Sulfoaluminate-Portland cement composite system additive, fast-hardening early-strength concrete and preparation method of concrete

A technology of portland cement and sulfoaluminate, applied in the direction of organic chemistry, can solve the problems that it is difficult to show good adaptability of the binary composite system, so as to enhance the high plastic retention effect, avoid the freezing of water at low temperature, increase the Effect of Calcium Solubility and System Alkalinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

[0033] Sulphoaluminate-Portland cement composite system admixture

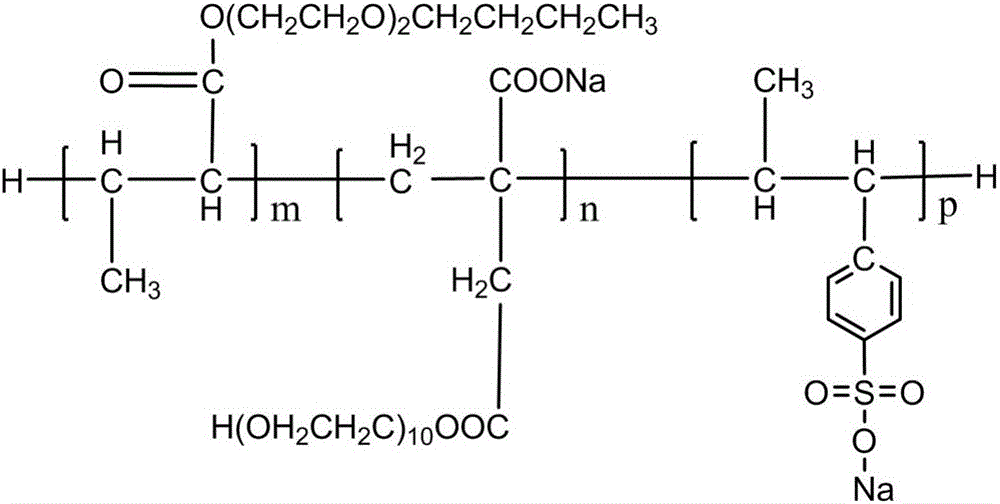

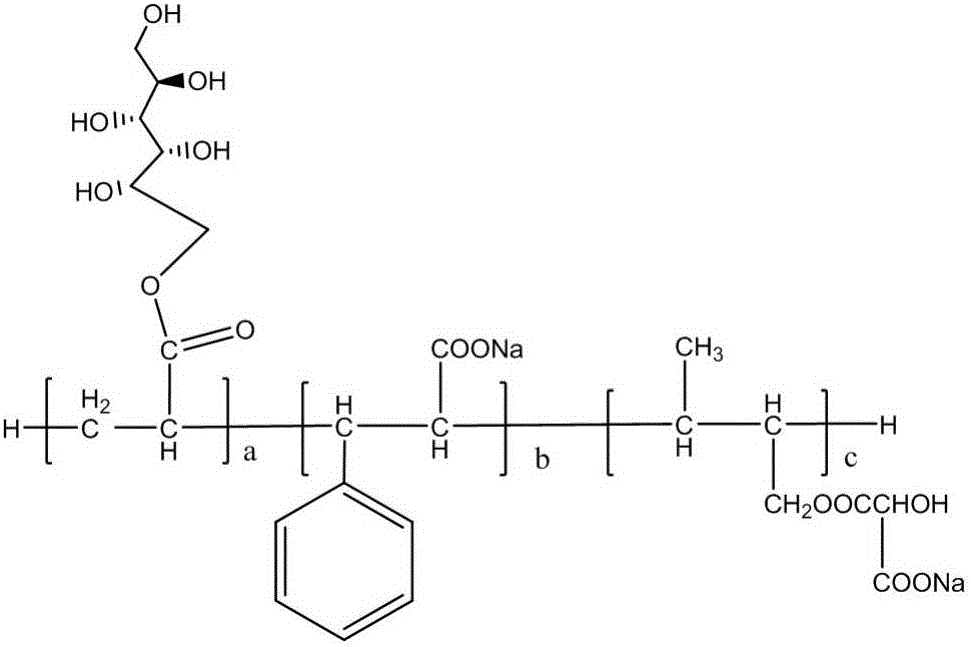

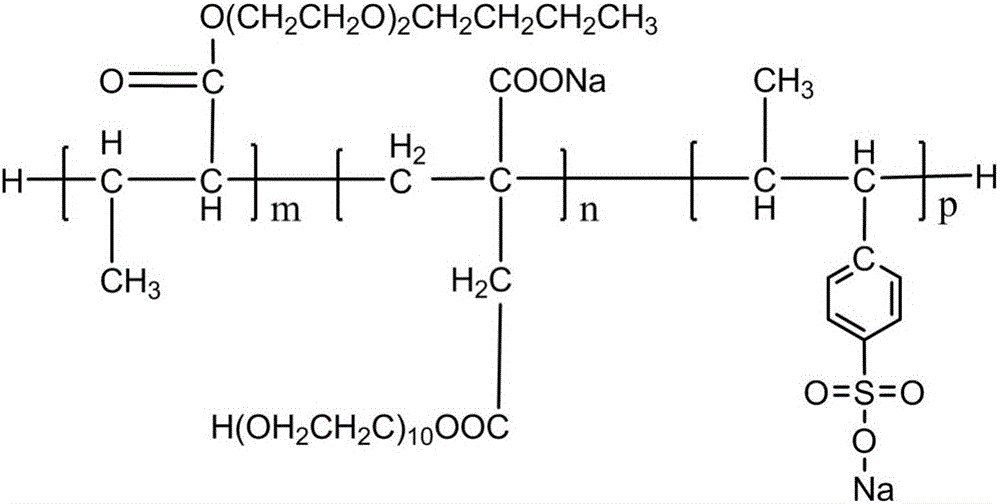

[0034] The mass percentages of each component in the admixture of the sulphoaluminate-Portland cement composite system described in Examples 1-3 are shown in Table 1, respectively. The structural formula of the water reducing agent used is:

[0035]

[0036] Wherein, m=48; n=44; p=22; the molecular weight of the water reducer is controlled to be 42000, and its preparation method comprises the following steps: 1) adding crotonic acid and polyethylene glycol butyl ether to the reaction in a molar ratio of 1:0.8 In the kettle A, add 4-dimethylaminopyridine accounting for 1.5% of the total mass of the solution in the reactor A and hydroquinone accounting for 0.3% of the total mass of the solution in the reactor A, stir and heat to 90° C., and keep warm for 6 hours to obtain product A ; Methylene succinic acid and polyvinyl alcohol are added in the reaction kettle B at a molar ratio of 1:1.2, and the concentrat...

Embodiment 4-6

[0049] Sulfoaluminate-Portland cement-based rapid-hardening early-strength concrete

[0050] The sulfoaluminate-portland cement composite system admixture prepared in Example 1 is used to prepare sulfoaluminate-portland cement-based rapid-hardening early-strength concrete. The mix ratio is shown in Table 4, and the performance test results of the concrete are shown in Table 5. Among them, sulfoaluminate-portland cement is made by mixing sulfoaluminate cement (SAC) and portland cement (POC). The specific mixing ratio is shown in Table 4.

[0051] The mixing ratio (kg / m3) of the rapid-hardening early-strength concrete prepared in table 4 embodiment 4~6 3 )

[0052]

[0053] The performance testing result of the rapid-hardening early-strength concrete prepared by table 5 embodiment 4-6

[0054]

[0055] As can be seen from Table 5, the concrete prepared by the sulphoaluminate-Portland cement composite system admixture prepared in Example 1, along with the increase of its ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com