Steel ball stepless speed change mechanism for cone pulley type bicycle

A technology of continuously variable speed change mechanism and bicycle, which is applied in vehicle gearboxes, vehicle parts, chain/belt transmission devices, etc. It can solve the problems of unstable speed change process, shifting shock, and laborious riding, etc., and achieve low processing cost , simple structure and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] specific implementation plan

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings.

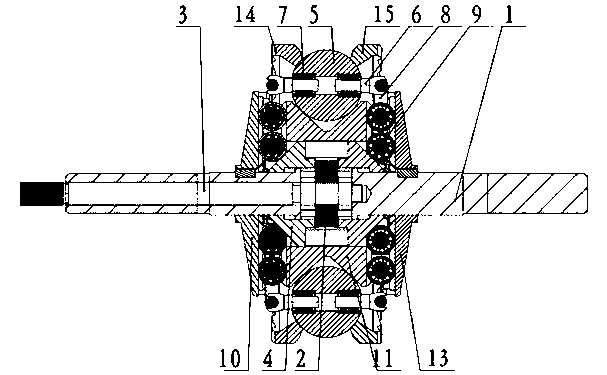

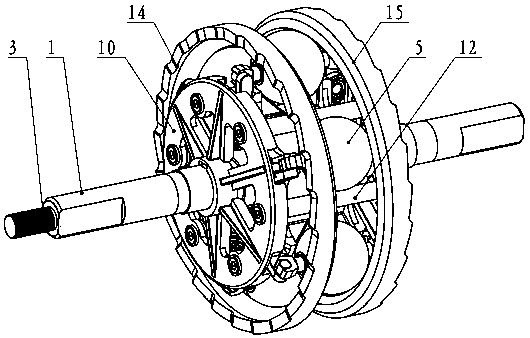

[0018] The present invention includes an input disc 14, an output disc 15, an axle speed regulating mechanism, a cone wheel speed change mechanism and a supporting guide device; the input disc 14 is connected with the sprocket drive mechanism, and the output disc 15 is connected with the output shell.

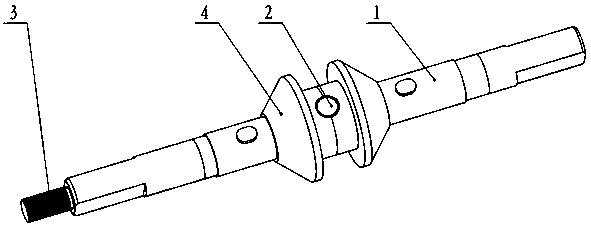

[0019] The axle speed regulating mechanism includes axle 1, gear speed regulating shaft 3, moving nut 2 and cone wheel slider 4; 3. Installed in the axle 1, the moving nut 2 passes through the through hole in the middle of the axle 1, and is installed on the gear speed regulating shaft 3 to form a spiral pair. When the driving gear speed regulating shaft 3 rotates, it drives the moving nut 2 in the middle of the axle 1 Axial movement in the through hole; the cone wheel slider 4 is divided into two parts, left and right, i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com