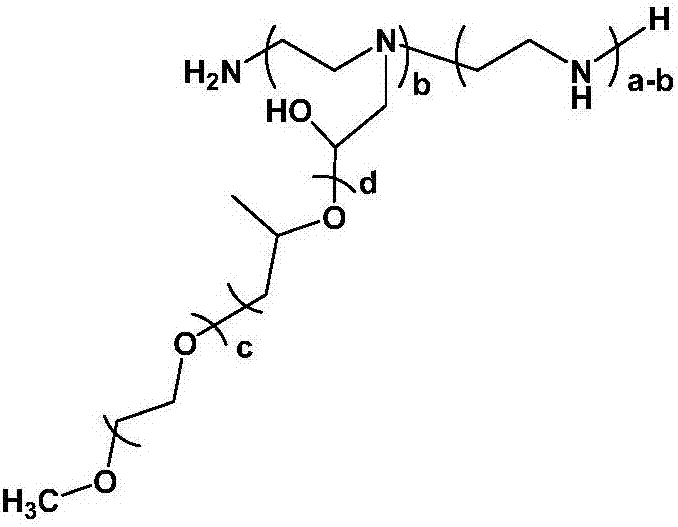

Aminated polyether intermediate, preparation method and application

An intermediate and polyether technology, which is applied in the field of concrete admixture preparation, can solve the problems of uncontrollable side reactions of copolymerization reaction, uncontrollable molecular structure and weight average molecular weight of water reducer, easy chain transfer of phosphorus-containing groups, etc. , to achieve the effect of high reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

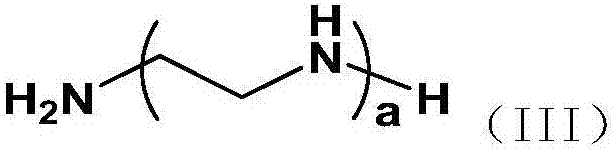

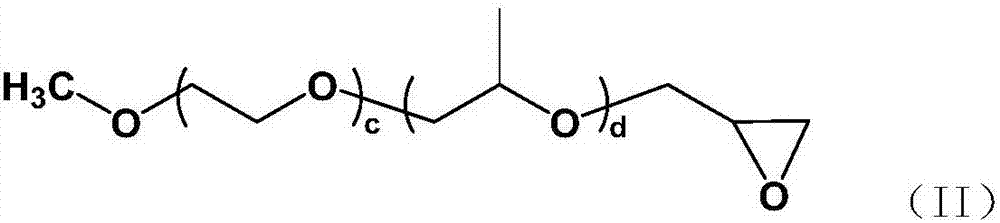

Method used

Image

Examples

Embodiment 1

[0072] Preparation of polyether-based glycidyl ether M-1.

[0073] Weigh 1000 parts of methoxypolyether (M n =1000, b=18, c=3) into the reactor, then add 300 parts of solvent water, and then add 42 parts of NaOH. After stirring evenly, control the temperature of the reaction system between 30°C and 60°C, weigh 278 parts of epichlorohydrin and gradually add it to the above reaction system, and then weigh 2 parts of the catalyst tetrabutylammonium bromide and add it to the reaction system. After the addition, the reaction kettle was closed, and the temperature was raised to 80° C., and the reaction was continued for 20 h. After the reaction, under the condition of 60℃~80℃, distill off the volatile components under reduced pressure, including the unreacted epichlorohydrin and the reaction solvent water, to obtain a viscous light brown solid, and the reaction system was titrated by acid-base titration In the consumption of NaOH, the conversion rate of methoxy polyether is 99.4%....

Embodiment 2

[0082] Weigh 1952 parts of polyethyleneimine (a=45) as a primer, and heat up to 60-80°C. Weigh 15840 parts of M-1 and add 15840 parts of water to dilute, then gradually add to the reaction system. After the addition was completed, the temperature was raised to 100° C., and the reaction was continued for 5 h to obtain a tan liquid. Add 6 parts of phosphoric acid to neutralize excess NaOH.

[0083] Use room temperature cooling circulating water to cool the reaction system, under the condition of strong stirring, add 1952 parts of concentrated hydrochloric acid, add 2706 parts of phosphorous acid, and then gradually add 2676 parts of 37wt% formaldehyde, after the addition is completed, the temperature is raised to 100 ° C, and the reaction is continued for 20 hours to obtain Wine red liquid, tested by GPC, the weight average molecular weight is 19894, PDI=1.91.

Embodiment 3

[0085] Weigh 877 parts of polyethyleneimine (a=20) as a primer, and heat up to 60-80°C. Weigh 16448 parts of M-2 and dilute with 10965 parts of water, then gradually add to the reaction system. After the addition was completed, the temperature was raised to 80° C., and the reaction was continued for 12 hours to obtain a tan liquid. Add 12 parts of phosphoric acid to neutralize excess KOH.

[0086] Use room temperature cooling circulating water to cool the reaction system, under the condition of strong stirring, add 877 parts of concentrated sulfuric acid, add 1292 parts of phosphorous acid, then gradually add 37wt% formaldehyde 1338 parts, after the addition is completed, the temperature is raised to 110 ° C, and the reaction is continued for 15 hours to obtain Wine red liquid, tested by GPC, the weight average molecular weight is 18642, PDI=1.71.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com