Full hydraulic transmission-based crawler bulldozer

A bulldozer, full hydraulic technology, applied to mechanically driven excavators/dredgers, earth movers/shovels, construction, etc., can solve frequent gear shift operations, low transmission system efficiency, and easy overload of bulldozer engines or flameout and other problems, to achieve the effect of improving operation performance, flexible layout, and improving operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

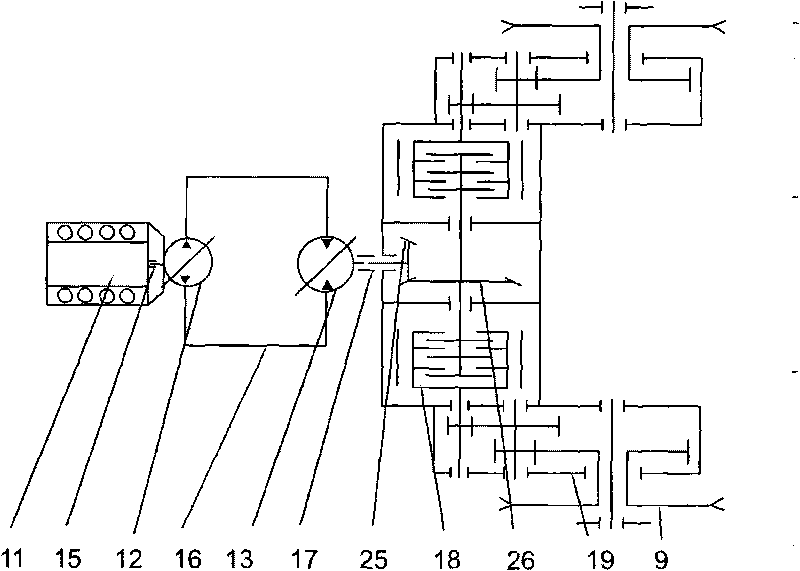

[0037] The method of the present invention will be further described below in conjunction with the accompanying drawings.

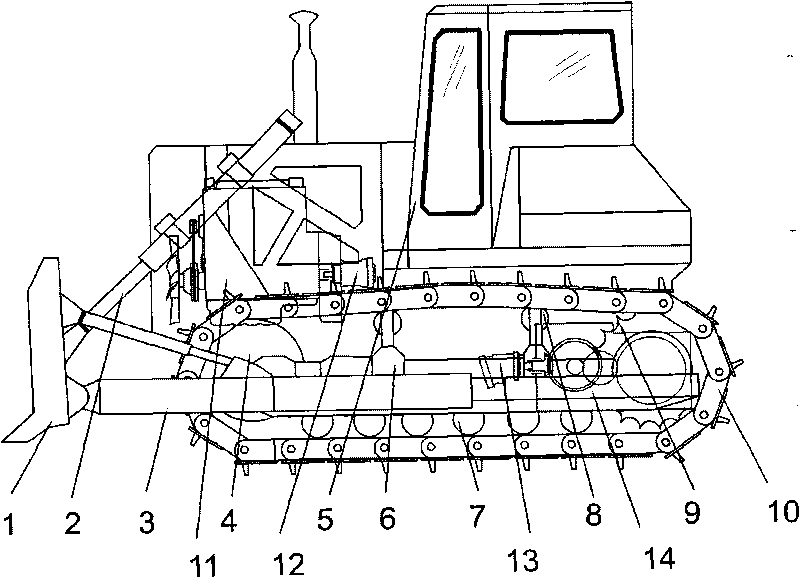

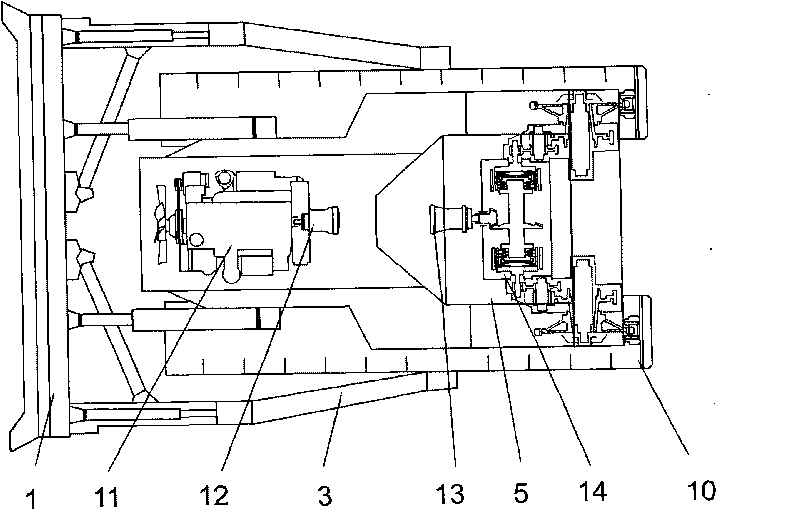

[0038] Structural layout of the whole machine

[0039] The structure of the full hydraulic transmission crawler bulldozer is as follows: figure 1 As shown, the inner side of the upper part of the bulldozer blade 1 is hinged with the piston rod of the hydraulic cylinder 2, and the cylinder wall of the hydraulic cylinder 2 is fixed on the vehicle body and the cab 5; the lower part of the bulldozer blade 1 is hinged with the push rod 3, and the push rod 3 It is hinged with the platform frame 6 through the trunnions. Through the movement of the hydraulic cylinder 2, the bulldozing blade 1 is raised and lowered. The trolley frame 6 is pressed on the crawler belt 10 through the roller 7, and the weight of the bulldozer is transmitted to the crawler belt 10; the front part of the trolley frame 6 has a guide wheel 4, and the upper part has a support sprocket 8;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com