A preparation method of polytetrafluoroethylene tube ribbon coating and polytetrafluoroethylene tube

A polytetrafluoroethylene tube and polytetrafluoroethylene technology, which is applied in the coating, metal material coating process, vacuum evaporation coating and other directions, can solve the complicated tube forming process, the non-transparent tube, and the inability of endoscopic medical depth. Accurate calibration and other issues to achieve the effect of ensuring mechanical transverse stiffness and longitudinal tensile strength, good edge uniformity, and reducing the difficulty of coloring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A method for preparing a polytetrafluoroethylene tube color ribbon coating, the preparation process steps comprising:

[0033] ① PTFE pipe body preparation and treatment.

[0034] The preparation method of the polytetrafluoroethylene pipe body is as follows: the polytetrafluoroethylene dispersion material and the auxiliary agent are mixed and matured, and then the polytetrafluoroethylene paste material is extruded, and molded and sintered. The molding and sintering process steps include extruding the polytetrafluoroethylene paste material into a tube mold, compacting and forming by a press, and sintering in a sintering furnace at 360° C., and the auxiliary agent is kerosene.

[0035] In this embodiment, the PTFE pipe body treatment method adopts plasma surface treatment.

[0036] The plasma surface treatment method is as follows: a put the polyvinyl chloride tube body into the plasma sputtering instrument, b evacuate the sputtering chamber to 0.5mbar, fill with inert g...

Embodiment 2

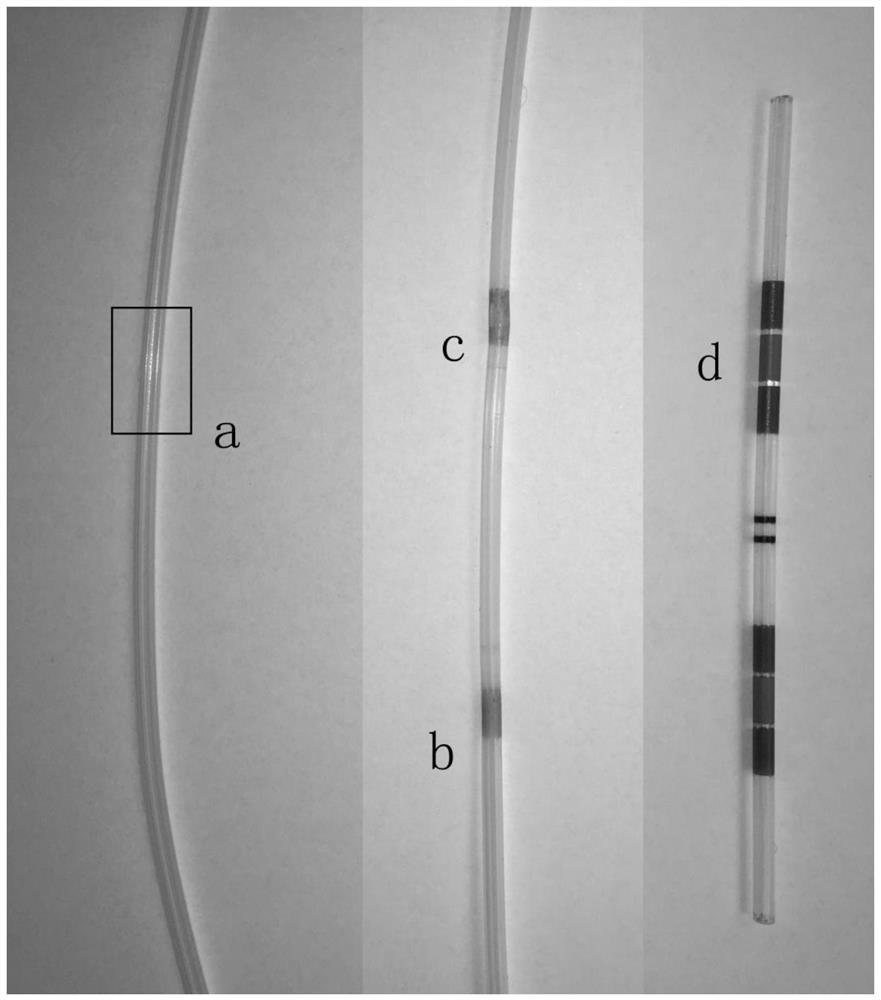

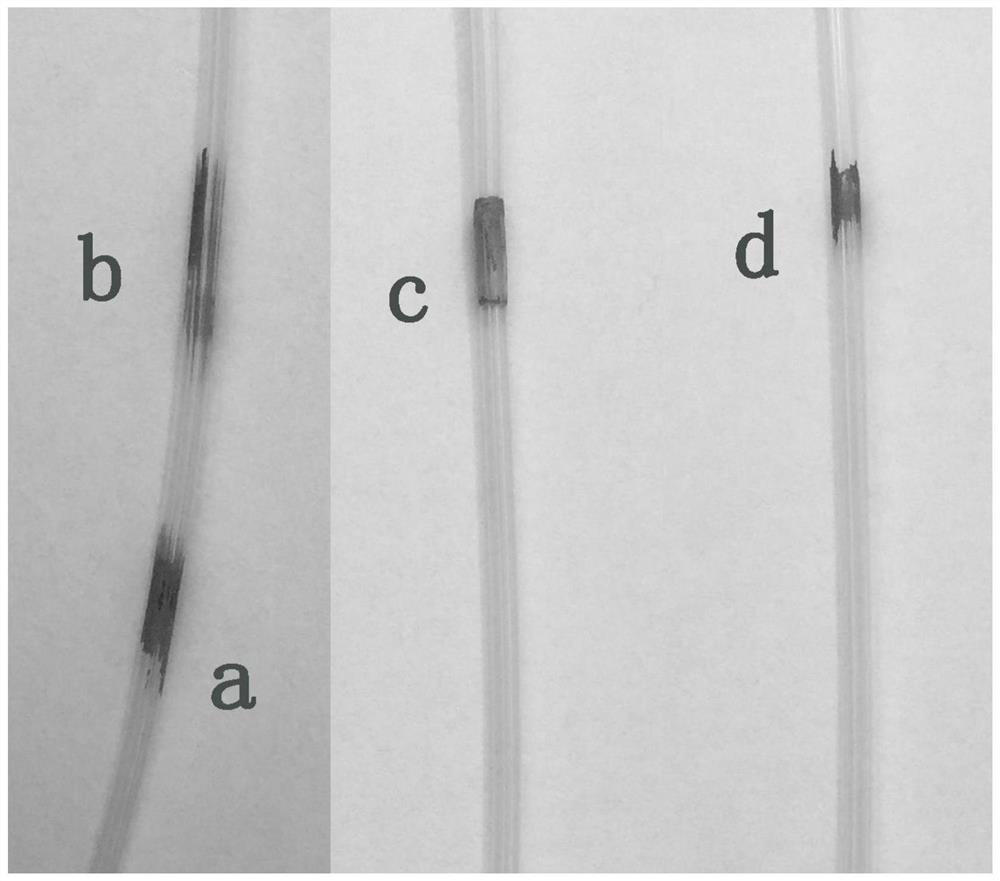

[0053] This example and its comparative example are implemented by the preparation method of Example 1, the difference is that the coating method of the ribbon pigment in this example is a ring printing method, and

[0054] 2a The tube body is treated with plasma surface, and the water-based pigment is added with tannin modifier;

[0055] 2b (Comparative Example 2) The tube body is treated with plasma surface, and the water-based pigment does not add tannin modifier;

[0056] The process of the ring printing method is as follows: the inner wall of the ring brush head is immersed in the modified ribbon pigment, the polytetrafluoroethylene tube is sent to the inside of the ring brush head, the bristles inside the ring brush head are attached to the outer wall of the tube, spin coating, The teflon tube is then sent out. The ring printing equipment has a simple structure and high production efficiency. However, the ring printing method is inevitably affected by the ring brush he...

Embodiment 3

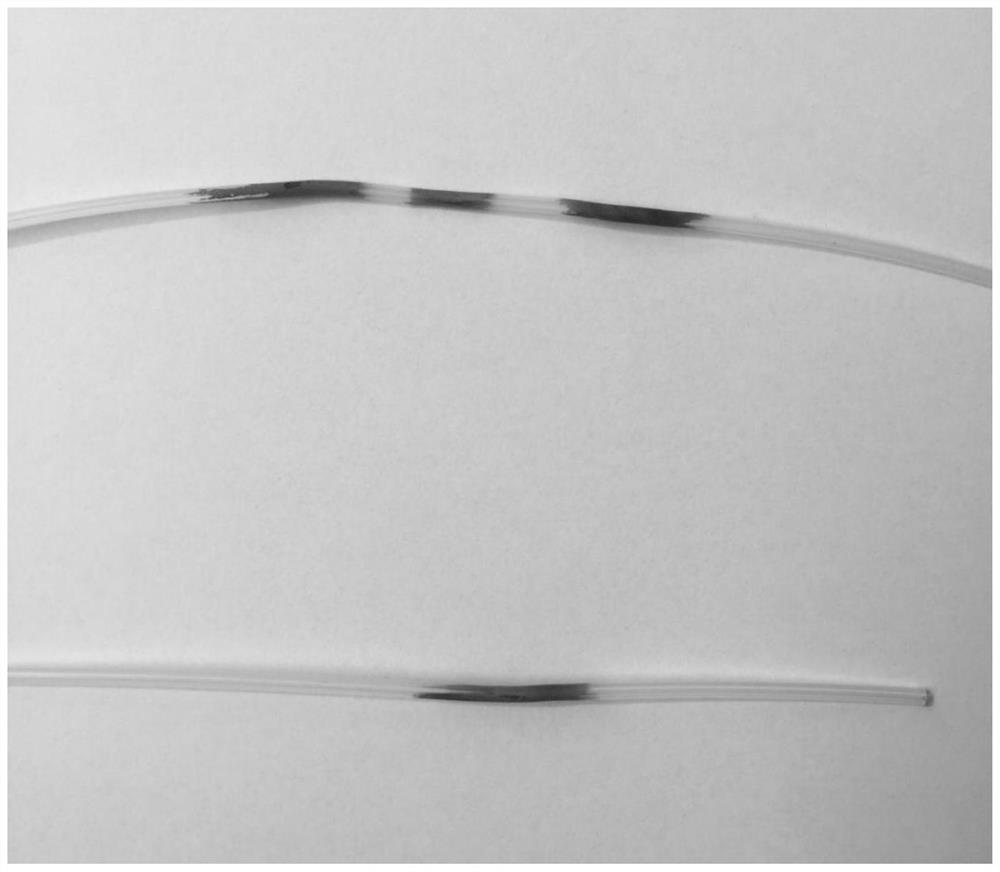

[0058] This example and its comparative example are implemented by the preparation method of Example 1, and the difference is that the method for treating the PTFE pipe body of this example adopts acid etching surface treatment, and

[0059] 2c The tube body is coated by cover-mold spraying, and the water-based pigment is added with tannin modifier;

[0060] 2d (Comparative Example 3) The tube body is coated by cover-mold spraying, and the water-based pigment does not add tannin modifier;

[0061] 3. The tube body is coated by the ring printing method, the water-based pigment is added with tannin modifier, and the coating is cured three times.

[0062] The acid etching surface treatment method is as follows: put the polyvinyl chloride pipe body into the acid etching tank, vibrate the acid etching for 3 minutes, clean with 50% ethanol aqueous solution, and dry the lotion for use; the treatment solution in the acid etching tank is 5wt% HCl and 1 wt% HF in hydrochloric acid-hydr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transparency | aaaaa | aaaaa |

| opacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com