Anti-fogging article and method for producing same

A technology for anti-fogging and article application in the direction of chemical instruments and methods, layered products, and other chemical processes. Moisture and ionic component reach, peel resistance improvement, interfacial stress relief effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

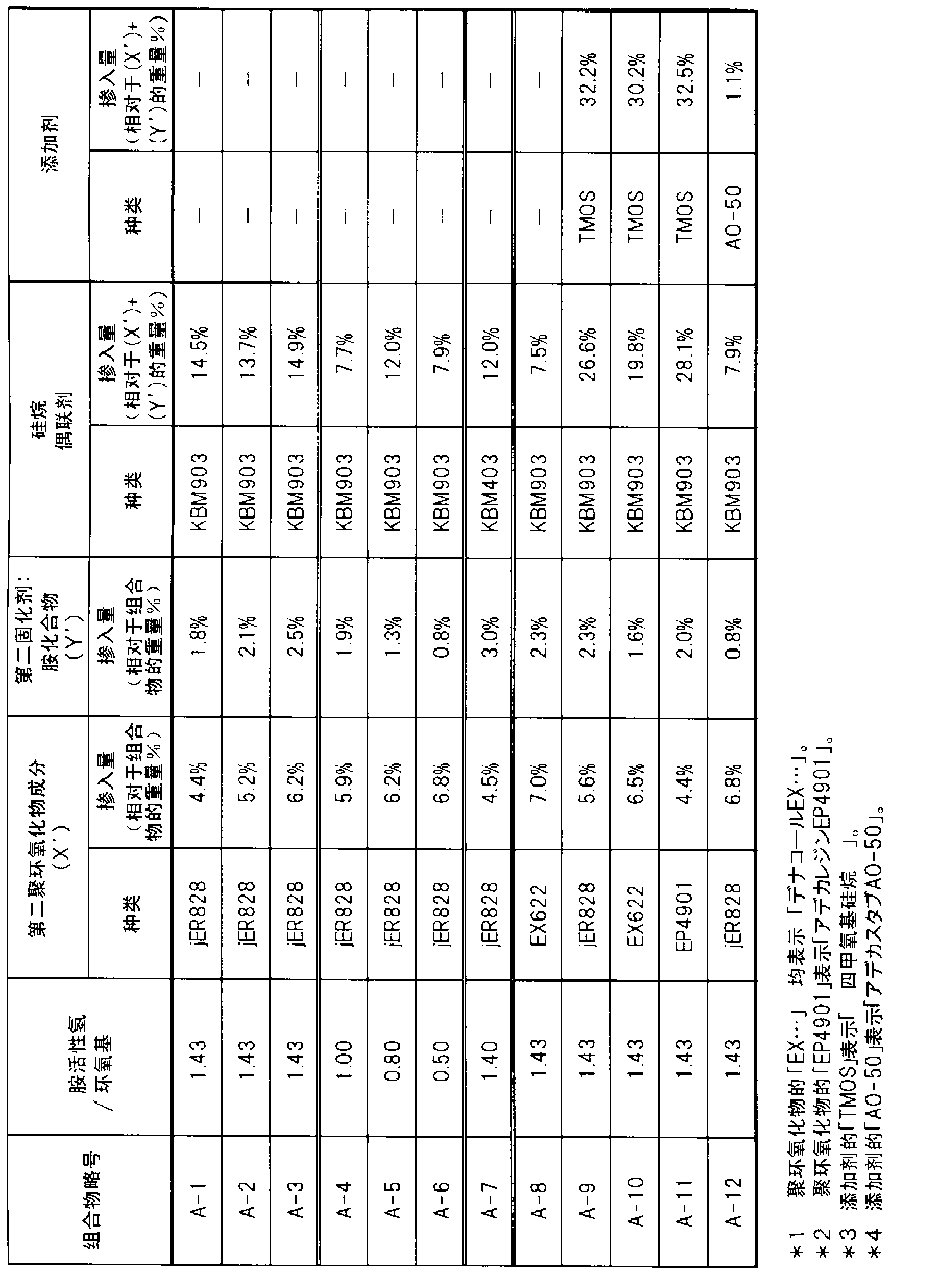

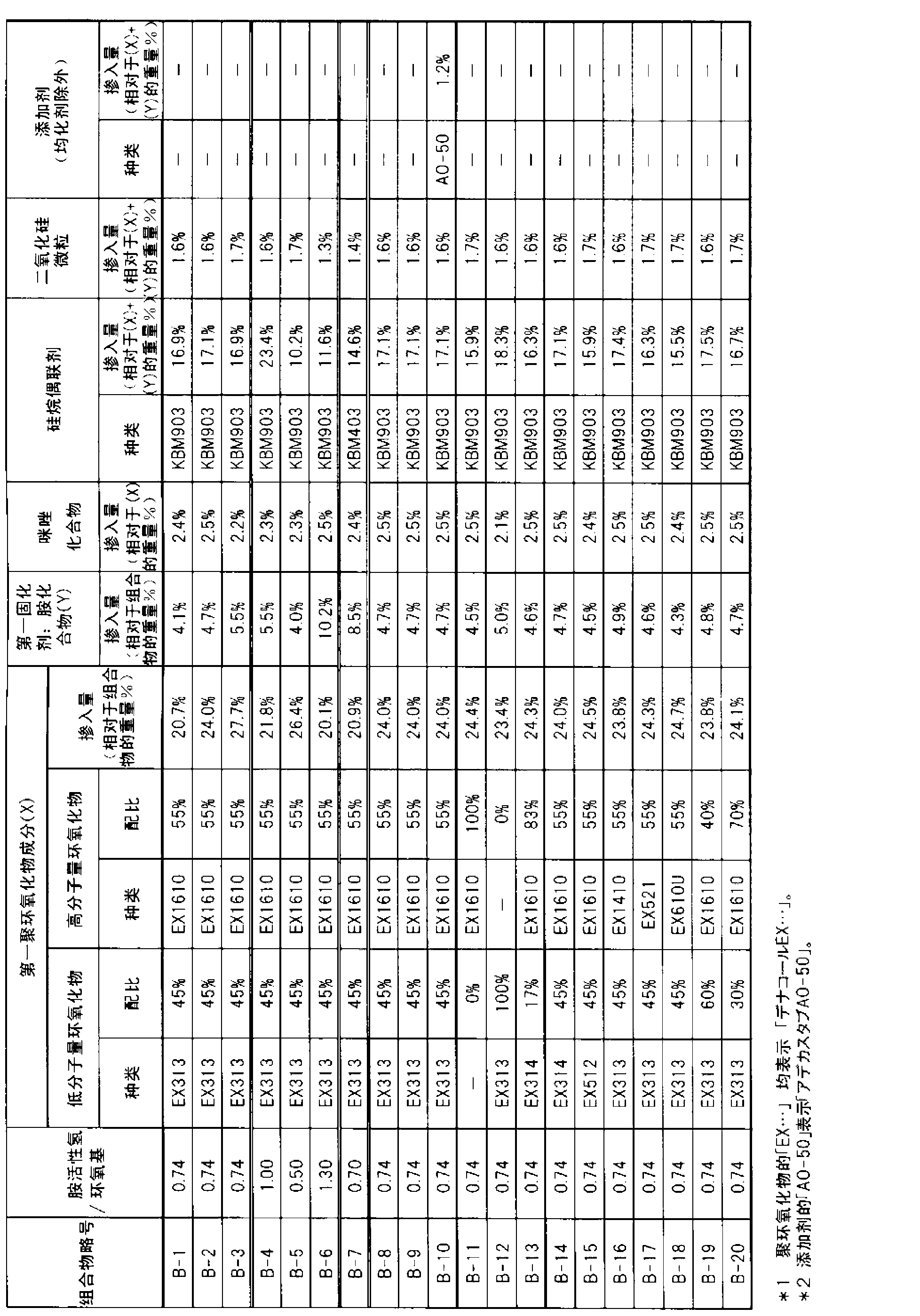

manufacture example A-1

[0269] Diacetone alcohol (8.07 g, manufactured by Junsei Chemical Co., Ltd.), bisphenol A diglycidyl ether (5.00 g, jER828, manufactured by Mitsubishi Chemical Corporation), and polyoxyalkylene triamine were placed in a glass container equipped with a stirrer and a thermometer. (2.06 g, Jefamin T403, manufactured by Huntsman Corporation) and aminosilane (1.01 g, KBM903, manufactured by Shin-Etsu Chemical Co., Ltd.), were stirred at 25° C. for 30 minutes. Next, it diluted 7 times with diacetone alcohol (made by Junsei Chemical Co., Ltd.), and obtained the composition (A-1) for base resin layer formation.

manufacture example A-2

[0271] Except that the dilution factor of diacetone alcohol was 6 times, the composition (A-2) for base resin layer formation was obtained by the method similar to manufacture example (A-1).

manufacture example A-3

[0273] The composition (A-3) for base resin layer formation was obtained by the method similar to manufacture example (A-1) except that the dilution factor of diacetone alcohol was 5 times.

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com