Chloride-free enhanced slump-retaining cement grinding aid and preparation method thereof

A cement grinding aid and slump-preserving technology, which is applied in the field of cement additives, can solve the problems of unsustainable cement strength, affecting the use effect of concrete, and the lack of obvious strength effect of cement in the later stage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

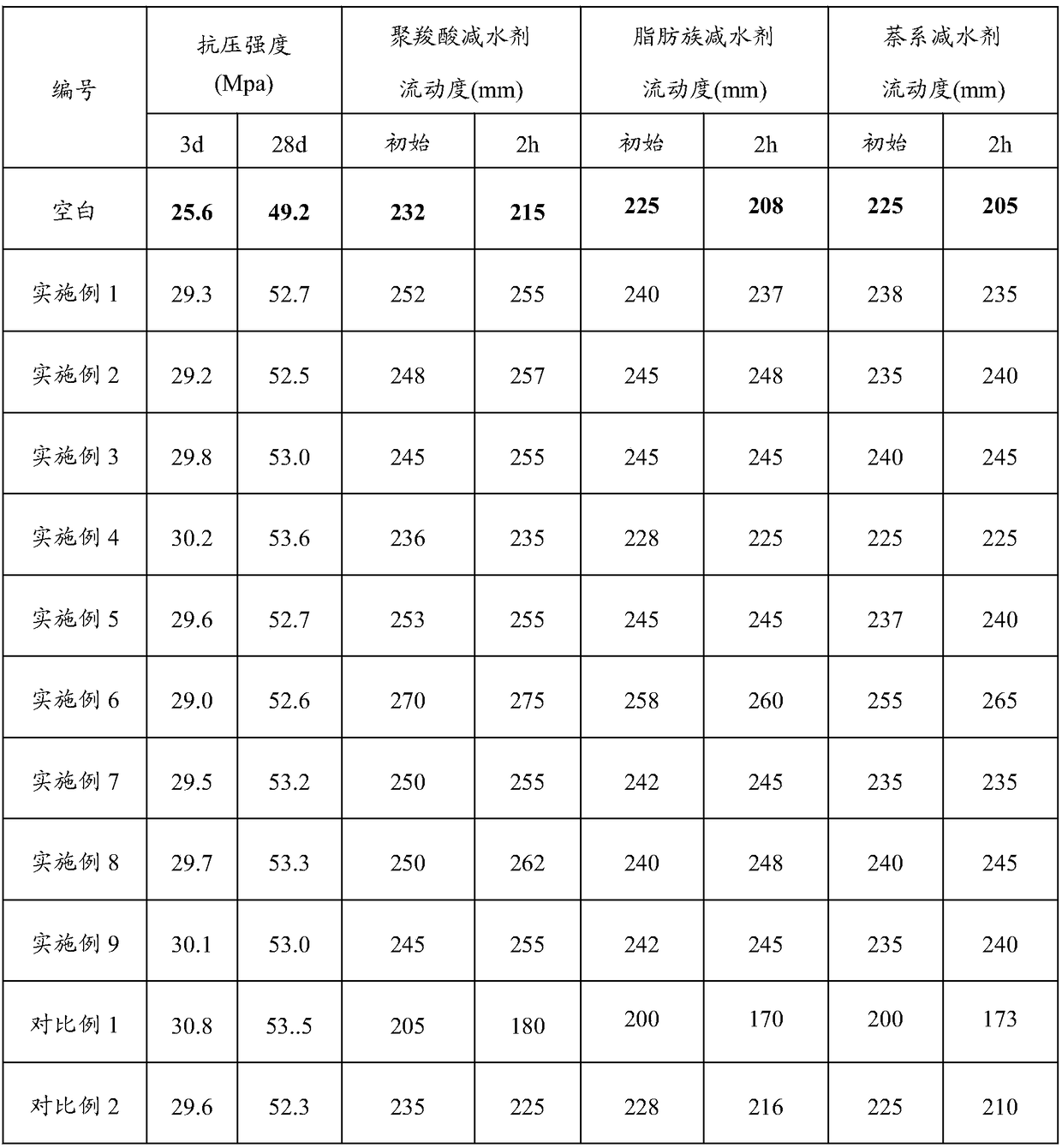

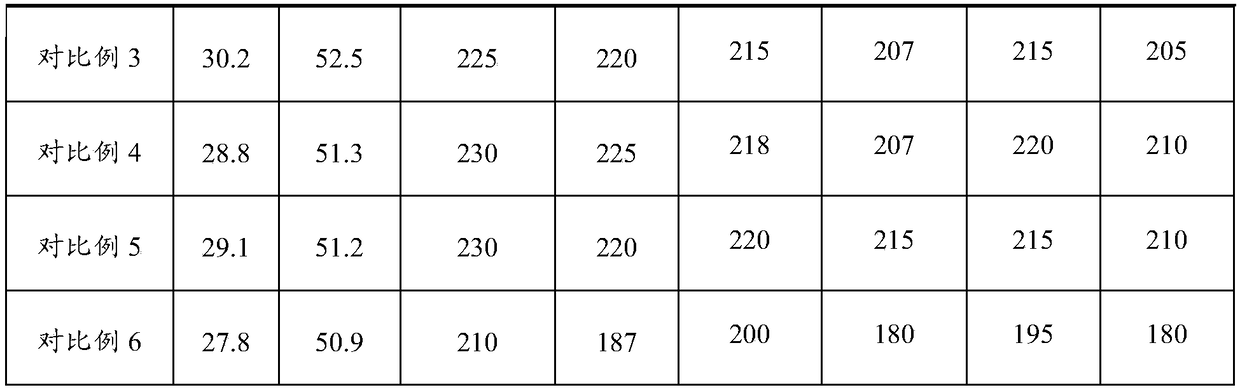

Examples

preparation example Construction

[0041] The present invention also provides a preparation method of the chlorine-free enhanced cement grinding aid described in the above technical solution, comprising the following steps:

[0042] 1) Weigh raw materials: diethanol monoisopropanolamine, triethanolamine, sodium formate, organic phosphonate retarder, polymer dispersant, molasses, and the remaining water;

[0043] 2) Add the water in step 1) into the mixing tank, stir, slowly add sodium formate to dissolve it completely, and continue stirring to obtain a sodium formate solution;

[0044] 3) Add diethanol monoisopropanolamine, triethanolamine, organic phosphonate retarder, and polymer dispersant in sequence to the sodium formate solution in step 2), and stir to obtain a mixed solution;

[0045] 4) Add molasses to the mixed solution in step 3), and stir to obtain cement grinding aid.

[0046] Preferably, the stirring time of step 3) is 2 min.

[0047] Preferably, the stirring time of step 4) is 5 minutes.

Embodiment 1

[0050] Prepare cement grinding aid, its composition raw material is by weight: 5 parts of diethanol monoisopropanolamine, 8 parts of triethanolamine, 15 parts of sodium formate, 1 part of disodium hydroxyethylidene diphosphonate, 1 part of polyepoxysuccinic acid parts, molasses 2 parts, water 68 parts;.

Embodiment 2

[0052] Prepare cement grinding aid, its composition raw material is by weight: 5 parts of diethanol monoisopropanolamine, 8 parts of triethanolamine, 15 parts of sodium formate, 1 part of potassium hydroxyethylidene diphosphonate, 1 part of sodium polyepoxysuccinate 1 part, 2 parts molasses, 68 parts water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com