High-speed paper carton forming device

A carton forming machine, high-speed technology, used in carton/carton manufacturing machinery, paper/cardboard containers, containers, etc., can solve problems such as reduced work efficiency, strong vibration, and high density of cardboard work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

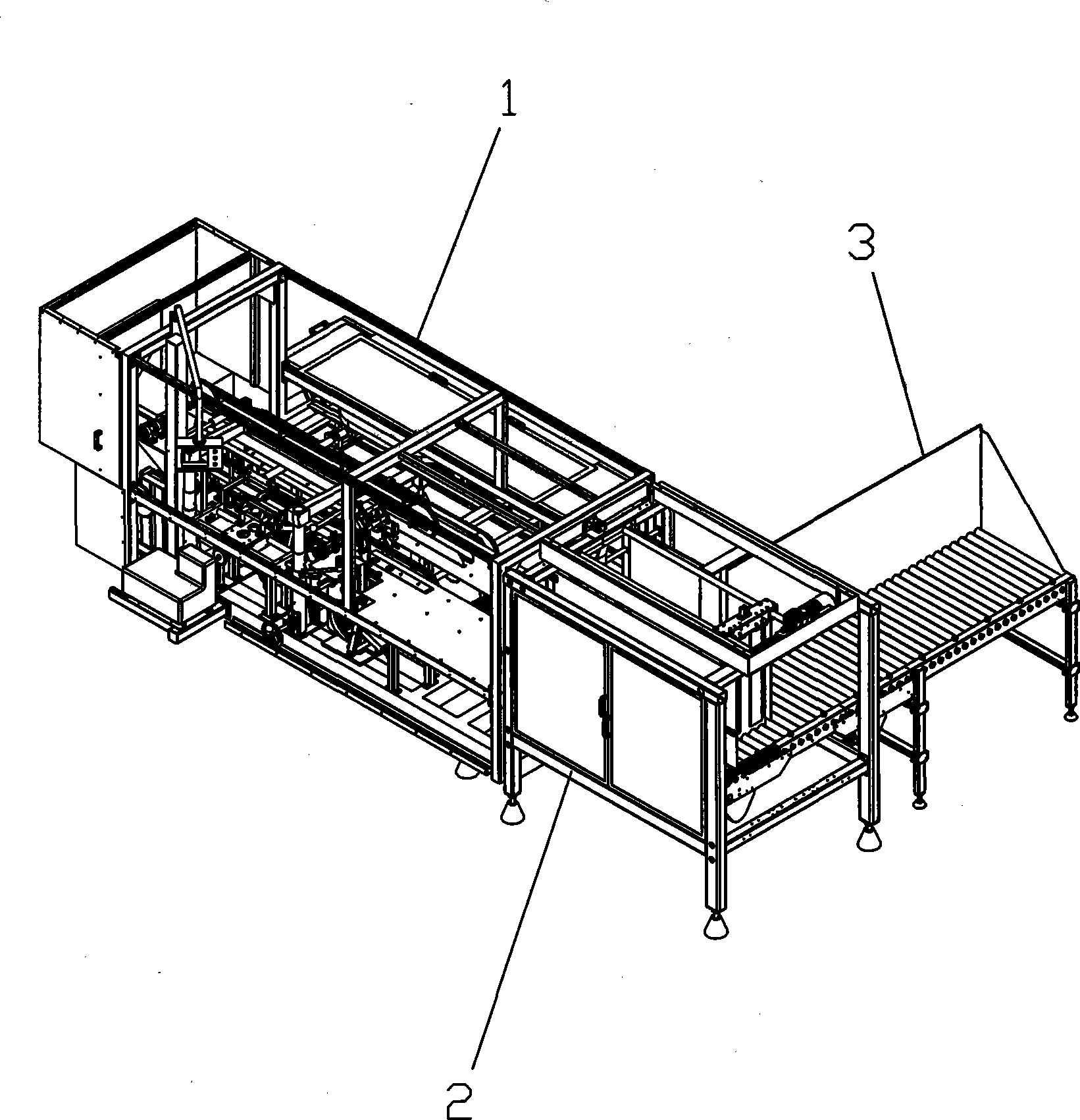

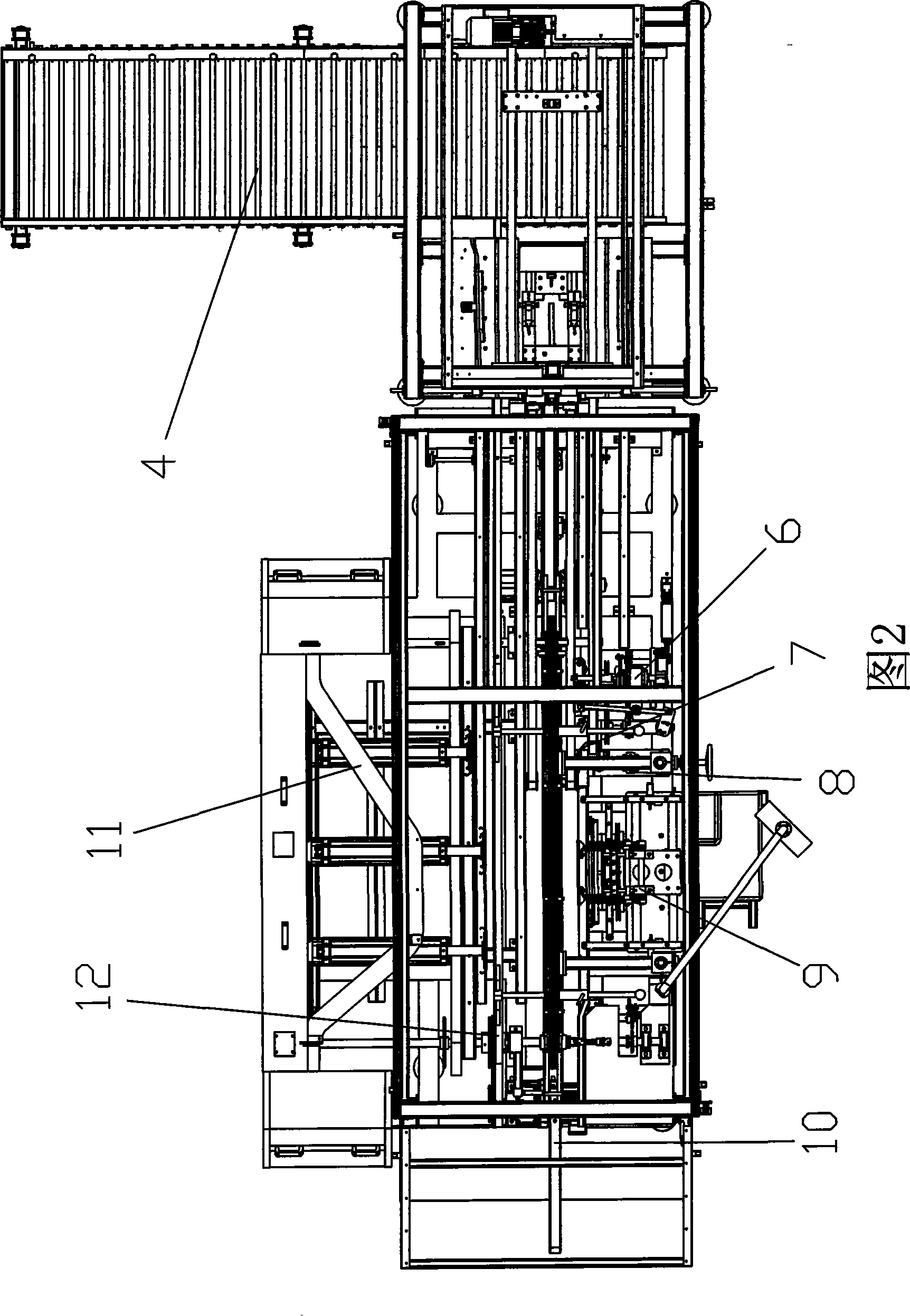

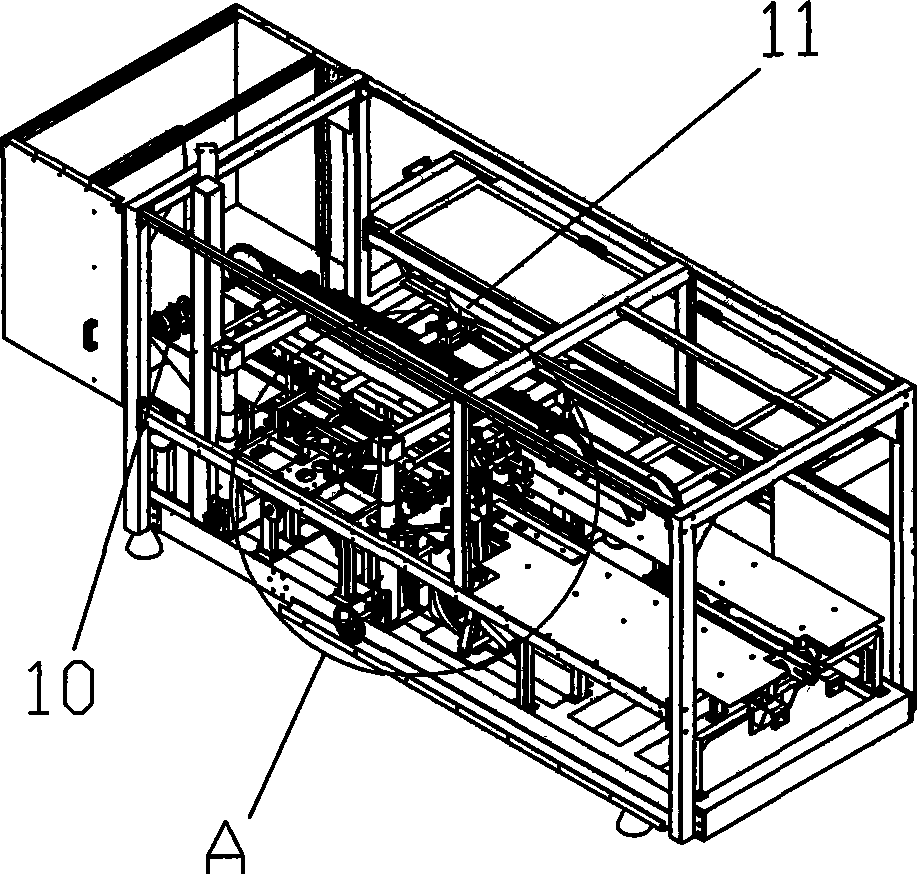

[0023] Such as figure 1 ,figure 2, image 3 , Figure 4 and Figure 9 As shown, a high-speed carton forming machine includes a main machine part 1, an ejector part 2 connected to the front end of the main machine part 1, and a stacking supply part 3 vertically connected to the other end of the ejector part 2, wherein the stacking supply part The roller conveyor belt assembly 4 of 3 is movable and adjustable, and the host part 1 includes a paper cutting and conveying assembly 5, an unpacking forming assembly 6, a box positioning assembly 7, a gluing assembly 8, an outer folding assembly 9, and a box output assembly arranged in sequence. The drop box assembly 10, and the pressure box forming assembly 11 and the upper dial box adjustment assembly 12 are related to be arranged on one side.

[0024] Such as Figure 5 , Figure 6 As shown, the press box molding assembly includes a frame 13, two small circulating guide rails 14 arranged in parallel, a circulating transmission ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com