Novel IGBT current feedback dead time compensation method

A dead-time compensation and current feedback technology, applied in the field of dead-time compensation, can solve the problems of increased low-order harmonics, system instability, and reduced output voltage fundamental wave amplitude, achieving low-speed performance improvement, good compensation effect, and current The effect of waveform distortion rate reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

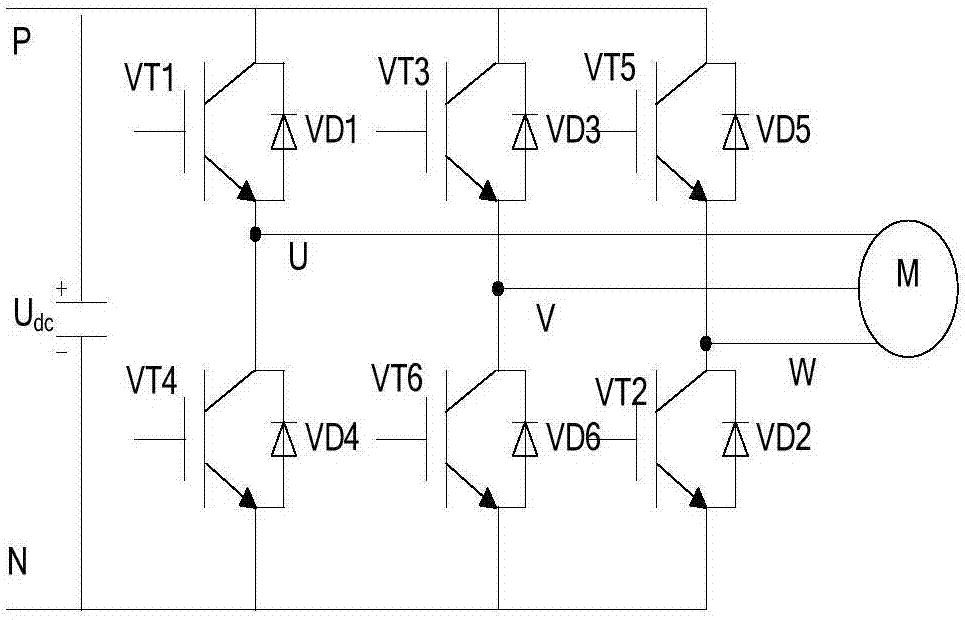

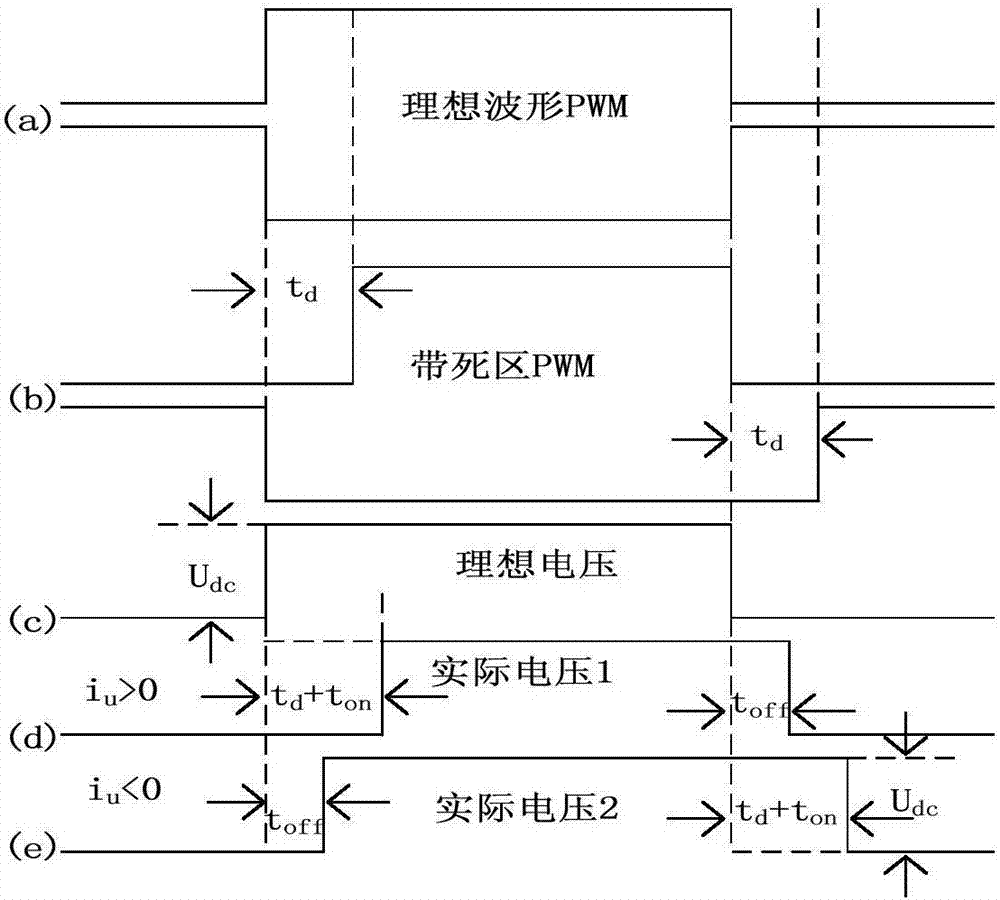

[0051] Usually in the inverter circuit of the frequency converter, the upper and lower power switching devices of the same phase bridge arm work in a complementary state. Such as figure 1As shown, the inverter circuit in the frequency converter is composed of 6 IGBT switch tubes, and the two switch tubes of VT1 and VT4, VT3 and VT6, VT5 and VT2 work in a complementary state respectively. The action of power devices requires a certain turn-on and turn-off time, and generally the turn-off time is longer than the turn-on time. In order to avoid shoot-through, time delay technology is adopted to insert enough dead time between the drive signals of the upper and lower transistors of the same-phase bridge arm to prevent shoot-through during the commutation process.

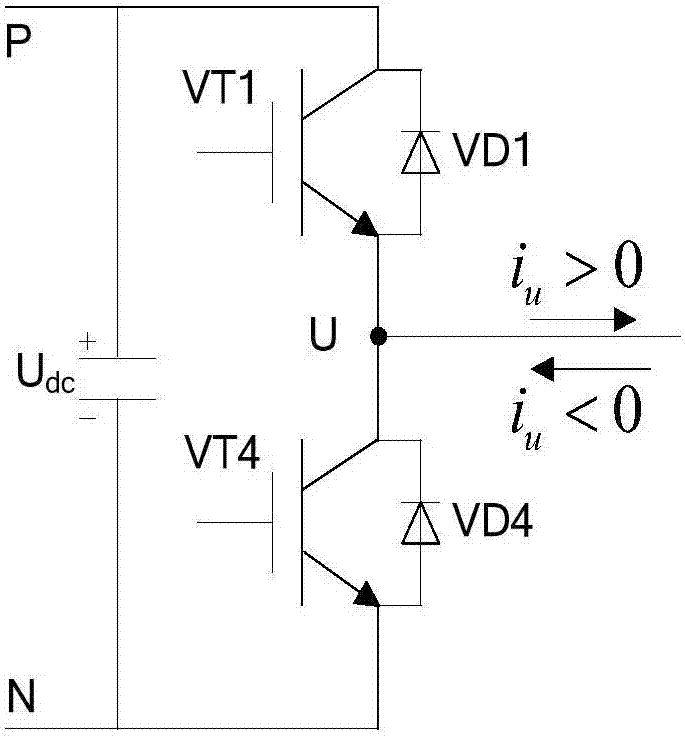

[0052] Take the U phase of the inverter as an example, assuming that i u A positive current flows out of the bridge arm, and a negative current flows into the bridge arm. Such as figure 2 As shown, when i u When >...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com