Permanent magnet motor rotor with nonuniform-distribution magnetic poles

A permanent magnet motor, evenly distributed technology, applied in the direction of adjusting/balancing rotor, magnetic circuit rotating parts, manufacturing stator/rotor body, etc., can solve the problems of vibration and noise, affecting motor performance, motor torque fluctuation, etc. Achieve good performance in terms of back EMF harmonics, superior low-speed performance, and low vibration and noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings.

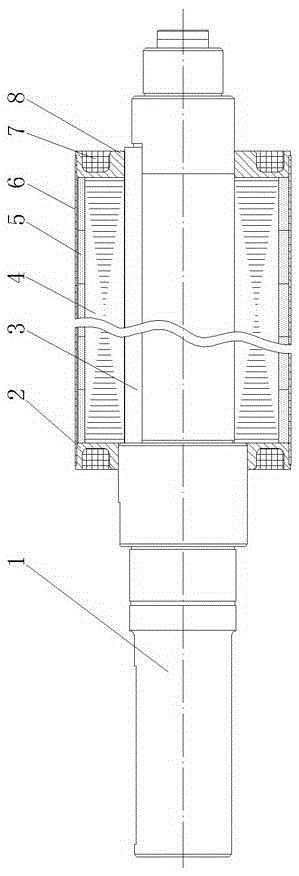

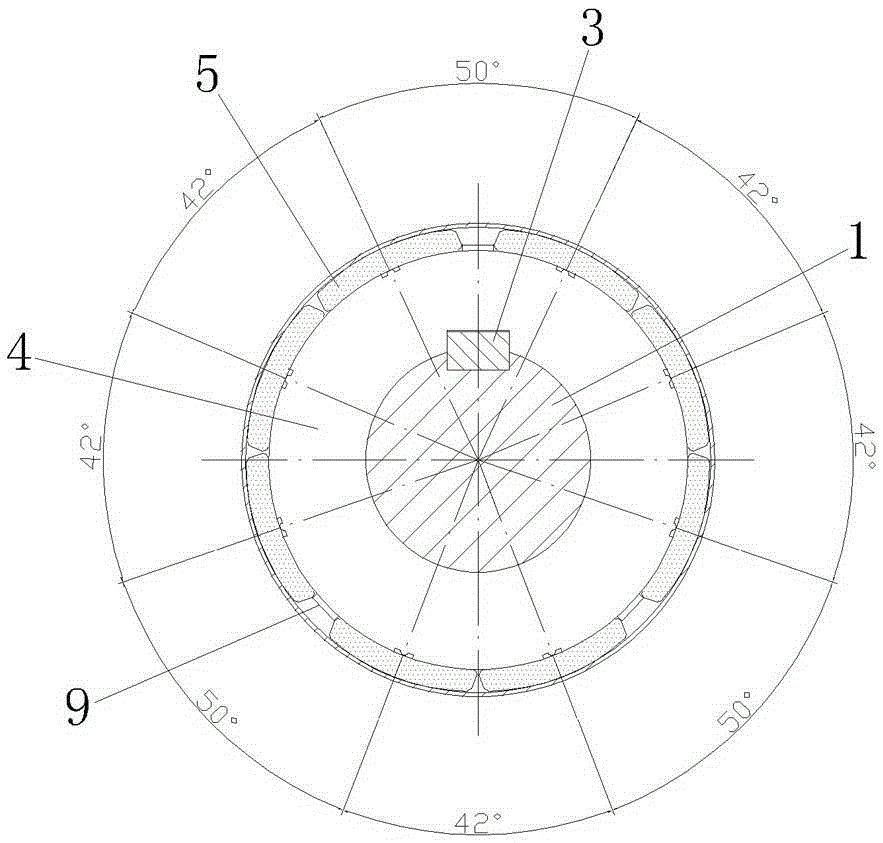

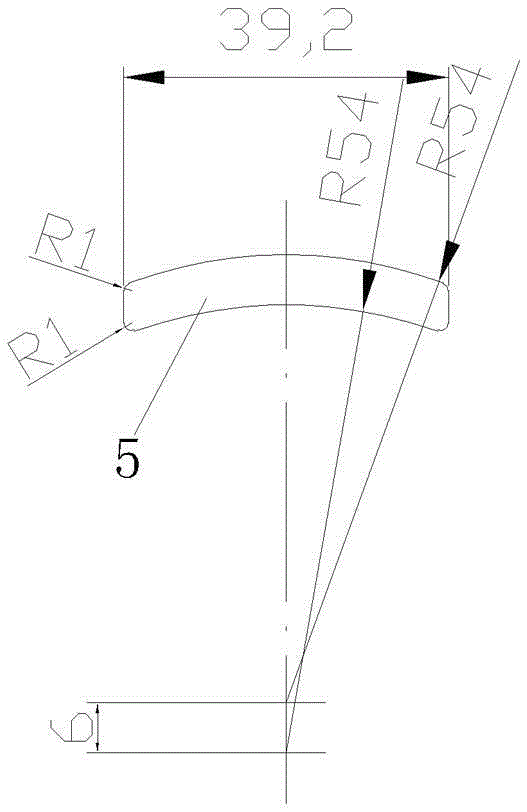

[0016] Such as figure 1 , figure 2 As shown, a permanent magnet motor rotor with non-uniform distribution of magnetic poles includes a rotating shaft 1, a rotor core 4, 8 magnetic poles 5, a first end fixing ring 2, a second end fixing ring 8, and a latitude-free belt 6. The rotor The iron core 4 is sleeved on the outside of the rotating shaft 1, the rotor core 4 is connected with the rotating shaft 1 through the key 3, the magnetic pole 5 is glued to the outer circumferential surface of the rotor core 4, and the rotating shaft 1 is respectively sleeved on the left and right ends of the rotor core 4 with first The end fixing ring 2, the second end fixing ring 8, and the non-weft tape 6 are wound on the surface of the magnetic pole 5, and the outer circumferential surface of the rotor core 4 is provided with three spacers 9 parallel to the rotation axis of the rotor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com