Method and device for improving the control level of lateral thickness difference of high-grade non-oriented silicon steel

A technology of grain-oriented silicon steel and thickness difference, which is applied in the field of steel rolling, can solve the problem of difficult to improve the control level of lateral thickness difference of high-grade non-oriented silicon steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

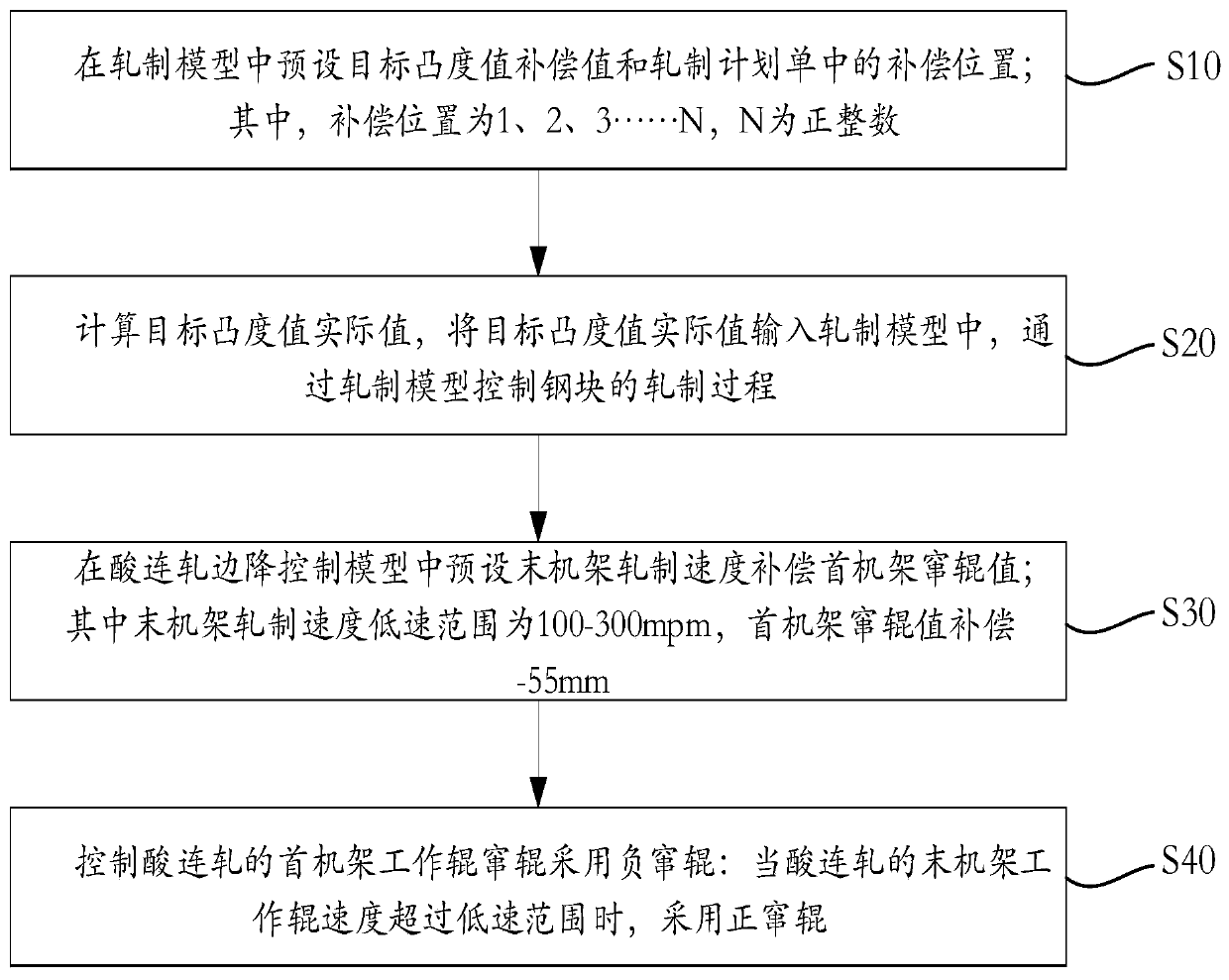

[0049] see figure 1 , an embodiment of the present invention provides a method for improving the control level of lateral thickness difference of high-grade non-oriented silicon steel, including:

[0050] Step S10, preset the compensation value of the target crown value in the rolling model and the compensation position in the rolling plan sheet; wherein, the compensation position is 1, 2, 3...N, N is a positive integer, which means that in the rolling plan The sequence number in the table.

[0051] Step S20, calculating the actual value of the target crown value, inputting the actual value of the target crown value into the rolling model, and controlling the rolling process of the steel block through the rolling model;

[0052] in:

[0053] When the steel block is the first block in the rolling plan, the actual value of the target crown value = the target crown value;

[0054]When the position of the steel block in the rolling plan is > 1, and the hot-rolled F5 or F6 work ...

Embodiment 2

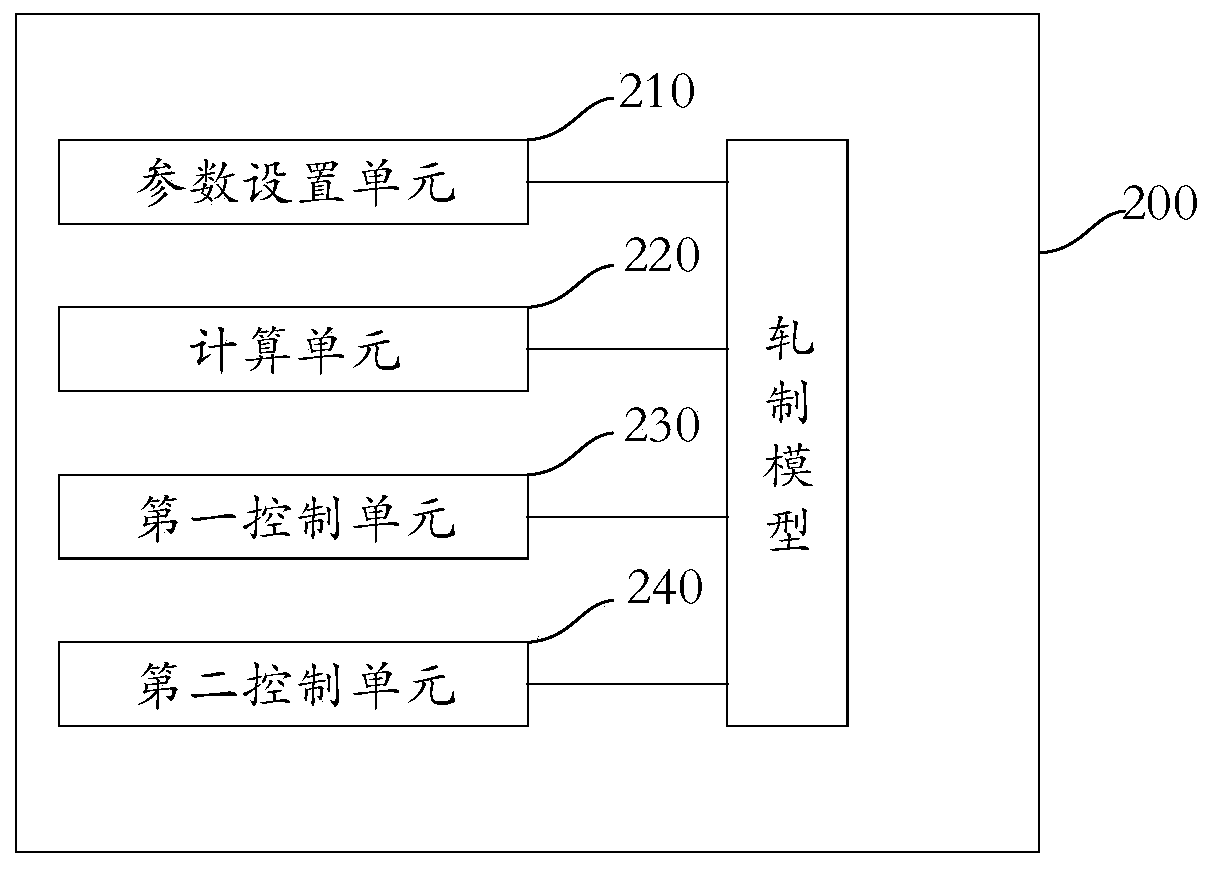

[0060] see figure 2 , this embodiment provides a device 200 for improving the control level of lateral thickness difference of high-grade non-oriented silicon steel, including:

[0061] The parameter setting unit 210 presets the compensation value of the target crown value in the rolling model and the compensation position in the rolling plan; wherein, the compensation position is 1, 2, 3...N, which are positive integers.

[0062] The calculation unit 220 calculates the actual value of the target crown value, inputs the actual value of the target crown value into the rolling model, and controls the rolling process of the steel block through the rolling model.

[0063] in:

[0064] When the steel block is the first block in the rolling plan, the actual value of the target crown value = the target crown value;

[0065] When the position of the steel block in the rolling plan is > 1, and the hot-rolled F5 or F6 work roll is a non-high-speed steel work roll, if the position of ...

Embodiment 3

[0070] see image 3 , the present embodiment provides a computer-readable storage medium 300 on which a computer program 310 is stored. It is characterized in that, when the computer program 310 is executed by a processor, the following steps are implemented:

[0071] The target crown value compensation value and the compensation position in the rolling plan sheet are preset in the rolling model; wherein, the compensation position is 1, 2, 3...N, and N is a positive integer.

[0072] Calculate the actual value of the target crown value, input the actual value of the target crown value into the rolling model, and control the rolling process of the steel block through the rolling model.

[0073] in:

[0074] When the steel block is the first block in the rolling plan, the actual value of the target crown value = the target crown value;

[0075] When the position of the steel block in the rolling plan is > 1, and the hot-rolled F5 or F6 work roll is a non-high-speed steel work ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com