Retarder for recycled aggregate mortar, and preparation method of retarder

A recycled aggregate and retarder technology, applied in the field of building materials, can solve the problems of large loss of mortar mixture consistency, poor fluidity of mortar mixture, and short operating time of mortar, so as to increase the setting time, Enhance the retarding effect and prolong the effect of setting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0030] Preparation Example 1: According to the ratio of raw materials in Table 1, (1) 10kg of corn stalks were pulverized into 1mm fiber material, the fiber material was placed in 5kg sodium hydroxide solution, kept at 30°C for 50min, and 5kg of ethanol and 5kg of chloroacetic acid, heated to 60°C in a water bath, and dried to a moisture content of 10%; (2) Heat the fiber material, 10kg of acrylic acid, 0.01kg of N,N-methylenebisacrylamide and 0.12kg of ammonium persulfate in a water bath to Stir at 70°C for 2 hours, dry, and crush to 0.4 mm to obtain straw colloid; (3) Mix 10 kg of phosphogypsum with straw colloid to obtain modified phosphogypsum, the particle size of which is 10 μm.

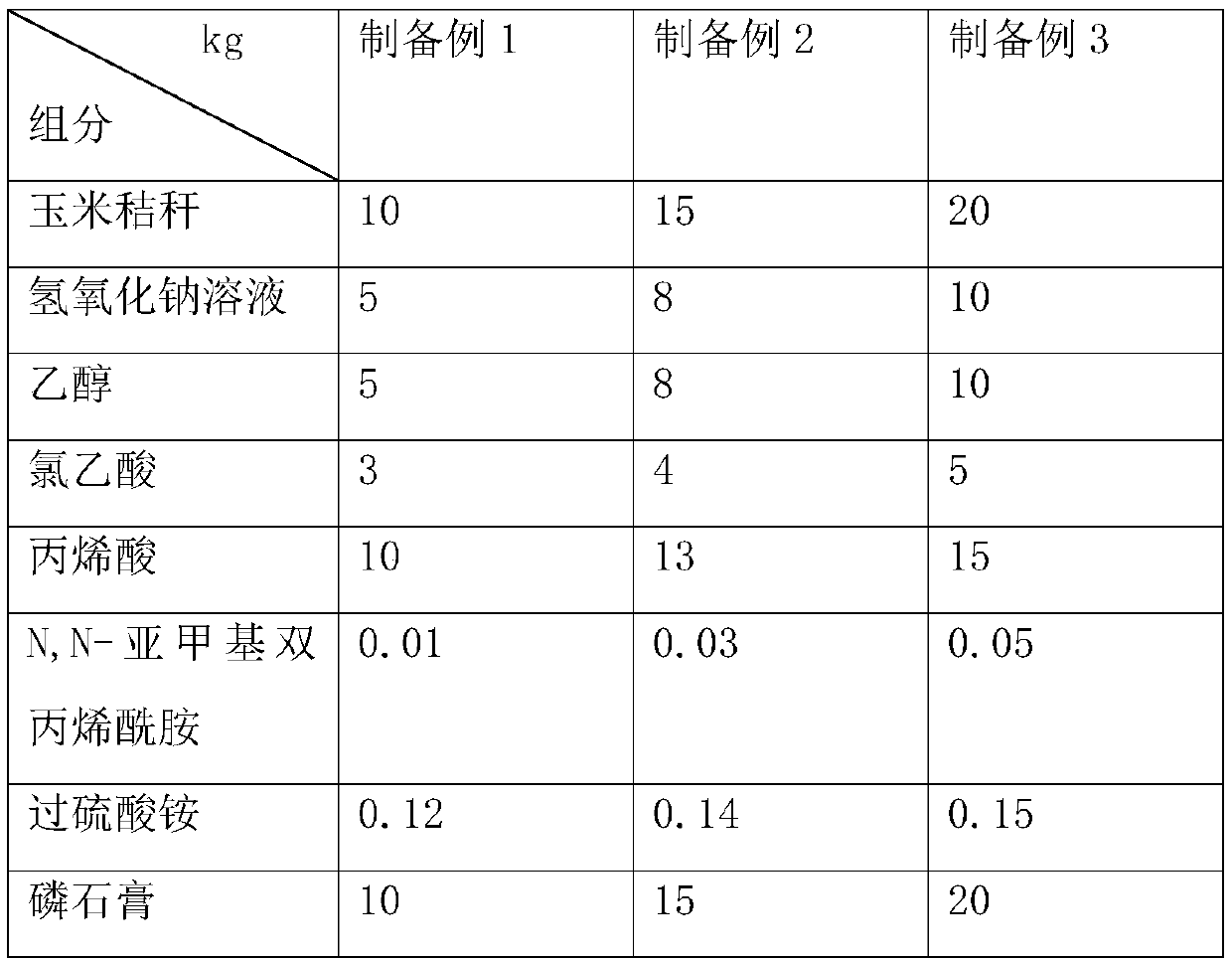

[0031]The raw material ratio of modified phosphogypsum in the preparation example 1-3 of table 1

[0032]

preparation example 2

[0033] Preparation example 2: according to the raw material proportioning in table 1, (1) 15kg corn stalks are pulverized into the fiber material of 8mm, fiber material is placed in 8kg sodium hydroxide solution, at 35 ℃ for 45min, add 8kg ethanol and 8kg of chloroacetic acid was heated to 65°C in a water bath and dried to a moisture content of 13%; (2) the fiber material, 13kg of acrylic acid, 0.03kg of N,N-methylenebisacrylamide and 0.14kg of ammonium persulfate were heated in a water bath to Stir at 75°C for 1.5h, dry, and crush to 0.5mm to obtain straw colloid; (3) Mix 15kg of phosphogypsum with straw colloid to obtain modified phosphogypsum with a particle size of 15μm.

preparation example 3

[0034] Preparation example 3: according to the raw material proportioning in table 1, (1) 20kg corn stalks are pulverized into the fibrous material of 15mm, the fibrous material is placed in 10kg sodium hydroxide solution, kept at 40 ℃ for 40min, add 10kg ethanol and 10kg of chloroacetic acid was heated to 70°C in a water bath and dried to a moisture content of 15%; (2) the fiber material, 15kg of acrylic acid, 0.05kg of N,N-methylenebisacrylamide and 0.14kg of ammonium persulfate were heated in a water bath to Stir at 80°C for 1 hour, dry, crush to 0.4mm to obtain straw colloid; (3) Mix 20kg of phosphogypsum with straw colloid to prepare modified phosphogypsum, the particle size of phosphogypsum is 20μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com