Methacryloyloxyethyl-dimethyl ammonium propanesulfonate and preparation method thereof

A technology of ammonium methacryloyloxyethyldimethylpropanesulfonate and ethyl dimethylamino methacrylate is applied in the preparation of sulfonates, organic chemistry, etc., and can solve the problems of high preparation cost, poor controllability, Complex preparation process and other problems, to achieve high yield, eliminate steel corrosion, and simplify the process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

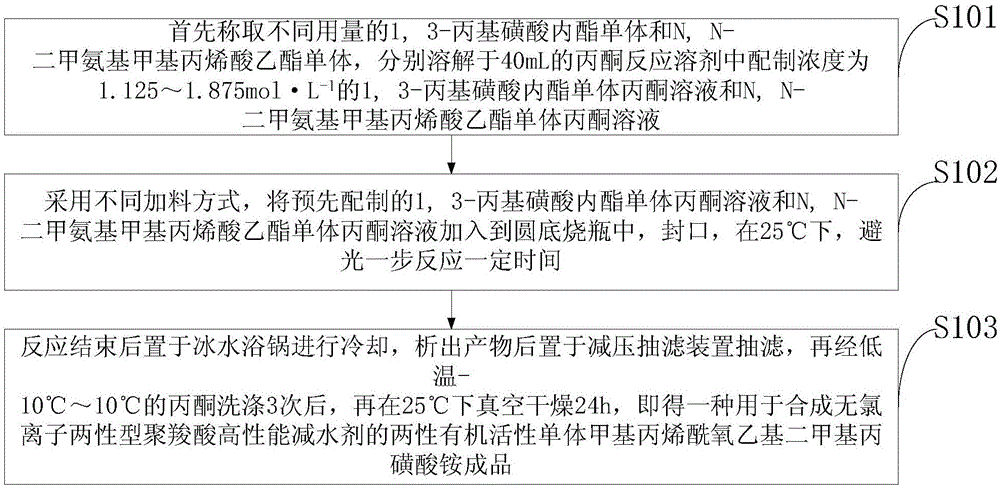

[0022] Such as figure 1 Shown: the preparation method of a kind of methacryloyloxyethyl ammonium dimethyl propane sulfonate provided by the invention comprises the following steps:

[0023] S101: First, weigh different amounts of 1, 3-propyl sultone monomer and N, N-dimethylaminoethyl methacrylate monomer, and dissolve them in 40 mL of acetone reaction solvent to prepare a concentration of 1.125- 1.875mol·L -1 1, 3-propyl sultone monomer acetone solution and N, N-dimethylaminoethyl methacrylate monomer acetone solution;

[0024] S102: Using different feeding methods, add the pre-prepared 1, 3-propyl sultone monomer acetone solution and N, N-dimethylaminoethyl methacrylate monomer acetone solution into the round bottom flask, seal , at 25°C, one-step reaction in the dark for a certain period of time;

[0025] S103: After the reaction is completed, place it in an ice-water bath for cooling. After the product is precipitated, place it in a vacuum filtration device for suction ...

Embodiment 1

[0040] Accurately weigh 1, 3-propyl sultone monomer (purity above 99%) and 9.4g of N, N-dimethylaminoethyl methacrylate monomer (purity above 99%), dissolve them separately Prepare 1,3-propyl sultone monomer acetone solution and N, N-dimethylaminoethyl methacrylate monomer acetone solution in 40mL of acetone reaction solvent; , 3-Propyl sultone monomer acetone solution and N, N-dimethylaminoethyl methacrylate monomer acetone solution were added to a round bottom flask, sealed, and reacted for a certain period of time at 25°C in the dark; Cool in an ice-water bath, filter with suction, wash with low-temperature acetone for 3 times, and then vacuum-dry at 25°C for 24 hours to obtain an amphoteric organic active monomer for synthesizing a chloride-free amphoteric polycarboxylate high-performance water reducer Ammonium methacryloxyethyl dimethyl propane sulfonate finished product.

[0041] Preferably, the molar ratio of 1,3-propyl sultone monomer to N, N-dimethylaminoethyl methac...

Embodiment 2

[0047] It is basically the same as Example 1, the difference is:

[0048] Preferably, the molar ratio of 1,3-propyl sultone monomer to N,N-dimethylaminoethyl methacrylate monomer in the step is 0.75:1.

[0049] Preferably, the different feeding methods in the steps are using the acetone reaction solvent as the base liquid, and adding N, N-dimethylaminoethyl methacrylate monomer and 1, 3-propyl sultone monomer in sequence.

[0050] Preferably, the one-step reaction time at 25° C. protected from light in the step is 36 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com