Tool manufacturing method for preventing air leakage of composite material forming tool

A composite material and forming tooling technology, which is applied in the field of tooling manufacturing to prevent composite material forming tooling from leaking, can solve problems affecting the use of forming tooling, tooling splitting or air leakage, and affecting tooling airtightness, etc., to reduce maintenance costs , to ensure the internal quality, to ensure the effect of high temperature air tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The technical scheme of the present invention will be clearly and completely described below in conjunction with the embodiments and the accompanying drawings. Obviously, the described embodiments are only preferred embodiments of the present invention, not all embodiments, nor are they intended to be a reference to the present invention. For other forms of limitations, any skilled person who is familiar with this field may use the disclosed technical content to make changes or remodel equivalent changes. However, any simple modifications, equivalent changes and modifications made to the above embodiments according to the technical essence of the present invention without departing from the content of the technical solution of the present invention still belong to the protection scope of the technical solution of the present invention.

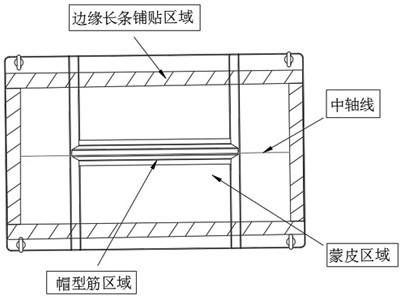

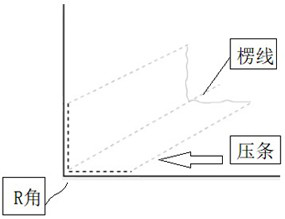

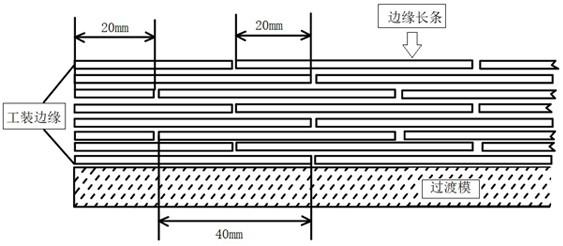

[0043] This embodiment is to manufacture a composite material forming tool for forming a certain type of composite material part. The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com