Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

540results about How to "Good anti-fog performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Self-cleaning epoxy resin anti-fog coating

InactiveCN101781506ALow costSolution to short lifePolyether coatingsEpoxy resin coatingsWeather resistanceFirming agent

The invention belongs to the technical field of chemical materials, particularly relates to a self-cleaning epoxy resin anti-fog coating, which has high transparency and is composed of epoxide resin, firming agent, hydrophilic high polymer, surface active agent, functional nano particles and the like according to a proper proportion. The coating can be applied on the surfaces of glass, plastics and other base materials, and has excellent anti-fog and self-cleaning effects, good weather resistance and long service life.

Owner:FUDAN UNIV

Reduced antifog level in oxygen scavenging film with antifog properties

InactiveUS20060099436A1Prevents and reduces condensationReduce surface tensionFlexible coversWrappersChemistryOxygen scavenger

A multilayer film includes a first and second outer layer each including a polymer; and an internal layer including an oxygen scavenger; where the first outer layer includes a blend of a polymer and an antifog agent, where the antifog agent includes at least one of a mono fatty acid derivative of glycerol, and a polyglycerol mono fatty acid derivative; and wherein the first outer layer includes from 0.1% to 3%, by weight of the first outer layer, of the antifog agent.

Owner:CRYOVAC INC

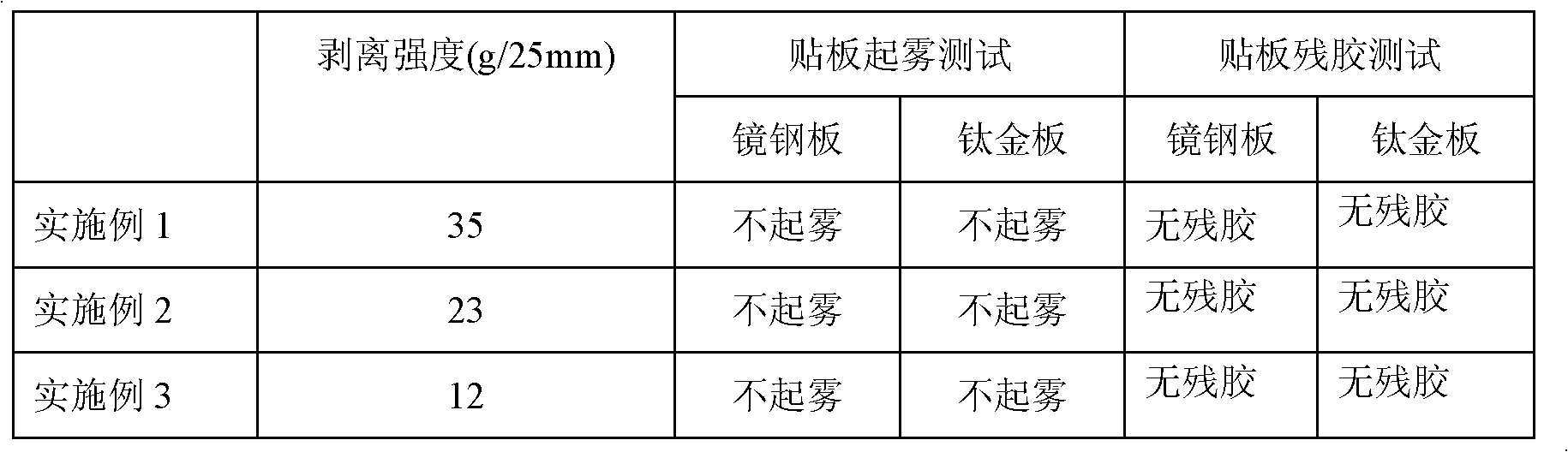

Fog-resistant aqueous pressure-sensitive adhesive and polyethylene protection film containing same

ActiveCN102492379APromote migrationResidue reductionFilm/foil adhesivesEster polymer adhesivesCross-linkTectorial membrane

The invention discloses a fog-resistant aqueous pressure-sensitive adhesive for a polyethylene protection film. The adhesive is prepared by using the manner of seeded emulsion polymerization. According to the invention, seeded emulsion is prepared at first, then pre-emulsion is added into the seeded emulsion drop by drop, the seeded emulsion and the pre-emulsion fully react by replenishing an initiator, cooling and pH value adjusting are carried out, and a discharged material is filtered. The invention also provides a polyethylene protection film containing the fog-resistant aqueous pressure-sensitive adhesive and a preparation method thereof. Through adjusting utilization amount of a cross-linking agent and gelatinizing content, an appropriate peeling strength of the emulsion pressure-sensitive adhesive prepared in the invention can be obtained; the prepared protection film has good fog resistance when applied on sheet materials like steel plates and titanium plates.

Owner:无锡达美新材料有限公司

Antifogging coating, preparation method of antifogging coating and antifogging glass

InactiveCN103664004AImprove mechanical propertiesHas a hydrophilic functionSolubilityHeat resistance

The invention provides an antifogging coating, a preparation method of the antifogging coating and antifogging glass. The antifogging coating disclosed by the invention comprises at least one crosslinking layer and at least one antifogging layer, wherein the crosslinking layer and the antifogging layer are alternatively arranged to form the antifogging coating; the crosslinking layer plated on a base is arranged at one side of the antifogging coating; the antifogging layer is arranged at the other side. The antifogging coating has the advantages of being lasting in anti-fogging performance, and good in abrasive resistance, heat resistance and resistance to water solubility. The preparation method of the antifogging coating provided by the invention is scientific and reasonable in steps, simple and feasible in technology, low in cost and wide in application range. The antifogging glass provided by the invention has an excellent anti-fogging effect when the light transmittance is ensured.

Owner:DALIAN POLYTECHNIC UNIVERSITY

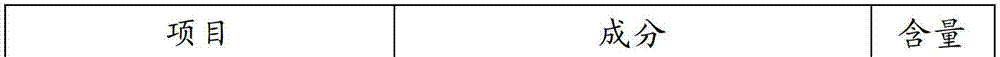

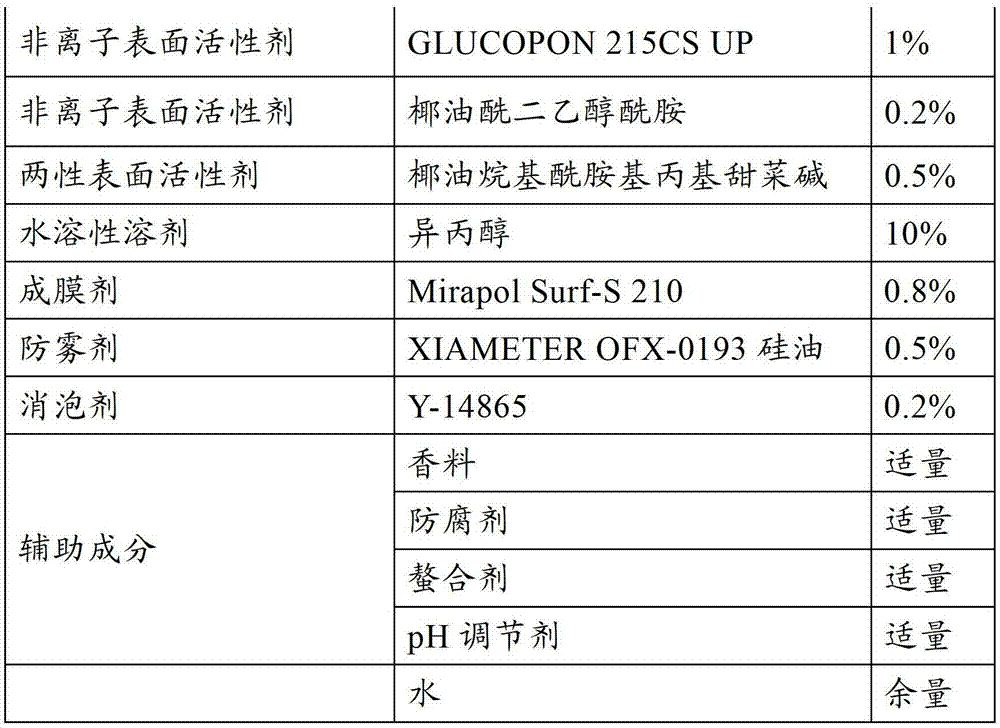

Lens cleaning solution and wet tissue

ActiveCN103160388AAffect the service lifeEasy to cleanSpectales/gogglesInorganic/elemental detergent compounding agentsSolubilityBoiling point

The invention relates to a lens cleaning solution which is mainly formed by mixing a water-solubility solvent with the boiling point smaller than 100 DEG C, a surface active agent, an ant-fogging agent and water. The invention also provides a wet tissue using the lens cleaning solution. Compared with the prior art, the water-solubility solvent with the boiling point smaller than 100 DEG C, the surface active agent, the anti-fogging agent and other functional medicament are selectively compounded, and the advantages of the components in the lens cleaning aspect are fully exerted, so that the lens cleaning solution and the wet tissue containing the lens cleaning solution not only can well clean dust, fingerprints, oil stains and other spots on the lens, but also has good anti-fogging performance, and can avoid the problems of rusting, mildew and the like caused by water being attached to the parts such as a lens frame and a lens bracket so as to avoid affecting the service life of eyeglasses.

Owner:GOLD HONG YE PAPER

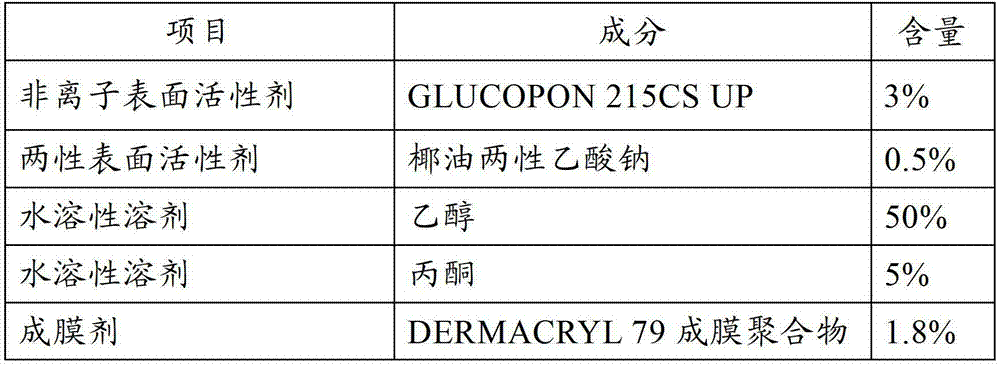

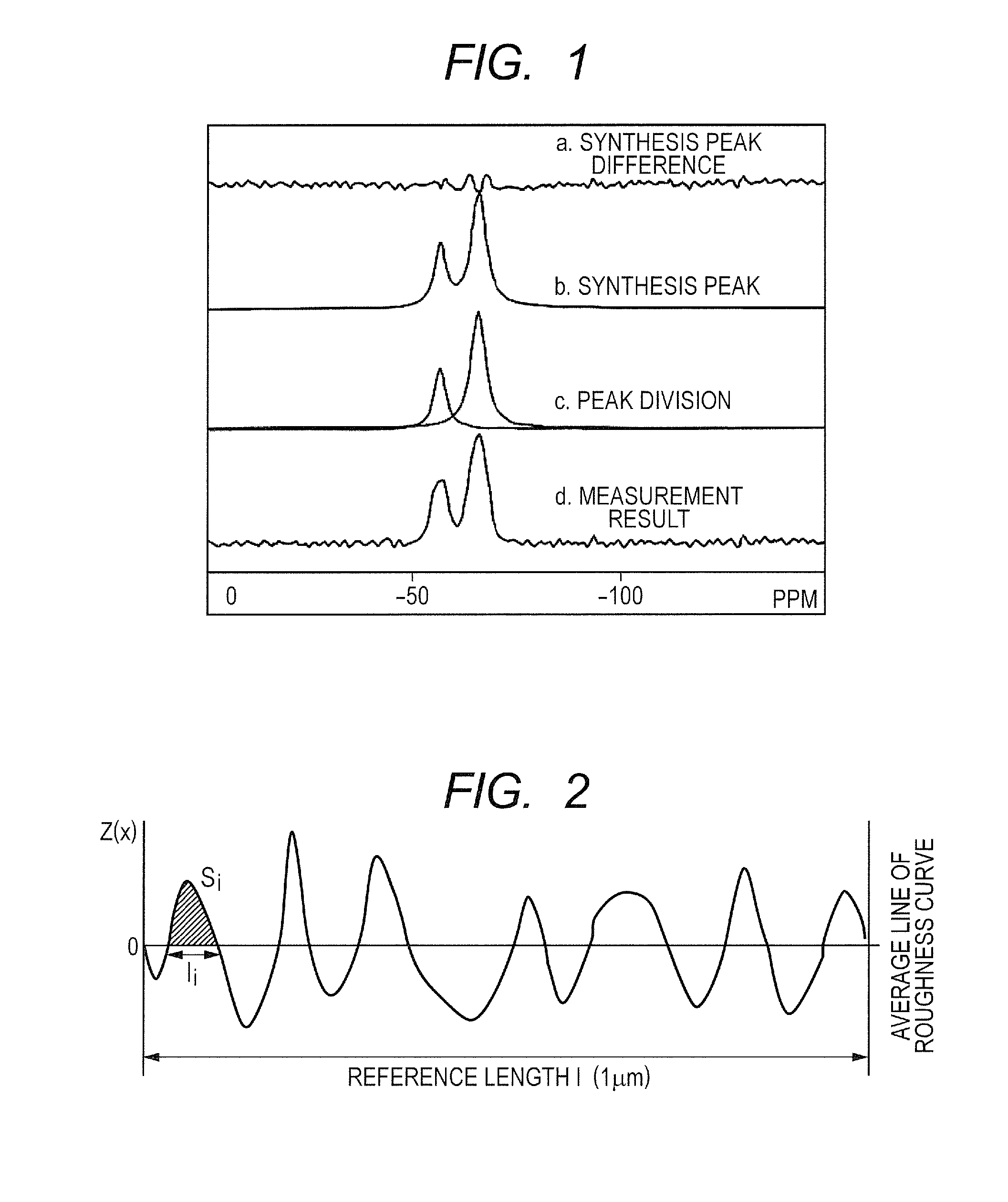

Toner

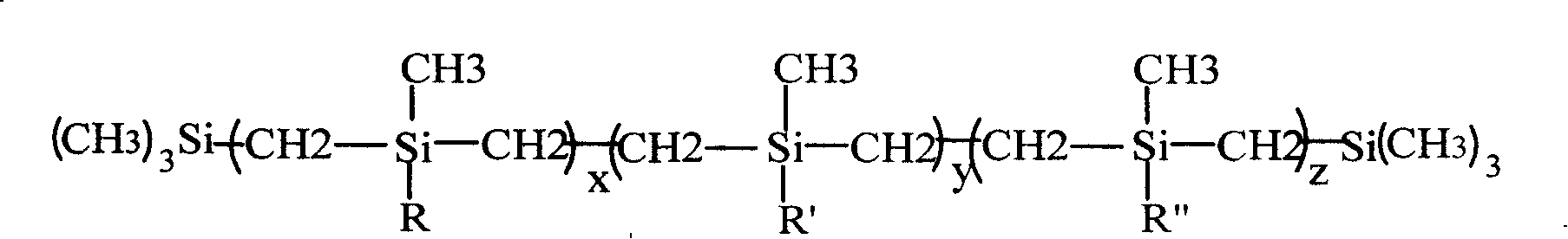

ActiveUS20160299446A1Improve transmission efficiencyGood anti-fog performanceDevelopersSurface layerX-ray

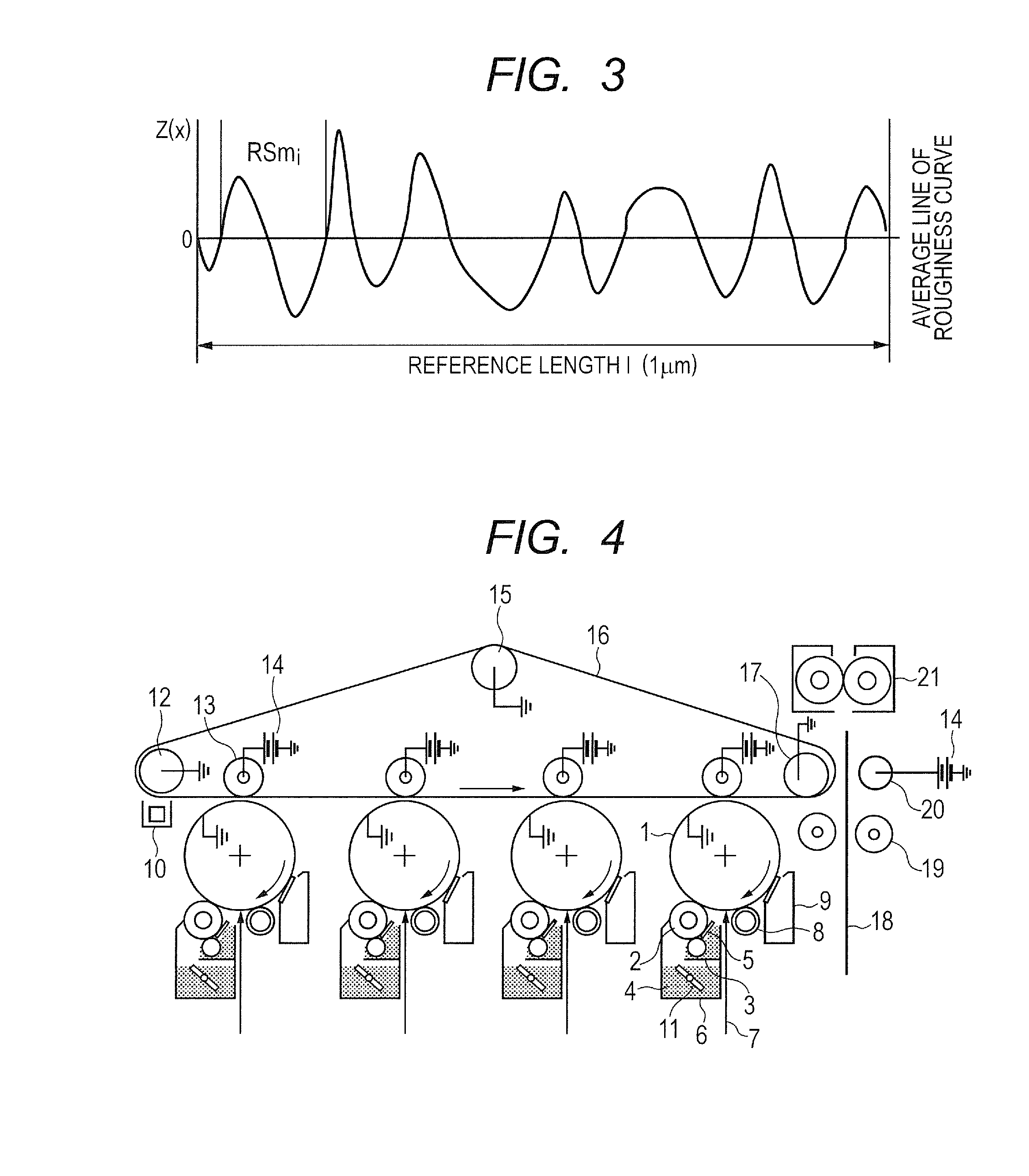

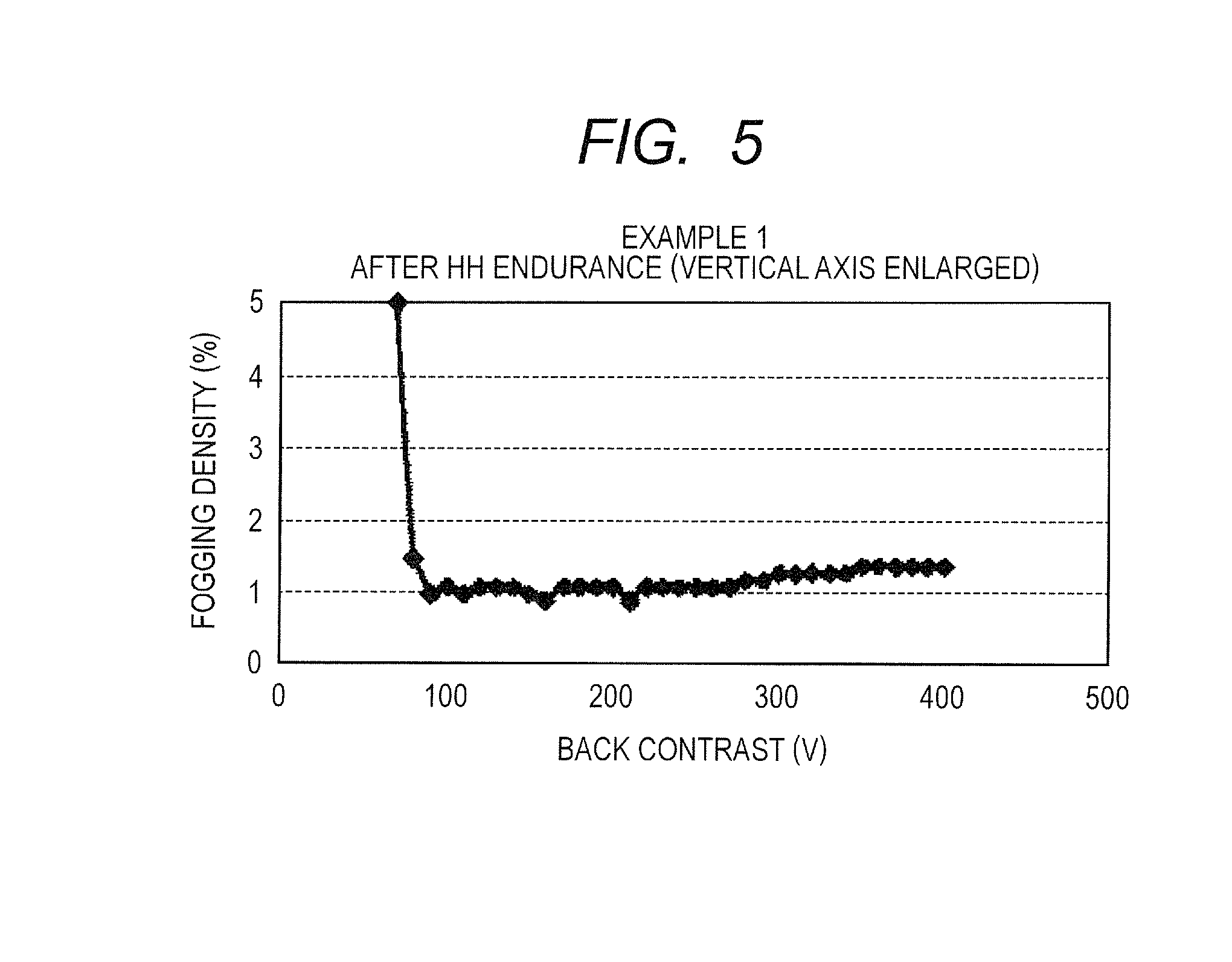

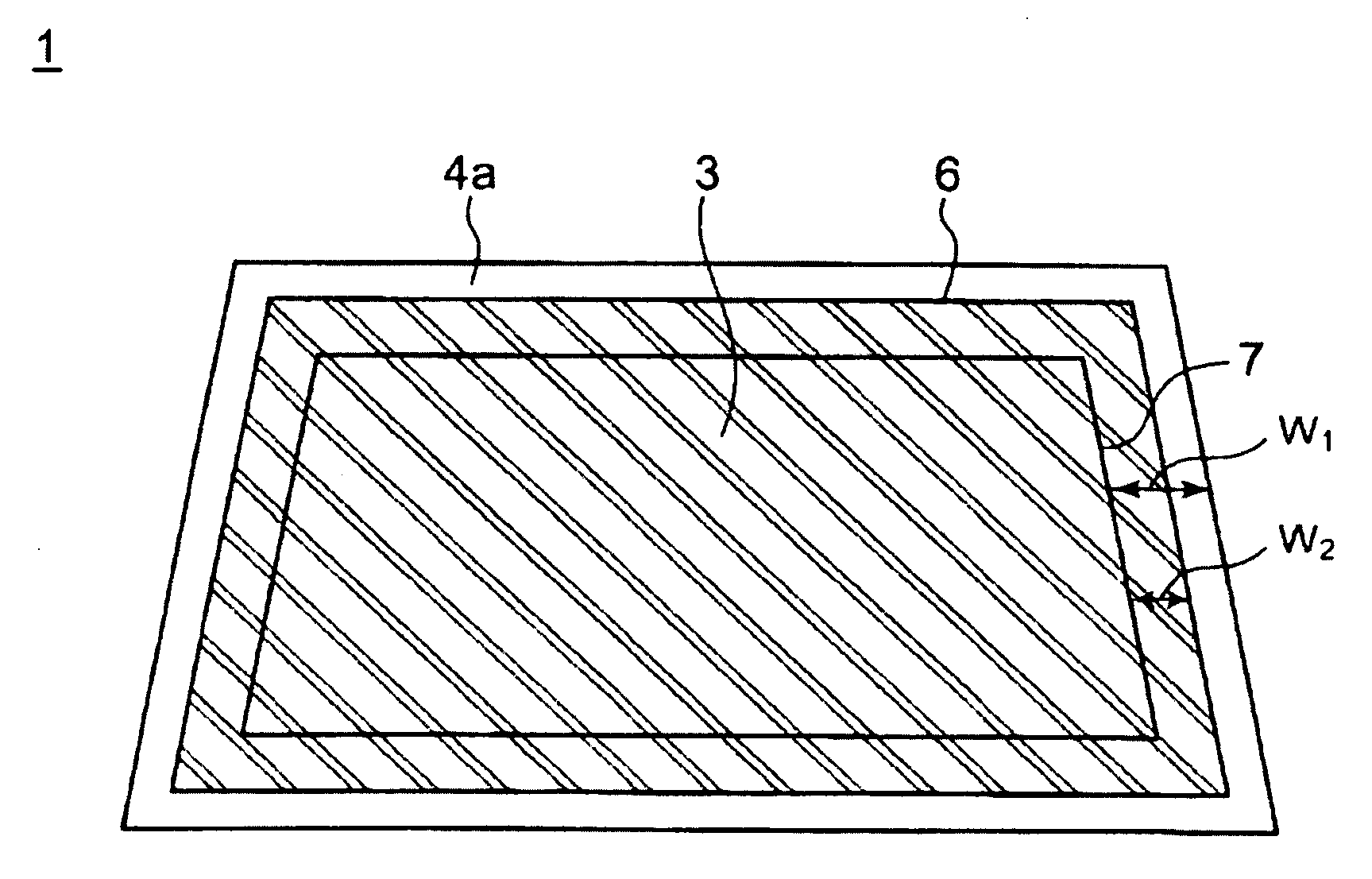

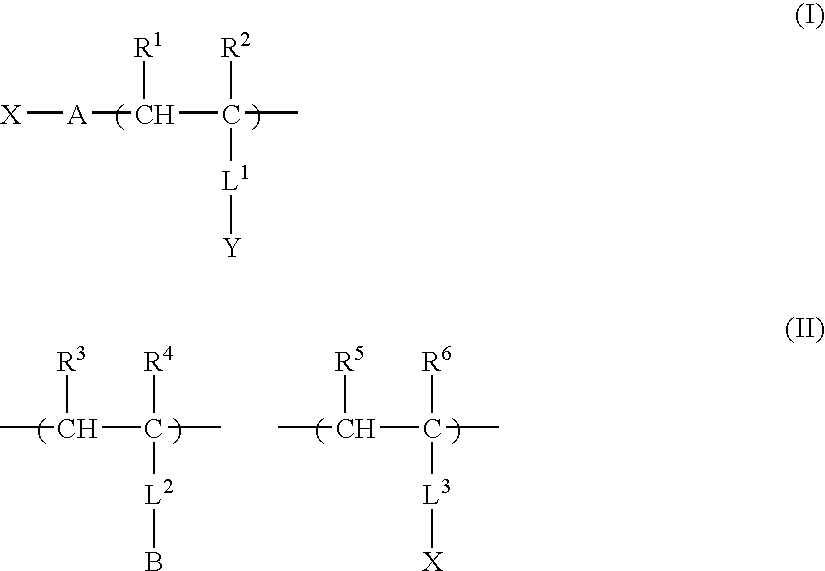

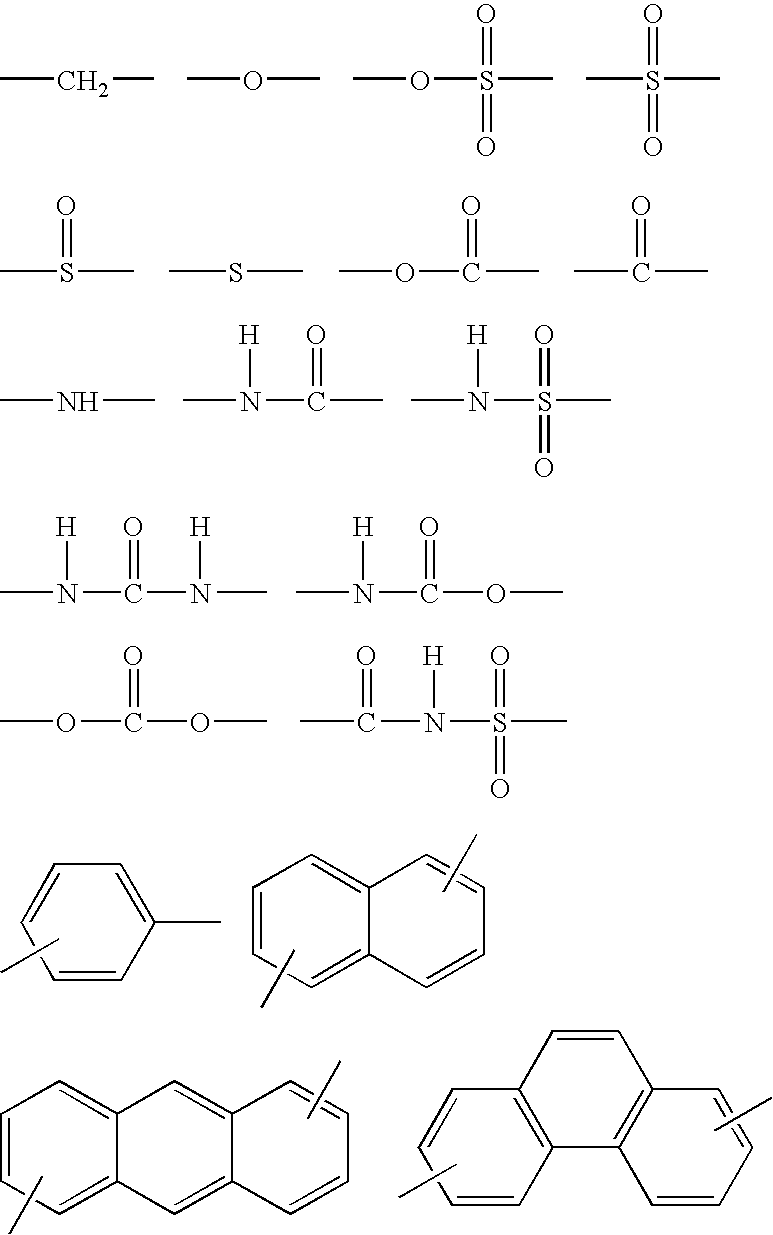

Provided is a toner, including toner particle having surface layer, in which: the surface layer includes organosilicon polymer which has a partial structure represented by formula (1); in 29Si—NMR measurement of tetrahydrofuran-insoluble matter of toner particle, a ratio of a peak area for the partial structure represented by formula (1) to a total peak area for the organosilicon polymer is 5.0% or more; in X-ray photoelectron spectroscopic analysis of a surface of toner particle, a ratio of a density of a silicon atom dSi in the surface of toner particle is 1.0 to 28.6 atom %; and in a roughness curve of toner particle measured by using a scanning probe microscope: an arithmetic average roughness Ra is 10 to 300 nm; σRa / Ra is 0.60 or less; an average length RSm of a roughness curve element is 20 to 500 nm; and σRSm / RSm is 0.60 or less.

Owner:CANON KK

Antifogging glass for a vehicle window, method for producing the same, and fixing structure for the same

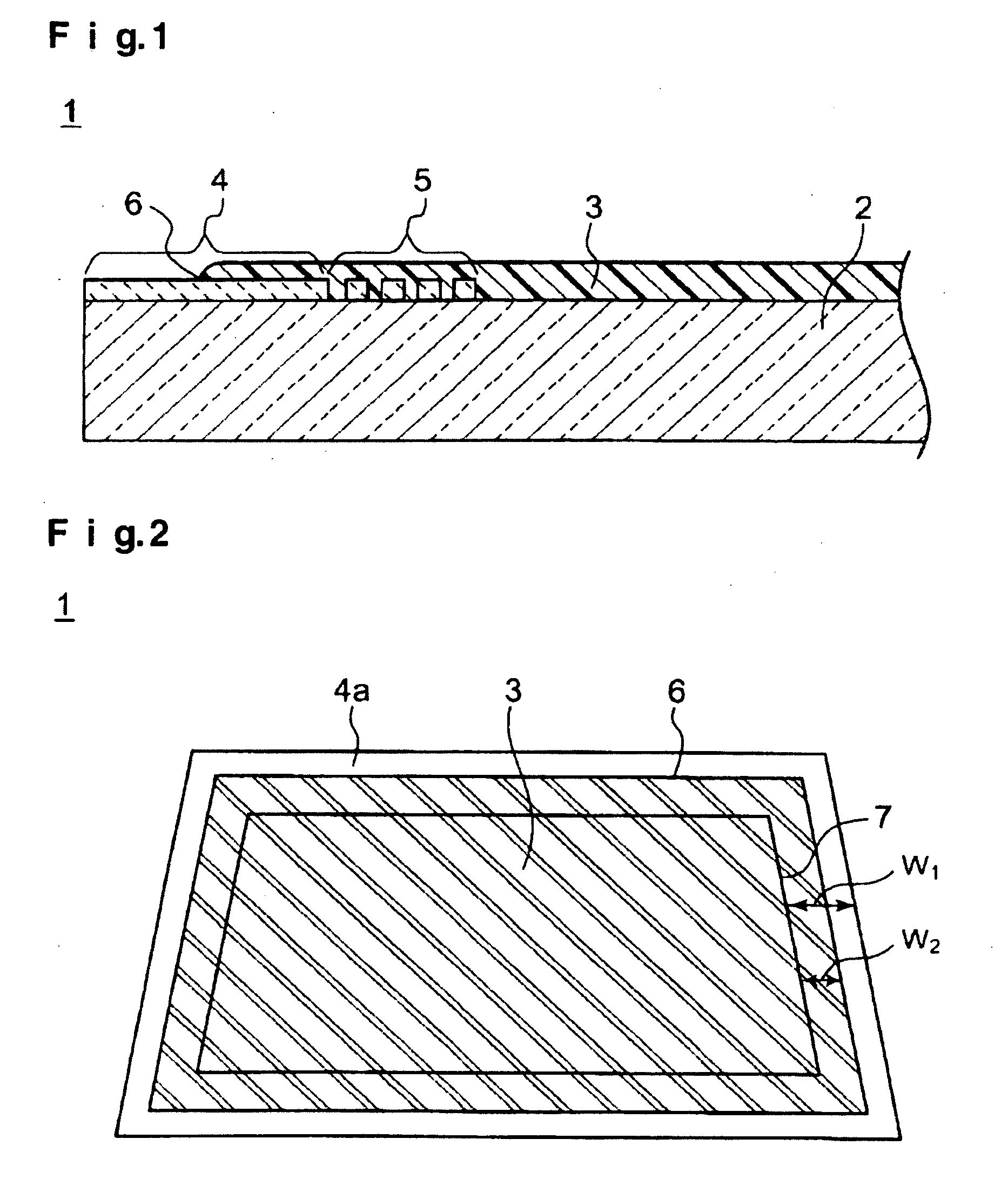

InactiveUS20090239017A1Reduce fatigueGood anti-fog performanceWindowsEngine sealsBand shapeGlass sheet

An antifogging glass is provided which has not only an excellent antifogging property but also an excellent appearance and provides an excellent visual effect to an observer.An antifogging glass for a vehicle window, comprising a glass sheet for a vehicle window and an antifogging film disposed on an interior side of the glass sheet, the glass sheet having a dark concealment region disposed in a band-shape on a peripheral edge portion thereof, and the antifogging film having an edge present in a position closer to a central portion of the glass sheet than an edge of the glass sheet and in the dark concealment region.

Owner:ASAHI GLASS CO LTD

Antibacterial PVC hard sheet suitable for packing medicament

The invention discloses an antibacterial PVC hard sheet suitable for packing a medicament, which comprises the following components in part by weight: 100 parts of PVC resin, 5 to 50 parts of plasticizer, 0.3 to 3.0 parts of stabilizer, 0.1 to 1.0 part of lubricant, 0.02 to 1.0 part of talcpowder, 0.5 to 5.0 parts of fog resistant agent and 0.2 to 2.0 parts of antibacterial agent. The antibacterial PVC hard sheet of the invention is suitable for blister packaging of the medicament and health-care products, particularly suitable for the blister packaging of natural products and Chinese medicinal preparations. The antibacterial PVC hard sheet can keep good adhesive force, transparency and atomization resistance while obtaining antibacterial performance, and meets the requirements of relevant state standards.

Owner:YANGZHOU KAIER CHEM

Low fogging thermoplastic elastomer composition and manufacturing method and use of same composition

This invention relates to a perfectly or partially crosslinked olefinic thermoplastic elastomer composition which comprises 10 to 90 parts by weight of a crystalline polyolefin (a), 90 to 10 parts by weight of an olefin-based copolymer rubber (b) (the total amount of the components (a) and (b) being 100 parts by weight) and 3 to 100 parts by weight of a paraffinic mineral oil softening agent (c) having an evaporation loss of 0.4% by weight or less at a condition of 200° C., atmospheric pressure and 1 hour and having a kinetic viscosity (40° C.) of 50 to 250 cSt; an olefinic thermoplastic elastomer composition which is obtainable by subjecting a mixture including 40 to 85 parts by weight of an ethylene-based copolymer rubber (A), 60 to 15 parts by weight of an olefinic resin (B) and 45 parts by weight or less of a softening agent (C) [the total amount of the components (A), (B) and (C) being 100 parts by weight] to dynamic heat treatment in the presence of a crossliking agent and which has a gloss value of 80% or more and a haze value of 10% or less on glass plate when subjected to the fogging test at a condition of 100° C. and 3 hours according to the prescription of A method of DIN 75201; and a manufacturing method and use of the compositions.

Owner:MITSUI CHEM INC

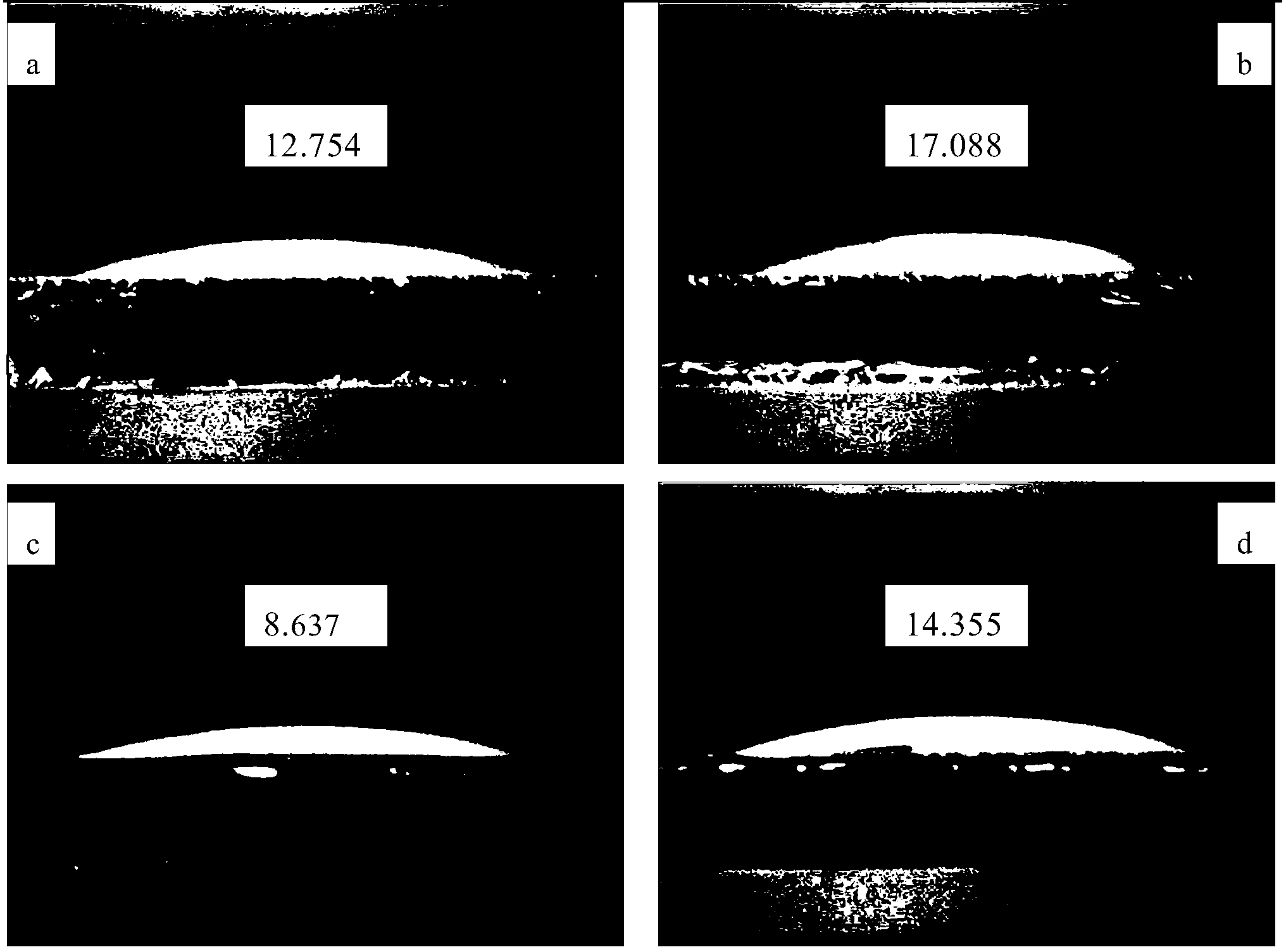

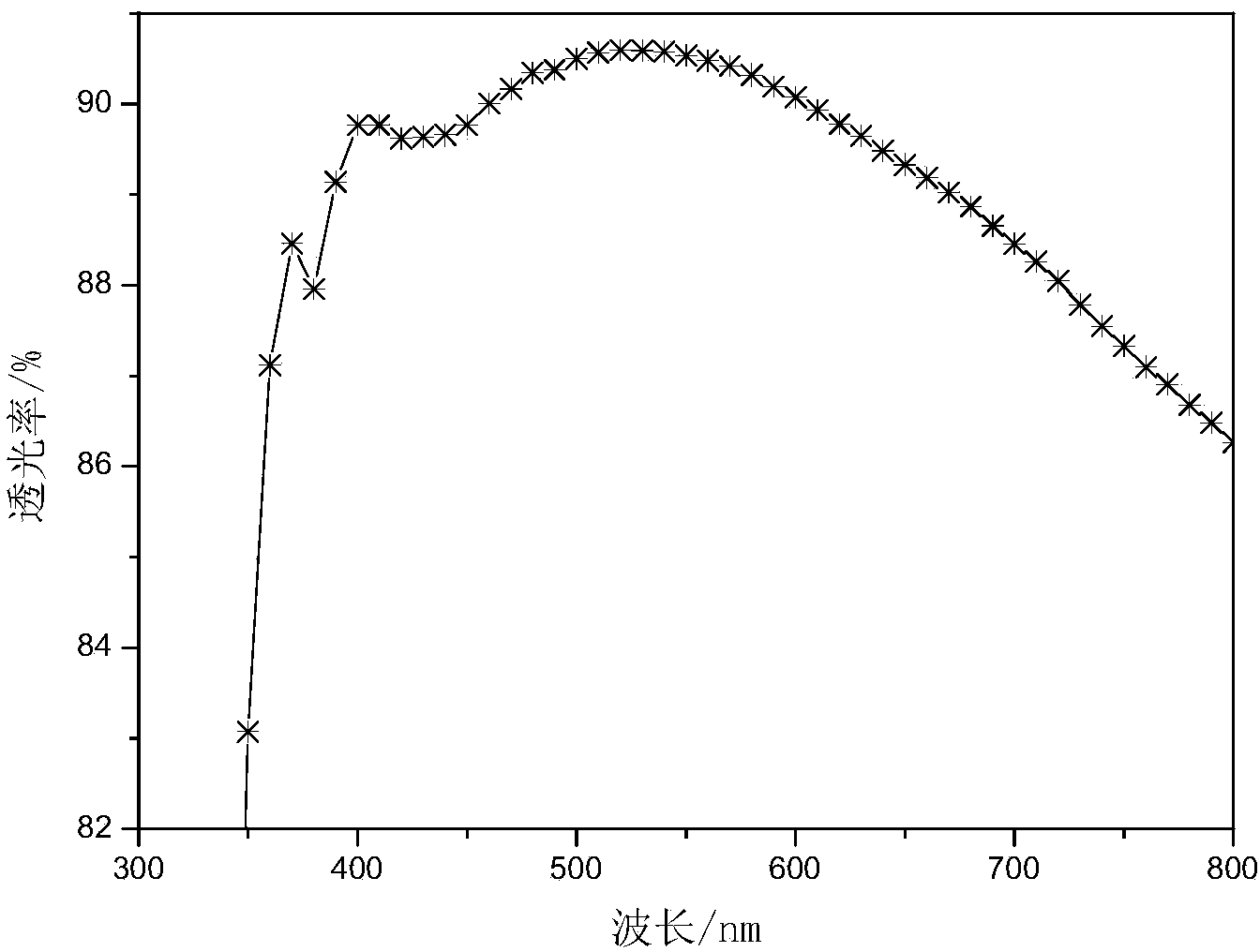

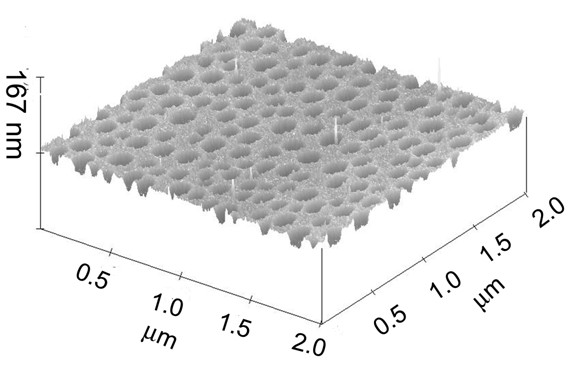

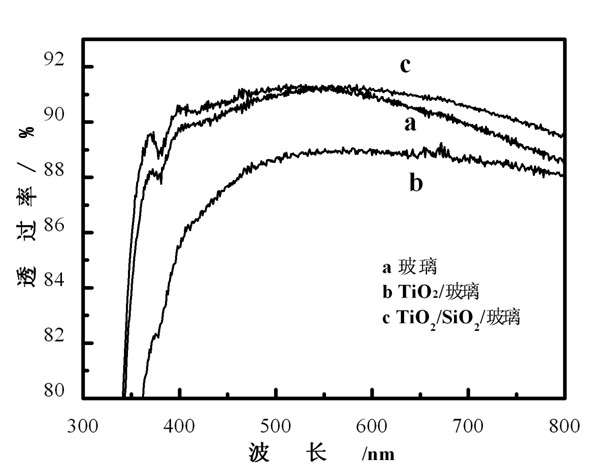

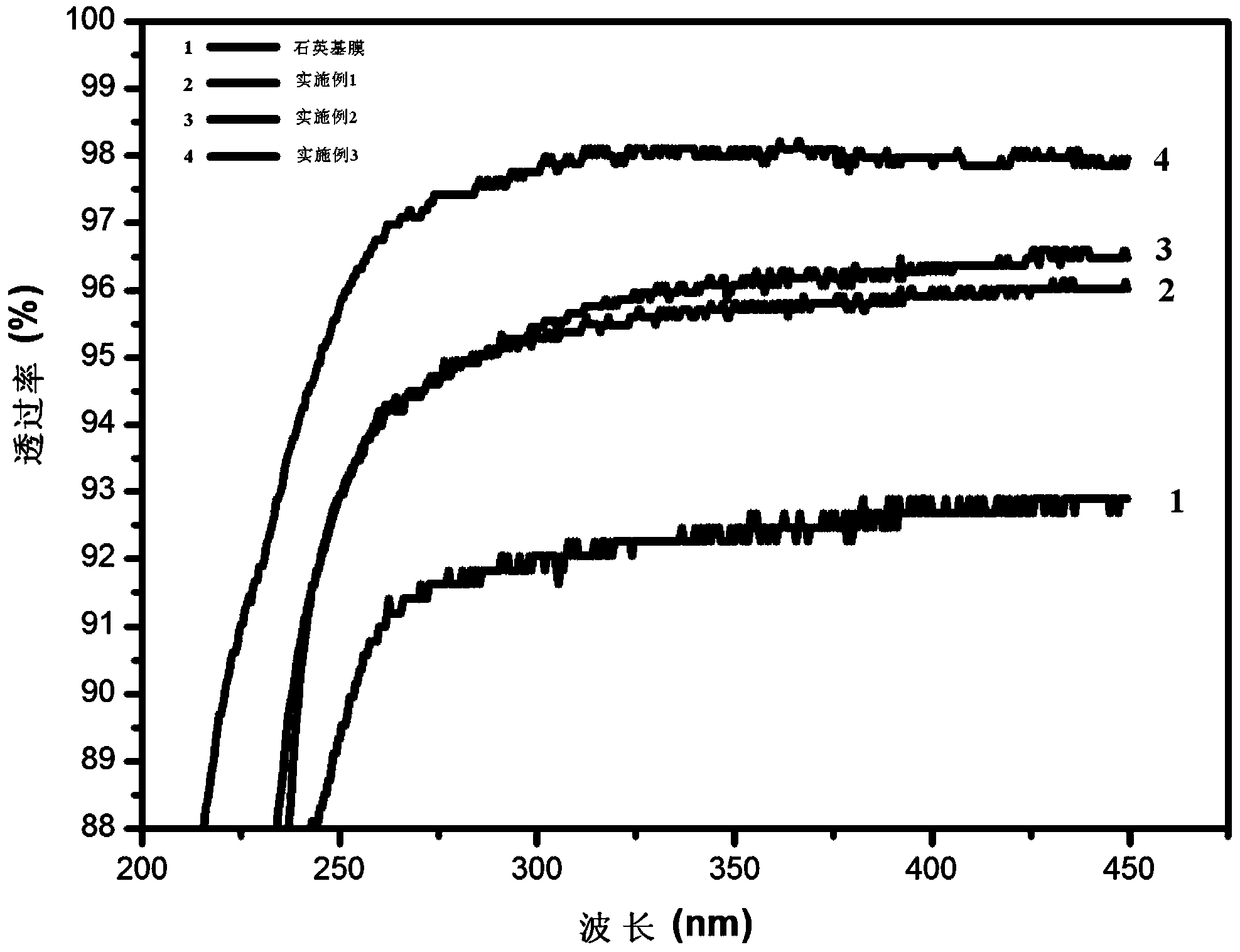

Preparation method of superhydrophilic TiO2/SiO2 porous bilaminar membrane

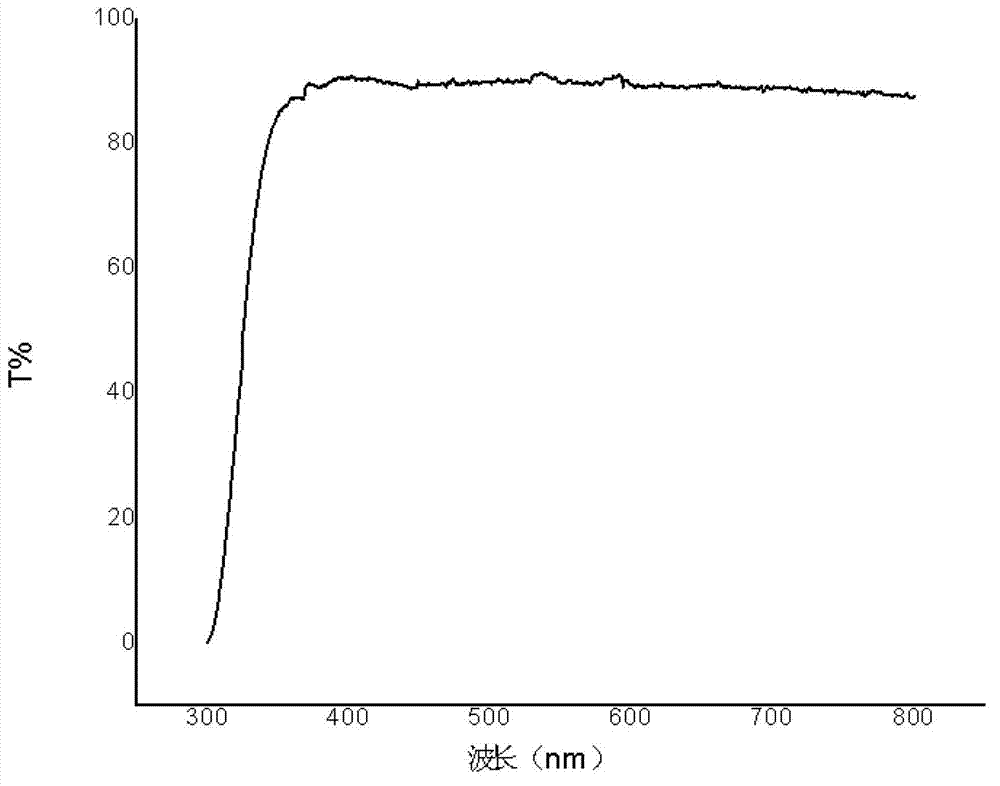

ActiveCN102432196AImprove transmittanceGood anti-fog performanceOther chemical processesPolyethylene glycolEngineering

The invention which provides a preparation method of a superhydrophilic TiO2 / SiO2 porous bilaminar membrane which has a high transmittance and can perform the superhydrophilicity under visible light belongs to the technical field of nanomaterials. The method comprises the following steps: 1, carrying out spin coating on a glass substrate with an SiO2 sol, drying, carrying out spin coating with a mixed solution of polyethylene glycol 2000 and TiO2, and drying the glass substrate in a drying box for 20-40min at 80-120DEG C; 2, heating the dried glass substrate in a muffle furnace to 450-550DEG C according to a heating rate of 2-3DEG C / min, and annealing for 2-3h; and 3, naturally cooling to room temperature after completing the anneal to obtain the superhydrophilic TiO2 / SiO2 porous bilaminar membrane. The prepared superhydrophilic TiO2 / SiO2 porous bilaminar membrane of the invention, which has a highly ordered porous structure and a high transmittance, can perform the superhydrophilicity under visible light and has a good antifog effect, can be applied to various antifog occasions of building glass, automobile rearview windows, windscreens, bathroom glass and the like.

Owner:NO 510 INST THE FIFTH RES INST OFCHINA AEROSPAE SCI & TECH

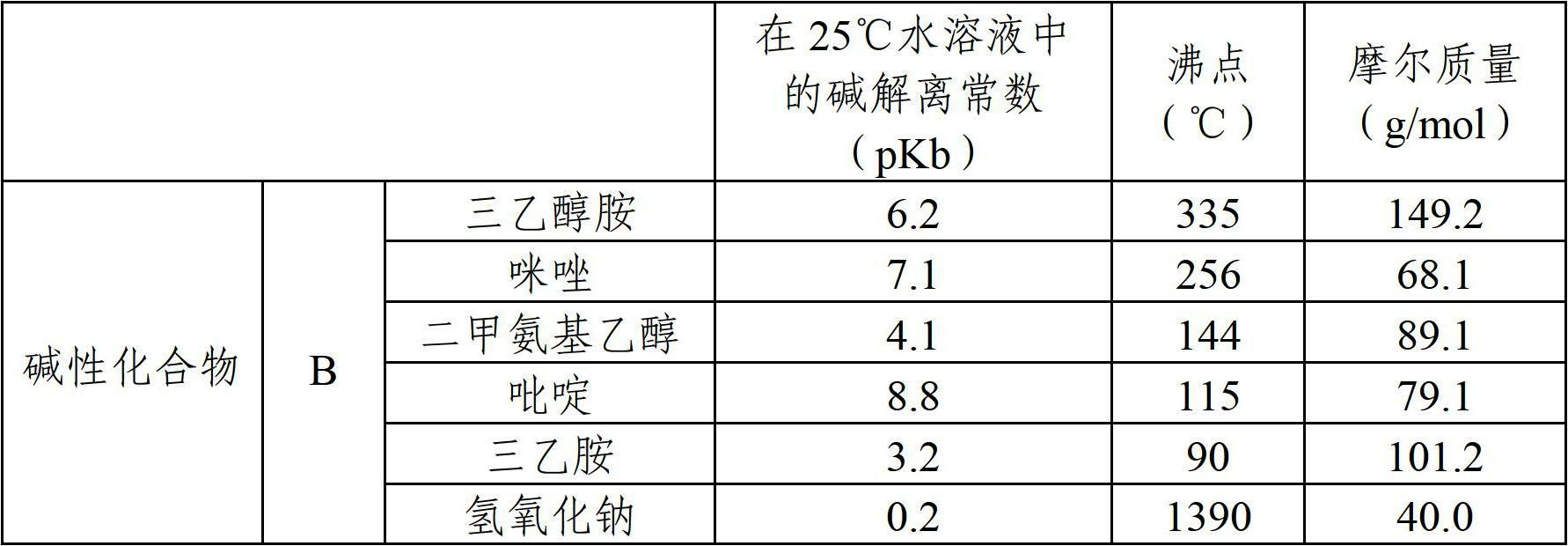

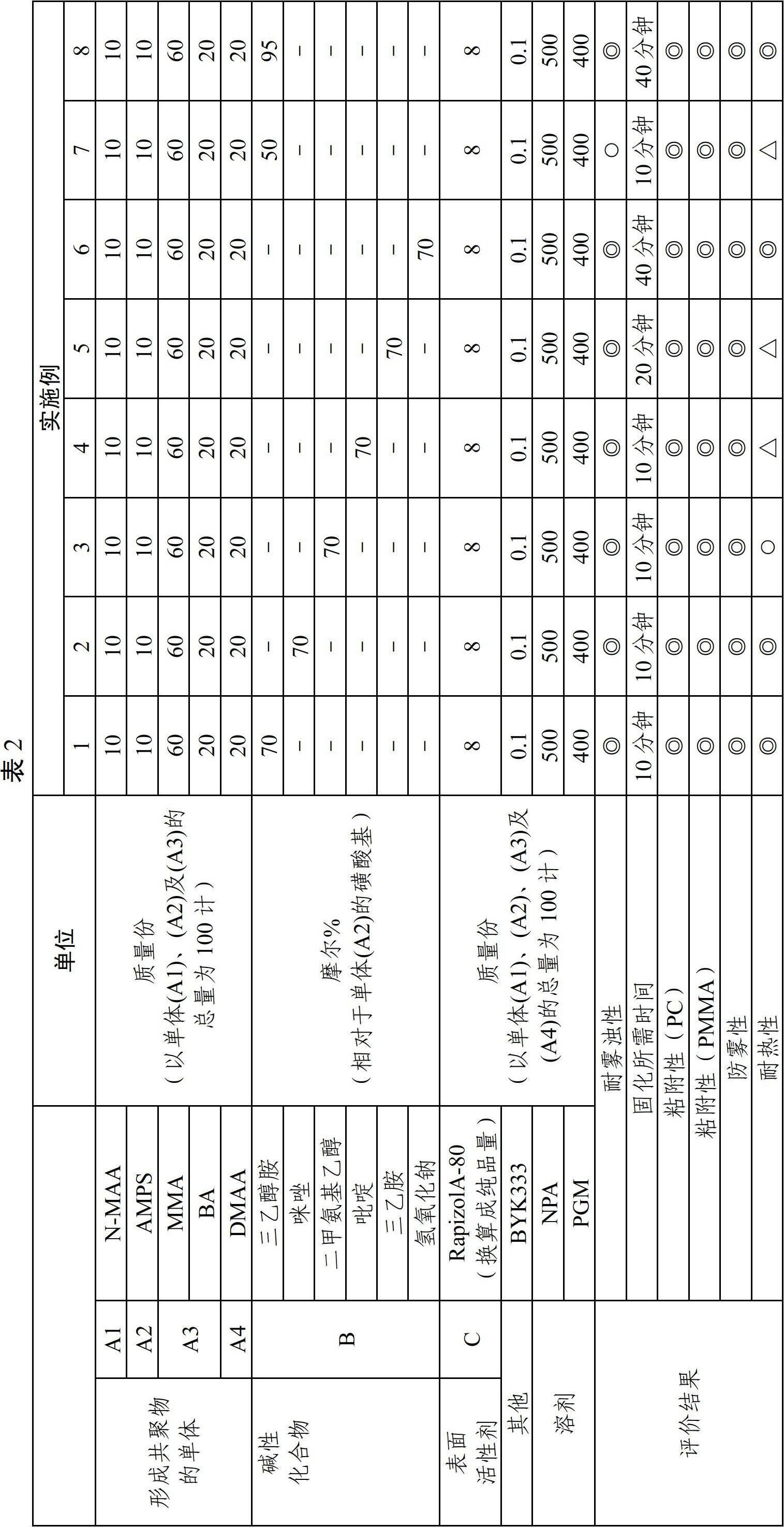

Anti-fog coating composition

ActiveCN102666753AImprove hydrophilicityImprove adhesionVehicle headlampsOther chemical processesHigh humidityHeat resistance

Provided is an anti-fog coating composition. When applied and dried even under high-humidity conditions, the anti-fog coating composition rarely suffers from blushing. Further, the anti-fog coating composition can be heat-cured even at low temperature in a short time and can form a coating film that exhibits excellent tight adhesion to a substrate and excellent heat resistance and anti-fog properties. The anti-fog coating composition comprises (A) a copolymer, (B) a basic compound such as amine, and (C) a surfactant such as anionic surfactant, said copolymer (A) being a copolymer prepared from a monomer mixture that comprises (A1) a vinyl monomer that has an N-methylol group or an N-alkoxymethylol group, (A2) a vinyl monomer that has a sulfonic acid group, and (A3) an alkyl (meth) acrylate monomer.

Owner:NOF CORP

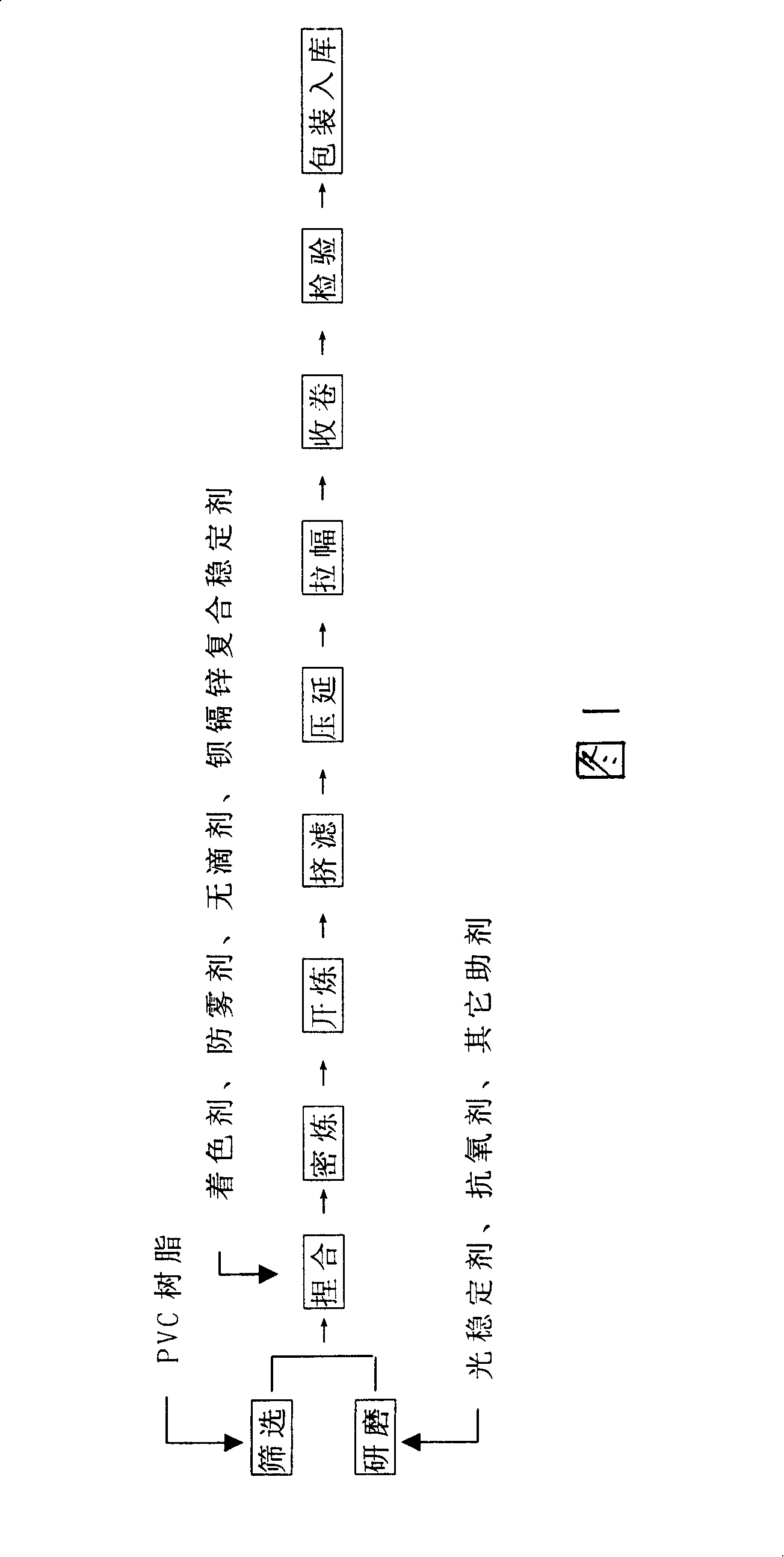

Polychloroethylene antifog non-drop greenhouse film

The invention relates to a transparent covering material for solar greenhouse in winter and for plastic greenhouse in early spring, in particular to a polyvinyl chloride antifogging dripless greenhouse film which can prevent from fogging in the greenhouse and enables the water drops in the condensed in the internal surface of the greenhouse film to wet and spread quickly. The polyvinyl chloride antifogging dripless greenhouse film adopts polyvinyl chloride resin as the base, adding plasticizer, heat stabilizer, ultraviolet absorbent, compound dripless agent and organosilicon antifogging agent into the polyvinyl chloride resin, and being prepared through calendering, stentering and other production process steps. The transparent covering material for solar greenhouse in winter and for plastic greenhouse in early spring has the advantages of good dripless antifogging effect, improvement of light transmittance for greenhouse film, incensement of light intensity, beneficial photosynthesis for crops, beneficial improvement of greenhouse temperature, acceleration of crops growth, and reduction of disease occurrence.

Owner:白山市喜丰塑业有限公司

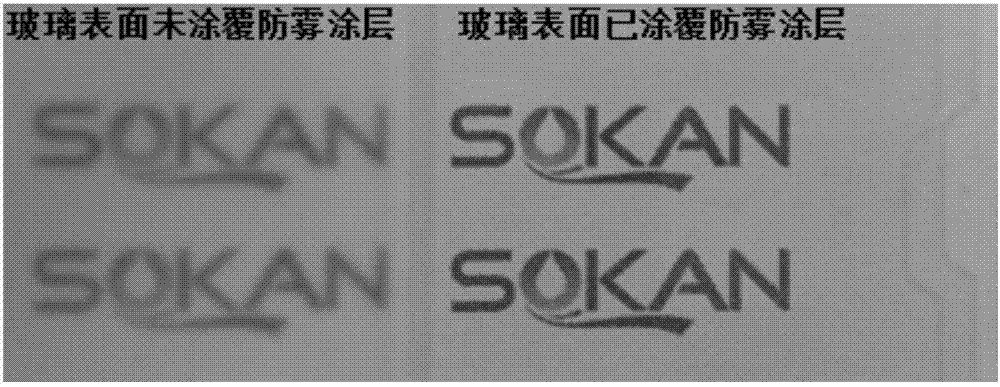

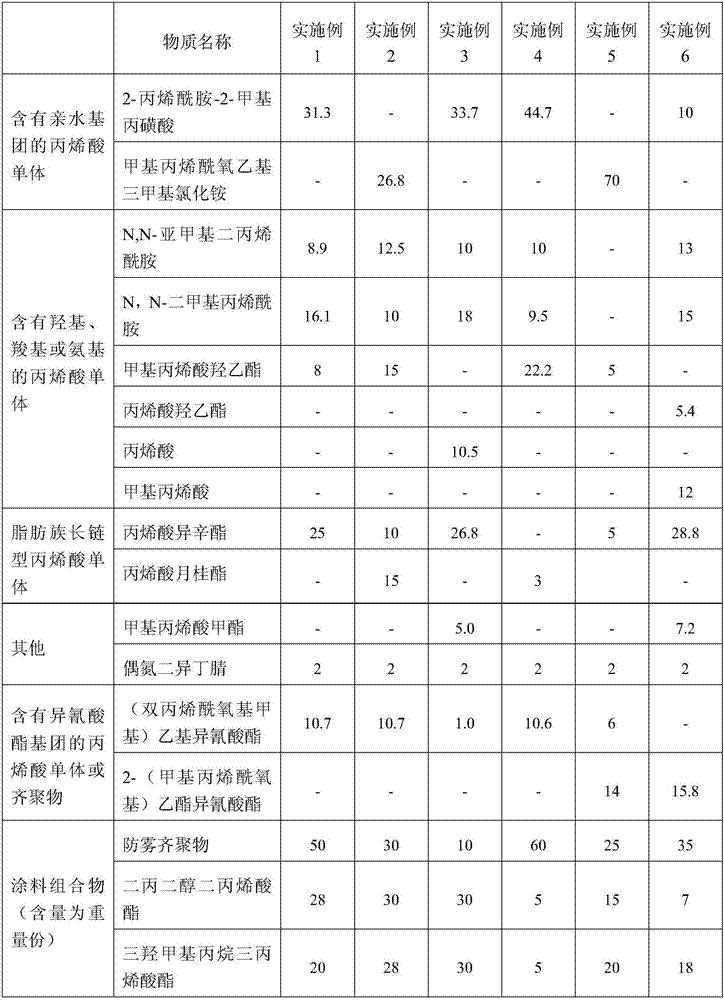

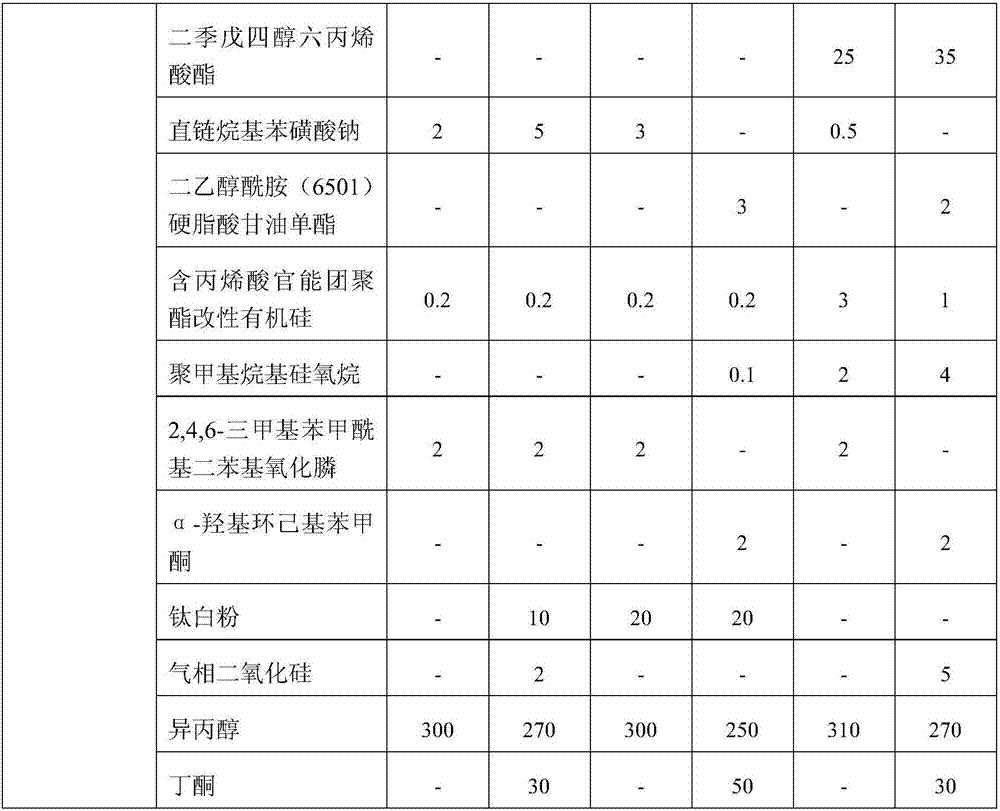

Anti-fogging oligomer, coating composition and preparation method thereof

ActiveCN106883344AGood anti-fog performanceImprove hydrolysis resistanceFireproof paintsAdhesion forceOligomer

The invention discloses an anti-fogging oligomer. The anti-fogging oligomer is obtained by polymerizing one or a mixture of multiple of acrylic monomers containing hydrophilic groups, acrylic monomers containing hydroxyl, carboxyl and amino and an aliphatic long-chain type acrylic monomer, and reacting with an isocyanate group-containing acrylic monomer or oligomer; the weight-average molecular weight of the anti-fogging oligomer is 2,000 to 100,000. The invention also discloses a coating composition comprising the anti-fogging oligomer and preparation methods of the anti-fogging oligomer and the coating composition. The anti-fogging oligomer can be coated on the surface of a transparent substrate directly or serving as part of the coating composition; the anti-fogging oligomer can be cured by using ultraviolet light after the contained hydroxyls, carboxyl or amino are reacted with the contained isocyanate groups; the contained hydroxyls, carboxyl or amino can also improve the adhesion force between the anti-fogging oligomer and the substrate; the anti-fogging oligomer has good hydrolysis resistance because of the aliphatic long-chain type acrylic monomer; the coating composition has good anti-fogging performance and has great adhesion force with the substrate.

Owner:HUNAN SOKAN NEW MATERIAL

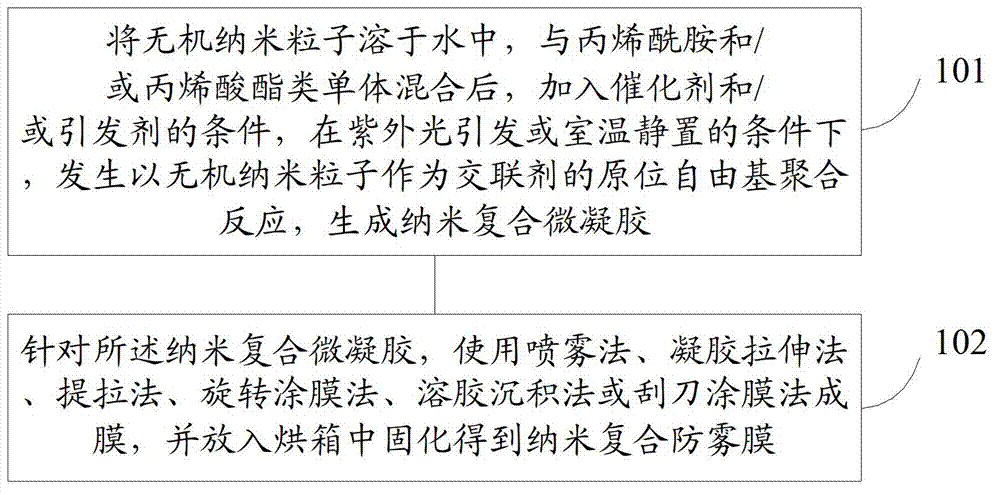

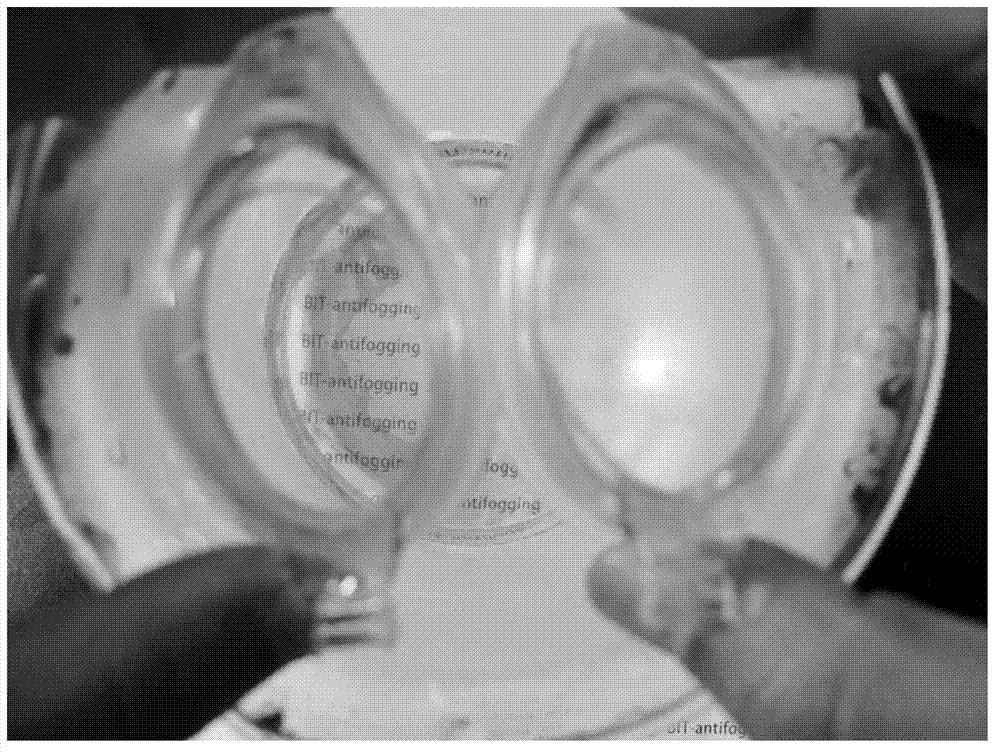

Preparation method for nanometer composite anti-fogging film

The invention provides a preparation method for a nanometer composite anti-fogging film. The method comprises the following steps: dissolving inorganic nanoparticles in water, mixing the dissolved inorganic nanoparticles with acrylamide and / or acrylic acid ester monomers, adding a catalyst and / or initiator and carrying out in situ free radical polymerization with the inorganic nanoparticles as a cross-linking agent under the condition of ultraviolet light initiation or standing at room temperature so as to produce nanometer composite microgel; and subjecting the nanometer composite microgel to film forming by using a spraying method, a gel stretch method, a Czochralski method, a spin-coating method, a sol deposition method or a blade coating method and curing an obtained film in a baking oven so as to obtain the nanometer composite anti-fogging film. The method for preparing the nanometer composite anti-fogging film in the invention can improve bonding force between a coating of the anti-fogging film and a substrate and anti-fogging duration time and wear resistance of the anti-fogging film.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

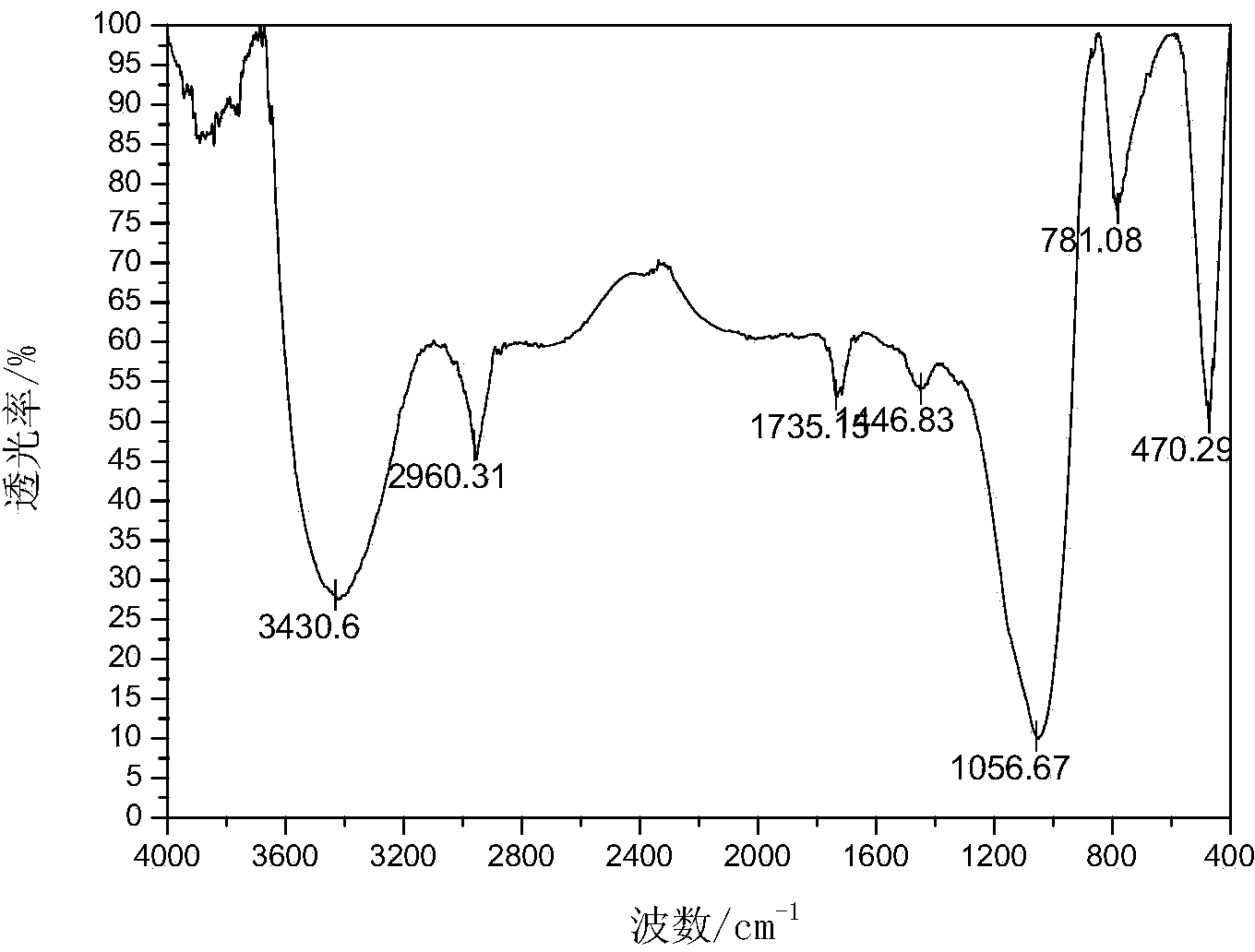

Super-hydrophilic self-cleaning SiO2 antifogging coating and preparation method thereof

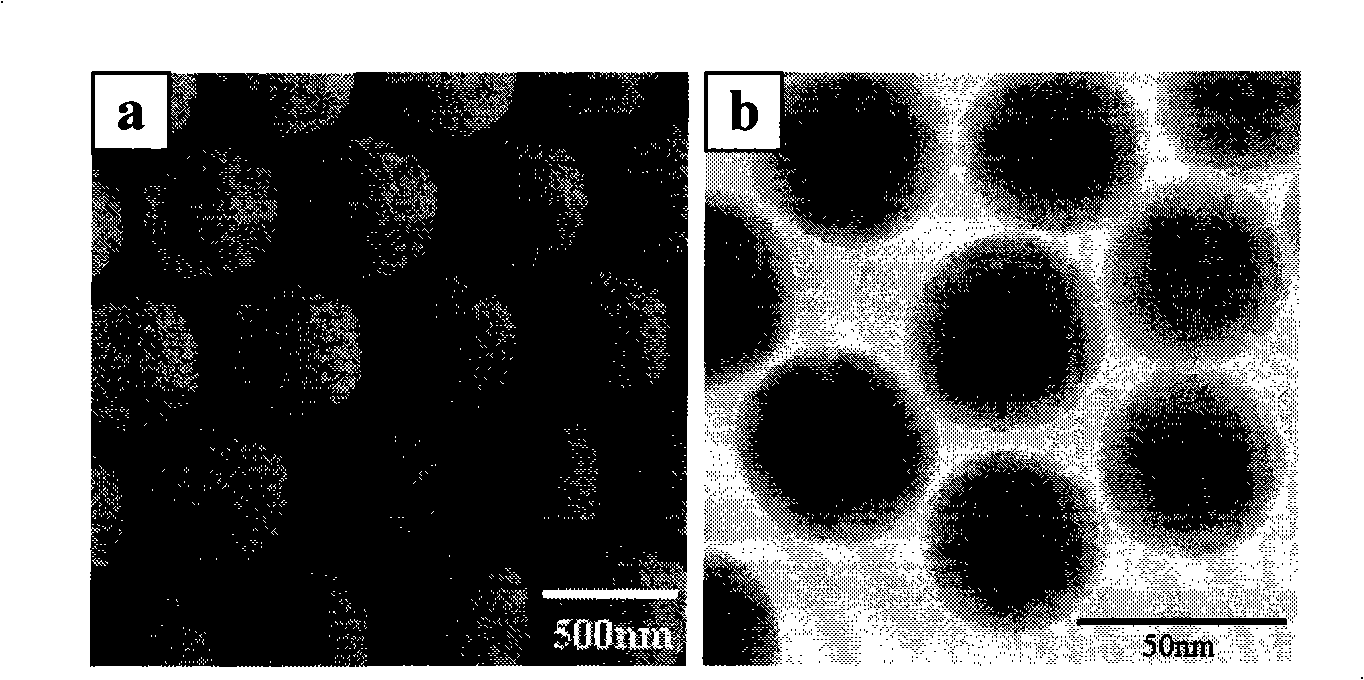

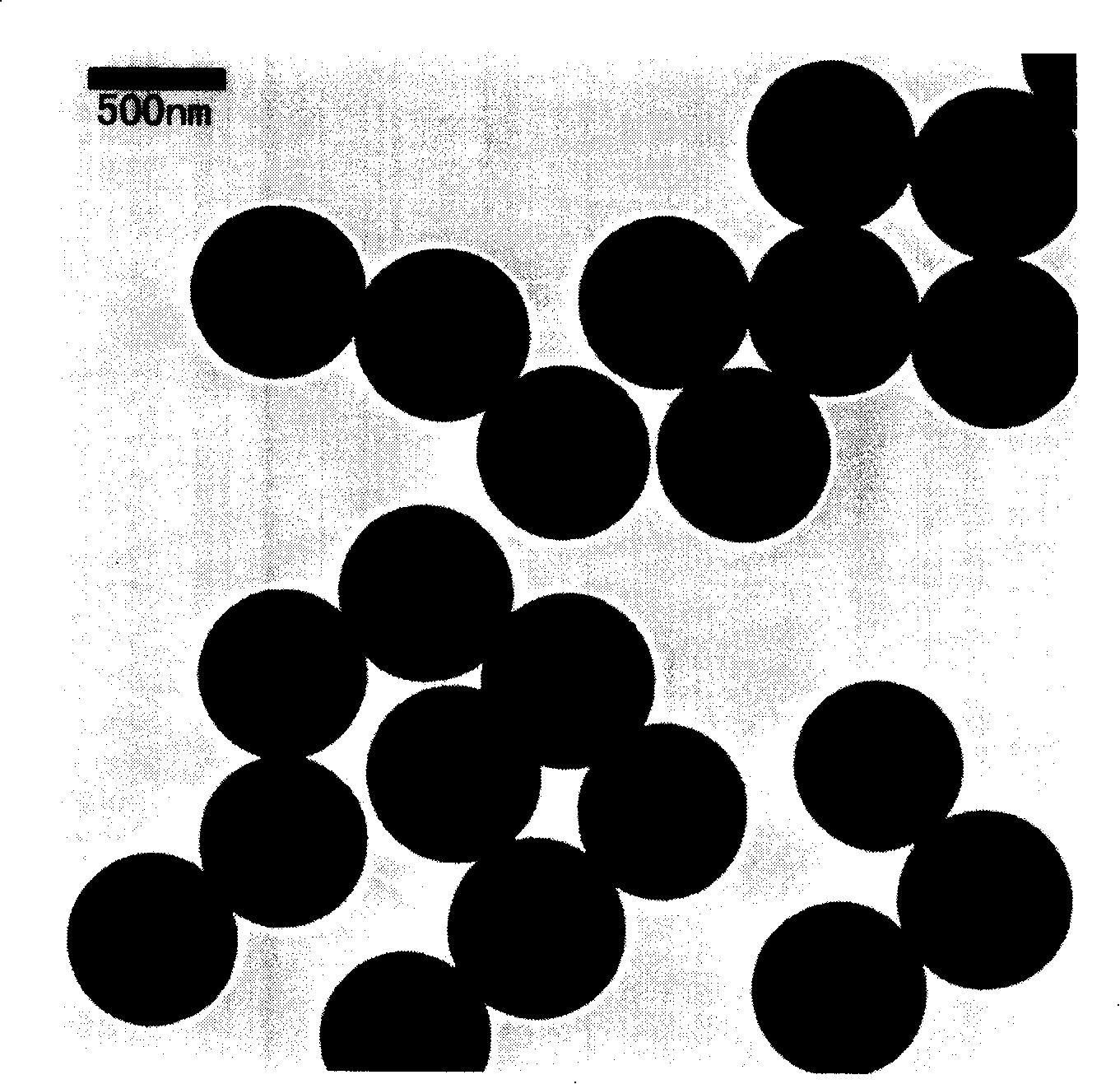

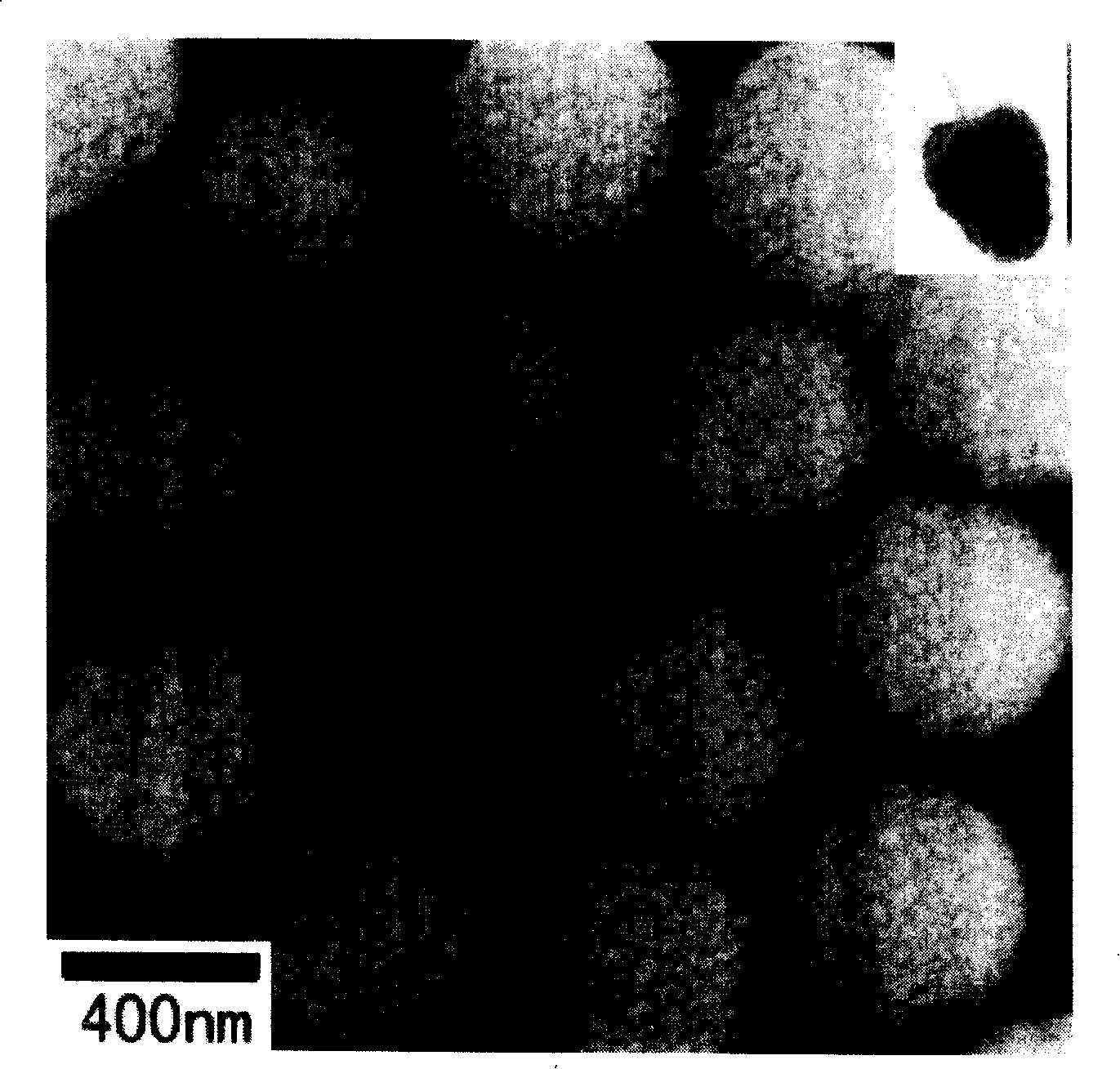

InactiveCN101538124ASimple equipmentRealize industrializationSilicaMaterials preparationCoated surface

The invention belongs to the technical field of nano material preparation, and in particular relates to a super-hydrophilic self-cleaning SiO2 antifogging coating and a preparation method thereof. The super-hydrophilic self-cleaning SiO2 antifogging coating is prepared by layer-by-layer electrostatic assembly and dipcoating method through simple and cheap instruments and is expected to realize industrialization. The coating is formed by SiO2 hollow spheres, and the surface of the coating formed by the SiO2 hollow spheres has a hierarchical coarse structure and a hierarchical nanoscale porous structure; and the coating can be used on glass products, and is particularly suitable for various substrates requiring antifogging treatment in a damp air environment, particularly in showery days in the south of China.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

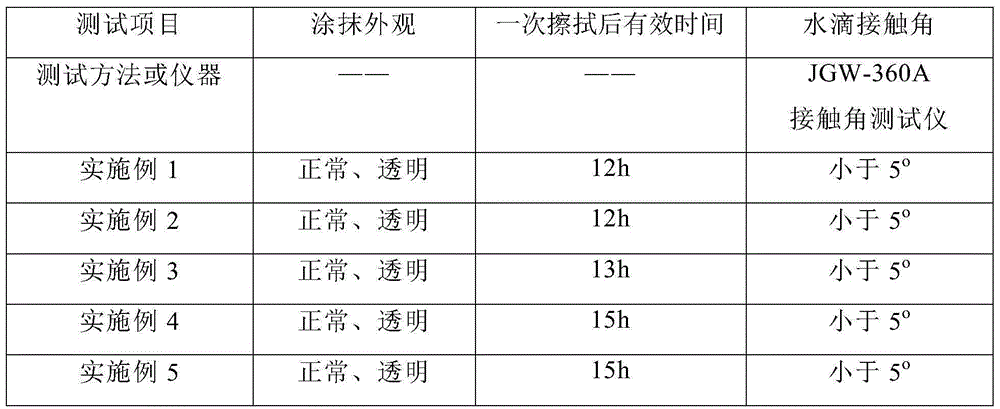

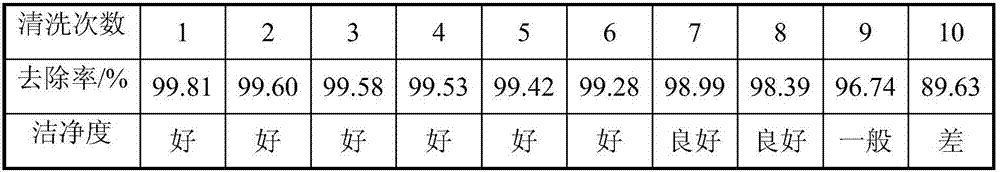

Nano antifogging paint composition and preparation method thereof

The invention provides a nano antifogging paint composition which comprises the following components in percentage by weight: nano silicon dioxide sol, nano titanium dioxide sol or doped nano titanium dioxide sol, polyorganosiloxane, alkylol amine, acrylamide and a film former. The preparation method of the nano antifogging paint composition comprises the following steps: mixing the nano silicon dioxide sol and nano titanium dioxide sol, adding the polyorganosiloxane, alkylol amine, acrylamide and film former at 60-90 DEG C, mixing, and reacting to obtain the nano antifogging paint. Compared with the prior art, the nano antifogging paint is convenient to use, and after a soft cloth soaked with the paint is used for wiping a glass surface, a transparent nano hydrophilic coating can be formed to have favorable antifogging effect; the effective time after one-time wiping can reach 12 hours; and after the antifogging effective time, the nano antifogging paint can be applied again to restore the antifogging effect.

Owner:SUZHOU ZHIJIAN NEW MATERIAL TECH CO LTD

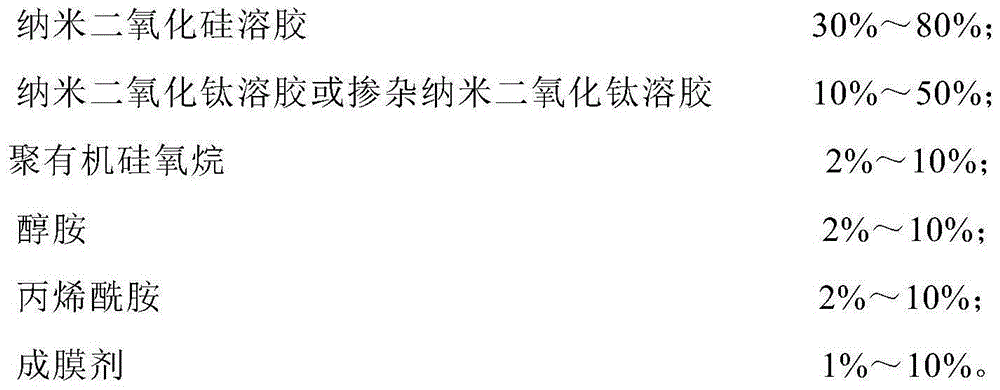

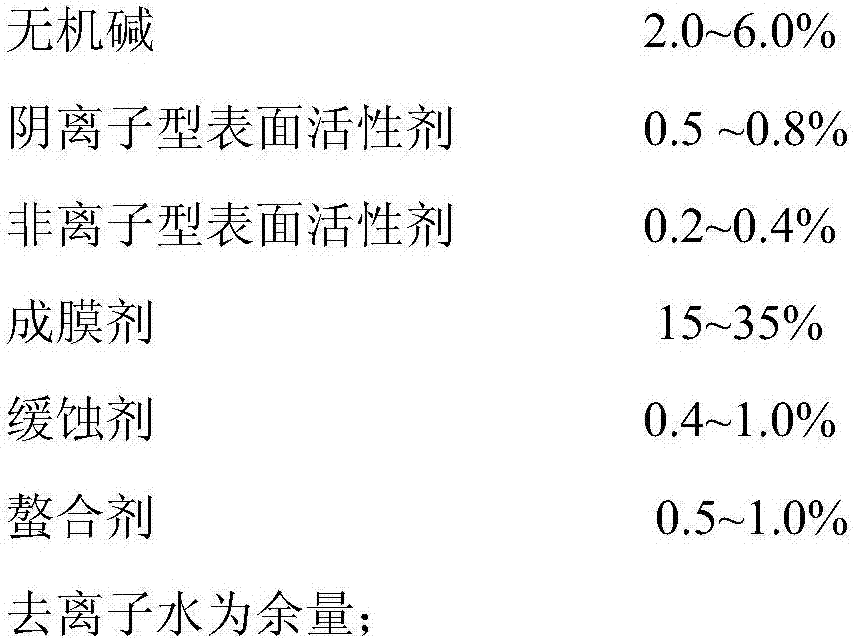

Environment-friendly optical glass cleaning agent and preparation method thereof

InactiveCN107057878AReduce the impactReduce concentrationInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsCleansing AgentsOptical glass

The invention discloses an environment-friendly optical glass cleaning agent and a preparation method thereof. The environment-friendly optical glass cleaning agent is prepared from the following raw materials in percentage by mass: 2 to 6 percent of inorganic alkali, 0.5 to 0.8 percent of anionic surfactant, 0.2 to 0.4 percent of non-ionic surfactant, 15 to 35 percent of film-forming agent, 0.4 to 1.0 percent of corrosion inhibitor, 0.5 to 1 percent of chelating agent and the balance of deionized water, wherein the anionic surfactant is prepared from sodium lauryl sulfate and fatty acid methyl ester sulfonate in a mass ratio of (5:1) to (1:1); the non-ionic surfactant is prepared from dodecyl glycoside; the film-forming agent is prepared from ethanol and ethylene glycol in a mass ratio of 1:1; the corrosion inhibitor is prepared from sodium citrate and triethanolamine in a mass ratio of 1:1. The optical glass cleaning agent disclosed by the invention has the advantages of good cleaning effect, high cleanliness of cleaned glass, no corrosion to the glass, high biodegradability, freeness from pollution, and low skin irritation.

Owner:CENT SOUTH UNIV

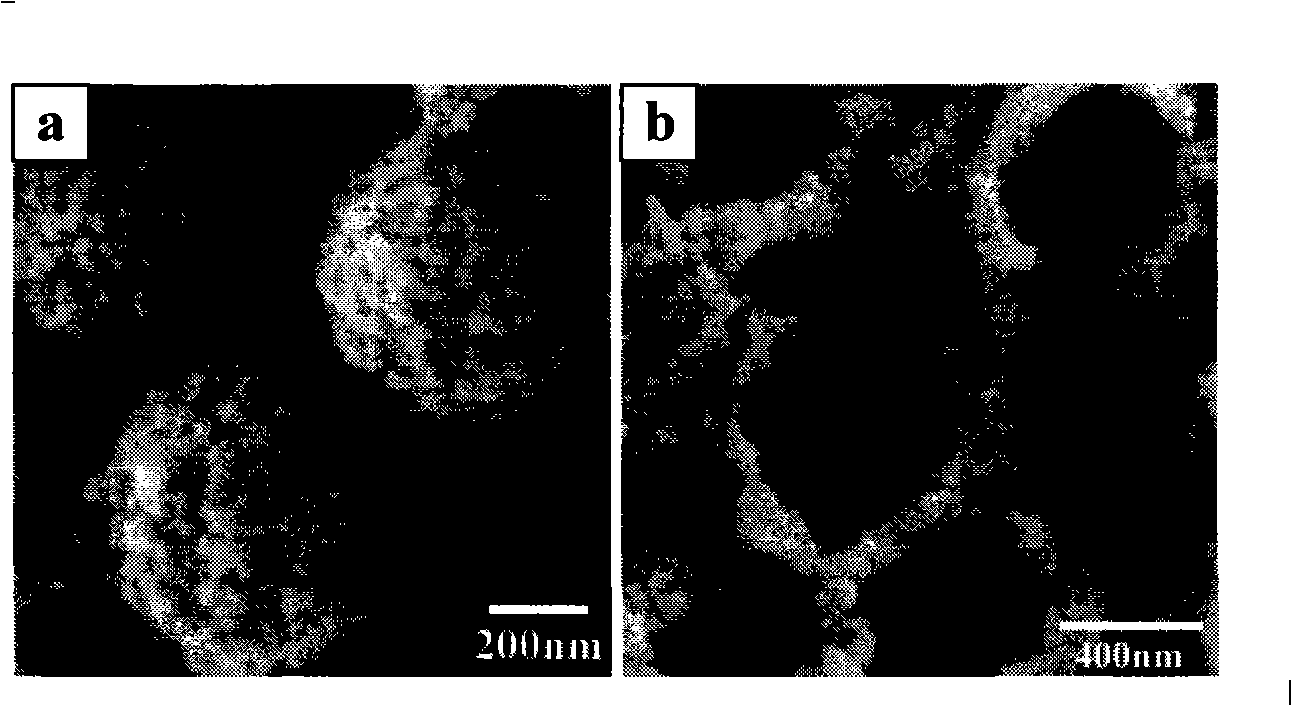

Ultra-hydrophilic self-cleaning anti-fog coat and its preparation method and use

The invention relates to a super-hydrophilic self-clean anti-fog coat, process of preparation, and application, belonging to nanometer material preparation technical field. The inventive super-hydrophilic self-clean anti-fog coat is assembled by statistic and prepared by dip-coating method, with simple and cheap device, to support industrialization. The surface structure of the coat is similar with natural lotus leaf surface, and the coat is assembled from silicon dioxide composite particles similar as natural raspberry fruit structure. The coat can be used on glass product, especially on the substrates demanding anti-fog treatment in damp air condition, as southern rainy weather.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Antifogging coating composition and article coated therewith

InactiveCN1535305AGood anti-fog performanceImprove adhesionLiquid surface applicatorsCoatingsCross-linkHydrophobic polymer

An antifogging paint composition for forming an antifogging coating film without generation of the running water trace. The antifogging paint composition contains a block or grafted copolymer comprising a hydrophilic polymer part formed from a vinyl monomer having a cross-linking functional group and a water-soluble vinyl monomer, and a hydrophobic polymer part formed from a non water-soluble vinyl monomer, and an acidic alkyl phosphate.

Owner:NOF CORP

Aqueous ultraviolet cure offset printing gloss oil

InactiveCN101348621ANo residueMeet environmental protection requirementsEmulsion paintsSolventOrganosilicon

The invention provides water ultraviolet curing offset-printing gloss oil for glazing printed matter surface. The prior ultraviolet glazing oil does not meet the residue requirements of the tobacco package industry, has certain volatility as well as irritation, and is still harmful to environment. The curing offset-printing gloss oil comprises the following components in weight percentage: 10 to 50 percent of polyurethane acrylic resin, 10 to 50 percent of epoxy acrylate resin, 5 to 20 percent of dipentaerythritol hexaacrylate, 1 to 10 percent of 4-(N, N-dimethylamino) ethyl benzoate, 1-10 percent of o-benzoyl methyl benzoate, 1 to 10 percent 4-chlorobenzophenone, 0.1 to 1.0 percent of BaBr2, 10 to 20 percent of water, 0.1 to 1 percent of organosilicon flatting agent, 0.1 to 1 percent of defoaming agents and 0.1 to 1 percent of antifogging agents. As more than 65 percent of the components of the curing offset-printing gloss oil do not volatilize, the curing offset-printing gloss oil is low in irritation and little in odor, has no solvent residue, and meets cigarette label residue requirements.

Owner:浙江美浓涂料有限公司

Anti-fog polyester film and preparation method thereof

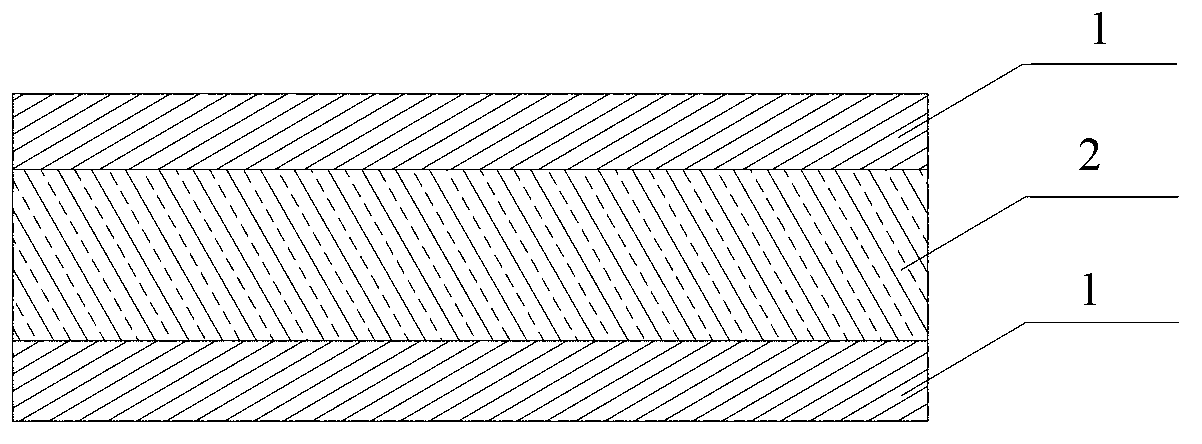

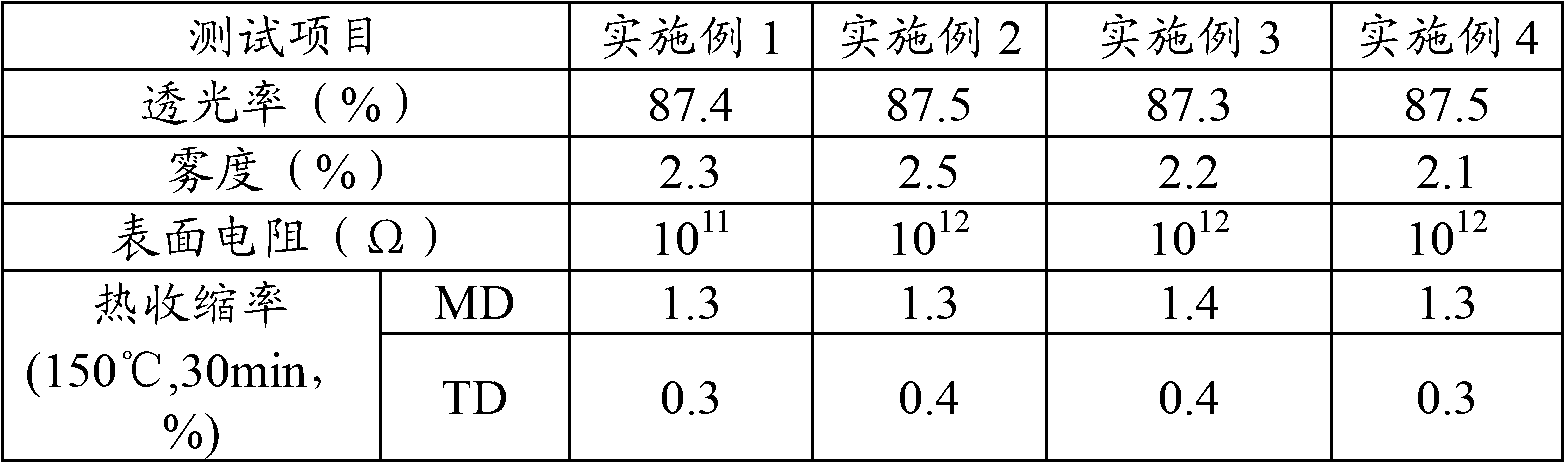

ActiveCN102794965AHigh transparencyImprove machinabilitySynthetic resin layered productsPolyesterHigh humidity

The invention relates to the technical field of functional polyester film, particularly relates to an anti-fog polyester film and a preparation method thereof, for solving the problems of thick thickness, bad thermostability, difficulty in applying in high-temperature high-humidity environment in existing anti-fog films. The anti-fog polyester film disclosed herein comprises a polyester base material, wherein the two sides of the base material is provided with anti-fog function layers, the polyester base material is a pure polyester layer, the material of the anti-fog function layers comprises 100 parts of polyester slices, 0.5-2.0 parts of anti-fogging agent, and 0.1-0.5 parts of synergist. The film disclosed herein has good transparency, good machining property, thin thickness, good thermostability, and good anti-fog performance, and can be applied in high-temperature high-humidity environment. The preparation method of the film is simple and easy to operate.

Owner:NINGBO CHANGYANG TECH

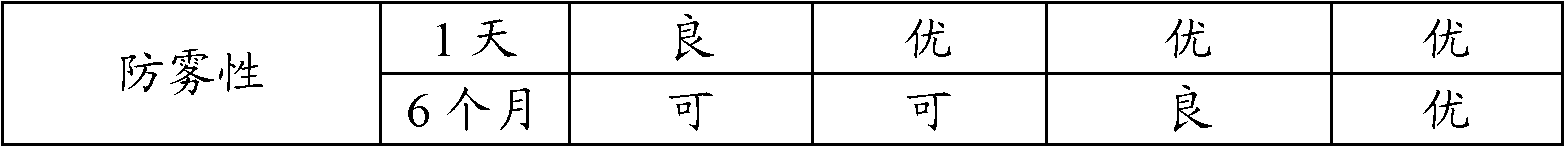

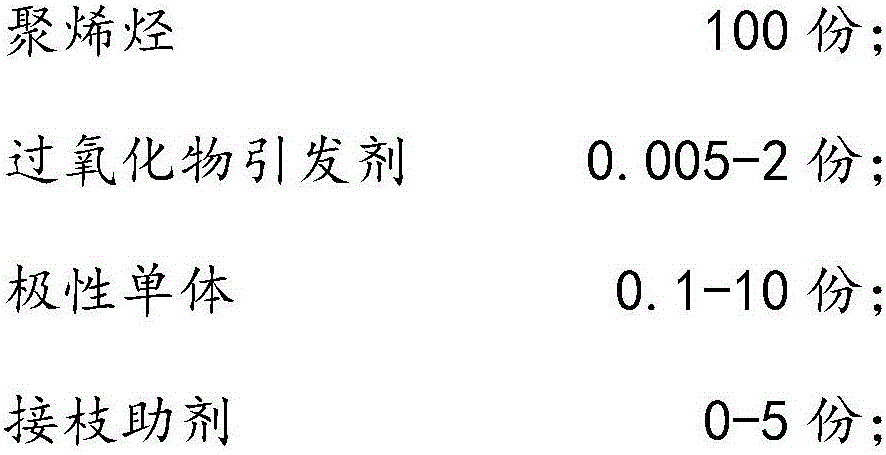

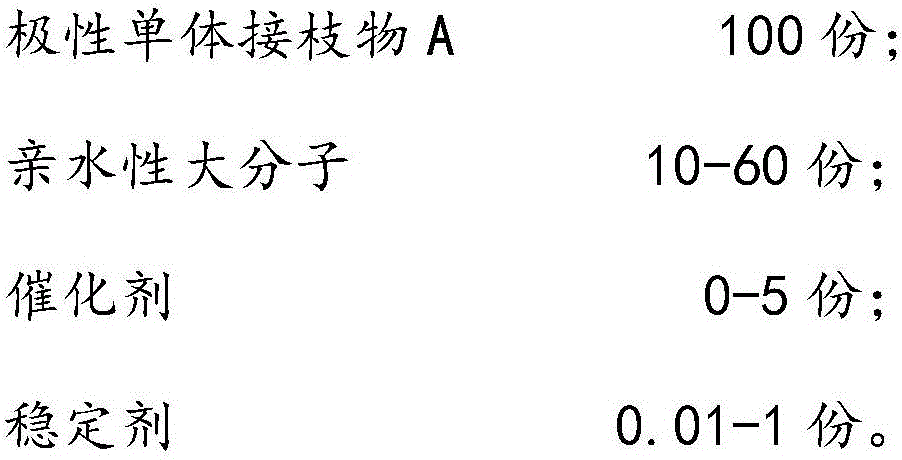

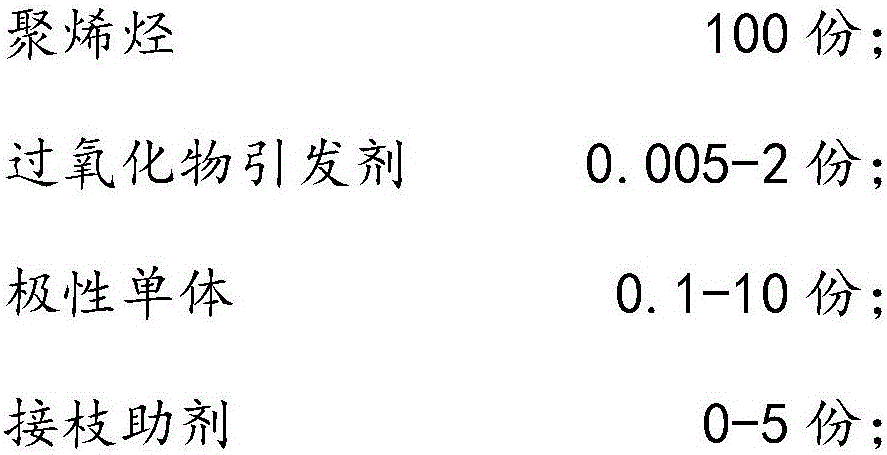

Anti-fog polyolefin graft copolymer and preparation method thereof

The invention discloses an anti-fog polyolefin graft copolymer and a preparation method thereof. The anti-fog polyolefin graft copolymer is prepared through a two-step grafting method. The method specifically comprises the following steps: (1) carrying out grafting reaction on polyolefin, a peroxide initiator and a polar monomer to obtain a polar monomer graft copolymer A; and (2) further grafting hydrophilic macromolecules into the polar monomer graft copolymer A through the action of a chemical bond to obtain the anti-fog polyolefin graft copolymer B. The anti-fog polyolefin graft copolymer has excellent hydrophilic performance, is not easy to run off due to rainwash and has a more lasting anti-fog effect.

Owner:GUANGZHOU LUSHAN NEW MATERIALS

Fluoroaliphatic group-containing copolymer

InactiveUS7105270B2Improve solubilityGood dispersibilitySemiconductor/solid-state device manufacturingDiazo compound compositionsResistHydrogen atom

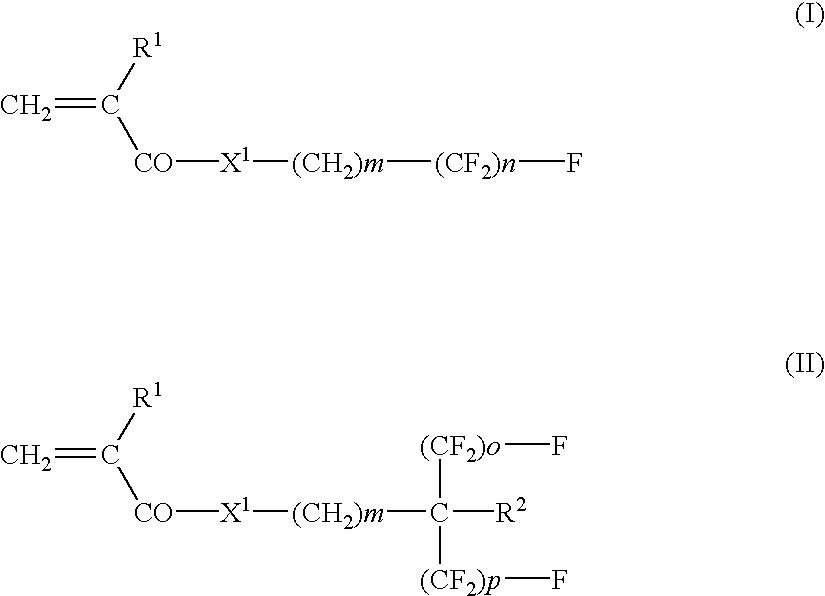

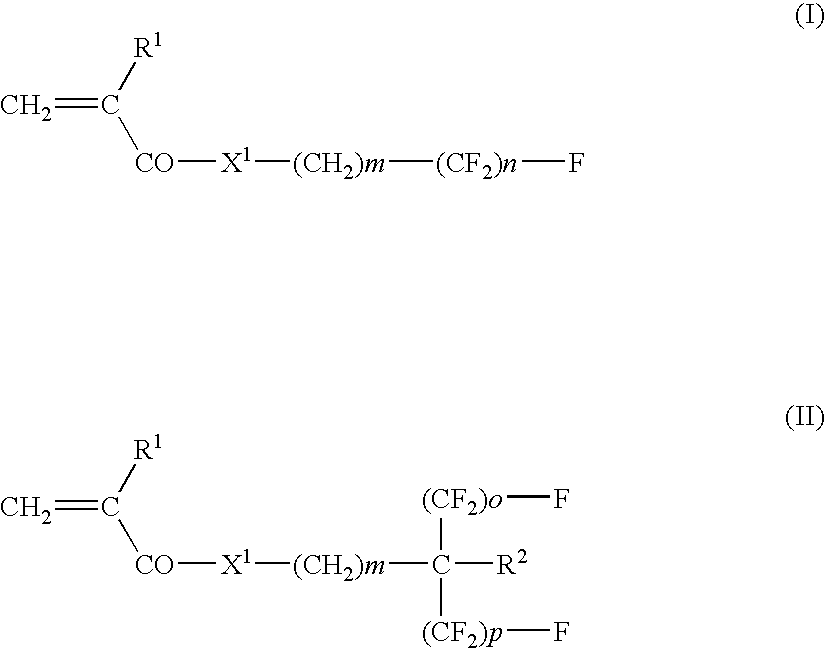

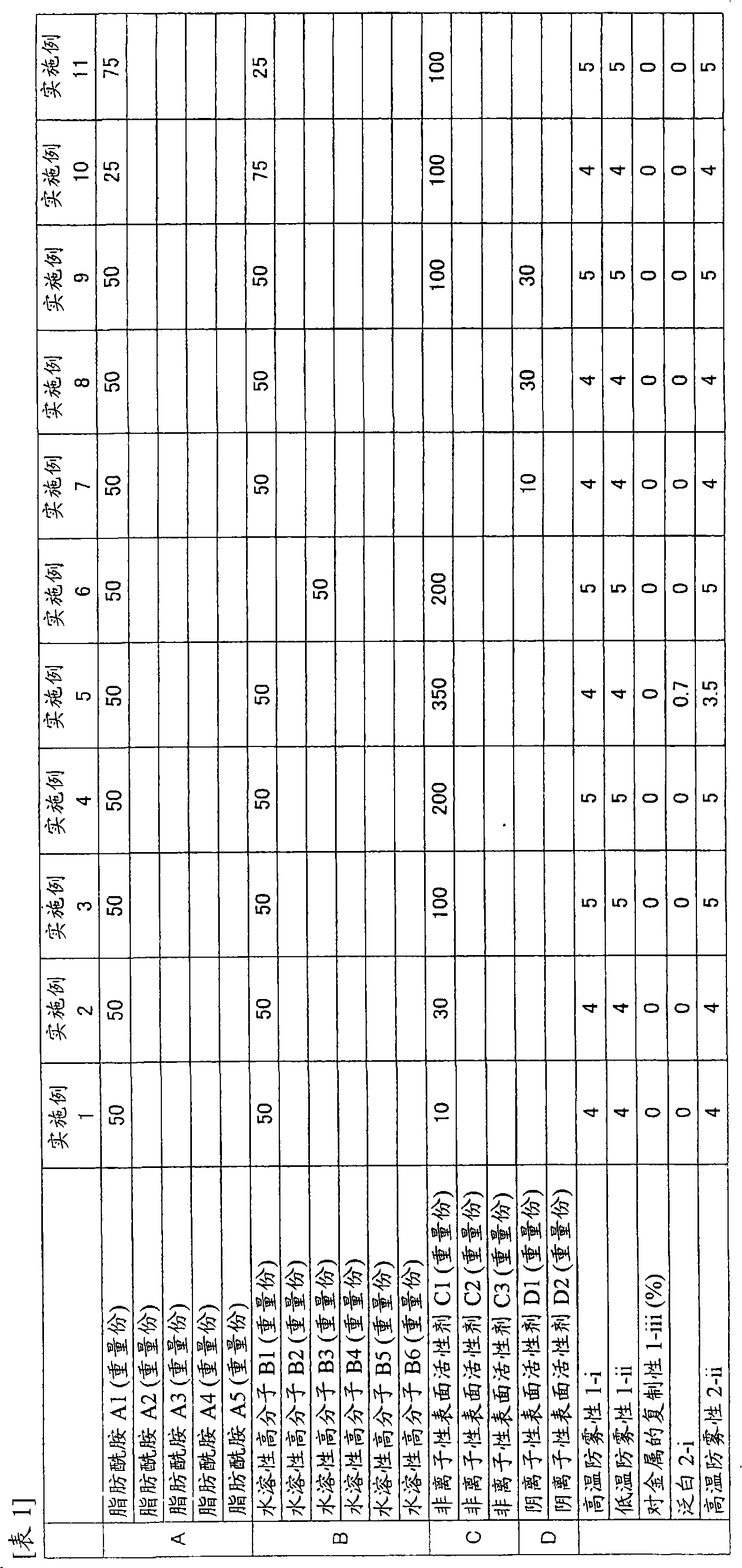

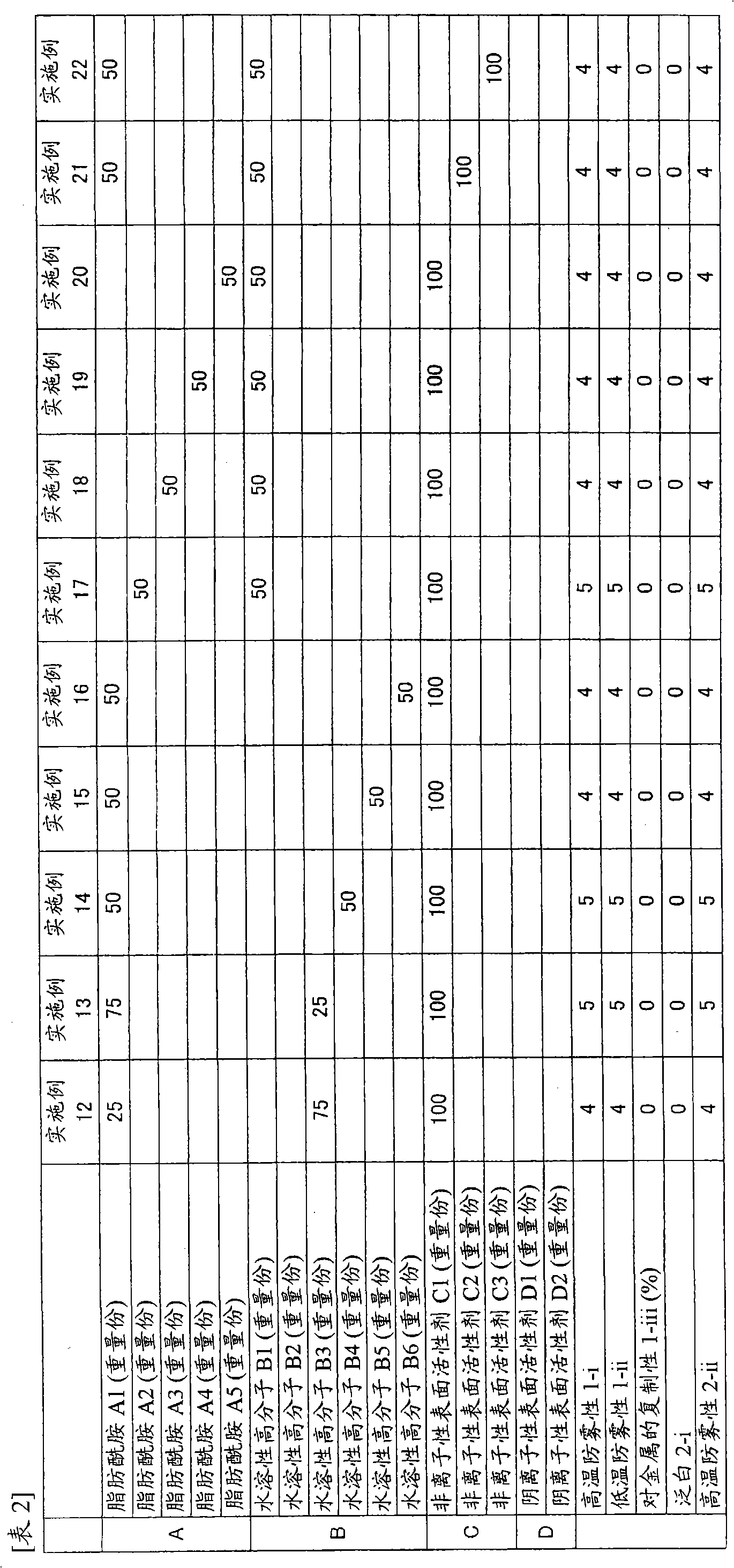

The present invention provides a copolymer comprising repeating units derived from (A) at least one fluoroalkyl (meth) acrylate represented by the following general formula (I) or (II):wherein, X1 represents —O— or —NR3—; R1 represents —H or —CH3; R3 represents a hydrogen atom, a substituted or unsubstituted alkyl group having 1 to 12 carbon atoms, a substituted or unsubstituted cycloalkyl group having 3 to 12 carbon atoms, a substituted or unsubstituted aryl group having 6 to 12 carbon atoms or a substituted or unsubstituted aralkyl group having 7 to 24 carbon atoms; R2 represents H or F; m is an integer ranging from 0 to 10; n is an integer of 2 or 3; and o and p each represents an integer of 1 or 2, and (B) at least one polyoxyalkylene group-containing ethylenically unsaturated monomer, and also provides an image-forming composition, a presensitized plate useful for preparing a lithographic printing plate, a paint composition or a photo resist composition comprising the copolymer. The fluoroaliphatic group-containing copolymer can provide a coating composition capable of simultaneously satisfying the requirements for the ability of a coating liquid to wet the base material and the uniform coating ability upon the application of the liquid and the post-processing aptitudes such as the re-coating ability of the coated film and developing ability as well as the foaming ability of the coating liquid.

Owner:FUJIFILM CORP

Anti-fogging surface treating agent and anti-fogging resin sheet

InactiveCN101555400AGood anti-fog performanceHigh quality appearanceFlexible coversWrappersSucroseSurface-active agents

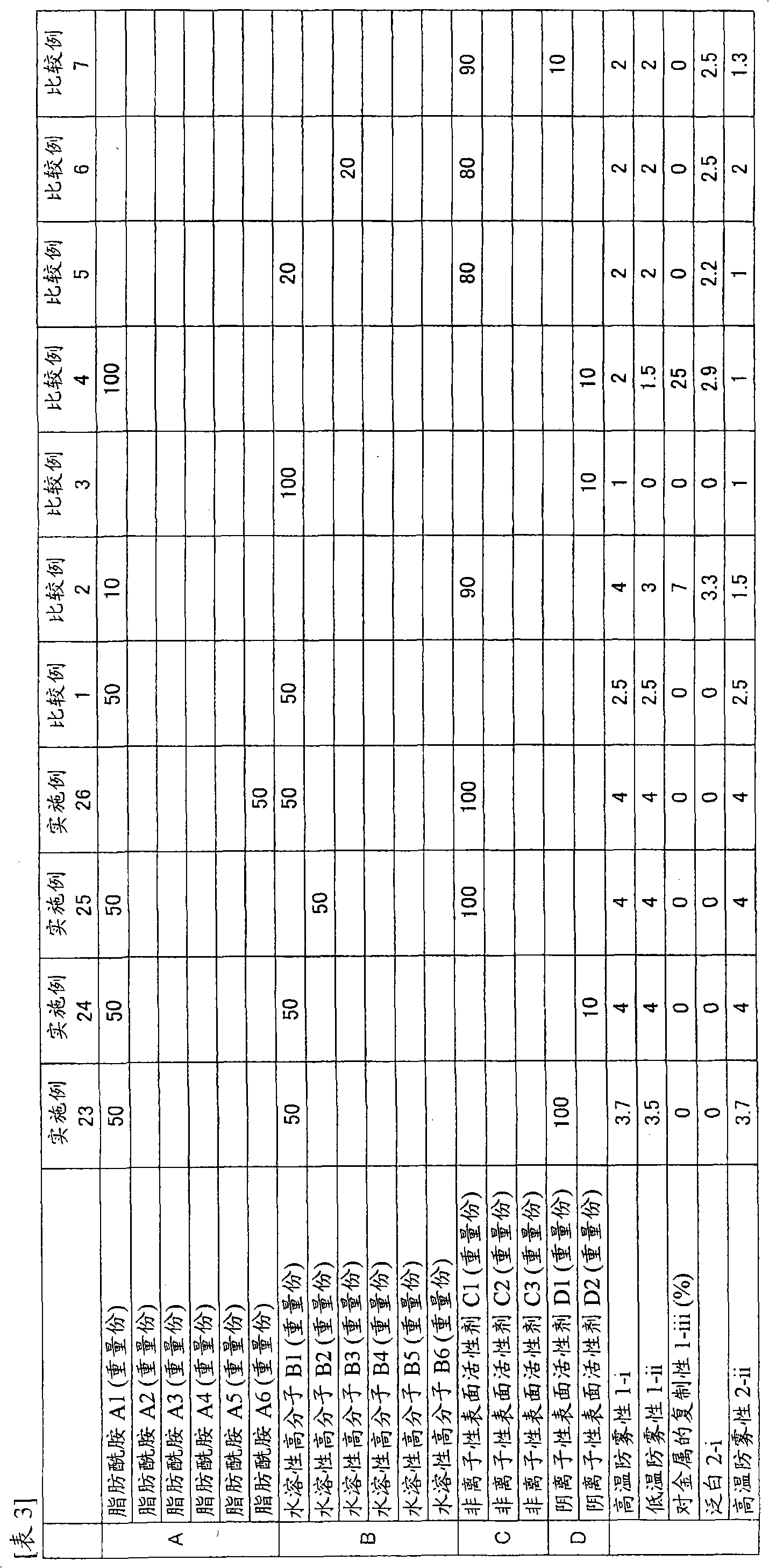

The object of the invention is to obtain an anti-fogging surface treating agent and an anti-fogging resin sheet having excellent anti-fogging property. In terms of 100 parts by weight of base composition, the anti-fogging surface treating agent contains 0.1 to 400 parts by weight (C) of non-ionic surface active agent such as sucrose fatty ester and the like, and / or 0.1 to 20 parts by weight (D) of anionic surface active agent such as paraffin sulfonate and the like. The base composition contains (A) C8-30 fatty amide such as alkanolamide and the like, and (B) water-soluble polymer such as vinyl pyrrolidone polymer. An anti-fogging resin sheet applied to shaping a deep-drawing container can be prepared by coating the surface treating agent on at least one face of the stilbene resin sheet.

Owner:DAICEL POLYMER LTD

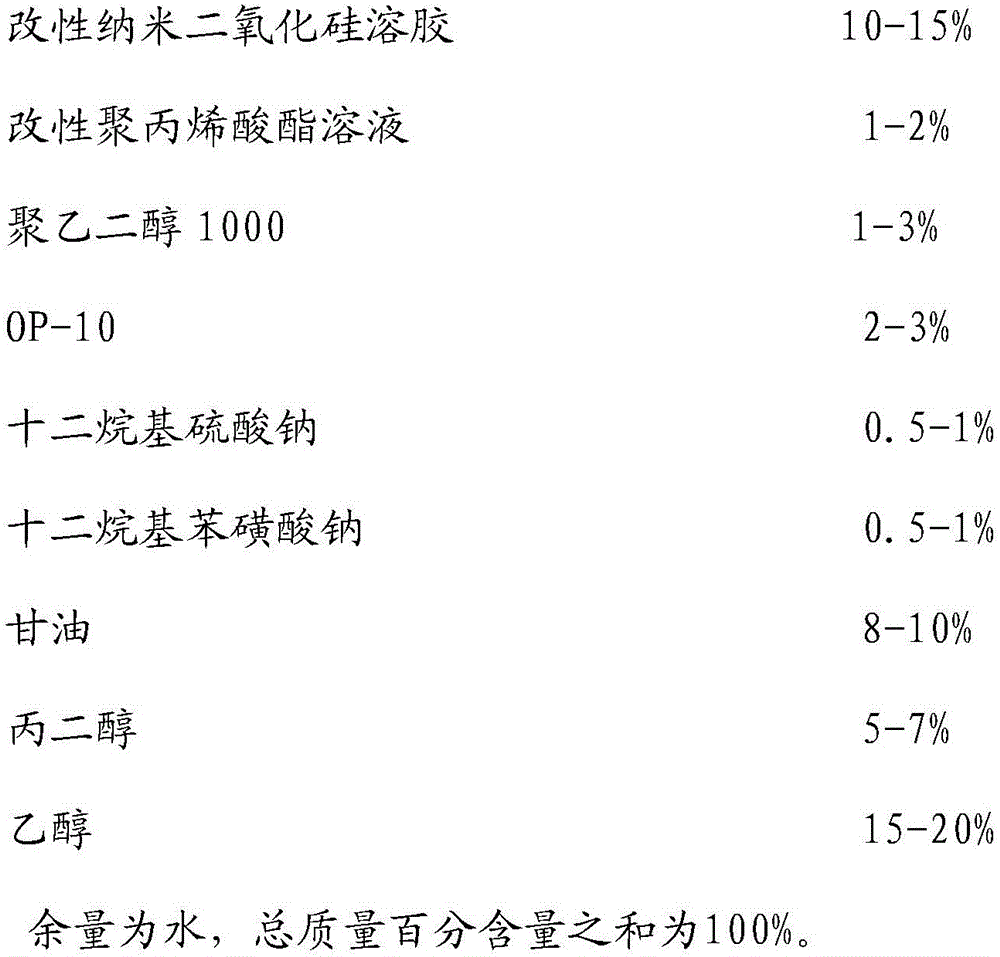

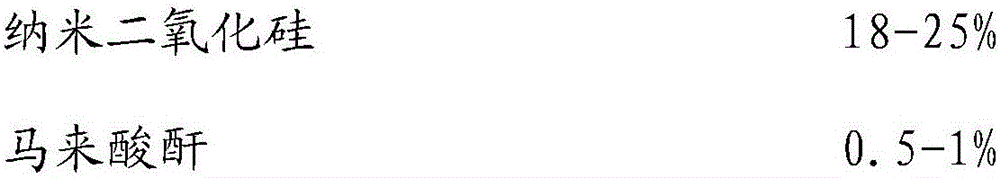

Long-acting anti-fog agent for automotive glass and preparation method of anti-fog agent

ActiveCN105713575ALong durationGood anti-fog performanceOther chemical processesPolyethylene glycolGlycerol

The invention belongs to the technical field of preparation of anti-fog agents for automotive glass and particularly discloses a long-acting anti-fog agent for automotive glass and a preparation method of the anti-fog agent. The anti-fog agent comprises raw materials in percentage by mass as follows: 10%-15% of modified nano-silica sol, 1%-2% of a modified polyacrylate solution, 1%-3% of polyethylene glycol 1000, 2%-3% of OP-10, 0.5%-1% of sodium dodecyl sulfate, 0.5%-1% of sodium dodecylbenzenesulfonate, 8%-10% of glycerin, 5%-7% of propylene glycol, 15%-20% of ethyl alcohol and the balance of water, and the sum of total mass percentage composition is 100%. The anti-fog effect of the anti-fog agent is greatly enhanced through adoption of modified super-hydrophilic nano-silica; with adoption of the modified polyacrylate solution with better adhesion performance, super-hydrophilic nanoparticles and surfactant components can adhere to the glass without falling, so that the durability of the anti-fog agent is enhanced, and the anti-fog effect can be kept for 3 months.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

Hydrophilic member and process for producing the same

InactiveUS7955656B2Good anti-fog performanceIncreased durabilityPretreated surfacesLiquid/solution decomposition chemical coatingPolymer sciencePtru catalyst

Owner:FUJIFILM CORP

Low fogging thermoplastic elastomer composition and manufacturing method and use of same composition

InactiveUS7049356B2Easy to handleImprove compatibilityMixingPolishing compositionsElastomerPolymer science

This invention relates to a perfectly or partially crosslinked olefinic thermoplastic elastomer composition which comprises 10 to 90 parts by weight of a crystalline polyolefin (a), 90 to 10 parts by weight of an olefin-based copolymer rubber (b) (the total amount of the components (a) and (b) being 100 parts by weight) and 3 to 100 parts by weight of a paraffinic mineral oil softening agent (c) having an evaporation loss of 0.4% by weight or less at a condition of 200° C., atmospheric pressure and 1 hour and having a kinetic viscosity (40° C.) of 50 to 250 cSt; an olefinic thermoplastic elastomer composition which is obtainable by subjecting a mixture including 40 to 85 parts by weight of an ethylene-based copolymer rubber (A), 60 to 15 parts by weight of an olefinic resin (B) and 45 parts by weight or less of a softening agent (C) [the total amount of the components (A), (B) and (C) being 100 parts by weight] to dynamic heat treatment in the presence of a crossliking agent and which has a gloss value of 80% or more and a haze value of 10% or less on glass plate when subjected to the fogging test at a condition of 100° C. and 3 hours according to the prescription of A method of DIN 75201; and a manufacturing method and use of the compositions.

Owner:MITSUI CHEM INC

Antifogging coating, manufacture method and antifogging glass thereof

ActiveCN104086093ALong-lasting and effective anti-fog effectWater resistantOrganic solventDistilled water

The invention relates to an antifogging coating, a manufacture method and antifogging glass thereof. The manufacture method comprises of the following steps:1, preprocessing the surface of a transparent material, namely, degreasing by using an organic solvent A, carrying out physical polishing, washing sequentially by tap water and distilled water, and drying; 2, mixing 5-10 parts by mass of maleic anhydride-grafted polyethylene, 10-40 parts by mass of inorganic nanometer material processed by a silane coupling agent and 1-5 parts by mass of catalyst into an organic reagent B, coating the surface of the transparent material processed in the step 1, and carrying out thermal processing on the transparent material in vacuum; and 3, dissolving 8-10 parts by mass of high-molecular polymer with hydrophilic functional groups and 2-6 parts by mass of surfactant into water, mixing uniformly, then coating the surface of the transparent material treated in the step 2, and carrying out thermal processing in vacuum so as to obtain the long-acting antifogging coating on the surface of the transparent material.

Owner:CHERY AUTOMOBILE CO LTD

Anti-fogging article and method for producing same

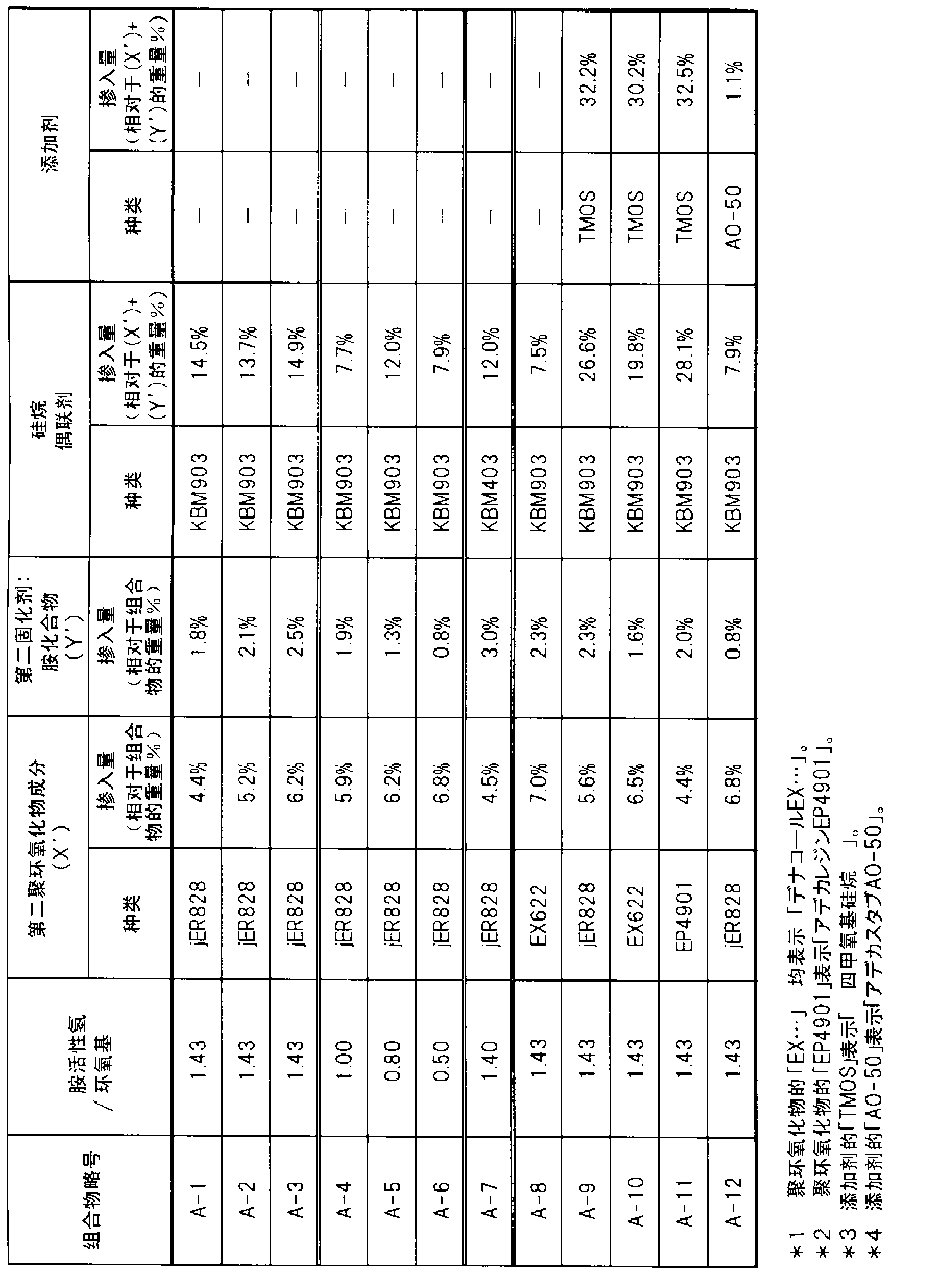

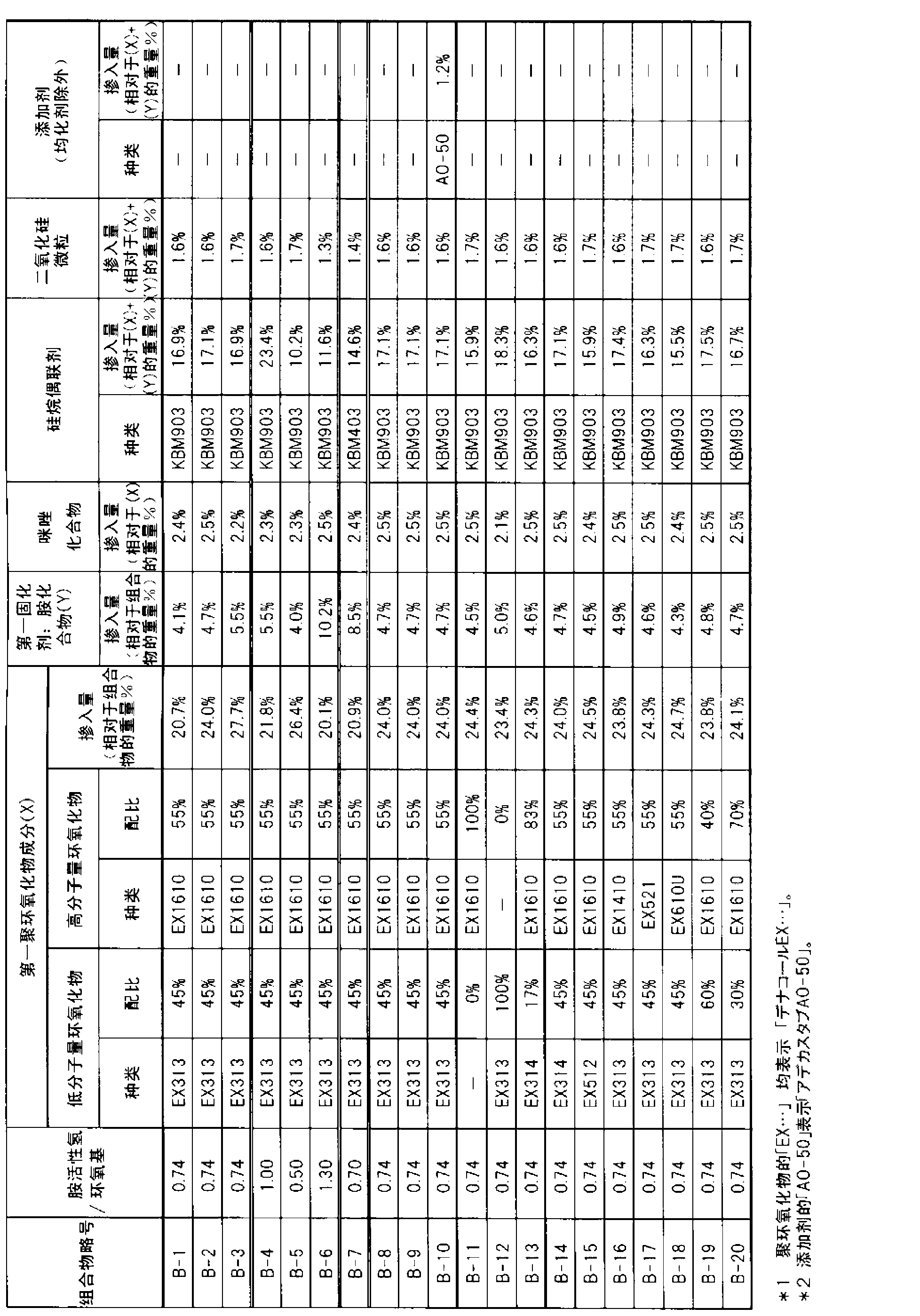

InactiveCN103228447AGood anti-fog performanceImprove wear resistanceOther chemical processesSynthetic resin layered productsEpoxySubstrate surface

An anti-fogging article having a substrate and an anti-fogging film on at least part of the surface of the substrate, wherein the anti-fogging film comprises a resin underlayer and a water-absorptive resin layer laminated in order on the substrate surface, the water-absorptive resin layer is composed mainly of a first cured epoxy resin obtained by reacting a water-absorptive resin layer-forming composition containing a first polyepoxide component consisting of a low molecular weight polyepoxide having molecular weight of from 200 to 800 and a high molecular weight polyepoxide having molecular weight of from 900 to 2,000 combined in mass ratio of from 30:70 to 70:30, and a first curing agent, and the resin underlayer is composed mainly of a second cured epoxy resin obtained by reacting a resin underlayer-forming composition containing a second polyepoxide component and a second curing agent, and has water absorption property lower than the water-absorptive resin layer.

Owner:ASAHI GLASS CO LTD

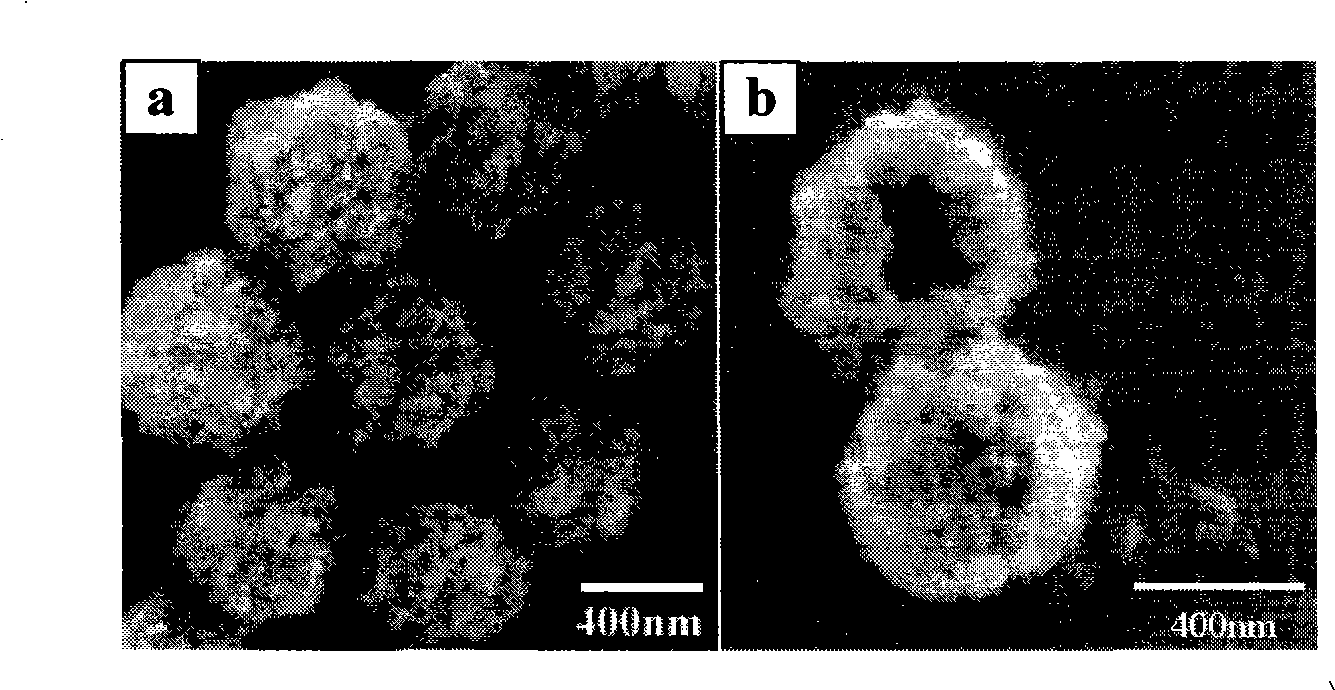

Nanometer calcium silicate hydrate super-hydrophilicity thin film as well as preparation method and applications of thin film

The invention discloses a nanometer calcium silicate hydrate super-hydrophilicity thin film as well as a preparation method and applications of the thin film and belongs to the field of functional composite materials. The preparation method comprises the steps of: soaking a pretreated base film with negative electric charges on surface in a 1.0-8.0g / L cationic polyelectrolyte solution containing 0.01mol / mL-0.1mol / mL soluble calcium salt for 10-30 minutes, then taking out the base film and flushing the base film with deionized water; soaking the base film in a 1.0-8.0g / L anionic polyelectrolyte solution containing 0.01mol / mL-0.1mol / mL soluble silicate for 10-30 minutes, then taking out the base film and completely flushing the base film with deionized water; repeating above operations for 1-3 times to obtain the polyelectrolyte nanometer calcium silicate hydrate super-hydrophilicity thin film. The super-hydrophilicity thin film has a super-hydrophilicity property and an excellent anti-fog property.

Owner:BEIJING UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com