Anti-fog polyolefin graft copolymer and preparation method thereof

A technology of polyolefin grafts and grafts, which is applied in the field of polyolefin grafts and their preparation, can solve the problems of poor compatibility between anti-fog agents and polyolefins, and the decline in anti-fog effects, and achieve long-term anti-fog Fog effect, not easy to lose effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

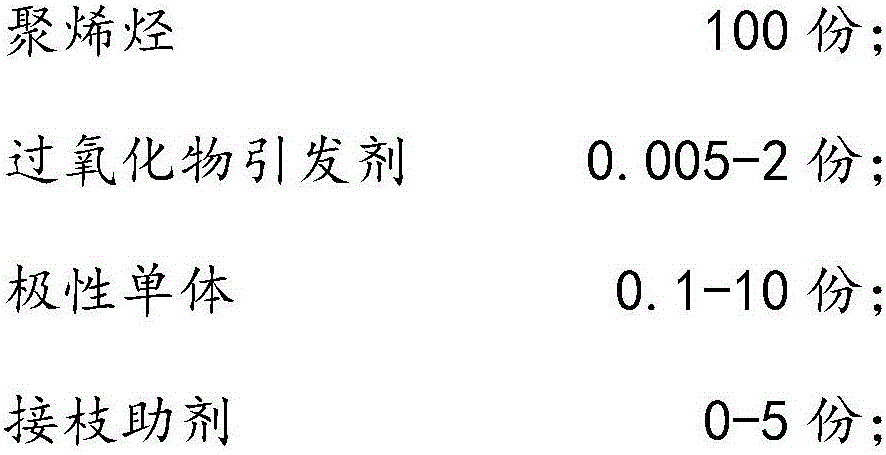

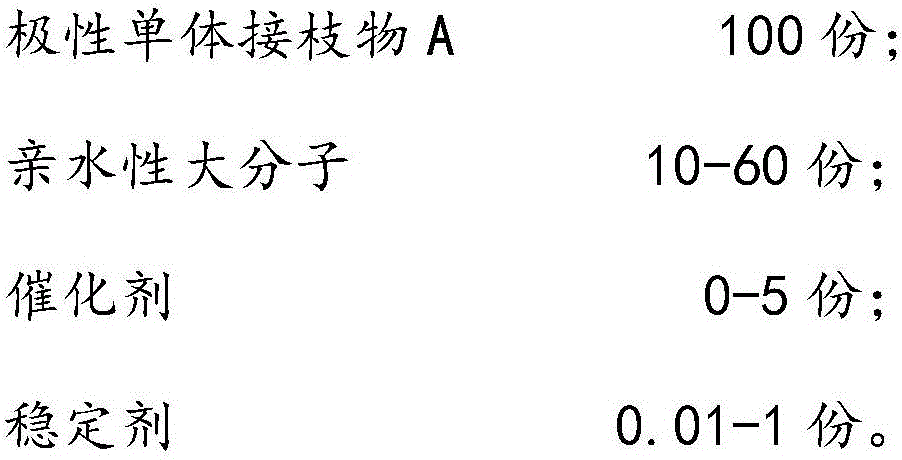

[0030] A kind of preparation method of anti-fog polyolefin graft, it is prepared by two-step grafting method, specifically comprises the following steps:

[0031] Grafting step 1: 100 parts of linear low density polyethylene (density 0.92g / cm 3 ; Melt index 1g / 10min (190°C, 2.16kg)), 0.05 parts of 2,5-dimethyl-2,5-bis(tert-butyl peroxy)hexane and 1 part of maleic anhydride were added to the mixer, Stirring speed 1000r / min, mixing 5min. Put the uniformly mixed materials into a φ65 twin-screw extruder with a screw length-to-diameter ratio of 36:1, a grafting temperature of 180°C, and a screw speed of 300 rpm. Extrude and granulate to obtain polar monomer graft A.

[0032] Grafting step 2: Add 100 parts of polar monomer graft A, 30 parts of polyethylene glycol (molecular weight 20,000) and 0.1 part of antioxidant B215 into the mixer, and mix for 5 minutes at a stirring speed of 1000 r / min. Put the uniformly mixed materials into a φ65 twin-screw extruder with a screw length-to-...

Embodiment 2

[0034] A kind of preparation method of anti-fog polyolefin graft, it is prepared by two-step grafting method, specifically comprises the following steps:

[0035] Grafting step 1: 100 parts of random copolymerized polypropylene (density 0.90g / cm 3; melt index 2g / 10min (230°C, 2.16kg)), 0.1 parts of 2,5-dimethyl-2,5-bis(tert-butyl peroxy)hexane, 0.1 parts of di-tert-butyl peroxide and Add 2 parts of maleic anhydride and 1 part of styrene into the mixer, stir at a speed of 1000r / min, and mix for 5 minutes. Put the uniformly mixed materials into a φ65 twin-screw extruder with a screw length-to-diameter ratio of 36:1, a grafting temperature of 200°C, and a screw speed of 200 rpm. Extrude and granulate to obtain polar monomer graft A.

[0036] Grafting step 2: 100 parts of polar monomer graft A, 20 parts of polyethylene glycol (molecular weight 30000), 0.05 part of antioxidant 1010, 0.05 part of antioxidant 168 and 0.01 part of 2-(2-hydroxy Add -3,5-di-tert-butylphenyl)-5-chloro...

Embodiment 3

[0038] A kind of preparation method of anti-fog polyolefin graft, it is prepared by two-step grafting method, specifically comprises the following steps:

[0039] Grafting step 1: 100 parts of impact copolymerized polypropylene (density 0.91g / cm3; melt index 1.8g / 10min (230°C, 2.16kg)), 1.5 parts of 2,5-dimethyl-2,5-di Add (tert-butyl peroxy)hexane, 5 parts of maleic acid, 5 parts of maleic anhydride and 0.5 part of triallyl isocyanurate into the mixer, stir at a speed of 1000 r / min, and mix for 5 minutes. Put the uniformly mixed materials into a φ65 twin-screw extruder with a screw length-to-diameter ratio of 32:1, a grafting temperature of 190°C, and a screw speed of 200 rpm. Extrude and granulate to obtain polar monomer graft A.

[0040] Grafting step 2: 100 parts of polar monomer graft A, 30 parts of polyvinyl alcohol (molecular weight 10000), 1 part of 4-dimethylaminopyridine, 0.5 part of antioxidant B215 and 0.5 part of 2-hydroxy-4 - Add n-octyloxybenzophenone into the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com