A cooling and welding device for thin-walled sheet metal parts

A welding device and technology for sheet metal parts, applied in the field of sheet metal parts welding, to achieve the effect of ensuring profile, reducing transient thermal deformation, and ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] see Figure 1-5 , the present invention provides a kind of technical scheme:

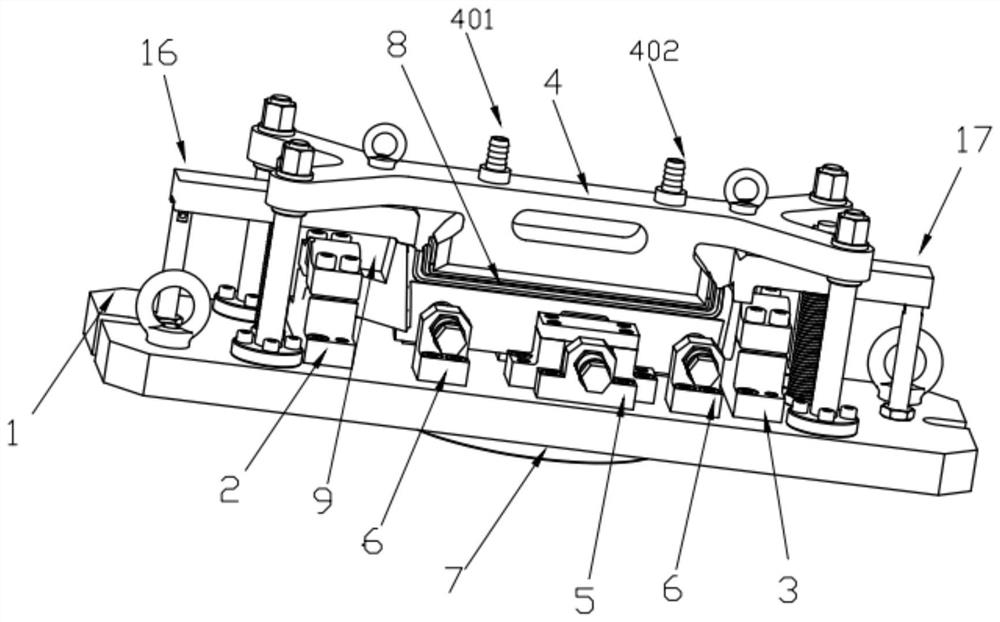

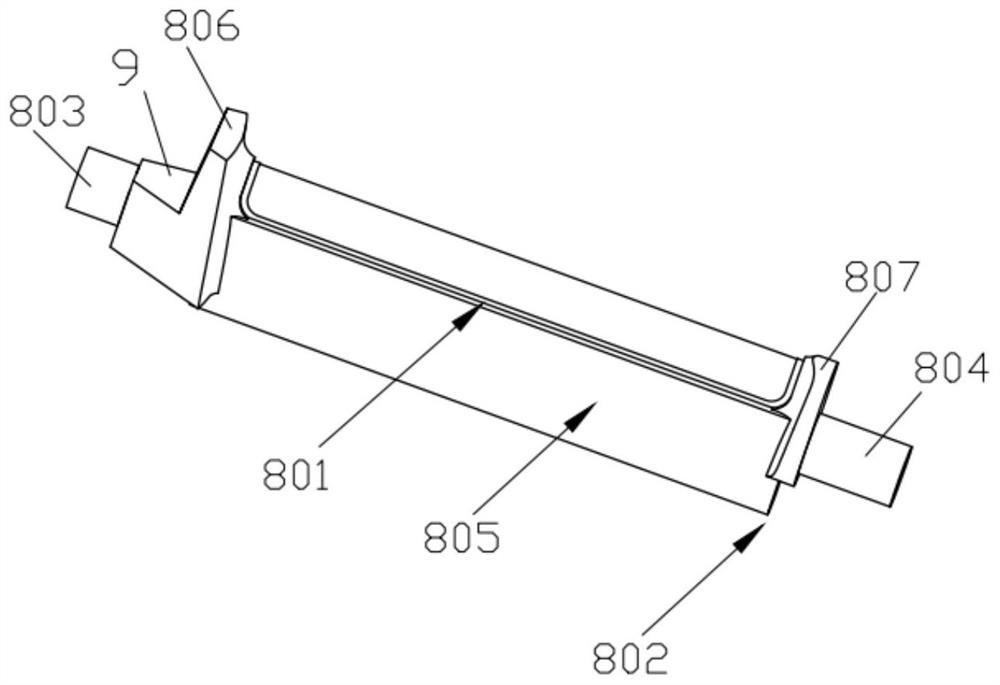

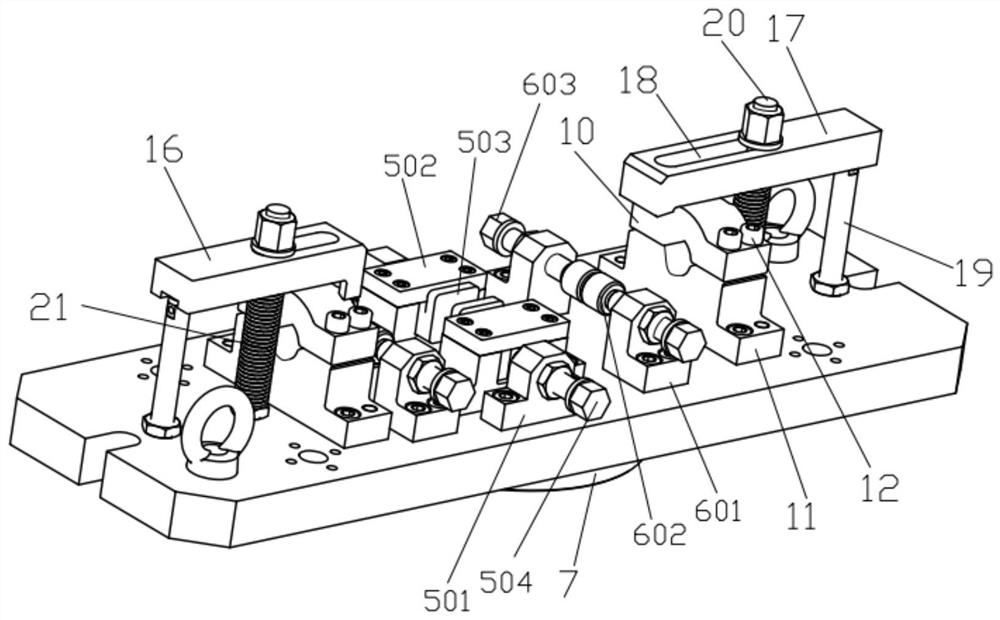

[0039] Please refer to Figure 1-2 , a cooling and welding device for thin-walled sheet metal parts 801, comprising a base 1, a first positioning seat 2, a second positioning seat 3, a profile positioning cooling mechanism 4, an angular positioning mechanism 5, a pressing mechanism 6 and a The positioning mandrel 7 of the welding turntable is connected, and a part to be welded 8 is installed between the first positioning seat 2 and the second positioning seat 3, and the part to be welded 8 includes a thin-walled sheet metal part 801 and a blade 802. The wall sheet metal part 801 is installed in cooperation with the top surface of the blade 802;

[0040]The first journal end 803 of the blade 802 is fixedly mounted on the first positioning seat 2, the second journal end 804 of the blade 802 is fixedly mounted on the second positioning seat 3, the profile is positioned for cooling The mechani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com