Method and device for adjusting misalignment of shells of mold for fan blade during assembling

The technology of an adjusting device and an adjusting method is applied in the field of mold clamping and dislocation adjustment of fan blade molds, which can solve problems such as non-compliance with process requirements, inaccurate adjustment of dislocation, and personal safety hazards of operating workers, so as to solve the problem of mold dislocation and facilitate assembly. The effect of mold misalignment adjustment and reduction of construction safety risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

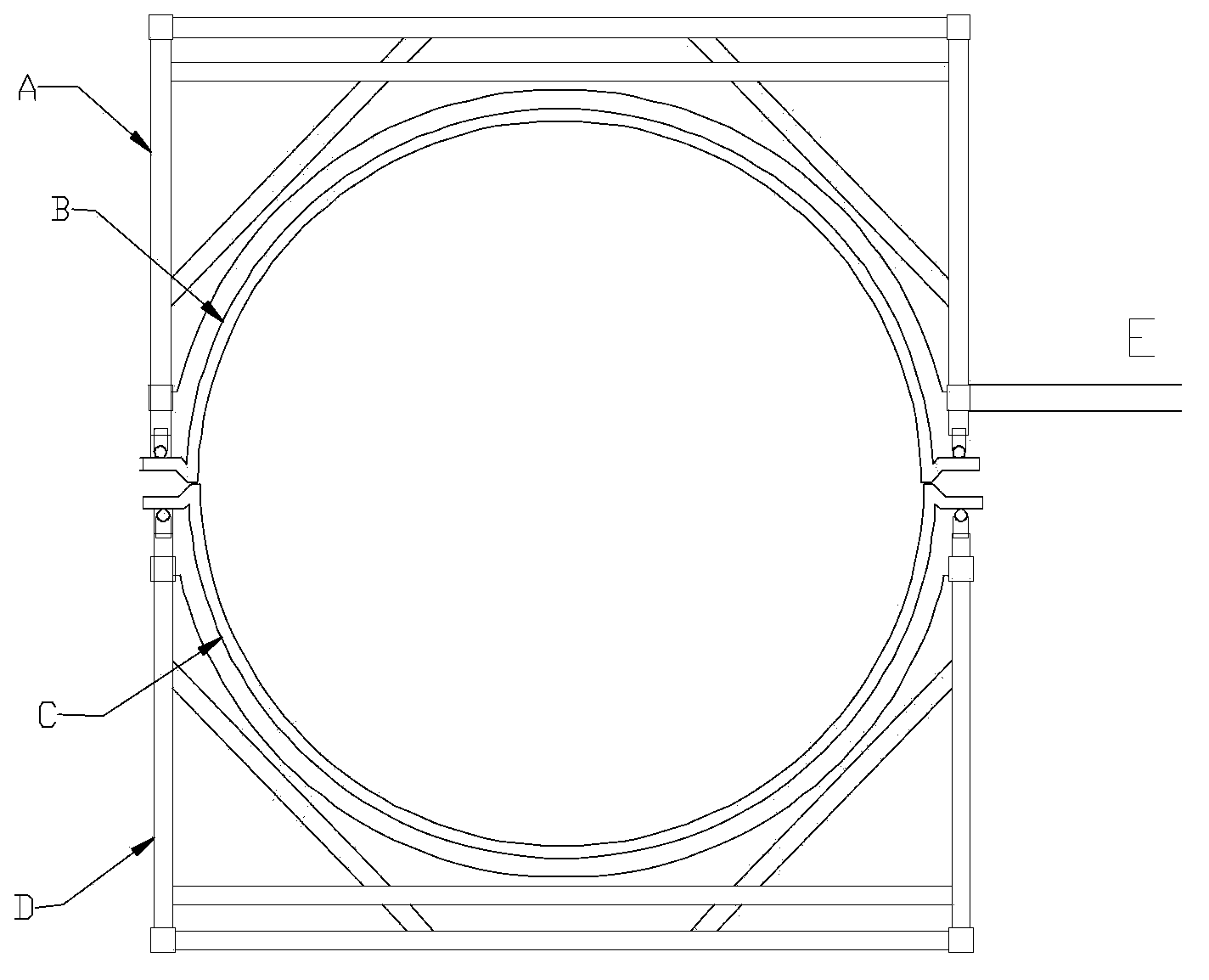

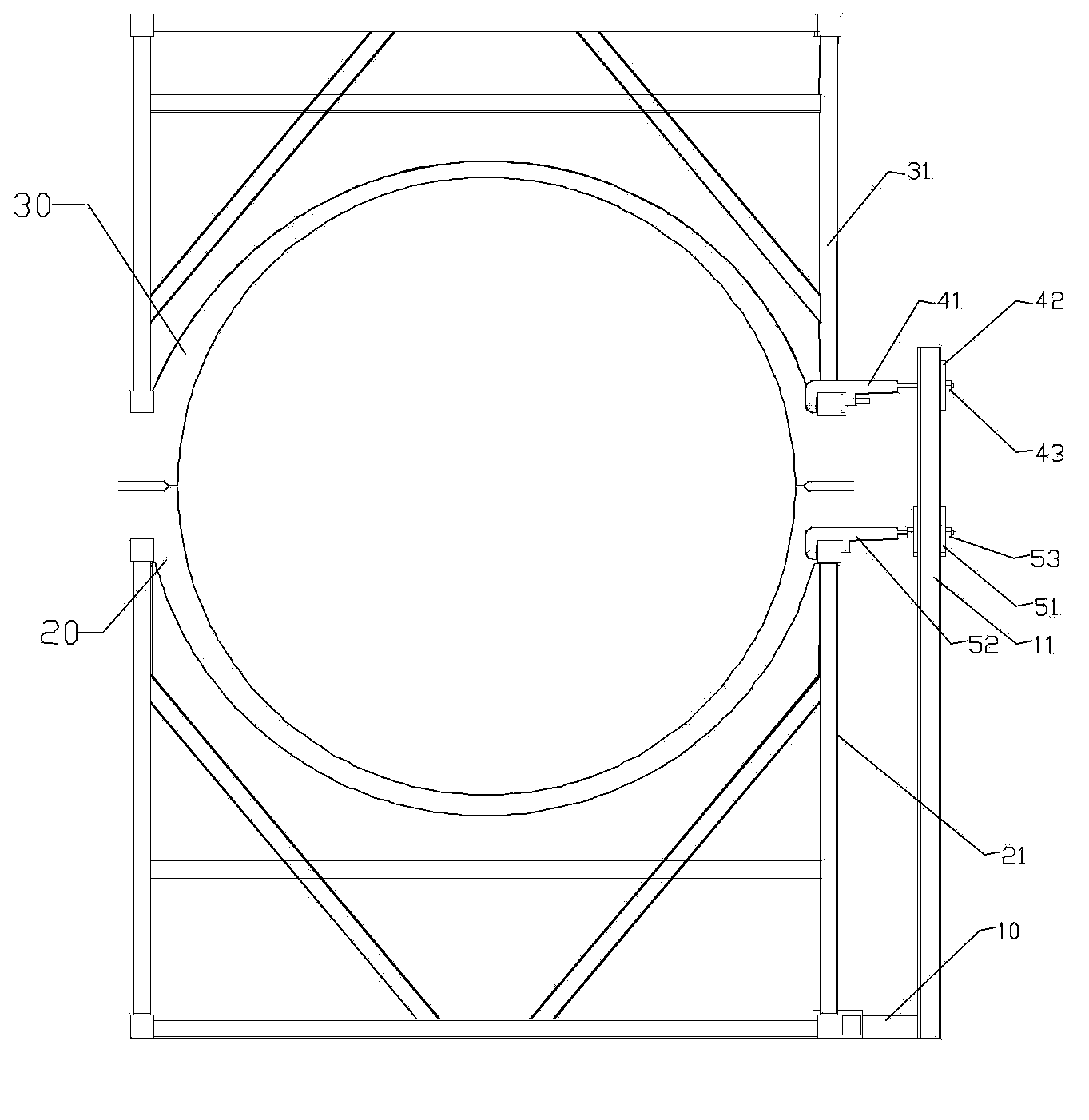

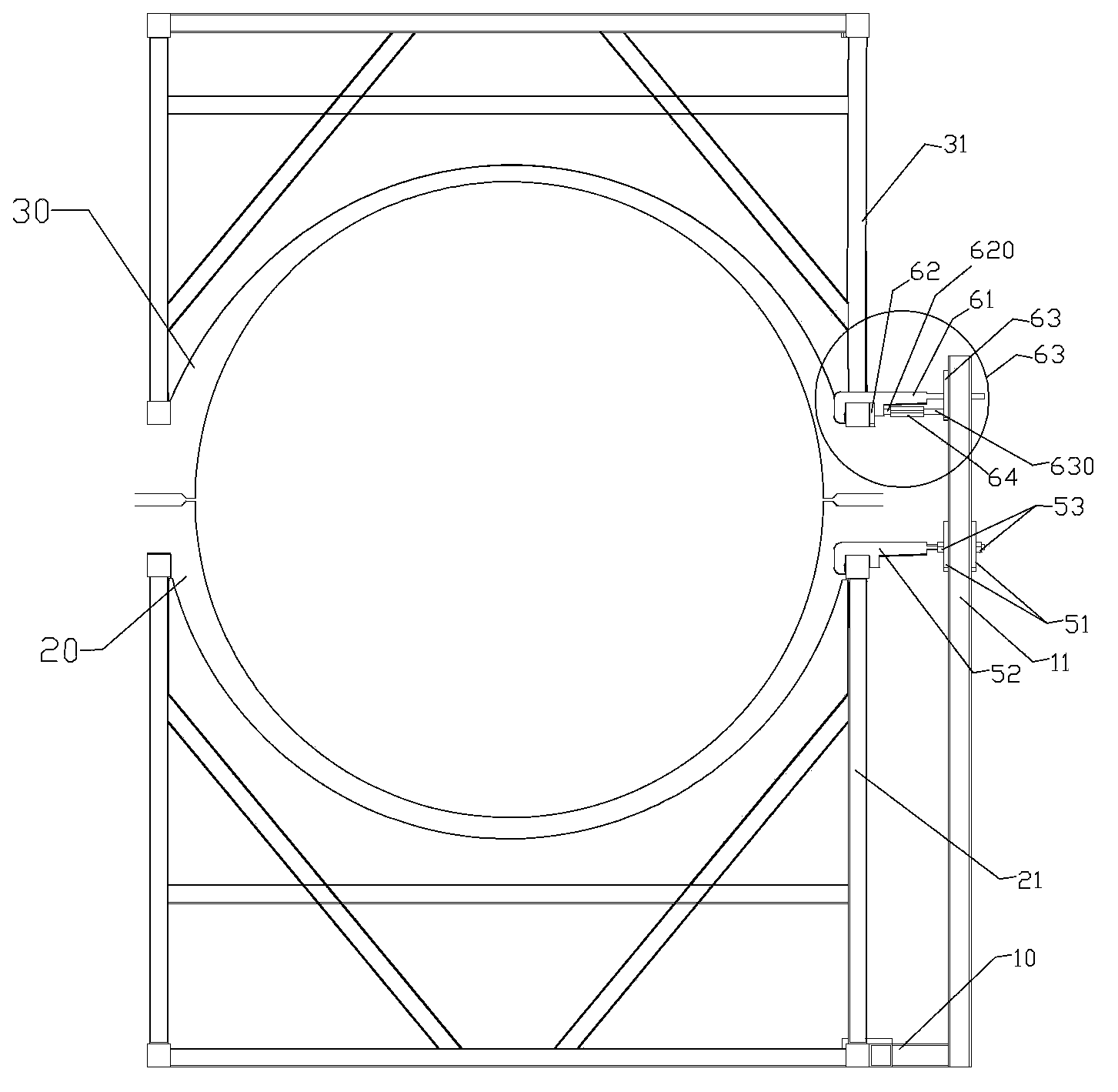

[0026] The blade mold includes an upper mold shell 30 and a lower mold shell 20 , the upper mold shell 30 is fixed on the upper mold steel frame 31 , and the lower mold shell 20 is fixed on the lower mold steel frame 21 . The lower mold shell 20 and the lower mold steel frame 21 are placed flat on the ground or on the table, the upper mold shell 30 and the upper mold steel frame 31 are placed flat on the lower mold shell 20 and the lower mold steel frame 21 by a crane, and the upper mold shell 30 After being docked with the lower formwork 20, a hollow blade cavity is formed.

[0027] A method for adjusting mold clamping and misalignment of fan blade molds. The adjustment method is as follows: a detachable adjustment device is installed on the steel frame of the lower mol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com