Nano antifogging paint composition and preparation method thereof

An anti-fog coating and composition technology, applied in the direction of coating, etc., can solve the problems of expensive instruments and equipment, complex technological process, etc., and achieve the effects of convenient use, good anti-fog effect, and recovery of anti-fog effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

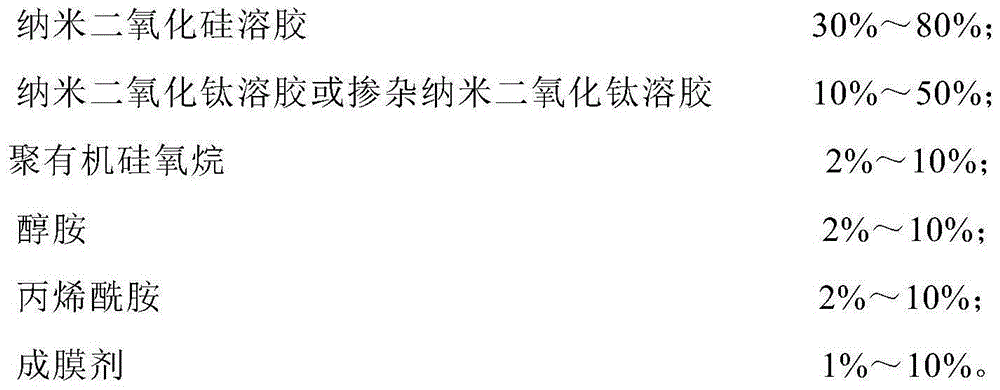

Method used

Image

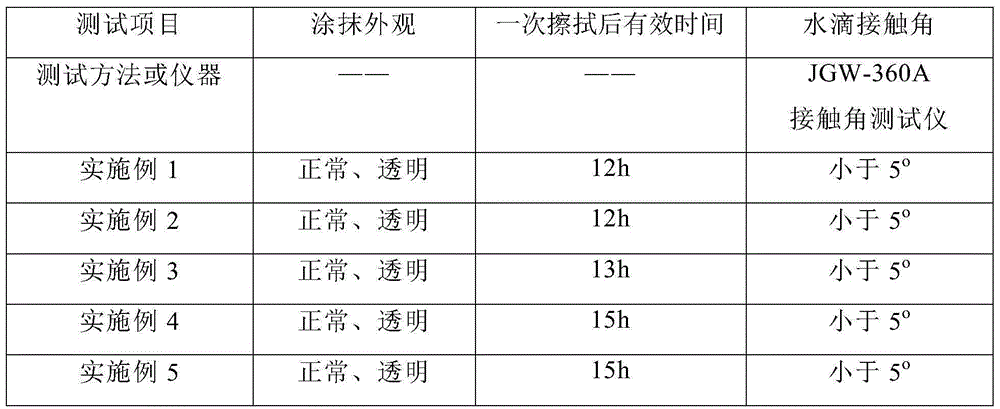

Examples

Embodiment 1

[0030] The preparation method of the nano anti-fog coating of the present embodiment comprises the steps:

[0031] One, prepare nano-silica sol and nano-titanium dioxide sol respectively, wherein, the preparation method of nano-silica sol is: according to weight percentage proportioning following raw material, sodium dodecylbenzene sulfonate 1%, ethyl orthosilicate 1%, 0.1% deionized water, 0.1% polyvinylpyrrolidone, 0.01% hydrochloric acid and 97.79% dehydrated alcohol, mixed and stirred for 2 hours at 80 ° C; wherein, the preparation method of nano-silica sol is: according to weight percentage Compared with the following raw materials, 1% sodium dodecylbenzenesulfonate, 1% butyl titanate, 0.1% deionized water, 0.1% polyvinylpyrrolidone, 0.01% hydrochloric acid and 97.79% absolute ethanol, mixed and stirred at 80°C 2 hours.

[0032] 2. Mix 50wt% nano-silica sol and 43wt% nano-titanium dioxide sol and add 2wt% polyorganosiloxane, 2wt% n-propanolamine, and 2wt% N-dimethylamino...

Embodiment 2

[0034] The preparation method of the nano anti-fog coating of the present embodiment comprises the steps:

[0035] One, prepare nano-silica sol and nano-titanium dioxide sol respectively, wherein, the preparation method of nano-silica sol is: according to weight percentage proportioning following raw material, sodium dodecylbenzenesulfonate 5%, ethyl orthosilicate 10%, deionized water 5%, polyvinylpyrrolidone 5%, hydrochloric acid 1% and dehydrated alcohol 74%, mixed and stirred for 4 hours at 80 ℃; Wherein, the preparation method of nano-silica sol is: according to weight percentage Compared with the following raw materials, sodium dodecylbenzenesulfonate 5%, butyl titanate 10%, deionized water 5%, polyvinylpyrrolidone 5%, hydrochloric acid 1% and absolute ethanol 74%, mixed and stirred at 80 ° C 4 hours.

[0036] 2. Mix 50wt% nano-silica sol and 10wt% nano-titanium dioxide sol and add 10wt% polyorganosiloxane, 10wt% diethanolamine, 10wt% N-dimethylaminoethylacrylamide, 10w...

Embodiment 3

[0038] The preparation method of the nano anti-fog coating of the present embodiment comprises the steps:

[0039] One, prepare nano-silica sol and nano-titanium dioxide sol respectively, wherein, the preparation method of nano-silica sol is: according to weight percentage ratio following raw material, sodium dodecylbenzene sulfonate 3%, ethyl orthosilicate 6%, deionized water 3%, polyvinylpyrrolidone 3%, hydrochloric acid 0.4% and absolute ethanol 84.6%, mixed and stirred at 80°C for 6 hours; wherein, the preparation method of nano-titanium dioxide sol is as follows: Raw materials, sodium dodecylbenzenesulfonate 3%, butyl titanate 6%, deionized water 3%, polyvinylpyrrolidone 3%, hydrochloric acid 0.4% and absolute ethanol 84.6%, mixed and stirred at 80°C for 6 hours .

[0040] 2. Mix 50wt% nano-silica sol and 22wt% nano-titanium dioxide sol and add 7wt% polyorganosiloxane, 7wt% isopropanolamine, 7wt% N, N-diethylpropylene at 80°C The amide and 7wt% propylene glycol ether we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com