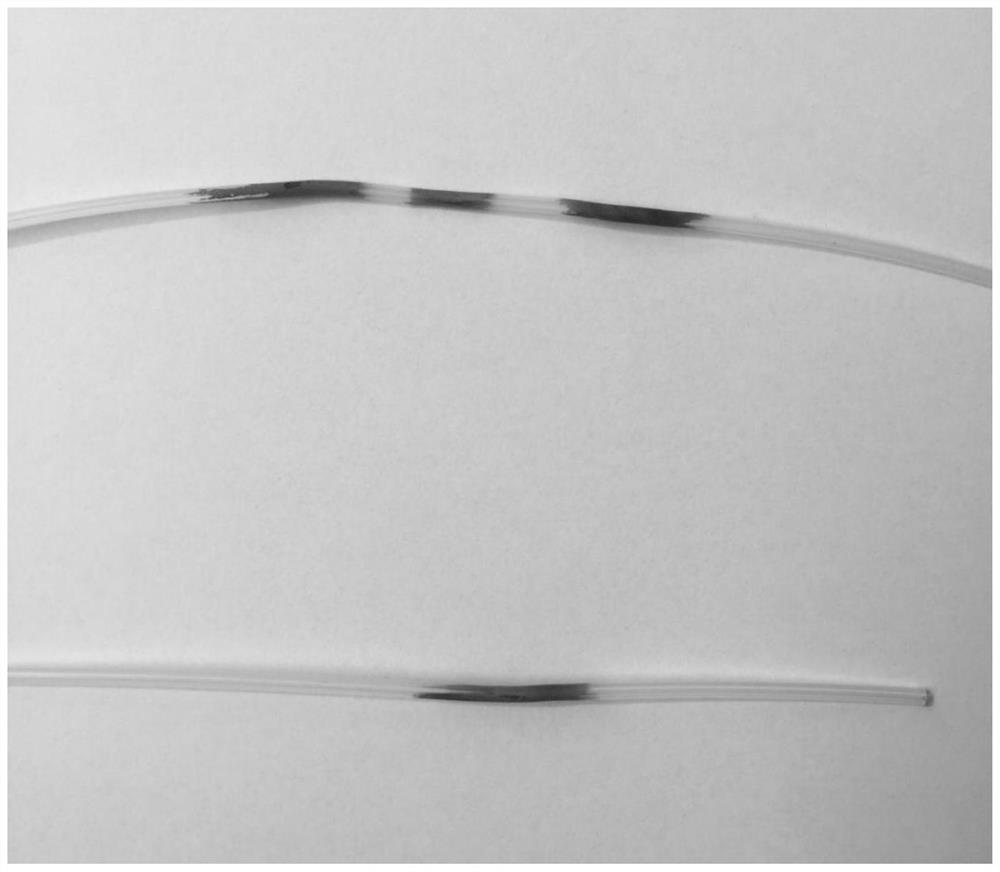

A preparation method of polytetrafluoroethylene tube ribbon coating and polytetrafluoroethylene tube

ActiveCN109942867BLower surface energyImprove surface reactivityVacuum evaporation coatingSputtering coatingBiomedical engineeringEndoscopy

The invention discloses a polytetrafluoroethylene tube ribbon coating preparation method and the polytetrafluoroethylene tube thereof. The modified coating material and the surface treatment of the tube are manufactured by adding an annular ribbon logo coating on the polytetrafluoroethylene tube. layer, which can improve the navigation and positioning of medical staff in endoscopic medical treatment.

Owner:青岛汉兴新材料有限公司

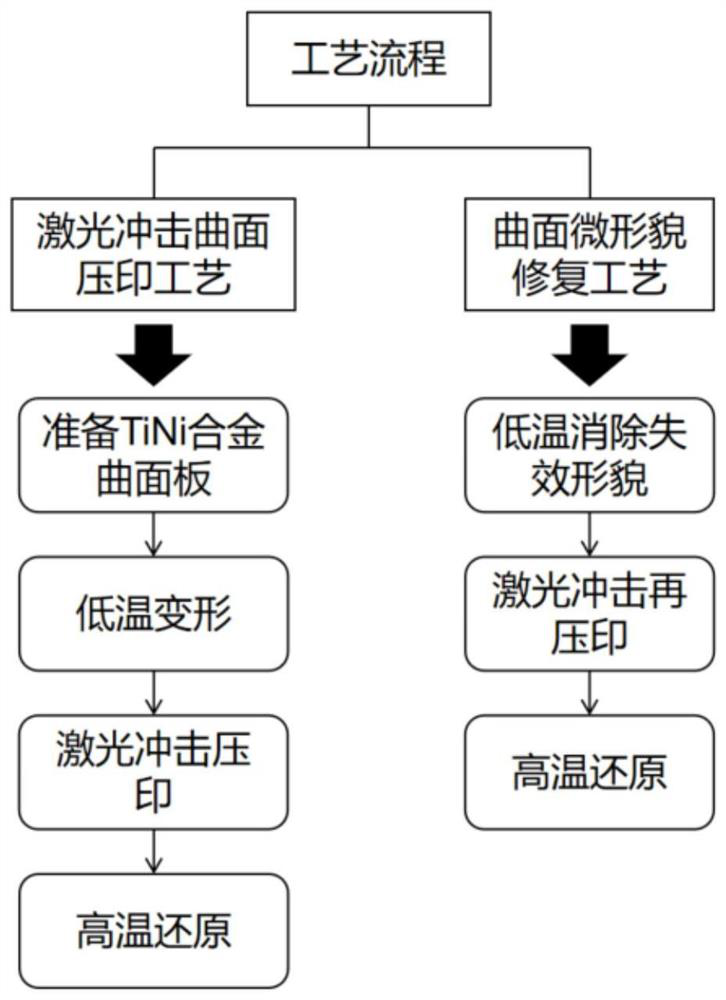

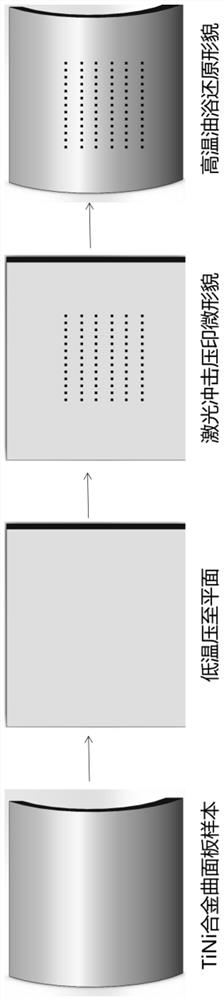

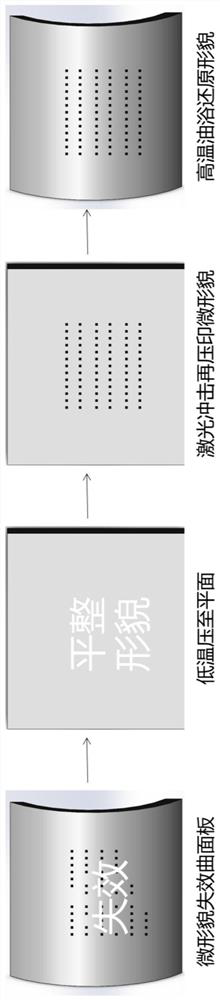

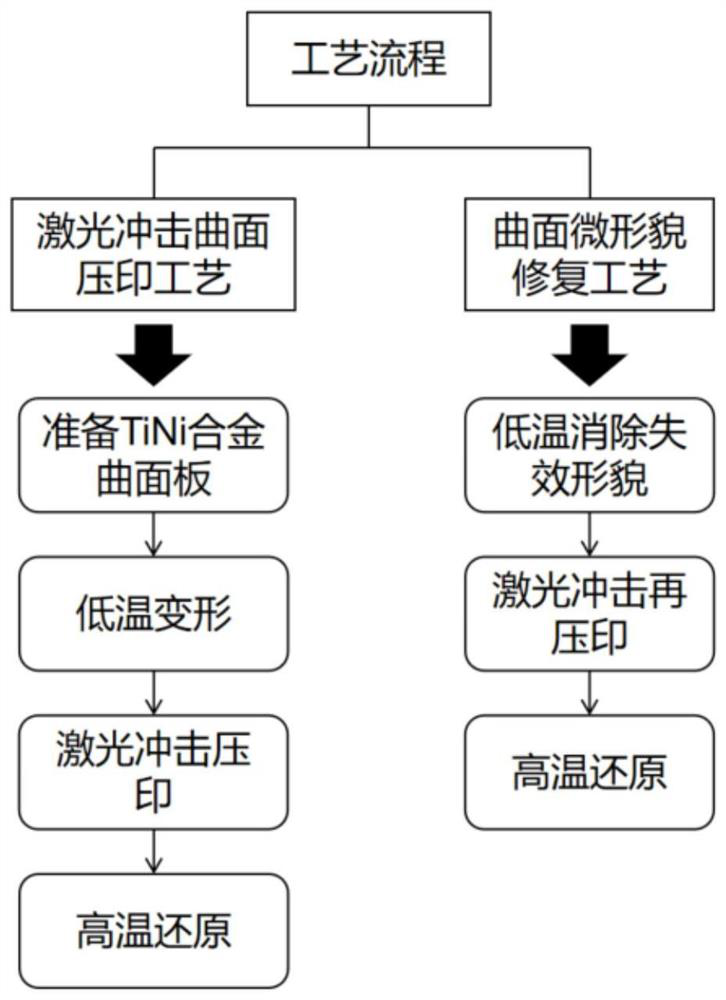

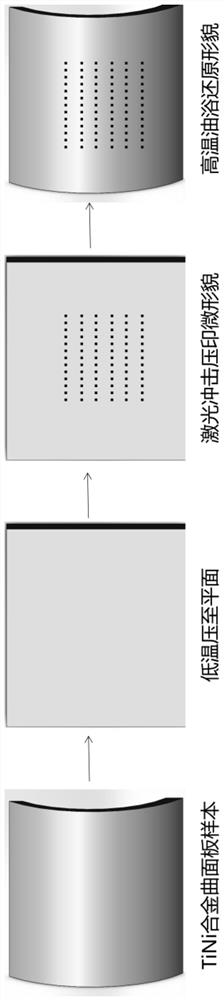

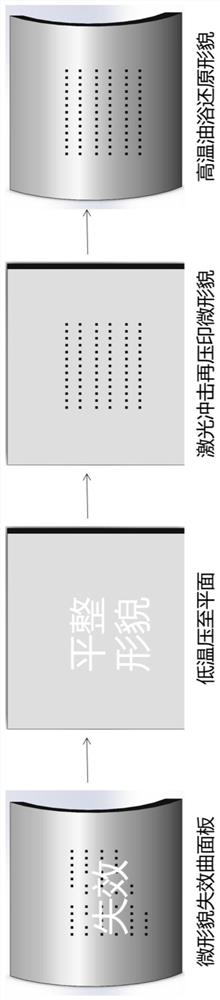

Laser shock curved surface embossing technology and curved surface micro-shape repair technology

ActiveCN111975206ANo problems with impaired curvatureUniform surface topographyProcess efficiency improvementLaser beam welding apparatusEmbossingMaterials science

The invention belongs to the field of laser surface texture forming, and particularly relates to a laser shock curved surface embossing technology and a curved surface micro-shape repair technology. According to the laser shock curved surface embossing technology and the curved surface micro-shape repair technology, a TiNi alloy curved surface plate is pressed to form a plane plate through low-temperature deformation, then the micro-shape is made on the surface of the plane plate through the laser shock embossing technology, the plane plate is recovered to form the curved surface plate throughthe high temperature, the significant influence on the micro-shape cannot be generated in the recovery process, only the overall height of the surface micro-shape is slightly reduced, and the uniformity of the micro-shape cannot be affected. The accessory micro-shape repair technology of the laser shock curved surface embossing technology can also efficiently recover the ineffective shape of metal.

Owner:JIANGSU UNIV

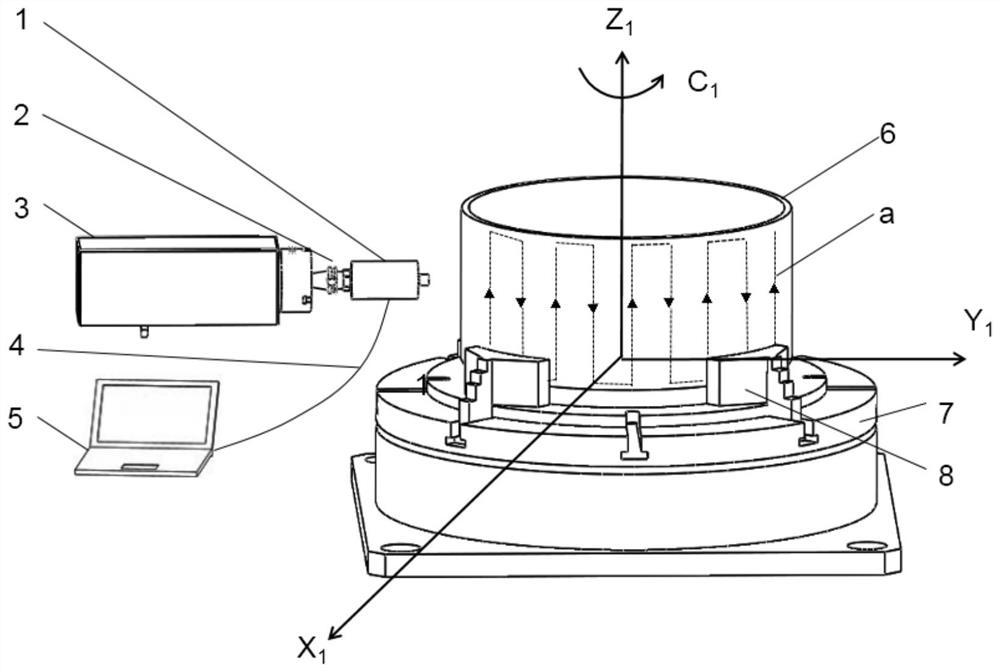

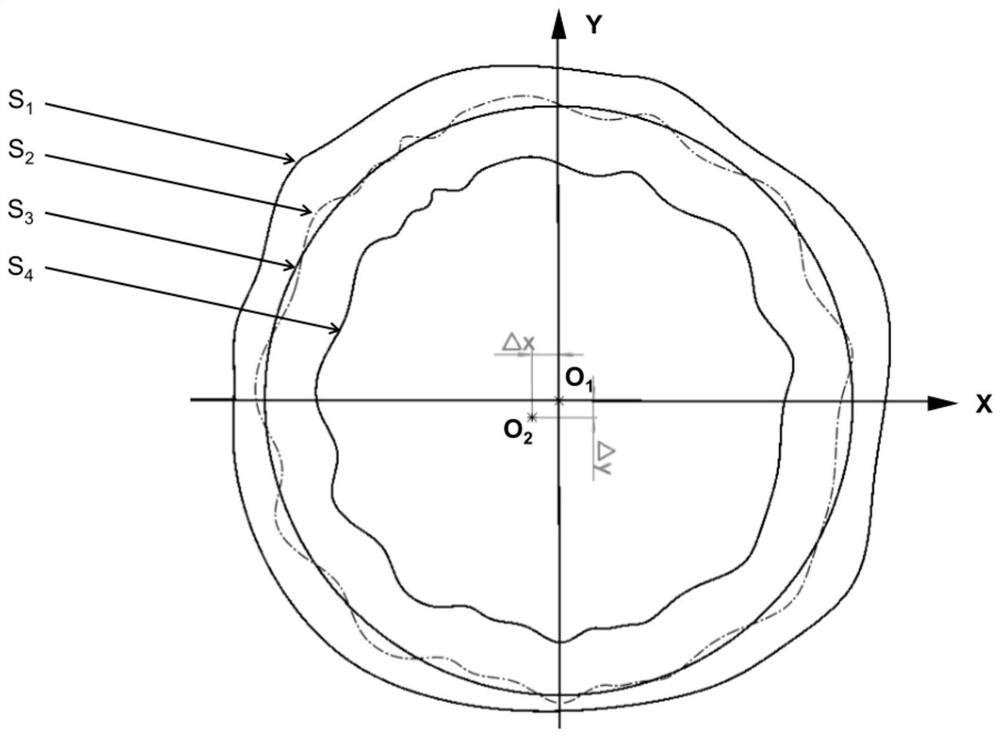

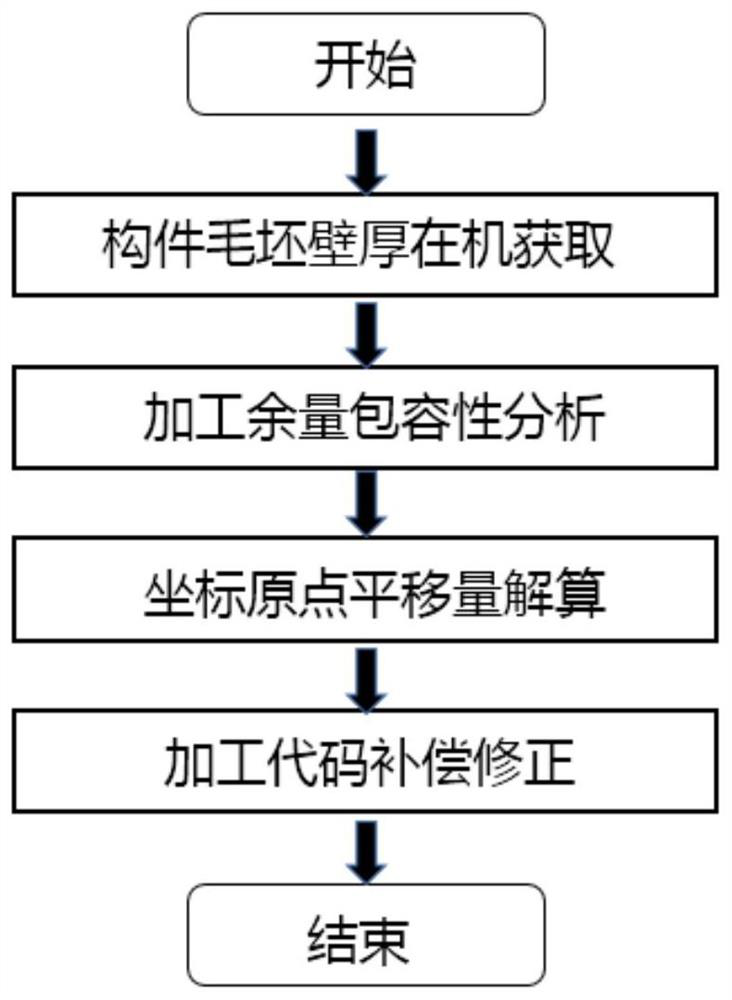

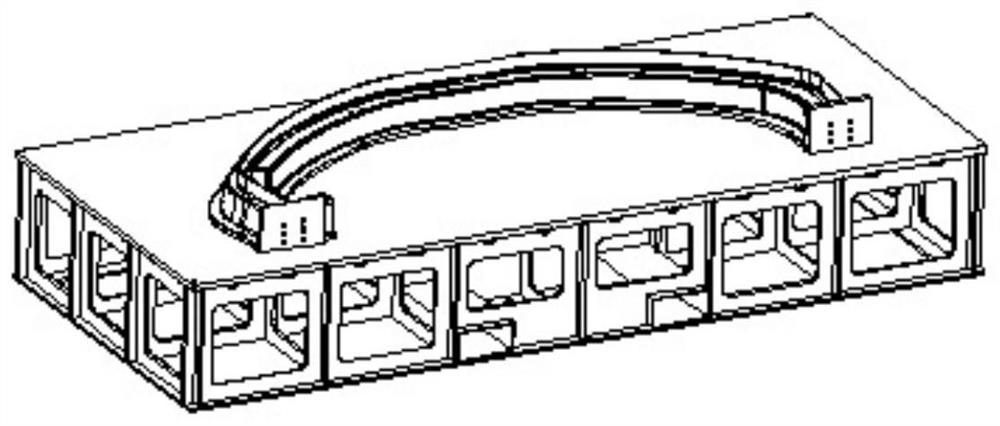

Complex component machining residual wall thickness self-adaptive compensation method based on coordinate origin translation

ActiveCN114001683AGuaranteed profileGuaranteed accuracyUsing wave/particle radiation meansNumerical controlControl engineering

The invention discloses a complex component machining residual wall thickness self-adaptive compensation method based on coordinate origin translation, and belongs to the technical field of measurement-machining integration. According to the method, on an open type numerical control platform, wall thickness data of a component is measured through an ultrasonic thickness measuring device, a machining target curved surface related to the residual wall thickness is reestablished, inclusiveness analysis is completed, coordinate origin translation amount calculation is conducted, and machining compensation is completed through machining code origin correction. According to the method, the defects of an existing residual wall thickness compensation method are overcome, the machining requirement that the residual wall thickness and the profile tolerance of the complex component are restrained at the same time is met, the machining precision is improved, the labor intensity is reduced, and self-adaptive compensation of the machining residual wall thickness of the complex component is achieved.

Owner:DALIAN UNIV OF TECH

A method for high-strength soft tooling to realize co-curing of L-shaped ribs and C-shaped frame structure composite parts

ActiveCN110370676BAvoid problems such as agingShorten the manufacturing cycleStructural engineeringCivil aviation

The invention provides a method for co-curing L-shaped reinforcing ribs and C-shaped frame structure composite parts with high-strength soft tooling. The co-curing of C-frame composite structural parts with reinforced ribs ensures that key parameters such as profile, thickness, and L-shaped axis of the part meet the high-demand civil aviation manufacturing standards, and avoids material damage caused by multiple curing. 2. During the molding process, the pressure applied to the L-shaped vertical rib and the C frame is uniform and accurate, and the heating rate of each part of the part is kept consistent. The above two points prevent the part from appearing in the R angle area. Poor problem; 3. Combine the uncured preform of the L-shaped vertical rib and the C-shaped web through soft tooling, avoiding the internal stress generated by the combination after the components are cured, and solving the forced assembly under the original technology Out-of-tolerance profile and internal non-destructive defects caused by components.

Owner:航天海鹰(镇江)特种材料有限公司

Semiconductor device and manufacturing method thereof

PendingCN112510016AEasy to shapeHigh shape accuracySemiconductor/solid-state device detailsSolid-state devicesDevice materialEngineering physics

The invention provides a semiconductor device and a manufacturing method thereof. When a component and a mark extending into a semiconductor substrate are formed in the same process, the maximum depthof the mark opening formed by etching is still smaller than the minimum depth of the component opening when the widths of the mark opening and the component opening are not changed; therefore, when the mark opening and the component opening are filled with the material I at the same time to form the mark and the component, the filling performance of the mark opening with smaller depth is good, and the morphology of the formed mark can be further guaranteed.

Owner:WUHAN XINXIN SEMICON MFG CO LTD

An automatic processing method for precision forging stator blades

ActiveCN108747232BGood formabilityEliminate the face milling processMilling equipment detailsSelf adaptiveMachining

The invention discloses a stator blade finish forging automatic machining method. The method adopts a self-adaption machining technology, and blade deviation, torsion, profile surface tolerance and machining consistency are ensured. The method is simple in machining procedure, computer control and management are adopted, controlled devices completely automatically finish the sequential operation,the degree of automatic operation is improved, multiple devices, multiple passes of procedures, repeated clamping and repeated standard conversion for original stator blade machining are reduced intotwo passes of procedures of machining, two times of clamping and one time of standard conversion on one kind of equipment, labor is saved, the production period of parts is shortened, and the production efficiency is improved.

Owner:AECC AVIATION POWER CO LTD

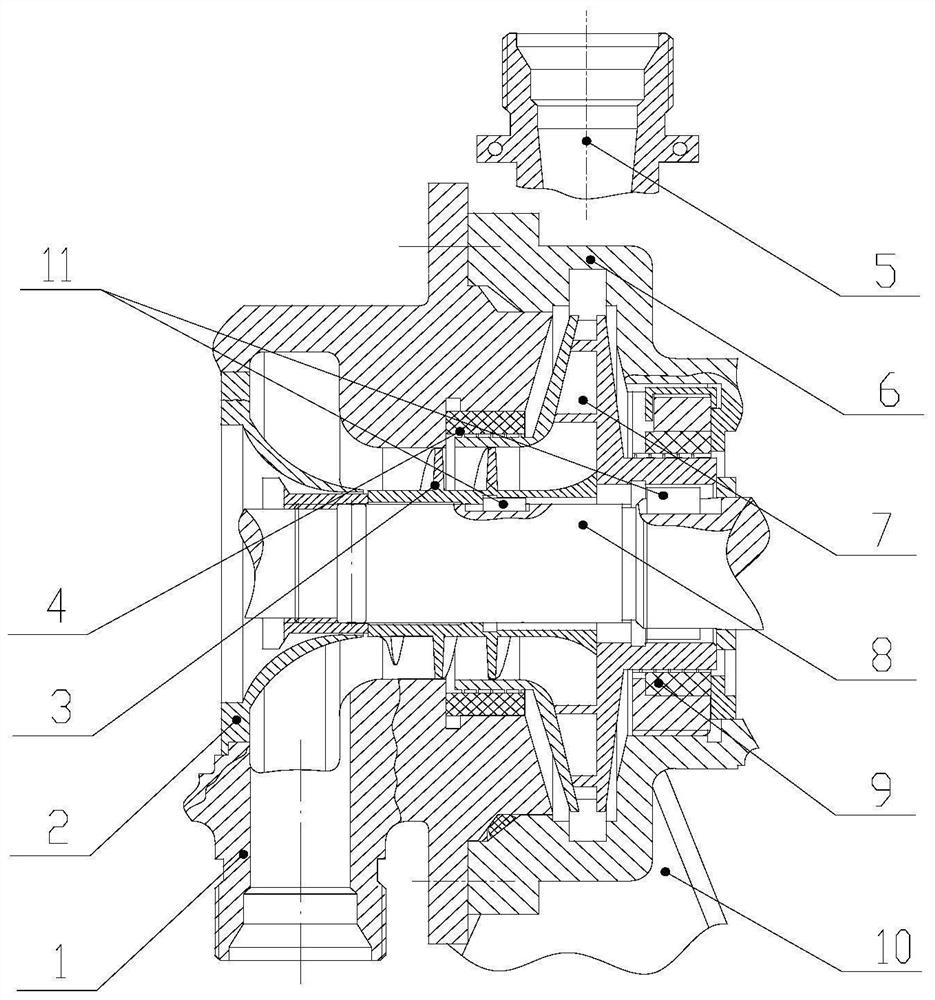

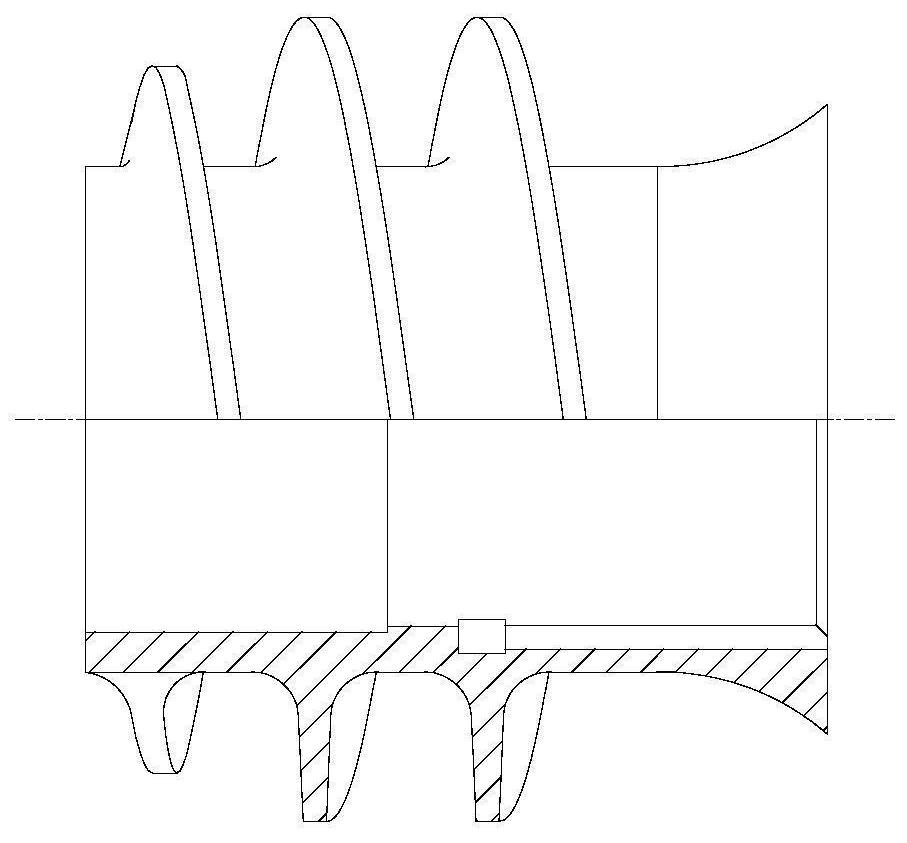

An ultra-low specific speed centrifugal pump device

ActiveCN109882423BGuarantee job stabilityEasy to processPump componentsPump installationsCombustion chamberSpiral blade

The invention discloses an ultra-low specific speed centrifugal pump device. The ultra-low specific speed centrifugal pump device includes a spiral blade, a centrifugal impeller, a transmission shaft,and a shell body, wherein the centrifugal impeller sleeves the transmission shaft, and the spiral blade is arranged at an inlet of the centrifugal impeller; a spiral line runner is formed between thespiral blade and the centrifugal impeller; the shell body sleeves the centrifugal impeller on the outside and the transmission, and a cavity is formed between the shell body and the transmission shaft; an inlet and an outlet are formed in the shell body in the radial direction of the transmission shaft; the end surface of an inlet of the centrifugal impeller towards to the cavity; and the cavitycommunicates with an external fuel storage box through the inlet of shell body, and an outlet of the centrifugal impeller is connected with a burning chamber of an external engine. The ultra-low specific speed centrifugal pump device has the advantages of having small structural size, light weight, high lift, low specific speed, and unsymmetrical dimethylhydrazine corrosion resistance, good anti-cavitation performance, high efficiency and the like; and the ultra-low specific speed centrifugal pump device can be widely used in upper stage small thrust pumping-pressure liquid-propellant rocket engines, and can used in the field of energy power with small flow and high exit pressure at the same time.

Owner:XIAN AEROSPACE PROPULSION INST

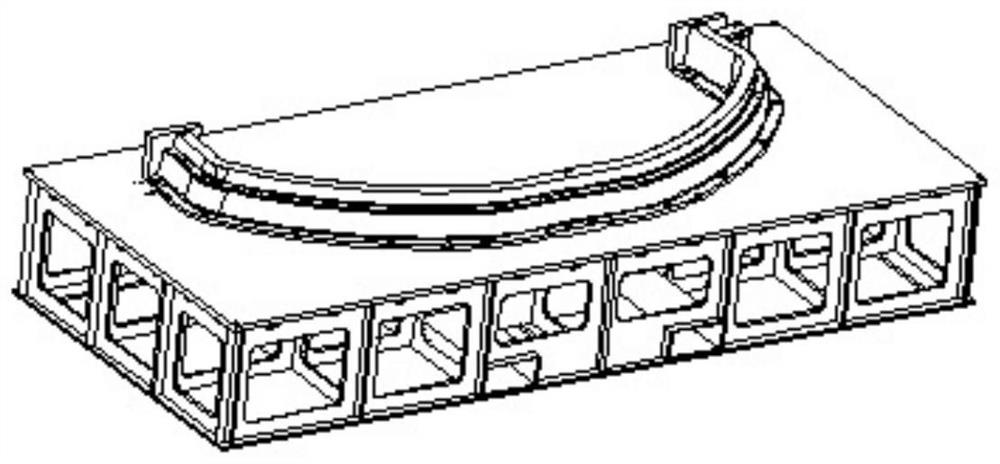

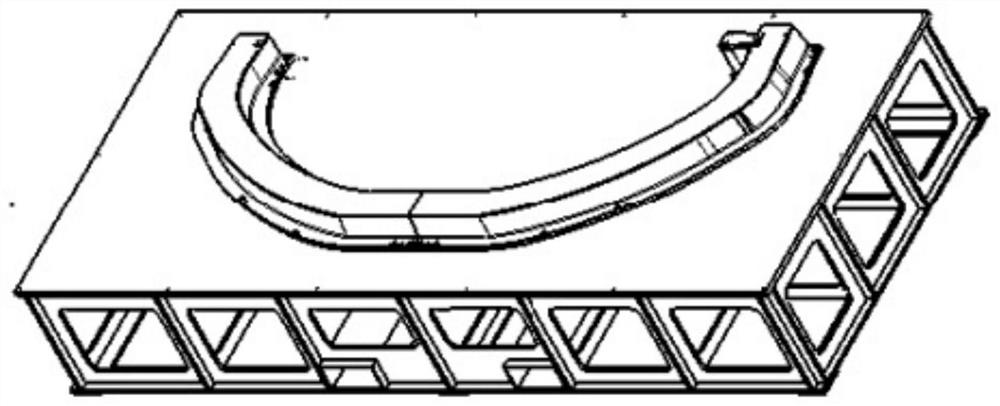

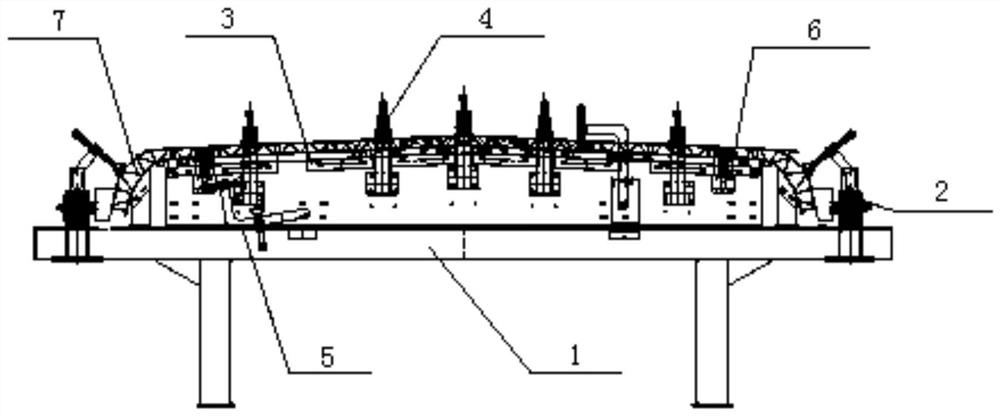

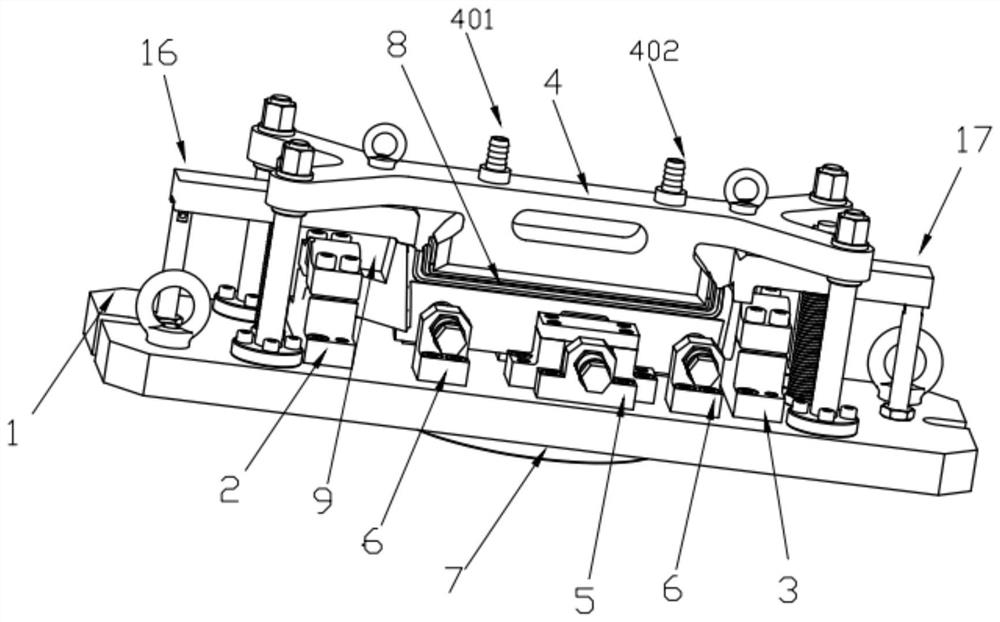

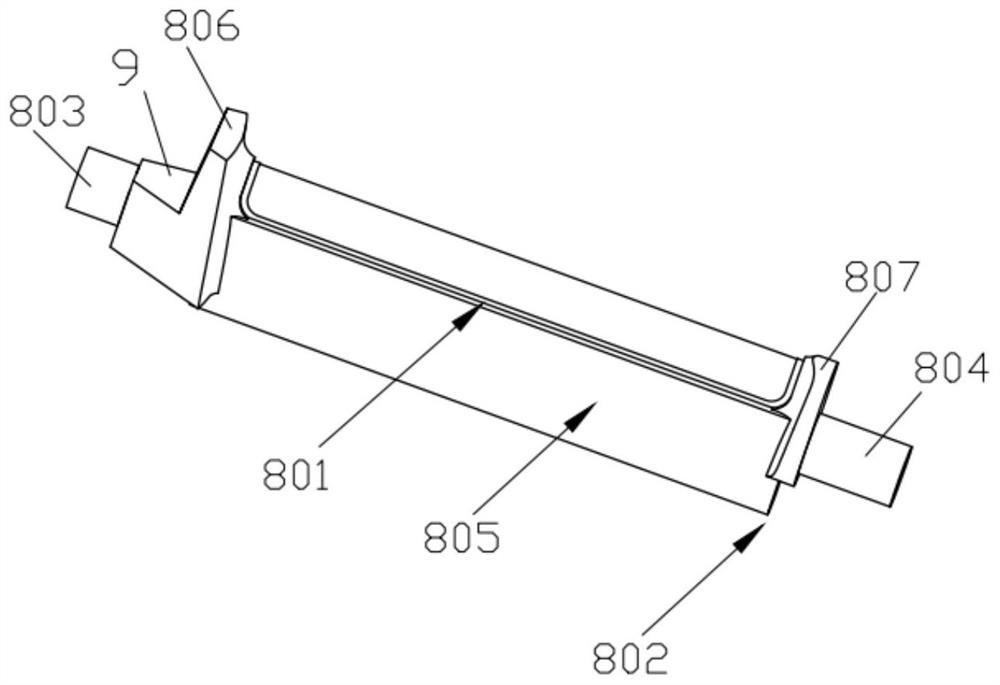

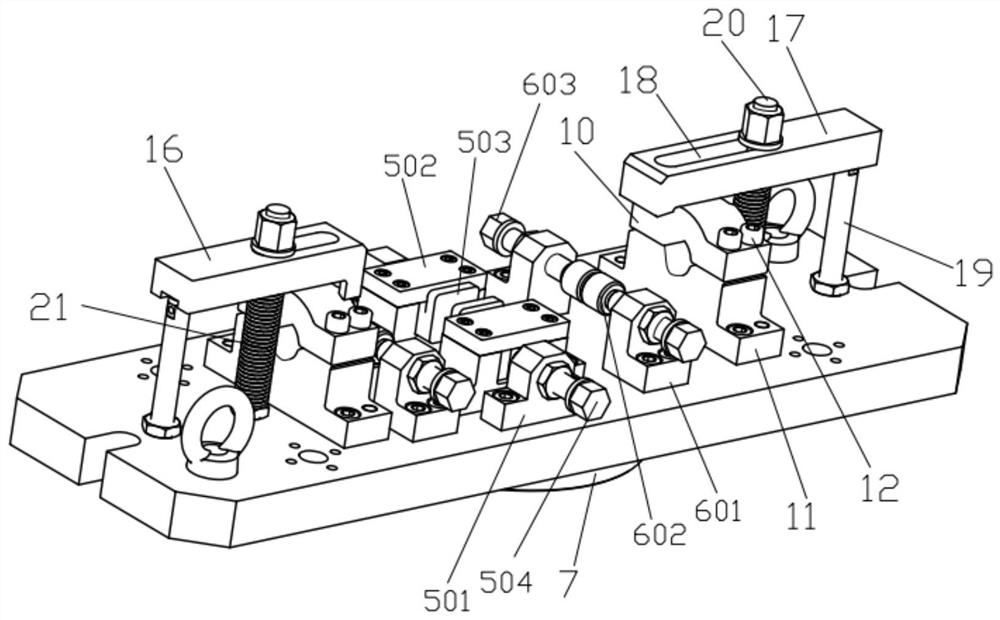

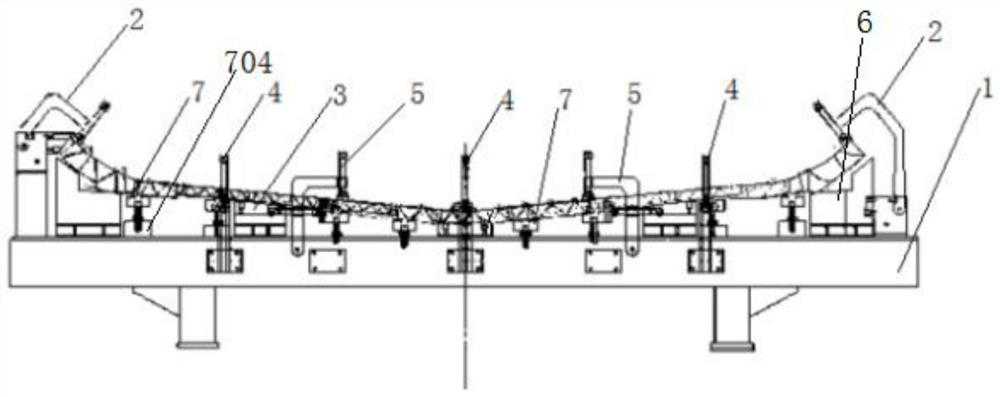

First and second position side positive assembly device for aluminum alloy subway type-A side wall

PendingCN111745347AImprove machining accuracyReduce processing costsWelding/cutting auxillary devicesAuxillary welding devicesWall plateAluminium alloy

The invention provides a first and second position side positive assembly device for an aluminum alloy subway type-A side wall. The first and second position side positive assembly device comprises across beam assembly used for providing supporting force, two deflection positioning blocks used for prefabricating side wall deflection and pressing a side wall upper edge beam and fixed to two ends of the cross beam assembly through bolts, a formwork assembly used for fixing the side wall and guaranteeing a side wall profile tolerance requirement, a door jacking and pressing device used for jacking and pressing side wall door section bars when first and second position side walls are switched, a doorway unit pressing device used for guaranteeing that the side wall is closely attached to the formwork assembly so as to guarantee the overall profile tolerance of the side wall, and a wall plate positioning block used for guaranteeing the width of a space from the side wall to a doorway. The first and second position side positive assembly device can be suitable for positive assembly of the first and second position side walls simultaneously, and thus, the site and tool cost are saved.

Owner:CSR CHENGDU

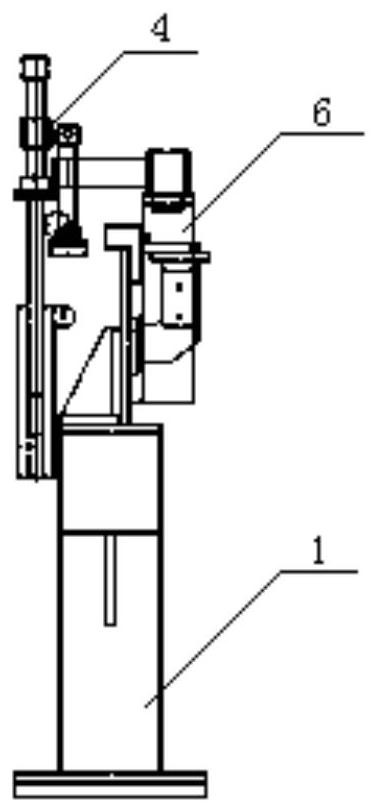

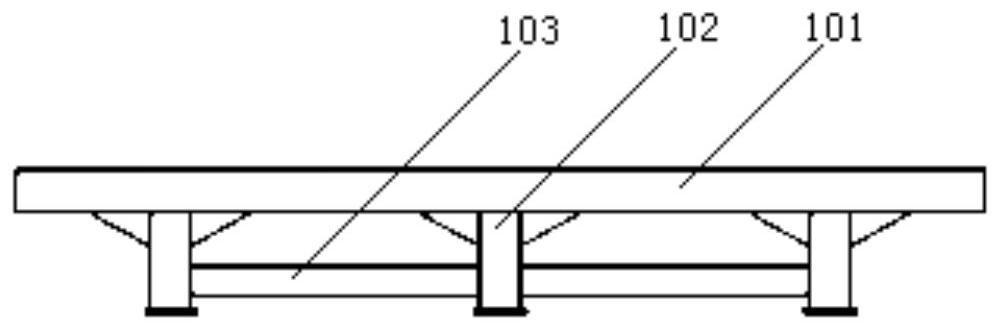

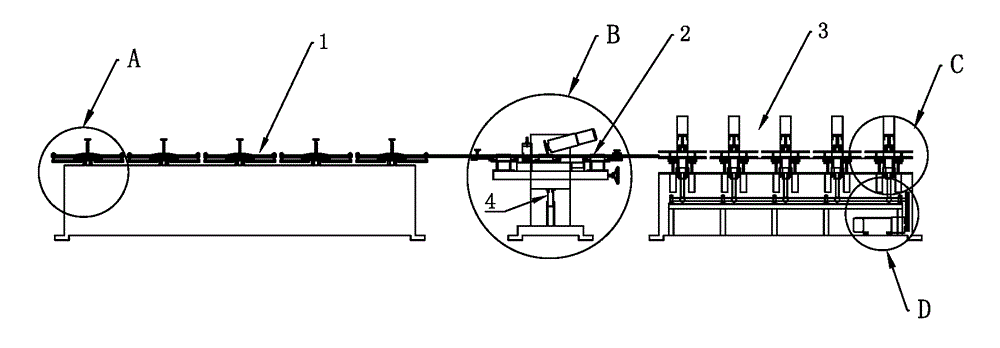

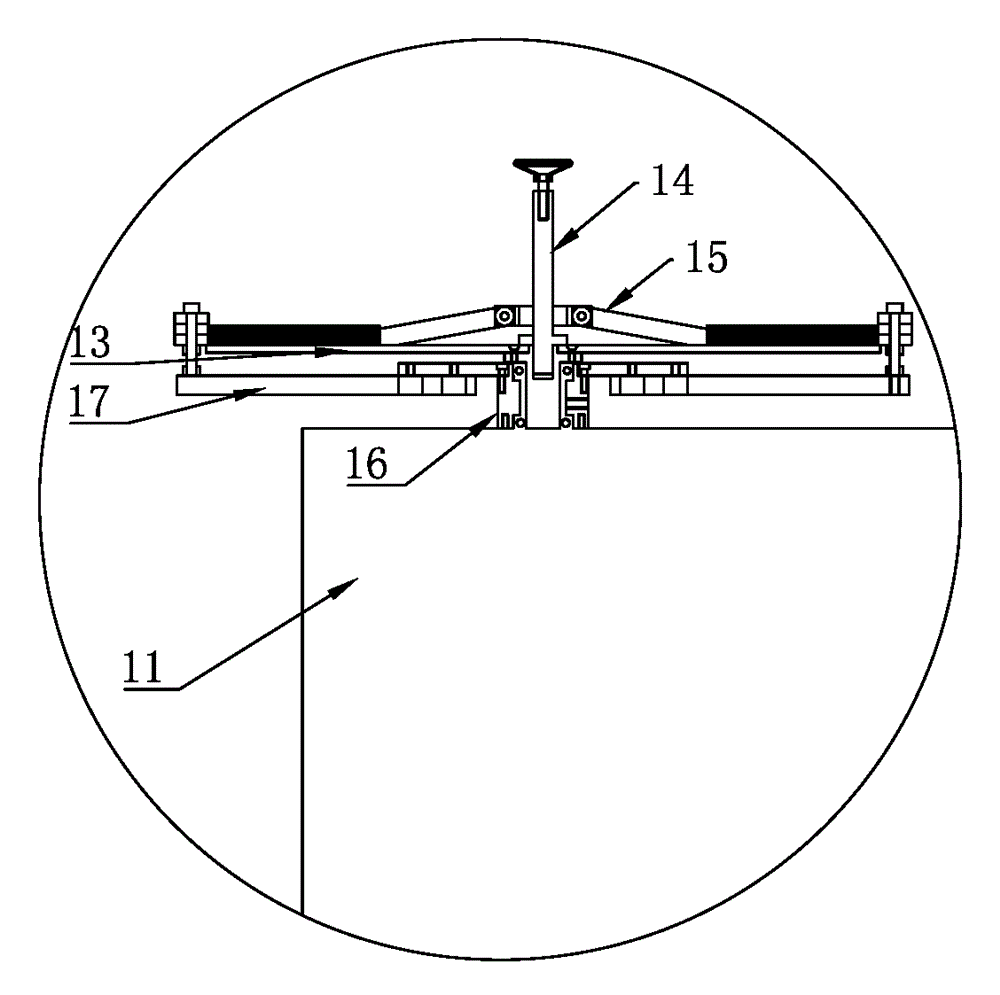

Precision band saw milling gear grinding machine

Owner:湖北华鑫科技股份有限公司

A Laser Shock Curved Surface Imprinting and Curved Surface Micro-topography Restoration Process

ActiveCN111975206BOne way memory effectDoes not completely eliminate surface microtopographyProcess efficiency improvementLaser beam welding apparatusEngineeringEmbossing

The invention belongs to the field of laser surface texture forming, and in particular relates to a laser impact curved surface embossing and curved surface micro-topography repairing process. The present invention presses the TiNi alloy curved plate into a plane through low-temperature deformation, then manufactures micro-topography on its surface through laser shock imprinting technology, and then restores the flat plate to a curved plate through high temperature, and this recovery process will not affect the micro-topography A larger effect would only slightly reduce the overall height of the surface microtopography without affecting its uniformity. The micro-morphology repair process attached to this process can also efficiently restore the failed morphology of the metal.

Owner:JIANGSU UNIV

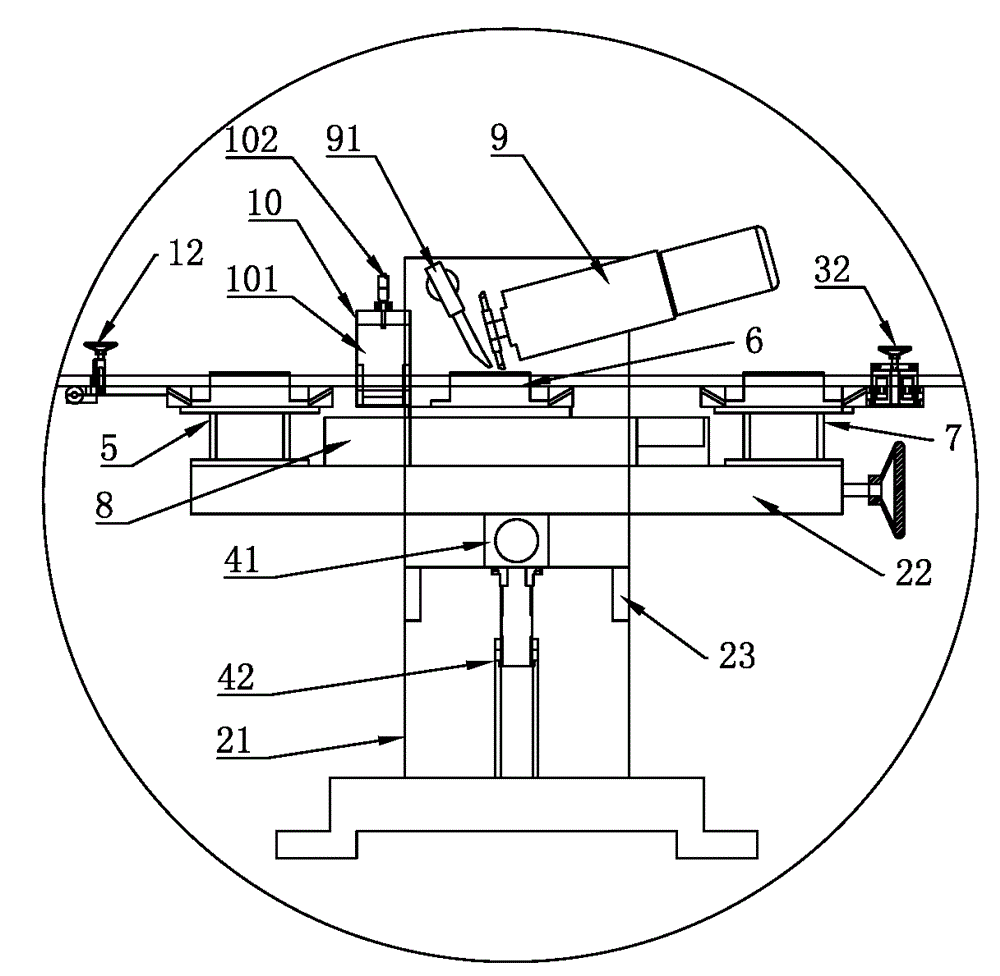

A cooling and welding device for thin-walled sheet metal parts

ActiveCN111644791BEasy to installReduce transient thermal deformationWelding/cutting auxillary devicesAuxillary welding devicesThermal deformationEngineering

The invention discloses a cooling and welding device for thin-walled sheet metal parts, comprising a base, a first positioning seat, a second positioning seat, a profile positioning cooling mechanism, an angular positioning mechanism, a pressing mechanism and a welding turntable for connecting Positioning mandrel, parts to be welded are installed between the first positioning seat and the second positioning seat, the parts to be welded include thin-walled sheet metal parts and blades, and the thin-walled sheet metal parts are installed in cooperation with the top surface of the blade; the first shaft of the blade The neck end is fixedly installed on the first positioning seat, the second journal end of the blade is fixedly installed on the second positioning seat, the profile positioning cooling mechanism is pressed against the thin-walled sheet metal part, and the angular positioning mechanism is pressed against the blade body of the blade In the middle of the side, the pressing mechanism is pressed against the two ends of the blade body of the blade; the welding device can reduce the transient thermal deformation of thin-walled sheet metal parts during the welding process, so as to ensure the profile of the sheet metal parts. .

Owner:AECC AERO SCI & TECH CO LTD

Aluminum alloy subway A-type vehicle side wall first-position side and second-position side reverse assembly device

PendingCN113664426AImprove machining accuracyGuaranteed profileWelding/cutting auxillary devicesAuxillary welding devicesMechanical engineeringWall plate

The invention provides an aluminum alloy subway A-type vehicle side wall first-position side and second-position side reverse assembly device. The device comprises a cross beam assembly, two edge beam positioning and pressing assemblies, a plurality of formwork assemblies, a door jacking and pressing device, a doorway unit pressing device, a wallboard positioning block and a reversible deformation device are installed on the cross beam assembly, and the reversible deformation device can be installed through the cross beam assembly; the edge beam positioning and pressing assemblies are used for prefabricating deflection of a side wall and pressing an edge beam on the side wall; the formwork assemblies are used for fixing a side wall profile and guaranteeing the profile tolerance requirement of the side wall; the door jacking and pressing device is of a turnover structure and is used for jacking and pressing a side wall doorway profile when a first-position side wall and a second-position side wall are switched. the doorway unit pressing device is used for guaranteeing the overall profile tolerance of the side wall; and the wallboard positioning block is used for guaranteeing the width from the side wall to a doorway. The device can be suitable for reverse assembly of the first-position side wall and the second-position side wall at the same time, the site and tool cost is saved, the multi-project switching function can be achieved by replacing nylon blocks, the operation is convenient and fast, and the working efficiency is improved.

Owner:CSR CHENGDU

A heat treatment deformation control method for an aluminum alloy hemispherical shell of an ellipsoidal surface storage tank

ActiveCN107513677BPrevent floatingFloat fastFurnace typesHeat treatment process controlAlloyQuenching

The invention relates to a heat treatment deformation control method for a large-diameter and large-modulus elliptical molded surface container semispherical shell and belongs to the technical field of container manufacturing. By means of the heat treatment deformation method, due to the fact that an integrated quenching and aging heat treatment tool is designed, the elliptical molded surface container semispherical shell and the heat treatment tool can be tightly matched, the quenching transfer time is shortened, the phenomenon that the top of the shell collapses and pits happen in the circumferential direction of the shell during quenching is avoided, quenching and time aging deformation is reduced, and therefore the heat treatment performance of the elliptical molded surface container semispherical shell can be ensured; and meanwhile, the subsequent machining precision of the shell is also ensured. In addition, a UCON water solution with the concentration ranging from 6% to 10% is adopted in the method to serve as a quenching medium, dynamic flowing of the water solution is maintained, the cooling speed and uniformity of the shell are ensured, meanwhile, quenching deformation is also controlled, and therefore the product precision is ensured.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

Tooling manufacturing method for preventing composite material forming tooling from air leakage

The invention discloses a tooling manufacturing method for preventing composite material forming tooling from air leakage. The composite material forming tooling is used for forming composite material parts; the composite material forming tooling is assembled from a composite material laying mold and a supporting frame; The above-mentioned composite material laying mold is based on the transition mold, and is made of tooling prepreg materials of different thicknesses by hot pressing; and in the process of laying, the bead is laid on the R area and the corner area of the transition mold, and the tooling The edge margin area of the frame is paved with tooling prepreg, and a long strip of seam is laid in the area of the butt joint. The photo frame paving avoids the expansion of edge defects to the inside caused by cutting and the splitting during bumping or demoulding during handling; the beading and seam patching strips further ensure the high temperature airtightness of the tooling. The tooling manufactured by the invention not only has good airtight performance, but also effectively reduces maintenance costs, ensures the molding quality and production cycle of composite parts, and has good practical and economic value.

Owner:航天海鹰(镇江)特种材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com