First and second position side positive assembly device for aluminum alloy subway type-A side wall

A technology of aluminum alloy and subway, which is applied in the direction of auxiliary devices, metal processing equipment, auxiliary welding equipment, etc., can solve the problems of sidewall tires occupying too much space and the inability to run multiple projects in parallel, and achieve the effect of saving processing costs and improving processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

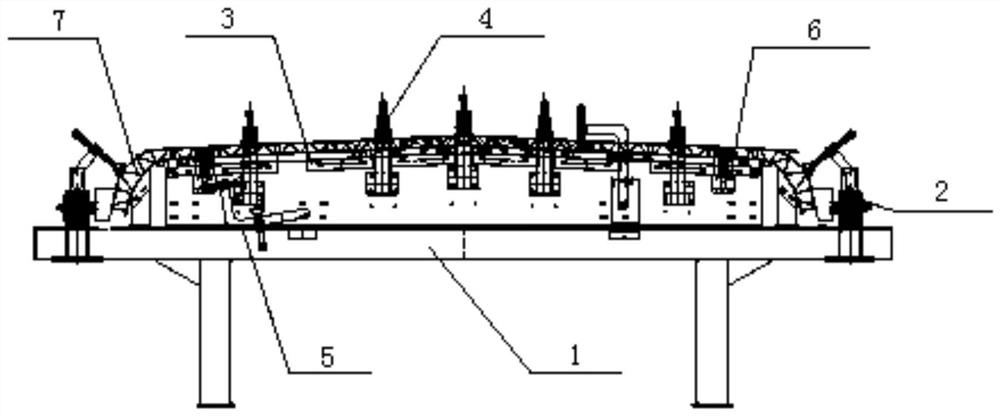

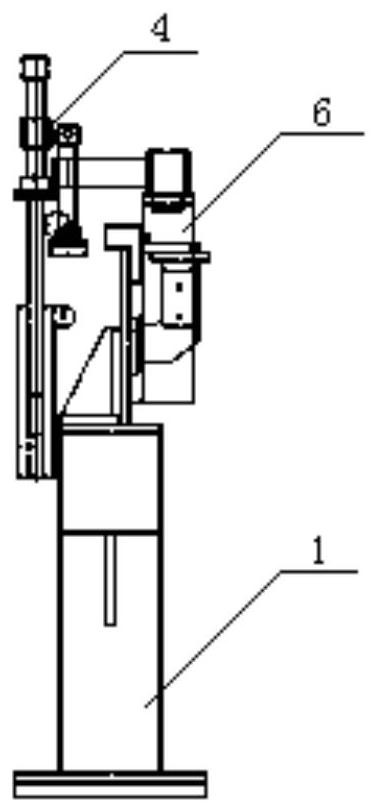

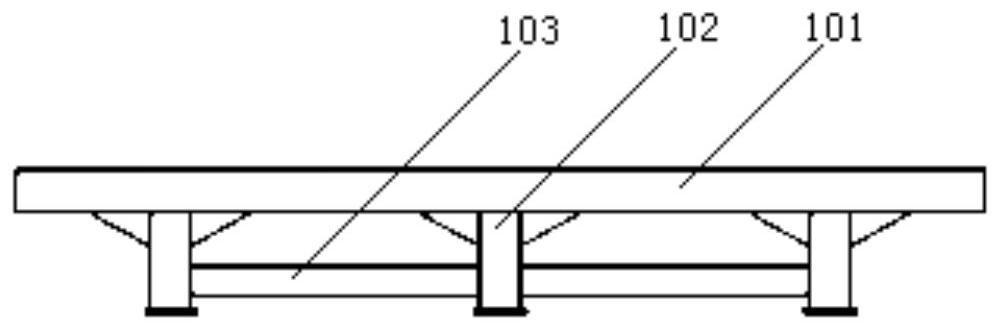

[0045] The core of the present invention is to provide an aluminum alloy subway A-type car side wall one- and two-position side positive assembly device, which can realize multi-item switching capability by replacing the nylon block, and can be used for one- and two-position side wall positive assembly at the same time. The cost of site and tooling is saved, and the construction efficiency is significantly improved.

[0046] It should be noted that the orientation words "up, down, left, right" appearing in this article refer to figure 1 up, down, left, and right directions. The orientation words appearing in this article are established based on the customary usage of those skilled in the art and the drawings in the specification, and their appearance should not affect the protection scope of the present invention.

[0047] In order to enable those skilled in the art to better understand the solution of the present invention, the present invention will be further described in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com