Sodium alginate modified ropivacaine hydrochloride multivesicular liposome microsphere as well as preparation method and application thereof

A technology of ropivacaine hydrochloride and multivesicular liposome, which is applied in the field of ropivacaine hydrochloride multivesicular liposome microspheres and preparation thereof, can solve the problem of excessive gelation of sodium alginate and unsuitability for injection administration , uneven coating and other problems, to reduce the time and cost, ensure the effect and shape of the capsule, and improve the stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0093] The preparation method of Rpv-MVLs-Alg microspheres is as follows:

[0094] Step 1: Formation of water-in-oil colostrum (W / O)

[0095] Inject 4ml of the first water phase into the 4ml oil phase with a 5ml syringe. The rate of injecting the first water phase into the oil phase is 0.2mL / s, and keep shaking. Homogenize for 9 minutes to form water-in-oil colostrum. Wherein, the solvent of the first aqueous phase is water; the solute composition is as follows: 37.5 mg / ml ropivacaine hydrochloride, 31 mg / ml glucose. The organic solvent of the oil phase is dichloromethane-chloroform (3:1); the solute composition is as follows: 16mg / ml egg yolk lecithin (PC), 8mg / ml cholesterol (TH), 2.5mg / mL, dipalmitoylphosphatidylcholine Base (DPPC), 4 mg / mL triolein (TO).

[0096] Step 2: Formation of water-in-oil-in-water (W / O / W) double emulsion

[0097] Add the colostrum obtained in step 1 into 25 mL of the second aqueous phase, and homogenize at 4000 rpm for 45 seconds to form a wate...

Embodiment 2

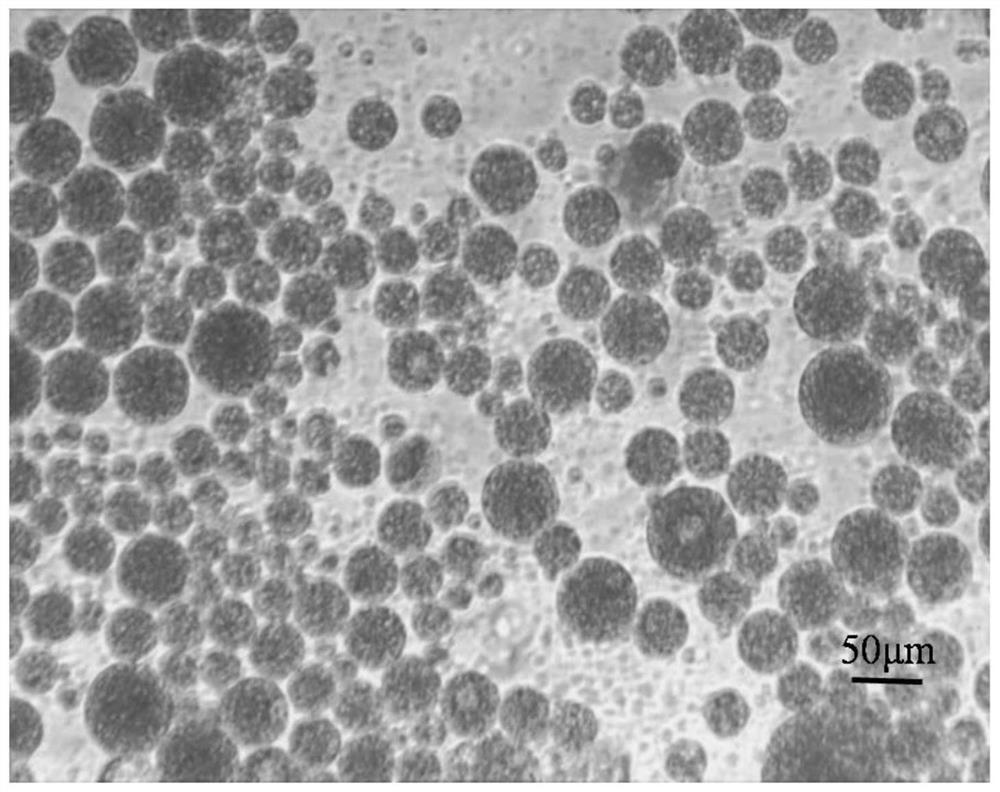

[0122] The difference between the preparation method of Rpv-MVLs-Alg microspheres provided in this example and Example 1 is that the pH of the system was adjusted to 6.0 during the gelation reaction in step 4.2 of this example, and the prepared Rpv The morphology of -MVLs-Alg microspheres is as follows Figure 6 As shown, it can be seen that the gelation of sodium alginate in the Rpv-MVLs-Alg microspheres prepared in this example is not complete, resulting in uneven coverage around the multivesicular liposomes.

Embodiment 3

[0136]The difference between the preparation method of Rpv-MVLs in this example and Example 1 is that the nitrogen purging temperature used in this example is 45°C, and the morphology of the prepared Rpv-MVLs is as follows Figure 13 As shown, the results show that the particle size of the Rpv-MVLs prepared in this example is small, and although there are complete edges, there are many fragments and the shape is irregular.

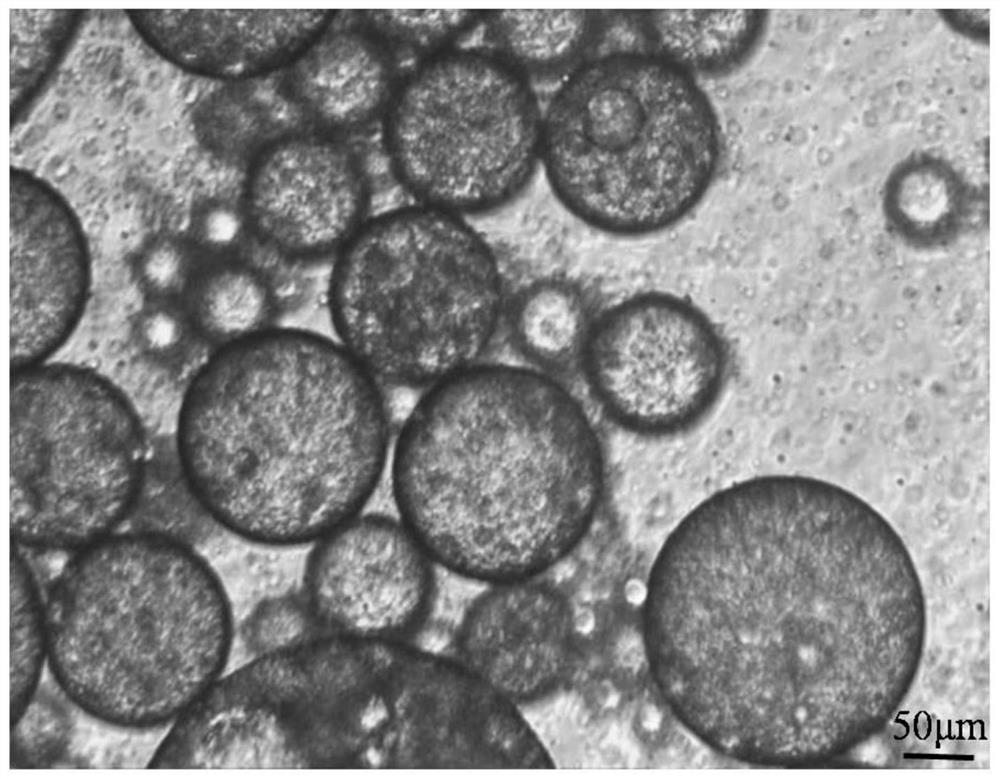

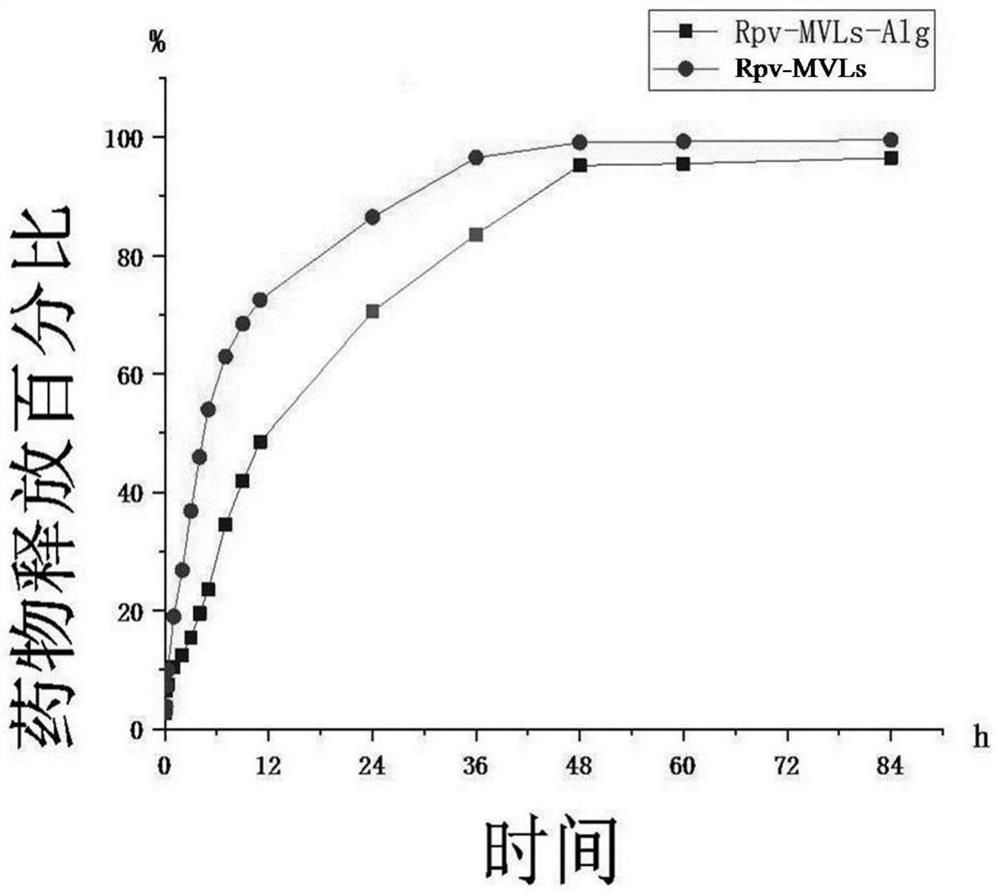

[0137] In summary, the preparation method of Rpv-MVLs-Alg microspheres provided in the examples of the present invention is to improve gelation by mixing nano-calcium carbonate and liquid paraffin evenly, and then adding multivesicular liposomes and sodium alginate in sequence. The uniformity of the reaction enables the sodium alginate to evenly coat the surface of the multivesicular liposome after the gelation reaction, and improves the slow-release effect and stability of the common ropivacaine hydrochloride multivesicular liposome. Also by changing the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com