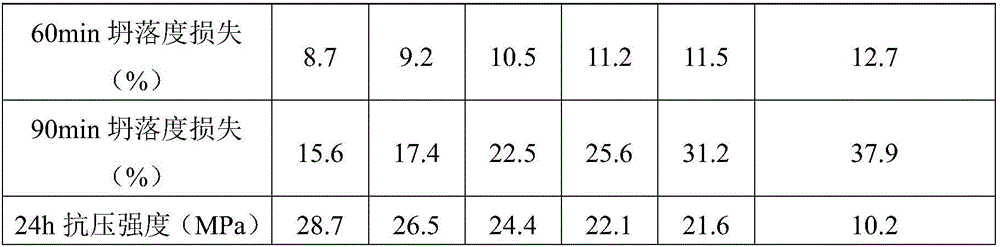

Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

67results about How to "Good plastic protection effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Slow-release type polycarboxylic water reducing agent, preparation method thereof and application

ActiveCN105174783AObvious beneficial effectHas an initial water-reducing effectAqueous solutionMechanical property

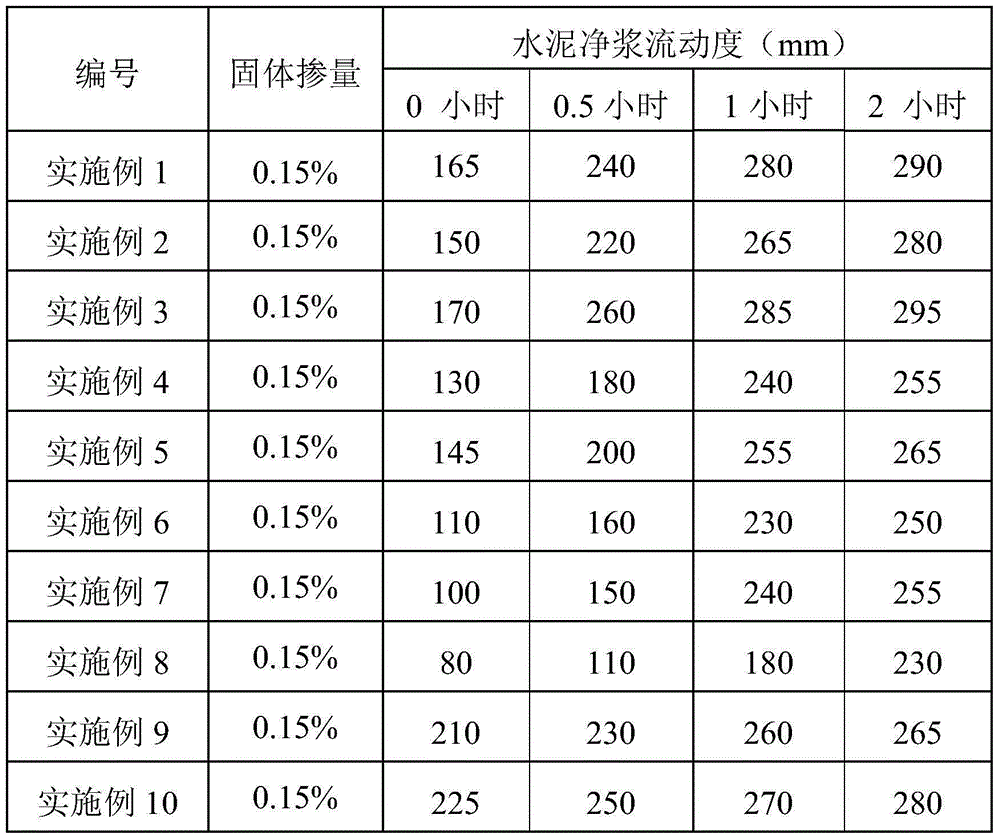

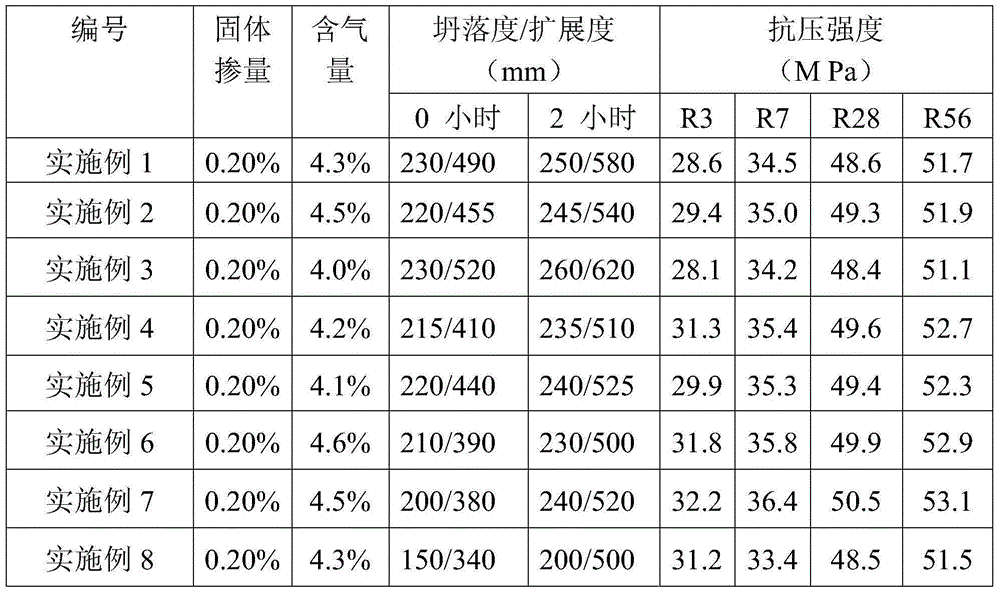

The invention belongs to the technical field of a concrete admixture in building materials and provides a slow-release type polycarboxylic water reducing agent, a preparation method thereof and application. The slow-release type polycarboxylic water reducing agent is synthesized by adopting a free-radical polymerization method in an aqueous solution. The slow-release type polycarboxylic water reducing agent is prepared by unsaturated polyoxyethylene ether, unsaturated acid or a mixture of unsaturated acid ester and the unsaturated acid, a chain transferring agent, an oxidizing agent, a reducing agent and water. The slow-release type polycarboxylic water reducing agent has the advantages of low doping amount, good plasticity-maintaining effect, good cement adaptability and good energy-saving and environmental-friendly effects and the like; the production process is simple; the equipment investment is less and the cost is low; by the adoption of the water reducing agent, water reducing components can be gradually released, and the content of the effective water reducing components in the concrete is guaranteed, and the plasticity of the concrete is maintained, and the cement hydration can be delayed, further the maintaining capability for the slump and the fluidity is excellent for concrete with large slump and concrete with medium and small slump respectively, and the large-volume concrete cracks generated by over-high hydration temperature can be reduced, and the mixability and the mechanical property of the concrete can be improved.

Owner:大连市建筑科学研究设计院股份有限公司

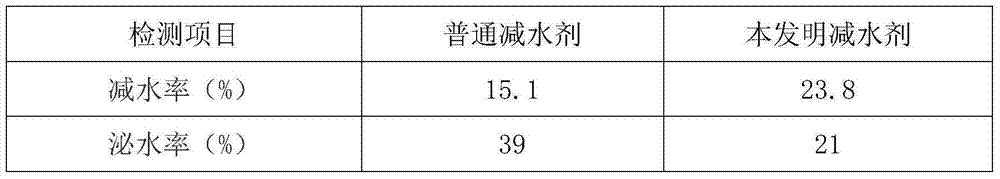

Low air leading reducing type polycarboxylic acid concrete water reducer and preparation method thereof

The invention relates to a low air leading reducing type polycarboxylic acid concrete water reducer and a preparation method thereof. The water reducer is formed by a single body A and a single body B in copolymerization according to the molar ratio of 1:3-3.5. The single body A is modified polyether TPEG, and the single body B is one or several of crylic acid, methyl acrylate, acrylamide, methacrylic acid, methyl methacrylate and methacrylamide. The preparation method includes first adding H2O2 into modified polyether TPEG water solution under the temperature of 50-55 DEG C, stirring the mixture for 10-15min, simultaneously dropping mixed water solution of ascorbic acid and a chain transfer agent and single body B solution respectively and continuously conducting reaction for 0.5-1.0 hour in heat insulation mode after dropping is finished to obtain the polycarboxylic acid water reducer after pH value adjustment. The water reducer has higher water reducing rate, has low air content and a certain reducing function if used for concrete and is the multifunctional high-efficiency water reducer integrating water reducing, reducing and low air leading.

Owner:山东华伟银凯建材科技股份有限公司

Concrete retarder

The invention discloses a concrete retarder which is prepared from the following components in parts by weight: 4-6 parts of ammonium phosphate, 5-7 parts of ammonium sulfate, 6-8 parts of sodium tripolyphosphate, 10-15 parts of amino trimethylene phosphonic acid, 3-7 parts of gelatin, 1-3 parts of glycerol, 2-4 parts of sodium citrate, 10-15 parts of zeolite powder, 10-15 parts of pumice powder, 3-5 parts of water reducer, 1-3 parts of dispersant and 0.4-0.6 part of surfactant. The concrete retarder has the advantages of good retarding effect, high strength, no pollution and the like, and is a concrete additive with developing future.

Owner:GUILIN HUAYUE ENVIRONMENTAL PROTECTION TECH CO LTD

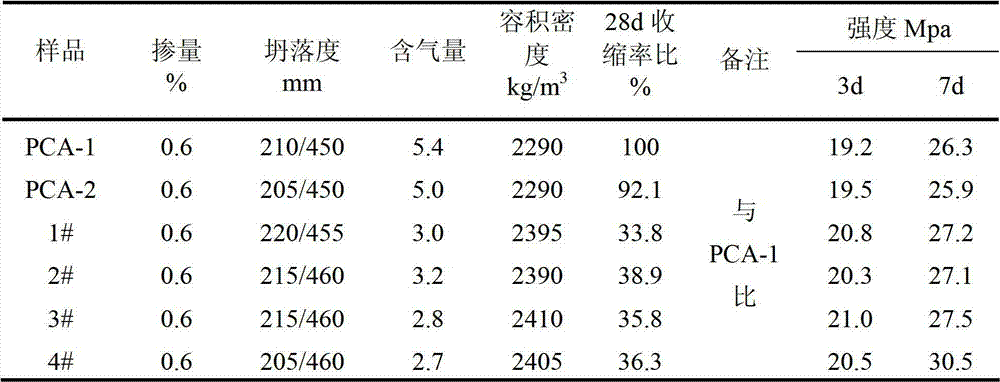

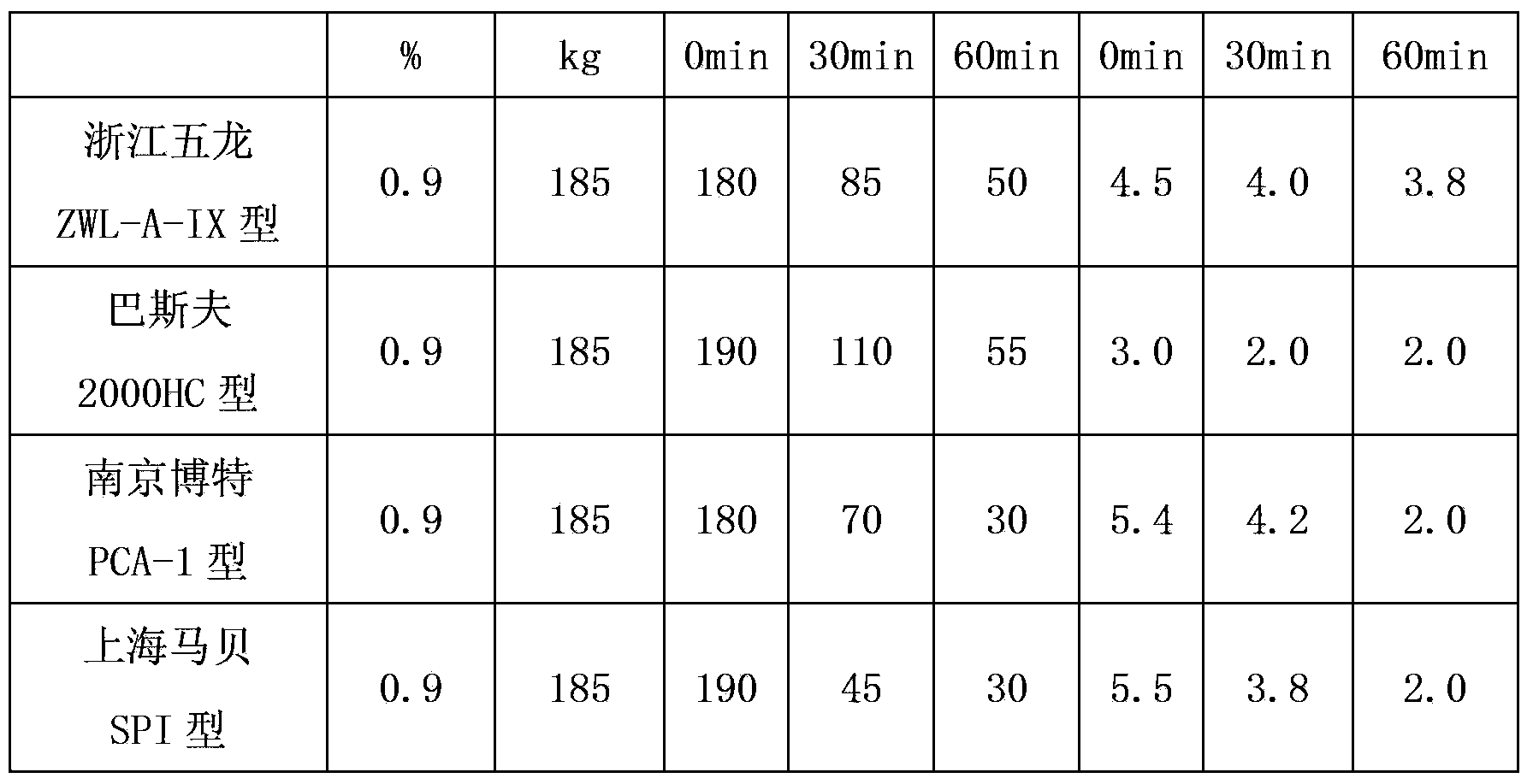

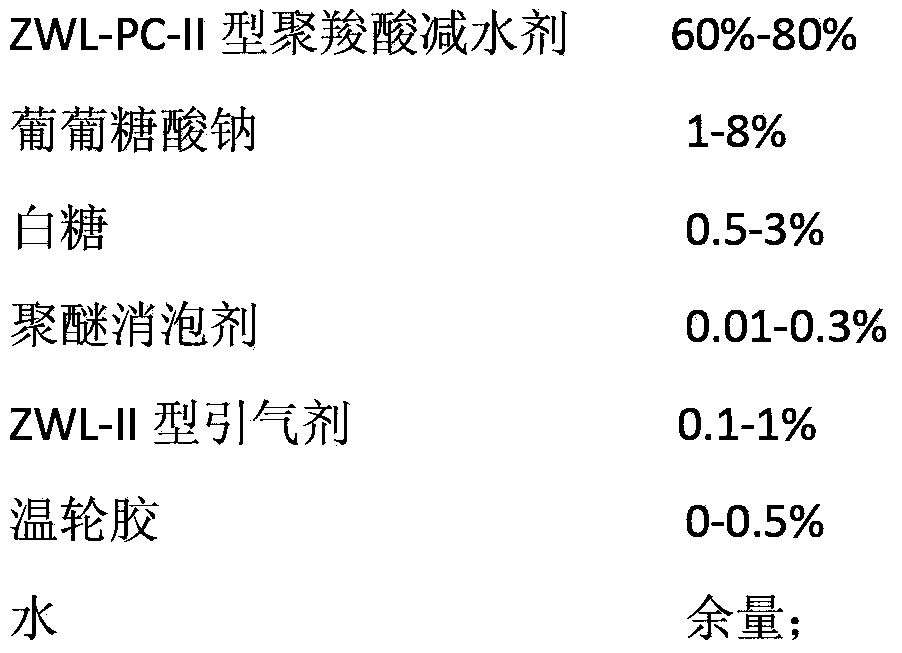

Nuclear-power concrete air-entraining polycarboxylic acid additive

The invention relates to a nuclear-power concrete air-entraining polycarboxylic acid additive which comprises the following substances: by weight, 60-80% of a ZWL-PC-II polycarboxylic acid water reducer, 1-8% of gluconic acid sodium salt, 0.5-3% of white sugar, 0.01-0.3% of a polyether antifoaming agent, 0.1-1% of a ZWL-II air-entrainer, 0-0.5% of Welan gum, and the balance water. According to the invention, Welan gum is used as a plastic retaining agent to control bleeding of concrete and sedimentation of cobblestone; By binary complex formulation of two retarders, namely sodium gluconate and white sugar, coagulation time of concrete is delayed, and early-stage heat of hydration of concrete is reduced; as the ZWL-II air-entrainer which fits with the ZWL-PC-II polycarboxylic acid water reducer is adopted, tiny, uniform and stable steam bubbles are introduced such that slump and gas content loss result of concrete completely meet construction requirements of nuclear-power concrete.

Owner:CHINA NUCLEAR CONSTR CONCRETE

Concrete retarder

The invention discloses concrete retarder. The concrete retarder comprises, by weight, 2-4 parts of sodium borate, 3-7 parts of monopotassium phosphate, 4-8 parts of calcium sulfate, 6-8 parts of etidronic acid, 3-5 parts of ethylene diamine tetraacetic acid, 1-4 parts of sorbitol, 25-30 parts of bentonite, 10-15 parts of vermiculite powder, 4-6 parts of a water reducing agent, 1-3 parts of a dispersing agent and 0.4-0,8 part of a surface active agent. The concrete retarder has the advantages of good retarding effect, high strength, free of pollution and the like, and is a concrete additive which is quite promising.

Owner:GUILIN HUAYUE ENVIRONMENTAL PROTECTION TECH CO LTD

Sulfoaluminate-Portland cement composite system additive, fast-hardening early-strength concrete and preparation method of concrete

The invention provides a sulfoaluminate-Portland cement composite system additive and prepared sulfoaluminate-Portland cement-based fast-hardening early-strength concrete. The sulfoaluminate-Portland cement composite system additive is prepared from components in percentage by mass as follows: 70%-78% of a water reducing agent, 1.2%-2.5% of an early-strength agent, 18%-25% of a retarder and 2%-4% of an anti-freezing agent. The sulfoaluminate-Portland cement composite system additive can significantly improve the initial flow performance of the sulfoaluminate-Portland cement-based concrete, delay the setting time of a cement composite system, reduce the slump loss and effectively resolve the contradiction between liquidity and early strength and has composite effects of water reduction, delayed coagulation, early strength and the like, and a related preparation method is simple and suitable for popularization and application.

Owner:HUBEI UNIV +1

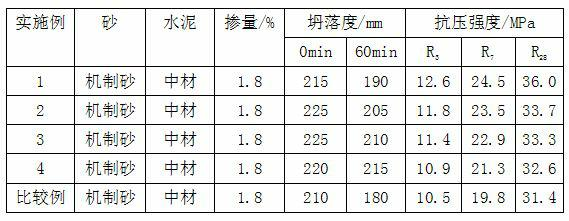

Polycarboxylic water reducer applicable to manufactured sand and preparation method of polycarboxylic water reducer

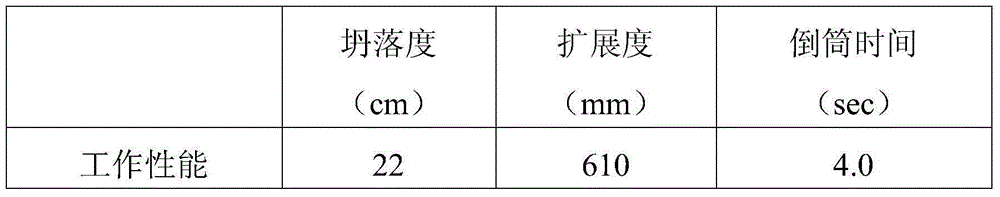

Disclosed are a polycarboxylic water reducer applicable to manufactured sand and a preparation method of the polycarboxylic water reducer. 96616 polycarboxylic water reducer mother liquor with the solid content of 40% is compounded with fatty alcohol sulphonate and polyether polyol to form the polycarboxylic water reducer. The preparation method includes adding the 96616 polycarboxylic water reducer mother liquor with the solid content of 40% into a reaction kettle; controlling the temperature to range from 25 DEG C to 30 DEG C; adding water and the fatty alcohol sulphonate while stirring; adding the polyether polyol after reacting for 30-50 minutes; and obtaining the polycarboxylic water reducer which has the solid content of 10% and is applicable to the manufactured sand after reacting for 1-1.5 hours at constant temperature. The polycarboxylic water reducer has the advantages that workability and flowing retention ability of manufactured sand class concrete are improved, and work performances of the concrete are enhanced. The preparation method is simple and facilitates production.

Owner:ZHUZHOU KAMILE SU BUILDING MATERIALS

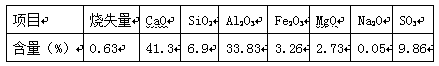

Preparation method of fluorine-containing shrink-reduced polycarboxylate water reducing agent

ActiveCN109280141AHigh water reduction rateLow plasticityShrinkage crackingOxidation-Reduction Agent

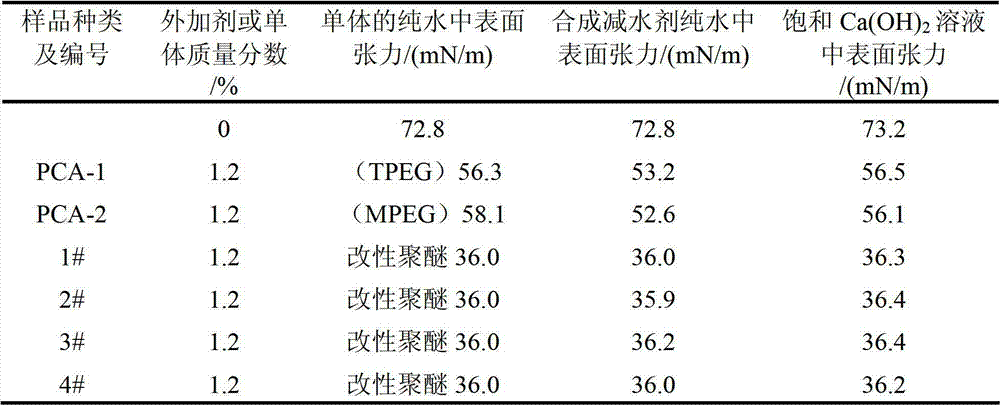

The invention discloses a preparation method of a fluorine-containing shrink-reduced polycarboxylate water reducing agent. The method particularly includes: 1) preparation of a polycarboxylate water reducing agent prepolymer: under effects of an initiator, a reducing agent and a chain transfer agent, performing a redox radical polymerization reaction to a carbonyl-containing monomer, an unsaturated acid monomer and an unsaturated macro-monomer to obtain a carbonyl-containing polycarboxylate water reducing agent prepolymer; 2) preparation of the fluorine-containing shrink-reduced polycarboxylate water reducing agent: performing a nucleophilic substitution reaction to the carbonyl-containing polycarboxylate water reducing agent prepolymer with a Prakash reagent (TMSCF3) to obtain the water reducing agent. The water reducing agent can significantly reduce surface tension and improve cement dispersibility, is high in shrinkage reducing performance on the basis of high water reduction, is good in compatibility with cement, is low in gas content when being applied to concrete, can effectively improve size stability of concrete and reduce shrinkage cracking and can improve the durabilityand service life of a concrete structure.

Owner:BEIJING UNIV OF TECH

Anti-crack concrete and preparation method thereof

InactiveCN111377675AImprove slump retentionImprove mechanical propertiesCrack resistanceStructural engineering

The invention relates to the technical field of concrete materials, in particular to anti-crack concrete and a preparation method thereof. The anti-crack concrete comprises the following components inparts by weight: 90-110 parts of Portland cement, 45-60 parts of water, 160-210 parts of gravels, 120-140 parts of sand, 20-30 parts of fly ash, 15-20 parts of a composite anti-crack agent, 9-12 parts of an additive and 2-5 parts of a composite water reducing agent. According to the invention, the composite anti-cracking agent is matched with the Portland cement, the fly ash, the admixture, the composite water reducing agent and other components, the compactness and the compressive strength of the anti-crack concrete can be improved, and the waterproof and shrinkage compensation effects of the concrete can be achieved, so that the prepared anti-crack concrete has excellent crack resistance, permeability resistance and compressive strength and is long in service life. The preparation method is simple and efficient, convenient to operate and control, stable in product quality and beneficial to industrial production.

Owner:东莞市易发混凝土有限公司

Novel concrete retarder

The invention disclsoes a novel concrete retarder. The novel concrete retarder is prepared from the following components in parts by weight: 2 to 5 parts of ammonium borate, 3 to 8 parts of sodium pyrophosphate, 4 to 9 parts of magnesium sulfate, 6 to 9 parts of diethylenetriaminepenta(methylenephosphonic) acid, 3 to 6 parts of sodium carboxymethyl cellulose, 1 to 4 parts of maltodextrin, 1 to 3 parts of sodium tartrate, 15 to 20 parts of palygorskite powder, 4 to 7 parts of a water reducing agent, 1 to 3 parts of a dispersant and 0.5 to 0.8 part of a surfactant. The novel concrete retarder provided by the invention has the advantages of excellent retarding effect, high strength, no pollution and the like, and is a concrete additive which has a very good development future.

Owner:GUILIN HUAYUE ENVIRONMENTAL PROTECTION TECH CO LTD

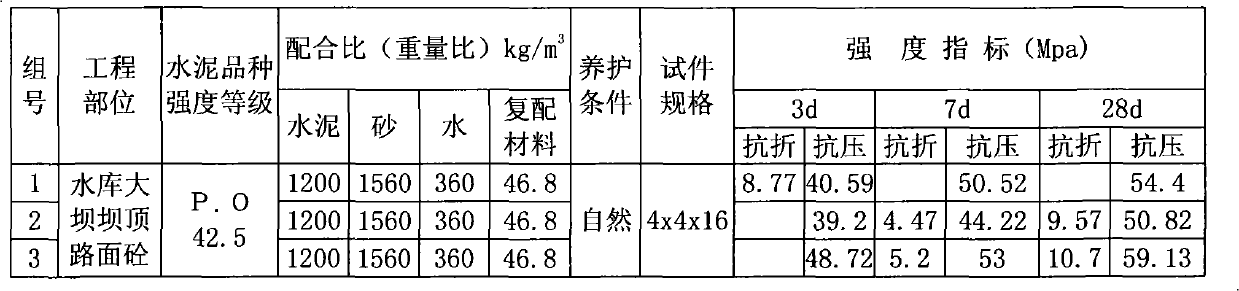

Hydraulic concrete surface layer slit sealing method

InactiveCN101994306AImprove adsorption capacityImprove adhesionMarine site engineeringGeneral purposeSurface layer

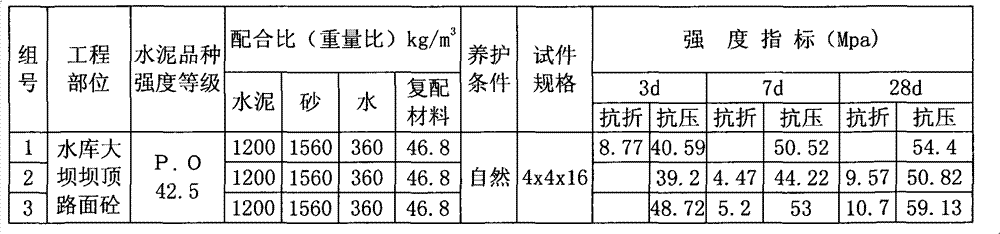

The invention relates to a hydraulic concrete surface layer slit sealing method belonging to a hydraulic concrete slit sealing method and comprising the following formula method: the formula contains 1000-1400 parts of general purpose portland cement PO42.5, 1100-2000 parts of medium coarse sand, 0-600 parts of chicken girt, 300-360 parts of water and a composite material; the method comprises the following steps of: (1) cutting a concrete surface layer crack; (2) cleaning the base surface of the concrete crack; and (3) preparing the composite material in the proportion of the formula, stirring the composite material with cement, the medium coarse sand and the water for 3 min at the stirring speed of 2000-2500R / min to form a cement gel material, and then pouring the cement gel material into slits. The invention is suitable for hydraulic concrete dam face slit treatment with better effect.

Owner:吉林省银河水利水电新技术设计有限公司

Slump-loss-resistant type polycarboxylate high-performance water reducing agent and preparation method thereof

The invention discloses a slump-loss-resistant type polycarboxylate high-performance water reducing agent and a preparation method thereof. The slump-loss-resistant type polycarboxylate high-performance water reducing agent comprises, by weight, 1000-1500 parts of polycarboxylate solution, 800-1300 parts of mono unsaturated carboxylate and derivatives thereof, 1000-1500 parts of calcium chloride, 50-100 parts of initiator, 50-80 parts of molecular weight regulator and 4000-5000 parts of water. The polycarboxylate solution comprises, by weight, 1000-1400 parts of fatty alcohol polyoxyethylene ether, 300-450 parts of acrylic acid, 25-30 parts of hydrogen peroxide, 50-65 parts of catalyst and 500-1000 parts of water. The mono unsaturated carboxylate and derivatives comprise, by weight, 100-250 parts of acrylic acid, 50-150 parts of methylacrylic acid, 50-80 parts of sodium chloride, 50-80 parts of calcium chloride solution and 100-150 parts of ammonium sulfate.

Owner:四川宇砼建材有限公司

High corrosion resistant marine cement cementing material and preparation method thereof

The invention relates to the construction field, and in particular relates to a high corrosion-resistant marine cement cementing material and a preparation method thereof, and the high corrosion-resistant marine cement cementing material comprises 20-25 parts of wollastonite; 80-100 parts of sulphoaluminate cement; 30-50 parts of nano-like hydrotalcite; 20-30 parts of fiber; 80-100 parts of coralreef sand; 50-60 parts of polyacrylamide; 20-30 parts of modified acrylic emulsion and 10-15 parts of additives; the invention aims to overcome the defects of the prior art and provide the high corrosion-resistant marine cement cementing material and the preparation method thereof. The high corrosion-resistant marine cement cementing material has the characteristics of good mechanical strength, durability and corrosion resistance, improved bending strength, improved cement density, better flocculation property, capability of reducing friction resistance between liquids, excellent impermeability, quick hardening, early strength, high later strength and the like.

Owner:广西云燕特种水泥建材有限公司

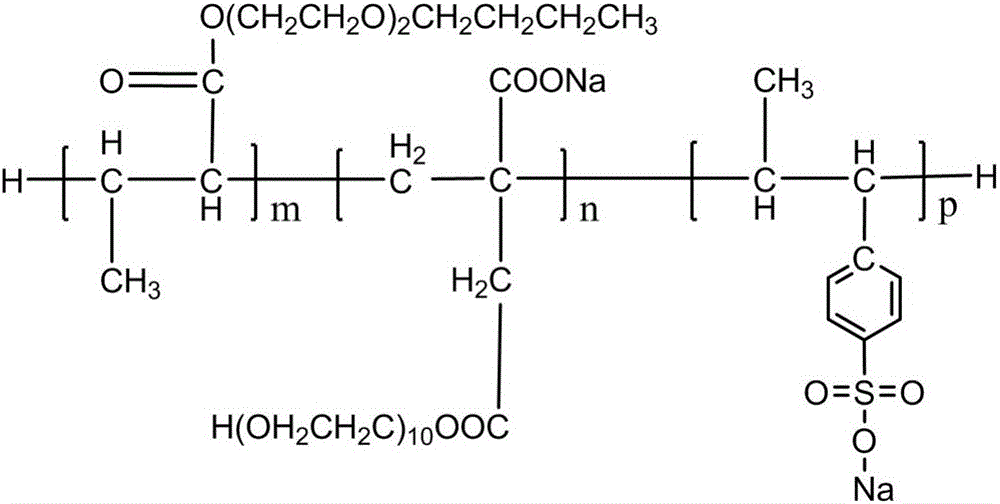

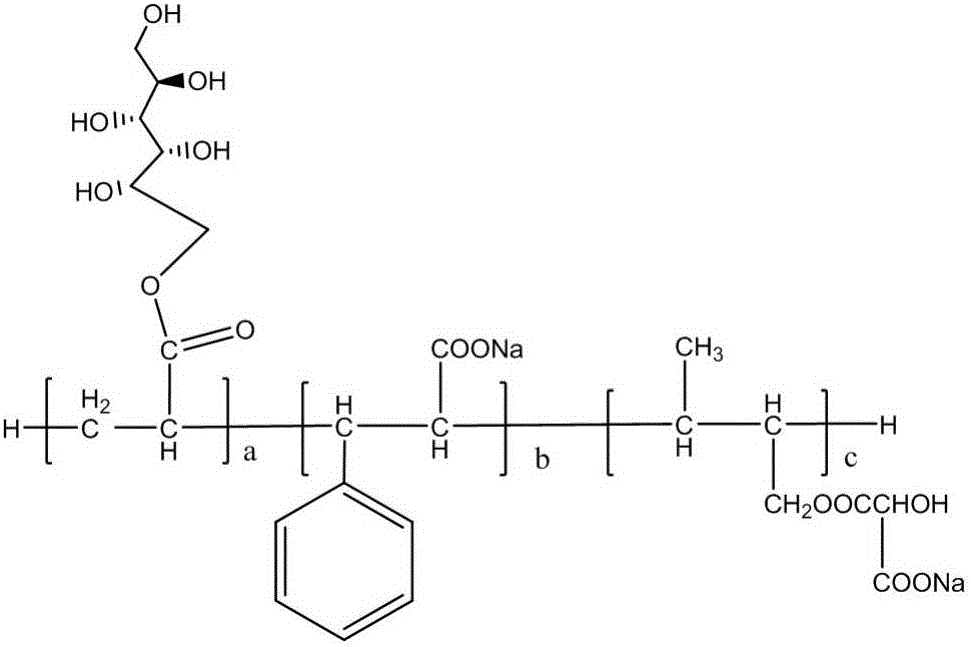

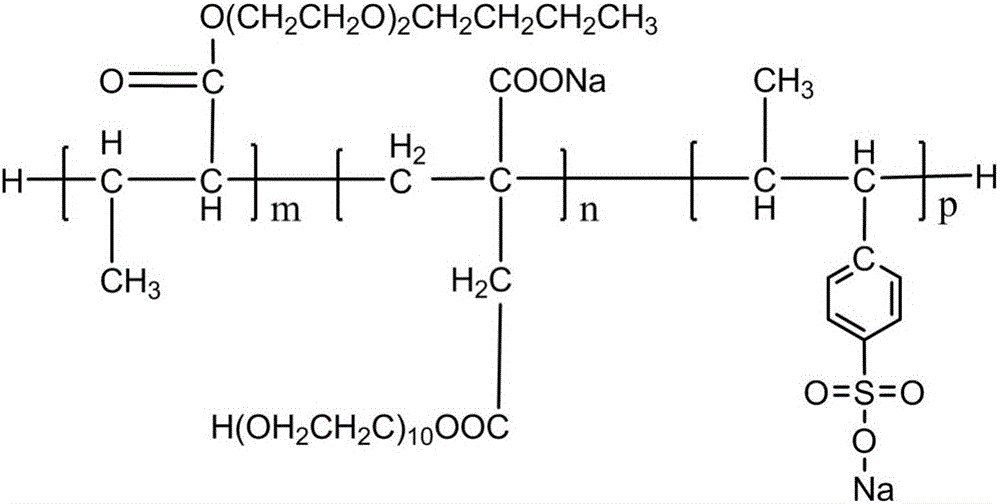

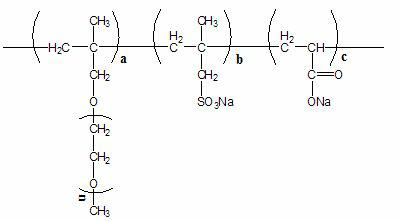

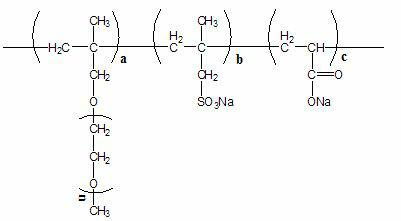

Novel polycarboxylic acid type cement additive and synthesis method thereof

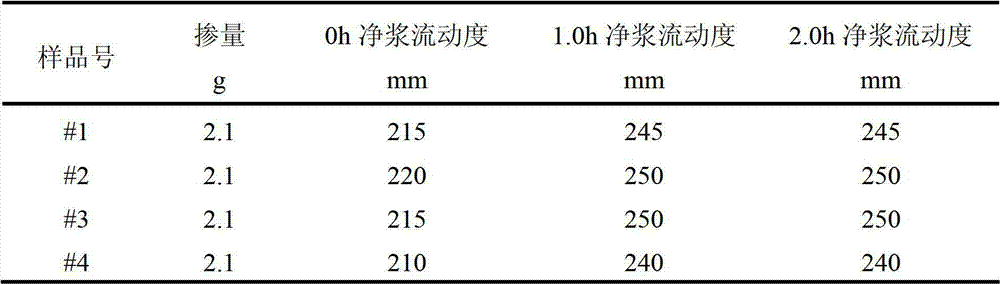

ActiveCN104530327AExcellent water reduction and plastic retentionNot easy to hydrolyzeWeight distributionComonomer

The invention provides a novel polycarboxylic acid type cement additive. The novel polycarboxylic acid type cement additive is formed by copolymerization of macromonomers containing polyoxyethylene ether groups and polymerization additives. The macromonomers contain the polyoxyethylene ether groups, and the molecular weight of the macromonomers is within 500-3000. The polymerization additives comprise comonomers, initiators, molecular weight modifiers and deionized water. The invention further provides a synthesis method of the novel polycarboxylic acid type cement additive. The method includes the steps of firstly, conditioning the macromonomers; secondly, blending the polymerization additives; thirdly, performing polymerization; fourthly, performing postprocessing. According to the novel polycarboxylic acid type cement additive, macromonomers with different molecular weights are mixed to obtain the macromonomers with wide molecular weight distribution to combine with proper polymerization technologies, and therefore the synthesized polymer can be better dispersed and extended structurally; accordingly, functions of all units in the polymer can be developed to the maximum degree, and the novel polycarboxylic acid type cement additive is excellent in performance especially in plasticity-maintaining performance and water reducing performance.

Owner:北京厚德交通科技股份有限公司 +1

Concrete retarder with good uniform mixing plasticity

The invention discloses a concrete retarder with good uniform mixing plasticity. The concrete retarder is characterized in being prepared from the following components in parts by weight: 5-8 parts ofhyperbranched borate, 10-20 parts of porous polysaccharide microspheres, 3-5 parts of zinc borosilicate, 3-6 parts of an ethylene potassium trifluoroborate / phosphoenolpyruvic acid / polyethylene glycolmonoallyl ether / 2-acrylamido-2-methylpropanesulfonic acid copolymer, 10-15 parts of attapulgite, 40-60 parts of water, 1-3 parts of an emulsifier and 3-5 parts of a cosolvent. The invention also discloses a preparation method of the concrete retarder. The concrete retarder disclosed by the invention is remarkable in retarding effect, capable of effectively improving the strength of concrete and reducing the slump loss of a concrete mixture, good in compatibility with an additive, small in mixing amount, low in cost, safe to use and environmentally friendly.

Owner:石旭艳

Water-reducing agent containing peanut shell powder

The invention discloses a water-reducing agent containing peanut shell powder. The water-reducing agent containing peanut shell powder is prepared by mixing the following raw materials in parts by weight: 30-50 parts of aromatic sulfamate formaldehyde condensate, 15-25 parts of sodium methylene bis-naphthalene sulfonate, 5-10 parts of 2-ethylhexyl phosphate, 10-15 parts of abitol polyoxyethylene ether monosulfosuccinate, 8-12 parts of fluoroplast, 10-15 parts of polyethyleneimine, 3-5 parts of erucamide, 4-8 parts of 8-hydroxyquinoline potassium sulfate, 3-6 parts of peanut shell powder, 5-10 parts of sea mud, 10-15 parts of waste mortar, 5-10 parts of collagen freeze-dried powder, 8-12 parts of sodium pyrrolidonecarboxlate, 5-10 parts of polyamide-epichlorohydrin resin, and 4-8 parts of auxiliaries. The water-reducing agent is high in water reducing rate which is up to more than 20%, excellent is plasticity retention property, good in cement adaptability, convenient to use, free from influence on properties by being directly doped into concrete, capable of improving the mobility, anti-seepage property and durability of the concrete, and wide in the range of application.

Owner:WUHU SANXING CONCRETE ADMIXTURE

Anti-freezing concrete composition and preparation method thereof

InactiveCN111377674AImprove slump retentionImprove mechanical propertiesPortland cementUltimate tensile strength

The invention relates to the technical field of concrete compositions, in particular to an anti-freezing concrete composition and a preparation method thereof. The invention discloses an anti-freezingconcrete composition. The concrete comprises the following components in parts by weight: 100-120 parts of Portland cement, 160-220 parts of gravels, 130-150 parts of sand, 25-35 parts of fly ash, 55-75 parts of water, 5-8 parts of polypropylene fibers, 11-16 parts of a composite antifreeze agent, 0.2-0.4 part of an air entraining agent, 10-15 parts of an additive and 2-5 parts of a composite water reducing agent. The anti-freezing concrete composition has good freezing resistance, strength and impermeability, can meet engineering requirements on durability and use safety of concrete under alow-temperature condition, and is simple and efficient in preparation method, convenient to operate and control, stable in product quality and beneficial to industrial production.

Owner:东莞市易发混凝土有限公司

Freeze-thaw resisting cement and its production process

The present invention discloses one kind of freeze-thaw resisting cement and its production process. The material consists of clinker 90-92 wt%, limestone 4.5-6 wt%, and gypsum 4.2-5.0 wt%, and the clinker has KHú¢0.90+ / -0.02, nú¢1.80+ / -0.10 and pú¢0.90+ / -0.10. It has the mineral composition of: C3Sú“54.0 wt%, C2Sú¥20.0 wt%, C3Aú“6.0 wt%, C4AFú¥14.0 wt%, and f-CaO less than 1.5 wt%. The freeze-thaw resisting cement has specific surface area over 350 sq m / Kg and fineness below 2.5 %, and after 250 times of freeze-thaw, it has 3-day breaking strength over 5.0 Mpa and compression strength over 25.0 Mpa, and 28-day breaking strength over 7.0 Mpa and compression strength over 50.0 Mpa. It has low C3A content, good freeze-thaw resisting performance, fast curing, high wear resistance and high permeation resistance.

Owner:CAOYUAN CEMENT XIZHUOZISHAN NEI MONGOL AUTONOMOUS REGION

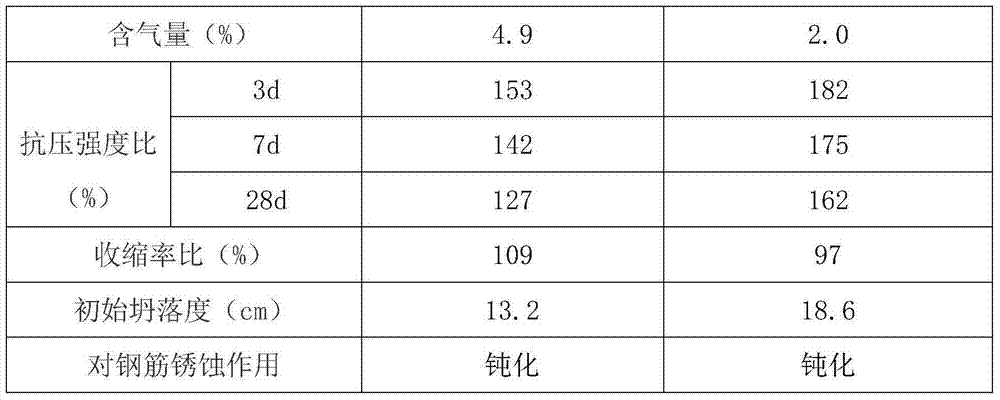

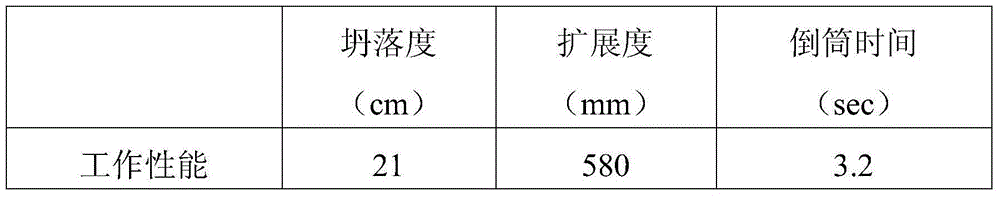

Preparation method of white carbon black-doped high performance concrete

The invention discloses a preparation method of white carbon black-doped high performance concrete. The method comprises the following steps: taking 16-20 parts by weight of Portland cement, 0.1-0.5 parts by weight of silicon micro-powder, 28-35 parts by weight of hill sand, 33-41 parts by weight of broken stones, 5-7 parts by weight of water, 0.3-0.6 parts by weight of an additive and 1-2 parts by weight of white carbon black, and processing above raw materials through an improved concrete production technology to obtain the white carbon black-doped high performance concrete. The strength of the concrete can reach 60-80MPa, the slump can reach 210-230mm, the extended degree can reach 550-630mm, the pouring time is shorter than 5s, and the concrete also has the advantages of low cost and very wide market prospect.

Owner:GUIZHOU CONSTR SCI RES & DESIGN INST OF CSCEC

Hydraulic concrete surface layer slit sealing method

The invention relates to a hydraulic concrete surface layer slit sealing method belonging to a hydraulic concrete slit sealing method and comprising the following formula method: the formula contains 1000-1400 parts of general purpose portland cement PO42.5, 1100-2000 parts of medium coarse sand, 0-600 parts of chicken girt, 300-360 parts of water and a composite material; the method comprises the following steps of: (1) cutting a concrete surface layer crack; (2) cleaning the base surface of the concrete crack; and (3) preparing the composite material in the proportion of the formula, stirring the composite material with cement, the medium coarse sand and the water for 3 min at the stirring speed of 2000-2500R / min to form a cement gel material, and then pouring the cement gel material into slits. The invention is suitable for hydraulic concrete dam face slit treatment with better effect.

Owner:吉林省银河水利水电新技术设计有限公司

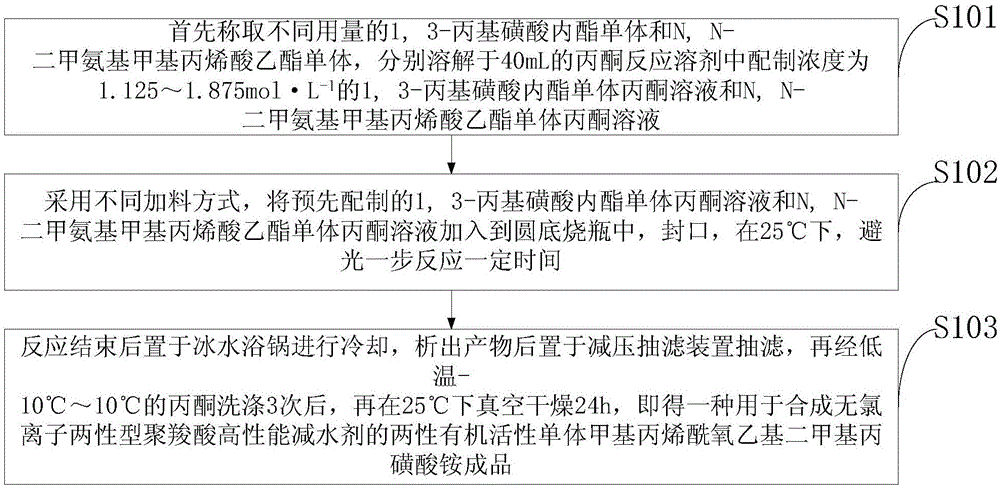

Methacryloyloxyethyl-dimethyl ammonium propanesulfonate and preparation method thereof

InactiveCN106278962ALow costSimple processSulfonic acids salts preparationRound-bottom flaskChemistry

The invention discloses methacryloyloxyethyl-dimethyl ammonium propanesulfonate and a preparation method and the molecular structure thereof. The method includes the steps that 1,3-propanesultone monomers and 2-(dimethylamino)ethyl methacrylate monomers with different use amounts are weighed first, a 1,3-propanesultone monomer acetone solution and a 2-(dimethylamino)ethyl methacrylate monomer acetone solution which are prepared in advance are added into a round-bottom flask in different adding modes, and a one-step reaction is carried out for a certain time under the light-proof condition; ice-water bath cooling, suction filtration and vacuum drying are carried out, and the finished product is obtained. Methacryloyloxyethyl-dimethyl ammonium propanesulfonate has excellent dispersing performance, superior plasticity maintaining performance and high early strength performance on cement systems or concrete; meanwhile, the potential hazard of reinforcement corrosion caused when methacryloyloxyethyl-dimethyl ammonium propanesulfonate is applied to reinforced concrete can be eliminated.

Owner:LIMING VOCATIONAL UNIV

Wet-mixed mortar admixture

The invention discloses a wet-mixed mortar admixture. The wet-mixed mortar admixture comprises a plastic regulating agent and a coagulation regulating agent, wherein the plastic regulating agent is prepared from components as follows: 5%-15% of a water reducer, 0.5%-2% of a water retaining agent, 0.5%-1.5% of an additive, 0.1%-0.6% of a shrinkage reducing agent, 0.5%-3% of a thixotropic lubricant, 0.2%-0.4% of a cosolvent and the balance of water; the coagulation regulating agent is prepared from components as follows: 5%-15% of a retarder, 0.2%-2% of a plastic retaining agent, 1%-3% of a stabilizer and the balance of water. The wet-mixed mortar admixture comprises the plastic regulating agent and the coagulation regulating agent, mortar has good plastic retaining property and workability due to mixing of the double components, the opening time is greatly prolonged, and the compressive strength and the adhesion stress of the mortar are improved.

Owner:惠州市金砂浆科技有限公司

Composite concrete retarder

The invention discloses a composite concrete retarder, made from, by weight, 2-6 parts of sodium fluorosilicate, 3-9 parts of sodium dihydrogen phosphate, 4-8 parts of ammonium bicarbonate, 4-6 parts of ammonium persulfate, 7-9 parts of glycine, 2-6 parts of sodium carboxymethyl cellulose, 2-4 parts of shell-lac, 1-3 parts of ammonium oxalate, 10-15 parts of halloysite, 15-20 parts of Al2O3-ZrO2 porous ceramic powder, 2-5 parts of a water-reducing agent, 1-3 parts of a dispersant, and 0.3-0.6 part of a surfactant. The composite concrete retarder has the advantages of good retarding effect, high strength, zero pollution and the like, and is a concrete admixture that is promising.

Owner:GUILIN HUAYUE ENVIRONMENTAL PROTECTION TECH CO LTD

Retarder for recycled aggregate mortar, and preparation method of retarder

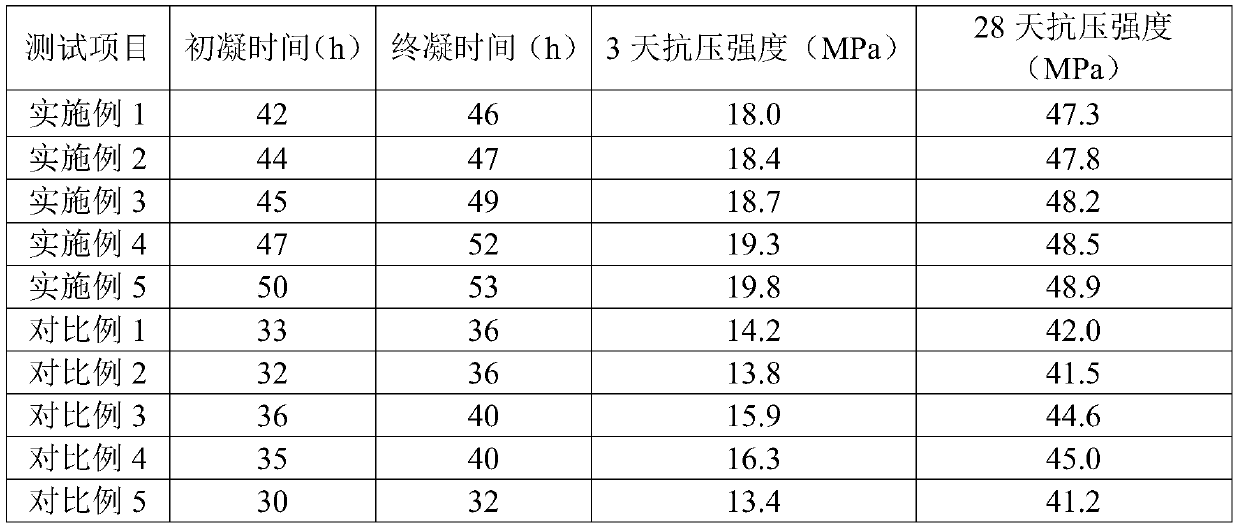

InactiveCN111333356AGood retarding effectHigh compressive strengthCompressive resistancePhosphogypsum

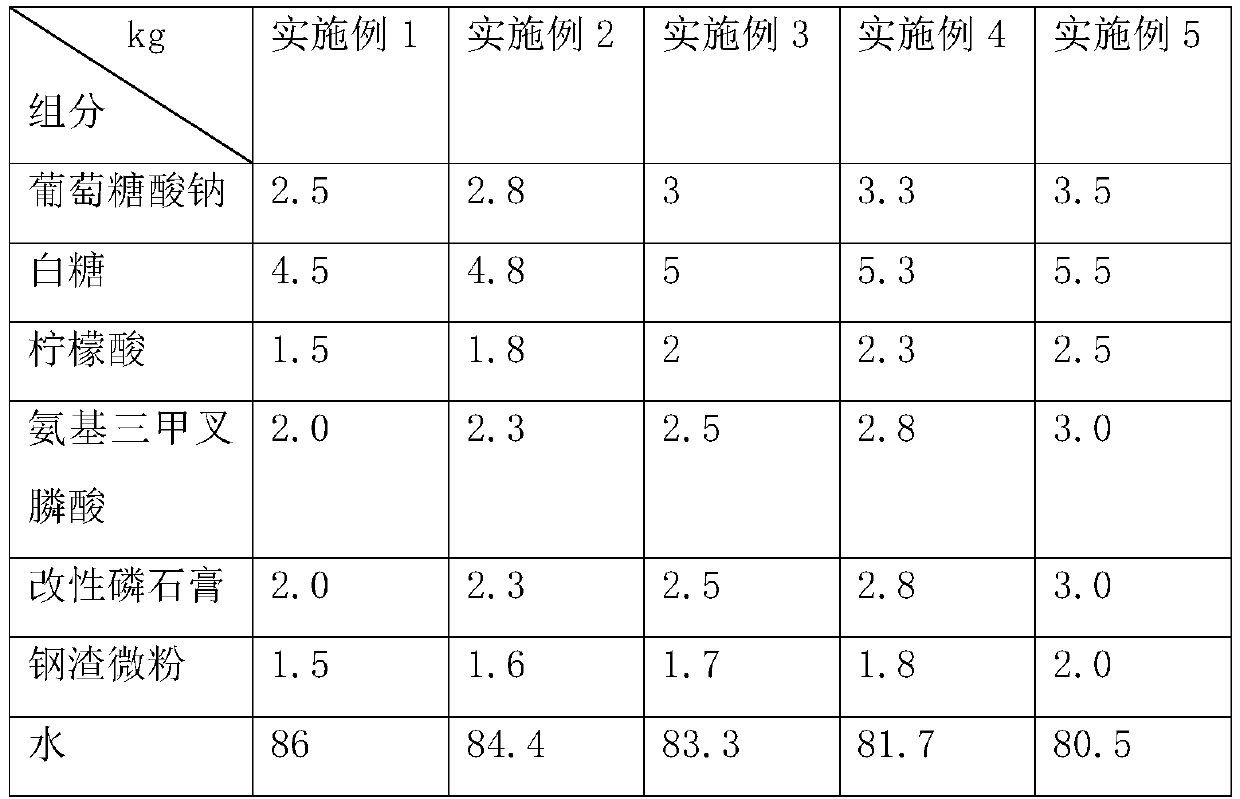

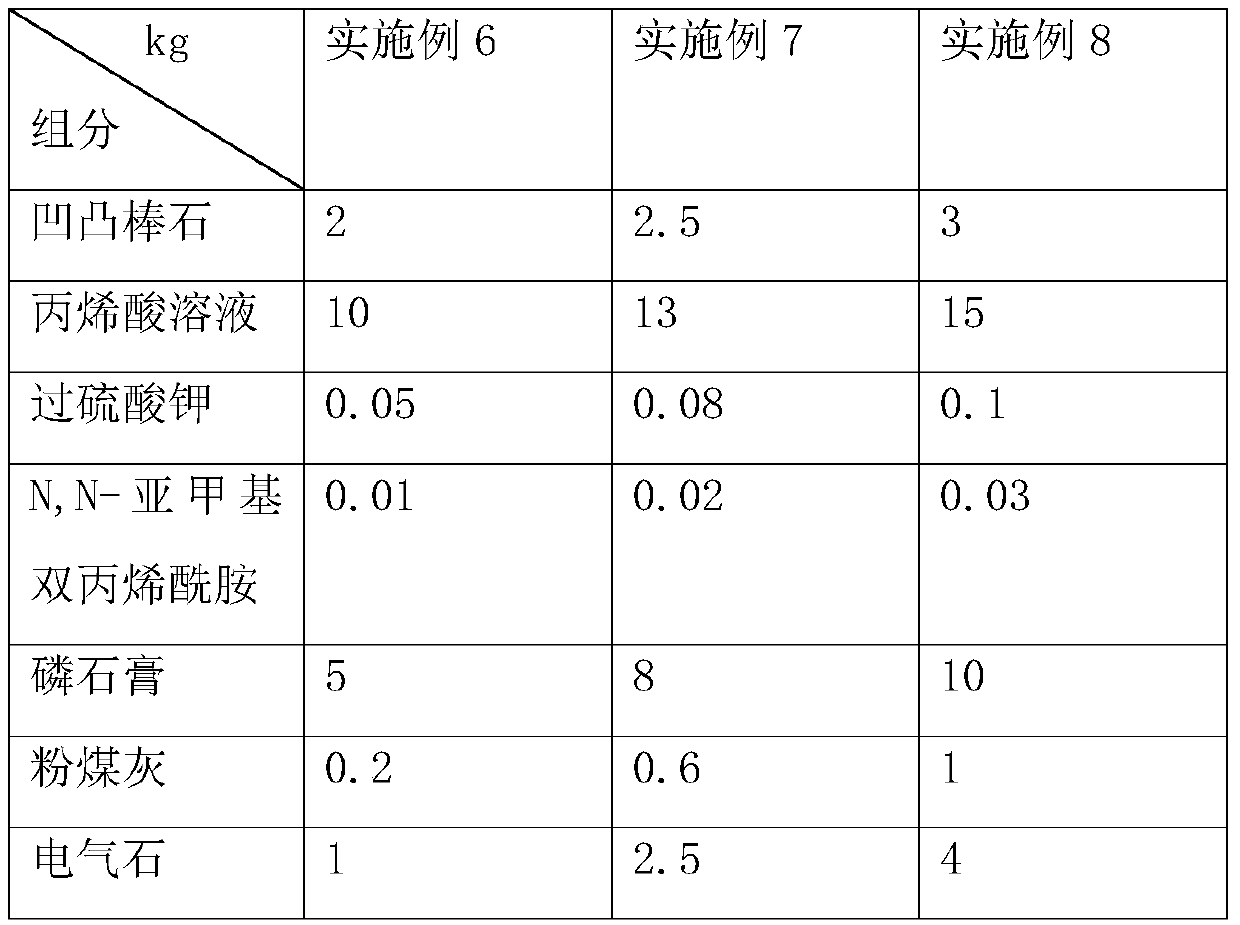

The invention discloses a retarder for recycled aggregate mortar, and a preparation method thereof, and relates to the technical field of building materials, wherein every 100 parts by weight of the retarder for the recycled aggregate mortar is prepared from the following components in parts by weight: 2.5 to 3.5 parts of sodium gluconate, 4.5 to 5.5 parts of white sugar, 1.5 to 2.5 parts of citric acid, 2 to 3 parts of amino trimethylene phosphonic acid, 2 to 3 parts of modified phosphogypsum, 1.5 to 2 parts of steel slag micro powder and the balance of water. The retarder for recycled aggregate mortar has the advantages of good compatibility with a cementing material, strong water retention and plasticity retention, prolongation of the setting time of the recycled aggregate mortar, prolongation of the operation time, and improvement of the compressive strength of the hardened mortar.

Owner:深圳市三绿科技有限公司

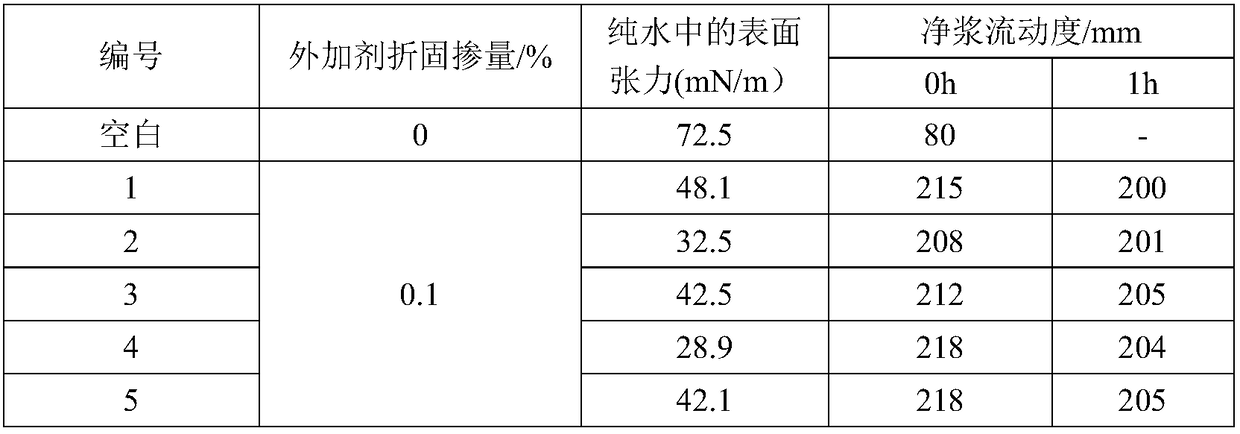

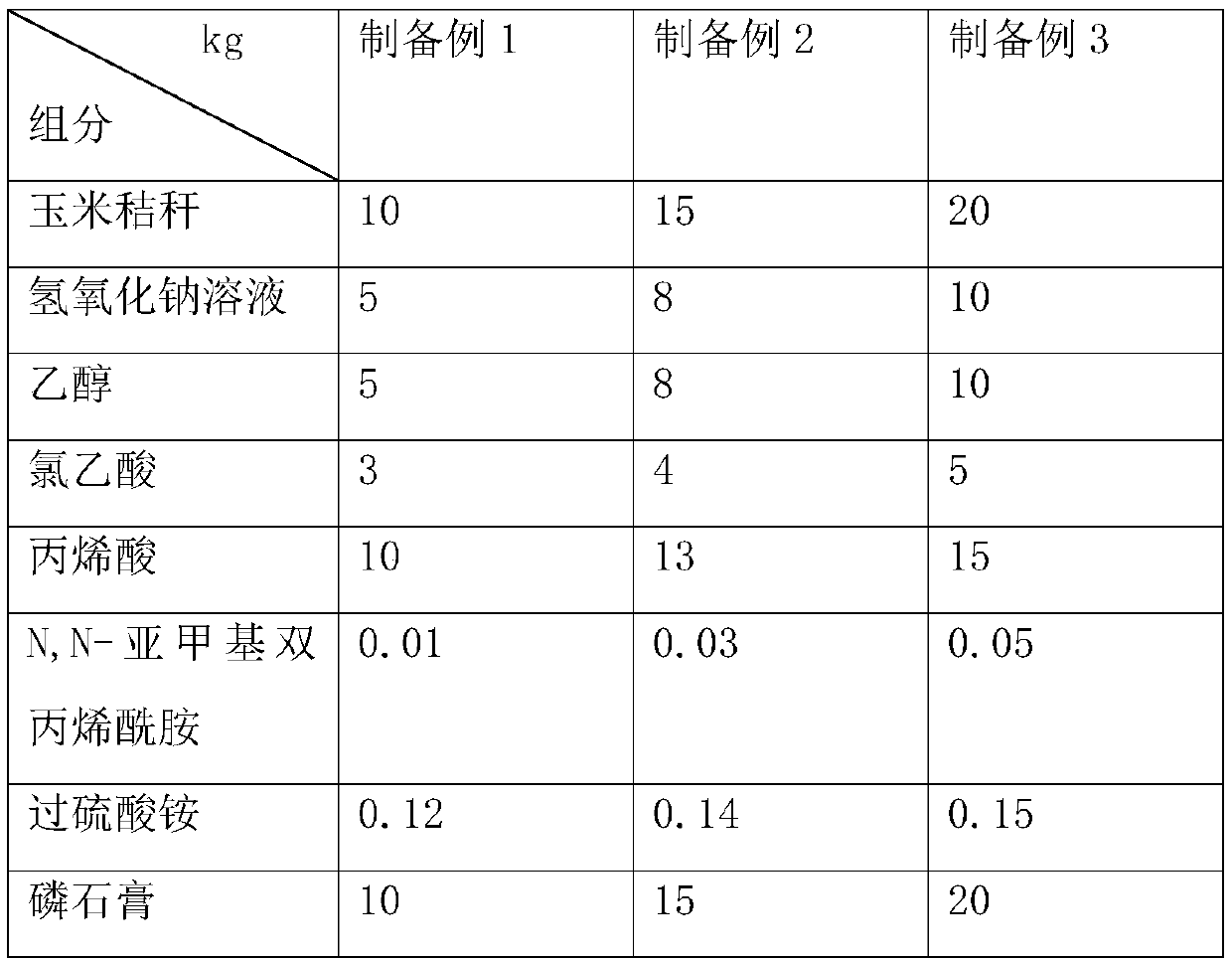

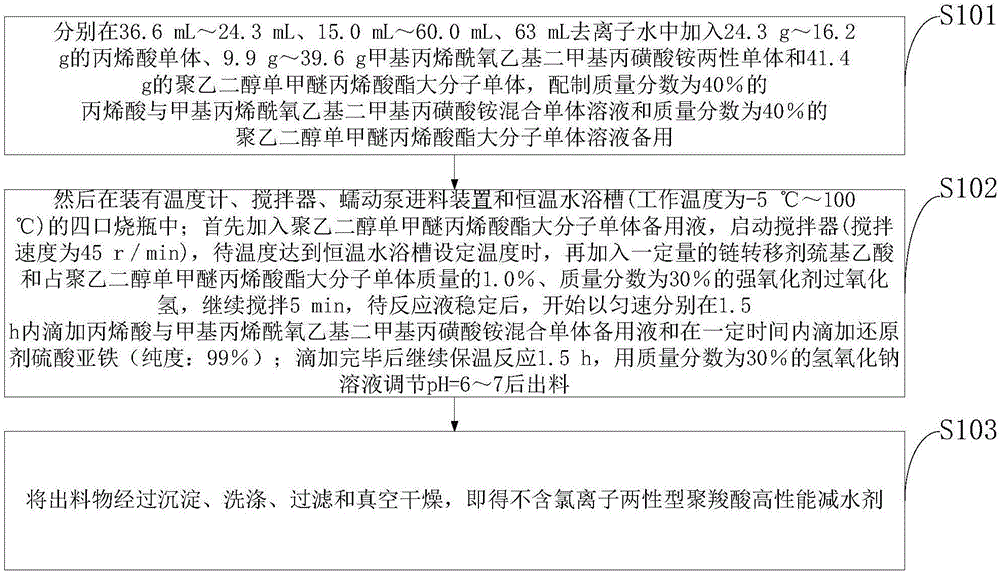

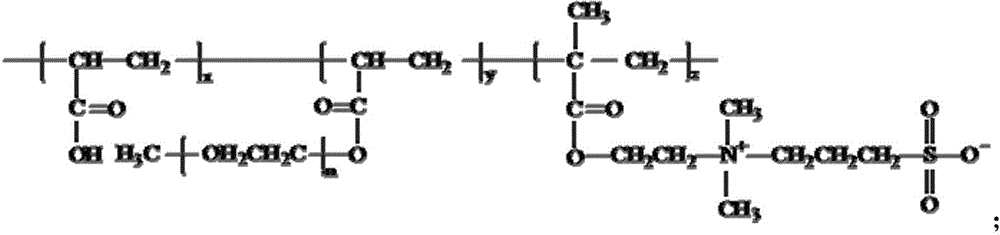

Chlorion-free amphiprotic polycarboxylic acid high-performance water reducing agent and preparation method thereof

The invention discloses a chlorion-free amphiprotic polycarboxylic acid high-performance water reducing agent and a preparation method thereof. The preparation method comprises the following steps: preparing an acrylic acid and methylacryloyloxyethyl dimethyl ammonium propanesulfonate mixed monomer solution and a polyethylene glycol monomethyl ether acrylate macromonomer solution; adding a chain transfer agent mercaptoacetic acid and a strong oxidant hydrogen peroxide; respectively dropwise adding the acrylic acid and methylacryloyloxyethyl dimethyl ammonium propanesulfonate mixed monomer solution and a reducing agent ferrous sulfate; and performing precipitation, washing, filtering and vacuum drying to obtain the chlorion-free amphiprotic polycarboxylic acid high-performance water reducing agent. According to the invention, by reasonably selecting the preparation monomer, a chlorion-free amphiprotic polycarboxylic acid high-performance water reducing agent can be obtained so as to eliminate potential hazard caused by rebar corrosion in reinforced concrete.

Owner:LIMING VOCATIONAL UNIV

Corrosion-resistant concrete material and preparation method thereof

InactiveCN111377673AImprove slump retentionImprove mechanical propertiesCompressive resistancePortland cement

The invention relates to the technical field of concrete materials, in particular to a corrosion-resistant concrete material and a preparation method thereof. The corrosion-resistant concrete materialis prepared from the following components in parts by weight: 90 to 110 parts of Portland cement, 70 to 100 parts of water, 170 to 230 parts of gravel, 120 to 140 parts of sand, 20 to 30 parts of flyash, 11 to 16 parts of additive, 2 to 5 parts of composite water reducing agent and 10 to 15 parts of calcium oxide-calcium sulphoaluminate composite expanding agent. The corrosion-resistant concretematerial has good corrosion resistance, impermeability and compressive strength and is long in service life; the preparation method is simple and efficient, operation and control are convenient, theproduct quality is stable, and industrial production is facilitated.

Owner:东莞市易发混凝土有限公司

Chlorine-free concrete and mortar waterproof agent

The invention discloses a chlorine-free concrete and mortar waterproof agent, and belongs to the technical field of additive. The chlorine-free concrete and mortar waterproof agent is prepared from, by weight, 80 to 90 parts of blast furnace slag, 20 to 25 parts of an expanding agent, 18 to 22 parts of furan resin, 15 to 20 parts of a naphthalene water reducer, 15 to 20 parts of sepiolite powder, 12 to 18 parts of cyclodextrin, 10 to 15 parts of nano silicon micro powder, 10 to 15 parts of organic bentonite, 8 to 12 parts of sugarcane wax, 6 to 10 parts of palmitic acid, 5 to 8 parts of hydrogenated castor oil, and 250 to 300 parts of water. The chlorine-free concrete and mortar waterproof agent possesses stable and reliable water resistance; insoluble silicates can be obtained via reaction of the active ingredients of the chlorine-free concrete and mortar waterproof agent with cement hydration products, so that water seepage channels can be blocked, and water tightness and impermeability of concrete and mortar are improved greatly.

Owner:滁州京安工贸有限责任公司

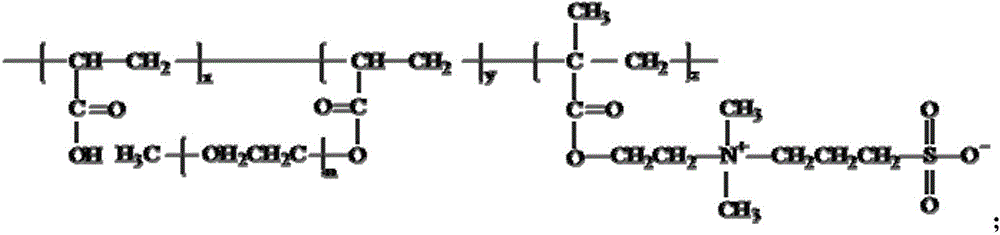

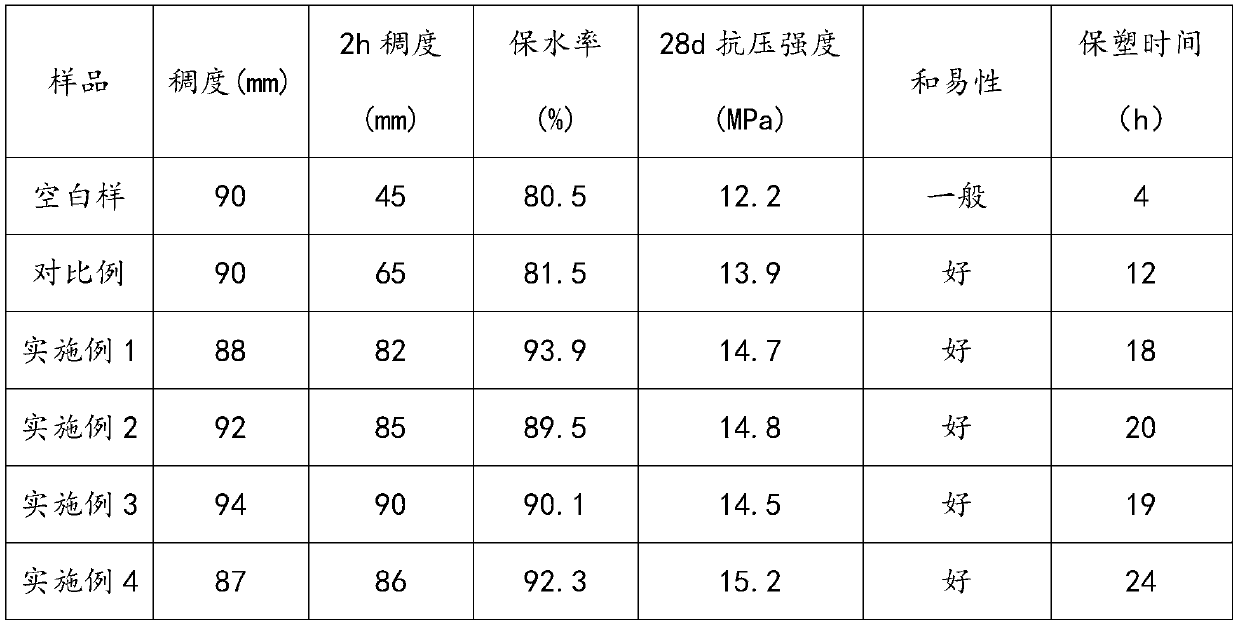

Stabilizer-plasticizer for wet mixed mortar and preparation method thereof

The invention relates to the technical field of building admixtures, specifically to a stabilizer-plasticizer for wet mixed mortar and a preparation method thereof. The preparation method comprises the following steps of: mixing 4-hydroxybutylvinyl polyoxyethylene ether monomer, acrylic acid, methylacryloyloxyethyl succinate and water, and adding hydrogen peroxide; carrying out a reaction, and then sequentially adding an aqueous solution of a reducing agent, an aqueous solution of a cocatalyst, and an aqueous solution composed of acrylic acid, 2-amino-3-p-hydroxyphenylpropionate, 3-dihydromyrcenol hydroxyphenylphosphinyl propionate and a chain transfer agent; and after a reaction is completed, adding polyvinyl alcohol and adjusting a pH value to 7 to 8 to prepare the stabilizer-plasticizer for wet mixed mortar. Compared with the prior art, mortar synthesized by using the stabilizer-plasticizer for wet mixed mortar provided by the invention has the advantages of low consistency loss, good water retention rate, high compressive strength, high long-term stability and the like, so significant progress is made.

Owner:KZJ NEW MATERIALS GROUP CO LTD

Anti-freezing concrete and preparation method thereof

The invention belongs to the field of building concrete, and particularly relates to a concrete admixture. The concrete admixture comprises components in percentage by weight as follows: 20%-30% of triethanolamine, 3%-5% of tartaric acid, 12%-25% of iron trichloride, 8%-12% of sodium chloride, 22%-25% of sucrose, 5%-10% of a surfactant and 20%-35% of sodium dodecyl sulfate. The multifunctional concrete admixture is reasonable in prescription and convenient to use, so that cement concrete can have the performance of water reduction, delayed coagulation, early strength, flexural strength, impermeability, anti-freezing, pumping and wear resistance.

Owner:QINGDAO RUNXIN WEIYE TECH & TRADE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com