High corrosion resistant marine cement cementing material and preparation method thereof

A cement glue and high-resistance technology, which is applied in the construction field, can solve problems such as aging, and achieve the effects of increasing density, reducing dry shrinkage, and reducing frictional resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

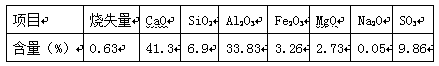

Method used

Image

Examples

Embodiment 1

[0063] A high-corrosion-resistant marine cement cementitious material, including the following raw materials in parts by weight: 20 parts of wollastonite; 80 parts of sulfoaluminate cement; 30 parts of nano-type hydrotalcite; 20 parts of fiber; 80 parts of coral reef sand; 50 parts of polyacrylamide; 20 parts of modified acrylic emulsion; 10 parts of admixture.

[0064] The preparation method of the high-corrosion-resistant marine cement cementitious material is as follows:

[0065] (1) Mix wollastonite, sulphoaluminate cement, nano hydrotalcite, and coral reef sand in parts by weight, crush them, and then calcinate at 600-800°C;

[0066] (2) After calcination, put it into a mixing bucket, add fiber, polyacrylamide, modified acrylic emulsion, and admixture in parts by weight in sequence, and stir with a high-shear mixer; the shear speed is 500 rpm, and the time is 10 minutes;

[0067] (3) The obtained material is dried in a dryer at a temperature of 80°C for 30 minutes. After...

Embodiment 2

[0069] A high-corrosion-resistant marine cement gelling material, comprising the following raw materials in parts by weight: 25 parts of wollastonite; 100 parts of sulphoaluminate cement; 50 parts of nano-type hydrotalcite; 30 parts of fiber; 100 parts of coral reef sand; 60 parts of polyacrylamide; 30 parts of modified acrylic emulsion; 15 parts of admixture.

[0070] The preparation method of the high-corrosion-resistant marine cement cementitious material is as follows:

[0071] (1) Mix wollastonite, sulfoaluminate cement, nano hydrotalcite, and coral reef sand in parts by weight, crush them, and then calcinate at 800°C;

[0072] (2) After calcination, put it into a mixing bucket, add fiber, polyacrylamide, modified acrylic acid emulsion, and admixture in parts by weight in sequence, and stir with a high-shear mixer; the shear speed is 1000 rpm, and the time is 15 minutes;

[0073] (3) The obtained material is dried in a dryer at a temperature of 150°C for 60 minutes. Afte...

Embodiment 3

[0075] A high-corrosion-resistant marine cement gelling material, comprising the following raw materials in parts by weight: 23 parts of wollastonite; 90 parts of sulphoaluminate cement; 40 parts of nano-type hydrotalcite; 25 parts of fiber; 90 parts of coral reef sand; 55 parts of polyacrylamide; 25 parts of modified acrylic emulsion; 13 parts of admixture.

[0076] The preparation method of the high-corrosion-resistant marine cement cementitious material is as follows:

[0077] (1) Mix wollastonite, sulfoaluminate cement, nano hydrotalcite, and coral reef sand in parts by weight, crush them, and then calcinate at 700°C;

[0078] (2) After calcination, put it into a mixing bucket, add fiber, polyacrylamide, modified acrylic acid emulsion, and admixture in parts by weight in sequence, and stir with a high-shear mixer; the shear speed is 800 rpm, and the time is 13 minutes;

[0079] (3) The obtained material is dried in a dryer at a temperature of 100°C for 45 minutes. After t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com