Cruciform tail control surfaces of an undersea vehicle

A vehicle and control surface technology, applied to underwater ships, ship components, propulsion components, etc., can solve problems such as axial symmetric flow deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

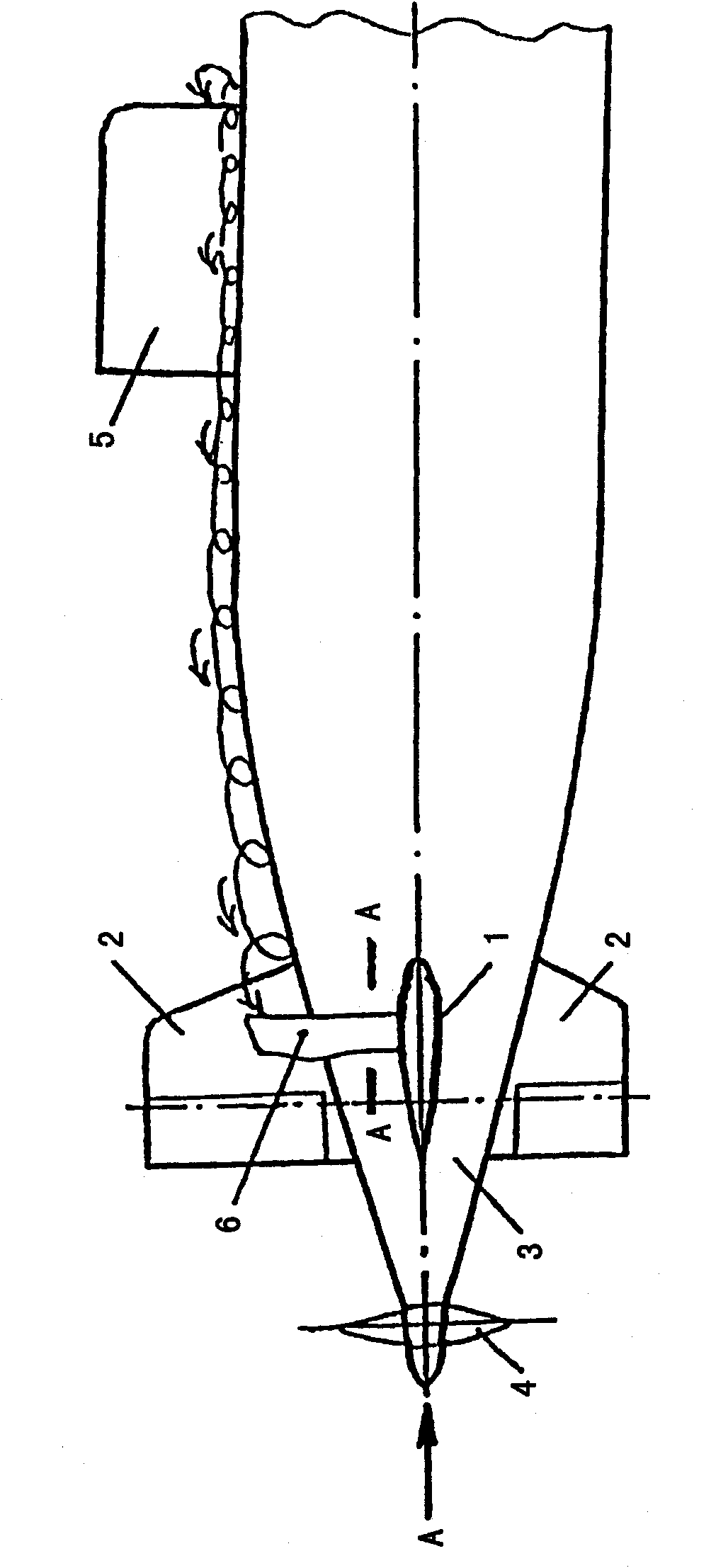

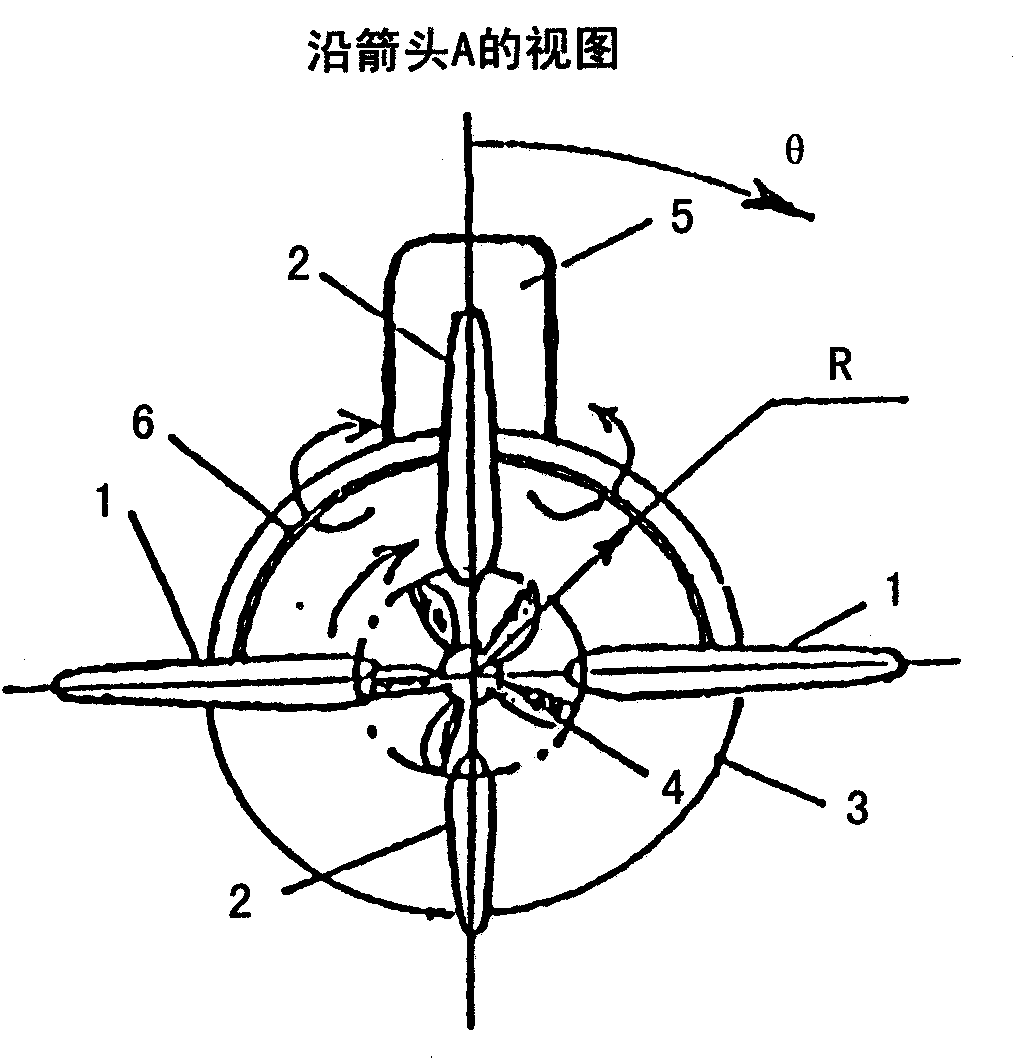

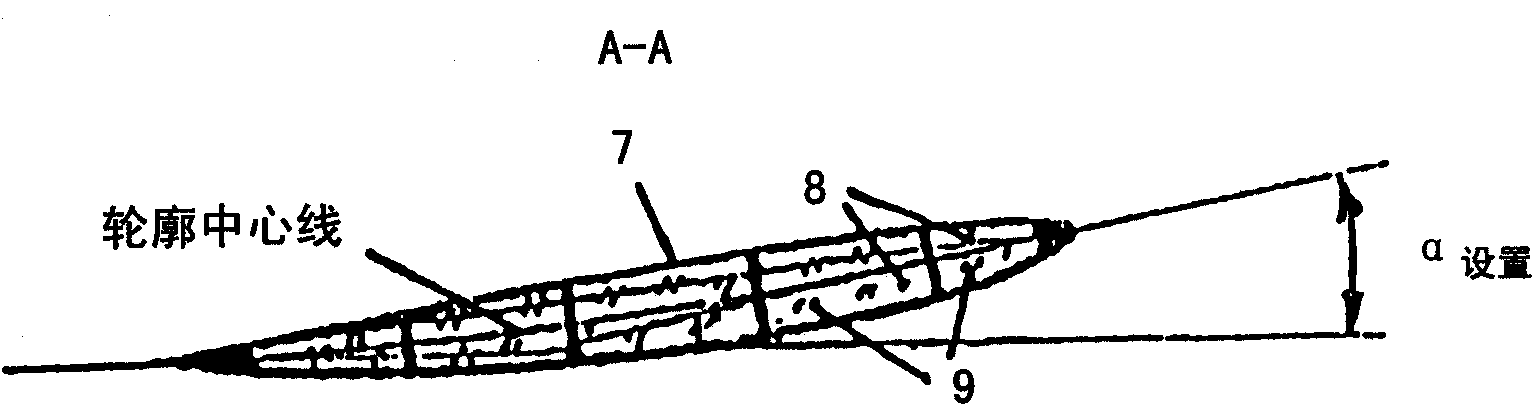

[0024] The tail control surface of the uniaxial UV comprises a horizontal protrusion 1 and a vertical upper and lower protrusion 2 - stabilizers, which are formed on the tail part of the hull 3 of the subsea vehicle before the propeller 4 . Stabilizers 1 and 2 have a fixed front and a movable tail. A guard 5 for the retractable device is formed in the tail portion of the UV housing 3 . figure 1 The horseshoe-shaped vortex generated by the shield 5 for the retractable device is shown conditionally. have a winged form with variable chord length ( image 3 ) and a variable setting angle α along the perimeter of the half-ring 设置 The half-rings 6 (vortex generators) are arranged on the fixed parts of the tail horizontal and vertical rudders (not shown). The radius of the half-ring and thus its fixed position on the stabilizer corresponds to 1.2-1.3 times the radius of the shell of the subsea vehicle in the area where the half-ring is arranged, where the maximum of the incident f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com