Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

84results about How to "Good low speed performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

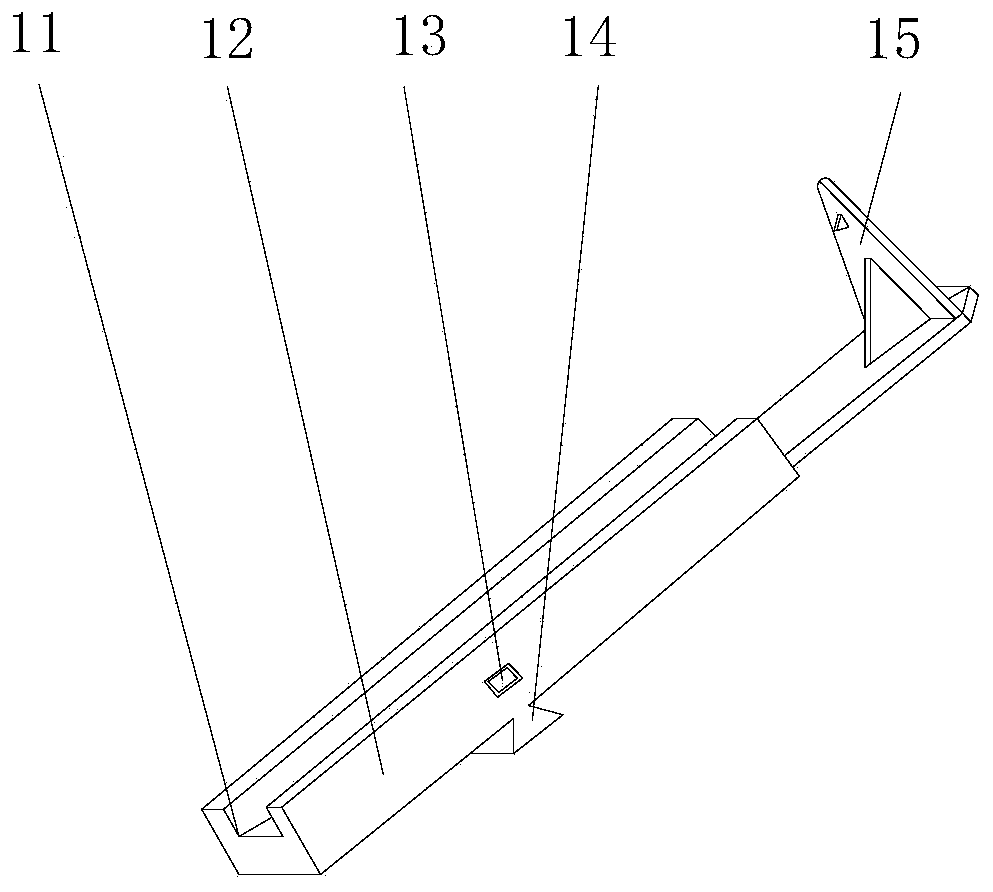

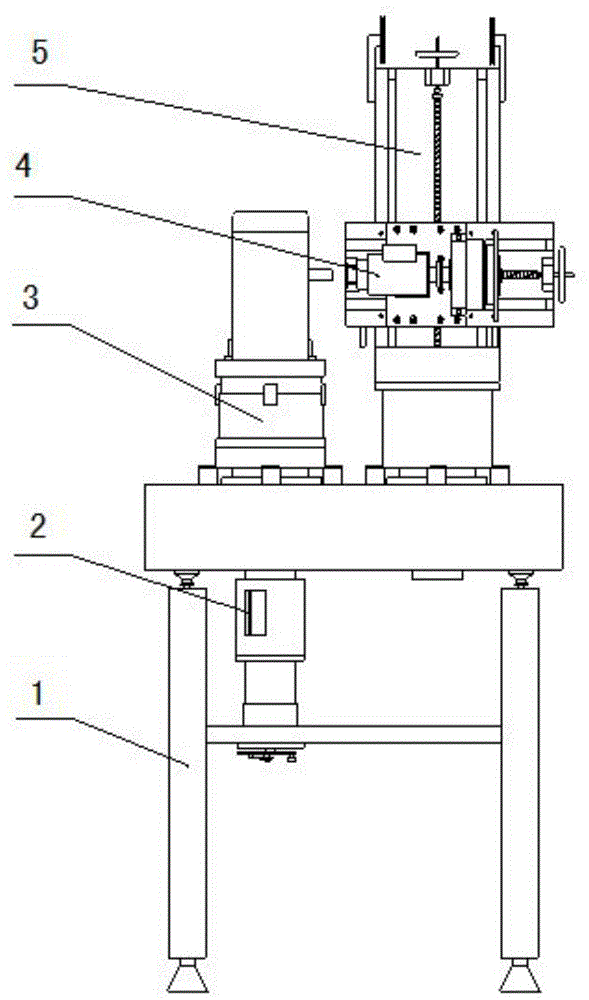

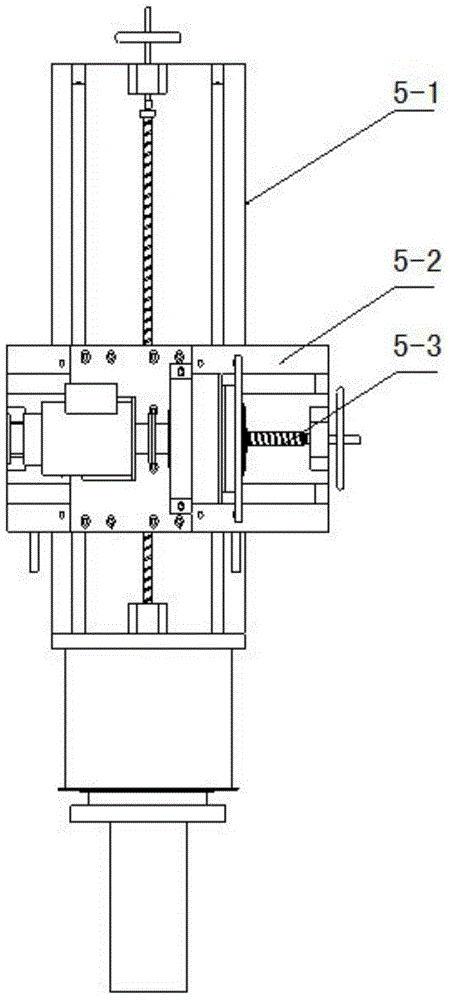

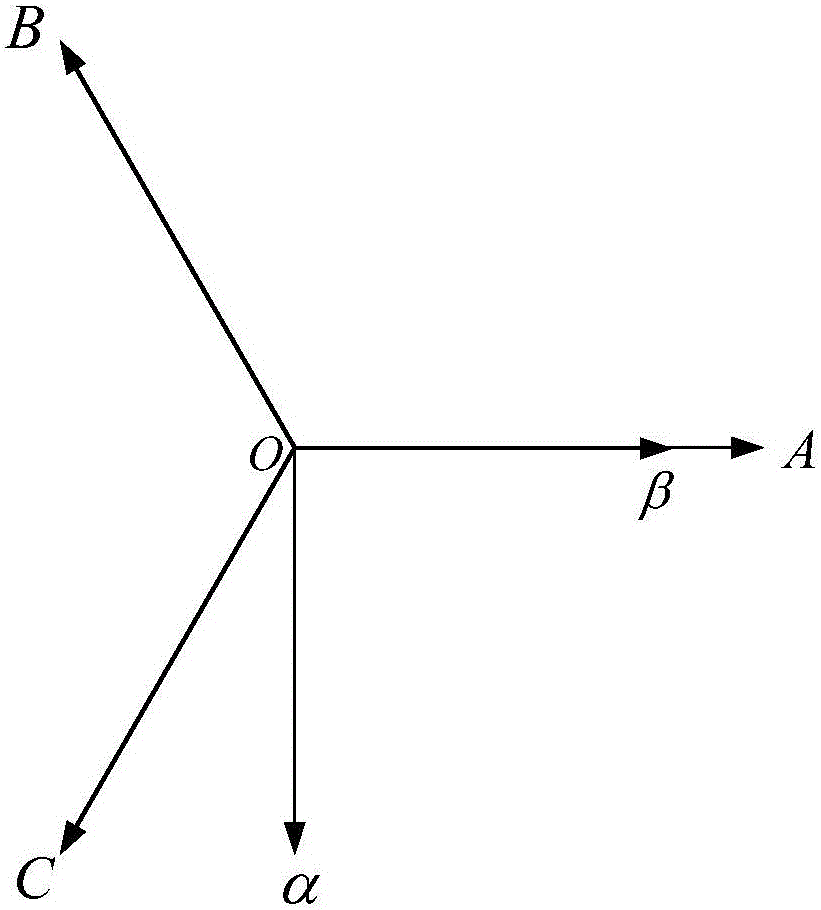

Space positioning platform

InactiveCN103738882ASimple structureReasonable designLifting framesRectangular coordinatesReciprocating motion

The invention discloses a space positioning platform which comprises an X-direction guide rail, a Y-direction guide rail driven by an X-direction driving mechanism to be in linear reciprocating motion along the X-direction guide rail, a Z-direction guide rail driven by a Y-direction driving mechanism to be in linear reciprocating motion along the Y-direction guide rail, and a carrying platform driven by a Z-direction driving mechanism to be in up-down reciprocating motion along the Z-direction guide rail. The Y-direction guide rail is mounted on the X-direction guide rail , the Z-direction guide rail is mounted on the Y-direction guide rail, the carrying platform is mounted on the Z-direction guide rail, and the X-direction driving mechanism, the Y-direction driving mechanism and the Z-direction driving mechanism form a servo driving system for adjusting position of the carrying platform in directions X-axis, Y-axis and Z-axis of a space rectangular coordinate system. The space positioning platform is simple in structure, reasonable in design, simple and convenient to use and operate, good in using effect and high in positioning efficiency, and the problem that an existing lifting device is single in moving direction, inaccurate in positioning, poor in reliability and the like can be effectively solved.

Owner:CHANGAN UNIV

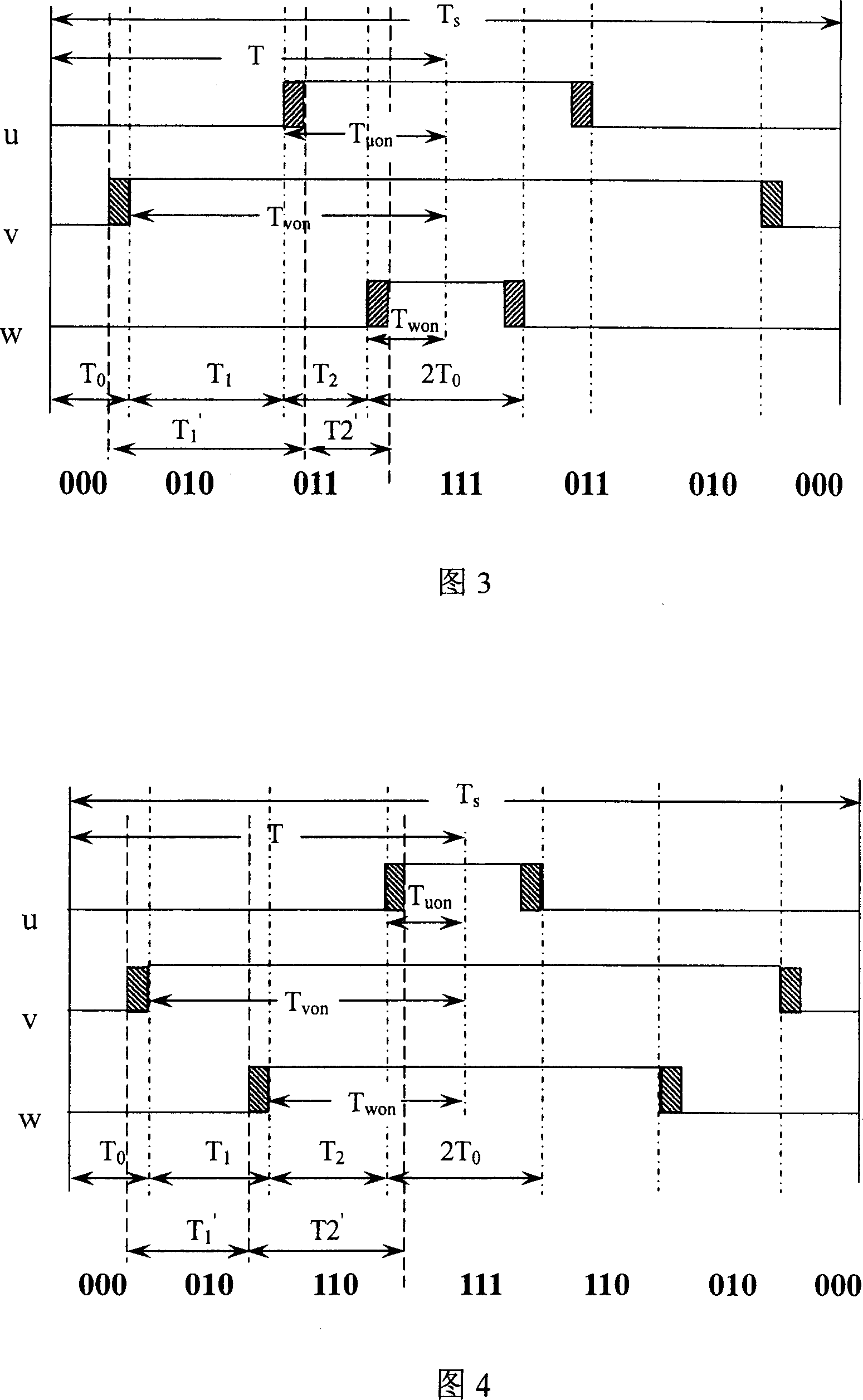

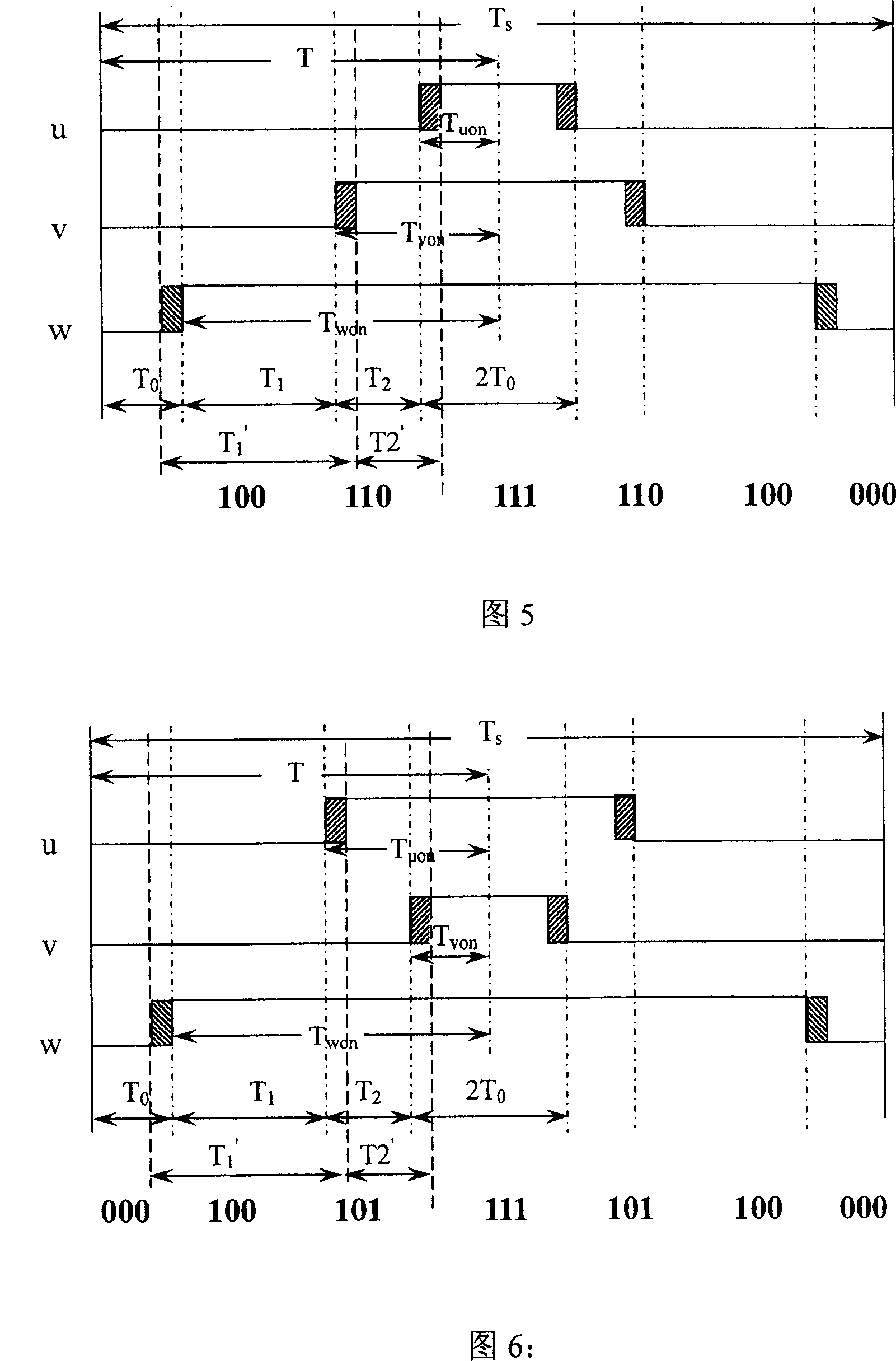

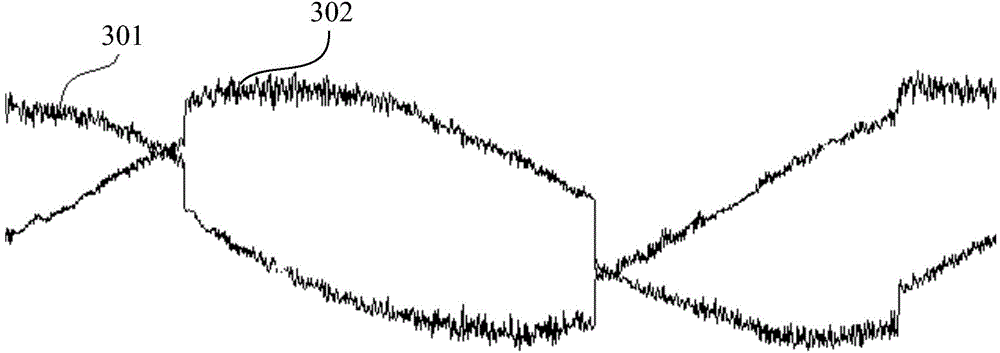

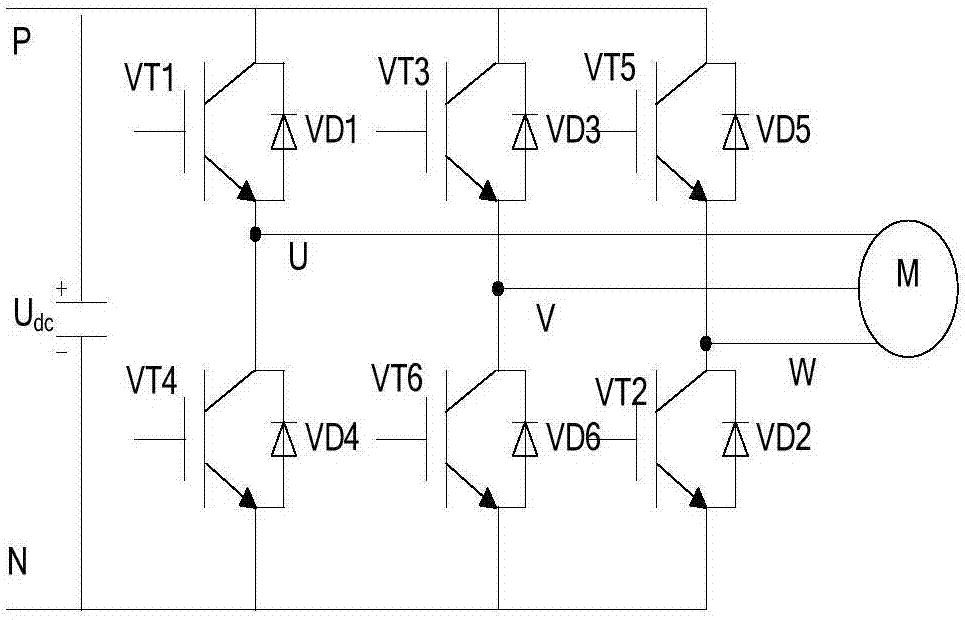

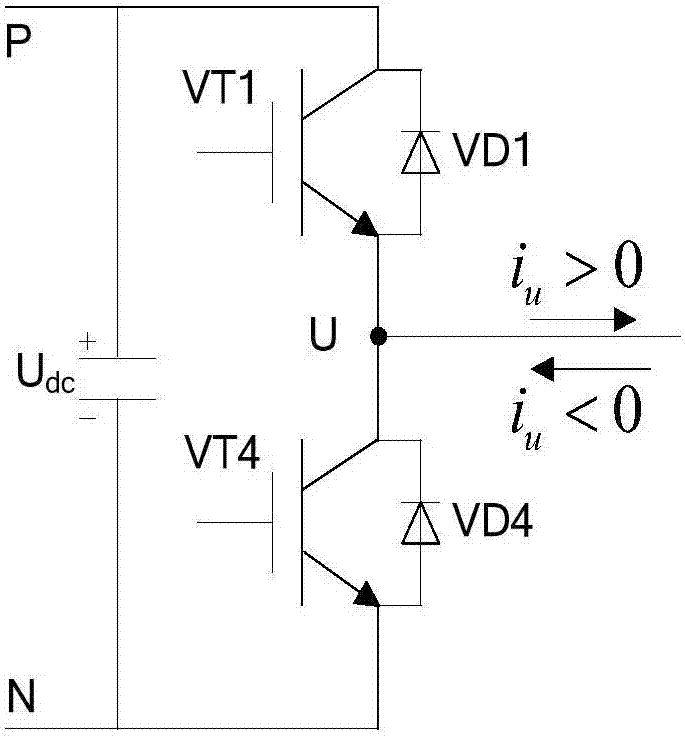

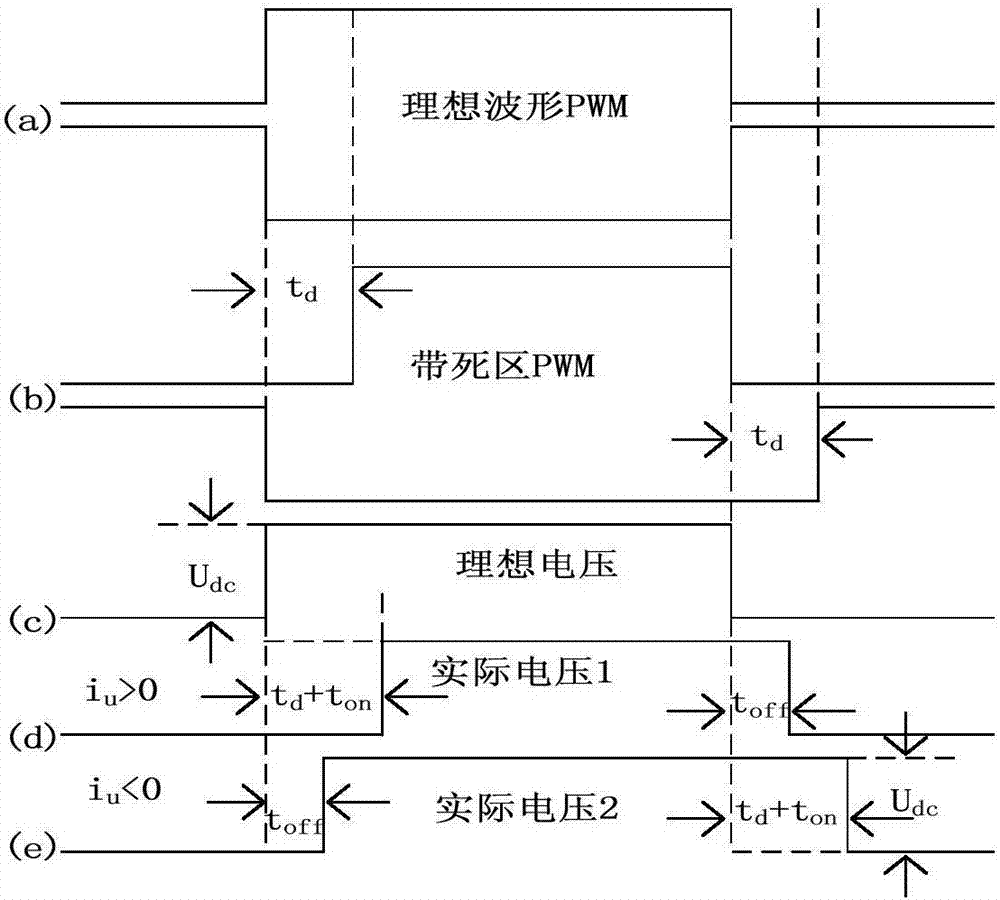

Dead zone compensating method for space vector pulse width modulating output

InactiveCN1988365AEliminate torque rippleGood low speed performanceElectronic commutation motor controlAC motor controlPhase currentsSynchronous motor

This invention relates to a dead zone compensation method for SVPWM output including: taking an expected value of the output three-phase voltage of a magnet synchronous motor as the pulse width expected value output by modulation of three bridge arm pulse width of an inverter, taking the combined value of the expected values of the pulse width output by the modulation of U, V and W as the voltage space vector output expected value of the inverter of an AC servo system, taking the designed dead zone time of the output pulse modulation as the expected value of the dead zone compensation time and utilizing the polarity of each output phase current of a magnet synchronous motor, the expected value of the voltage space vector and that of the dead zone compensation time to compute the acting time of each voltage space vector.

Owner:AUTOMATION RES & DESIGN INST OF METALLURGICAL IND

Magnetic-gas bearing and method for making compliant foil

InactiveCN1730959AShorten the axial lengthImprove performanceBearing componentsMagnetic bearingsMagnetic tension forceMagnetic poles

The mixed magnetic air journal bearing is mixed bearing of active magnetically suspension bearing and dynamic pressure air journal bearing, and includes active magnetically suspension radial bearing, elastic foil embedded between magnetic poles of the magnetically suspension radial bearing, and locking mechanism comprising locking wedge block, inclined blocks, bearing block, gag, screw and stop washer. The elastic foil with pre-wedged angle, has one end held onto the magnetic pole and has higher static and dynamic performance than rigid bearing. Owing to the magnetic force to suspend the rotor in the balance position and fluid force to deform the foil for coupling the interval of the air film, the rotor-bearing reaches ultimate stable balance. The bearing has simple structure, has the advantages of both active magnetically suspension bearing and foil bearing, excellent damping characteristic and improved structure rigidity and dynamic characteristic.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

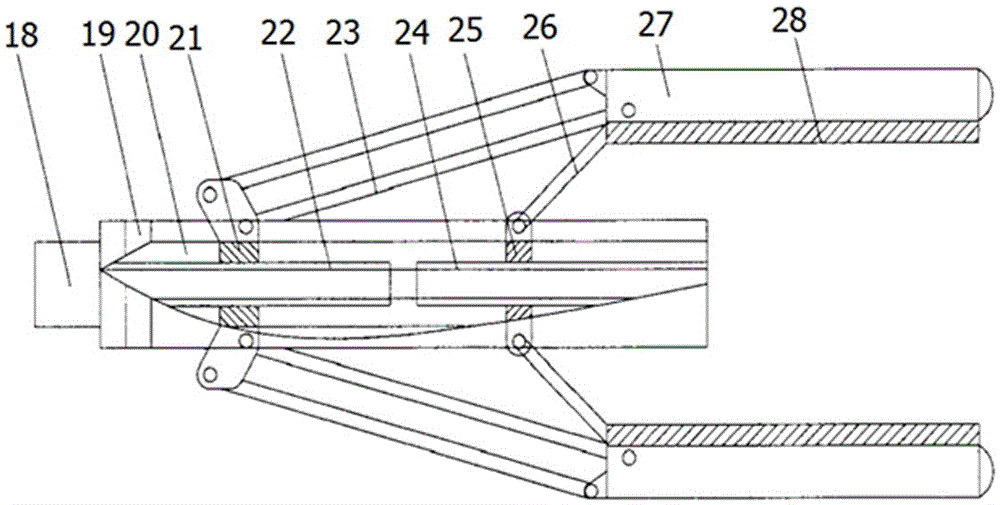

Novel five-freedom-degree manipulator

InactiveCN106541395AReduce pollutionMove quicklyProgramme-controlled manipulatorEngineeringDegrees of freedom

A novel five-freedom-degree manipulator is composed of a machine base, a waist, a stand arm, a cantilever, a wrist, an end effector, a driving device and a transmission device. The novel five-freedom-degree manipulator has five freedom degrees, can simulate human hand actions, has the advantages of rapid action, good applicability, rapid response and the like, and is high in stability, and the phenomenon that the manipulator cannot work normally due to being easily affected by the environment is avoided; and in the using process, the manipulator is unobvious in leakage, low in environmental pollution, simple in structure, high in rigidity, good in low-speed performance, large in power, high in positioning precision, extremely high in production reliability, quite high in flexibility and high in universality.

Owner:张桂春

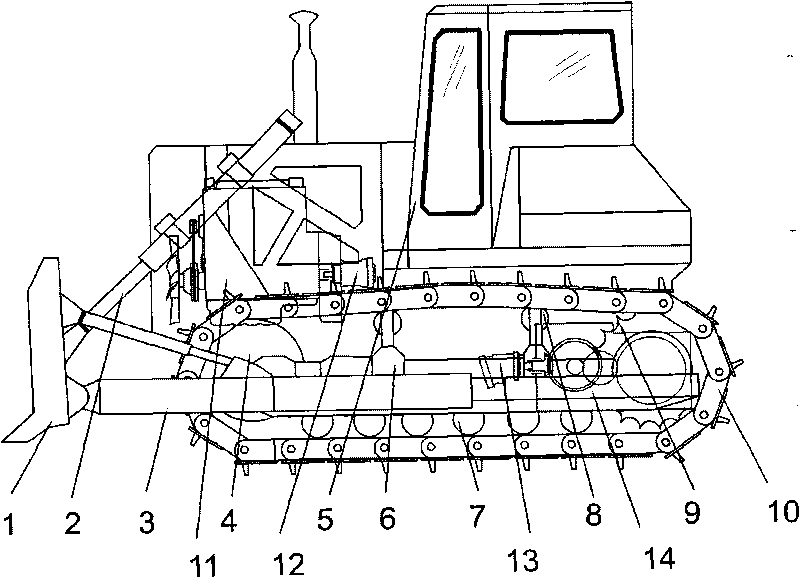

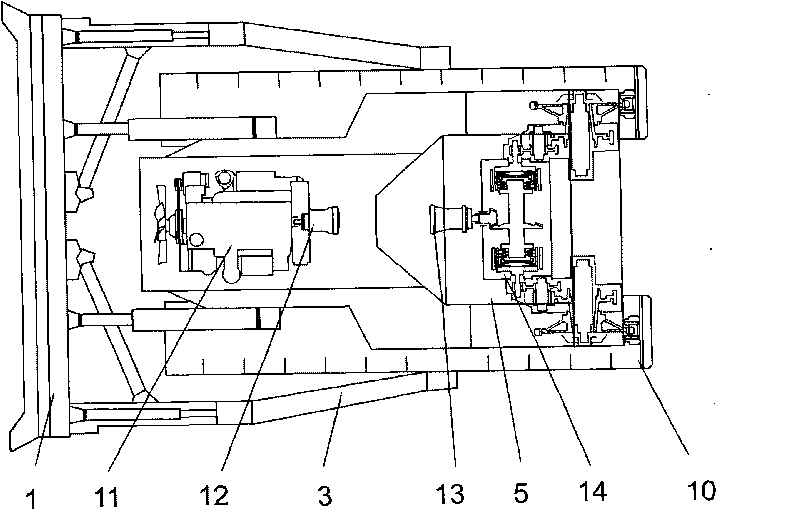

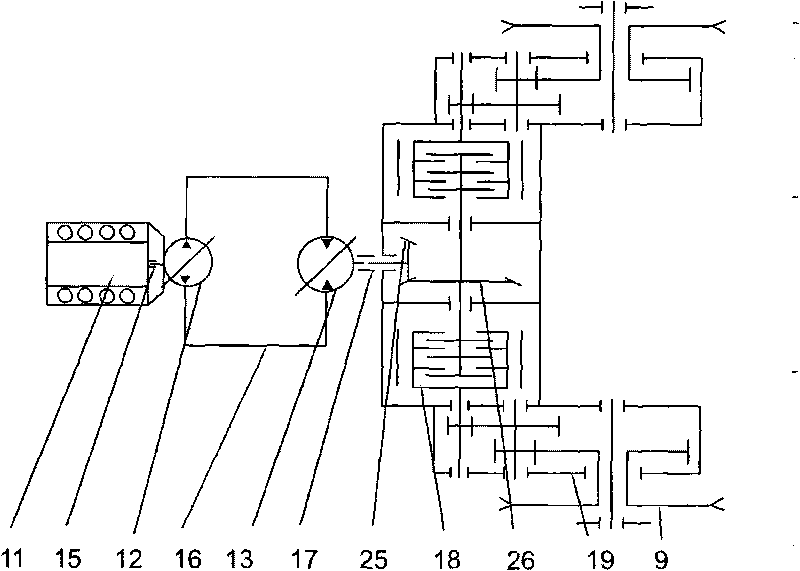

Full hydraulic transmission-based crawler bulldozer

InactiveCN101736765ARealize stepless transmissionImplement power controlMechanical machines/dredgersVehicle frameAgricultural engineering

The invention belongs to the technical field of mechanical engineering, and particularly relates to a full hydraulic transmission-based crawler bulldozer. The full hydraulic transmission-based crawler bulldozer consists of a bulldozer blade, a hydraulic oil cylinder, a push rod, a body, a cab, a frame, a track roller, a carrier roller, a drive sprocket, a crawler track, an engine, a variable hydraulic pump, a hydraulic motor, a crawler drive axle, a hydraulic hose and couplings, wherein the upper part of the bulldozer blade is hinged with the hydraulic oil cylinder; the wall of the hydraulic oil cylinder is fixed to the body and the cab; the lower part of the bulldozer blade is hinged with the push rod; the push rod is hinged with the frame; the frame is positioned on the crawler track through the track roller; the front part of the frame is provided with a guide roller, and the upper part of the frame is provided with the carrier roller; the engine is connected with the variable hydraulic pump through a first coupling; the variable hydraulic pump is connected with the hydraulic motor through the hydraulic hose; the hydraulic motor is connected with the crawler drive axle through a second coupling; the crawler drive axle drives the drive sprocket; and the drive sprocket is engaged with the crawler track. The engine can be flexibly arranged because the hydraulic hose for conveying hydraulic fluid has the characteristic of flexibility. The full hydraulic transmission-based crawler bulldozer realizes stepless transmission of the bulldozer in a true sense; the power of the hydraulic motor cannot be interrupted during a variable-displacement gear change; and the operation is simple.

Owner:TONGJI UNIV

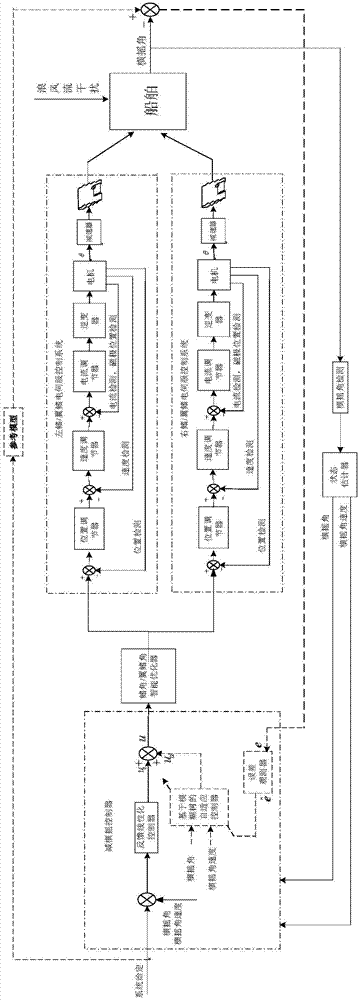

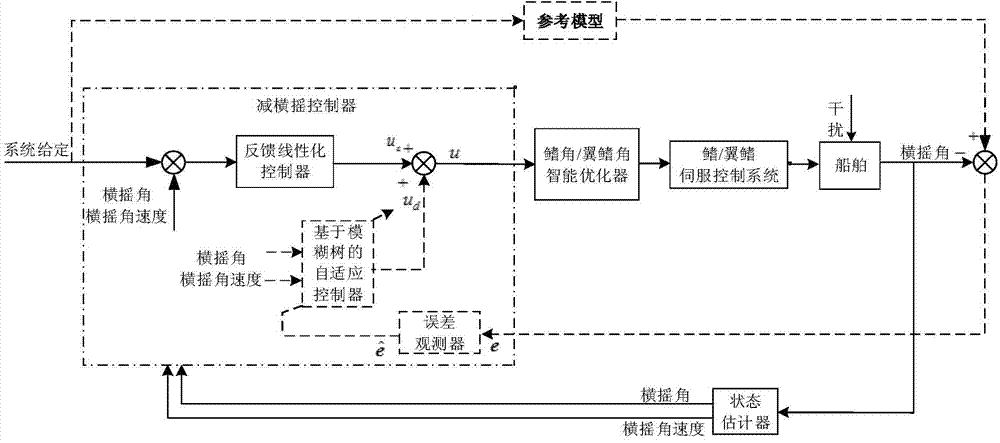

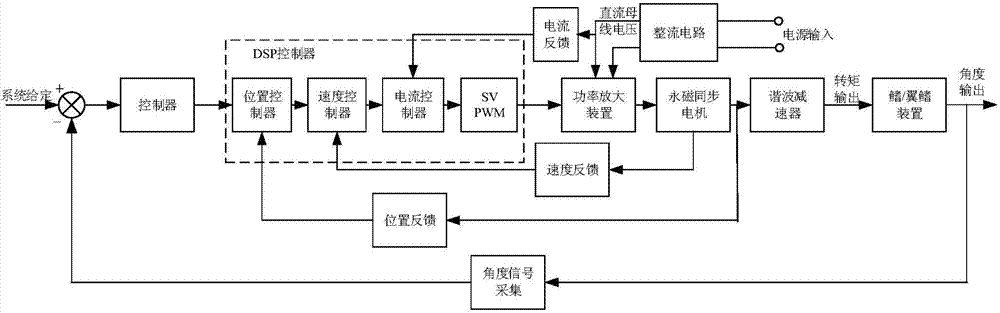

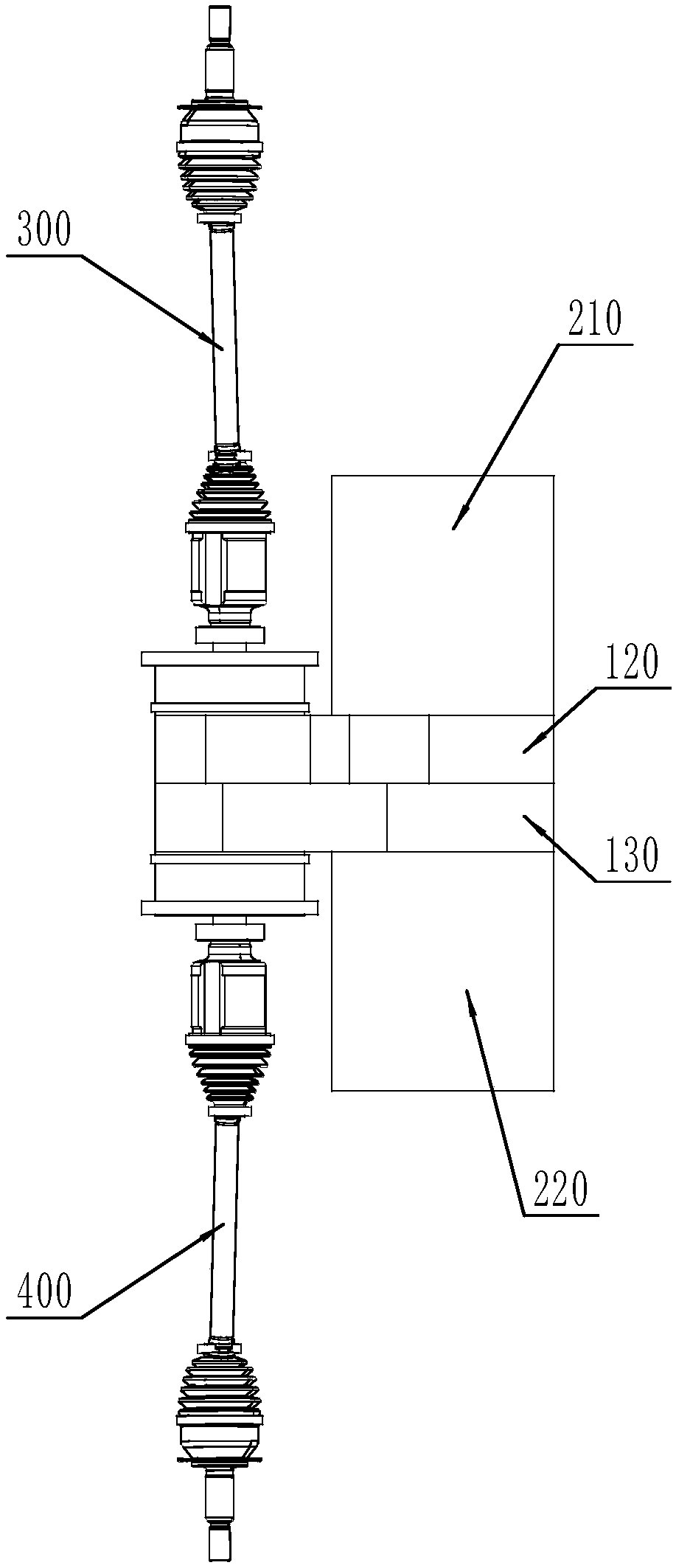

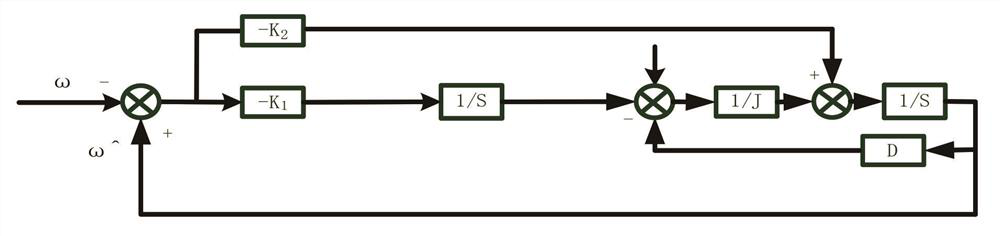

Ship electric servo fin and wing fin rolling stabilization intelligent vector control method

InactiveCN103895832AEasy to controlImprove shortcomingsVessel movement reduction by foilsControl vectorStabilization control

The invention relates to a ship electric servo fin and wing fin rolling stabilization intelligent vector control method. The method includes the steps that a rolling detection device detects a rolling angle, the rolling angle and the rolling angular velocity of a system are estimated through a state estimator, and values obtained by subtracting the rolling angle and the rolling angular velocity from set values are sent to a feedback linearization controller; output of the feedback linearization controller is corrected through a self-adaptive controller based on a fuzzy tree, and then required rolling righting moment is obtained; corrected output signals are namely output signals of a rolling stabilization controller and are sent to a fin angle and wing fin angle intelligent optimizer, wherein the rolling stabilization controller is composed of the feedback linearization controller, the self-adaptive controller based on the fuzzy tree and an error observer; the fin angle and wing fin angle intelligent optimizer conducts angle distribution, generates real-time fin angle and wing fin angle instructions and sends the real-time fin angle and wing fin angle instructions to a fin and wing fin electric servo system; the fin and wing fin electric servo system is based on vector control and drives a fin and wing fins to rotate, the required righting moment is generated, and then rolling stabilization control over a ship is achieved.

Owner:HARBIN ENG UNIV

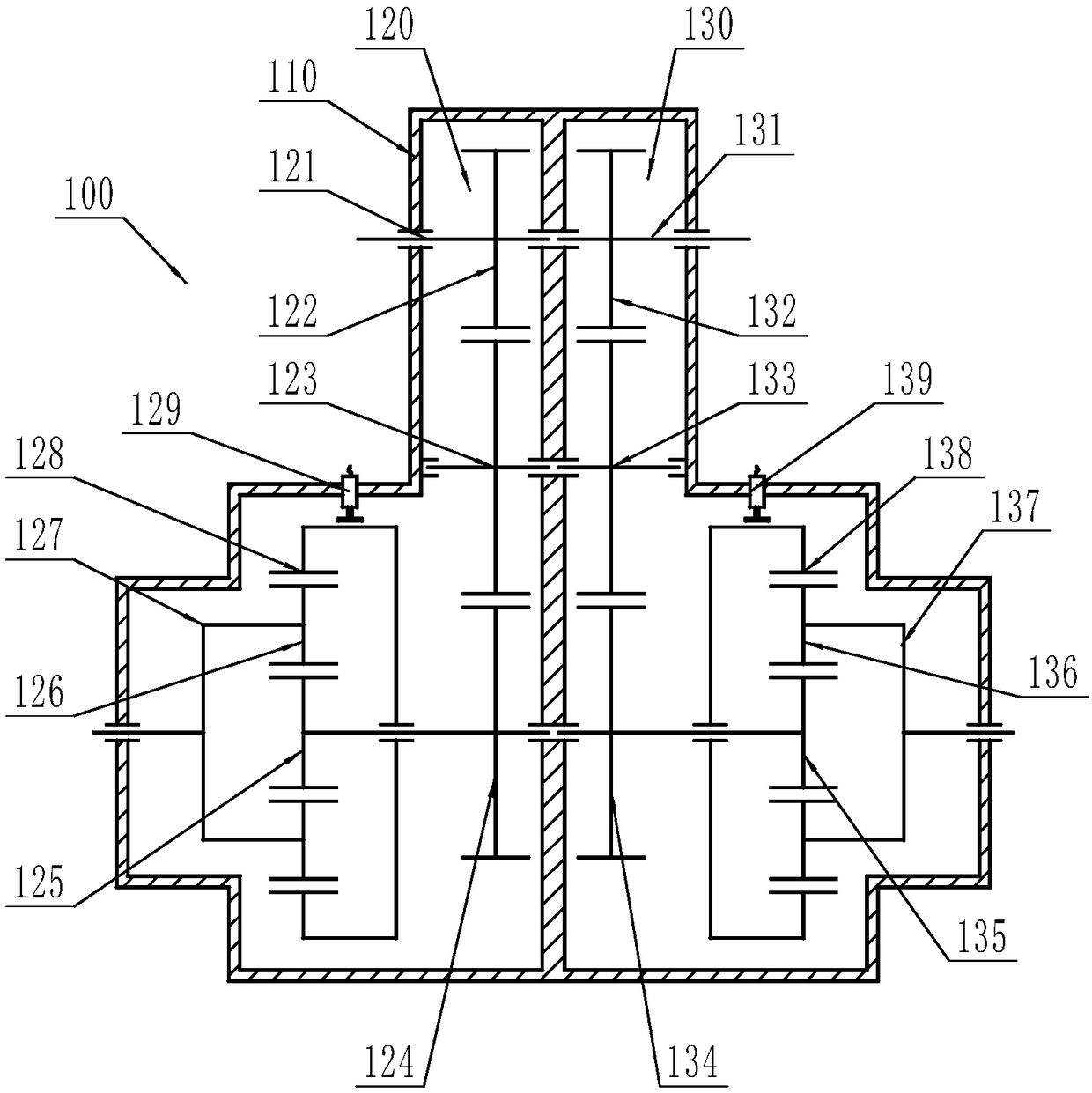

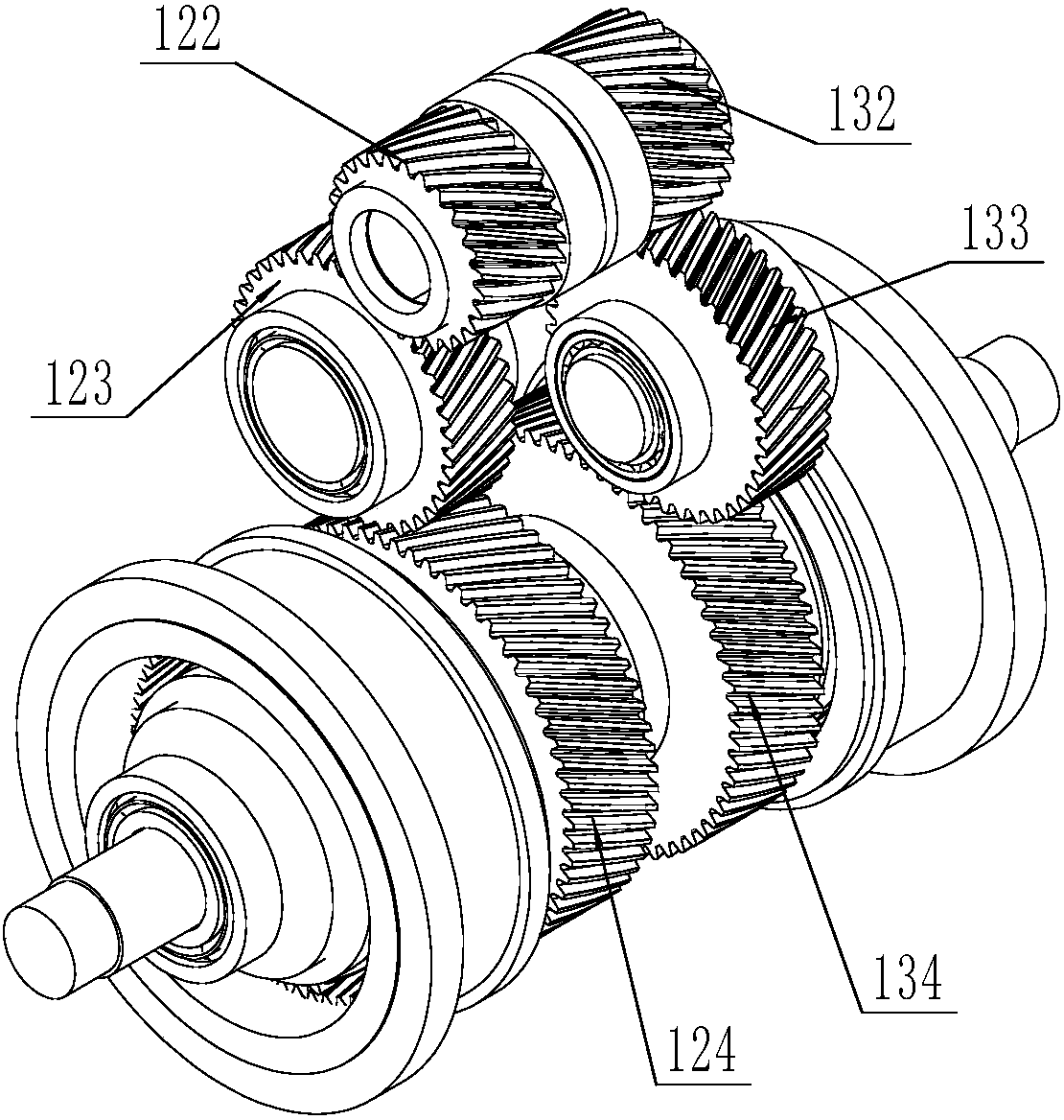

Electric vehicle and dual-motor planet gear power transmission system thereof

ActiveCN108528186AFree rotationAvoid out-of-control phenomenaElectric propulsion mountingToothed gearingsLow speedVehicle frame

The invention belongs to the field of automobiles, particularly provides an electric vehicle and a dual-motor planet gear power transmission system thereof and is intended to solve at least one of theproblems of the prior art that wheels of an electric vehicle driven by a single motor cannot output high torque through a reducer and wheels of the electric vehicle driven by the single motor are unsuitable for independent adjustment of driving torque. The dual-motor planet gear power transmission system mainly comprises two power transmission subsystems which are identical; each power transmission subsystem includes a motor and a reducer arranged on an auxiliary frame, and the motor is connected with an axle shaft of the electric vehicle through the reducer such that wheels can be driven torotate. Each reducer mainly includes a single-stage cylindrical gear reduction mechanism and a planet gear reduction mechanism which are in driving connection, the two mechanisms enable the reducer togain a high reduction ratio at the premise of compact layout space, and therefore, the electric vehicle can gain better low-speed performance.

Owner:NIO ANHUI HLDG CO LTD

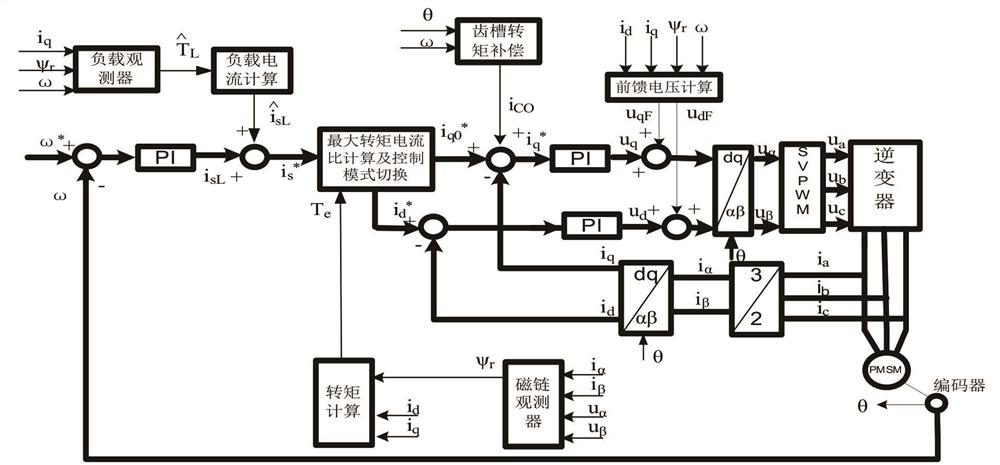

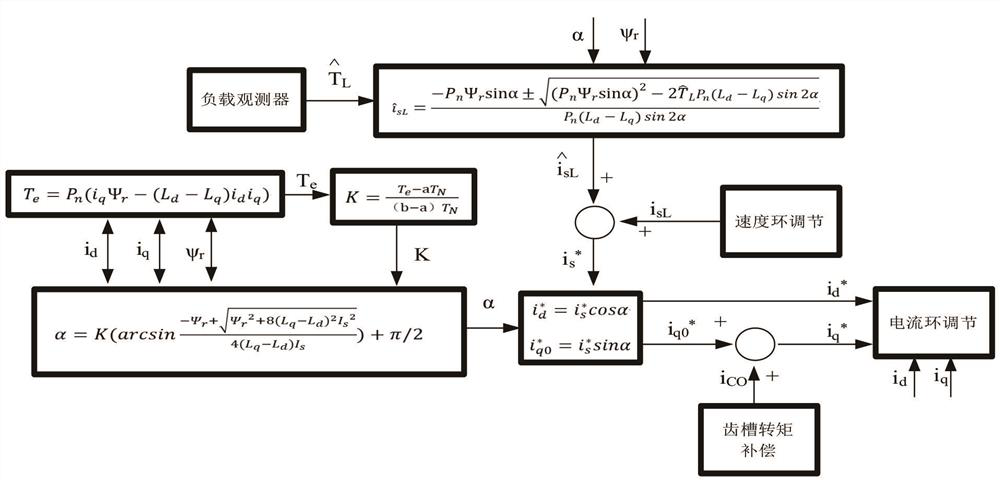

Permanent magnet motor control method suitable for low-speed direct-drive elevator

ActiveCN112054729AImprove stabilityImprove torque response speedTorque ripple controlVector control systemsMaximum torqueLoad torque

The invention belongs to the technical field of low-speed direct-drive elevator control, and particularly discloses a permanent magnet motor control method suitable for a low-speed direct-drive elevator. An id = 0 control mode and a maximum torque current ratio control mode are combined, the characteristic that id = 0 control current is completely decoupled during light load is utilized, cogging torque ripples are reduced by accurately compensating q-axis current, the operation stability of the elevator is improved, the cogging torque is smaller than the load torque after the load is increased, the influence on the system is weakened, at the moment, maximum torque current ratio control is adopted, the unit current torque output capacity is improved, smooth switching of the two control modes is achieved by controlling the included angle between the stator current and the rotor, the system torque response speed is greatly increased, and starting and stopping impact of the elevator is reduced. According to the invention, the permanent magnet motor can be controlled to realize strong torque output, good low-speed performance and rapid dynamic response, so that the low-speed direct-drive elevator system reaches the optimal working state.

Owner:LUOYANG CITIC HIC AUTOMATION ENG

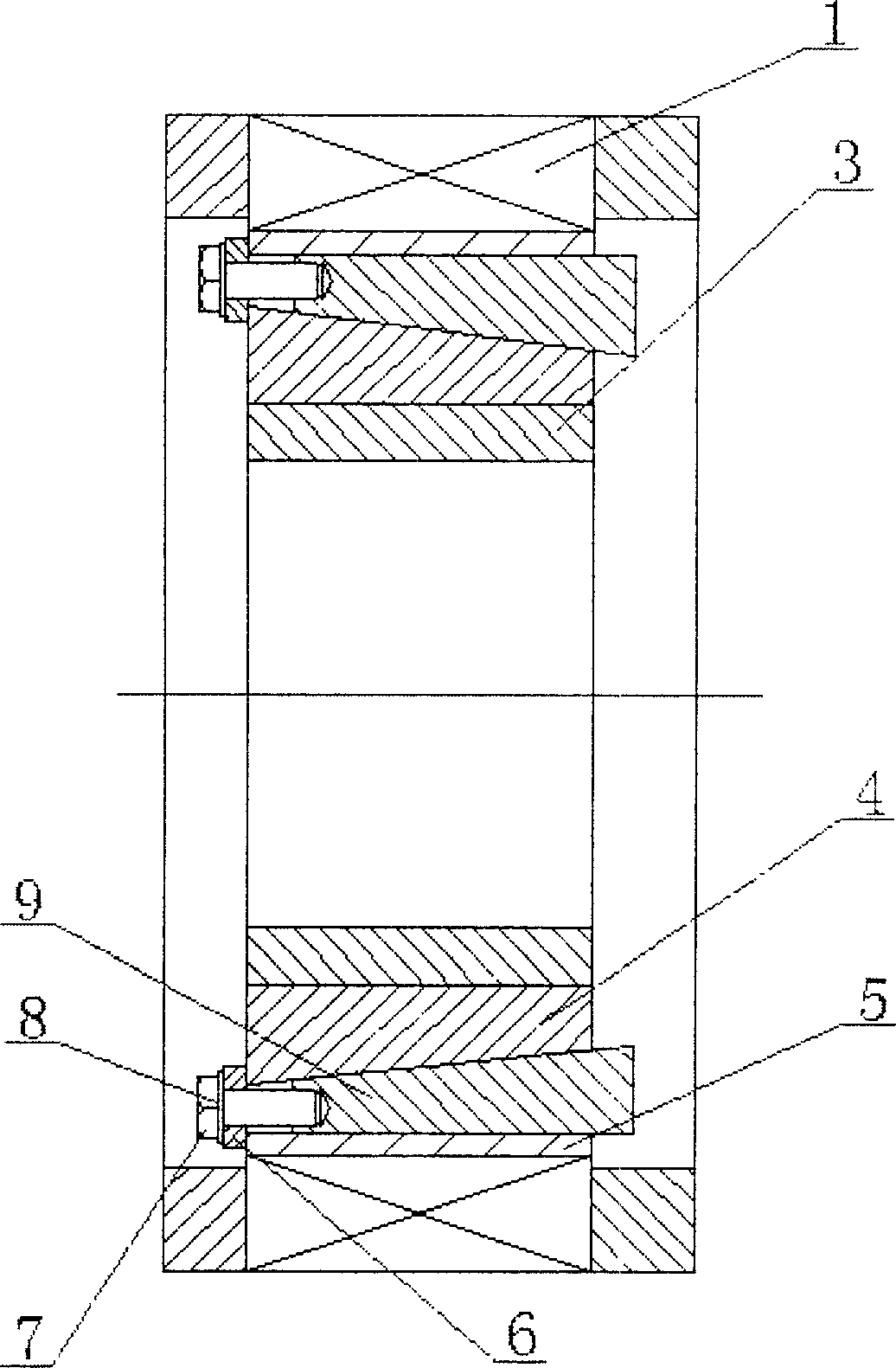

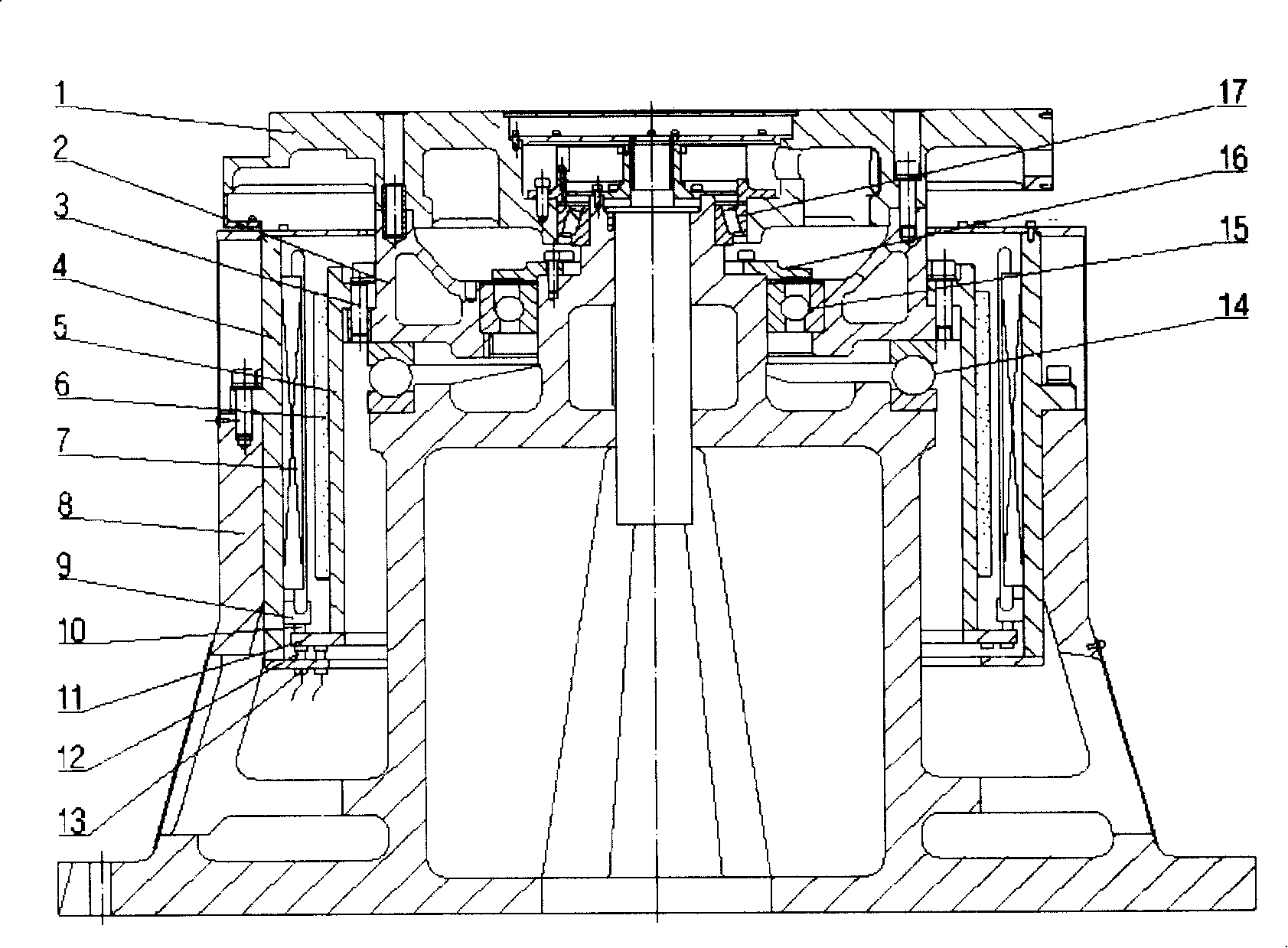

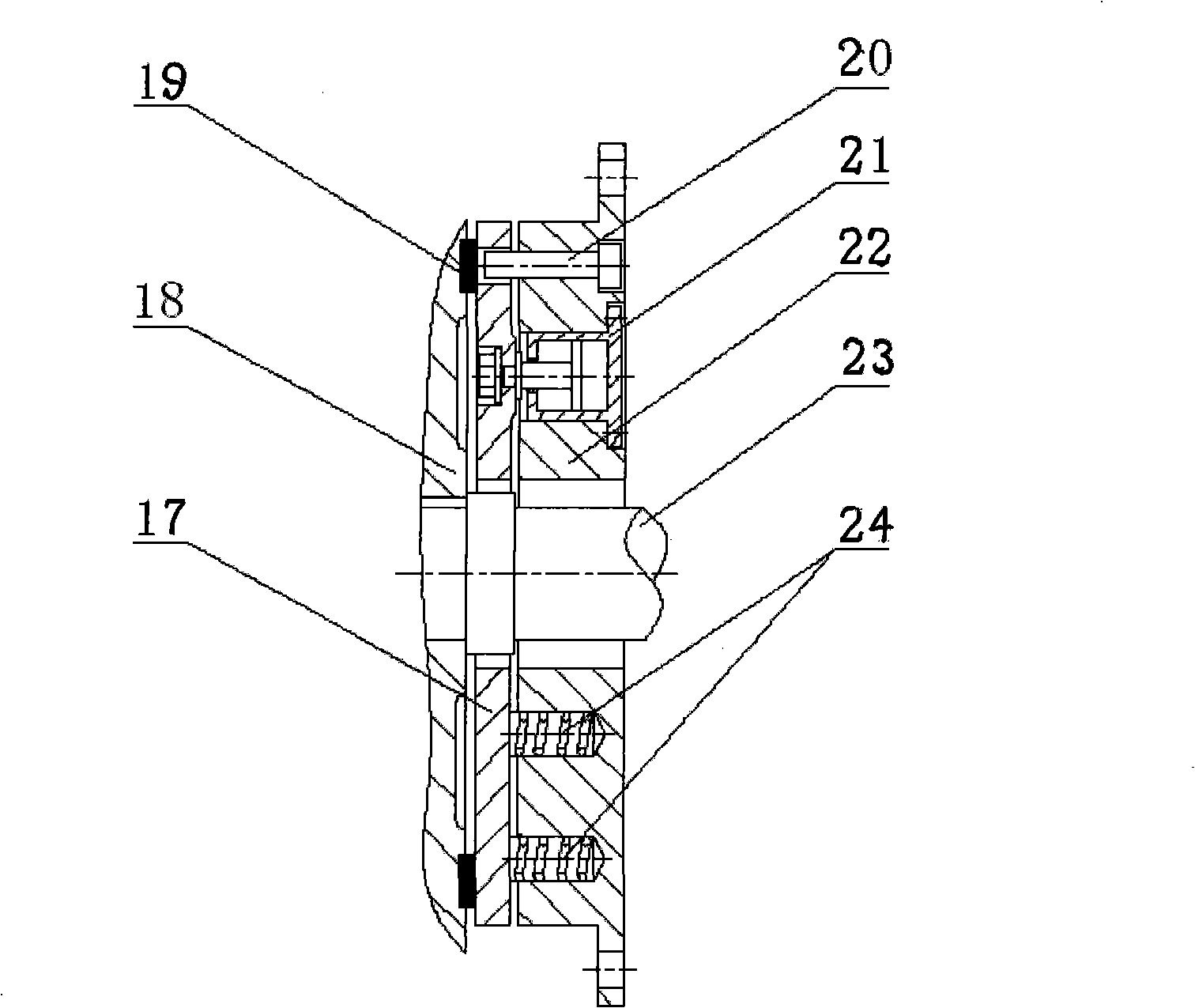

Novel direct current driving turntable structure

InactiveCN101162857ASmall moment of inertiaSmall torque fluctuationMagnetic circuit rotating partsDC commutatorBall bearingThrust bearing

The invention relates to a novel rotary table driven by a DC motor. The motor stator is mounted on a frame, windings and an iron core are mounted on the inner side of the stator, and a commutator is arranged at the lower end of the windings. The wire inlet terminal and the brush of the conducting ring are fixed on the lower end of the stator; the motor stator is fixed on the main shaft; the worktable face is connected to the main shaft by bolts; an alnico is fixed on the stator, the brush with a conducting ring is mounted on the bottom of the stator by a frame; the brush of the commutator is mounted on the brush frame provided with a conducting ring, and the brush of the commutator contacts with the commutator; and the conducting-ring brush contacts with the conducting ring arranged on the brush frame provided with a conducting ring. The part between the main shaft and the frame is supported by a thrust ball bearing and an angular-contact ball bearing, and the part between the worktable face connected with the main shaft and the frame is supported by a tapered roller bearing. The rotary table with such structure has the advantages of that the rotor has small moment of inertia, the fluctuation of moment is small, the speed is low, the performance is sound, and the cost is low; particularly when load acceleration requires relatively high control accuracy, such structure is easy to meet the technical requirements of the rotary table and reduce the cost.

Owner:AVIC BEIJING CHANGCHENG AVIATION MEASUREMENT & CONTROL TECH INST +1

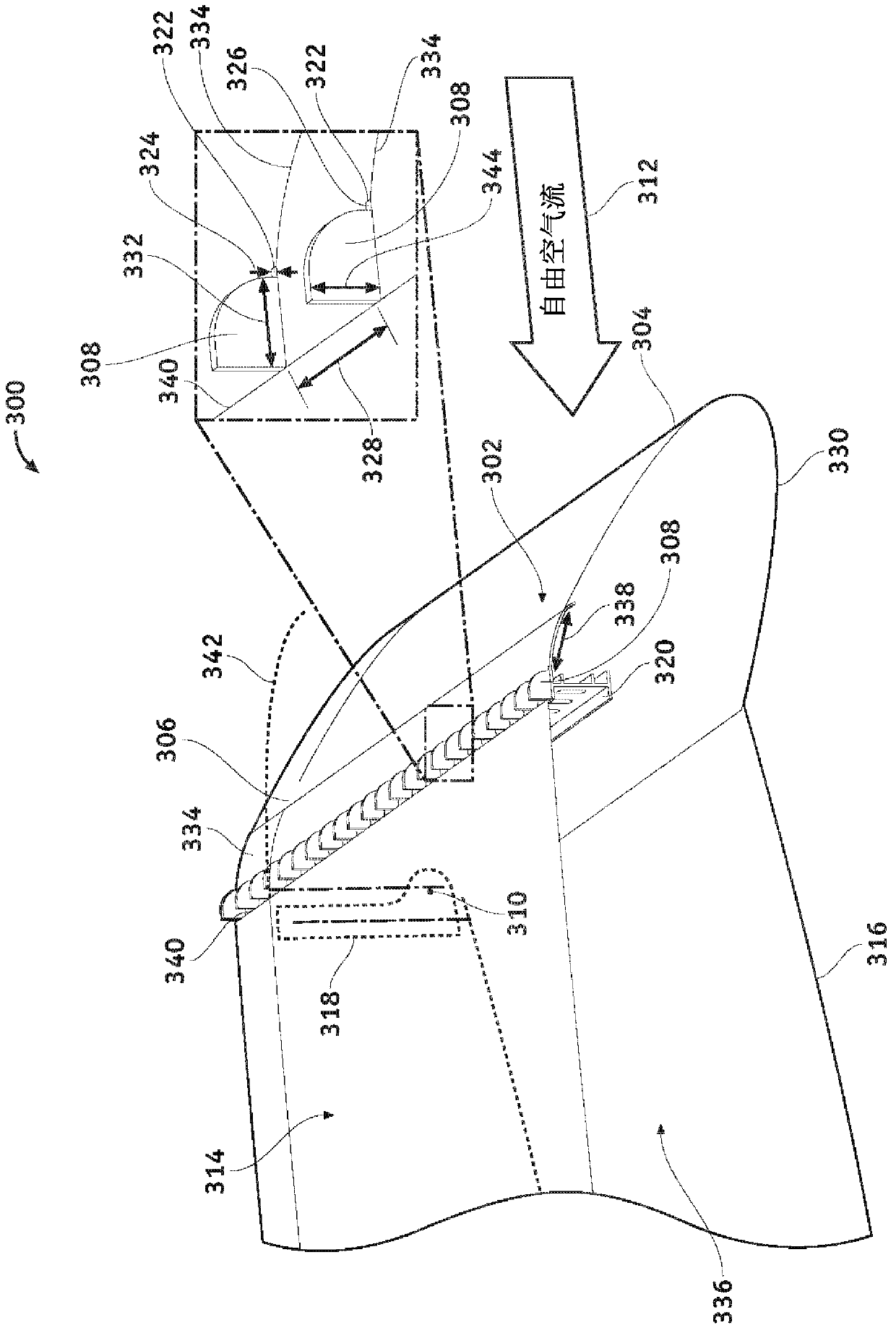

Retractable vortex generator

ActiveCN102862674AImprove low-speed performanceMaintenance intensiveInfluencers by generating vorticesBoundary layer controlsLeading edgeLow speed

A device and methods for low speed performance improvement of a lifting surface assembly (300) are disclosed. At least one vortex generator (308) is coupled to the lifting surface assembly, and the vortex generator is extended through the lifting surface assembly by drooping a hinged leading edge device (302) coupled to the lifting surface assembly to increase lift. The vortex generator is retracted inside the lifting surface assembly to decrease drag.

Owner:THE BOEING CO

Secondary air injection system

InactiveCN103511064AReduce harmless ingredientsReduce the amount of precious metalsInternal combustion piston enginesExhaust apparatusInjection airGuide tube

The invention discloses a secondary air injection system. The secondary air injection system supplying some of air introduced into an intake manifold to an exhaust manifold may include: an electric supercharger compressing air introduced through an air duct; throttle valves installed at an upstream of the intake manifold and controlling the amount of air introduced into the intake manifold by controlling the amount of air passing through the electric supercharger; secondary air valves installed on branching paths branched from intake, lines that link the electric supercharger and the throttle vales and controlling the amount of air for secondary air injection; and an injector that post-combusts exhaust gas discharged from an engine by injecting secondary air passing through the secondary air valve to a runner of the manifold.

Owner:HYUNDAI MOTOR CO LTD

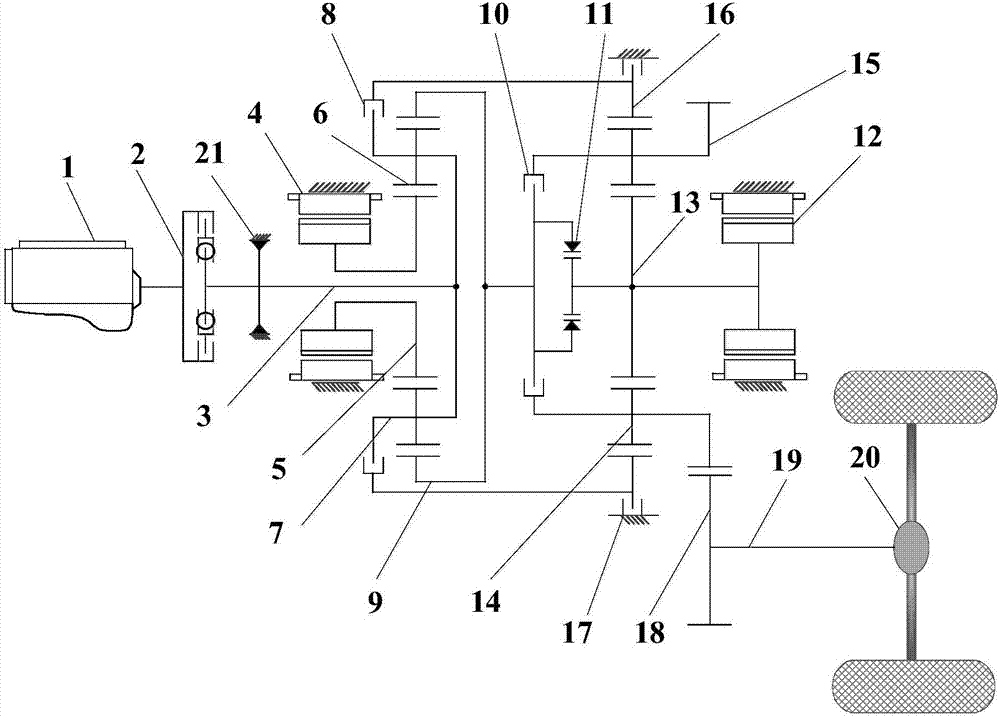

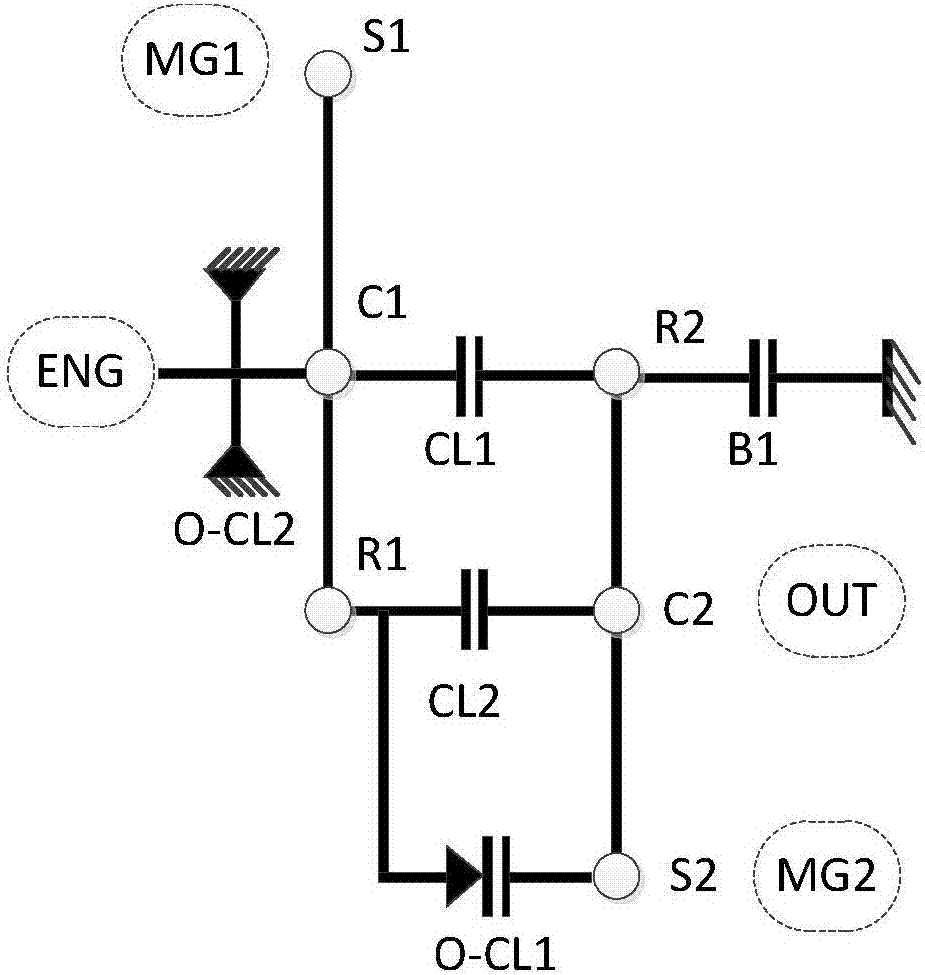

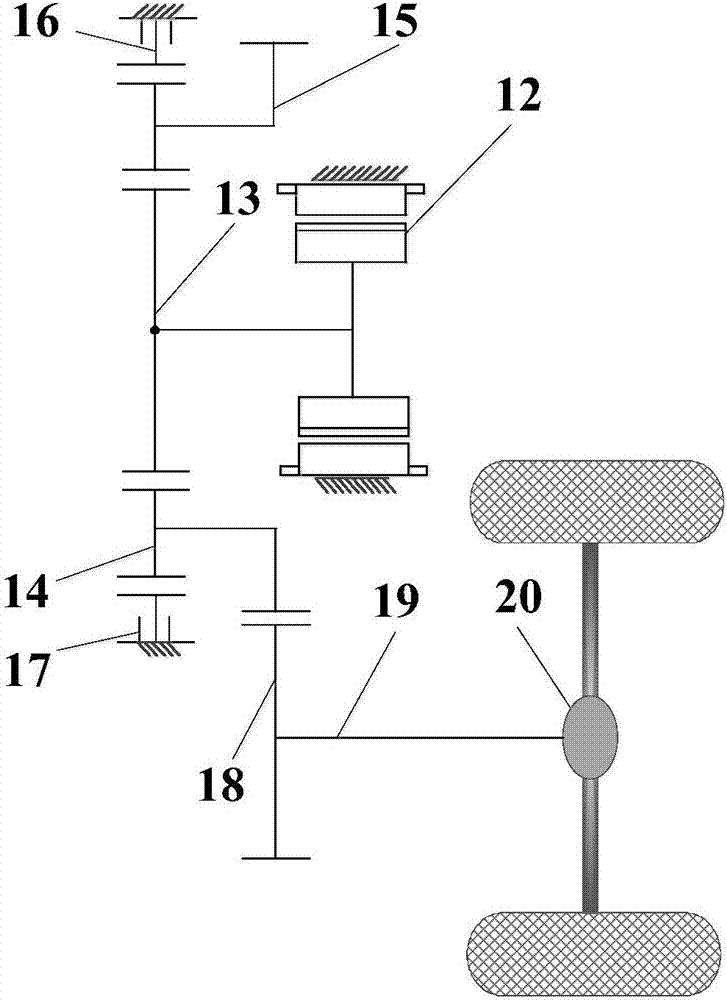

Planetary gear series-parallel twin-mode hybrid vehicle drive system

InactiveCN106976390AEliminate idle fuel consumptionImprove fuel economyHybrid vehiclesGas pressure propulsion mountingLow speedElectric machine

The invention discloses a planetary gear series-parallel twin-mode hybrid vehicle drive system and relates to the technical field of vehicles. The system comprises an engine, a front planetary gear train, a rear planetary gear train, a first clutch, a second clutch, an overrun clutch, a backstop, a brake, a first motor and a second motor. Conversion among different working modes can be achieved through combination and separation of the clutches and the brake. The system is compact in structural design, the power grades of the motors are effectively decreased, the sizes of the motors are reduced, the slope climbing performance of the vehicle in a pure electric mode is improved, and the low-speed performance of the vehicle in the pure electric mode is improved; the defect that parasitic power is generated when the vehicle travels in a high-speed area is overcome, the high-efficiency range of a hybrid power system is enlarged, and the economic efficiency of the vehicle is improved; and the problems that the acceleration performance of the vehicle is poor and the slope climbing capability is limited in a low-speed area are solved, and the dynamic property and the economic efficiency of the vehicle are improved.

Owner:JILIN UNIV

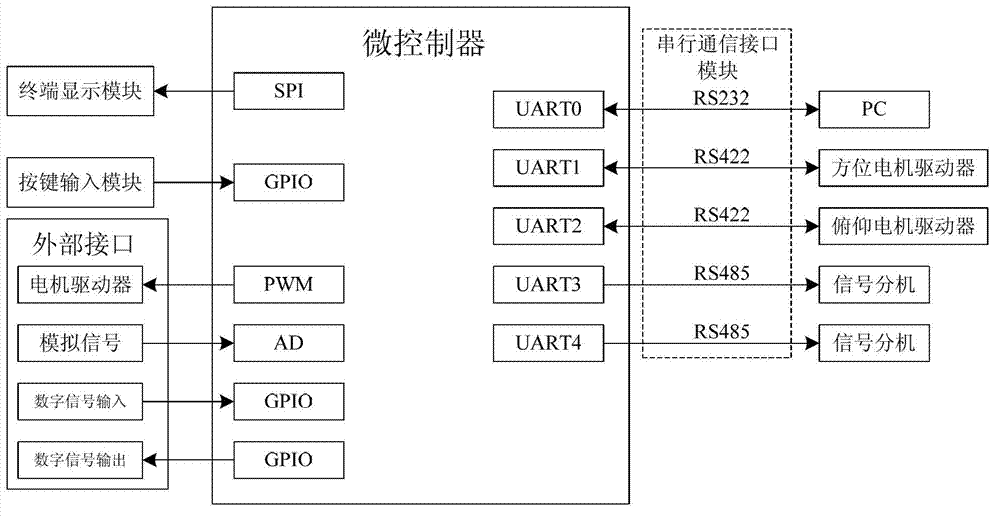

Turntable servo control system

InactiveCN103076813AHigh positioning accuracyHigh control precisionControl using feedbackMicrocontrollerControl system

The invention discloses a turntable servo control system, and belongs to the field of turntable servo. The turntable servo control system comprises a terminal display module, a press key input module, a serial communication interface module and a microcontroller, wherein the serial communication interface module comprises an RS232 module, two RS422 modules and two RS485 modules, the RS232 module is connected with a PC (personal computer), the RS422 modules are connected with a bearing motor driver and a pitch motor driver, the RS485 modules are connected with signal extensions, the microcontroller is used for obtaining the current angle information of the turntable through the serial communication interface module and displaying the current angle information on the terminal display module in a real-time way, and the press key input module is used for switching the turntable control methods and controlling the turning of the turntable. The turntable servo control system has the advantages that the turntable control methods are flexible, and the performance is stable and reliable.

Owner:中船鹏力(南京)大气海洋信息系统有限公司

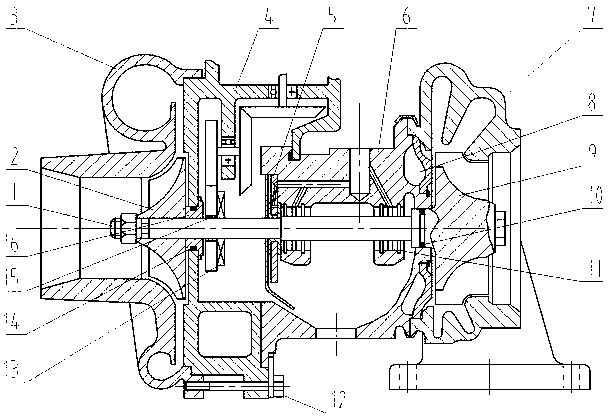

Electric auxiliary engaging and disengaging type power turbine composite supercharger

PendingCN107939513AImprove stabilityImprove reliabilityInternal combustion piston enginesMagnetically actuated clutchesElectricityTurbocharger

The invention relates to an electric auxiliary engaging and disengaging type power turbine composite supercharger, and belongs to the field of vehicle motive power machines. According to a motor external scheme, a motor dynamo acts as an auxiliary motor to be arranged outside the supercharger, motor energy is transmitted to a rotor shaft of the supercharger through a gear box, and an engaging anddisengaging device can be controlled to engage the gear box with the rotor shaft and disengage the gear box from the rotor shaft according to different working conditions; and under a high-speed working condition of the motor dynamo, surplus energy of the rotor shaft can drive the motor dynamo to generate electricity through the gear box. With such motor external scheme, the influence on an electronic component of the motor dynamo by high temperature is avoided effectively, and efficient distribution and utilization of energy of the supercharger is realized; and the turbine end of the supercharger is connected with a power turbine in series, and secondary exhaust gas subjected to work by a turbine of the supercharger drives the power turbine, so that the motor dynamo is driven to generateelectricity for energy storage, the utilization ratio of energy of the exhaust gas is raised, and the economy of the motor dynamo is improved.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

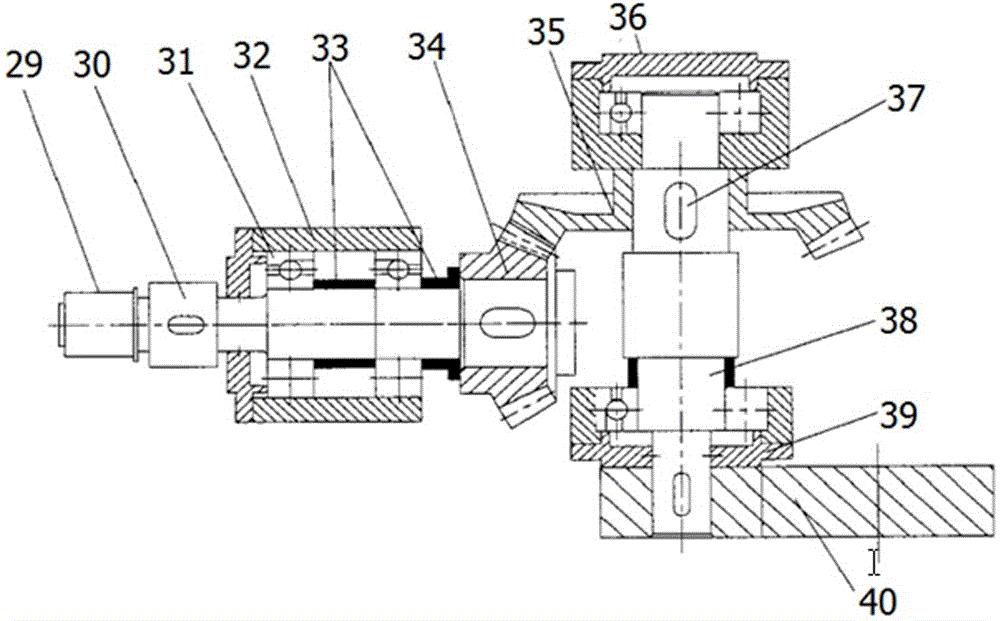

Precise shaft dynamic torque measuring instrument

ActiveCN104977112AAddress reliabilityFix stability issuesApparatus for force/torque/work measurementFriction torqueCoupling

A precise shaft dynamic torque measuring instrument relates to a shaft measurement technology and solves the problem that shaft friction torque can not be accurately measured and the test scope is small. The precise shaft dynamic torque measuring instrument comprises a structure adjusting subsystem, a pitching and yaw detection shaft subsystem, a positioning installation subsystem, a lateral roller detection shaft subsystem and a support and detection platform subsystem and measures friction torque of a fake load on vertical shaft direction. A torque motor drives a torque sensor to rotate through a toothed shaft, the displacement is adjusted on the vertical and horizontal direction, and a handwheel is rotated to move a leading screw nut mechanism vertically or horizontally along a linear guide rail. A rotary table drives a vertical sliding bench fixed together with a connection board to realize rotation of changing angle at certain level. A counterweight block is added on a fixed pulley on the vertical sliding bench to prevent extra torque, and verticality precision is ensured.

Owner:CHANGCHUN UNIV OF SCI & TECH

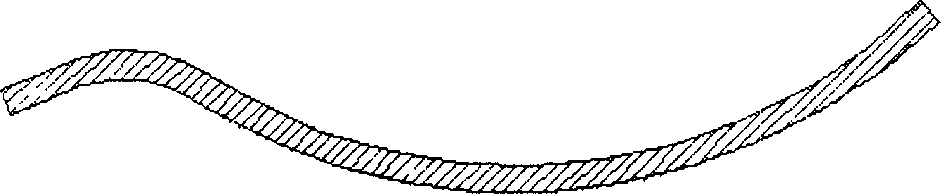

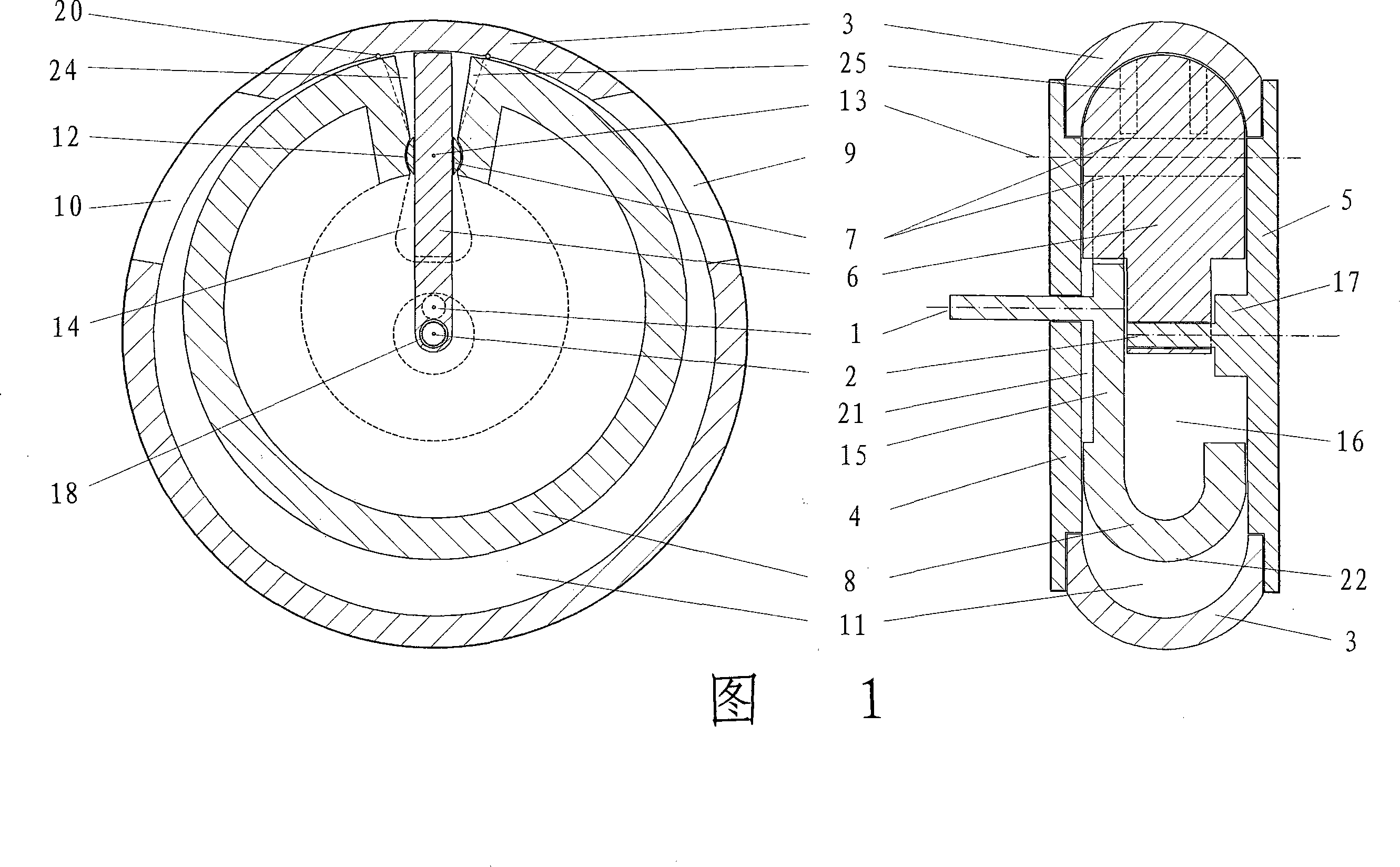

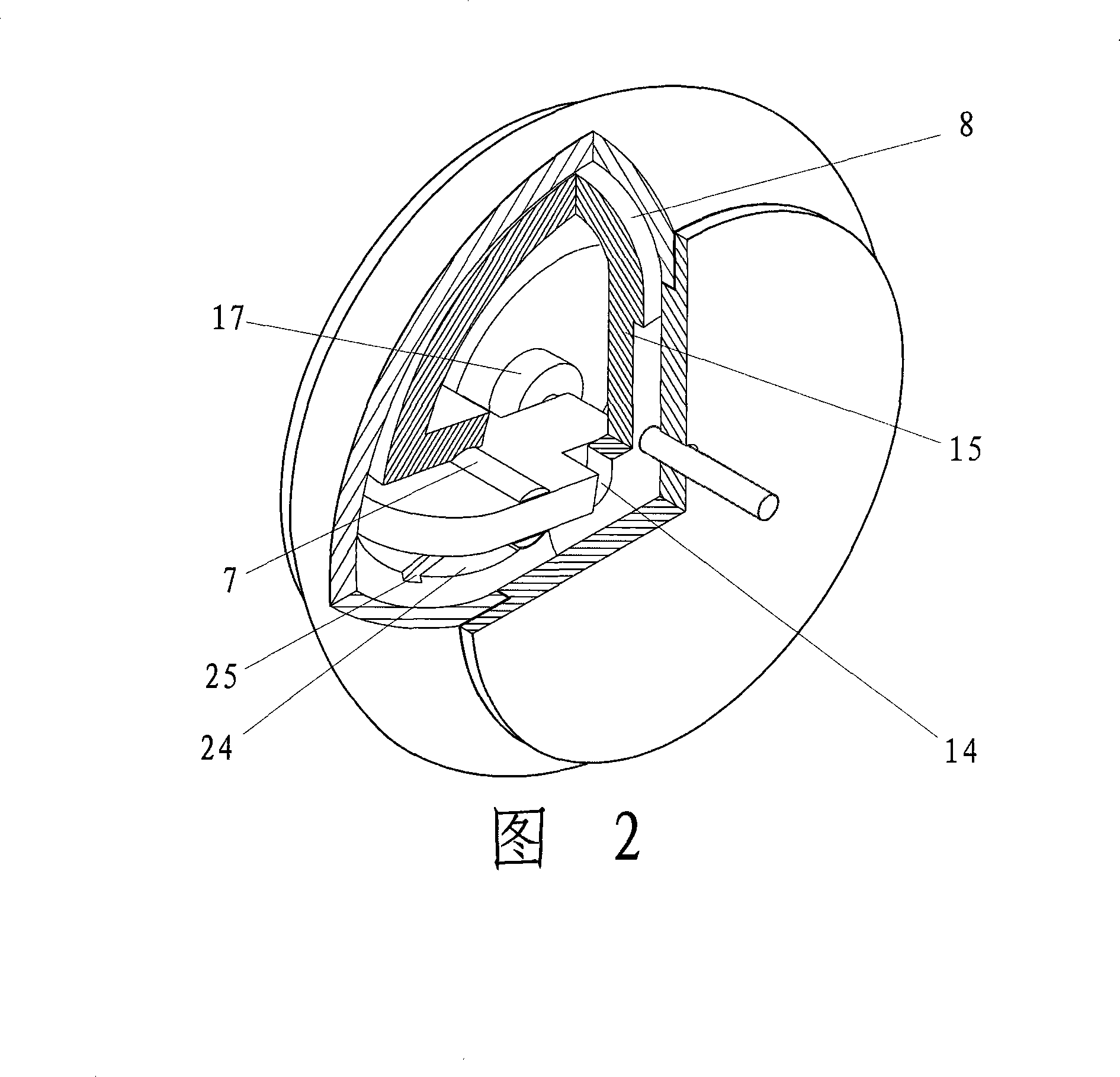

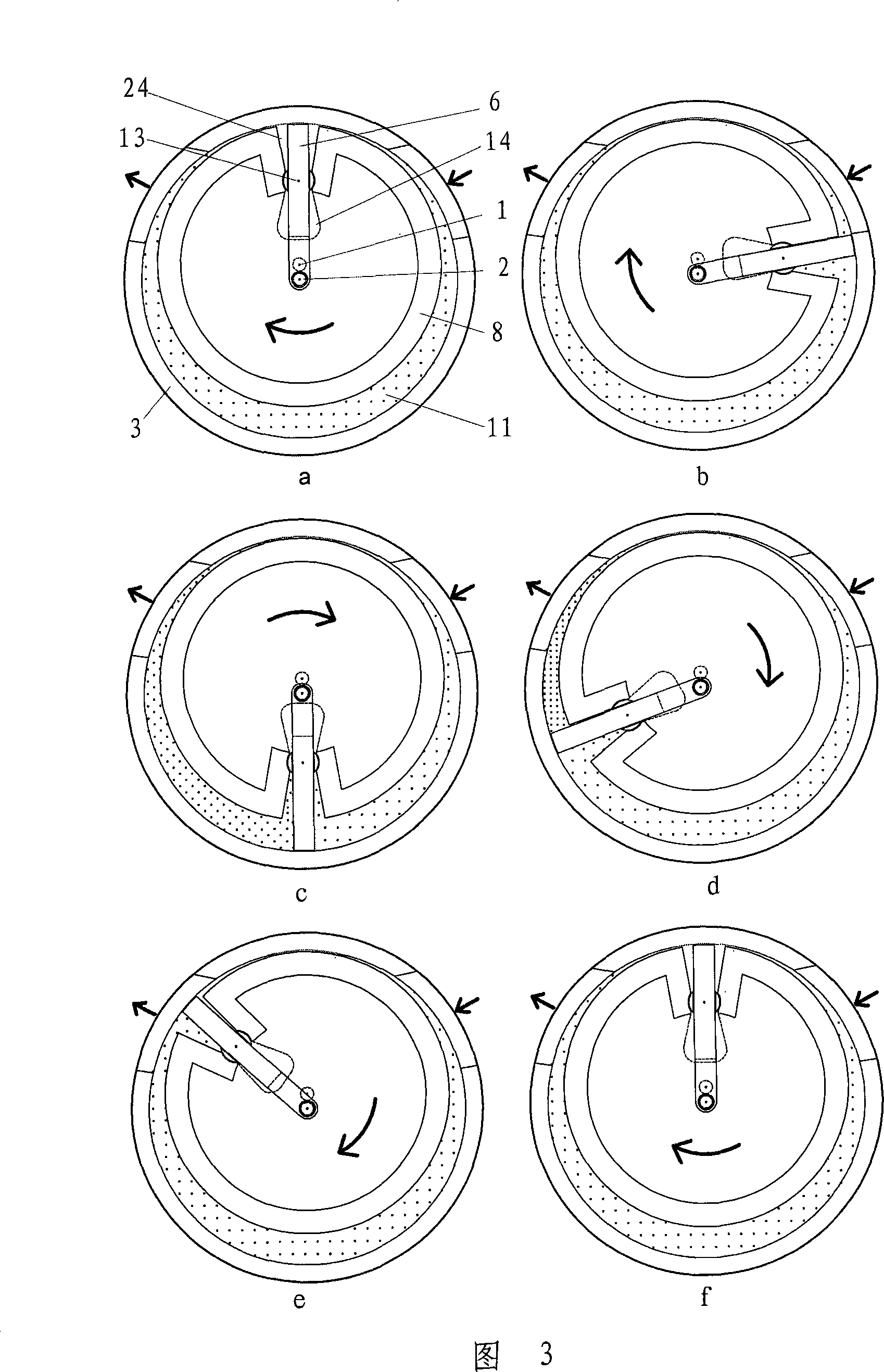

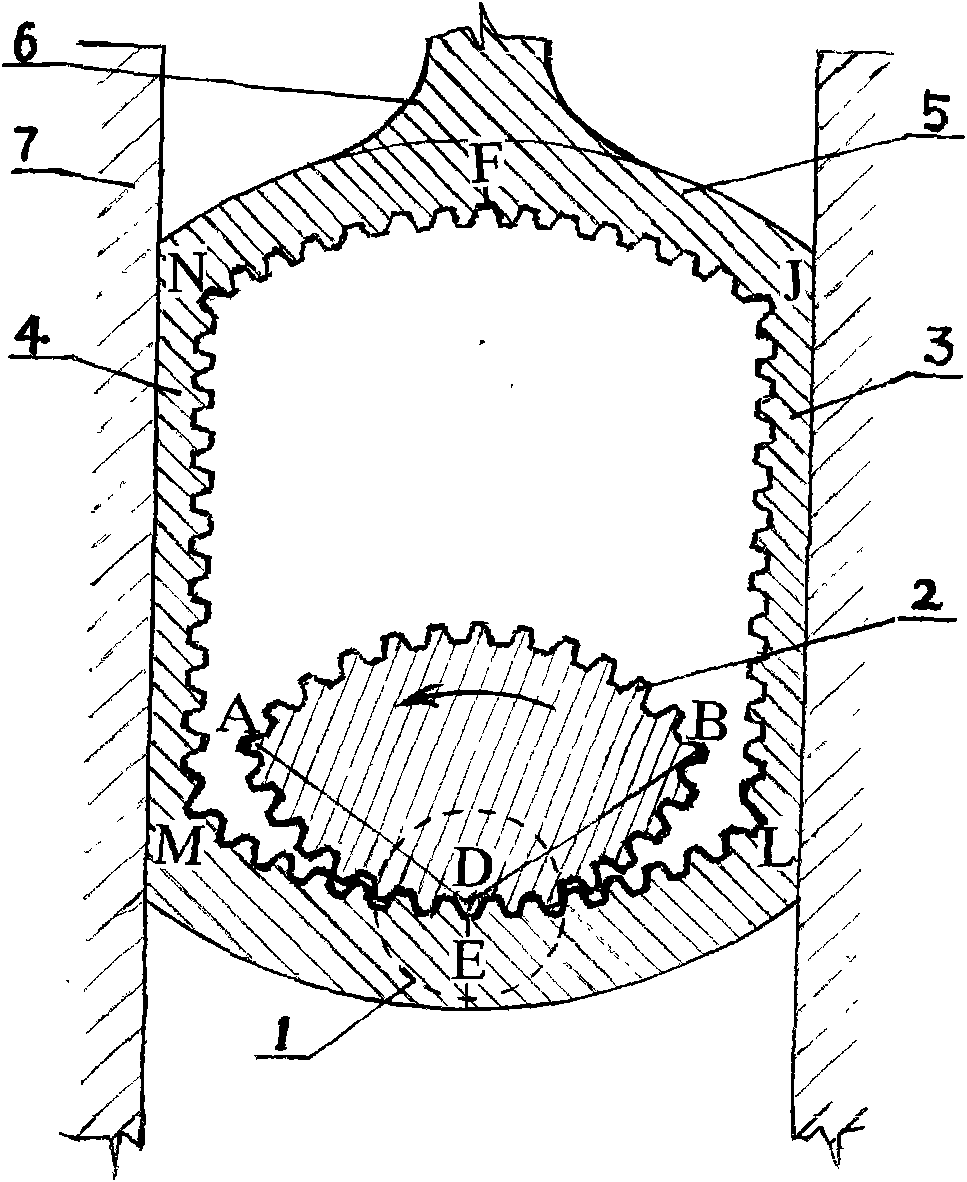

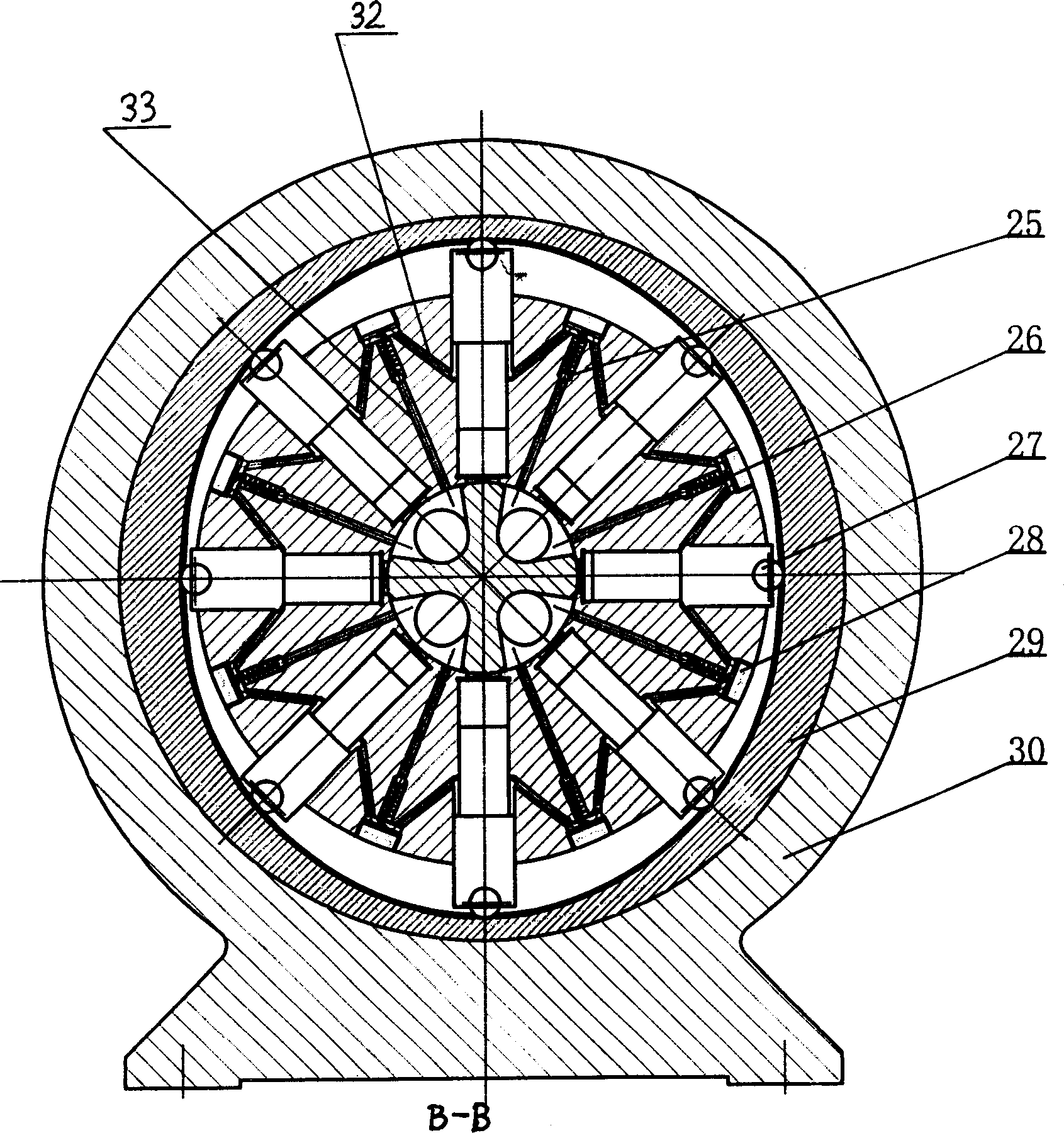

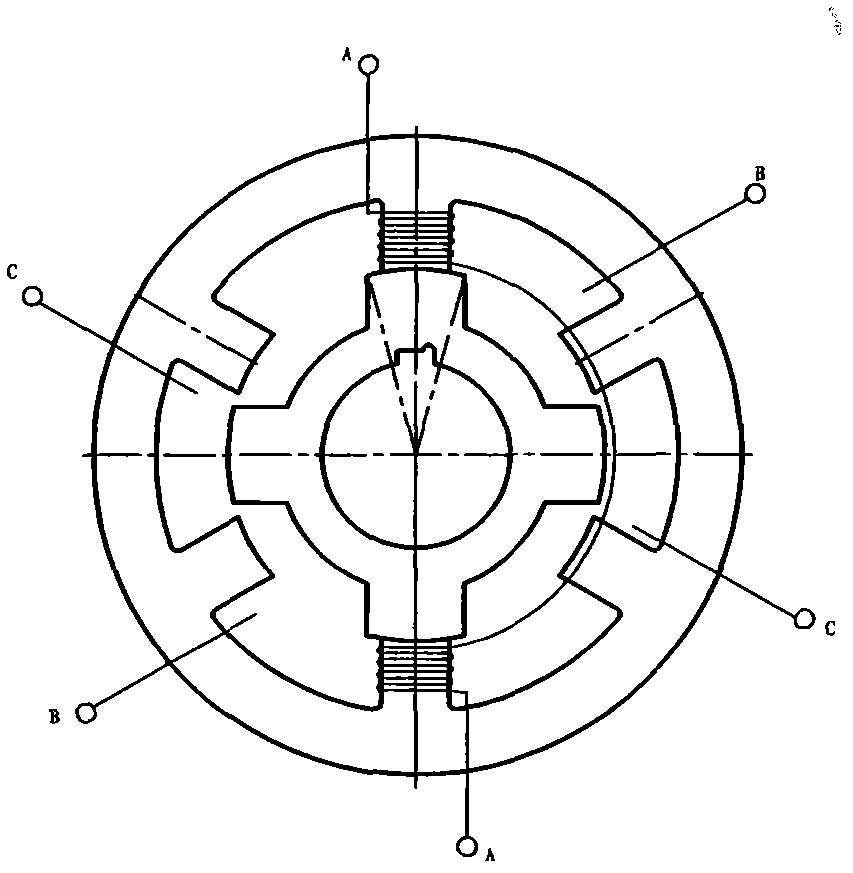

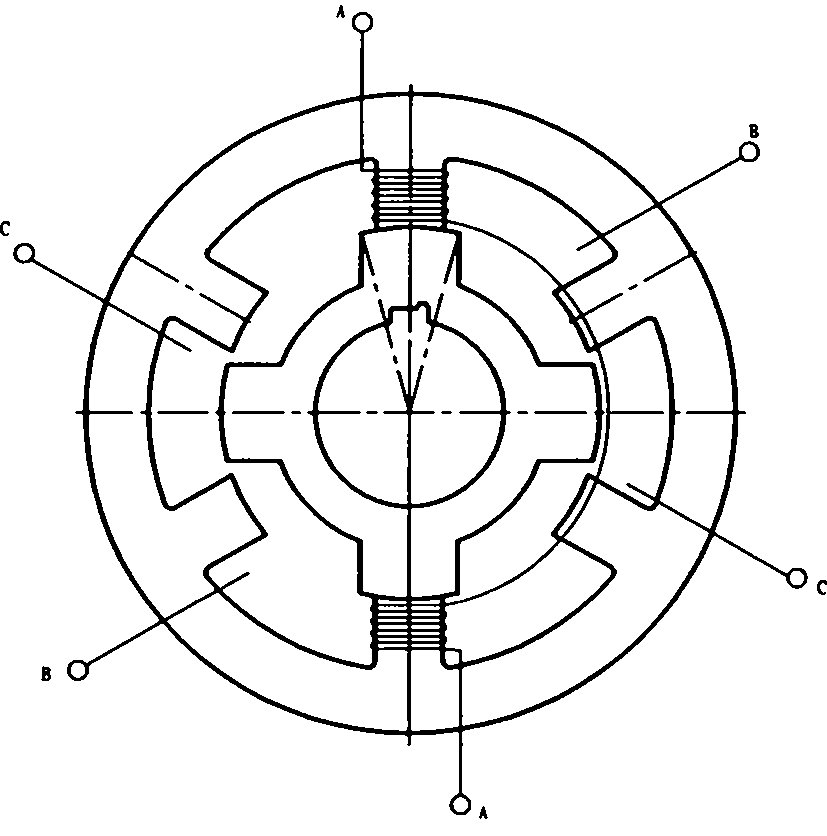

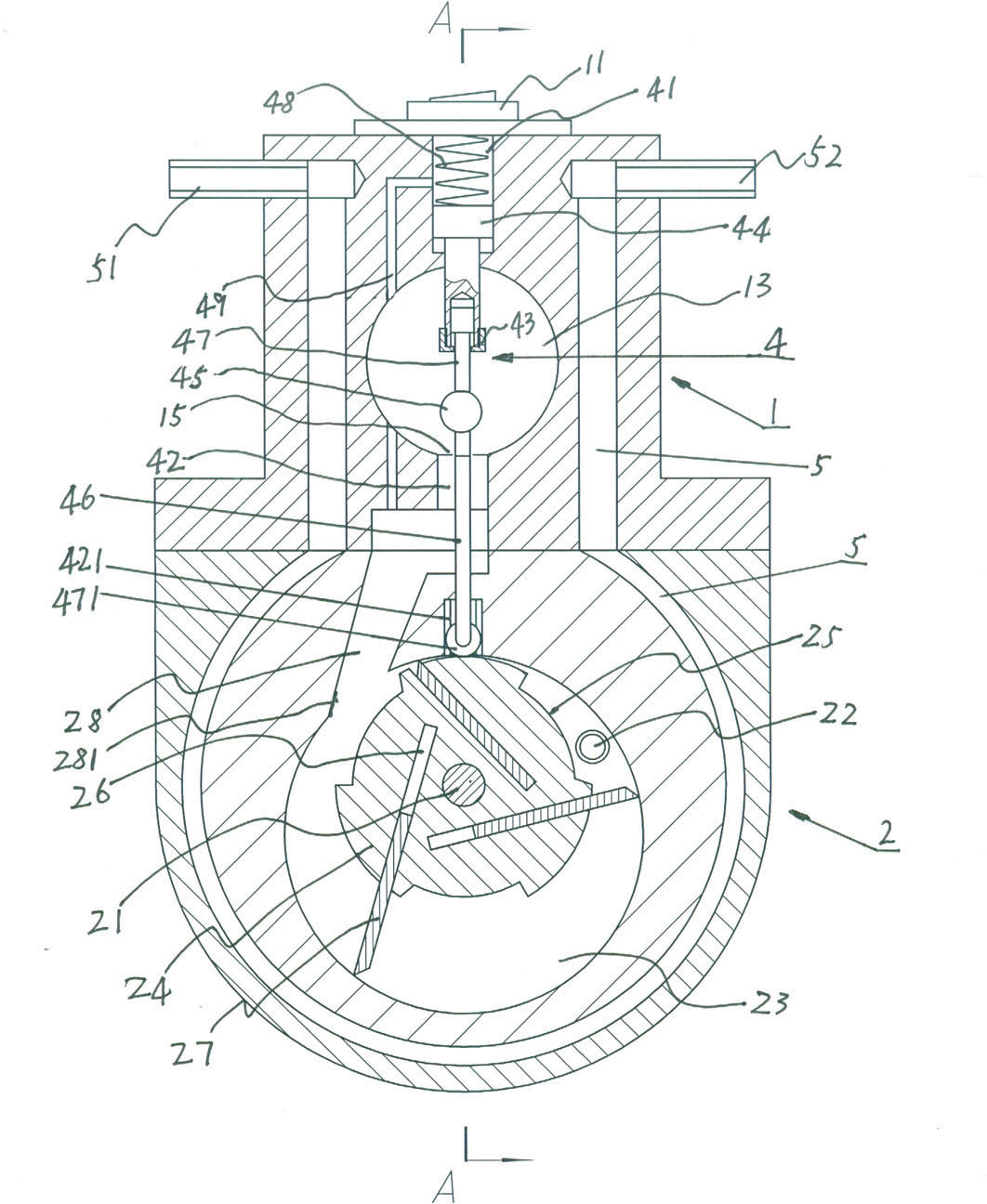

Curved sliding vane type rotary compressor

InactiveCN101187370AGood low speed performanceReduce mechanical wearSealing arrangement for pumpsRotary piston pumpsEngineeringCylinder block

The invention relates to a curved slide vane rotating compressor, comprising a circular cylinder body, a first end cap, a second end cap, a circular rotor, and at least one slide vane. The radial inner end face of the cylinder body is a ring-shaped curved face, and is respectively and smoothly connected with axial inner walls of the first and the second end caps. The radial outer end face of the rotor is a curved face which is hermetically engaged with the radial inner end face of the cylinder body, and is respectively and smoothly connected with the axial end faces on the two sides of the rotor. The radial outer end face of the slide vane is a curved face which is hermetically engaged with the radial inner end face of the cylinder body, and is respectively and smoothly connected with the axial end faces on the two sides of the slide vane. The axial end faces on the two sides of the rotor are respectively and hermetically engaged with the inner walls of the first and the second end caps, and the axial end faces on the two sides of the slide vane are respectively and hermetically engaged with the axial inner walls of the first and the second end caps. The invention removes a connecting edge angle, and the working face of a sealing element such as the slide vane, the rotor and the cylinder body is excessively smoothed, which has the advantages of favorable low speed performance, small machinery damage, less leakage, and long service life and the like.

Owner:李东林

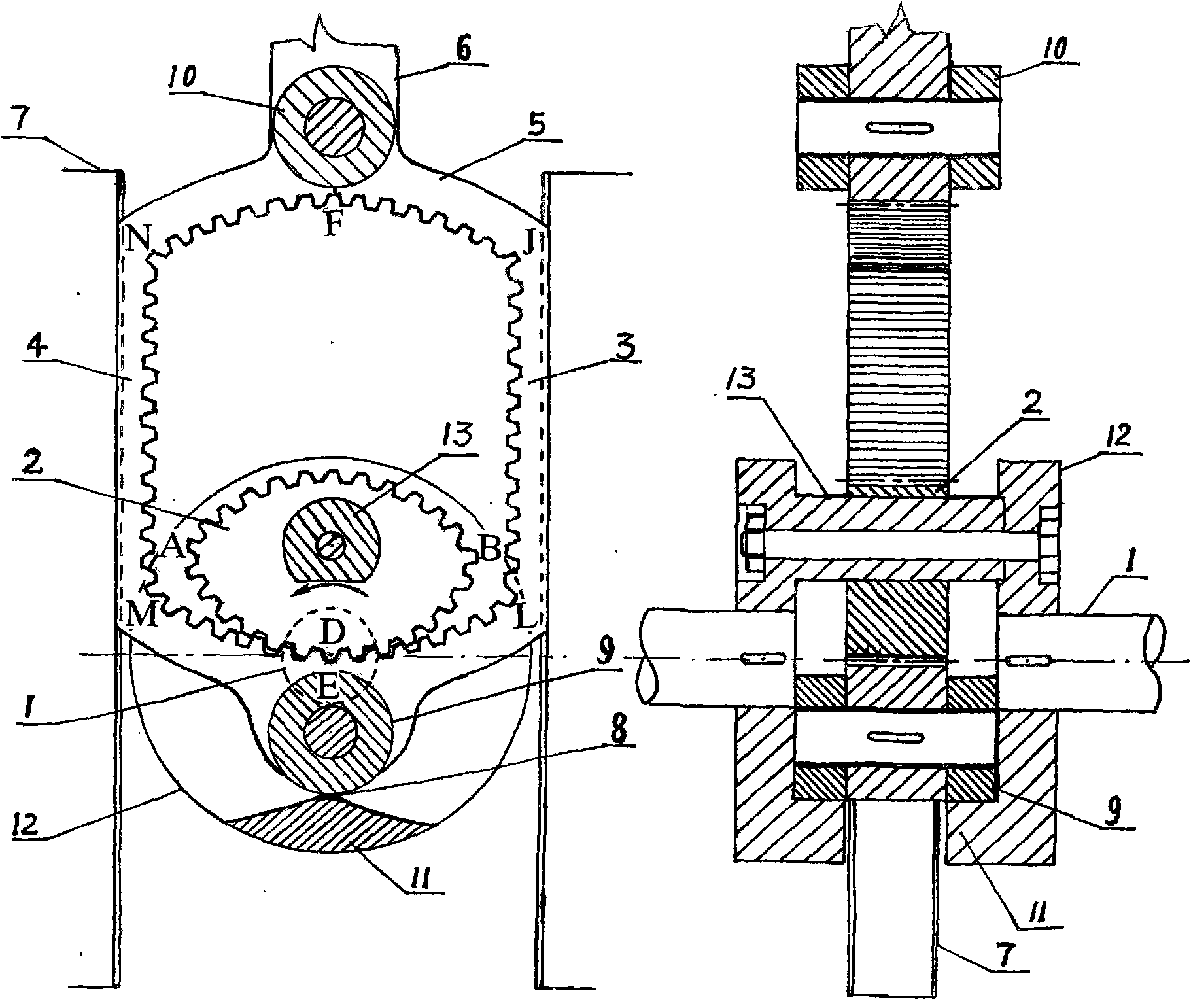

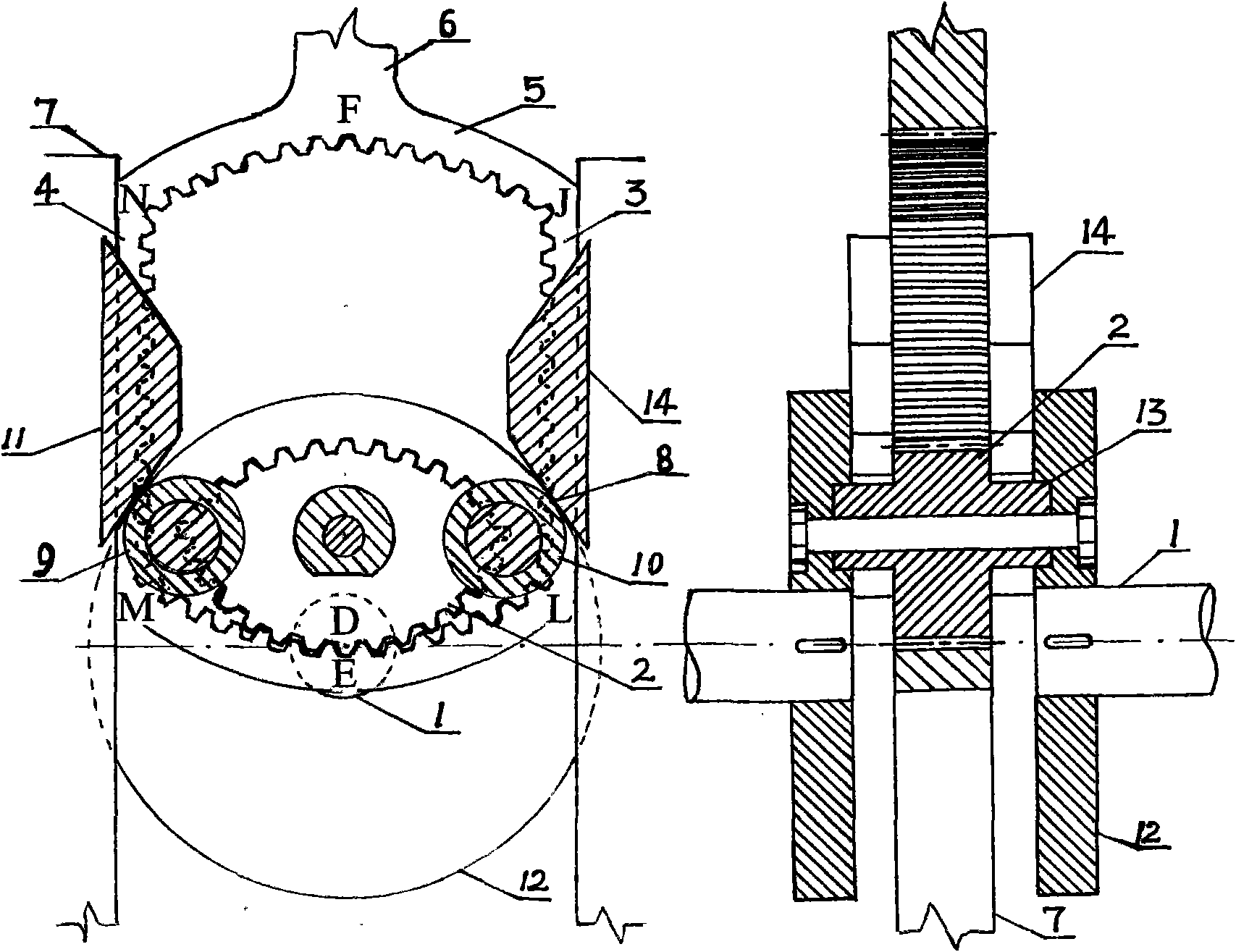

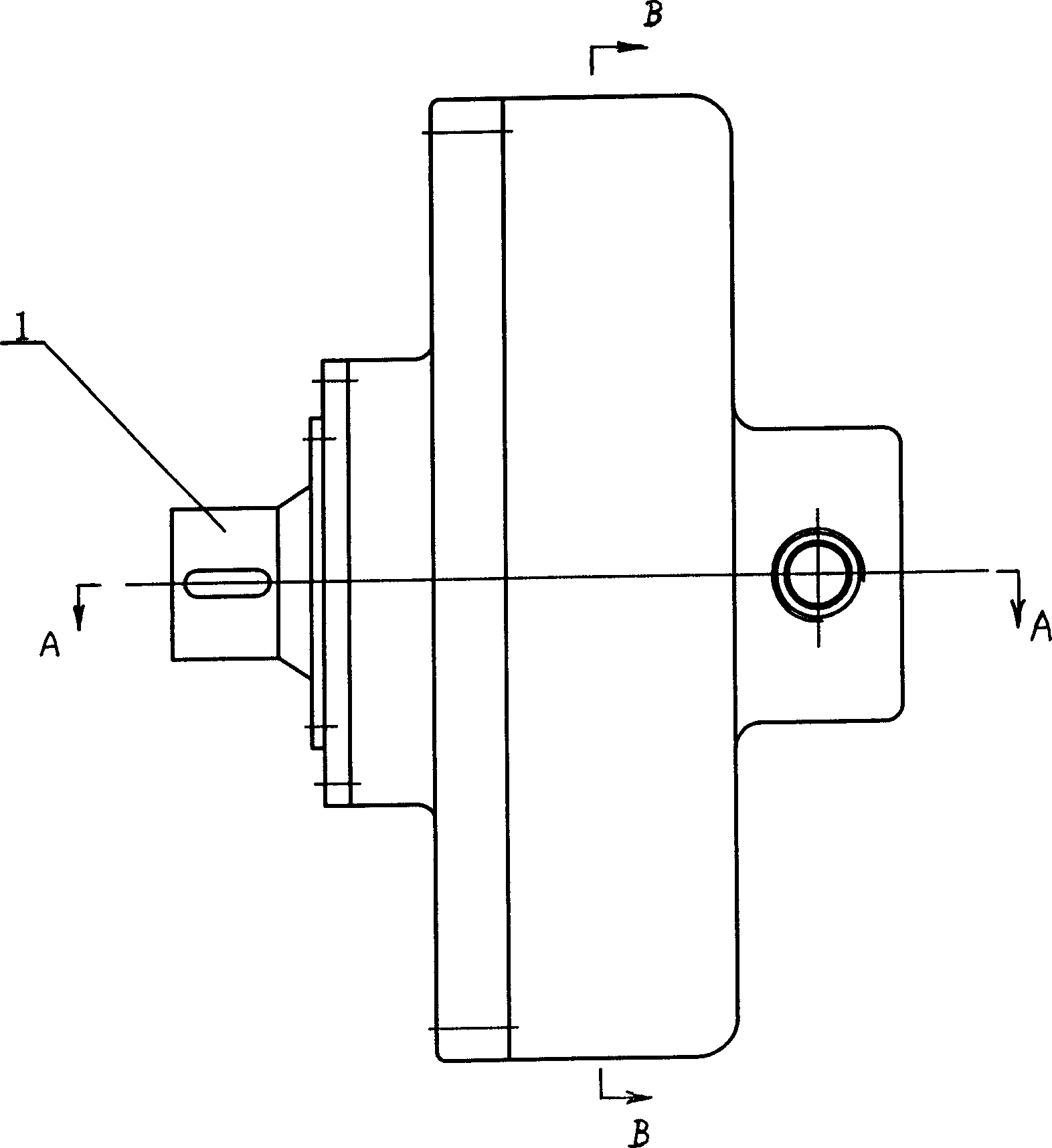

Gear rack reciprocating motion mechanism and engine thereof

InactiveCN101586646AImprove transmission efficiencyGood low speed performanceMachines/enginesFriction gearingsTime extensionLow speed

The invention relates to a gear rack reciprocating motion mechanism and an engine thereof and designs a minimum semicircular gear, semidiameter of which is zero. Utilizing chronotropic action of non-circular gear in the semicircular rack, process of gear movement is from acceleration from standstill, speed reduction to motionless, therefore impact of the gear by the rack is eliminated, and continuous rotation of the gear and reciprocating shockless shifting of the rack are realized. In addition, the invention can reciprocating move in different types to improve mechanical efficiency. For example, reciprocating motion of fast forward and slow backward can prolong admission period and working time of the engine. Compression time is shortened, and exhaust can adjust a valve to keep in good order. Power per liter of the engine is increased, low speed property is improved, use ratio is improved largely and energy is saved.

Owner:马燕翔

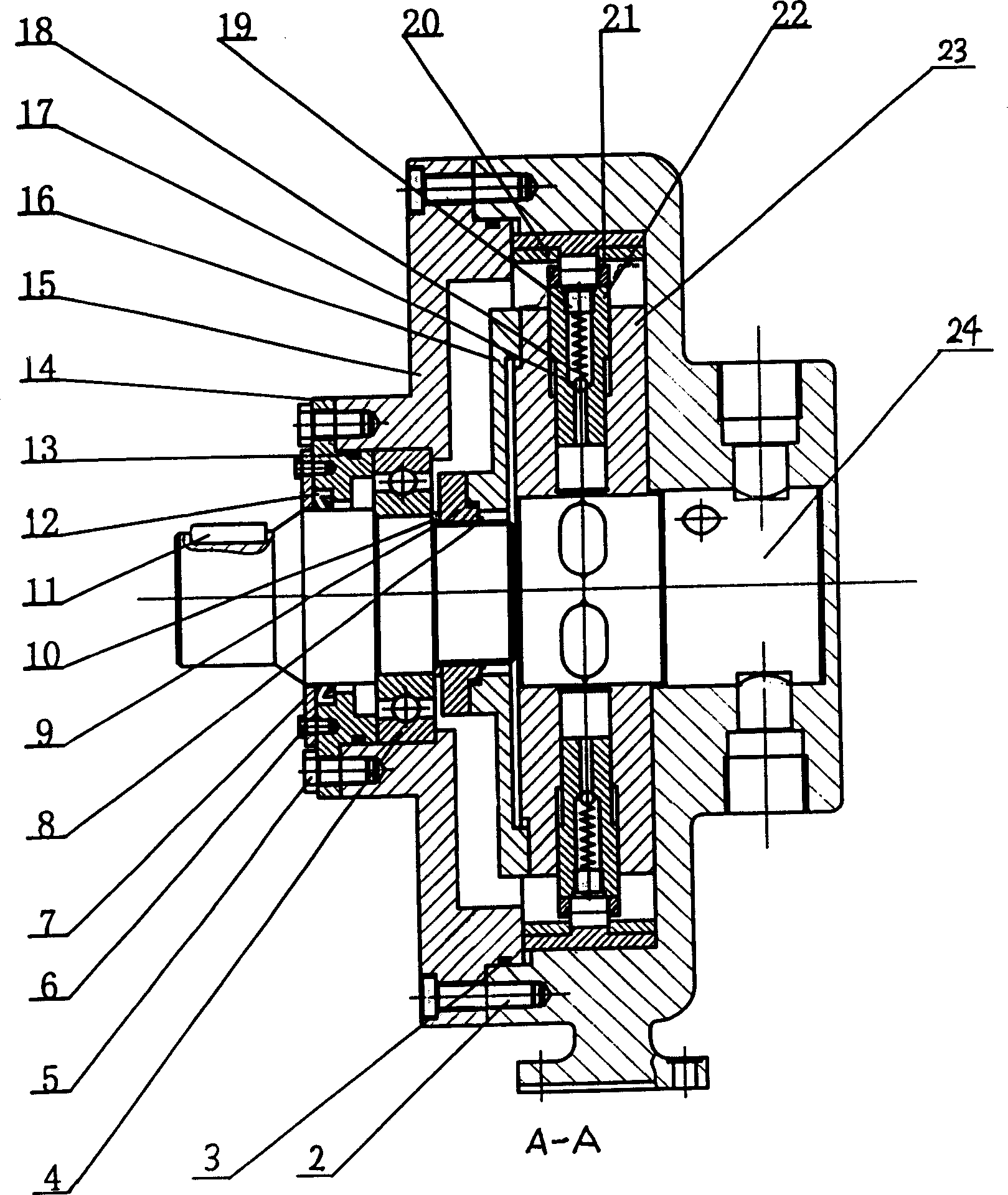

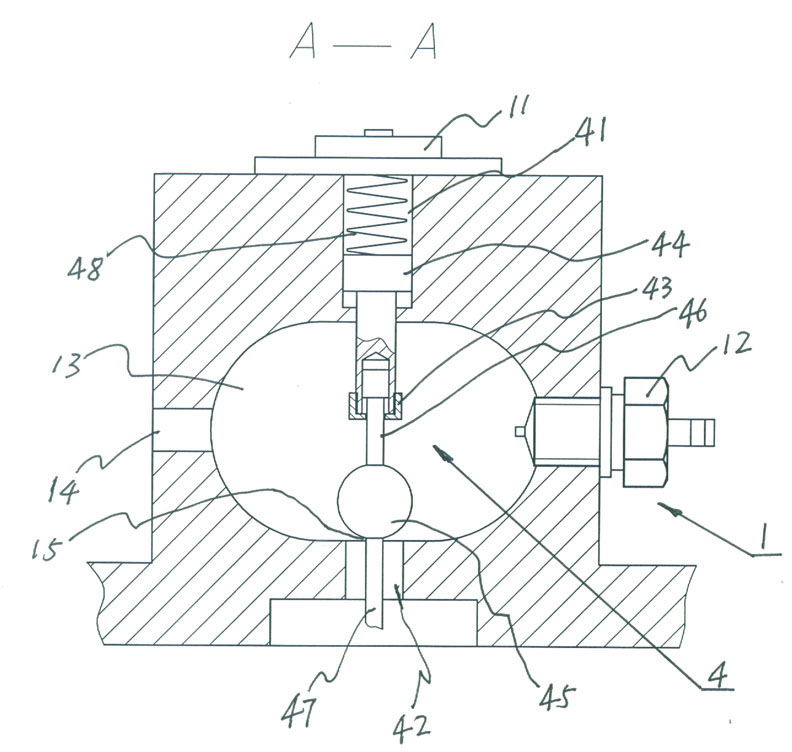

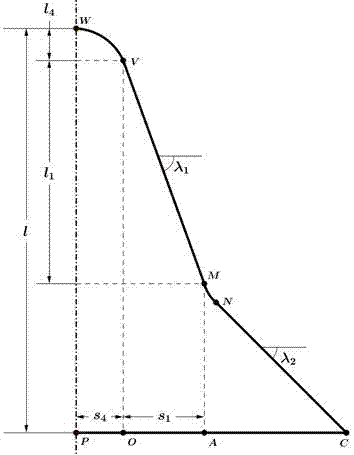

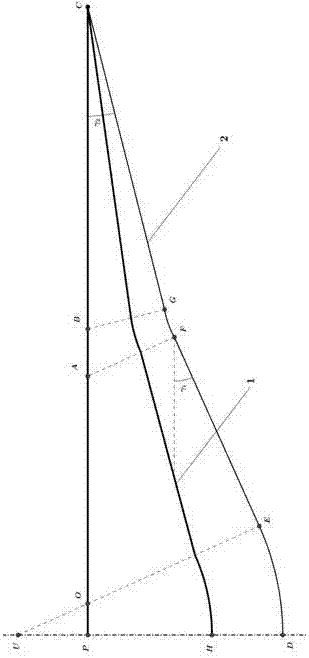

Double action radial plunger pump

InactiveCN1683789ASolve partial wearSolve the phenomenon of shaft holdingPositive-displacement liquid enginesMulti-cylinder pumpsRadial piston pumpEngineering

The double action radial plunger pump has plunger installed inside the plunger hole in the rotor, and features the stepped plunger comprising at least two coaxial sections of different outer diameters and the plunger hole in the corresponding shape. The stepped plunger has one radial notch in the end far from the flow distributing shaft, and inside the notch there is one annular holding cavity with the axis of the stepped plunger as axis. Inside the stepped plunger, there is one axial through hole, inside which one monoway valve comprising spring and piston is installed. The inner stator surface has projection curve in the flow distributing axis direction comprising smoothly connected octonal curves.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

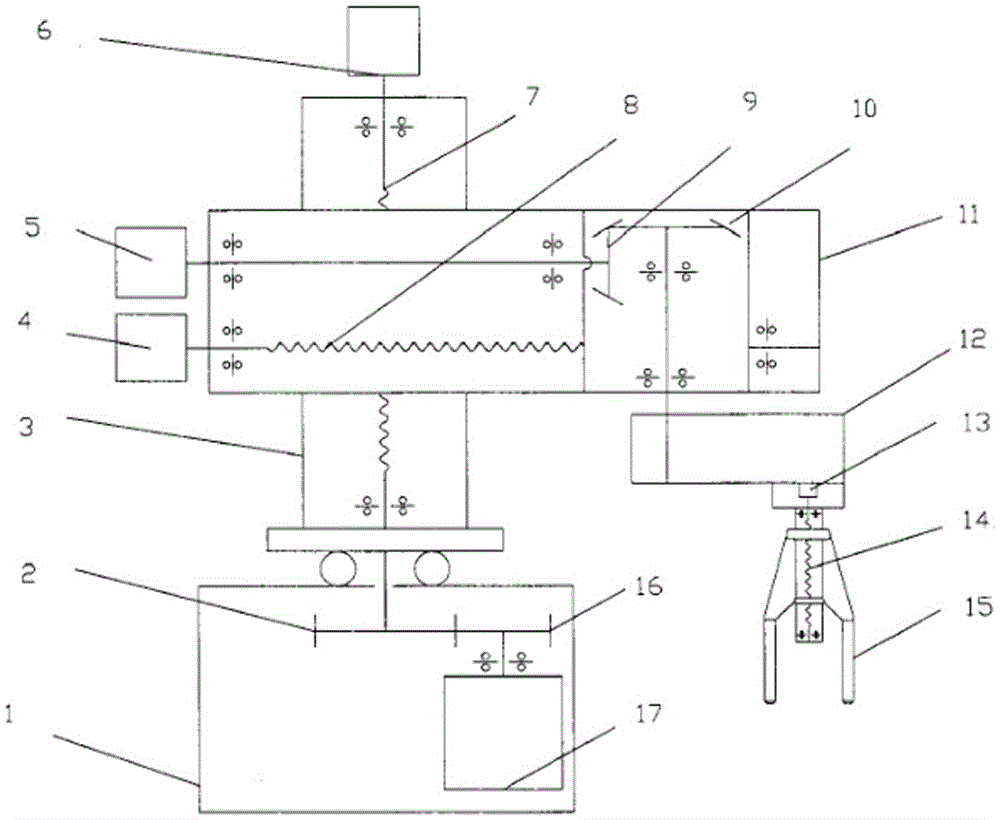

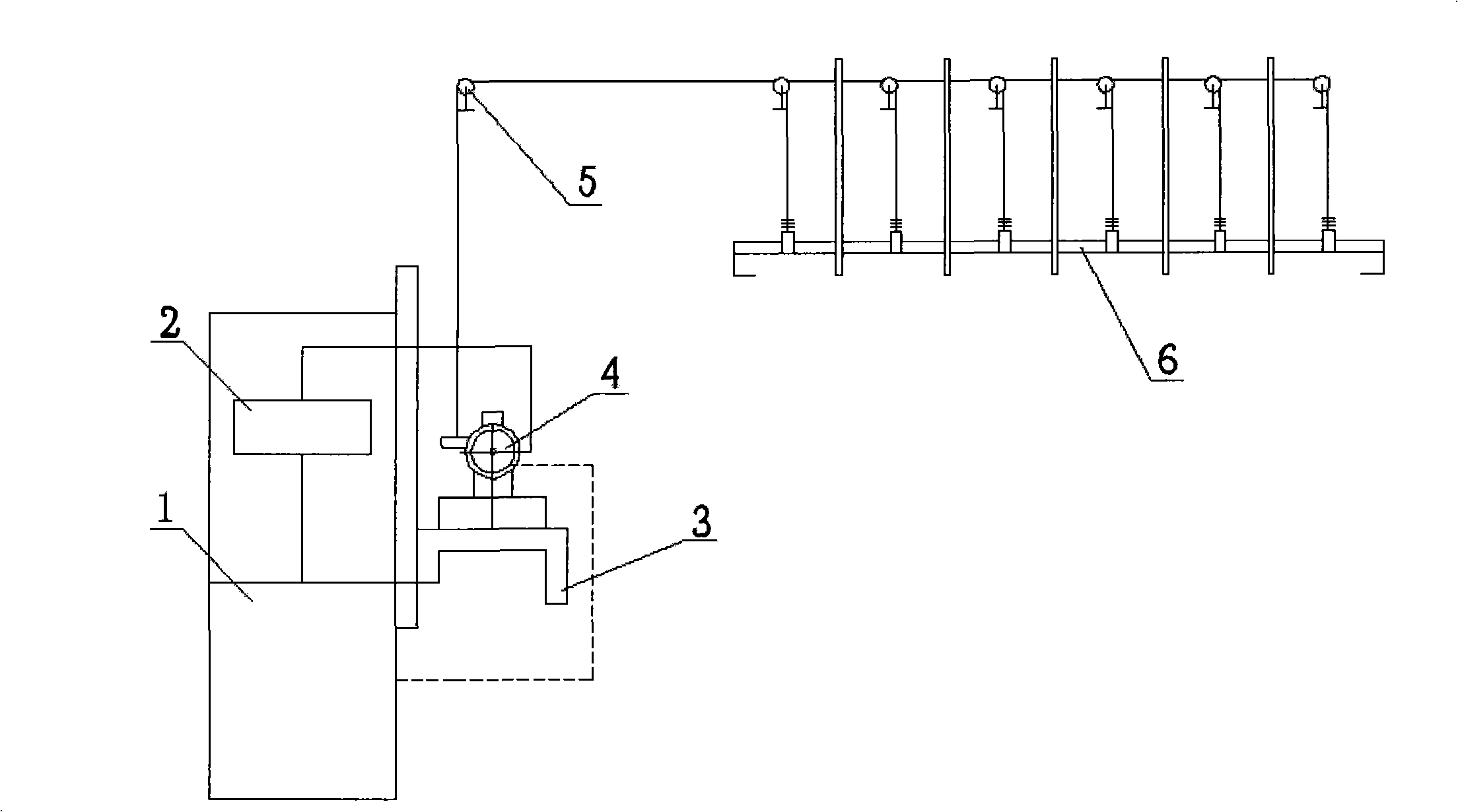

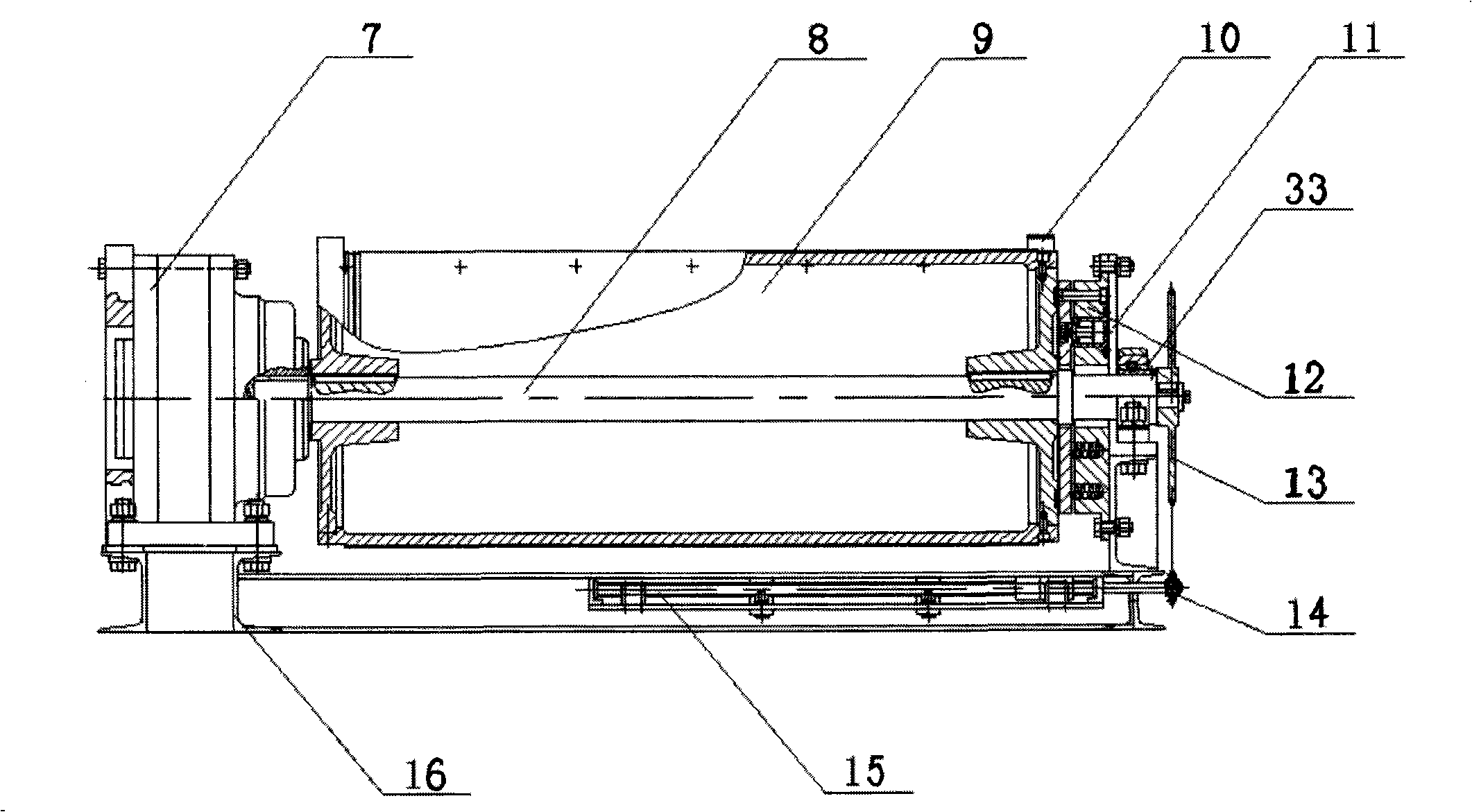

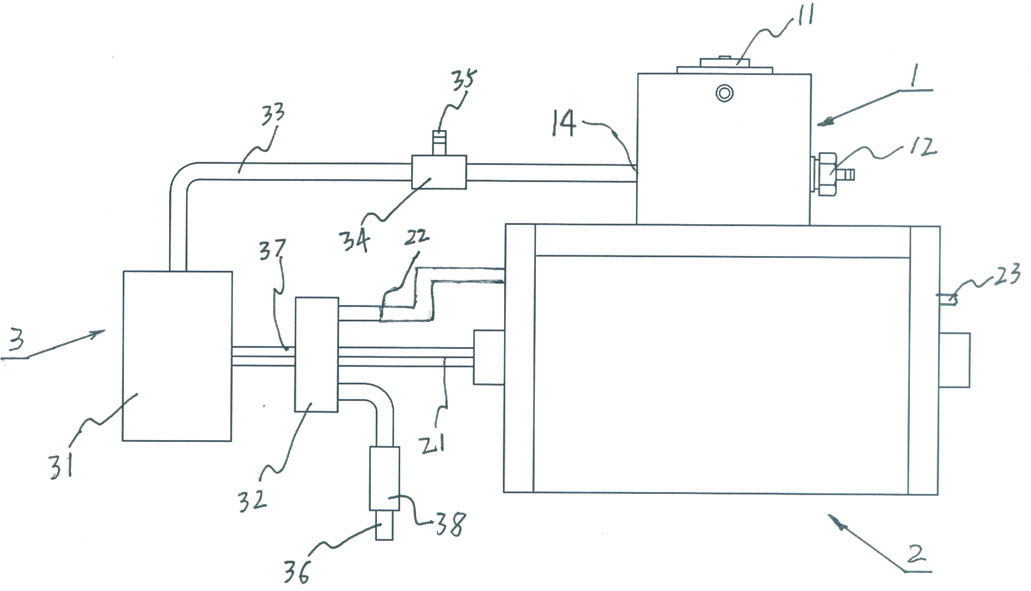

Hydraulically driven and controlled stage hanger rod system

InactiveCN101254889AInput signal power is smallReduce dead zonePortable liftingRoundaboutsHydraulic motorControl system

A hydraulically driven and controlled stage suspender system comprises a pulley system (5); a suspender (6); and a driver (4) disposed on an overbridge (3), wherein a pump station (1) and a control system (2) connected with the driver (4) are disposed on the overbridge (3); the driver (4) comprises a pedestal (16); a hydraulic motor (7) is disposed on the pedestal (16); one end of a transmission shaft (8) is connected with the dynamic output terminal of the hydraulic motor (7); a roll (9) is disposed on the transmission shaft (8); a position retainer (10) is disposed on the roll (9); the other end of the transmission shaft (8) is disposed on a support (11) on the end of pedestal (16) through an insert bearing with housing (33); a hydraulic brake (12) is disposed at a position on the support (11) corresponding to the end surface of the roll; and a proportional lead screw (15) is disposed on the pedestal (16). The stage suspender system has the advantages of convenient control, reliability and high efficiency.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

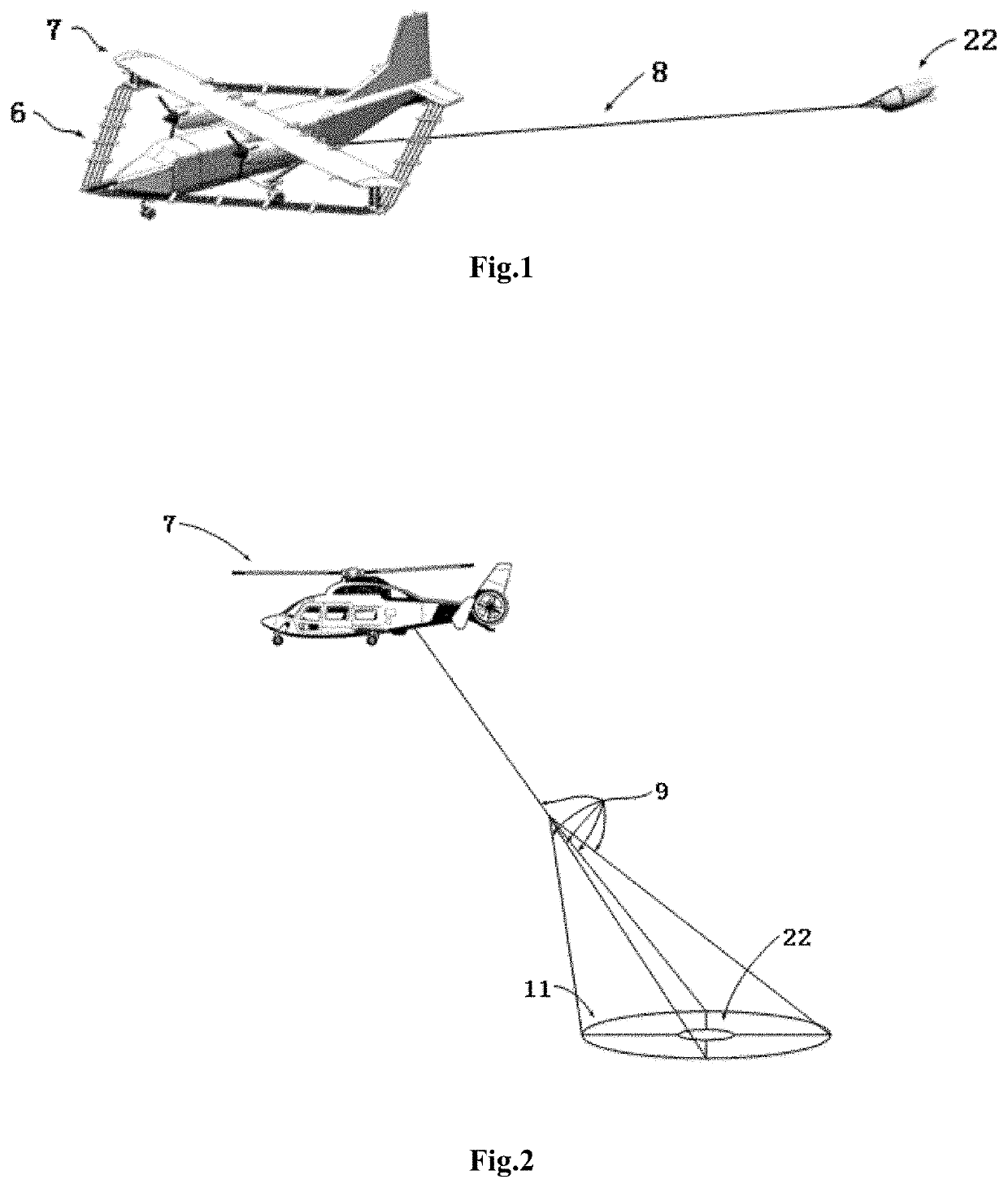

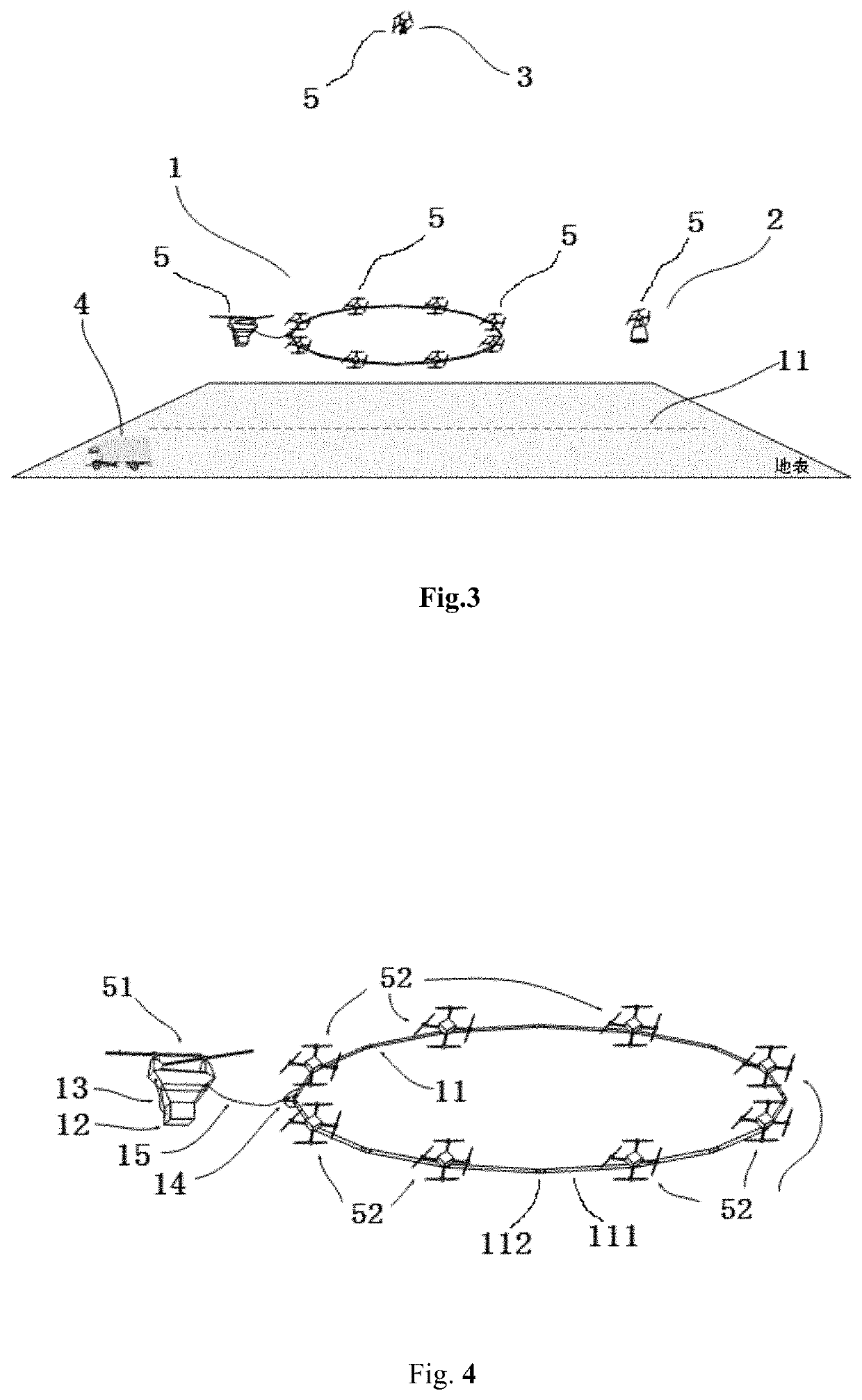

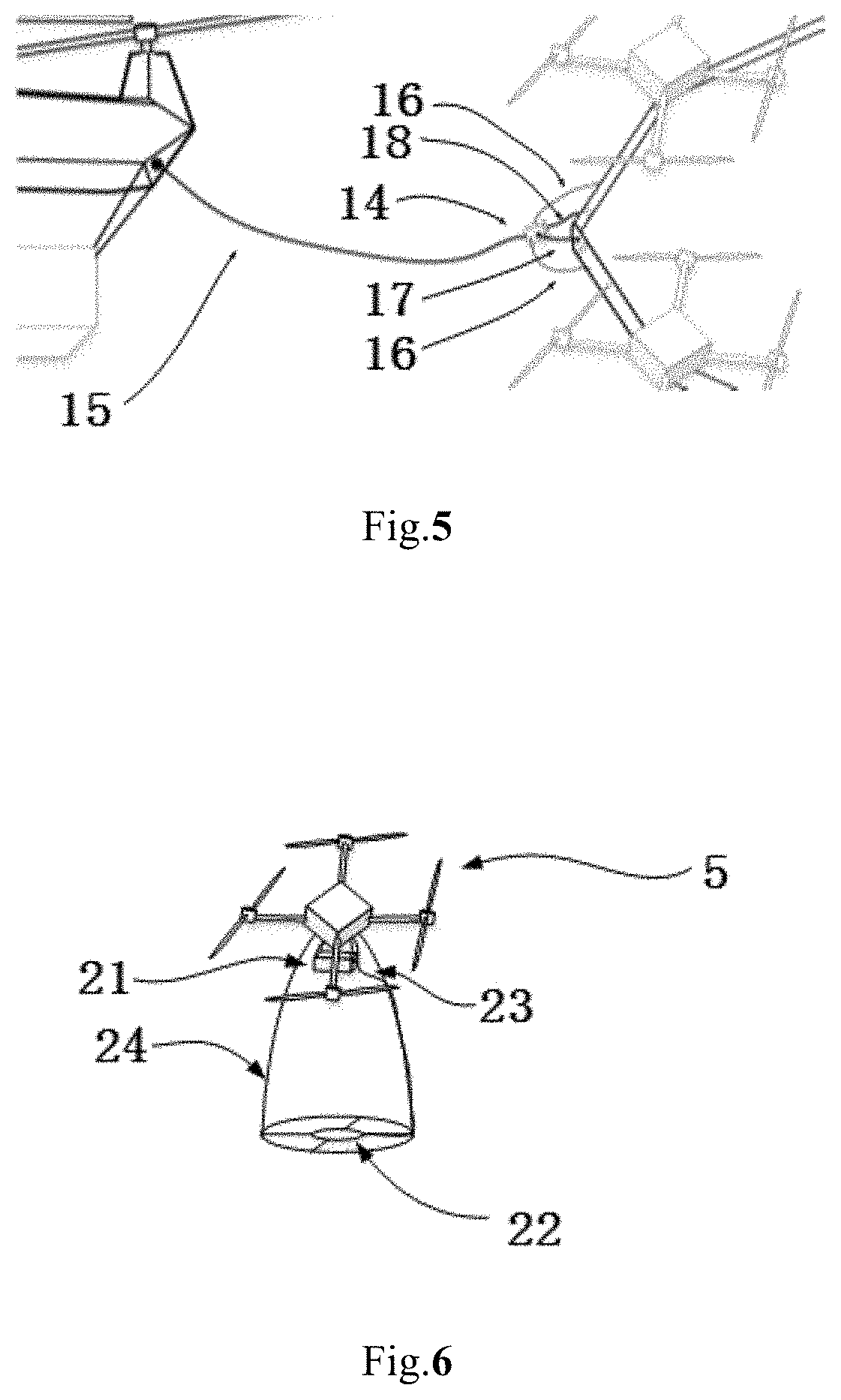

Distributed Airborne Electromagnetic Detection System

InactiveUS20210302613A1Improve performanceShorten the lengthUnmanned aerial vehiclesRemote controlled aircraftUncrewed vehicleTrunking

The present disclosure discloses a distributed airborne electromagnetic detection system, and relates to an airborne electromagnetic detection technology. The distributed airborne electromagnetic detection system comprises at least one transmitting system, at least one receiving system, at least one trunk module, and an earth station, and also a plurality of Unmanned Aerial Vehicles (UAVs) for carrying the transmitting system, the receiving system, and the trunk module. The distributed airborne electromagnetic detection system does not require high performance or high economical efficiency for a single UAV; under precise synchronous flight conditions, the distance between a type I UAV and a transmitting loop structure can be greatly reduced, thereby significantly reducing the length of unwanted transmitting cable; and in addition, due to the better low-altitude low-speed performance of UAVs, the traveling speed of the entire system can be further reduced, thus obtaining higher quality data.

Owner:WU XIN +2

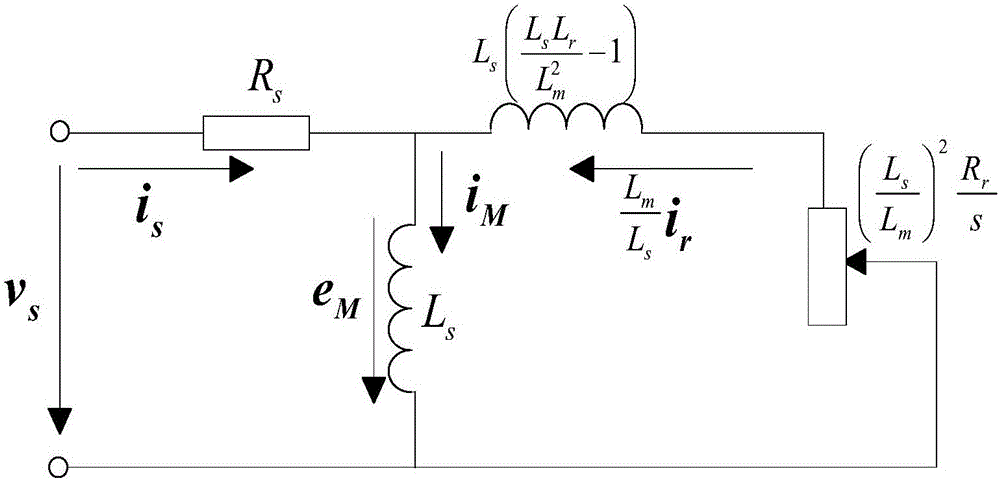

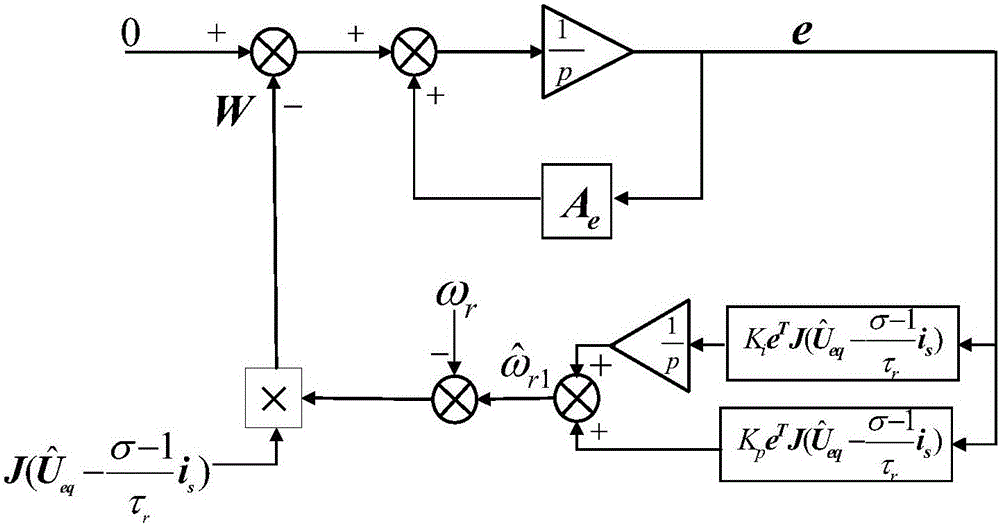

Rotor electric angle speed observation method for asynchronous motor

ActiveCN105932924AImprove robustnessImprove convergence speedElectronic commutation motor controlVector control systemsReference modelEquation of state

The invention discloses a rotor electric angle speed observation method for an asynchronous motor. The electric angle speed observation method comprises the following steps: simplifying a gamma-type equivalent circuit by defining an intermediate current vector im, and establishing a state equation of the intermediate current vector im; then constructing a sliding mode observer about the intermediate current vector im, observing to obtain an equivalent sliding mode control quantity Ueq as a reference model, establishing a state equation of the equivalent sliding mode control quantity Ueq as an adjustable model, and obtaining a rotor electric angle speed observation value as shown in the specification through a model reference self-adaptive method. Meanwhile, a rotor electric angle speed feedforward value as shown in the specification obtained by the equivalent sliding mode control quantity Ueq is fused into the rotor electric angle speed observation value as shown in the specification to obtain a rotor electric angle speed final observation value as shown in the specification, so that the convergence speed and dynamic performance of the model reference self-adaptive method are promoted, and the disadvantages of direct calculation method parameter robustness are also overcome. Researches show that the rotor electric angle speed observation method for the asynchronous motor provided by the invention has better steady state and dynamic performance and higher parameter robustness.

Owner:HEFEI UNIV OF TECH

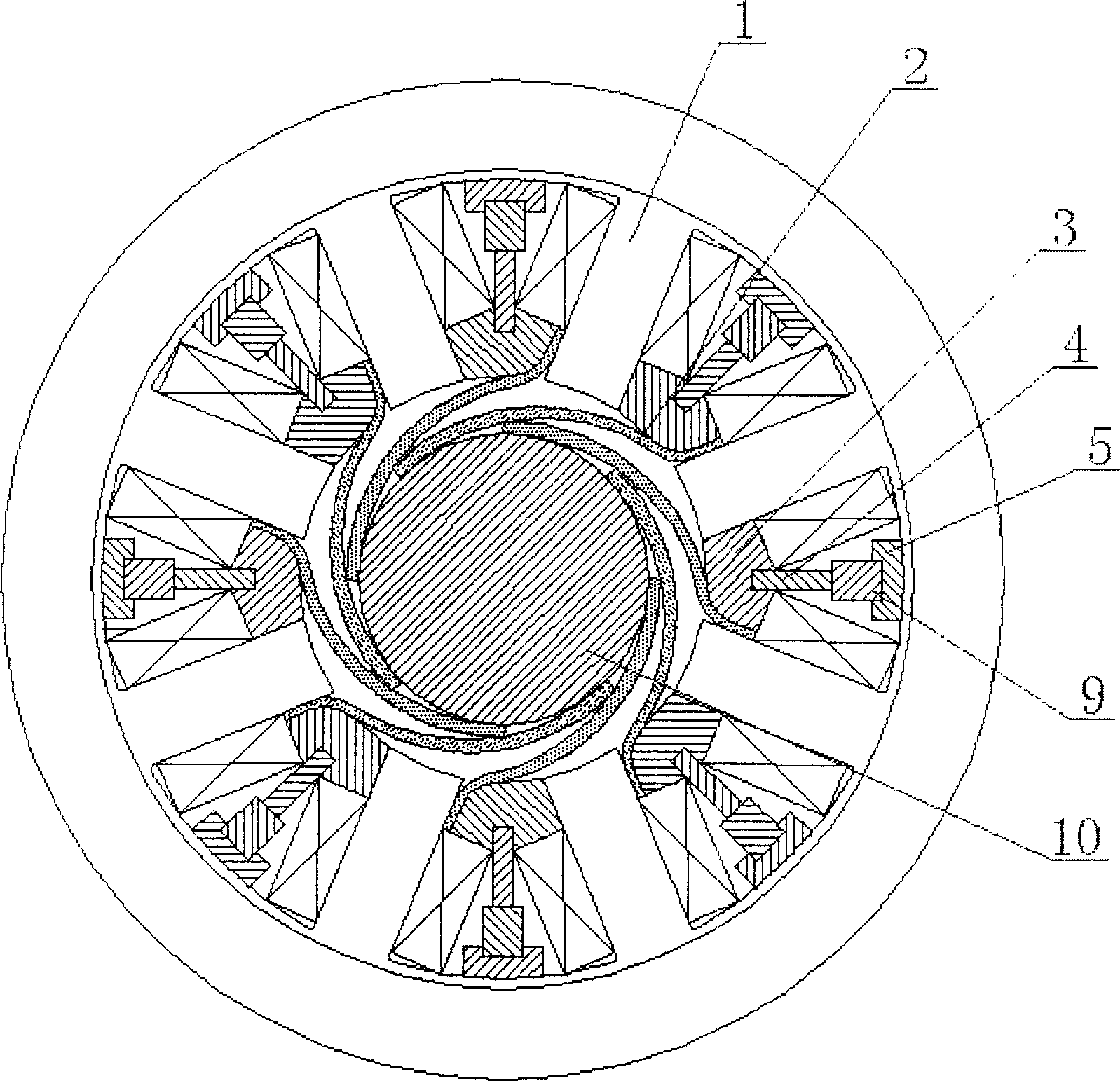

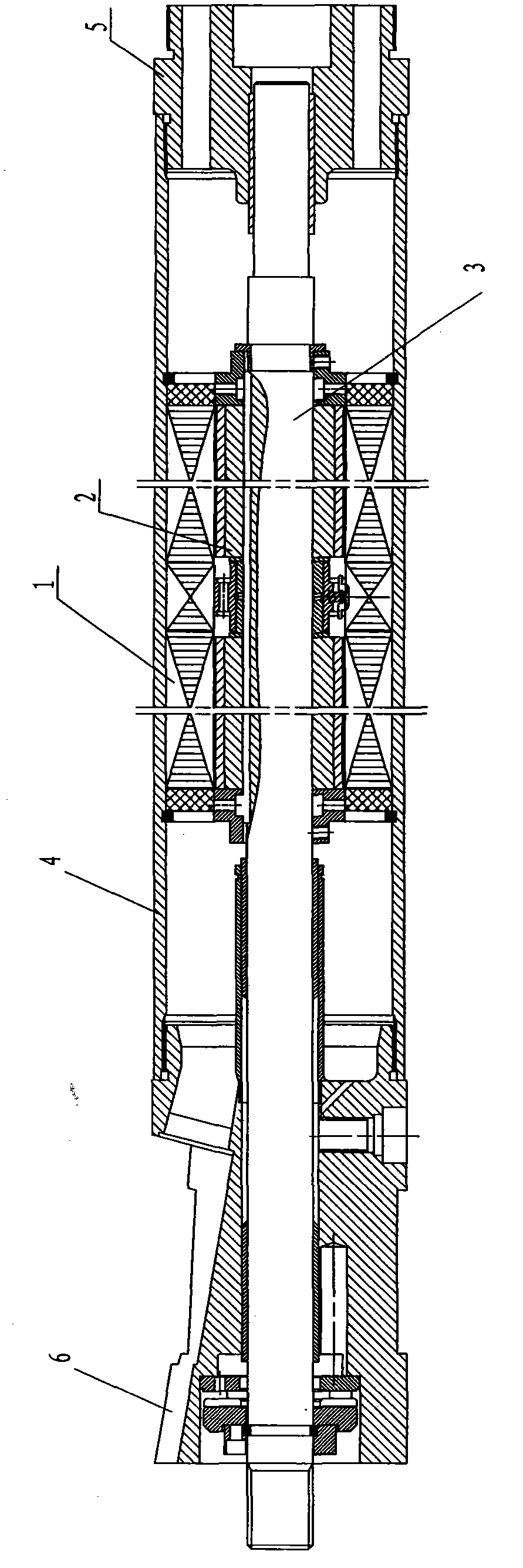

Switched reluctance motor of directly-driven submersible screw pump

InactiveCN102035334AStable structureSimple preparation processMagnetic circuit rotating partsMagnetic circuit stationary partsElectric machineThree-phase

The invention discloses a switched reluctance motor, which comprises a stator, a rotor and an electric shaft, wherein the rotor is fixed on the electric shaft; the stator is arranged outside the rotor; the motor has a three-phase 6 / 4 structure; the stator is provided with three groups of stator teeth which are arranged radially oppositely; each stator tooth is provided with a centralized winding coil; two radially opposite coils are connected in series to form a winding; and the rotor is provided with two groups of rotor teeth, namely four rotor teeth. The switched reluctance motor has a simple structure, so that output power can be increased by increasing the axial lengths of the stator and the rotor or increasing the section number of a generating structure consisting of the stator and the rotor which are connected in series. Therefore, radial size of the motor can be reduced, the switched reluctance motor can be provided with a slender structure and is suitable for underground operation and the common prejudice that the switched reluctance motor cannot be applied to underground operation because of a large radial size in the prior art is changed.

Owner:万奥普(北京)石油工程技术开发研究院有限公司 +1

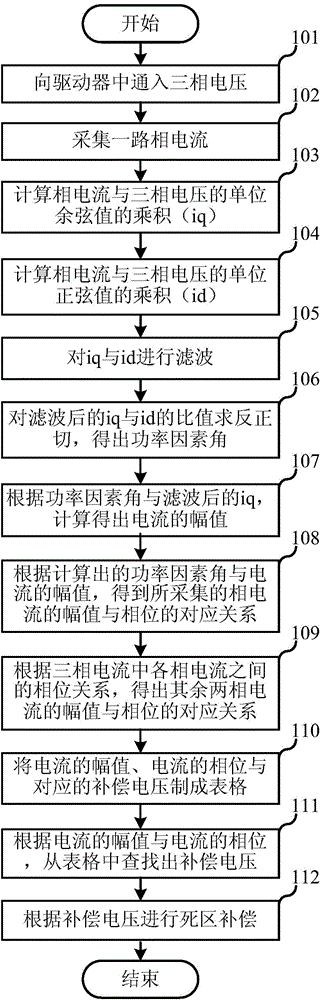

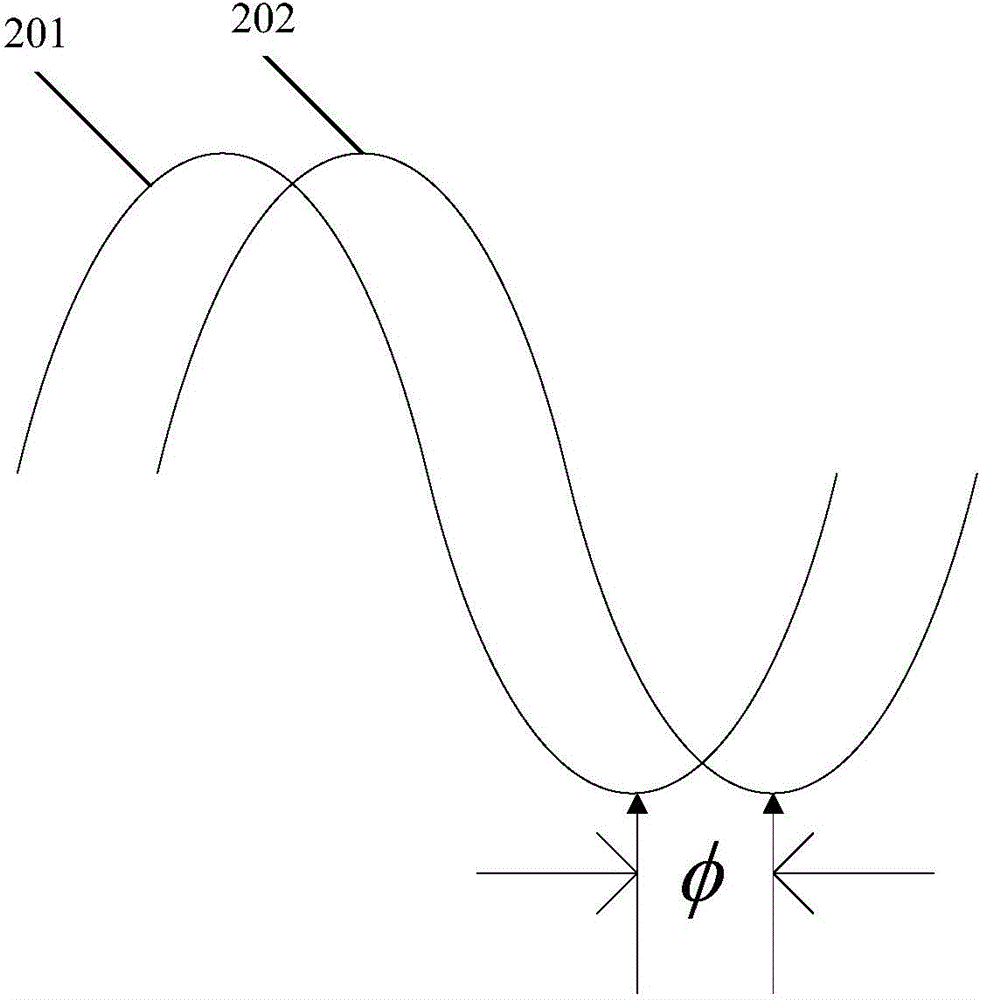

Dead-time compensation method and system of open-loop driver

The invention relates to the technical field of alternating-current servo frequency converter and discloses a dead-time compensation method and system of an open-loop driver. The method includes: calculating the power factor angle of the voltage and currents in the driver and the amplitude of the currents; performing online current setting according to the amplitude and power factor angle of the currents to obtain the correspondence of the amplitude and the phase of the currents; performing dead-time compensation according to the correspondence; wherein the magnitude of compensation voltage is acquired according to the amplitude of the currents, and the positive and negative of the compensation voltage are judged according to the phase of the corresponding currents. By the method, current direction can be judged accurately, interference on dead-time compensation is reduced, and the precision of the output voltage is increased; zero current clamping problem caused by the incorrect current direction judging can be avoided, system jittering and noises are reduced, control precision is increased, and system low-speed performance is improved.

Owner:SHANGHAI STEP ELECTRIC +1

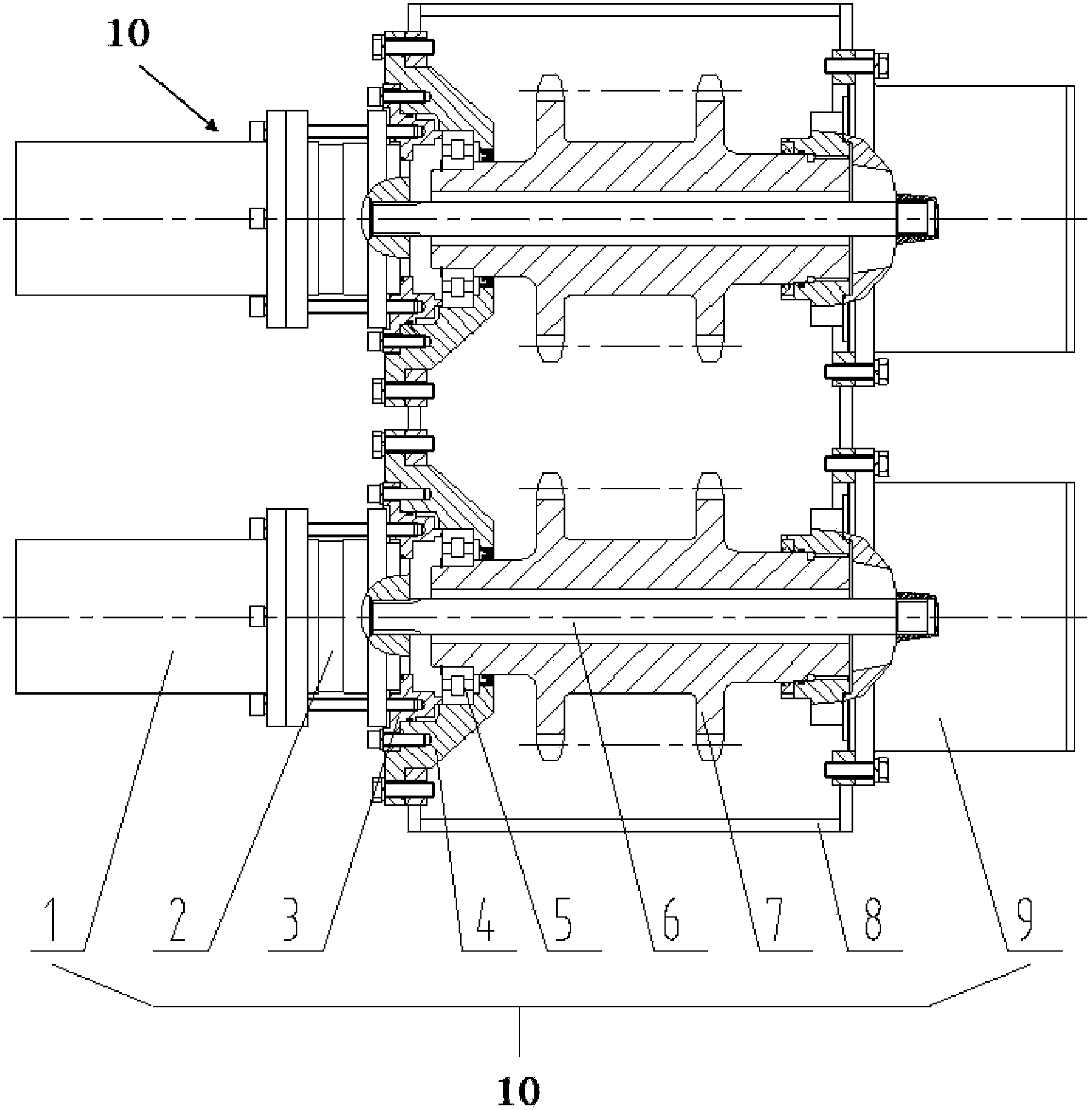

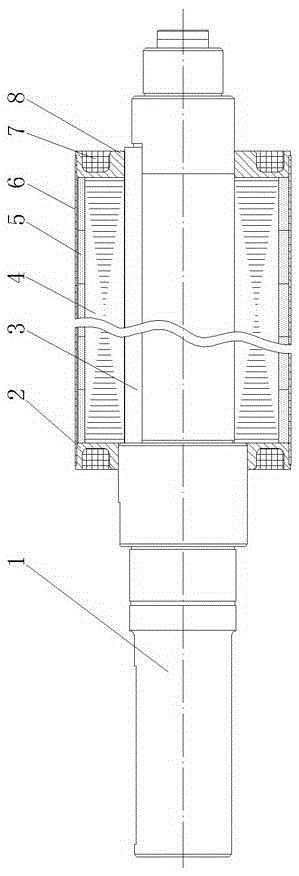

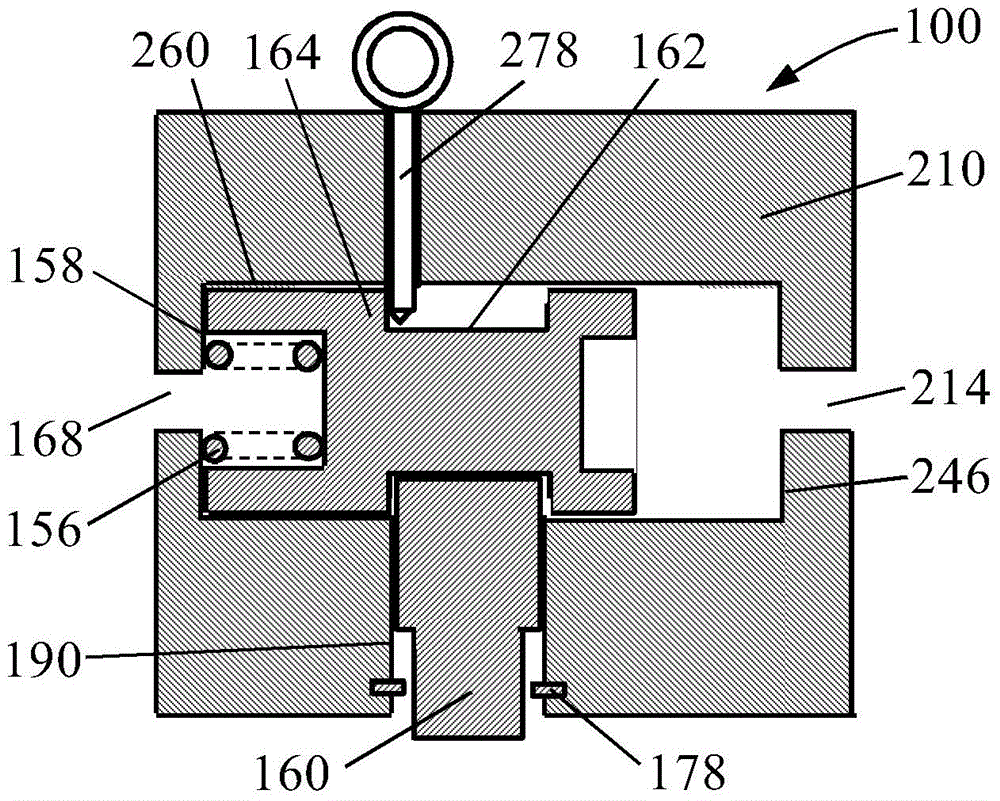

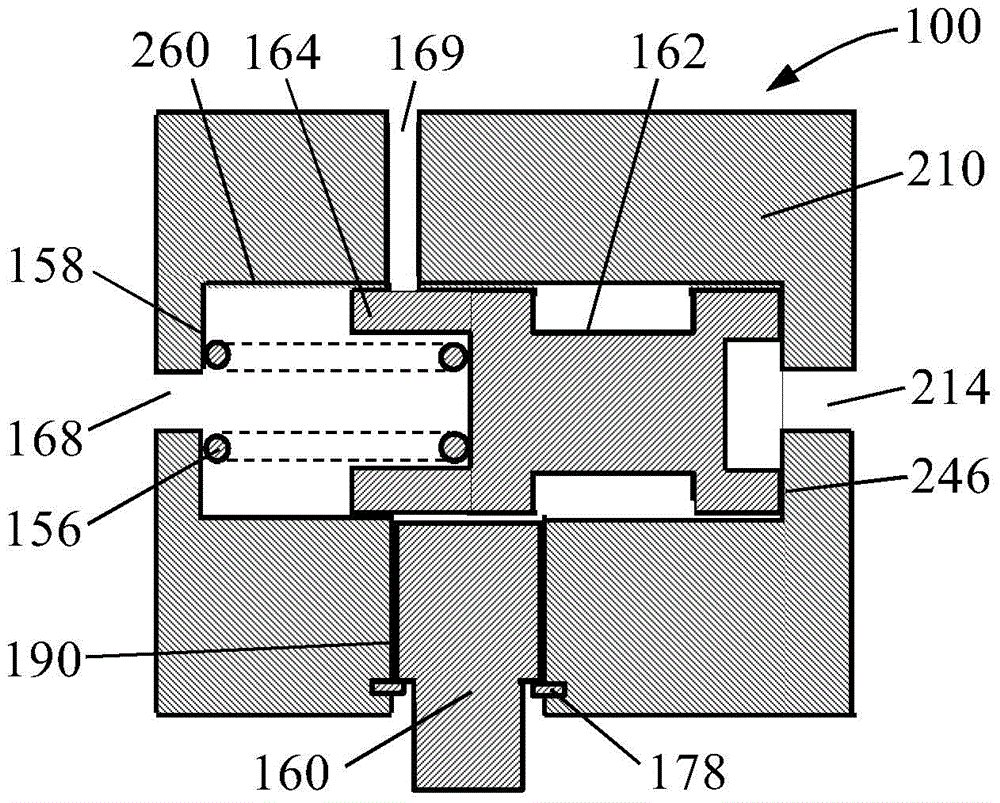

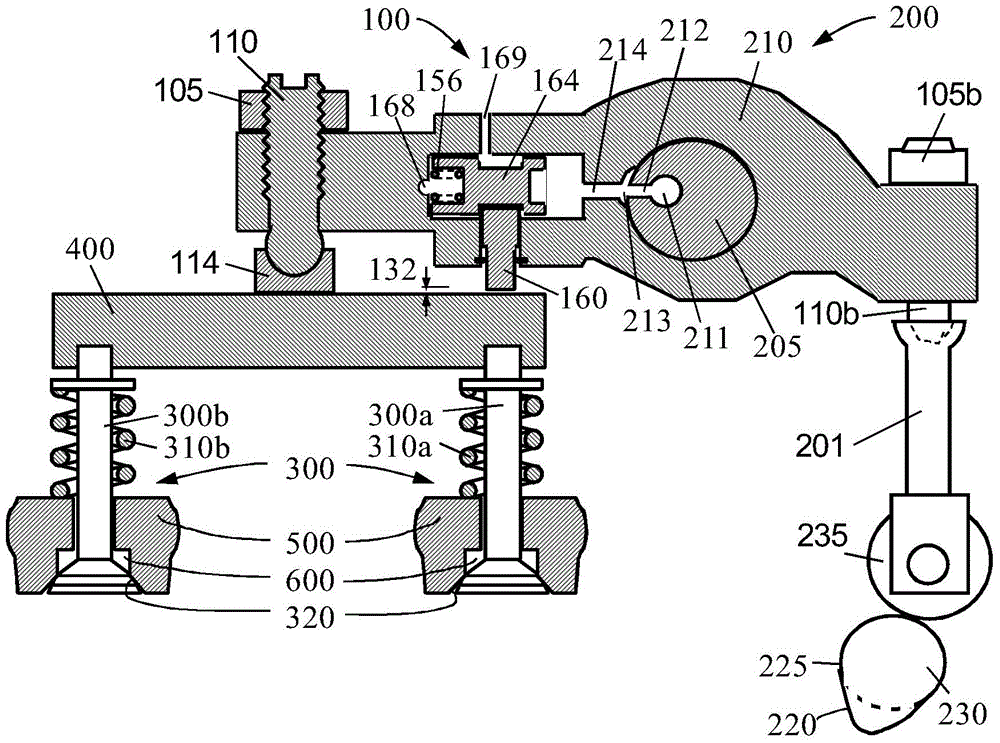

Injection head driving device for coiled tubing

ActiveCN103510891AEasy to installEfficient use ofDrilling rodsDrilling casingsHydraulic motorCoiled tubing

The invention discloses an injection head driving device for coiled tubing, and belongs to the field of petroleum. The injection head driving device for the coiled tubing comprises two sets of hydraulic motor driving mechanisms arranged in an injection head box body, and each set of hydraulic motor driving mechanism comprises a hydraulic motor, a hydraulic brake device, a connecting disc, a bearing block, a planetary reducer, a bearing, a sprocket shaft and a central shaft. The hydraulic motors and the planetary reducers are mounted on the two sides of the injection head box body respectively, the sprocket shafts are hollow shafts, the central shafts penetrates through the sprocket shafts, one end of each central shaft is connected with the output end of each hydraulic motor, and the other end of each central shaft is connected with the input end of each planetary reducer. The injection head driving device for the coiled tubing has the advantages of being compact and symmetrical in structure, good in balance performance, easy to lift, operate and mount, high in driving efficiency and good in low speed stability.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

Rotary piston type internal-combustion engine

InactiveCN101975106AReduce volumeHigh torqueInternal combustion piston enginesCombustion chamberEngineering

The invention relates to a rotary piston type internal-combustion engine, comprising a cylinder body; wherein the cylinder body is internally provided with a combustion chamber and a working chamber which is communicated with the combustion chamber by virtue of a through hole as well as an energy exchange assembly which is arranged on the cylinder body and is stretched from the combustion chamber to the working chamber, and the working chamber is internally provided with a rotary piston limited by an output shaft. The combustion chamber and the working chamber are separate and are mutually communicated, so that working medium in the combustion chamber can enter into the working chamber according to the preset direction, and a force in the same direction can be generated to do work to the rotary piston, so that the internal-combustion engine in the structure has good economic performance and dynamic performance.

Owner:孟庆达

Curved head double-sweepback osculating cone wave rider with transition section

ActiveCN107253521AWithout sacrificing volumetric efficiencyImprove aerodynamic performanceInfluencers by generating vorticesDrag reductionLeading edgeEngineering

The invention discloses a curved head double-sweepback osculating cone wave rider with a transition section. The front parts of the wave rider are crossed to form a curved surface head; one front part of the wave rider comprises two straight line sections and a transition curve for connecting the two straight line sections; a first straight line section corresponds to a first sweepback angle from a cusp; a second straight line section corresponds to a second sweepback angle; the angles of the two sweepback angles are controllable in a design procedure; the two straight line sections are connected by the transition curve and a first-order derivative and a second first-order derivative are continued. According to the curved head double-sweepback osculating cone wave rider, a stable separation vortex is generated on an upper surface through the straight line front part with controllable double sweepback angles, so that the aerodynamic performance of the upper surface is improved without reducing the volumetric efficiency of an aircraft, and thus the design of the upper surface is greatly facilitated.

Owner:CALCULATION AERODYNAMICS INST CHINA AERODYNAMICS RES & DEV CENT

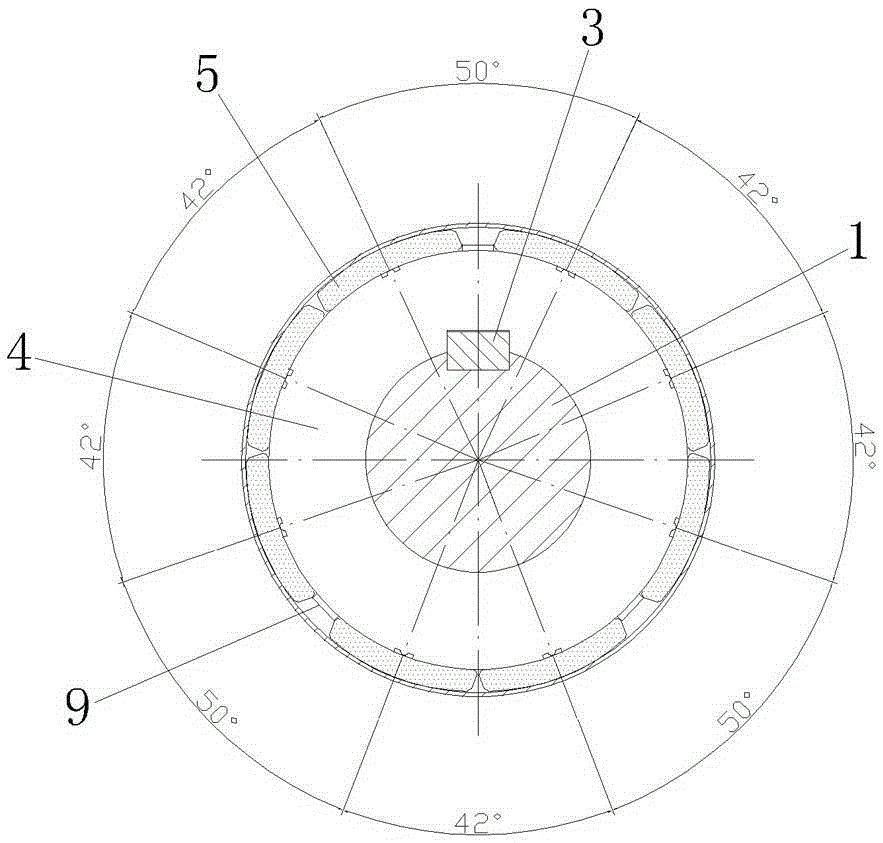

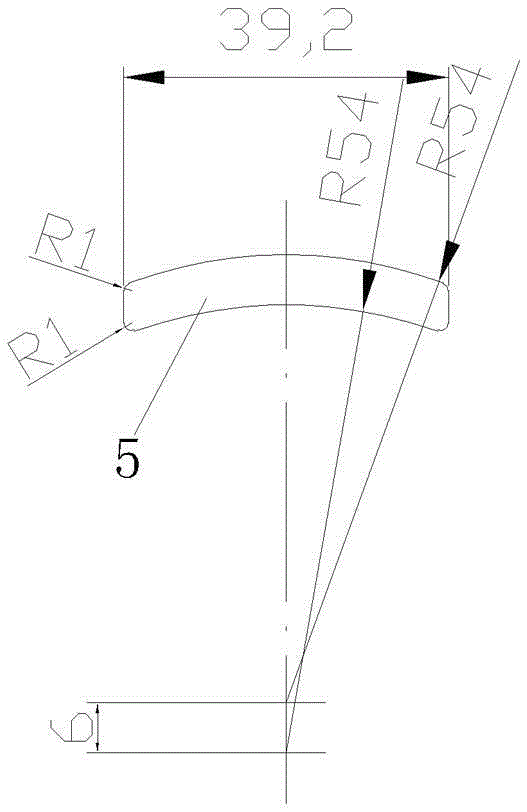

Permanent magnet motor rotor with nonuniform-distribution magnetic poles

InactiveCN105262259AReduce vibration and noiseGuaranteed uptimeWindingsMagnetic circuit rotating partsLow speedHarmonic

A permanent magnet motor rotor with nonuniform-distribution magnetic poles comprises a rotating shaft, a rotor iron core, 8 magnetic poles, a first end portion fixing ring, a second end portion fixing ring and a weftless band. The rotor iron core sleeves an outer side of the rotating shaft and the rotor iron core is connected to the rotating shaft through a key. The magnetic poles are cemented to an outer circumference surface of the rotor iron core. The first end portion fixing ring and the second end portion fixing ring sleeve left and right ends of the rotating shaft relative to the rotor iron core respectively. The weftless band winds a surface of the magnetic poles. The outer circumference surface of the rotor iron core is provided with three separation edges which are mutually parallel to a rotation axis of the rotor iron core. The three separation edges divide three gaps used for arranging the magnetic poles on the outer circumference surface of the rotor iron core. Three magnetic poles, three magnetic poles and two magnetic poles are arranged in the three gaps respectively. By using the motor rotor of the invention, a torque of a tooth groove can be reduced so that a vibration noise of the motor is small and operation is stable. Good performance on a counter electromotive force harmonic aspect is possessed. Simultaneously, low speed performance of the motor is superior, which is good for accurate speed and position control.

Owner:SHANGHAI FINEPOWER TECH

Novel IGBT current feedback dead time compensation method

InactiveCN107171541AGood low speed performanceGood compensationPower conversion systemsPower inverterLow speed

The invention relates to an IGBT current feedback dead time compensation method comprising the following steps: designing a peripheral hardware circuit, sampling the output voltage of an inverter, and determining whether the voltage is at a high or low level; taking an output signal as an input signal of a current direction logic loop, and taking a drive signal of IGBTs in the upper and lower bridge arms of the inverter as a trigger signal through a logic OR gate; and inputting a final output signal of the hardware circuit to a microprocessor via an I / O port as a logic signal for judging the direction of current, getting the amount of dead time compensation through judgment, generating a PWM pulse needed, and finally completing dead time compensation. Through the method, the direction of current can be determined accurately. Moreover, whether the current is at a zero-crossing point can be determined, and transition compensation can be carried out in the zero-crossing point stage. The compensation effect is good. The current waveform distortion rate is decreased. The low-speed performance of motors is significantly improved.

Owner:NANJING UNIV OF SCI & TECH

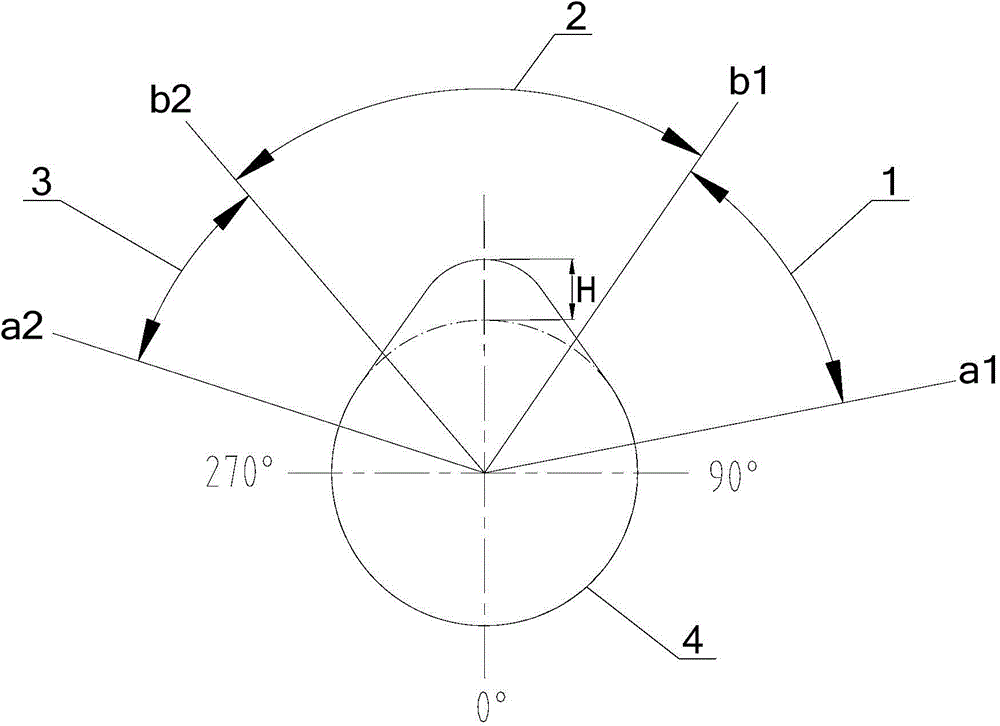

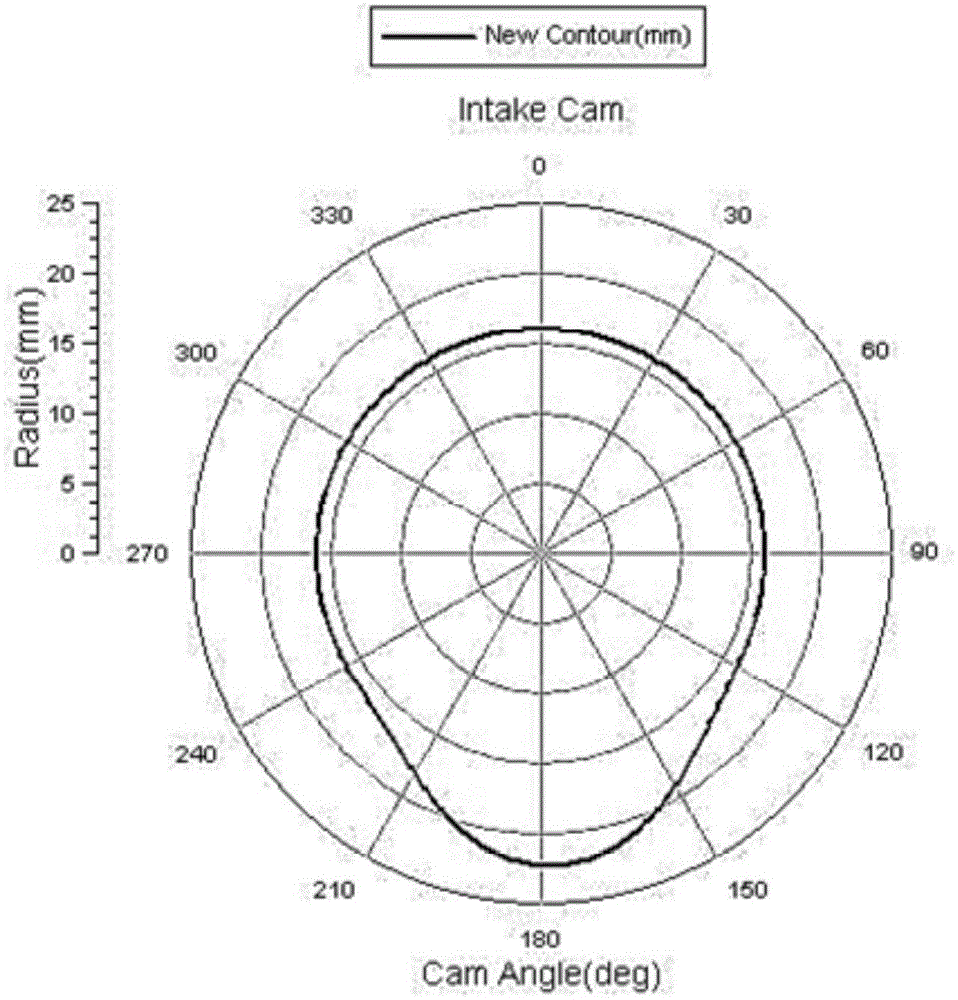

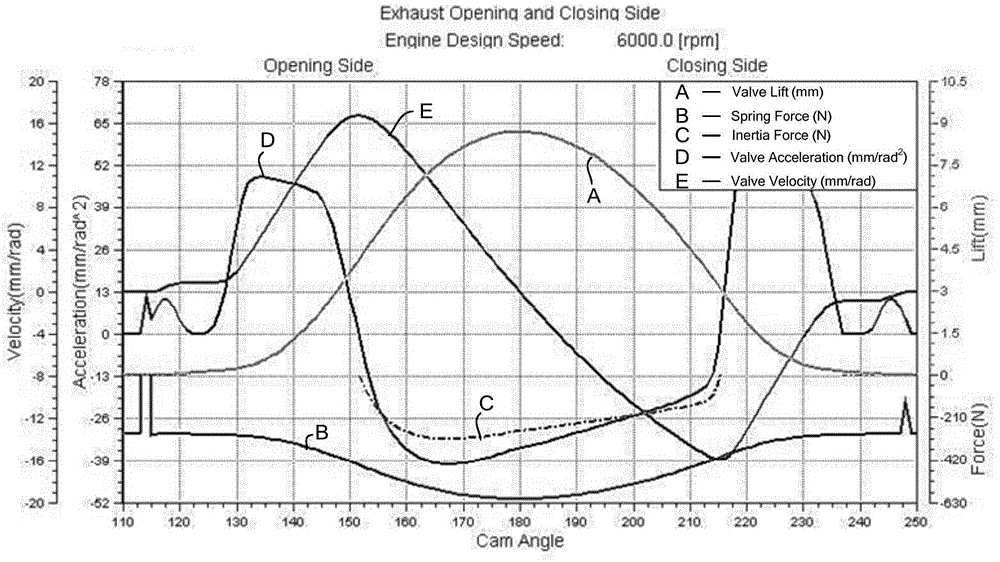

Exhaust cam of pressurizing type gasoline direct injection engine

The invention discloses an exhaust cam of a pressurizing type gasoline direct injection engine. A cam molded line of the exhaust cam comprises an air valve opening side buffering section, an air valve closing side buffering section, a working section and a base circle section, wherein a wrapping angle of the working section is in a range of 240-250 degrees; an included angle of the air valve opening side buffering section is 25-30 degrees and the height of the buffering section is more than 0.15mm; the maximum lift H of the cam molded line is 5mm-5.5mm. The test of the exhaust cam shows that the exhaust cam enables an engine to keep the output of 350N.m torque in a rotary speed range of 1500r / min-4500r / min; meanwhile, a design target of output power being 155Kw is reached under the condition that the rotary speed of the engine is a rated rotary speed being lower than 5500r / min; therefore, the engine can provide higher torque and power under low-speed operation, the lagging degree is reduced, and the low-speed performance of the engine is improved.

Owner:力帆科技(集团)股份有限公司

Method for improving low-speed performance of multi-cylinder engine

ActiveCN104421009AGood low speed performanceImprove idle speedValve arrangementsOutput powerLow speedExhaust valve

The invention relates to a method for improving low-speed performance of a multi-cylinder engine. The method comprises a process of keeping an engine valve open in constant by using a solid-chained mechanism. In the first predetermined engine speed, a working piston of the solid-chained mechanism is placed on the operating position, forming the mechanical link with the engine valve, keeping the opened engine valve from closing; and in the first predetermined engine speed or the lower engine speed including zero, keeping the engine valve open in constant. Before the engine start and during the start, the working piston of the solid-chained mechanism keeps the engine valve open in constant sequentially, until the engine speed is increased from zero to the second predetermined engine speed, the working piston is switched from the operating position to the non-operating position, and cancelling the effect on the engine valve. The method uses the novel method and mechanism, and is capable of keeping an inlet valve or an exhaust valve of the engine open in constant, improving the parking, starting and idling performance of the engine, and reducing the fuel consumption and discharge of the engine.

Owner:SHANGHAI UNIVERSOON AUTOPARTS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com