Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

113results about How to "High quality appearance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Functional Unit with Button Functions

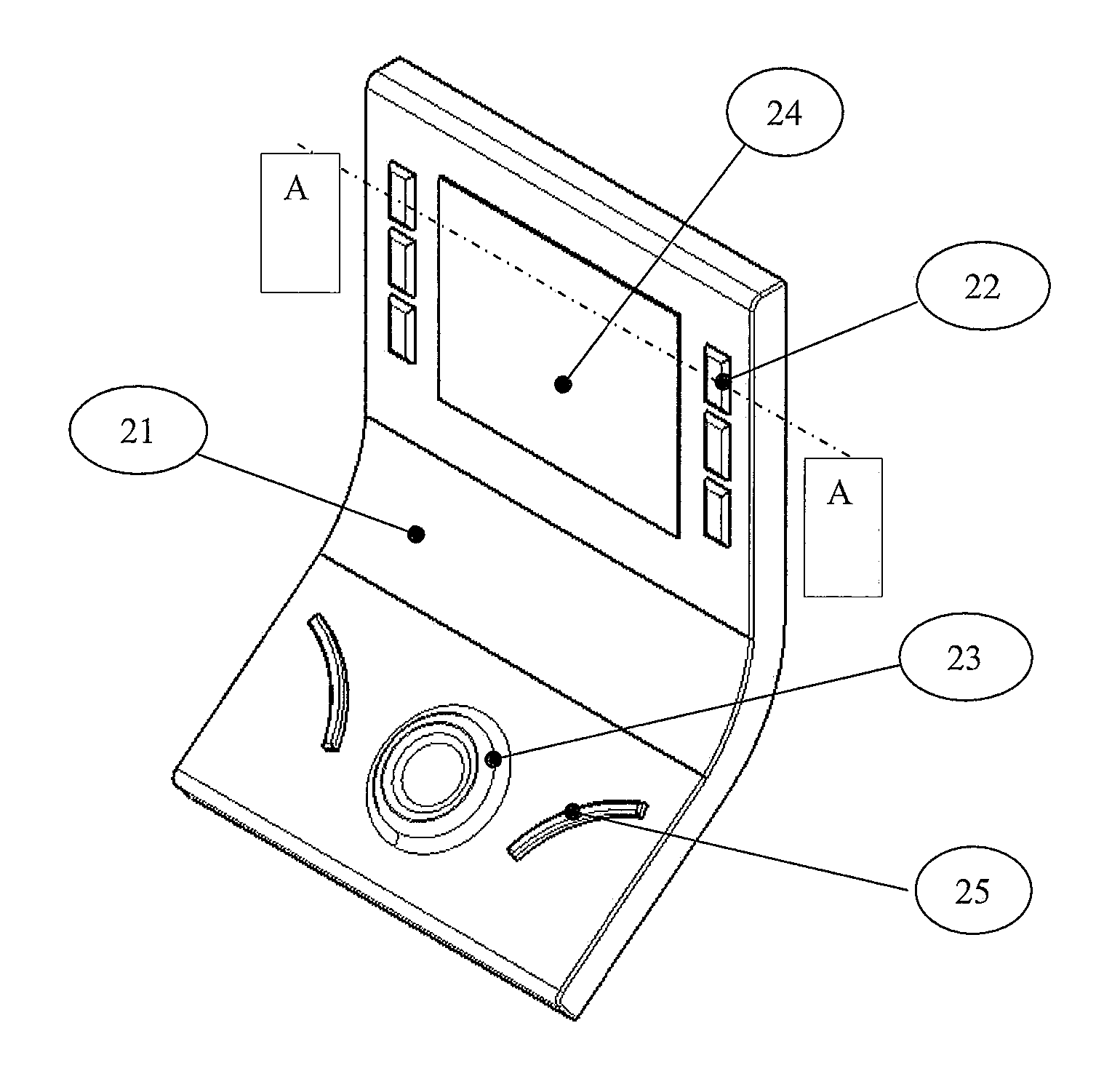

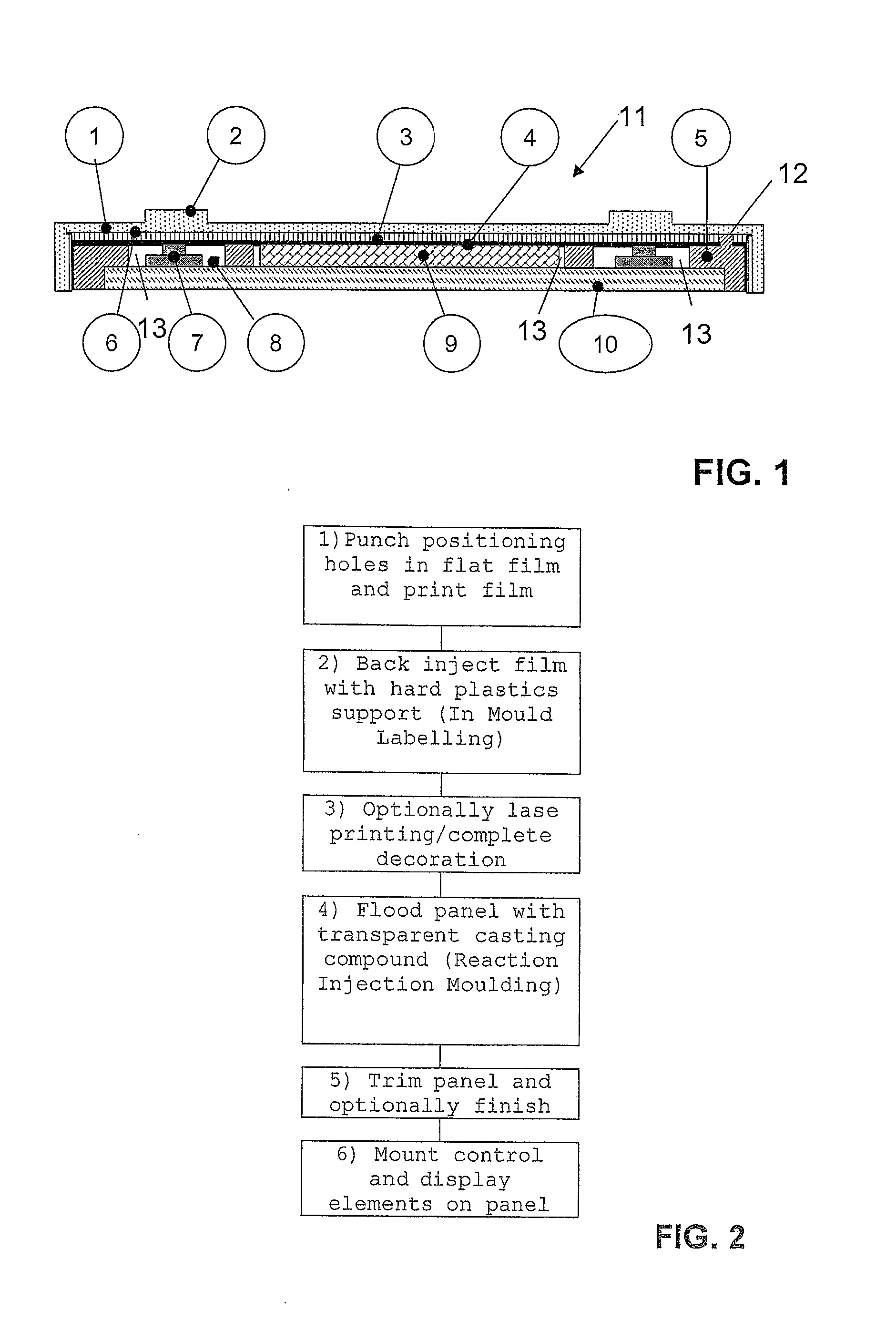

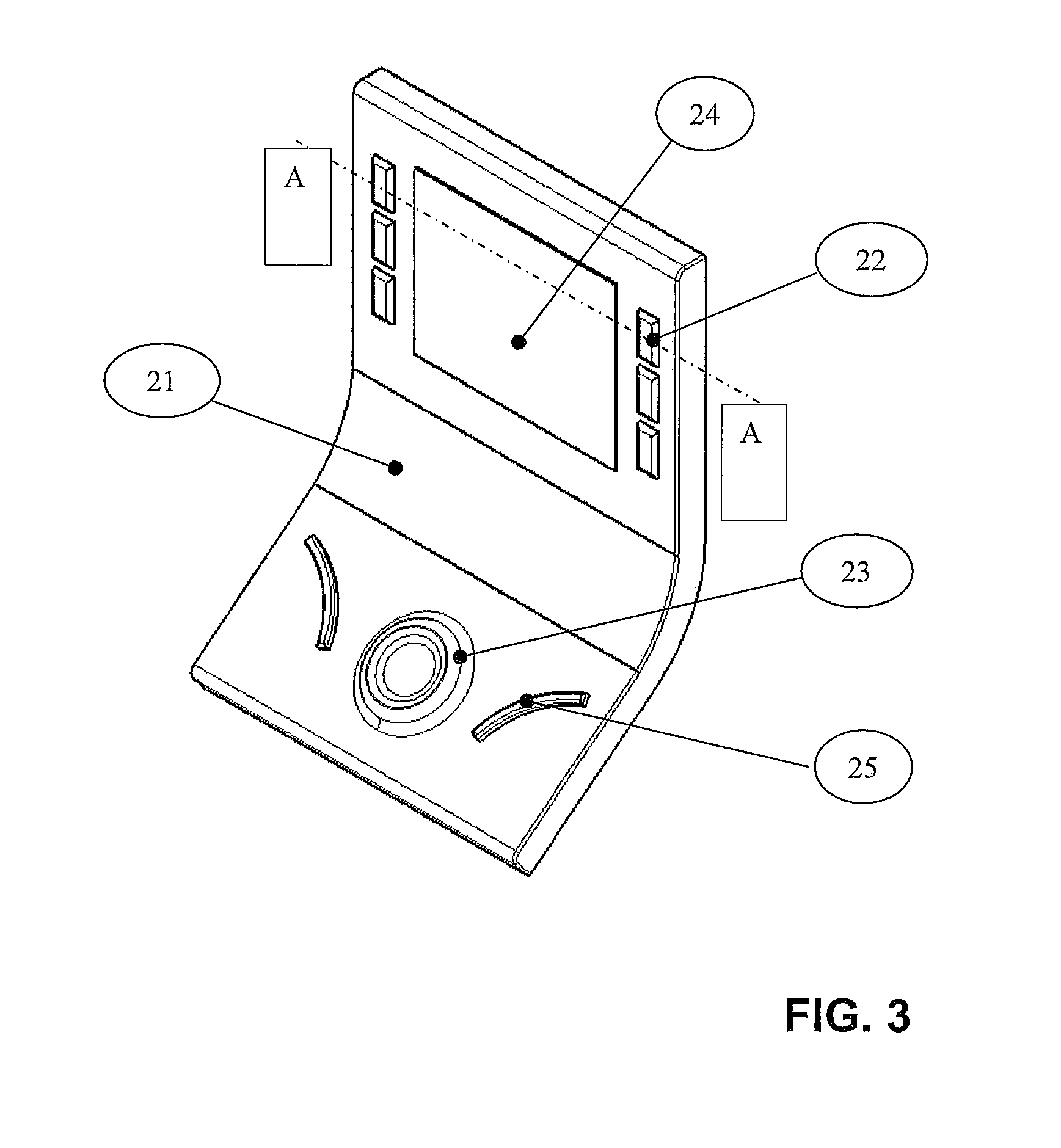

ActiveUS20120306757A1High quality appearanceInput/output for user-computer interactionDashboard fitting arrangementsSurface layerEngineering

The invention relates to a method of producing a multifunctional functional unit with a rigid support structure, in which control elements and / or display elements are arranged behind a transparent surface layer which is continuous over substantially the entire functional unit. The method includes punching a positioning hole in a transparent plastic film with a thickness in the range of 0.1-0.4 mm; positioning the film into an injection mould using the positioning hole, with a corresponding positioning means for engaging in the positioning hole; back-injecting film to form a plastics support on the first side, the injection mould being designed such that, of the plastic film is not back-injected at the control elements and / or display elements, on the second side the plastics film is flooded with a transparent curing casting compound to form a continuous transparent surface layer.

Owner:ABATEK INT

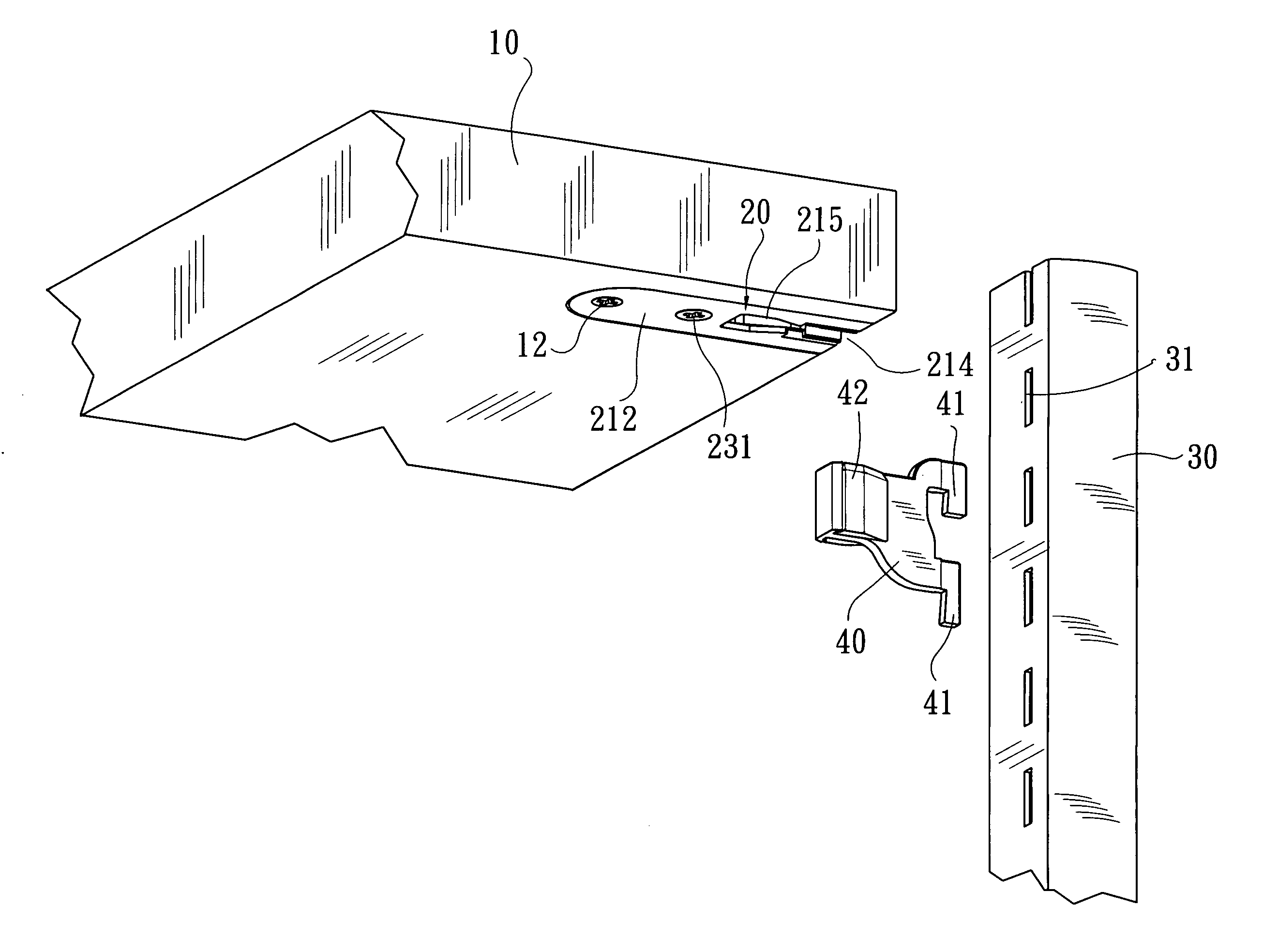

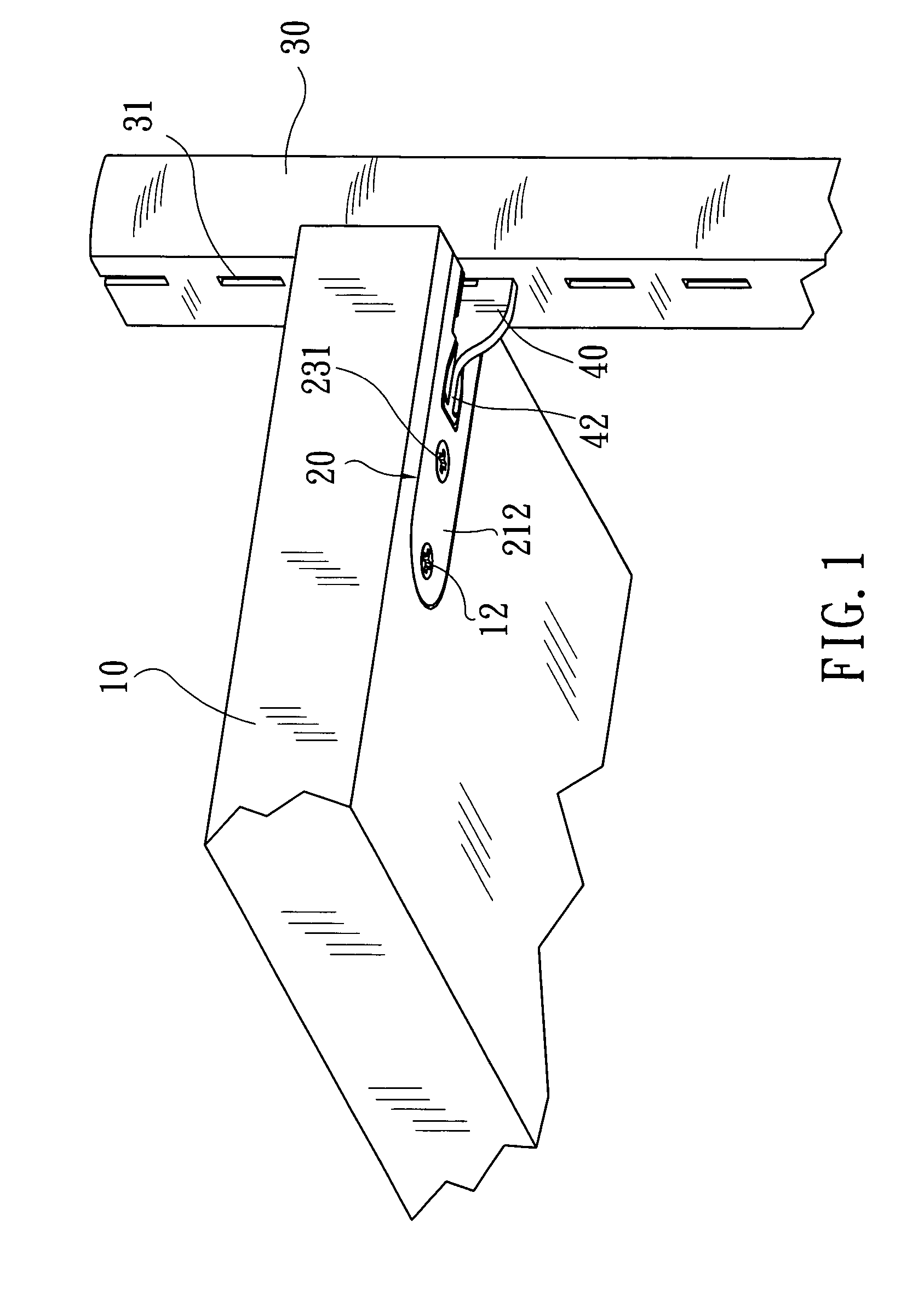

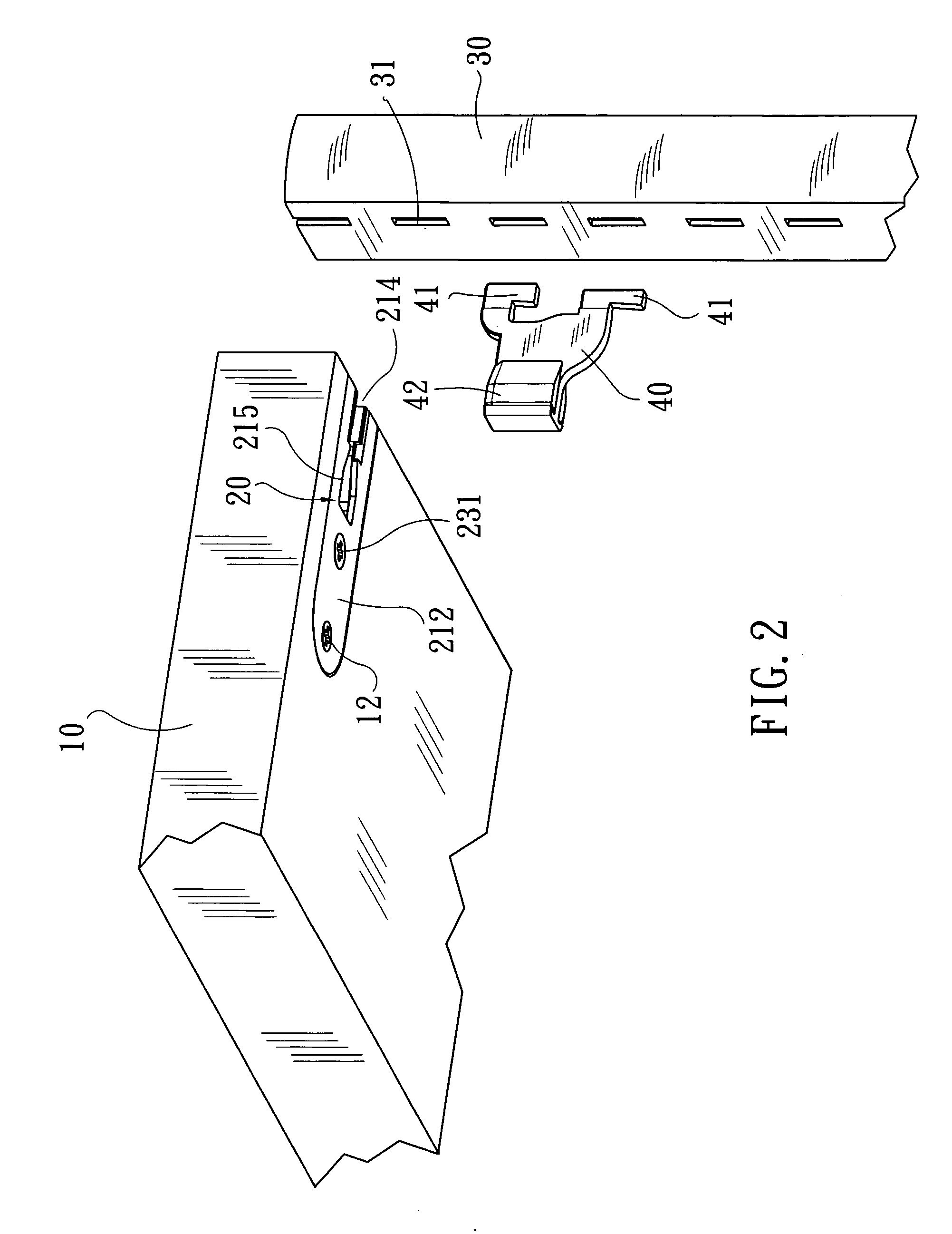

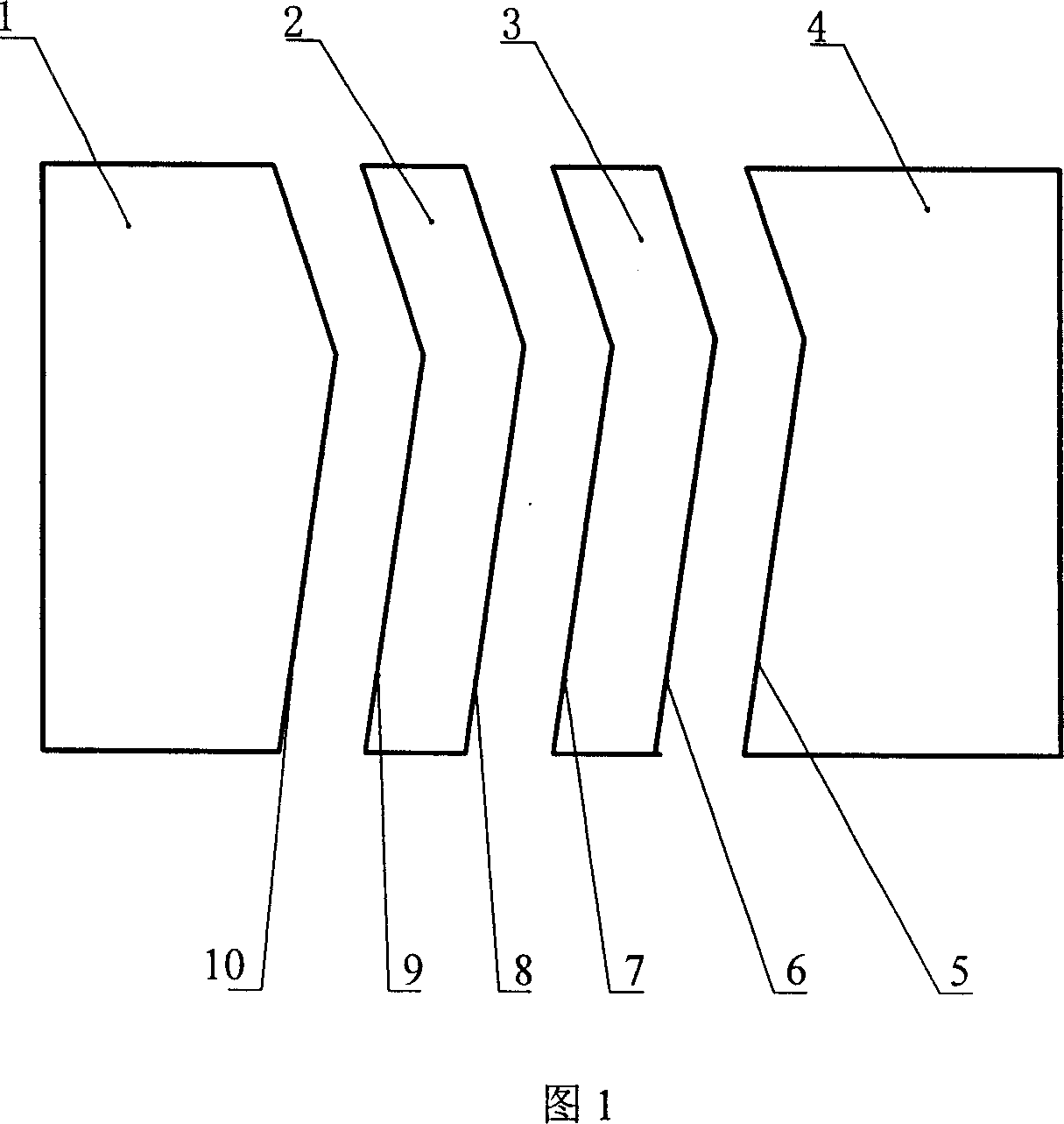

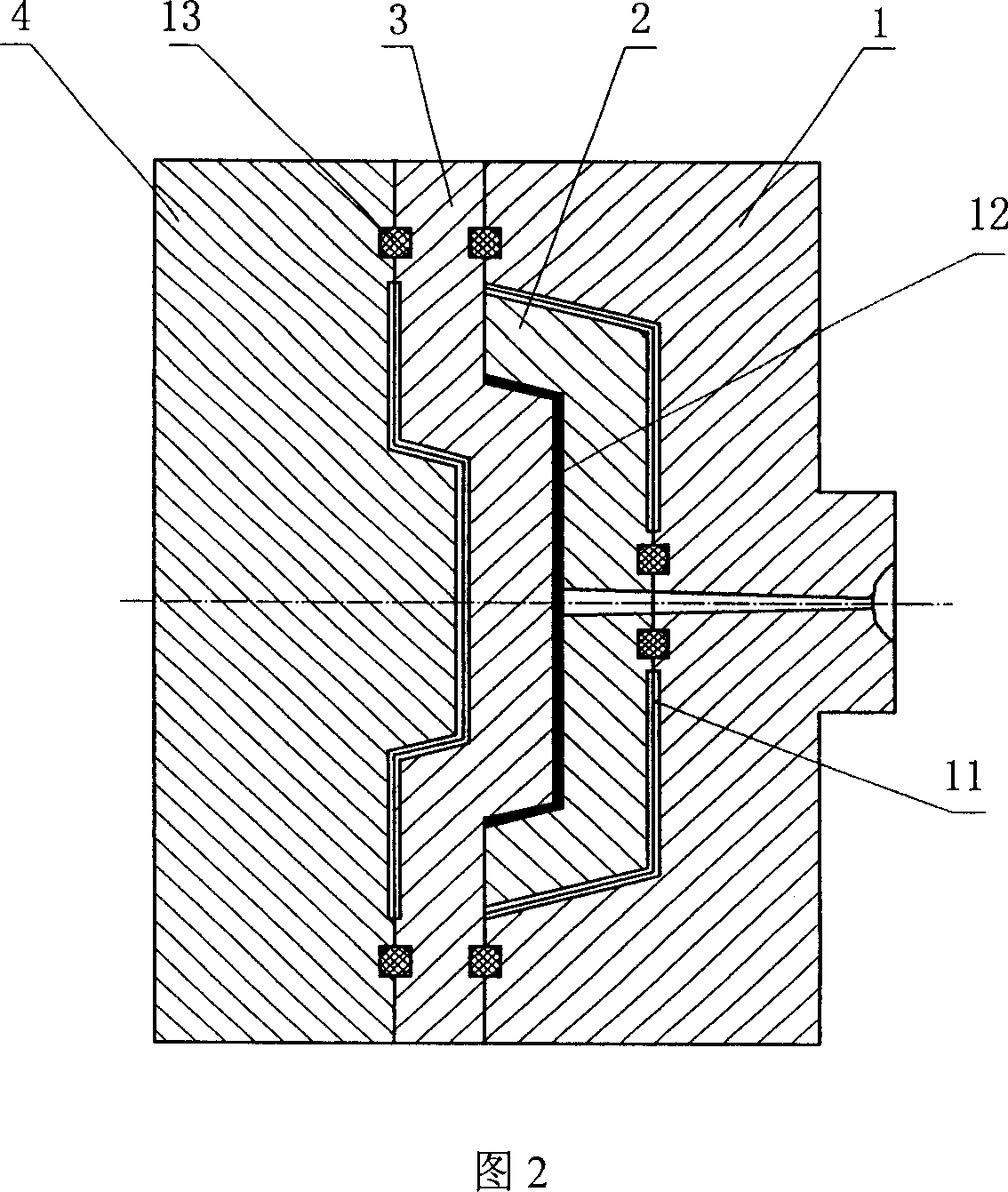

Coupling mechanism for connecting board-type shelf to vertical post of a sectional rack

InactiveUS20070110511A1High quality appearanceFacilitate convenient storage and transportRod connectionsBranching pipesEngineeringHead parts

A coupling mechanism includes a locating unit fitted in a groove preformed at each lower corner of a board-type shelf; a tightness control element located in the locating unit to couple to an engaging head of a hanger hooked to a vertical post, which engaging head is moved into the tightness control element via a window provided at a bottom of the locating unit; and an adjusting unit including a slide movably supported on two oblique guide slots on the tightness control element and an adjusting screw mounted on the locating unit to thread through the slide. When the adjusting screw is turned, the slide is moved up or down along the oblique slots to loosen or tighten the tightness control element from or against the engaging head of the hanger, enabling easy removal or connection of the shelf from or to the vertical post.

Owner:PROTREND ENTERPRISE CO LTD

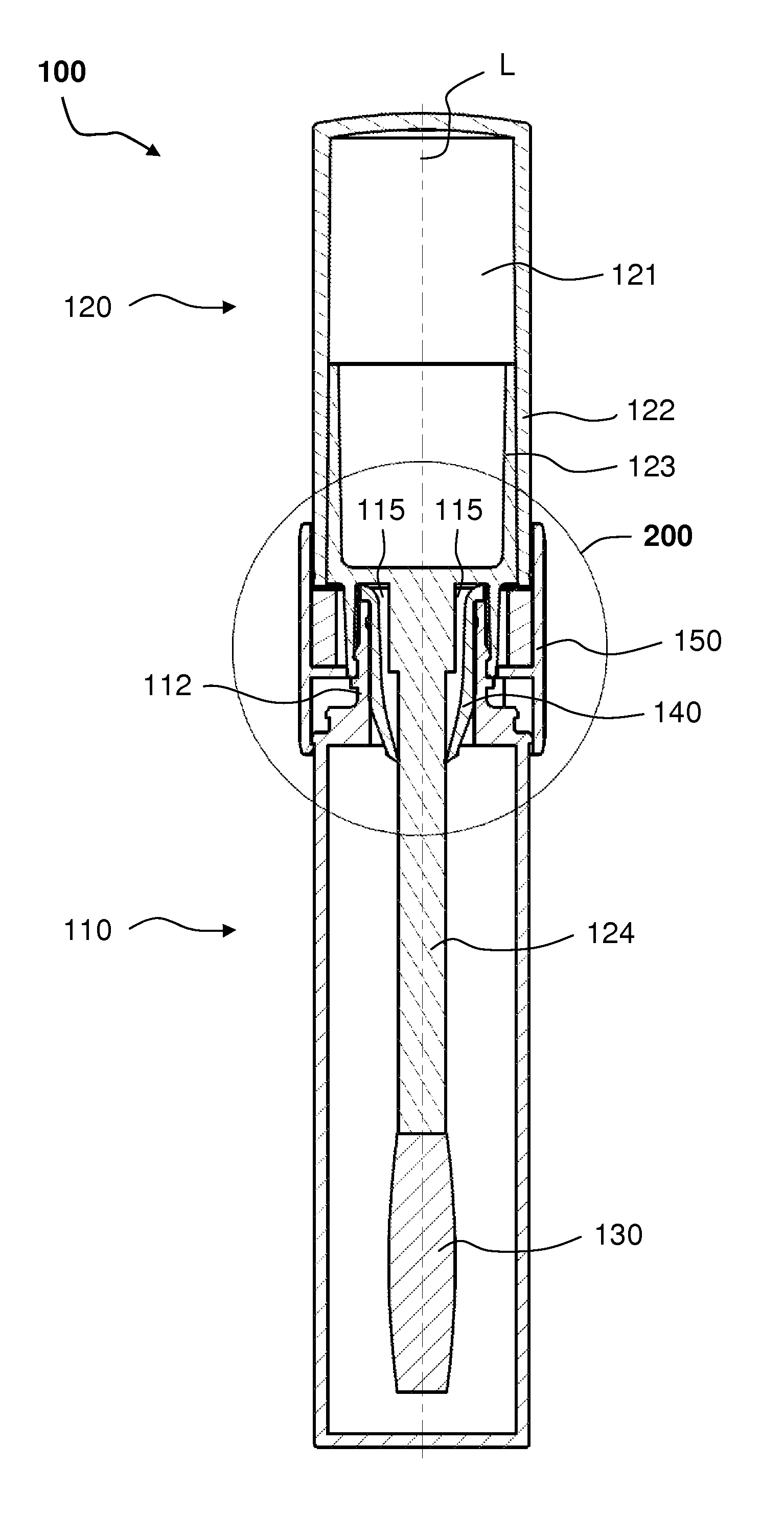

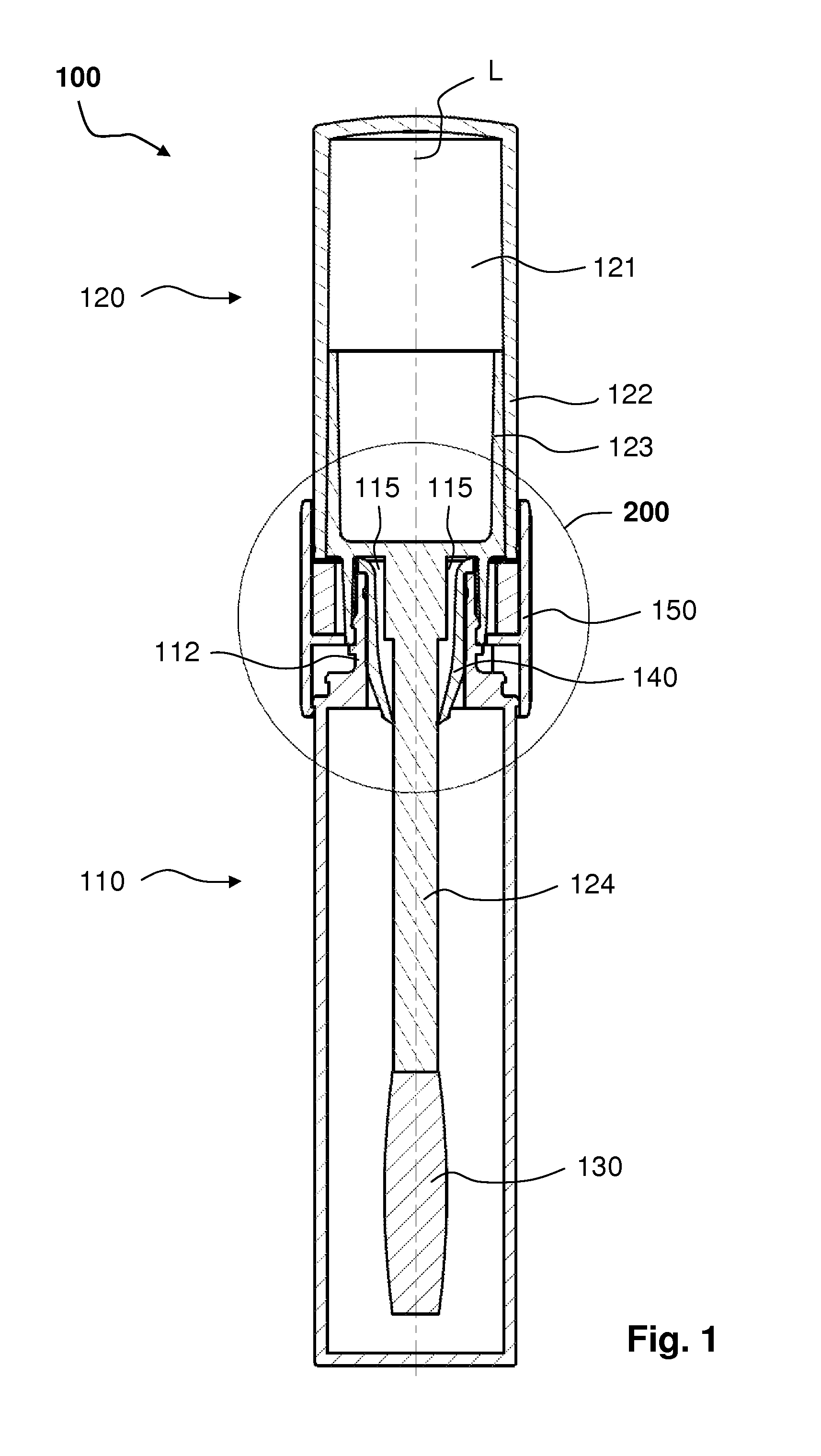

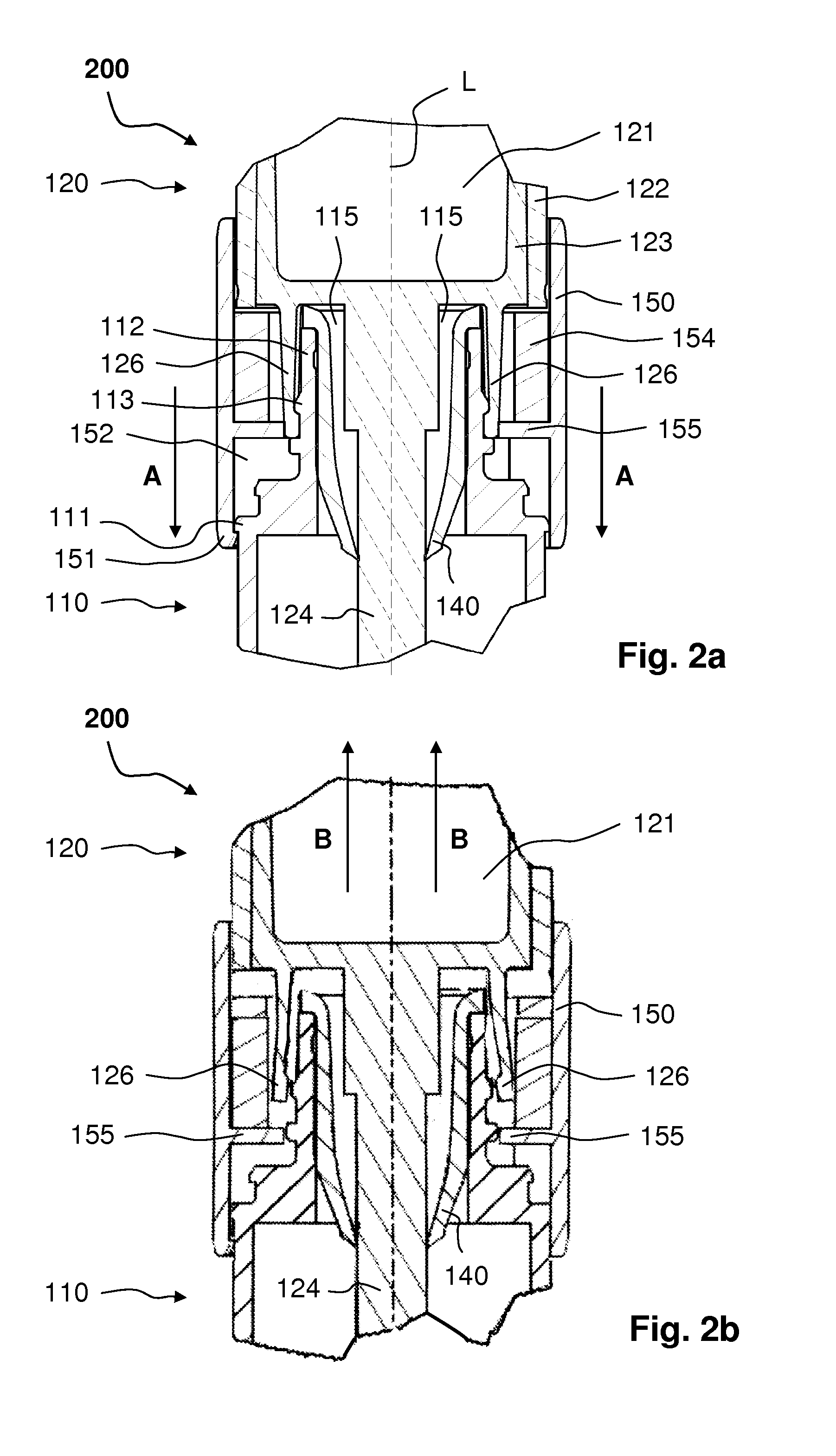

Cosmetics unit with latching closure that can be blocked

InactiveUS20120279876A1Easy to startImprove protectionBrushesOther accessoriesEngineeringMechanical engineering

The invention relates to a cosmetics container for a liquid or pasty cosmetic, comprising a storage container having a removal opening, and a closure cap for opening and closing this removal opening. The closure cap can be detachably locked in its closing position on the storage container using at least one latching device that acts between the closure cap and the storage container. The cosmetics container further comprises at least one locking device which is able to assume at least one release position and at least one blocking position, and which in the blocking position blocks the latching element in such a way that a lock existing between the closure cap and the storage container cannot be released and the closure cap thus cannot be moved out of its closing position.

Owner:GEKA

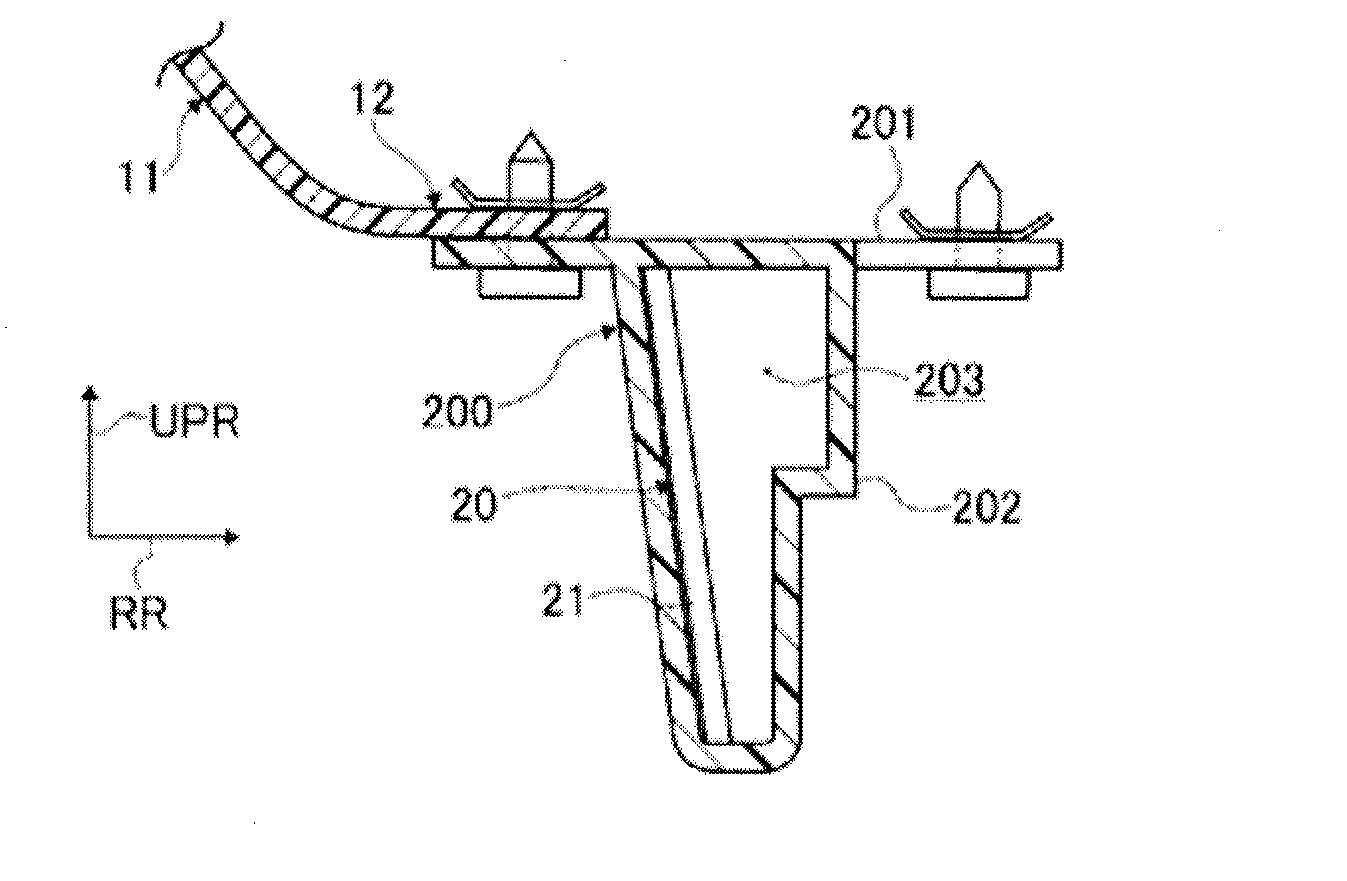

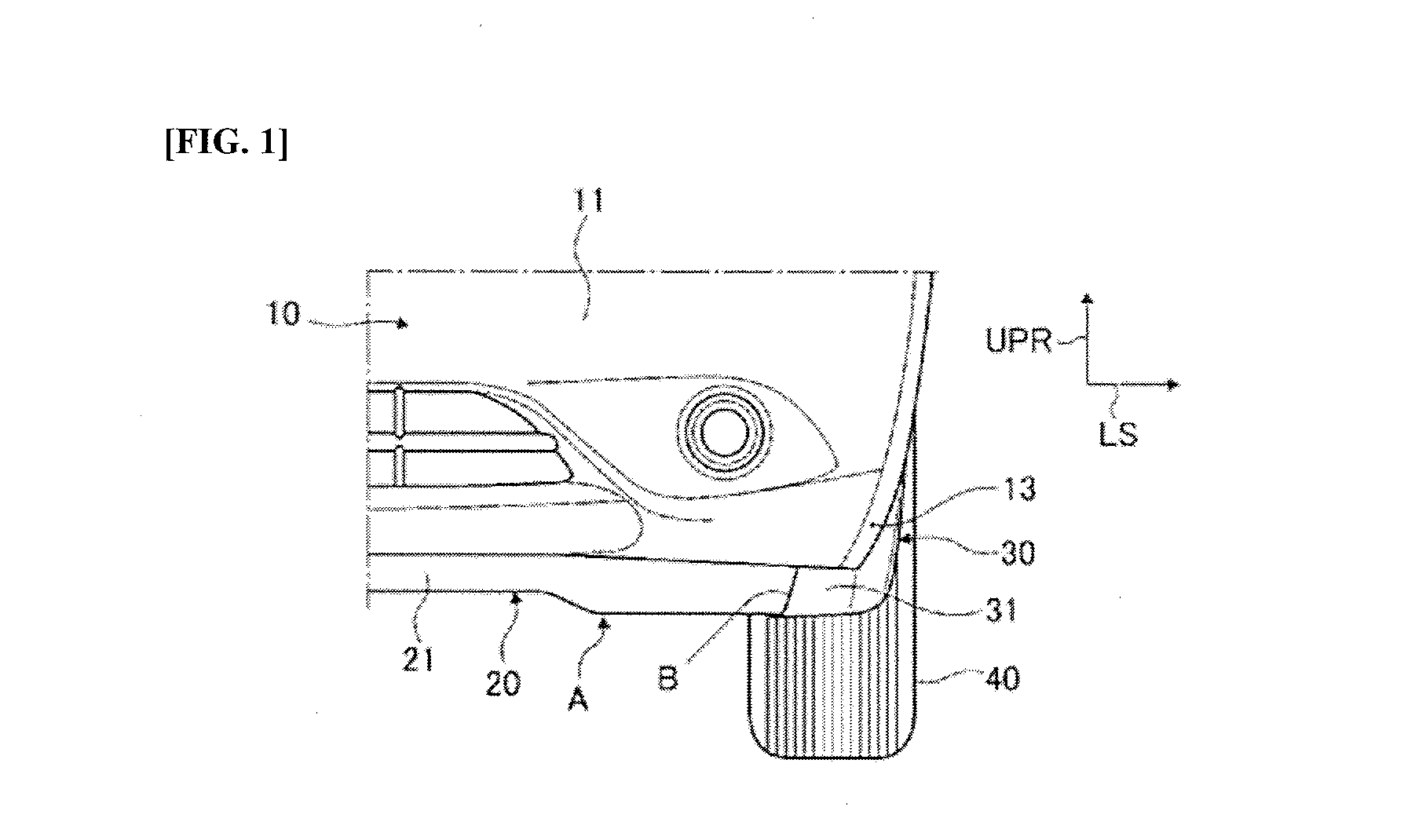

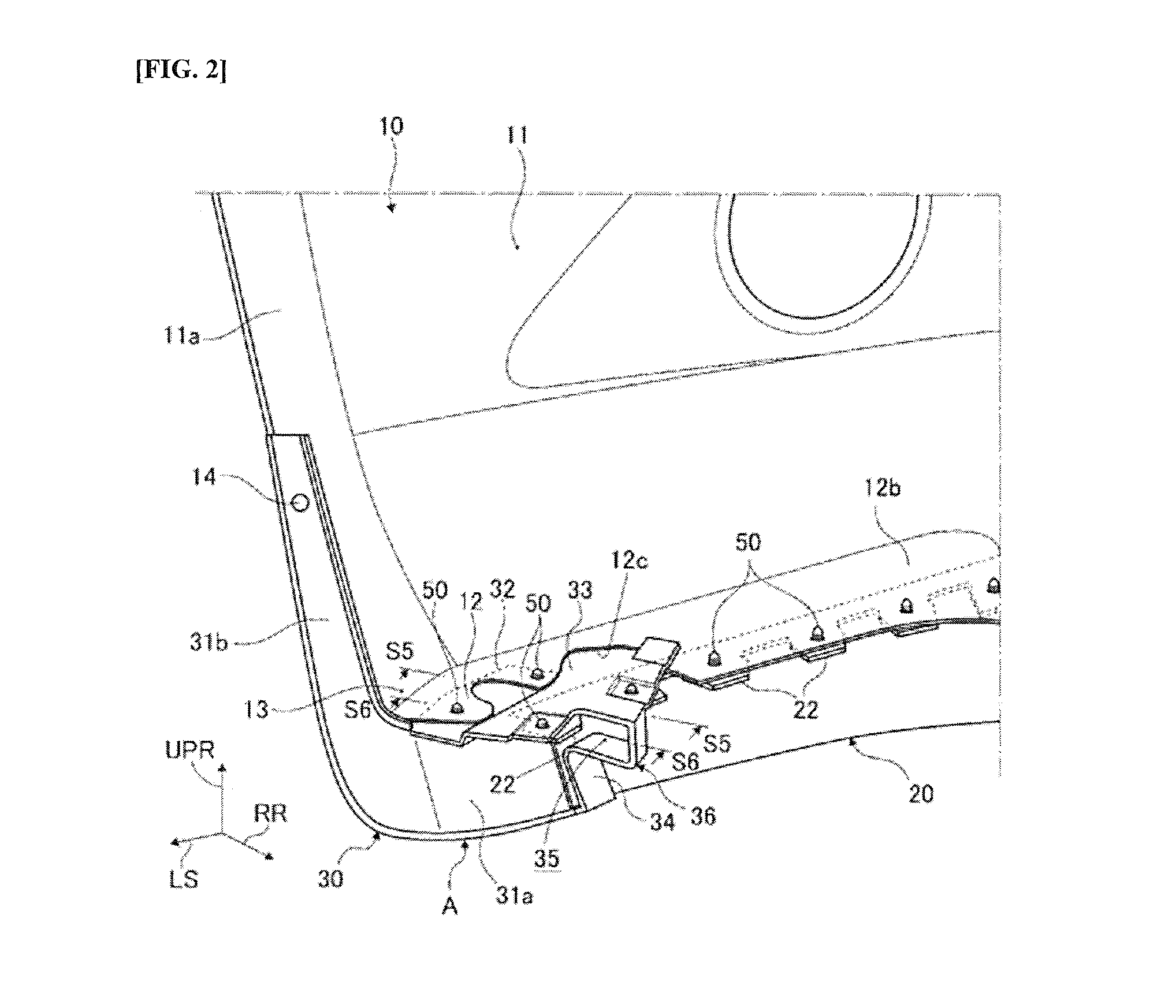

Front spoiler device

ActiveUS20150210324A1Improve aerodynamicsControl appearance qualityVehicle seatsWindowsFlangeAerospace engineering

A front spoiler device configured to be installed on a vehicle having a vehicle width direction, a vehicle upward direction, a vehicle downward direction, a vehicle forward direction, and vehicle rearward direction, has a front bumper, a bumper fascia that forms an outer surface of the front bumper, a spoiler supporting flange portion extending in the vehicle rearward direction from a lower end of the bumper fascia, a spoiler body extending along the lower end of the bumper fascia in the vehicle width direction, the spoiler body being provided with a vertical wall portion facing the vehicle forward direction, and two diffuser portions, each of which is connected to each lateral end of the spoiler body, each of which extends in the vehicle downward direction and in the vehicle width direction along a corner portion of each lateral end on the lower end of the bumper fascia.

Owner:NISSAN MOTOR CO LTD

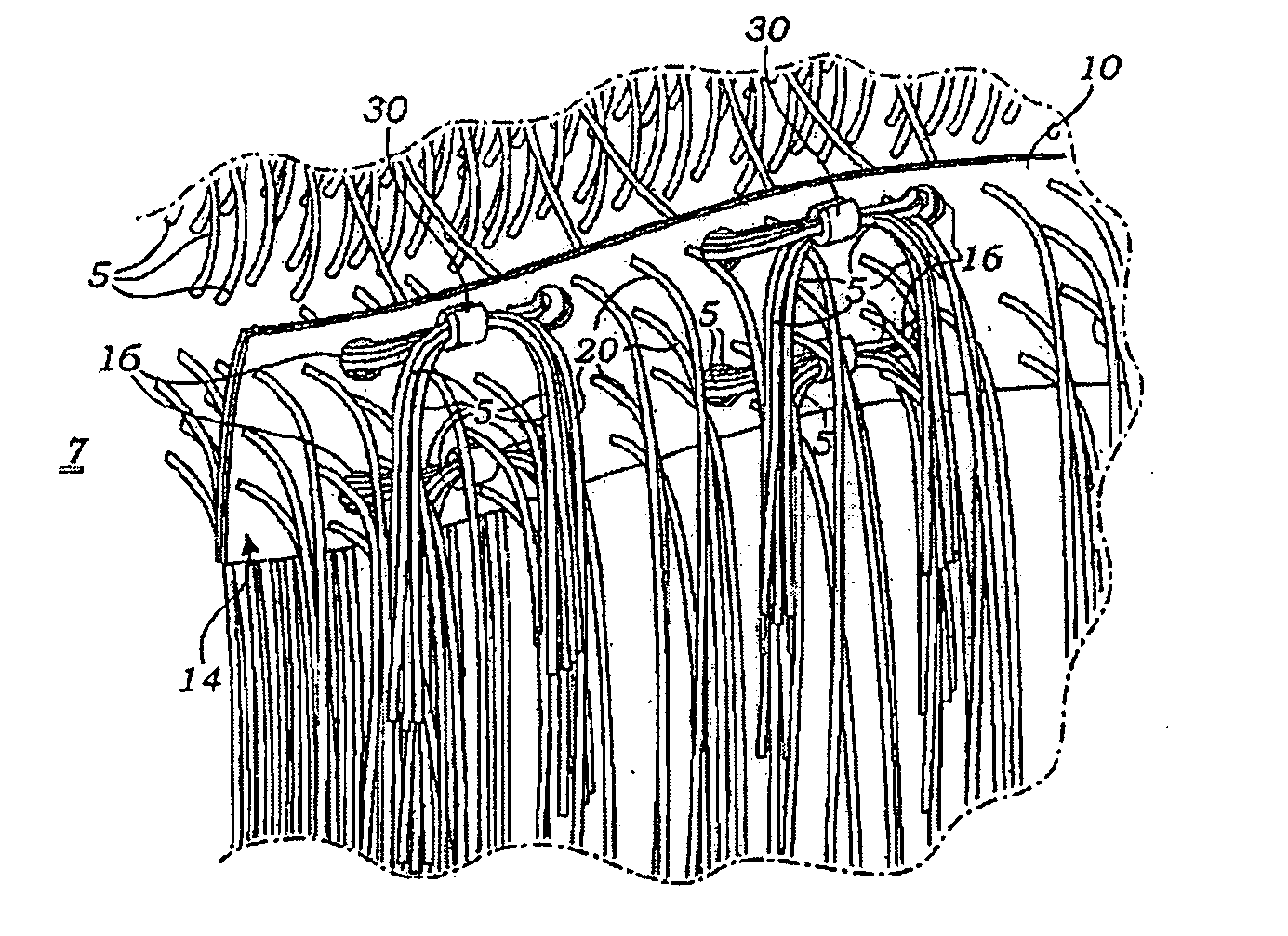

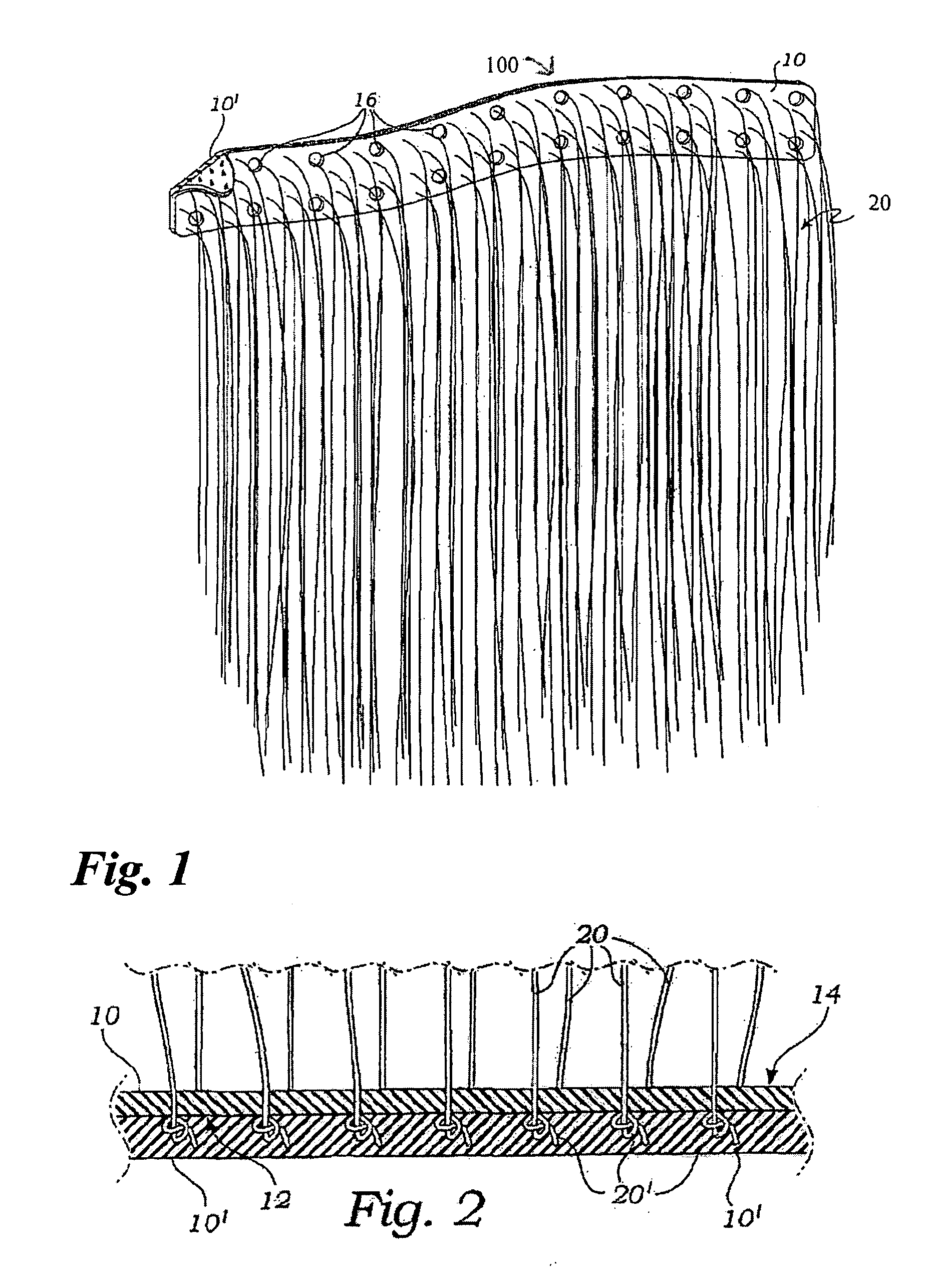

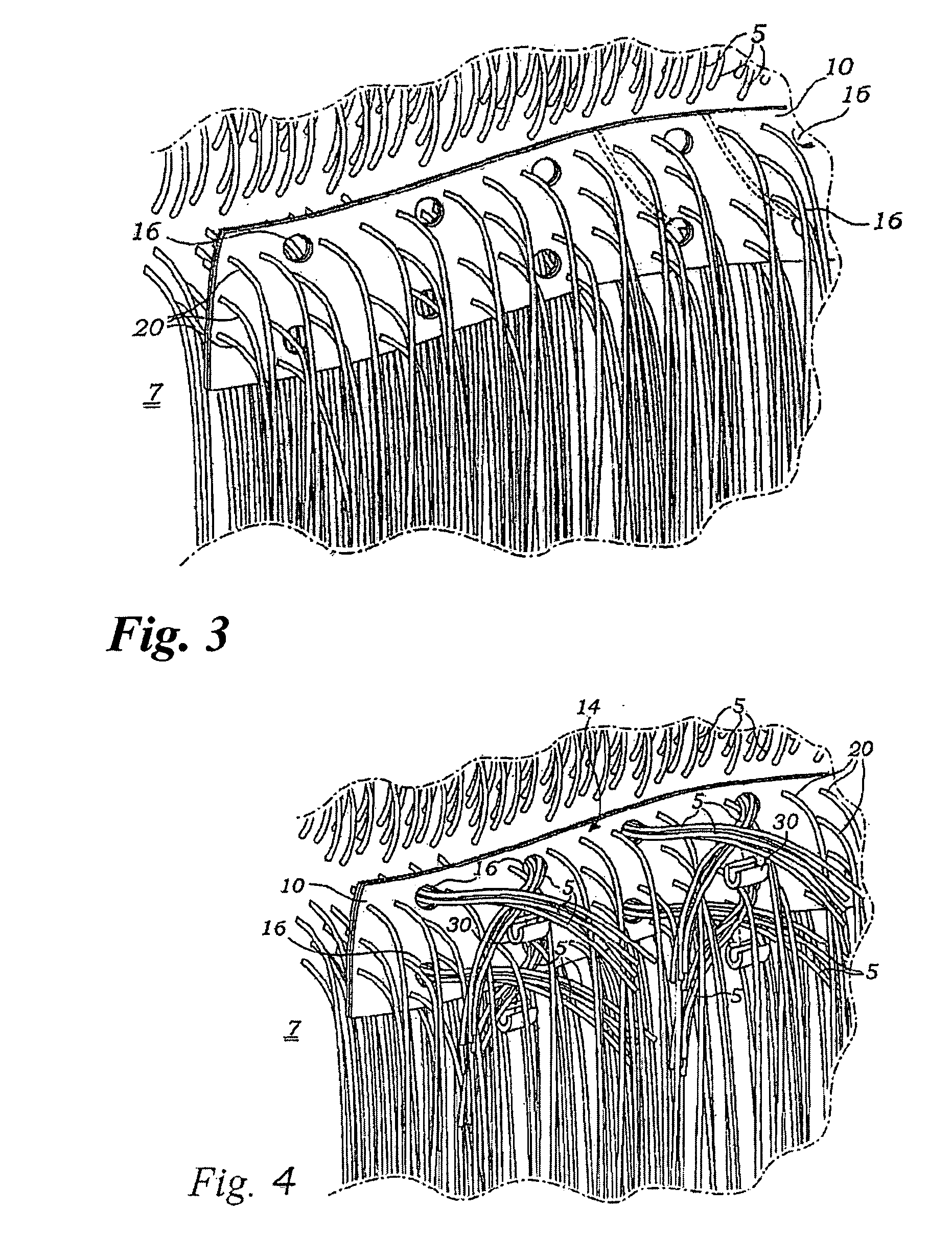

Hair extension

InactiveUS20060086368A1Simple and quick attachmentHigh quality appearanceHair accessoriesToupeesEngineeringBiomedical engineering

Owner:SALINAS HORTENCIA

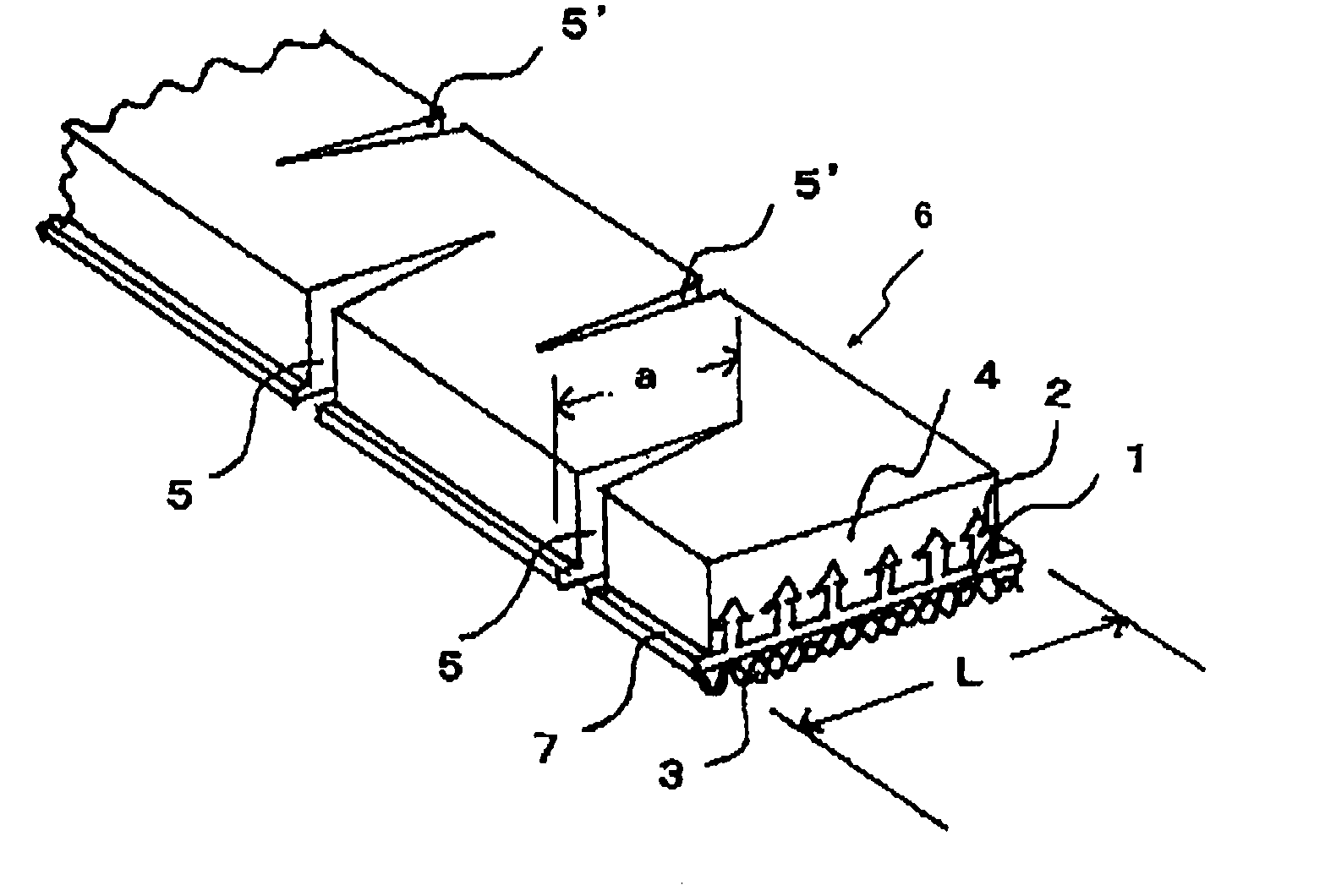

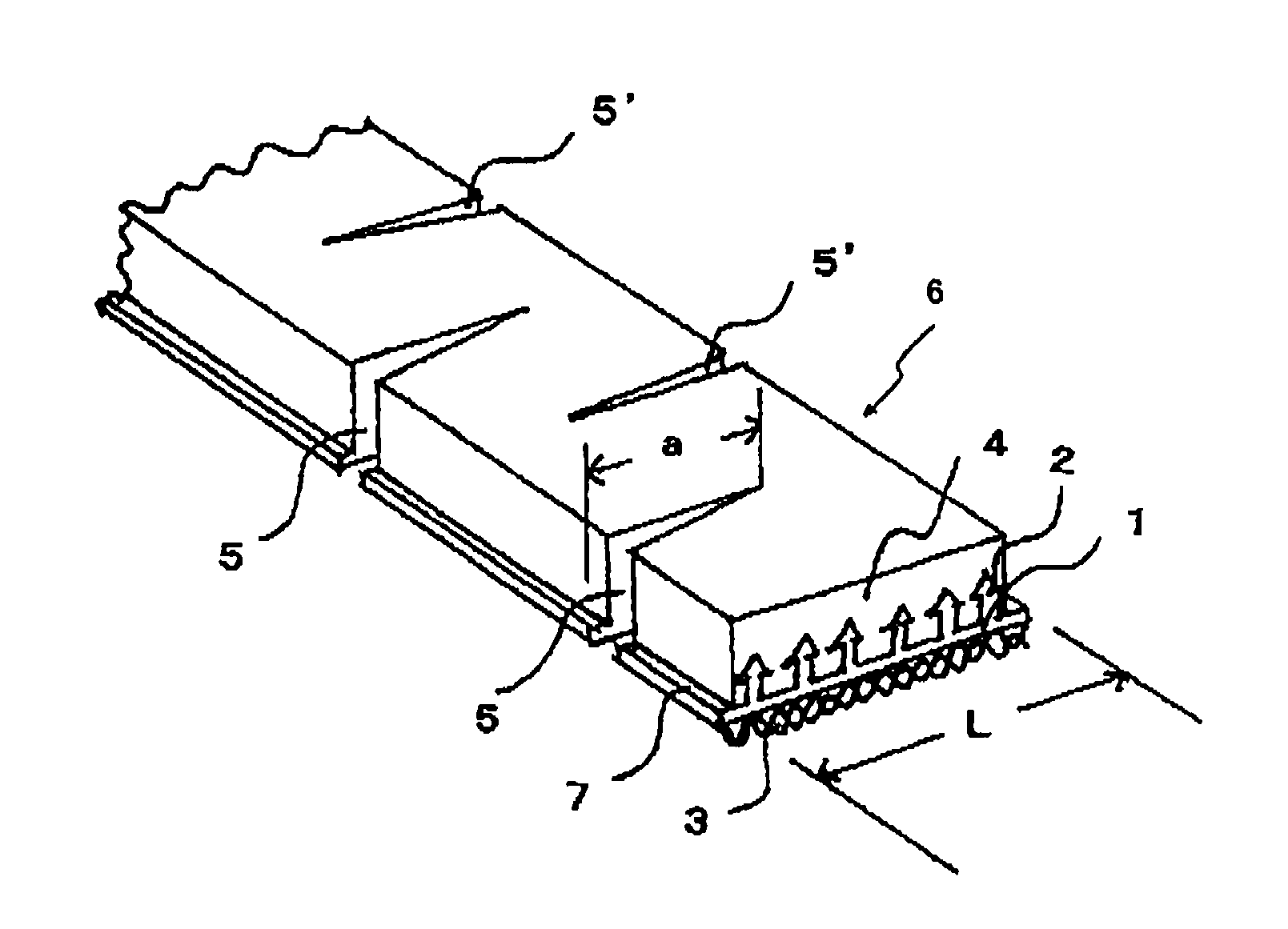

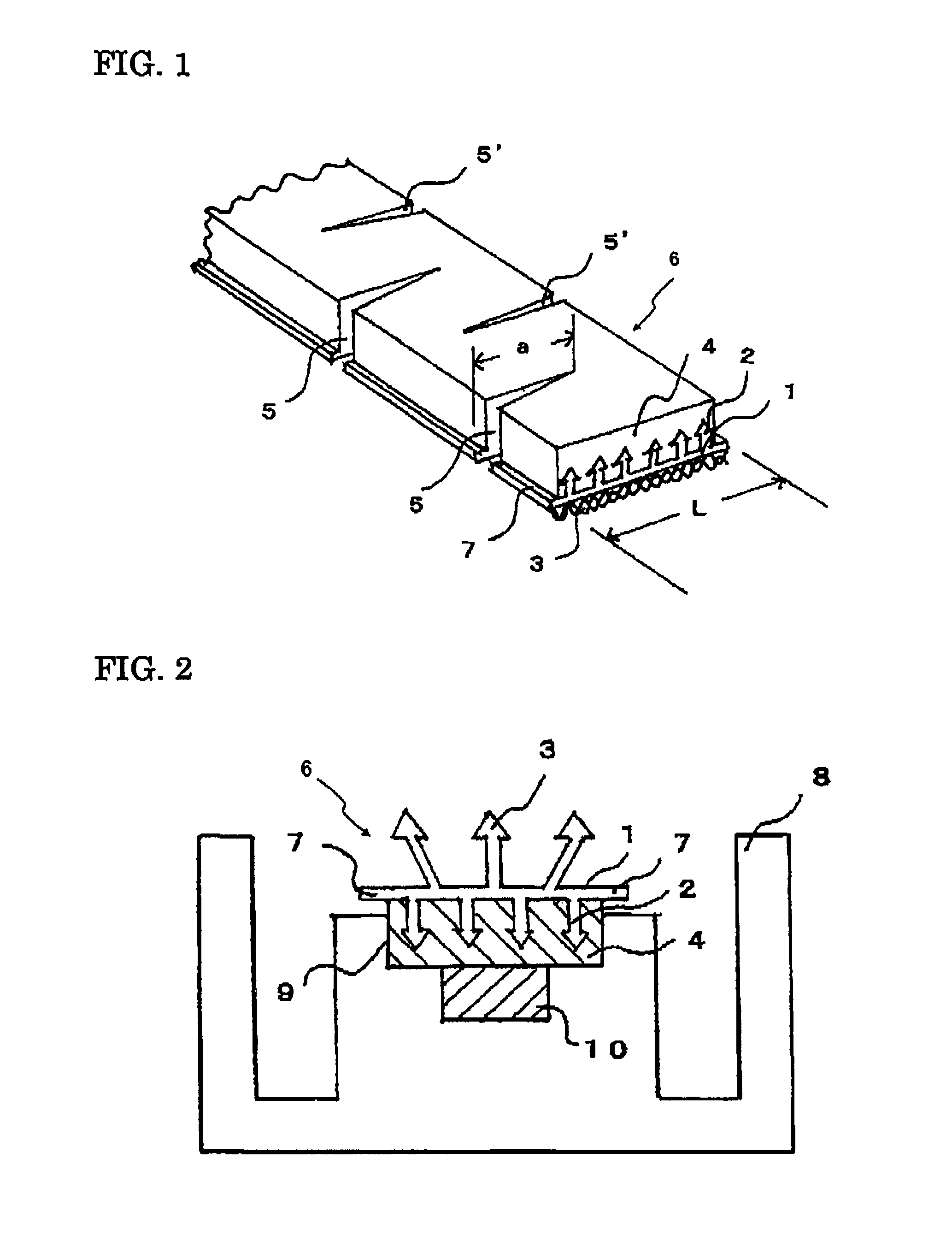

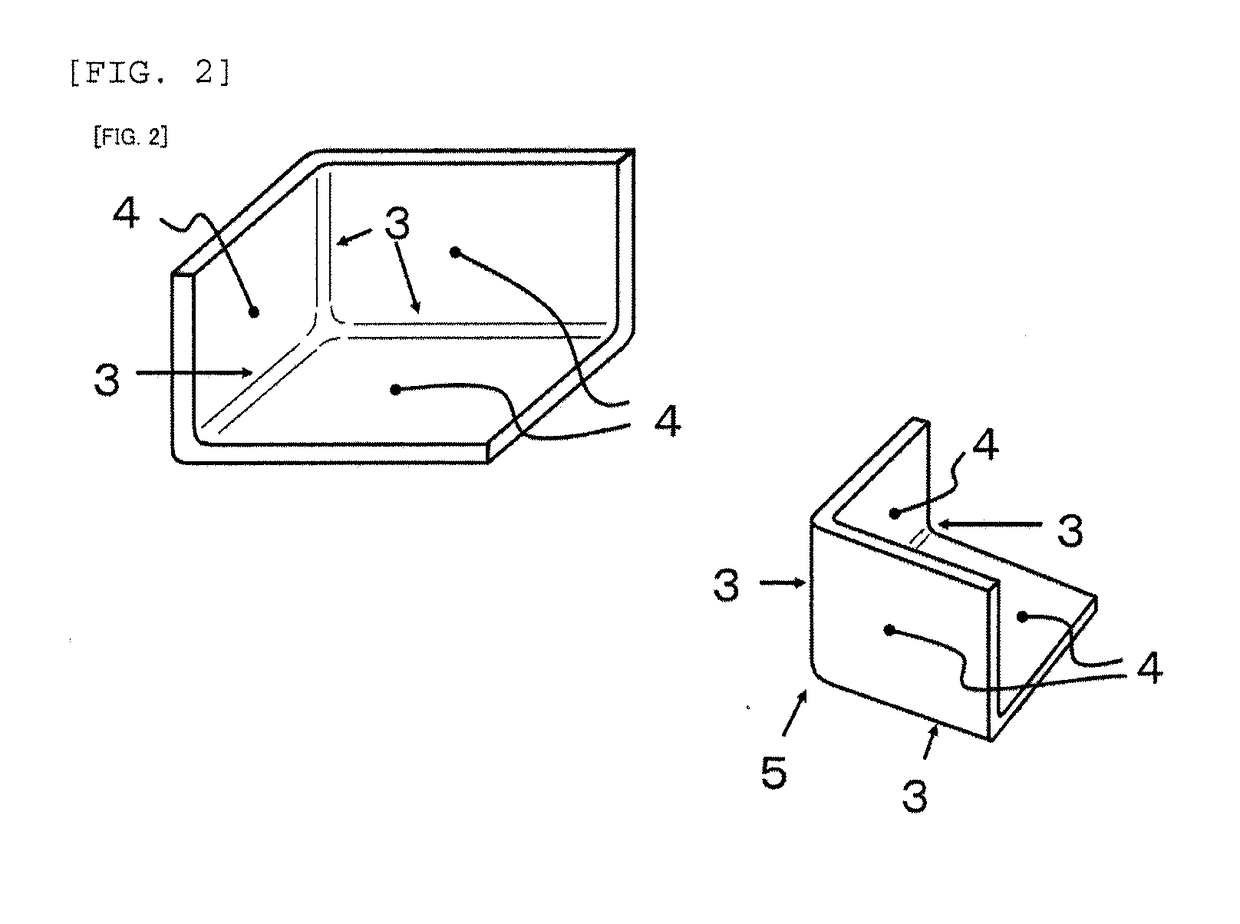

Hooking member for in-mold molding

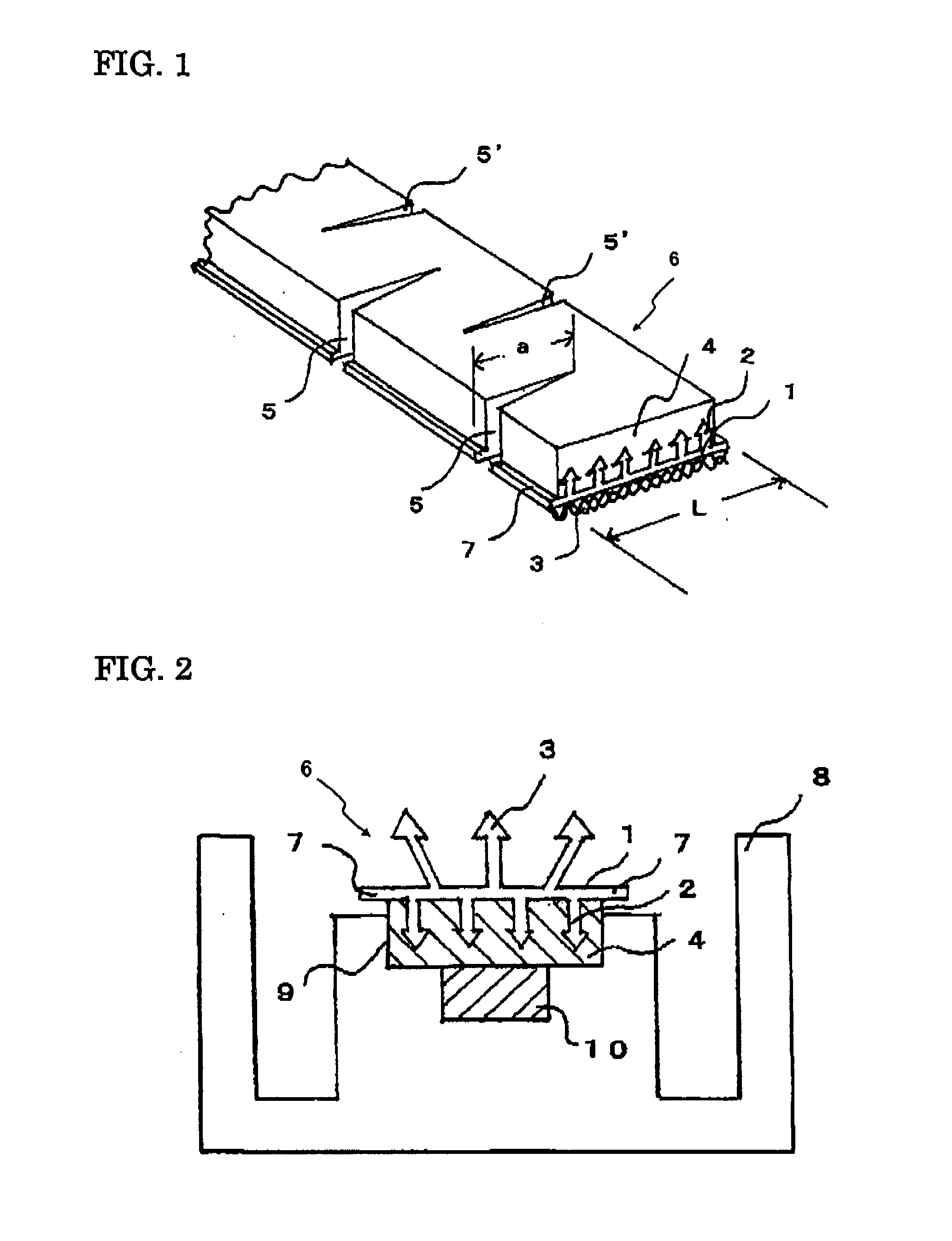

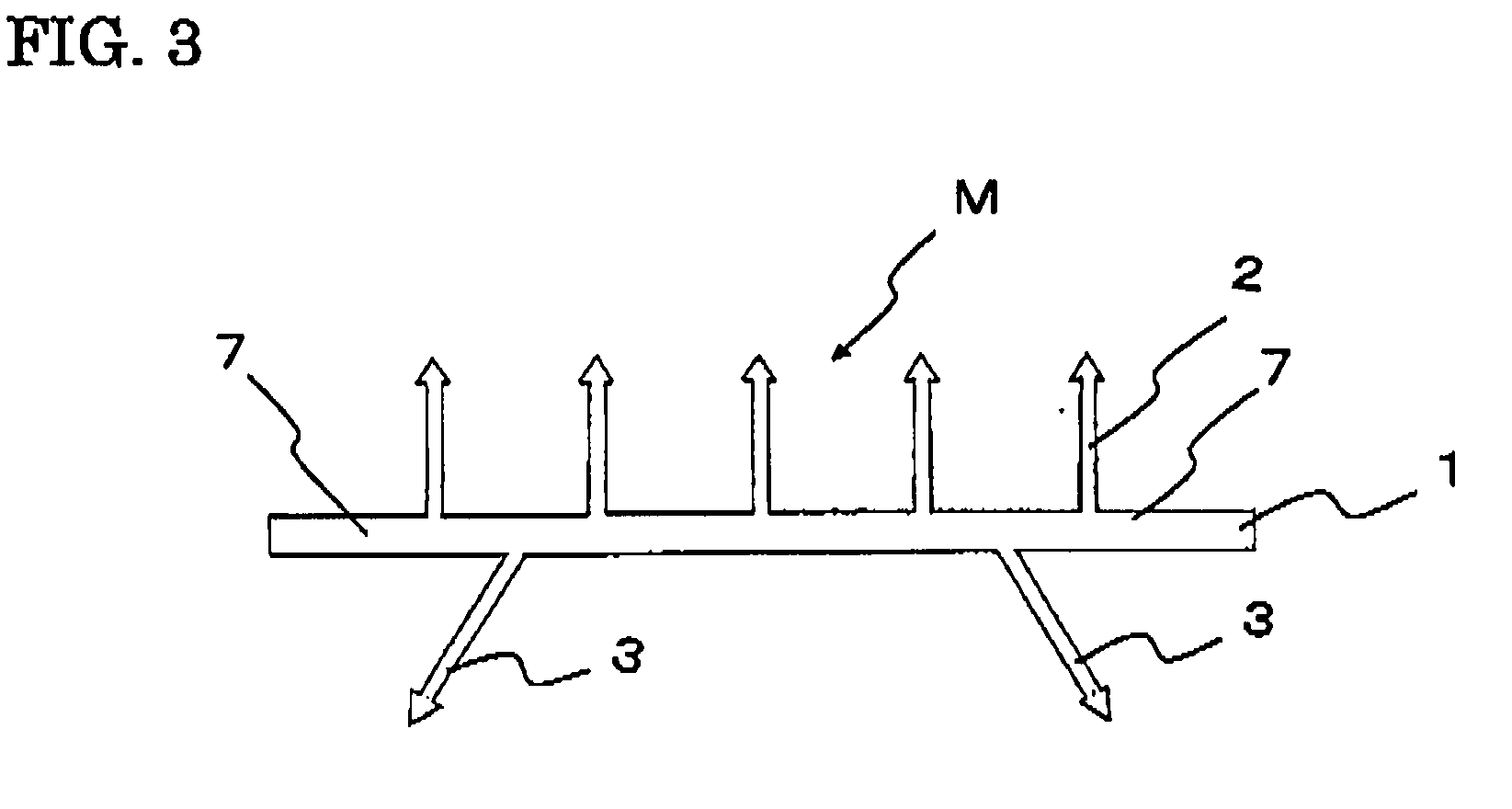

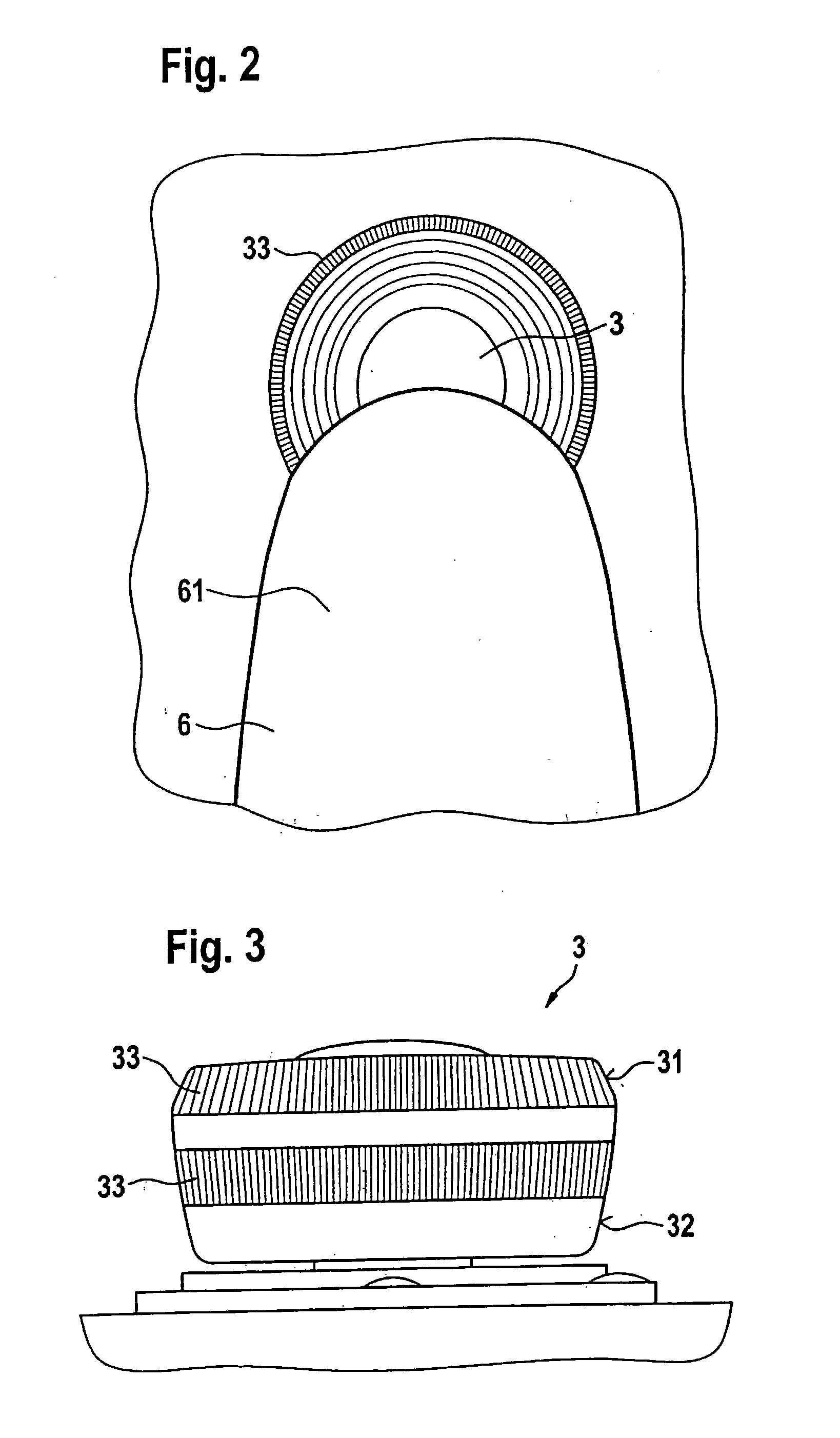

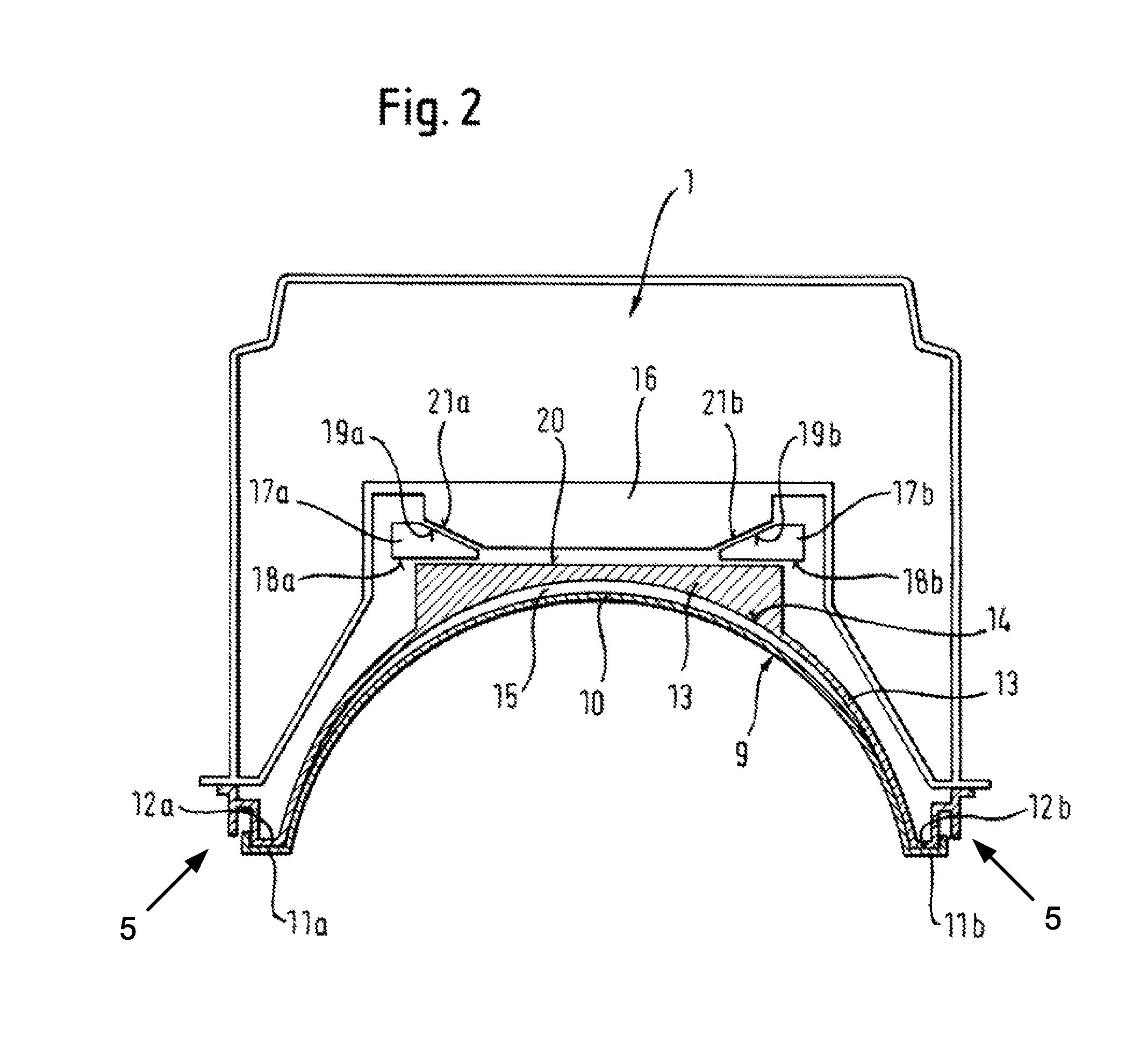

ActiveUS20110030176A1High quality appearanceBending stabilitySnap fastenersLayered productsElastomerFastener

A mold-in fastening member which is composed of a strip of substrate, engaging elements formed on one surface of the substrate, and an elastomer layer completely surrounding the engaging elements, the substrate having slits or notches which extend from a widthwise central portion of the substrate to a widthwise end portion of the substrate. The mold-in fastening member bends in conformity with a two- or three-dimensionally complicated shape of a molded article. The mold-in fastening member prevents the surface having the engaging elements from being covered with a foamable liquid molding resin during a mold-in process, thereby preventing the engaging elements from losing the engaging function.

Owner:KURARAY FASTENING CO LTD

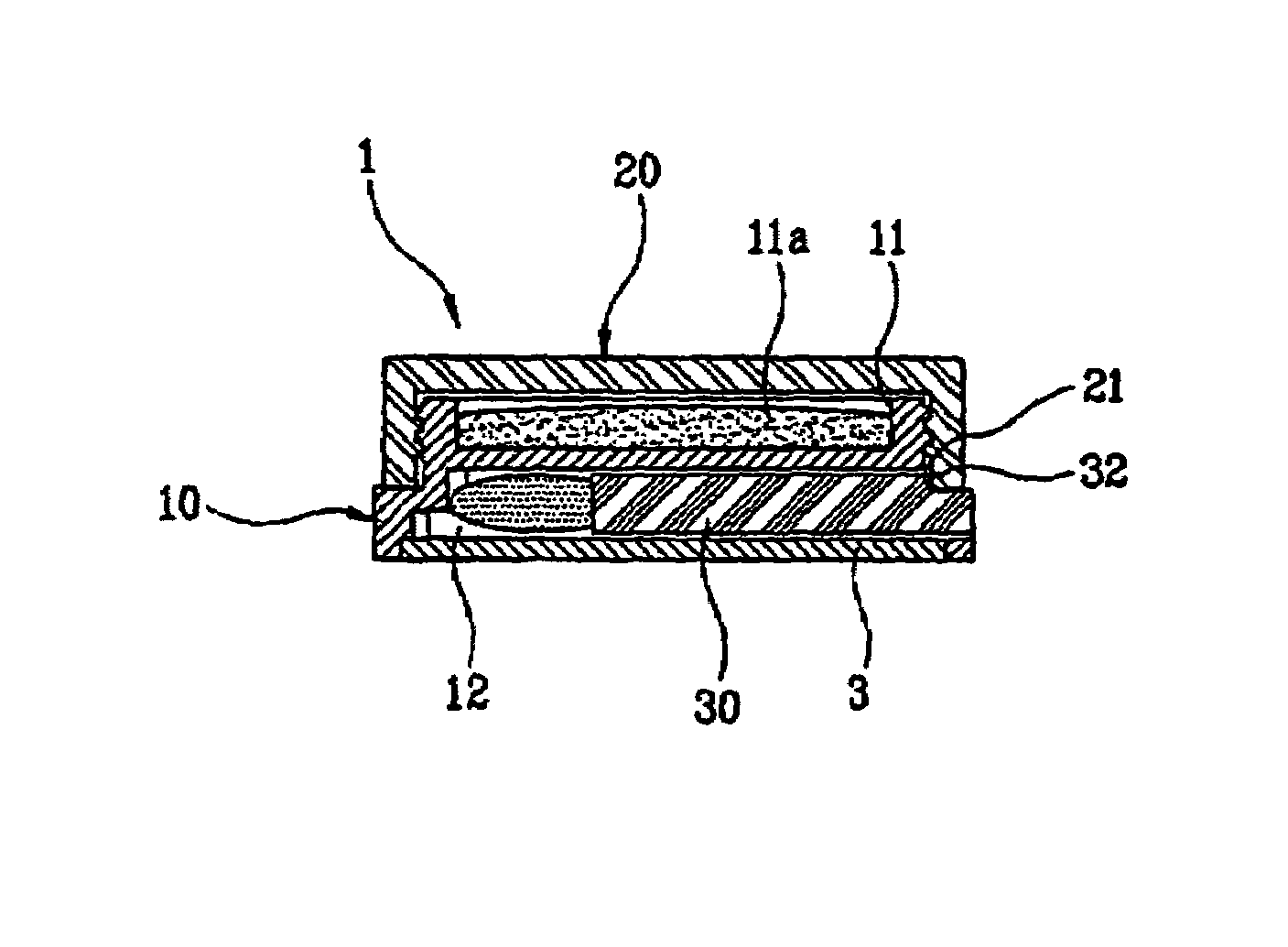

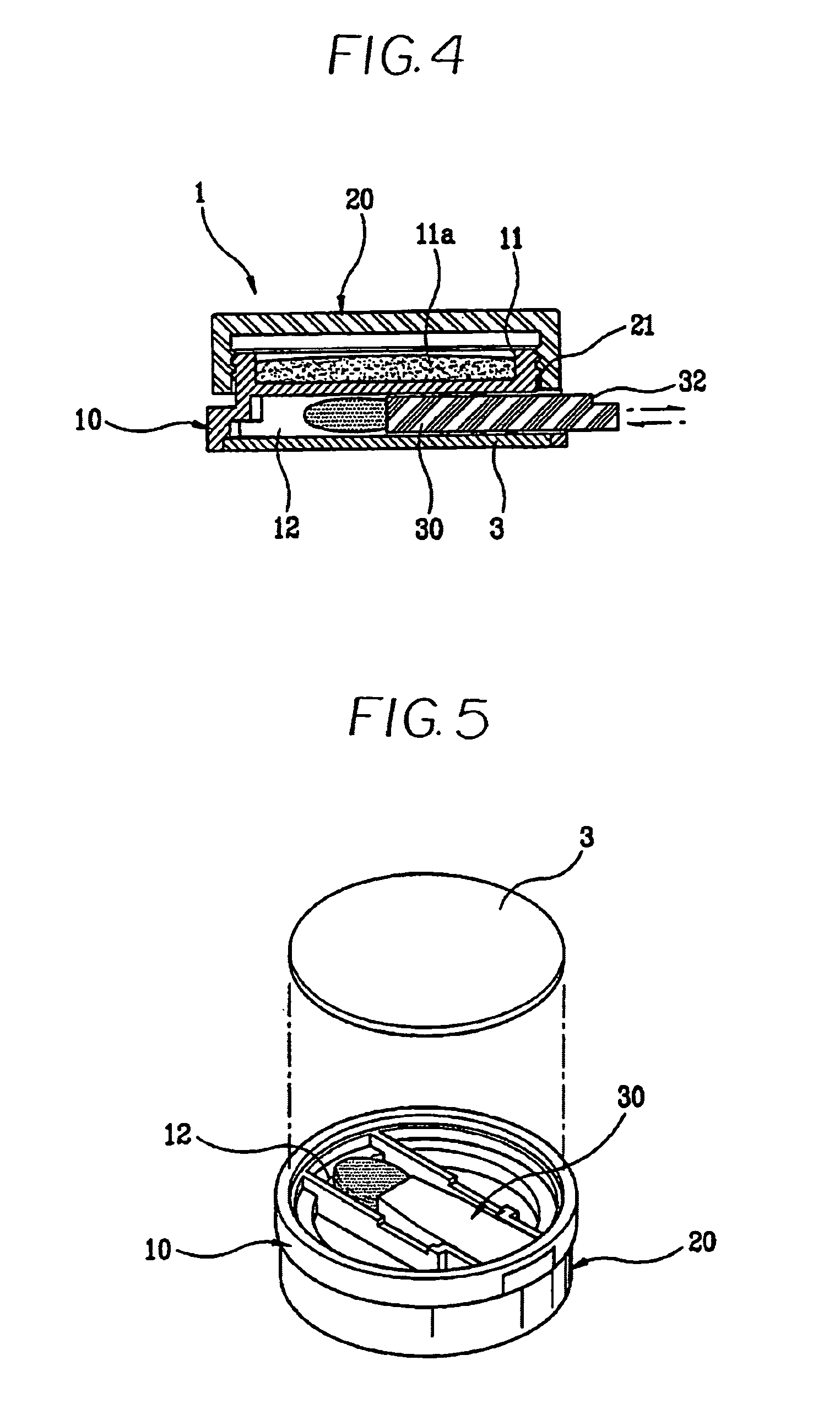

Cosmetics case having receipt drawing toilet set

InactiveUS7083354B2Easily carry toilet setHigh quality appearanceCleaning machinesContainer/bottle contructionReceiptEngineering

A cosmetic case 1 having receipt function of toilet set comprising a case body 10 having a receipt part 11 to receive cosmetics 11a and a case cover 20 to close / open top portion of the case body 10, characterized in that a receipt space 12 is formed on bottom portion of the case body 10 to carry a toilet set 30; the toilet set 30 having a hook threshold 32 at upper portion of one end thereof to allow the toilet set 30 capable of being received into and / or pulled out of the receipt space 12 by the case cover 20 when the case cover 20 is assembled with and / or disassembled from the case body 10. The cosmetics case 1 can easily include the toilet set 30, provide convenience to consumers, as well as achieving improvement of performance and high-quality appearance of the case 1.

Owner:BYUN YOUNG KWANG

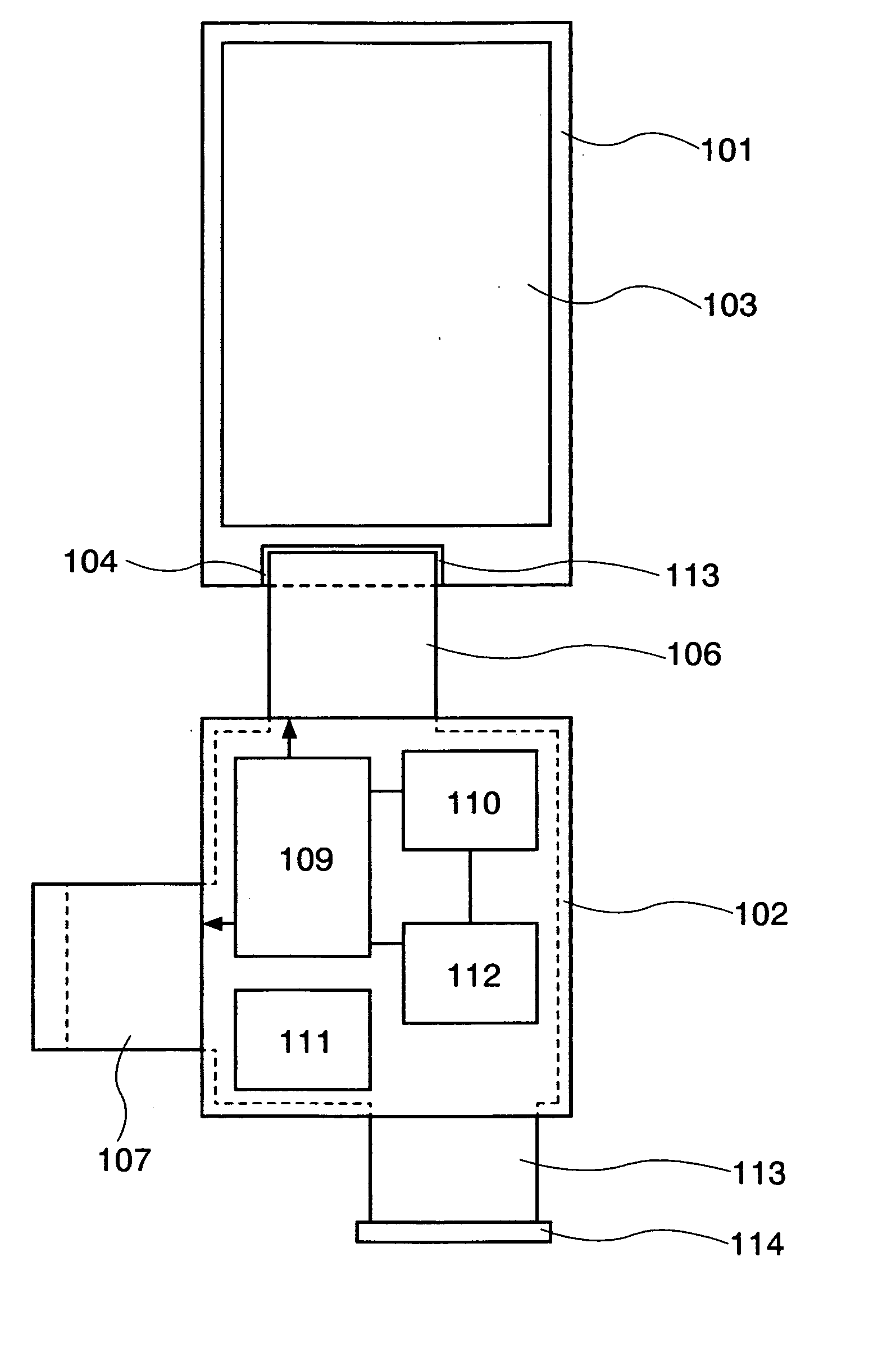

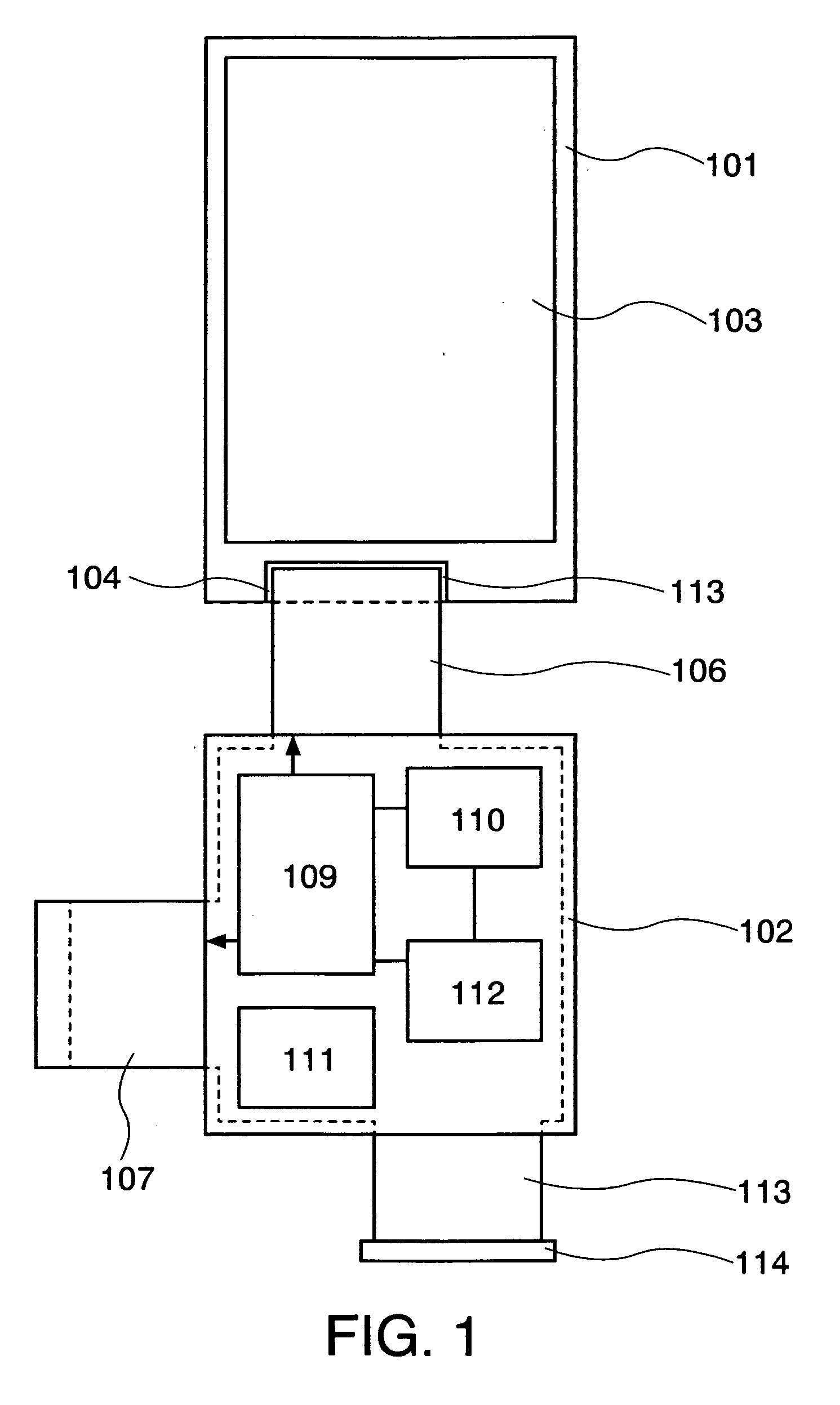

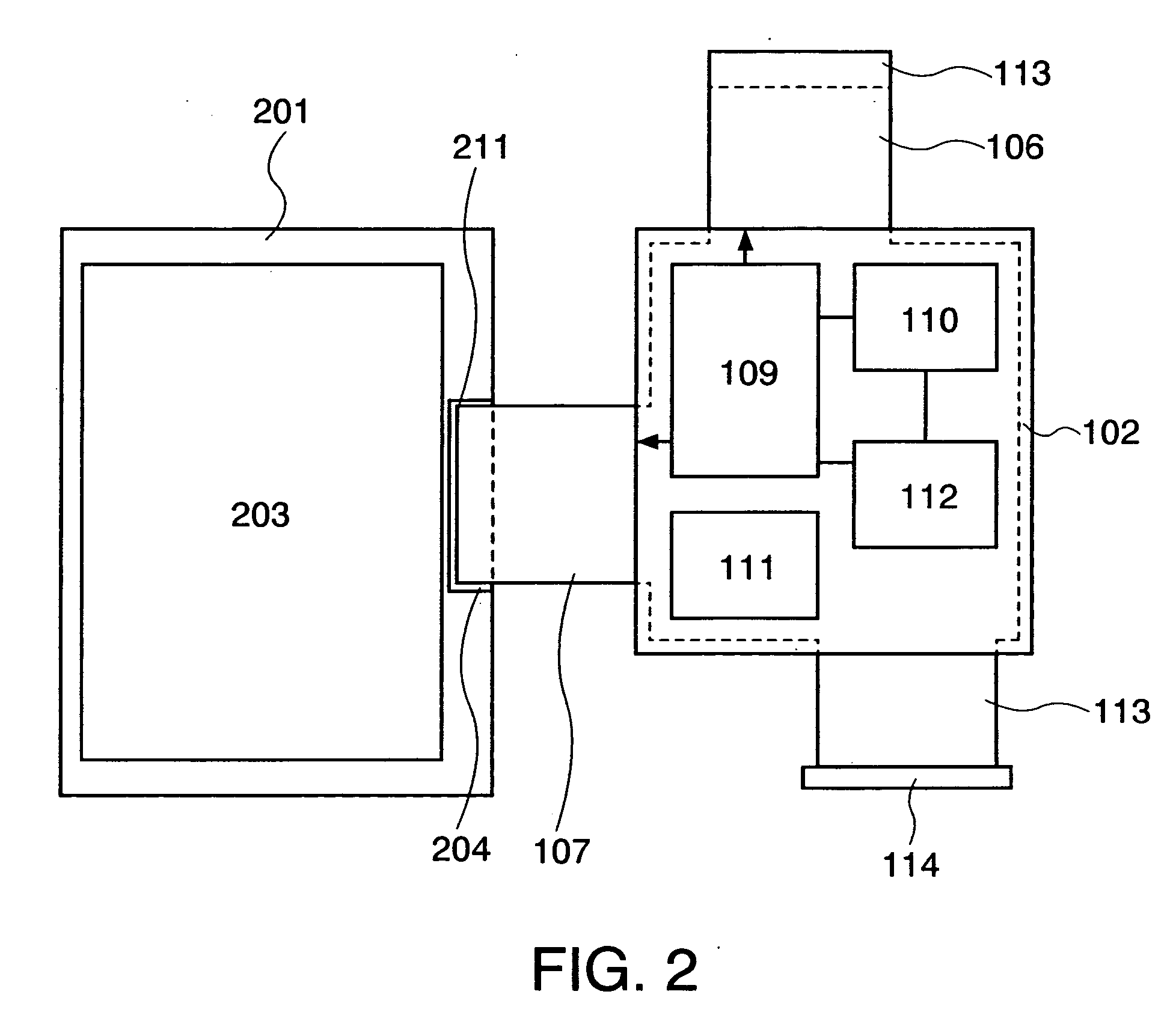

Display module and electronic device using the same

InactiveUS20070126721A1High quality appearanceLower display costsCathode-ray tube indicatorsPrinted circuit manufactureEngineeringControl circuit

A display module is provided, which comprises a stacked printed circuit board, and a control circuit mounted on the stacked printed circuit board. The stacked printed circuit board includes at least a first printed wiring board, a second printed wiring board, and a flexible insulating substrate interposed between the first printed wiring board and the second printed wiring board. The flexible insulating substrate includes at least a first connecting portion and a second connecting portion. A display panel is electrically connected to one of the first connecting portion and the second connecting portion. The control circuit includes a memory. The control circuit supplies an electrical signal to the one of the first connecting portion and the second connecting portion in accordance with a data stored in the memory.

Owner:SEMICON ENERGY LAB CO LTD

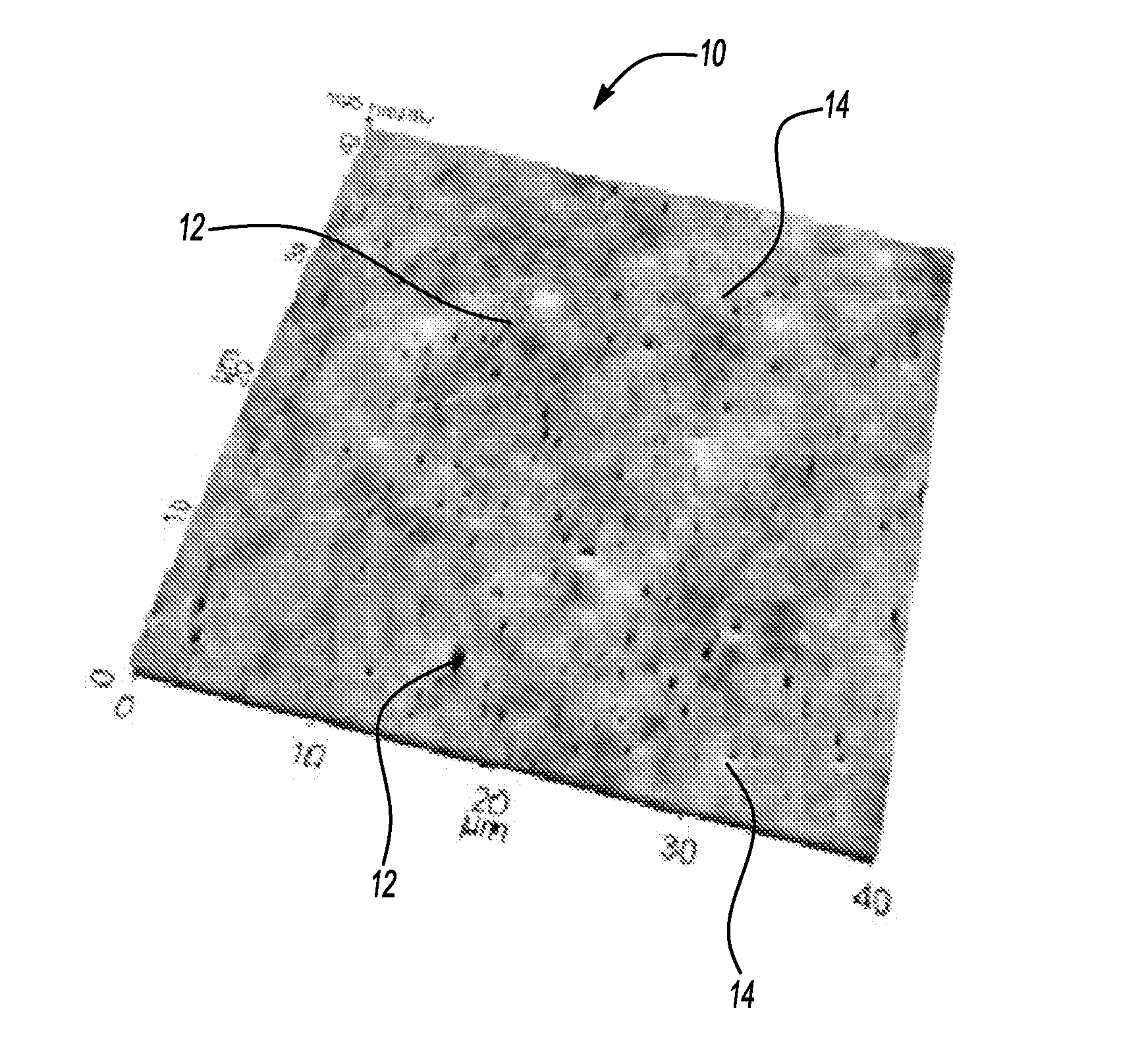

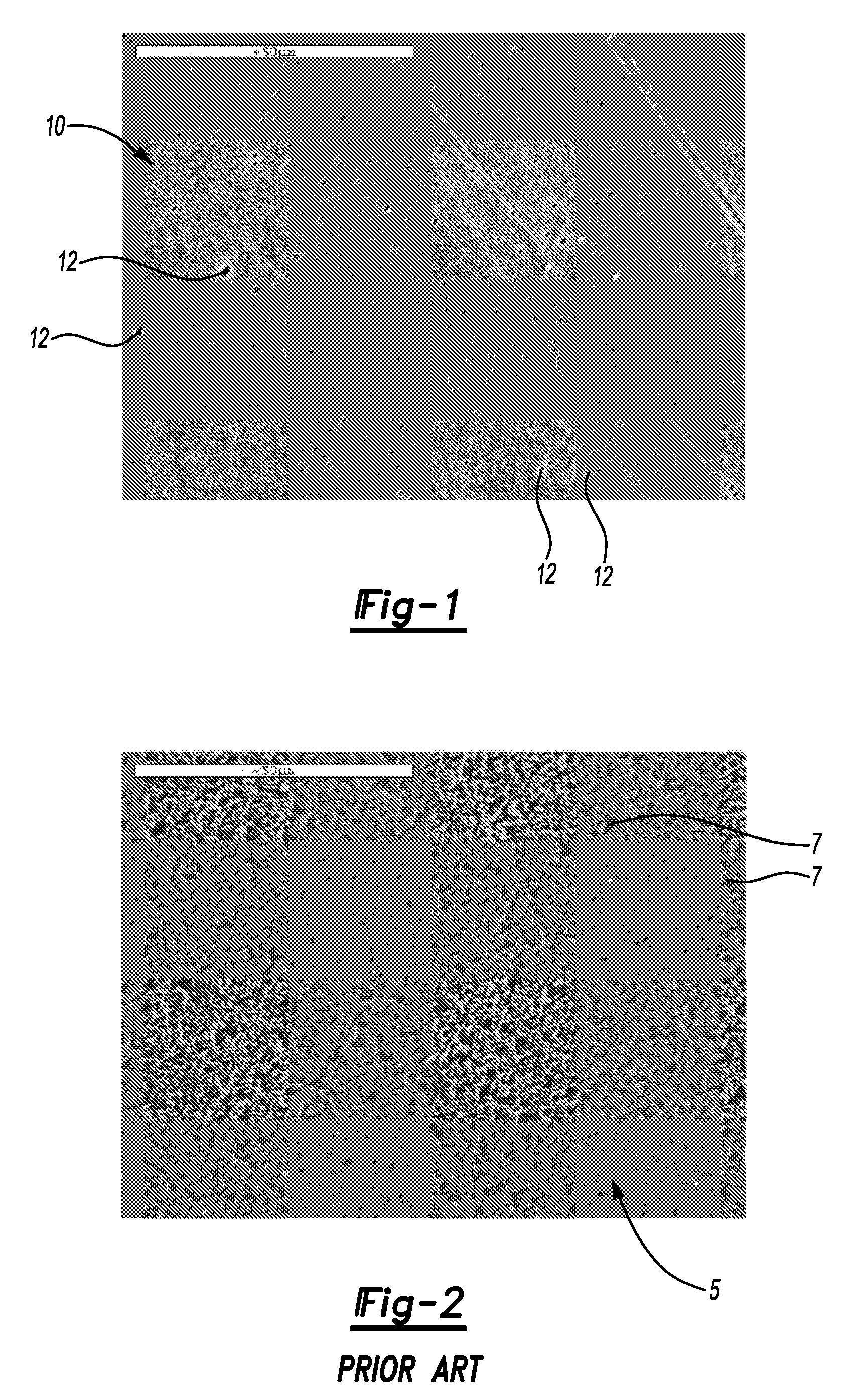

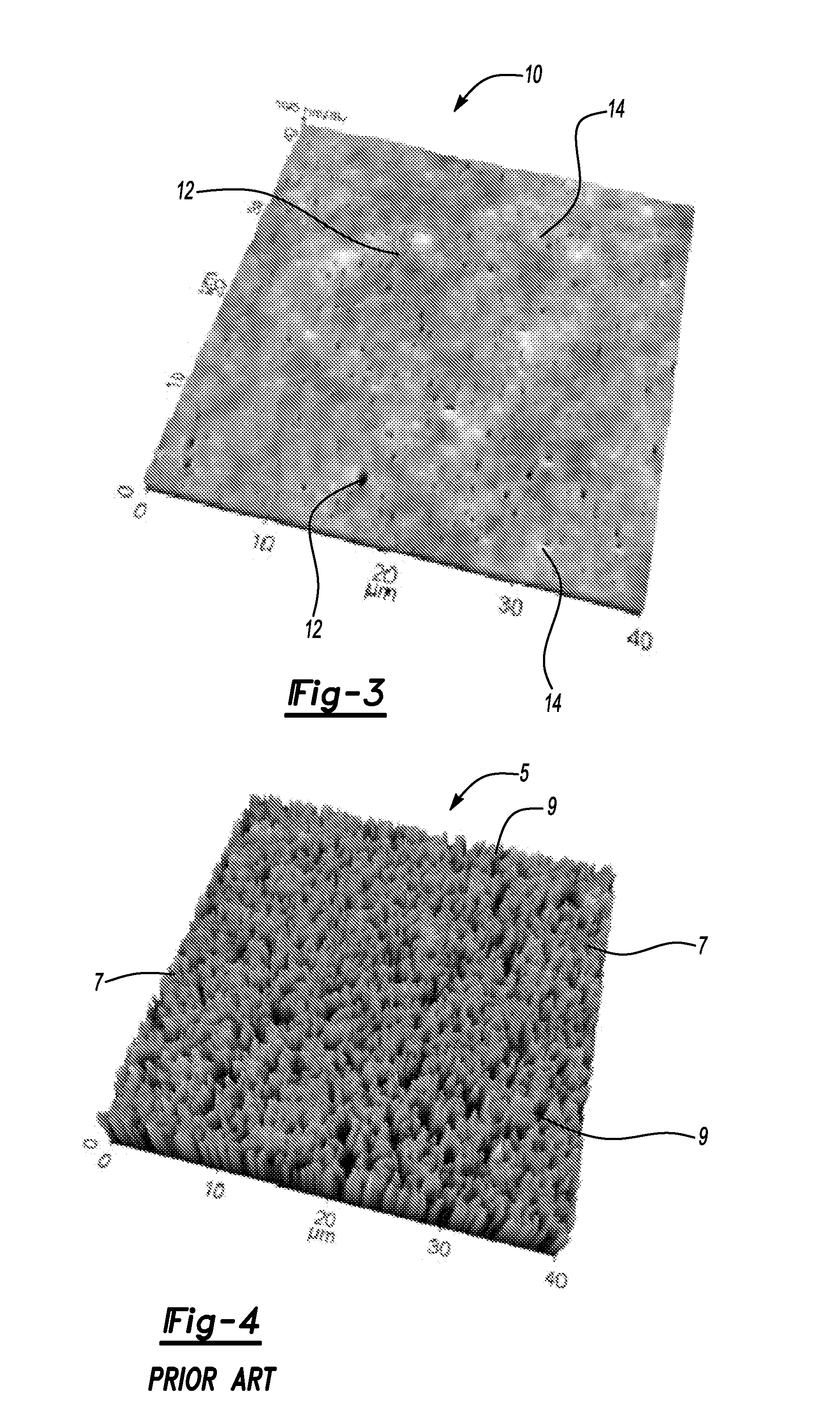

Decorative surface finish and method of forming same

ActiveUS20110045317A1Less surface rougheningHigh-quality appearancePretreated surfacesLiquid/solution decomposition chemical coatingThin metalSurface finish

A decorative metal finish for a part with a non-conductive surface where the non-conductive surface is lightly roughened to improve its adherence capabilities. A thin metal layer is electrolessly deposited on the lightly roughened surface to provide a bright durable metal finish on the non-conductive surface. An translucent finish is deposited over the thin metal layer to provide protection for the metal finish.

Owner:LACKS INDUSTRIES INC

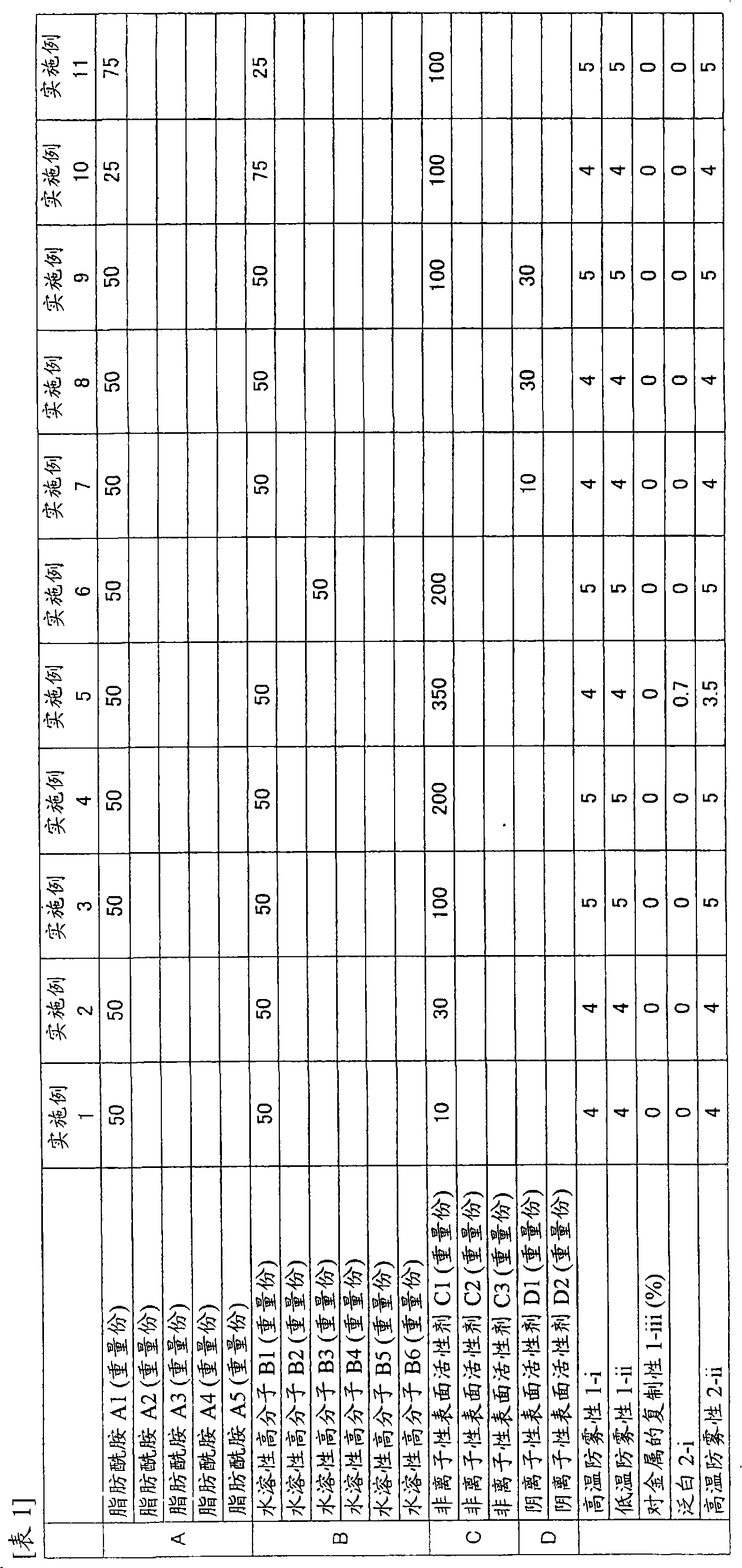

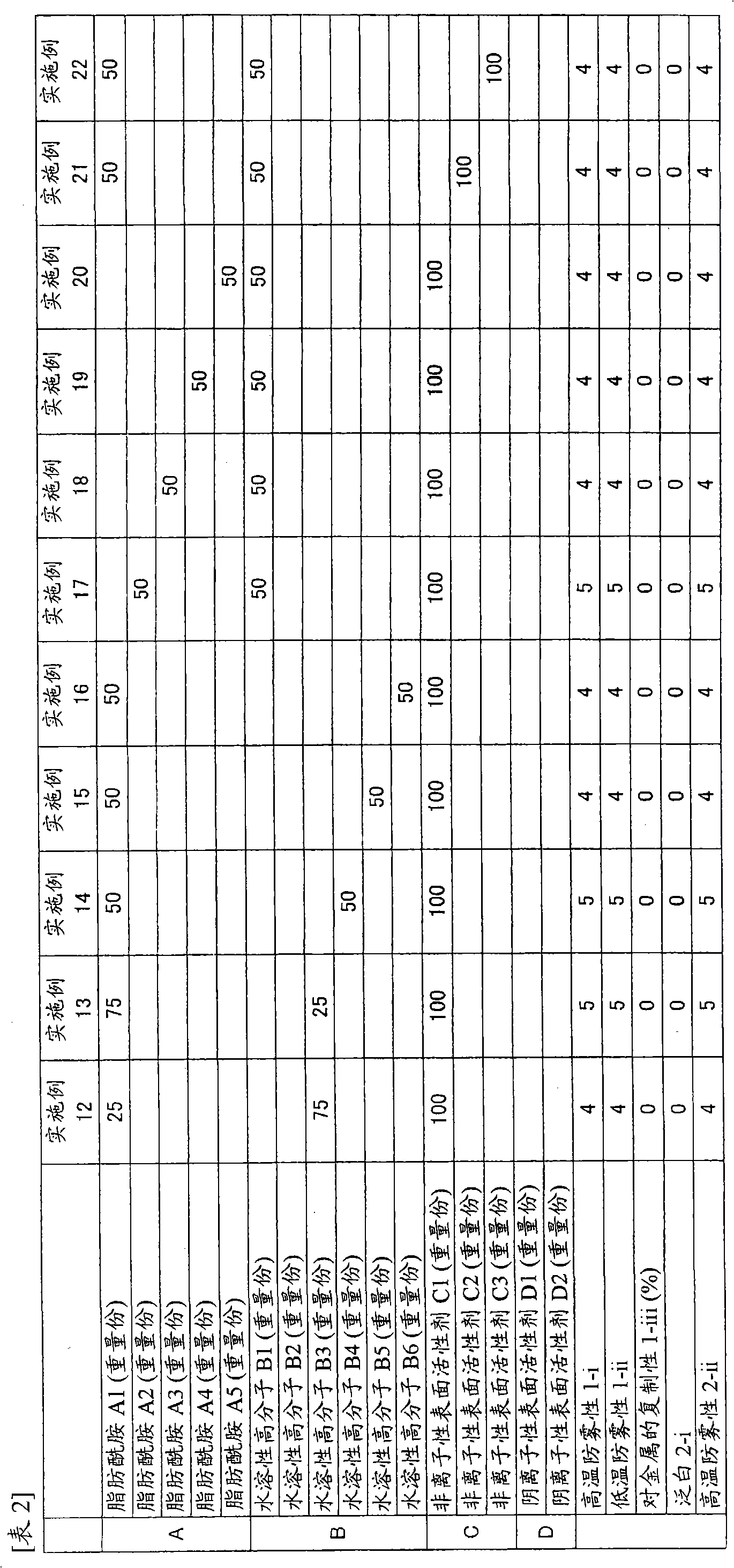

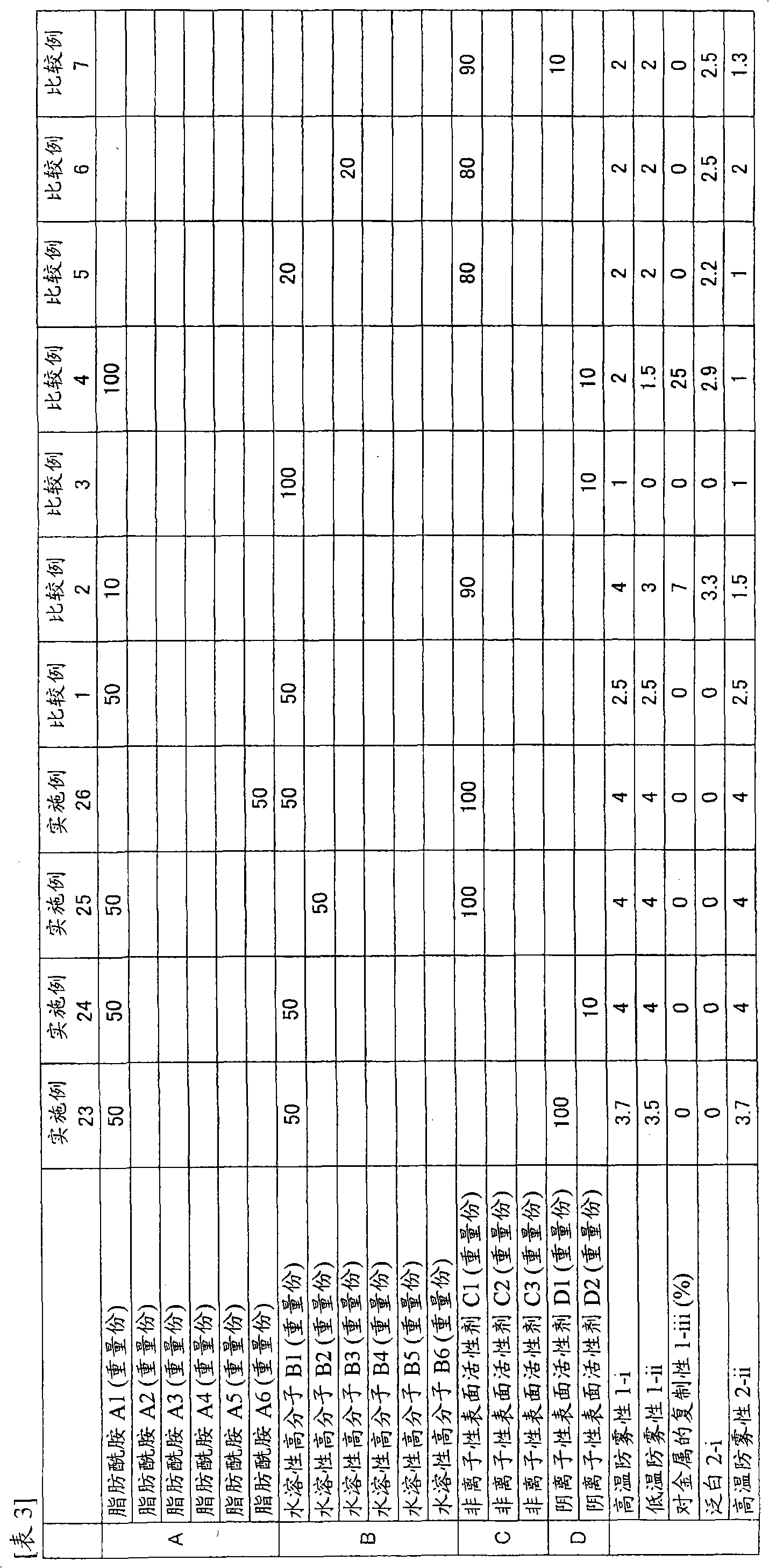

Anti-fogging surface treating agent and anti-fogging resin sheet

InactiveCN101555400AGood anti-fog performanceHigh quality appearanceFlexible coversWrappersSucroseSurface-active agents

The object of the invention is to obtain an anti-fogging surface treating agent and an anti-fogging resin sheet having excellent anti-fogging property. In terms of 100 parts by weight of base composition, the anti-fogging surface treating agent contains 0.1 to 400 parts by weight (C) of non-ionic surface active agent such as sucrose fatty ester and the like, and / or 0.1 to 20 parts by weight (D) of anionic surface active agent such as paraffin sulfonate and the like. The base composition contains (A) C8-30 fatty amide such as alkanolamide and the like, and (B) water-soluble polymer such as vinyl pyrrolidone polymer. An anti-fogging resin sheet applied to shaping a deep-drawing container can be prepared by coating the surface treating agent on at least one face of the stilbene resin sheet.

Owner:DAICEL POLYMER LTD

Hooking member for in-mold molding

A mold-in fastening member which is composed of a strip of substrate, engaging elements formed on one surface of the substrate, and an elastomer layer completely surrounding the engaging elements, the substrate having slits or notches which extend from a widthwise central portion of the substrate to a widthwise end portion of the substrate. The mold-in fastening member bends in conformity with a two- or three-dimensionally complicated shape of a molded article. The mold-in fastening member prevents the surface having the engaging elements from being covered with a foamable liquid molding resin during a mold-in process, thereby preventing the engaging elements from losing the engaging function.

Owner:KURARAY FASTENING CO LTD

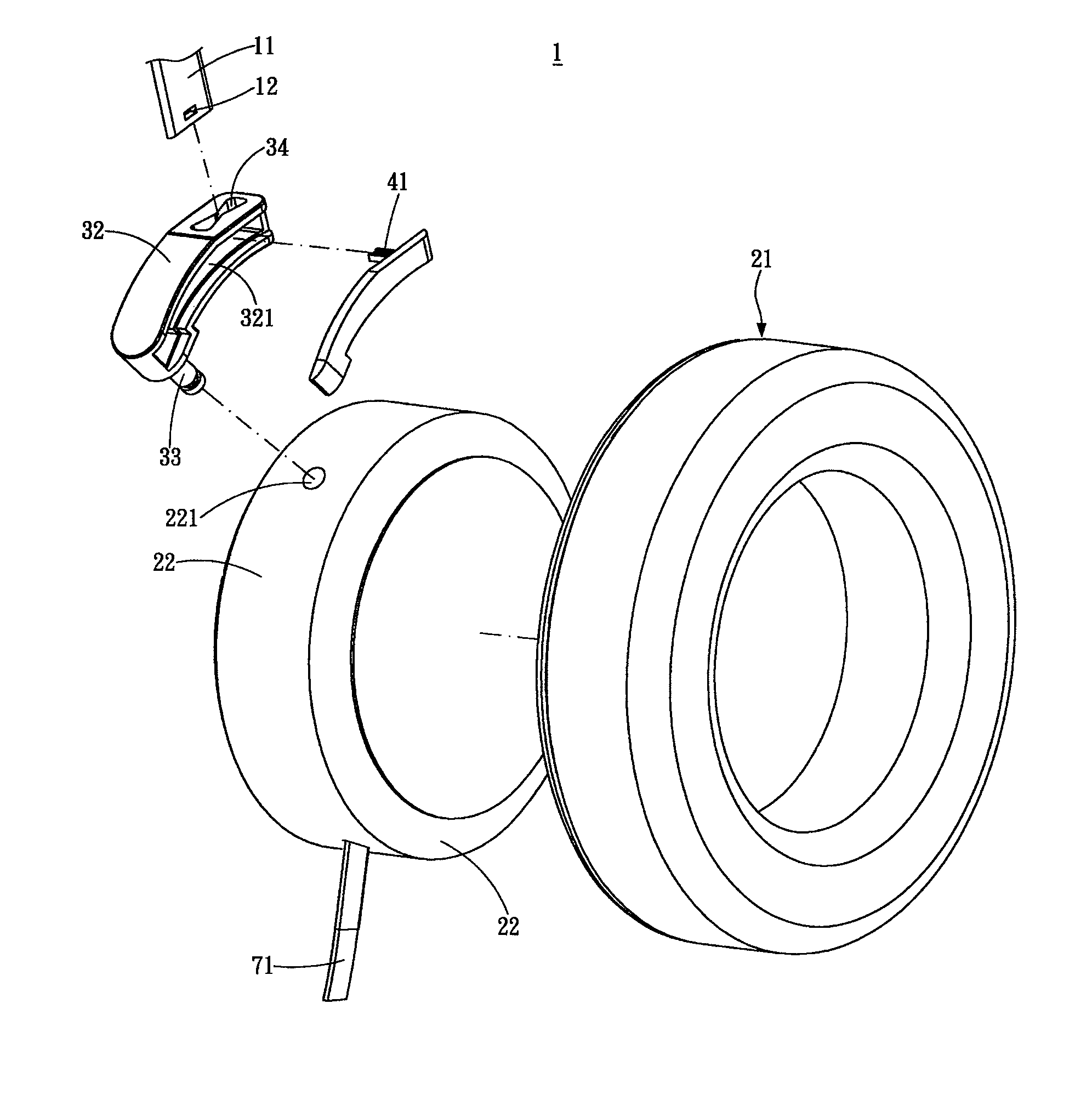

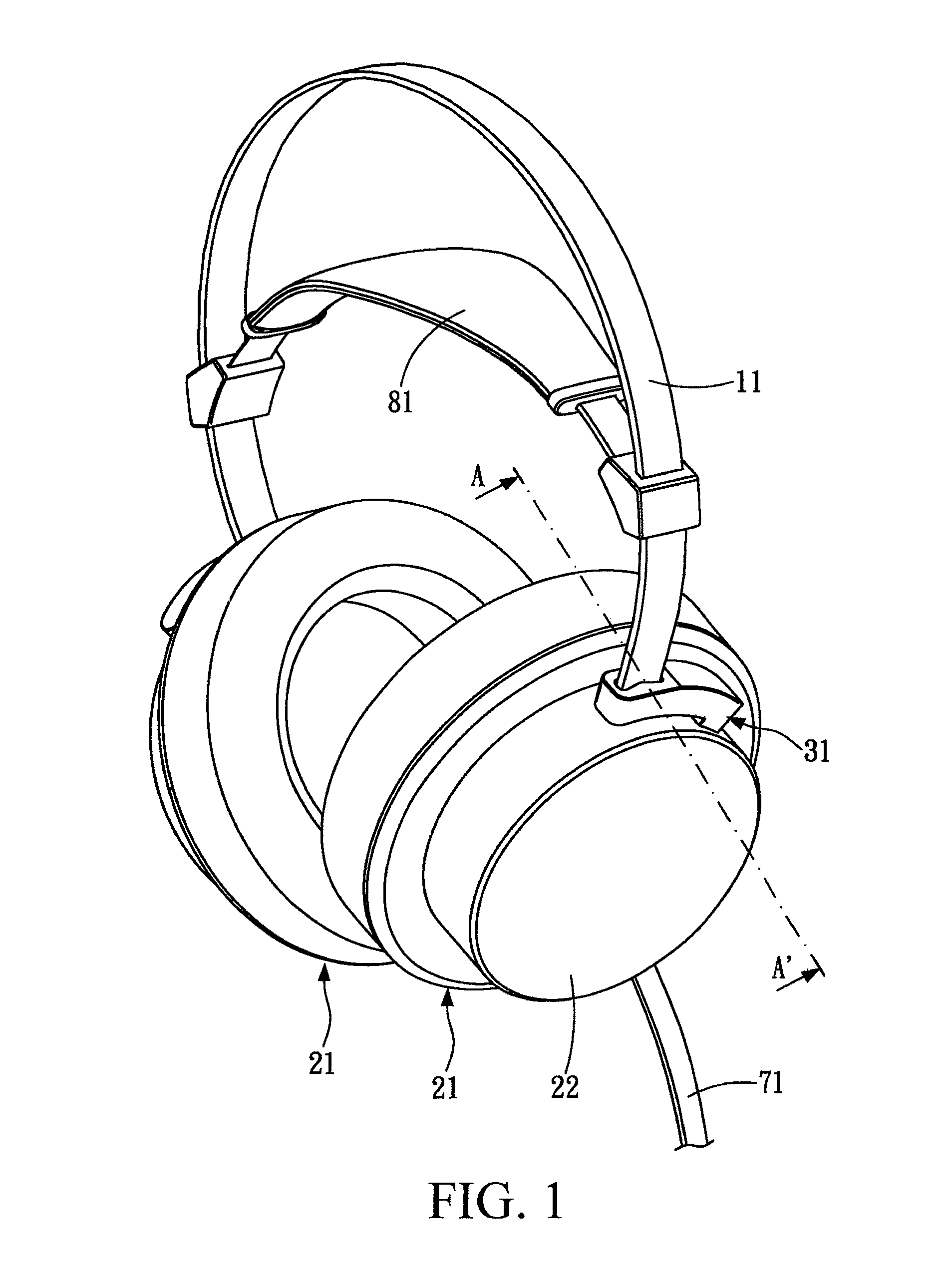

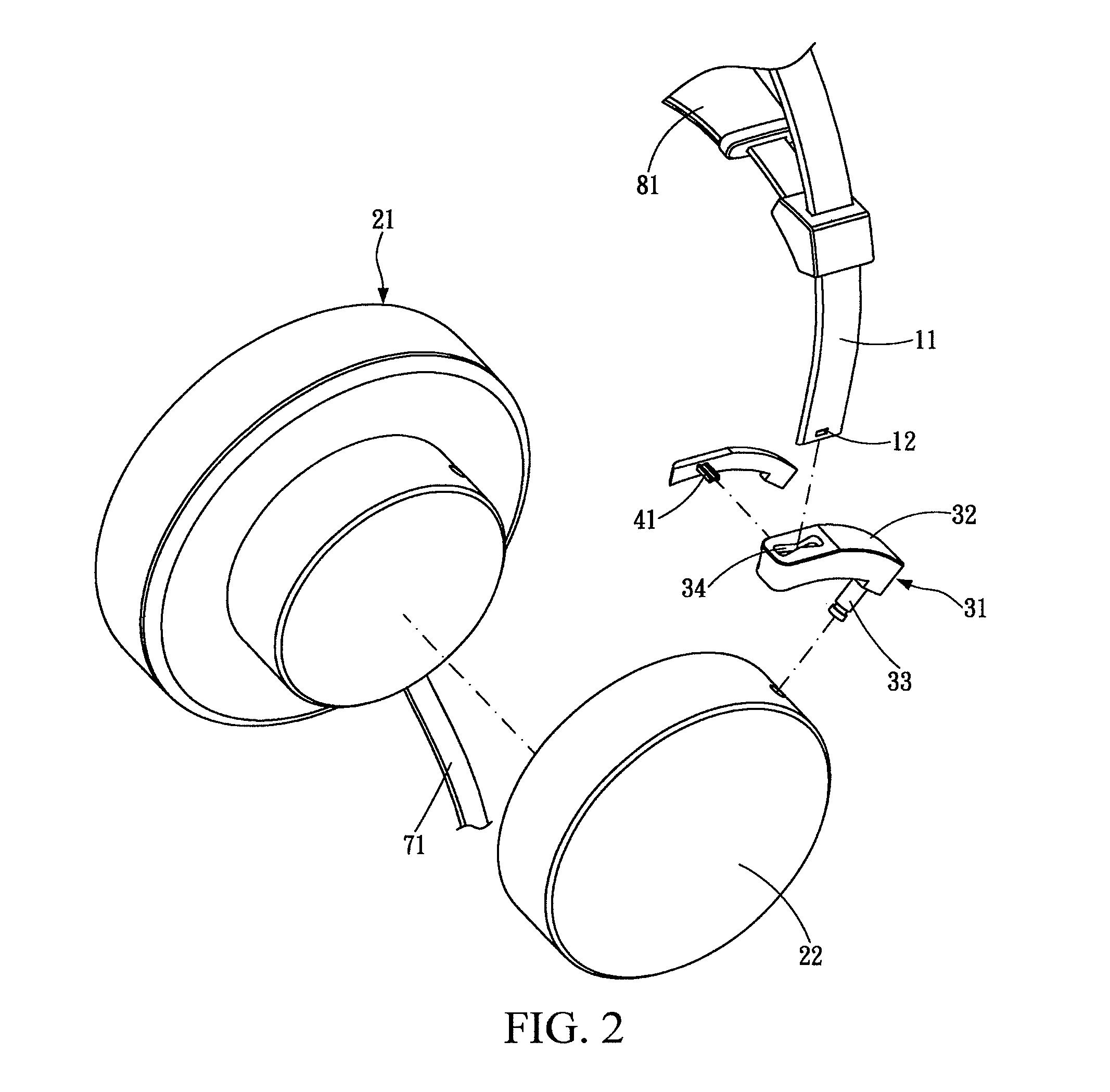

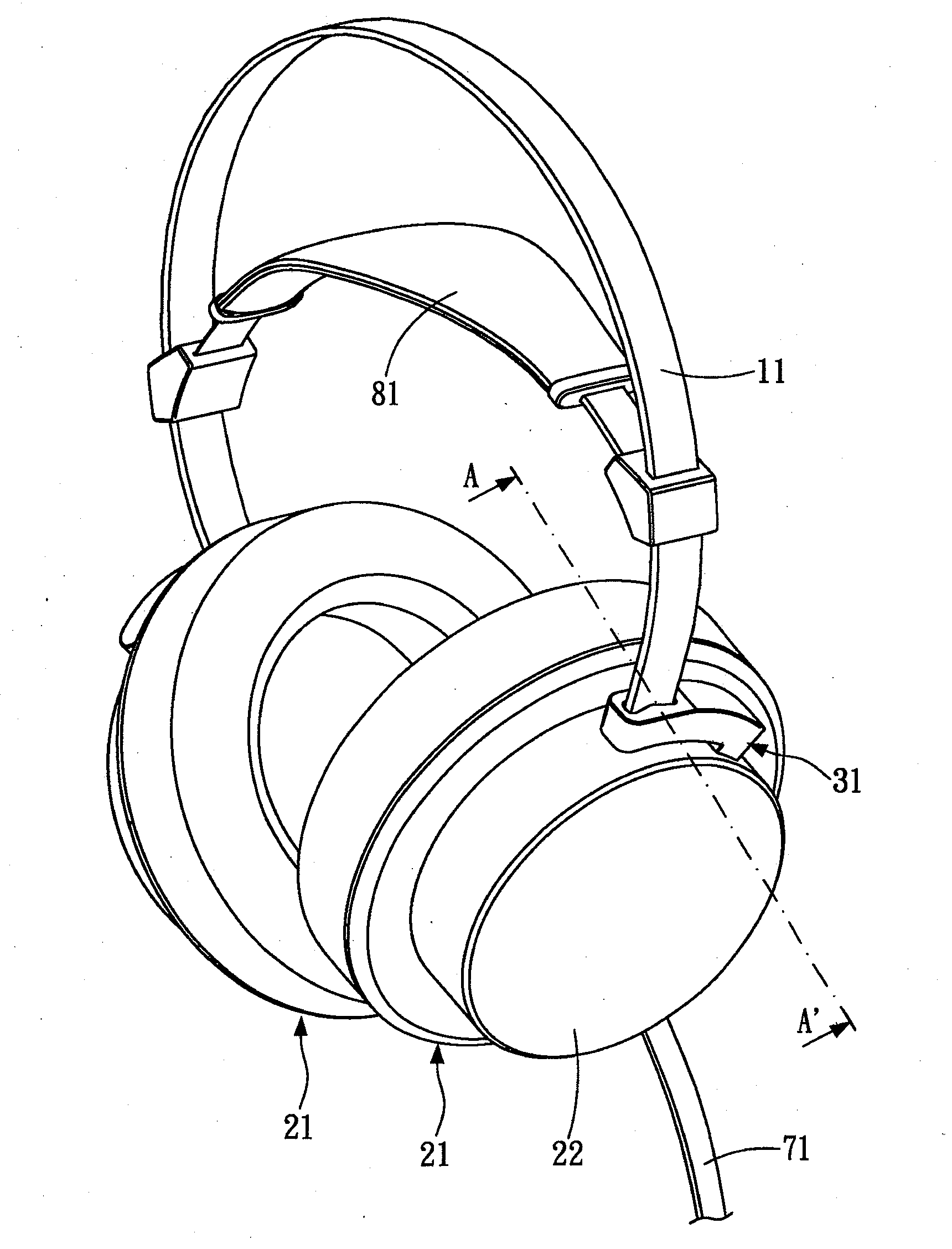

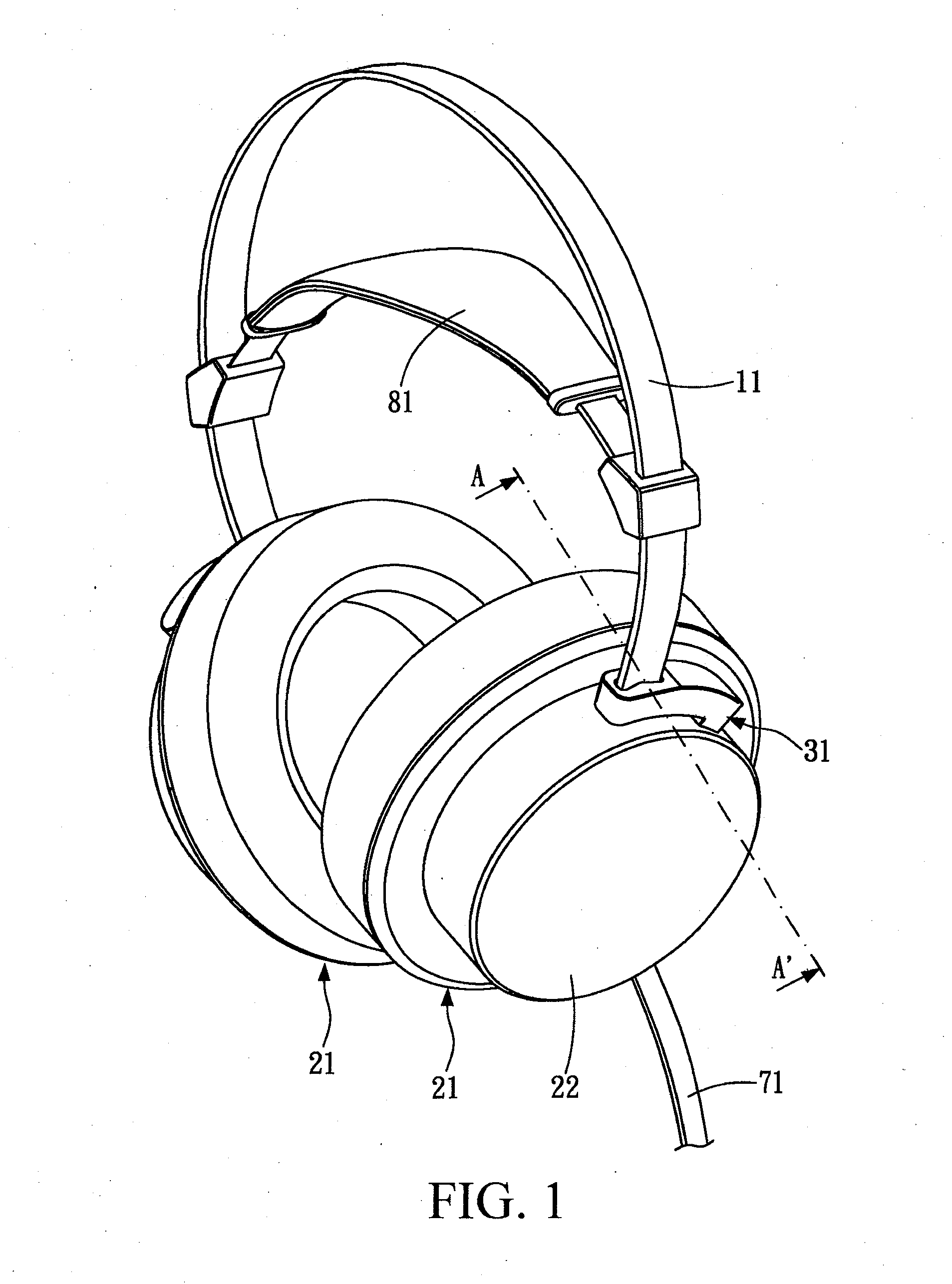

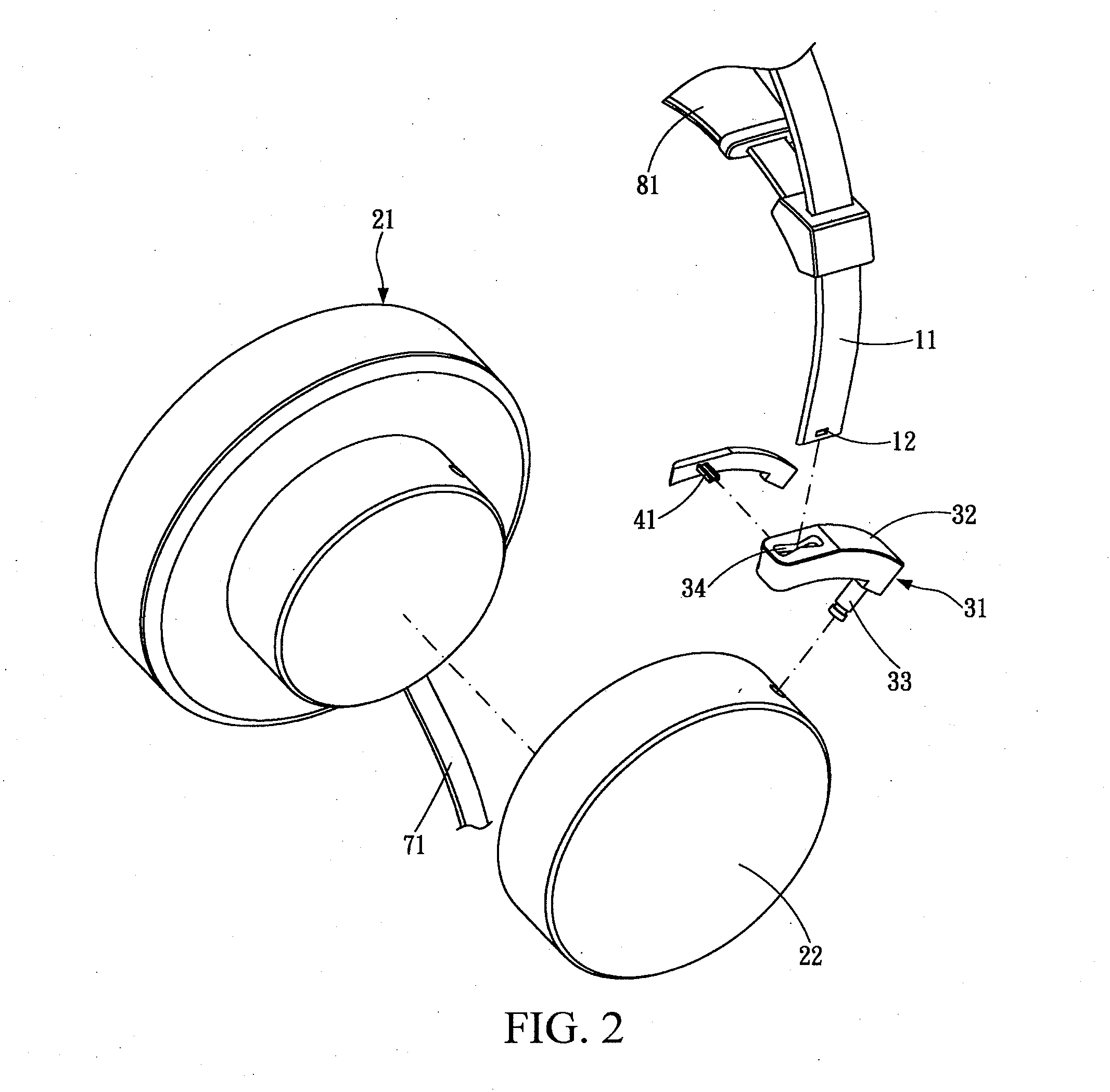

Earphone single-shaft structure

InactiveUS8774442B2Improve fitGood lookingPiezoelectric/electrostrictive microphonesElectrostatic transducer microphonesMechanical engineeringEngineering

Owner:JETVOX ACOUSTIC

Method for realizing uniform heating and cooling of plastic injection mould

The present invention provides one kind of method of heating and cooling plastic injecting mold. The method includes splitting each of the movable mold and the fixed mold into two parts, one inner part and one outer part, assembled together; making the split movable mold and the fixed mold possess the required profile, and machining water / air channels in the split movable mold and the fixed mold for both heating and cooling. The present invention has water / air channels for both heating and cooling in the same distance to the profile of the mold cavity, so that it has homogeneous heating and cooling and capacity of obtaining high quality plastic injecting formation product.

Owner:SHANDONG UNIV

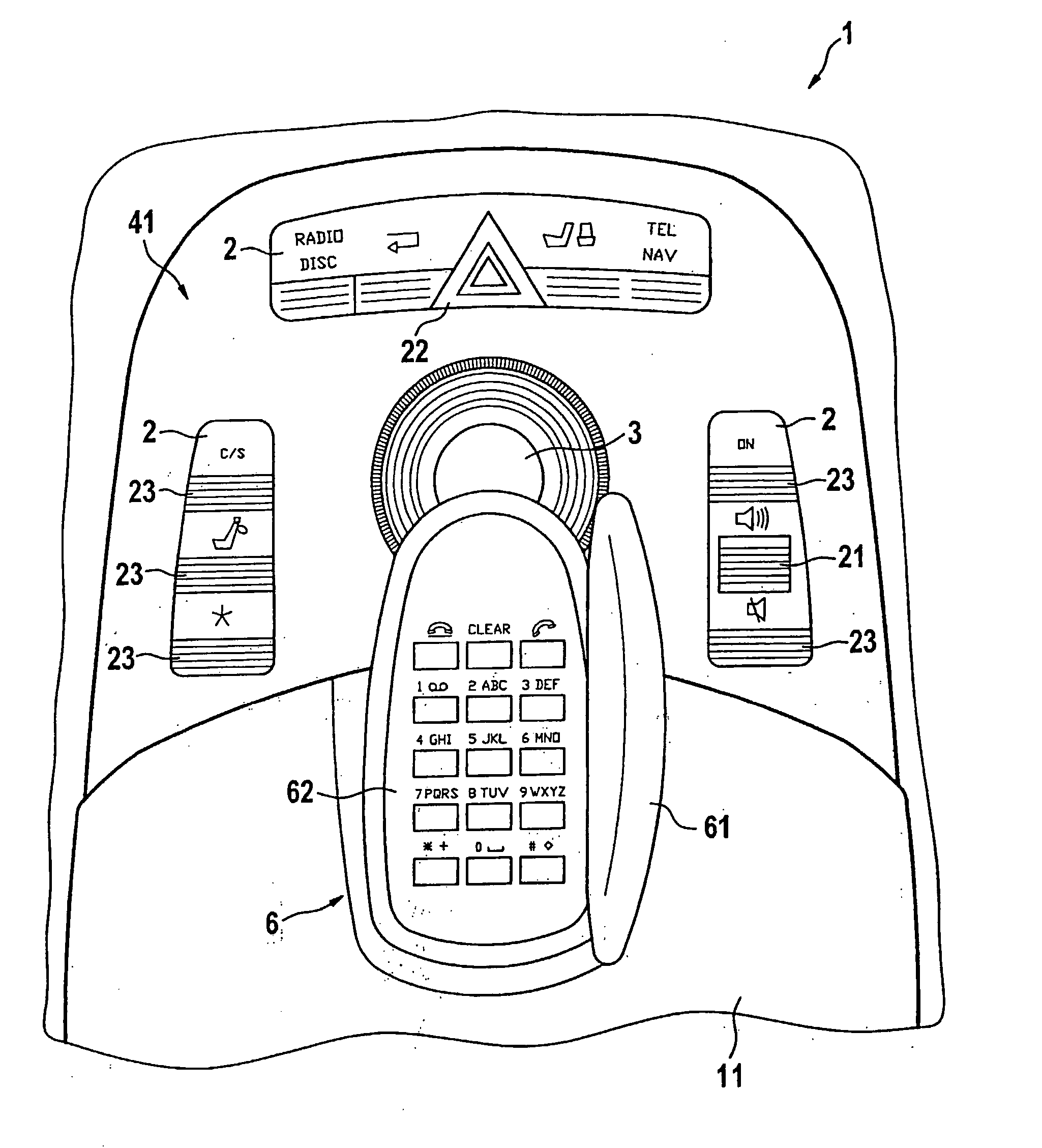

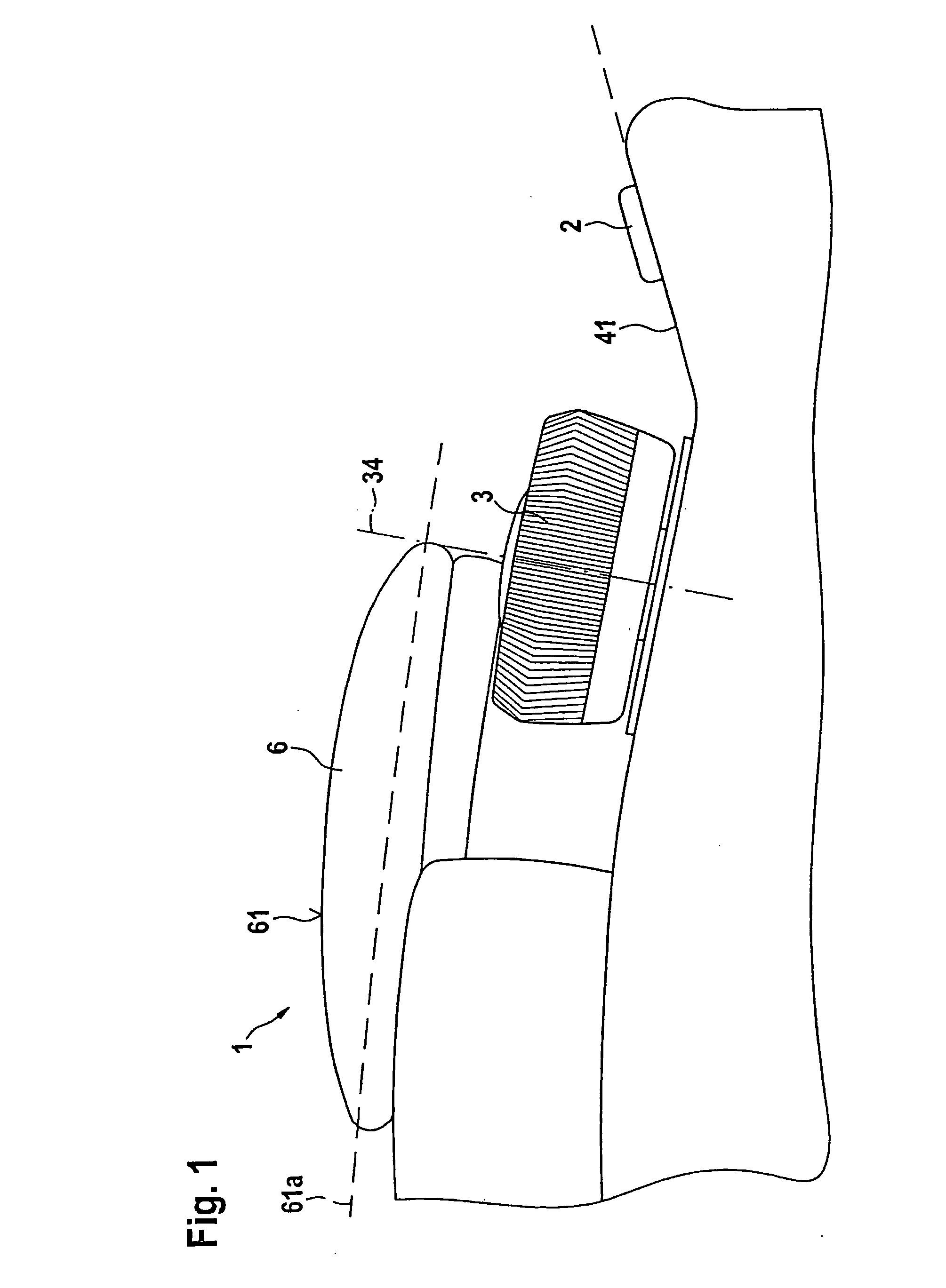

Operational Control for a Vehicle

InactiveUS20070273207A1Increase the number ofPoint is fixedVehicle seatsElectric devicesDriver/operatorEngineering

An operating device for a vehicle has operating elements for operating different electrical equipment such as, for example, a navigation device, an audio system, a heating and / or air conditioning system and / or a telephone. In order to permit the driver of a vehicle to operate such units as conveniently as possible, and to avert his attention as little as possible during driving operation, it is proposed to design the operating device such that the operating device has a support body that prescribes a fixed position of the operating hand and has operating elements in the form of a control wheel and keys surrounding the control wheel. The keys are arranged in an operating plane such that they enclose an obtuse angle with the support surface formed by the support body.

Owner:DAIMLER AG

Earphone single-shaft structure

InactiveUS20140153766A1Great difference in appearanceQuality improvementDeaf-aid setsEarpiece/earphone manufacture/assemblyEngineeringMechanical engineering

Owner:JETVOX ACOUSTIC

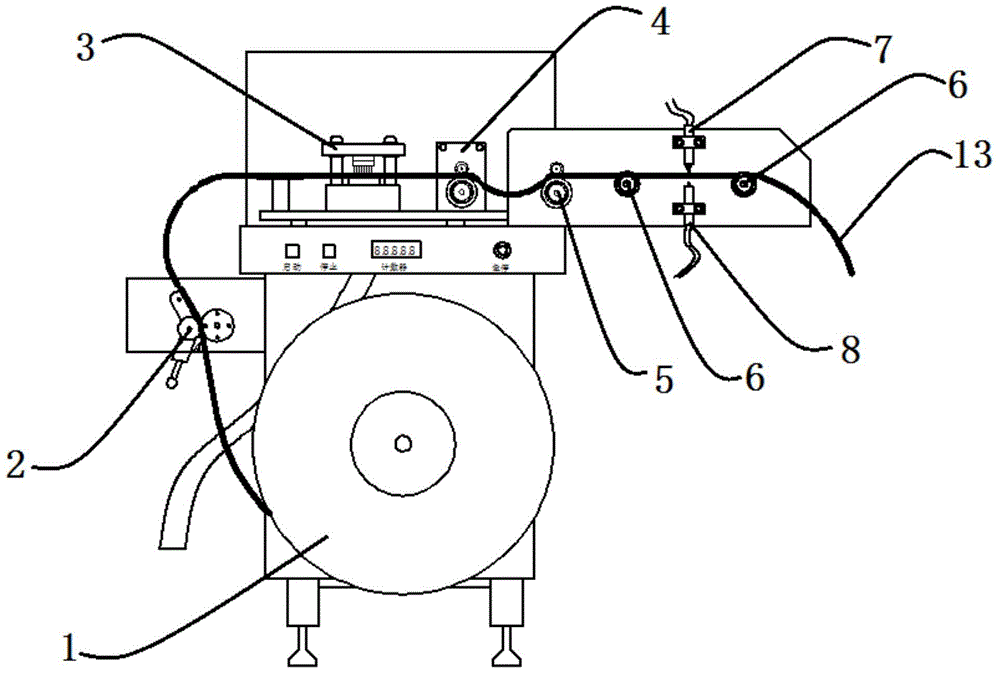

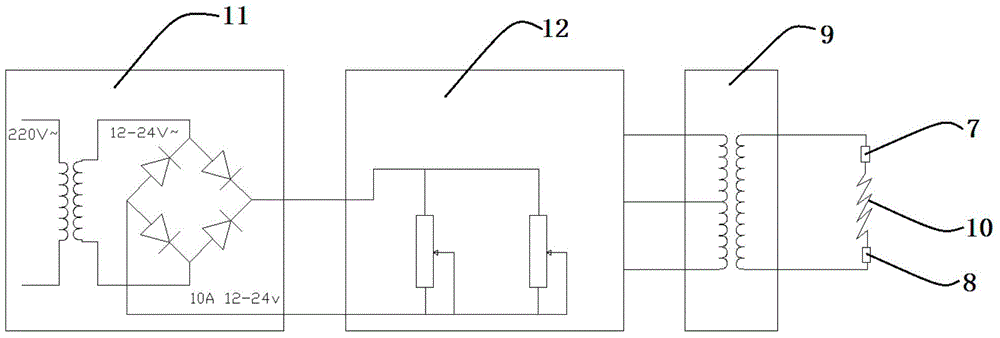

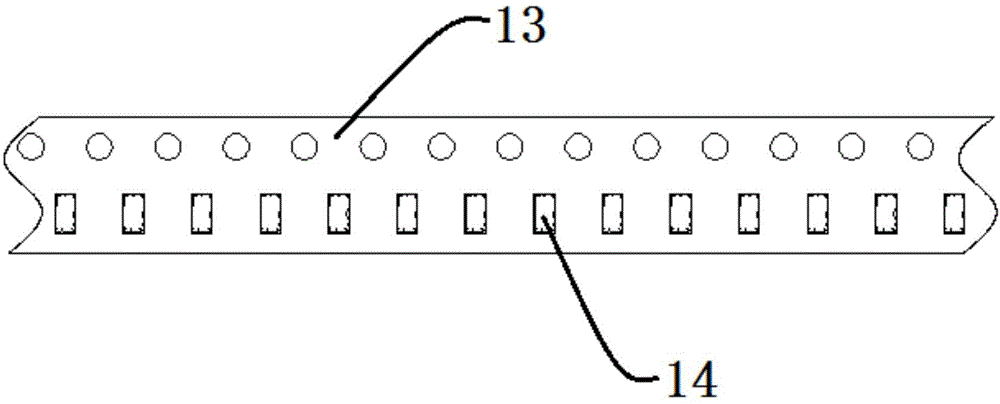

Deburring system and method for paper carrier band

InactiveCN104942880AEnergy concentrationReduce lossMetal working apparatusPunchingLow power dissipation

The invention discloses a deburring system and method for a paper carrier band. The deburring system and method are used in cooperation with a paper carrier band punching device at the same time. The deburring system is characterized by comprising a slicer pulling mechanism, a constant speed feeding mechanism, two discharging supporting wheels of the same height, an anode electrode and a cathode electrode, wherein the slicer pulling mechanism and the constant speed feeding mechanism are sequentially arranged on the rear side of a punching die, and the anode electrode and the cathode electrode are arranged between the two discharging supporting wheels. Meanwhile, the anode electrode and the cathode electrode are symmetrically fixed above the below a paper carrier band conducting constant speed discharging respectively. The anode electrode and the cathode electrode are connected through a high voltage pack, and an electric arc is formed in a hole punched in the paper carrier band. The deburring system and method have the advantages that the technology method is simple, power consumption is lowered, the environment is improved, the product quality is improved, and the deburring efficiency is improved.

Owner:张宝宝

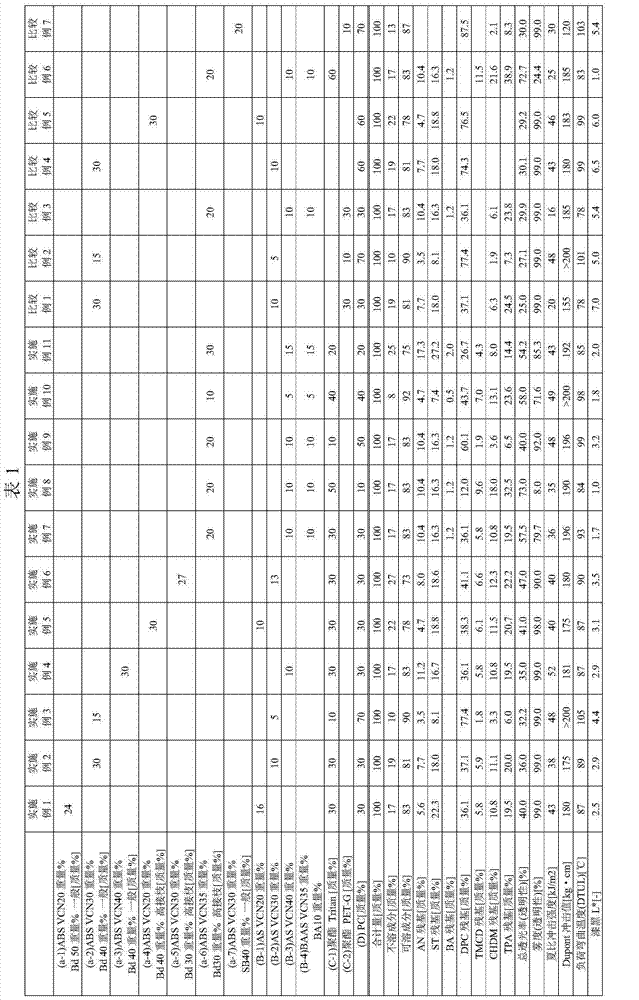

Thermoplastic resin composition and molded product thereof

A thermoplastic resin composition comprising (A) a graft copolymer produced by grafting at least one monomer selected from the group consisting of an aromatic vinyl monomer, a vinyl cyanide monomer and other copolymerizable monomers onto a rubbery polymer, (B) a polymer produced by polymerizing at least one monomer selected from the group consisting of an aromatic vinyl monomer, a vinyl cyanide monomer and other copolymerizable monomers, (C) an amorphous polyester and (D) an aromatic polycarbonate, wherein the component (C) contains diol components, and wherein a 2,2,4,4-tetramethyl-1,3-cyclobutanediol (TMCD) residue and a 1,4-cyclohexanedimethanol (CHDM) residue are contained in amounts of 10 to 70 mol% and 30 to 90 mol%, respectively, relative to the total molar percentage, i.e., 100 mol%, of the diol components.

Owner:NIPPON A & L INC

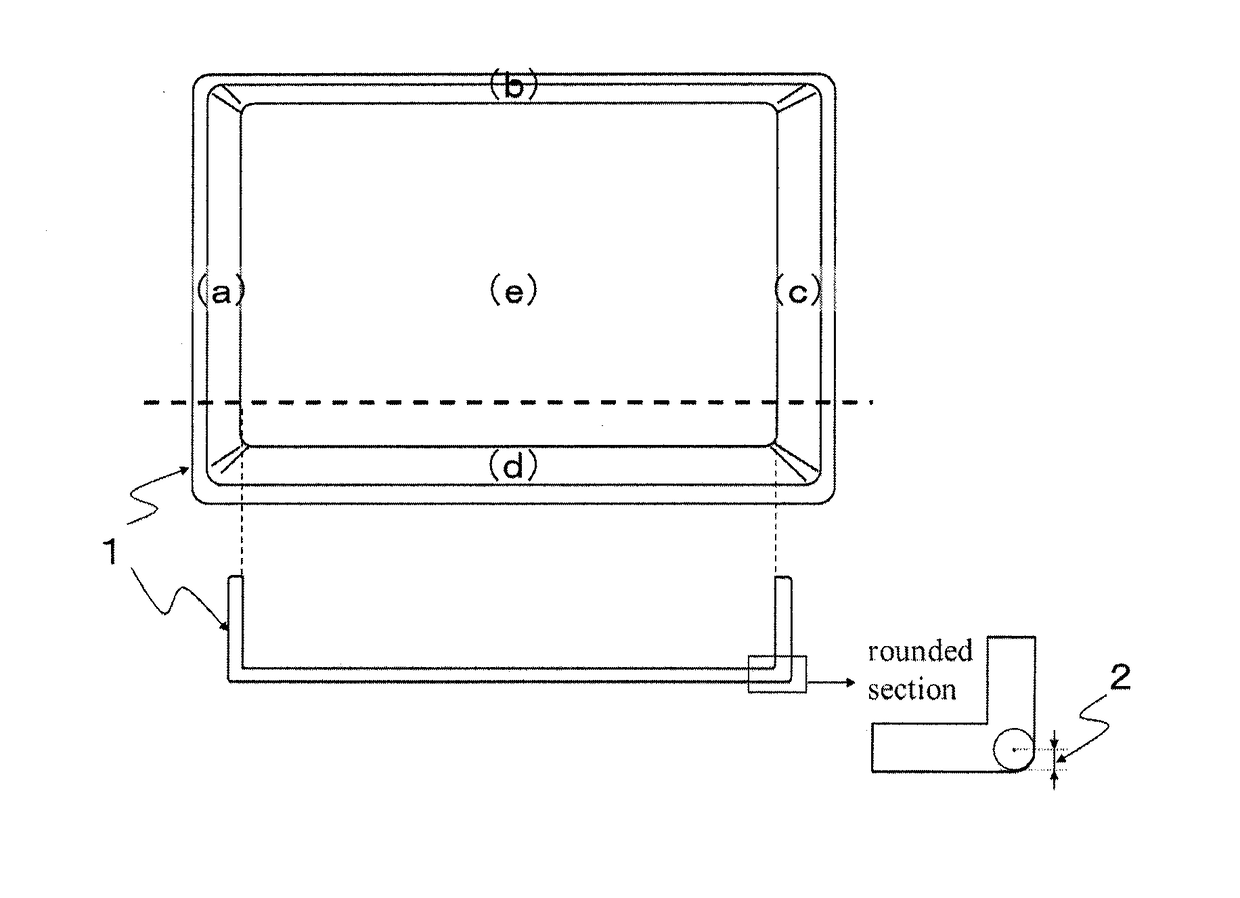

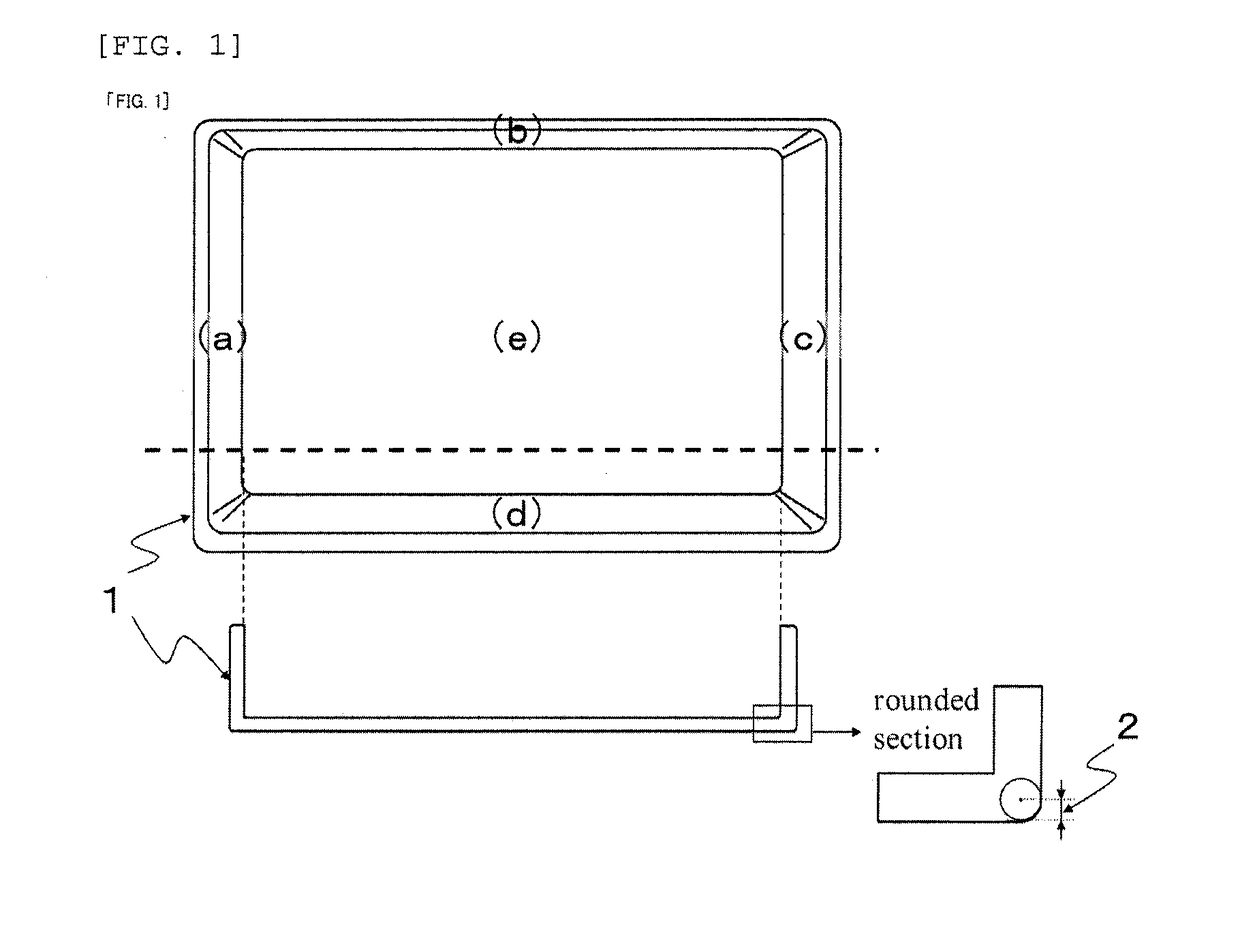

Method for producing back plate of liquid crystal television

InactiveCN103203310AGood lookingHigh quality appearancePretreated surfacesCoatingsProduction lineStrip steel

The invention relates to the field of color-coated steel sheet production, and particularly to a method for producing a back plate of a liquid crystal television. The method is characterized in that the raw steel material is required to be deep-draw steel at DX53D+Z or above; the surface is required to reach the quality standard of FB level or above; and started with the process control adjustment of pre-treatment, coating and packaging, curing, cooling procedures and coiling technology in the production process, the method for producing the back plate of the liquid crystal television comprises the specific control steps of: 1) carrying out the pre-treatment process, including, pre-degreasing, pre-cleaning, pre-rinsing, and controlling a speed of a production line within 50-70 m / min; 2) passivating, and coating primer and finish paint on the front side of the product and back paint of a product; 3) drying and curing at 18-226 DEC G; 4) cooling strip steel; and 5) using a paper sleeve when coiling the strip steel on line. Compared with the prior art, the method for producing the back plate of the liquid crystal television has the beneficial effects of realizing the quality characteristic requirements of the back plate of the liquid crystal television, and realizing production of a back plate of a liquid crystal television with a good appearance and excellent performances through a color coating technology.

Owner:ANGANG STEEL CO LTD

Nonwoven Fabric For Artificial Leather And Process For Producing Artificial Leather Substrate

ActiveUS20080163469A1Avoid damageImproved shape stabilityDomestic upholsteryPattern makingPunchingNonwoven fabric

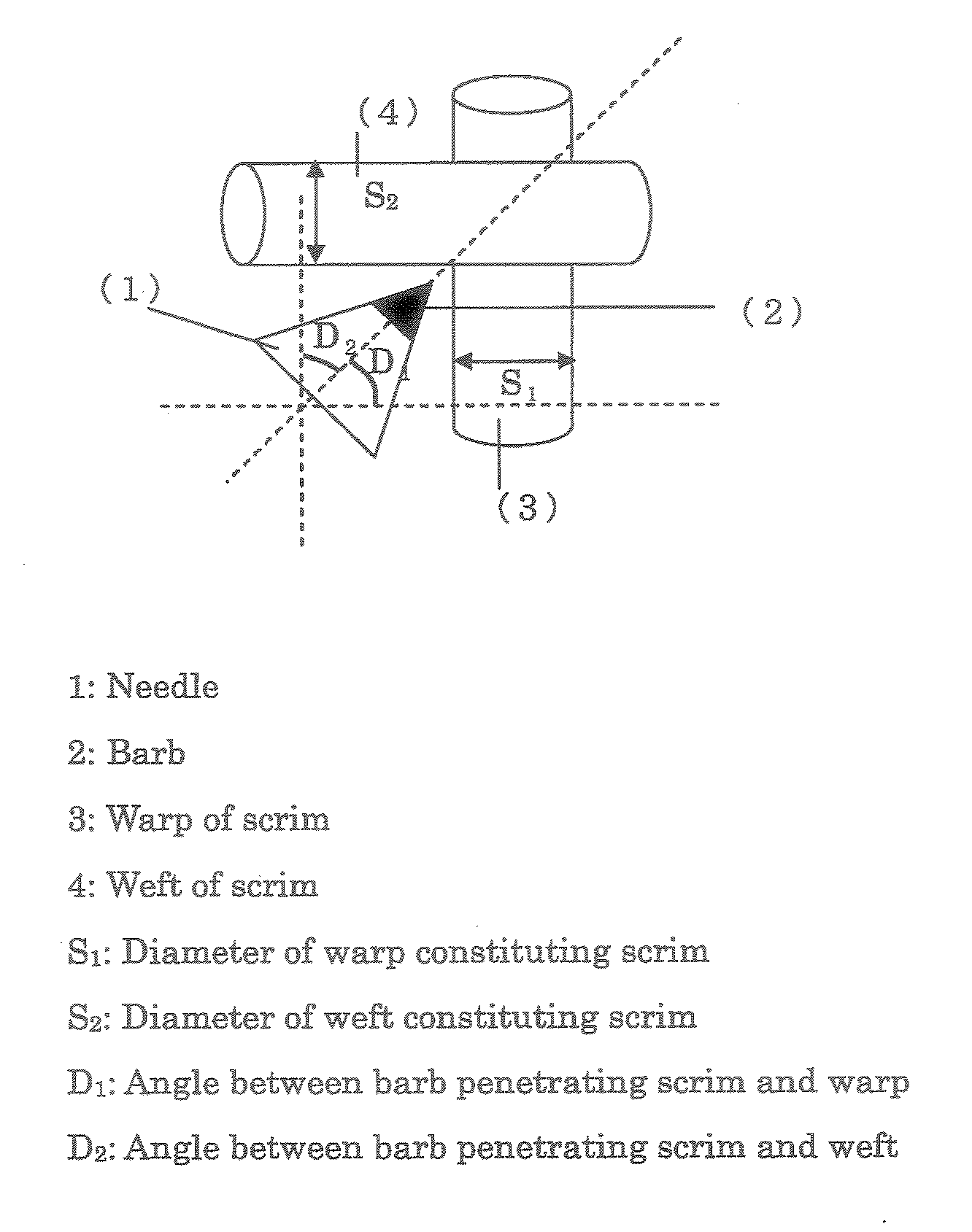

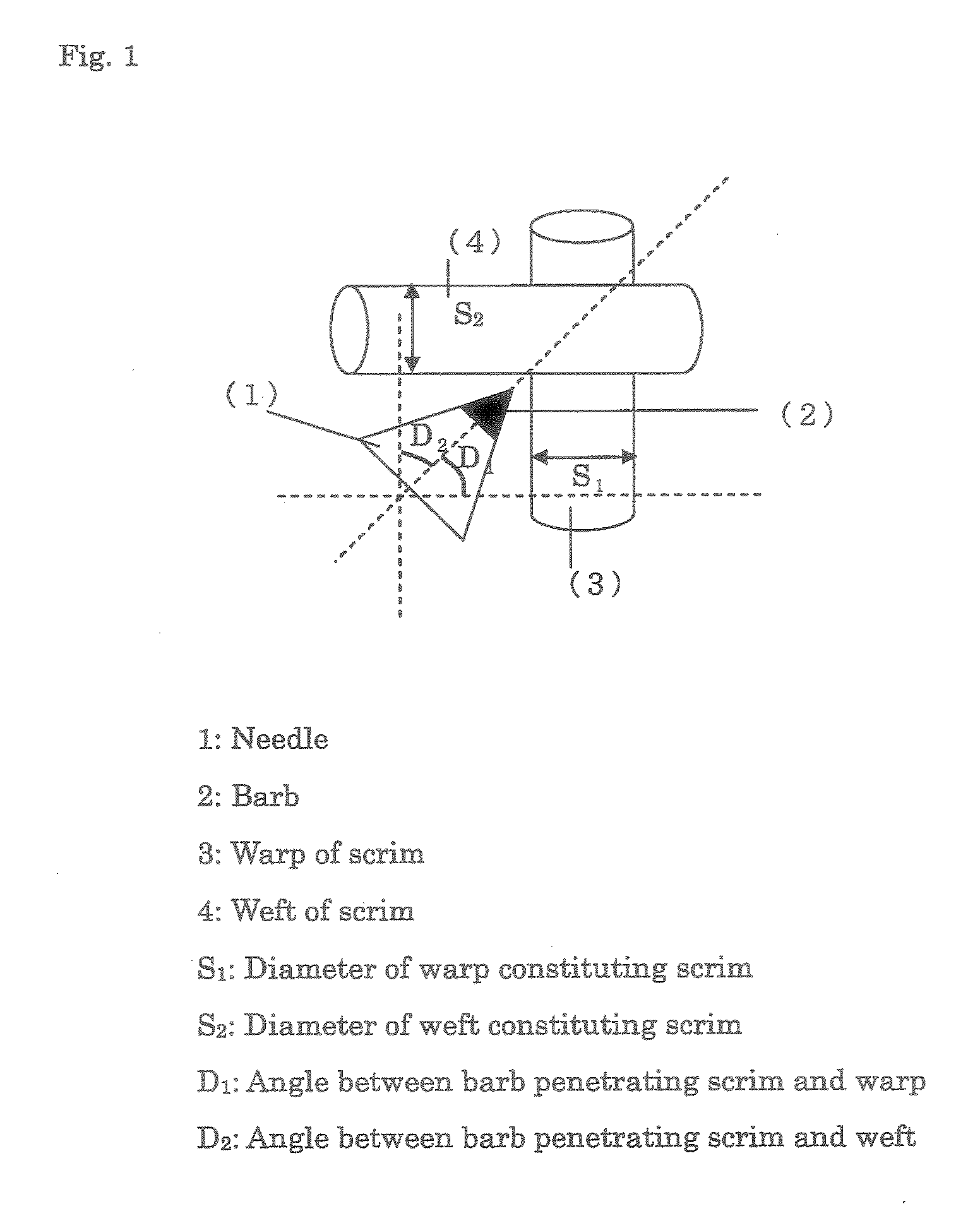

Problem to be Solved To provide a method of producing a nonwoven fabric for artificial leather and substrate for artificial leather which is capable of providing the substrate for artificial leather having a sufficient shape stability by producing the nonwoven fabric for artificial leather without causing serious damages to the scrim.Means for Solving Problem A method of producing a nonwoven fabric for artificial leather, including a step of entanglement for uniting superposed fiber web and scrim by a needle punching, wherein the needle punching is performed in a manner satisfying the following formulae 1 and 2;S1<2P≦S1 / cos(D1×(π / 180)) (1)S2<2P≦S2 / cos(D2×(π / 180)) (2)wherein S1 is a diameter of warps constituting the scrim, S2 is a diameter of wefts constituting the scrim, D1 is an angle between the warps and barbs which penetrate the scrim, D2 is an angle between the wefts and barbs which penetrate the scrim, and P is a total barb depth of the barbs.

Owner:KURARAY CO LTD

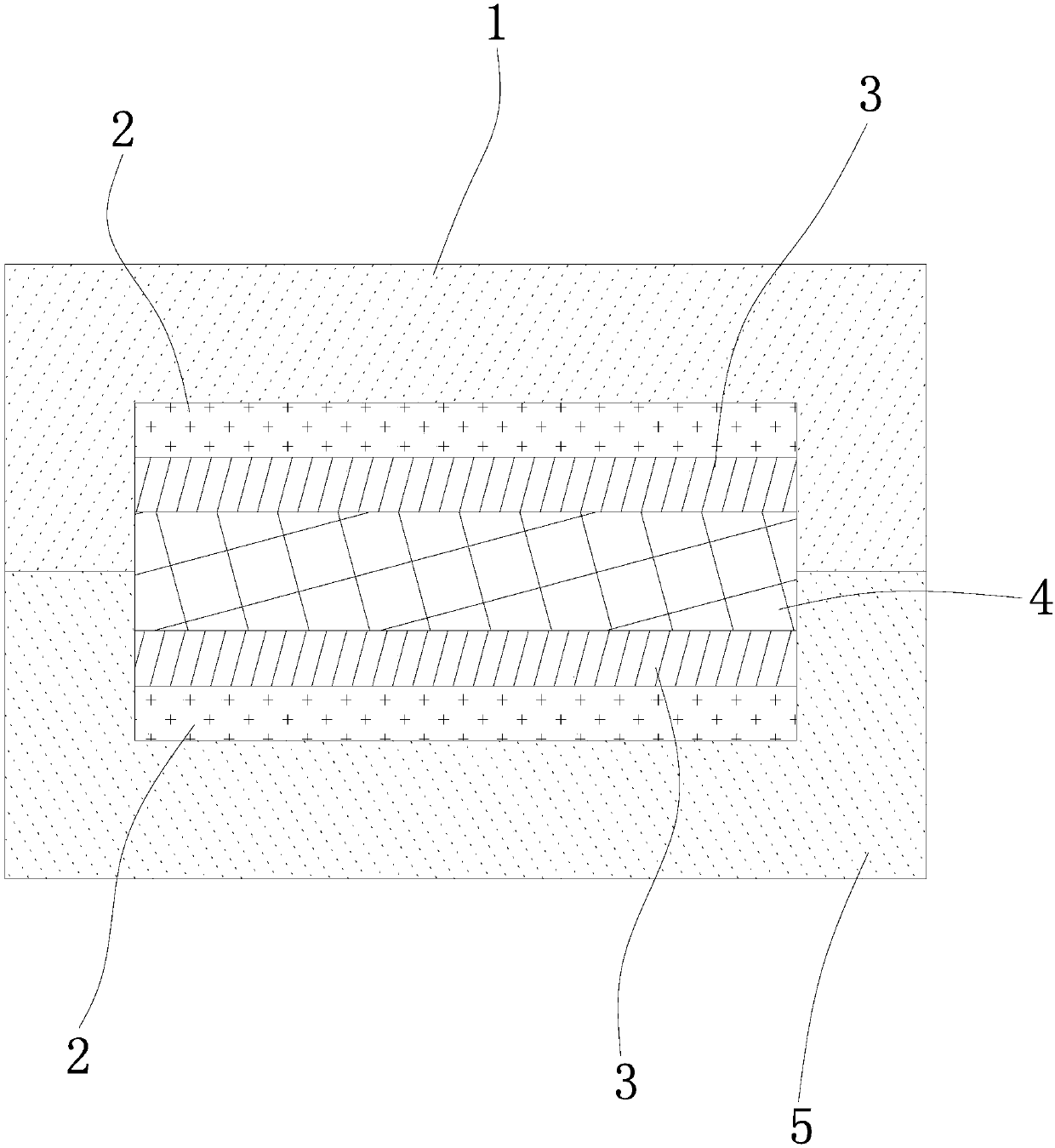

Preparation method of lightweight and high-strength high-energy glue-rigid foam composite material structure

The invention discloses a preparation method of a lightweight and high-strength high-energy glue-rigid foam composite material structure. The preparation method comprises the following steps: cuttinghigh-energy glue, fiber pre-soaking cloth and rigid foam; wrapping the rigid foam with the high-energy glue and wrapping the high-energy glue with the fiber pre-soaking cloth; putting the obtained pre-formed product into a mold, closing the mold and covering tightly, and heating the mold at 100 to 200 DEG C for 10 to 60 minutes, so that the high-energy glue in the product is heated to generate anexpanding force from inside to outside and the fiber pre-soaking cloth is solidified and formed at high temperature; and performing cooling operation on the formed mold and opening the mold to take out the high-energy glue-rigid foam composite material structure, wherein the maximal expanding strength of the high-energy glue in the heating expansion process is less than or equal to the compressivestrength of the rigid foam subjected to 10 percent of compressive deformation. The high-energy glue-rigid foam composite material structure has lightweight and high-strength effects, and can be applied in the fields of aerospace, new-energy automobiles and the like which need the lightweight and high-strength composite materials.

Owner:XIAMEN HOWER MATERIAL

Creamy o/w emulsion composition and production process thereof

ActiveUS20110112045A1Improve emulsion stabilityEffective displayBiocideCosmetic preparationsEmulsionAlcohol

A major object of the present invention is to provide a creamy O / W emulsion composition containing an adenosine phosphate ester, more specifically, to provide a creamy O / W emulsion composition containing an adenosine phosphate ester, which ensures emulsification stability and a superior feel during use. Specifically, the present invention provides a creamy O / W emulsion composition containing the following Components (A) to (F) at the following proportions based on its total amount:(A) not less than 0.1 wt. % of adenosine phosphate ester selected from at least one member selected from the group consisting of cyclic adenosine 3′,5′-monophosphate, adenosine monophosphate, adenosine diphosphate, adenosine triphosphate, and salts thereof;(B) 0.5 to 6 wt. % of polyglycerin fatty acid ester;(C) 0.05 to 0.7 wt. % of acrylic acid-alkyl methacrylate copolymer;(D) 0.5 to 10 wt. % of amphiphilic lipid;(E) 0.5 to 20 wt. % of polyhydric alcohol; and(F) 0.3 to 5 wt. % of self-emulsifiable glycerin fatty acid ester.

Owner:OTSUKA PHARM CO LTD

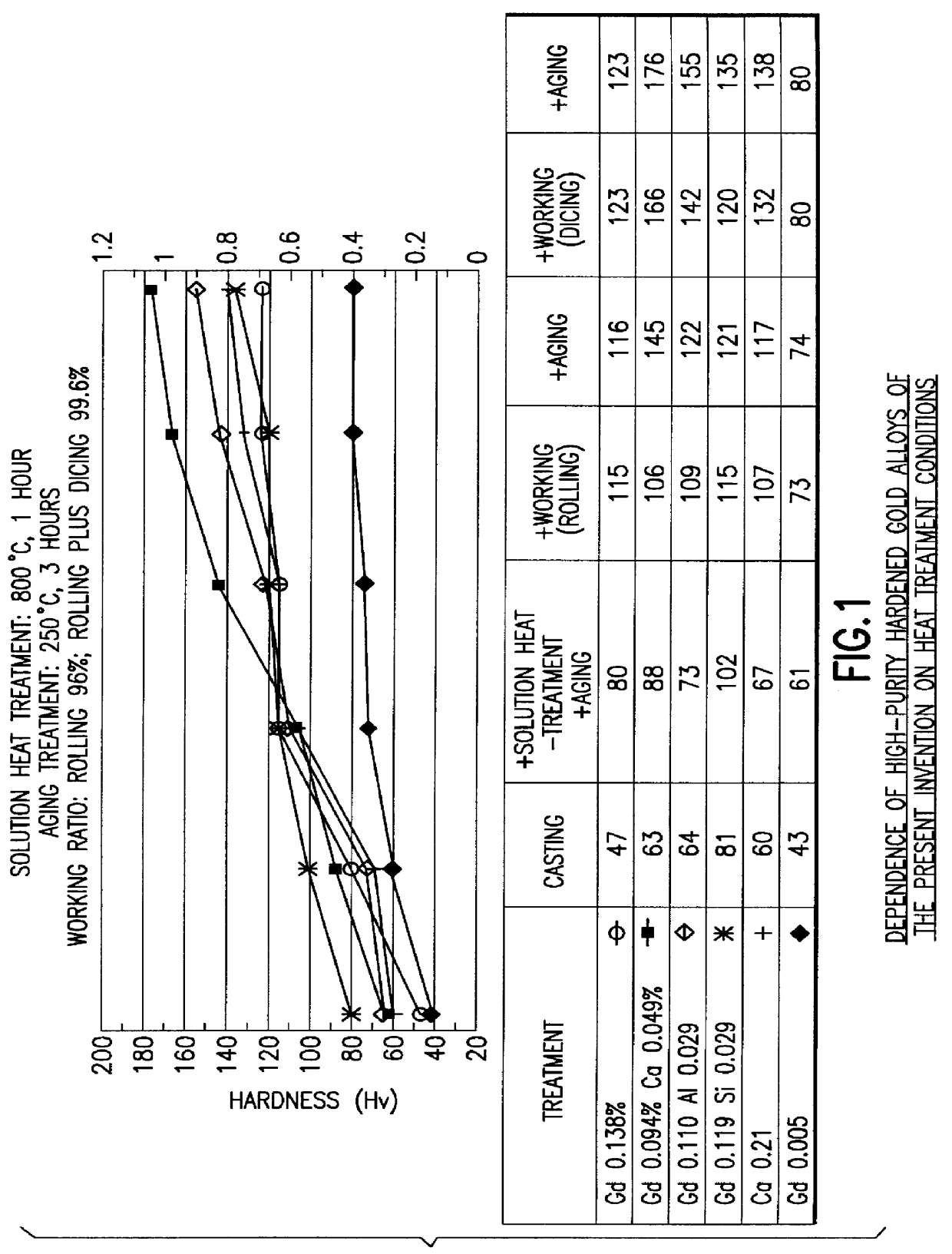

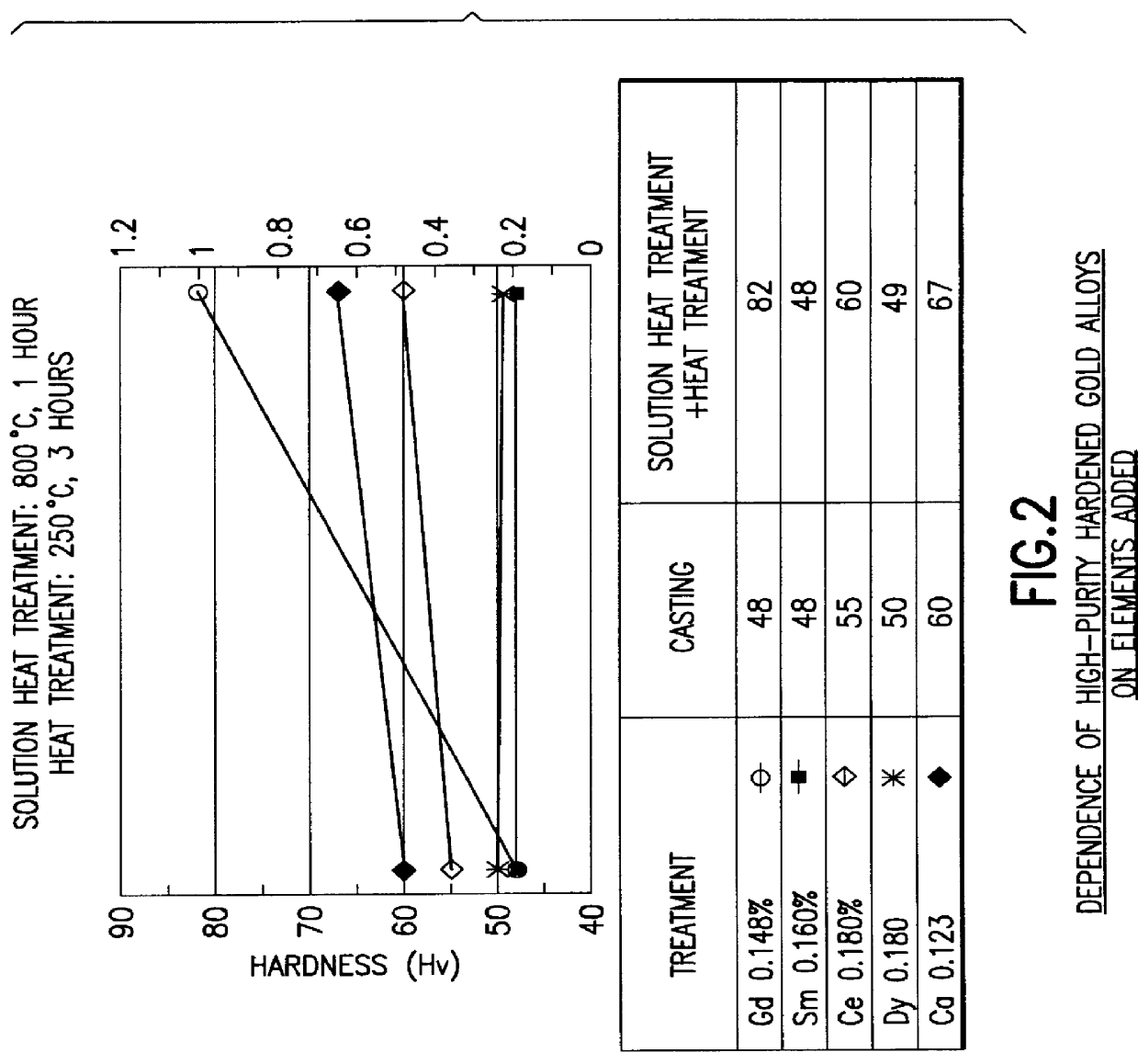

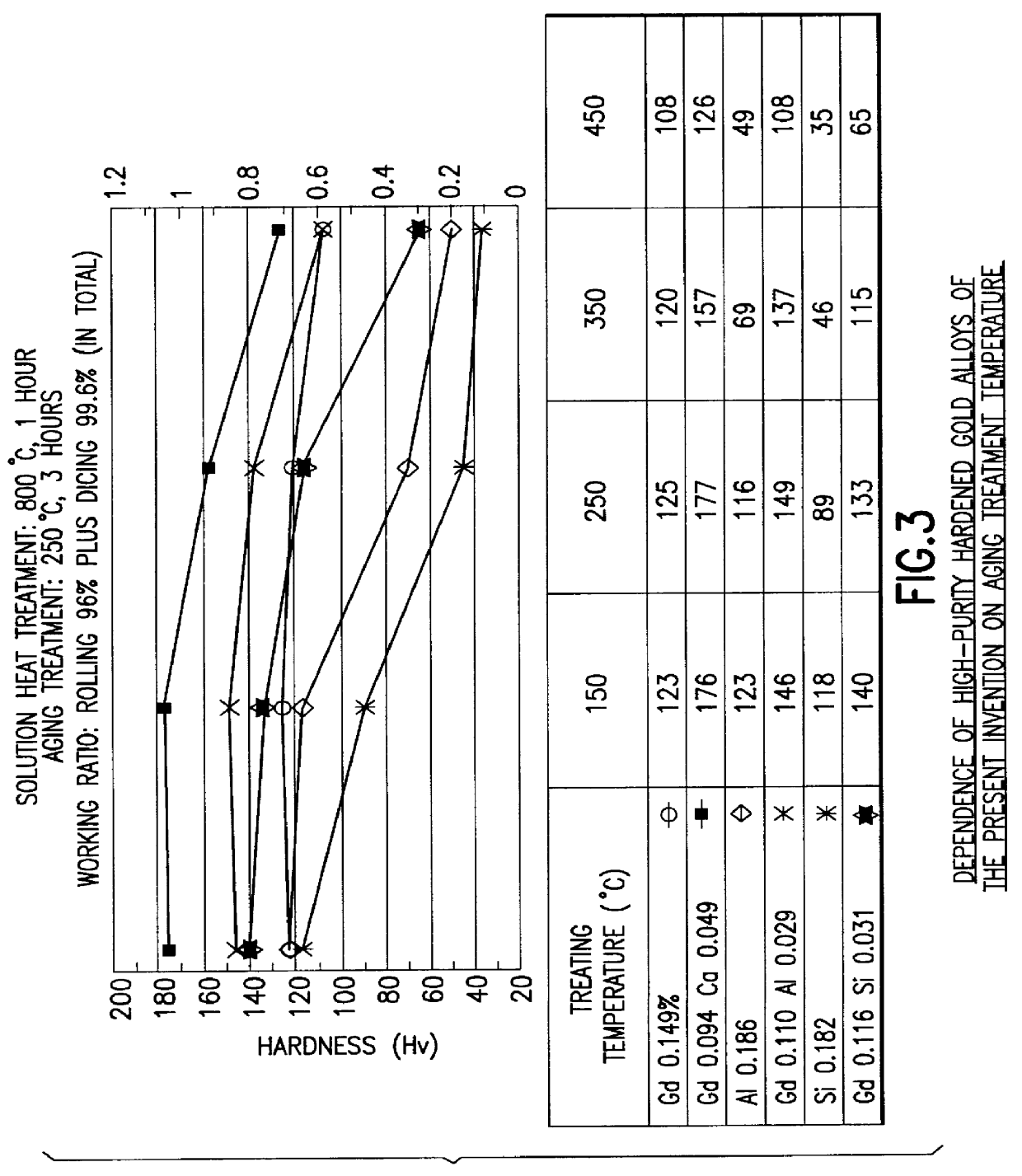

High-purity hardened gold alloy and a process of producing the same

A high-purity hard gold alloy containing 50 ppm or more of Gd and one or more of other additional elements in Au having a purity of 99.7% by weight or more, such that a total content of the additional elements is 100 to 3000 ppm. The high-purity gold alloy can be hardened to a level approximately equivalent to that of 18-karat gold at a relatively low working ratio, and the high-purity gold alloy thus hardened is not extremely softened by a heat treatment performed as a post-treatment, such as brazing or welding.

Owner:OGASA KAZUO

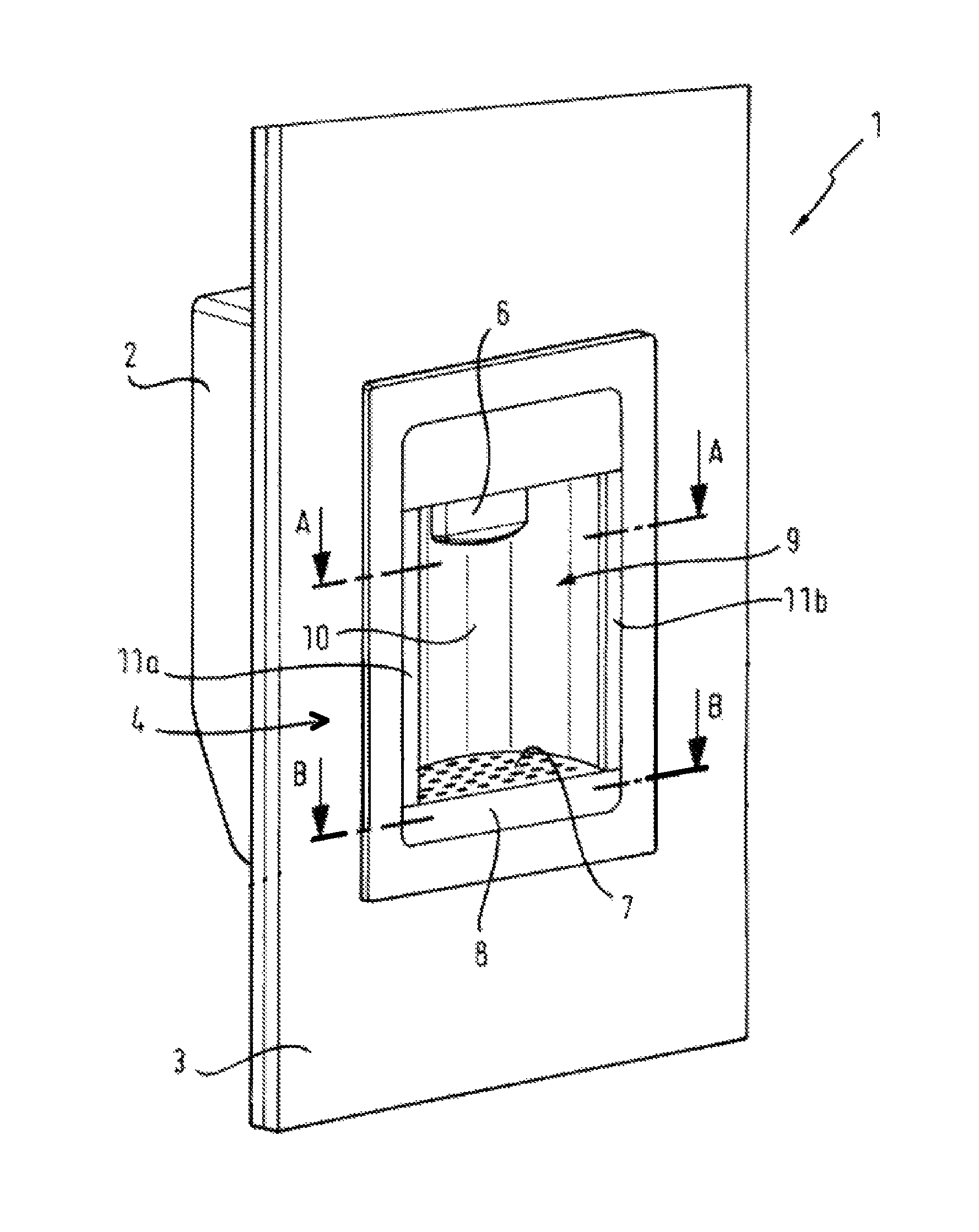

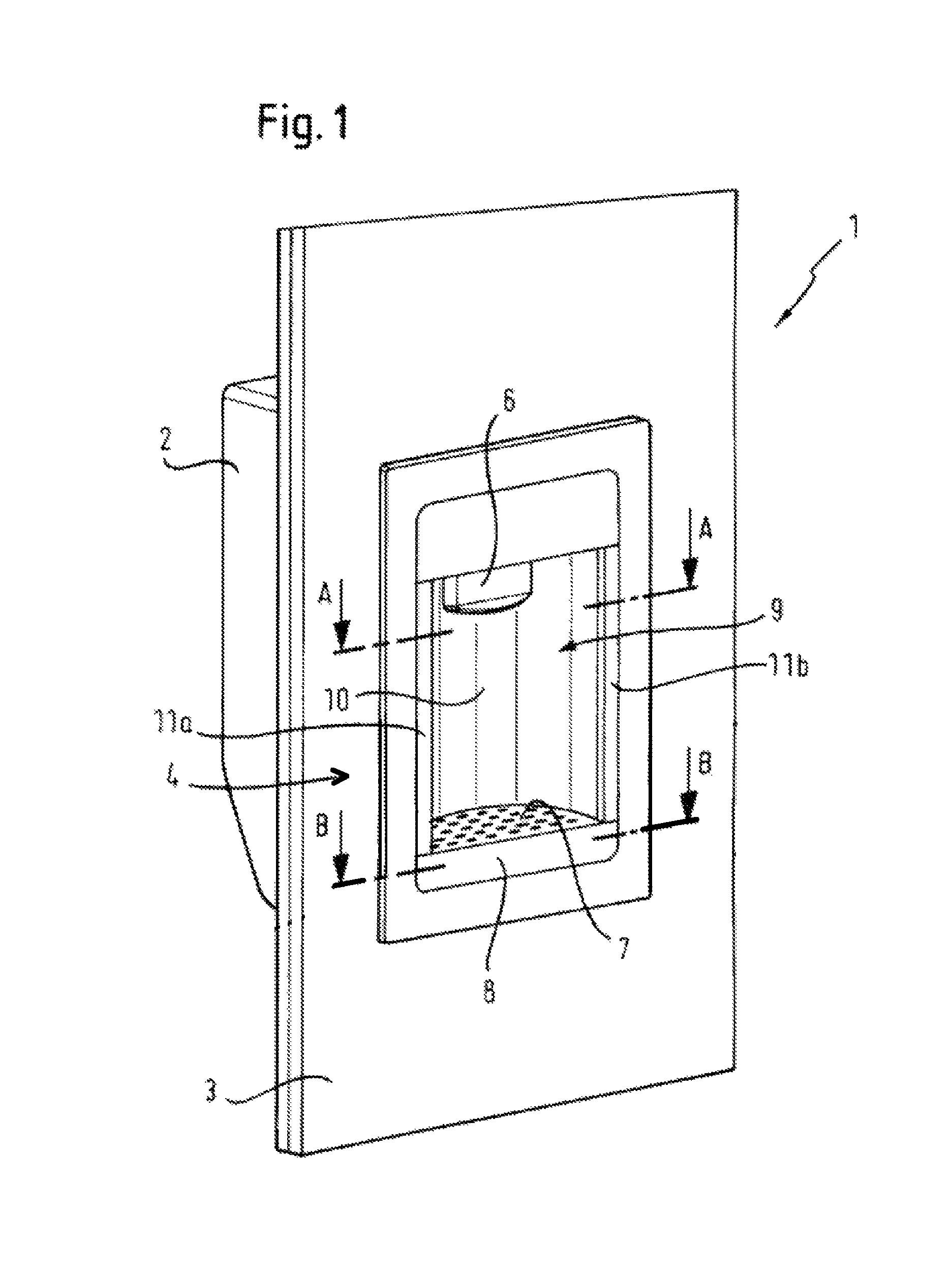

Output unit of a refrigeration device, refrigeration device and method for installing a refrigeration device

InactiveUS8966927B2Stable positionCompensate for manufacturing tolerancesDomestic cooling apparatusLighting and heating apparatusEngineeringRefrigeration

An output unit of a refrigeration device having a niche with a rear wall, which is provided with a cover, and a method of installing the output unit. The cover includes a dish-shaped section, which is curved inward into the niche and bounded by opposite edge sections, which are connected with a niche frame. In an exemplary embodiment of the invention, the edge sections at front supporting surfaces of the niche frame are held in contact in an installation end position, wherein the dish-shaped section is pulled by fastening means against the rear wall of the niche. By these means, it is ensured that the narrowest or most uniform gap possible between the cover and the place of installation is guaranteed and, in addition, fastening means are not visible to the user.

Owner:BSH BOSCH & SIEMENS HAUSGERAETE GMBH

Sheet of inner lattice of chamois imitation and similar leather, and its mfg. method

The suede-finished leather-like sheet of the present invention comprises a fiber-entangled nonwoven fabric comprising a layer (I) made of a microfine fiber (A) having an average fineness of 0.5 dtex or less and a layer (II) made of a microfine fiber (B) having an average fineness equal to or less than that of the microfine fiber (A), and a polymeric elastomer impregnated in the fiber-entangled nonwoven fabric. The layers (I) and (II) are integrated by entanglement such that a ratio of the microfine fiber (A) to the microfine fiber (B) is 10 / 90 to 90 / 10 by mass. The surface of the layer (I) is a napped surface made mainly of a raised microfine fiber (A). The microfine fibers (A) and (B) are respectively formed by converting a microfine fiber-forming fiber (a) and a microfine fiber-forming fiber (b), each having an elongation at break and a tenacity of specific ranges, into microfine fibers. The suede-finished leather-like sheet simultaneously exhibits a soft feel like natural leathers and good mechanical properties, especially good shape stability and tear strength.

Owner:KURARAY CO LTD

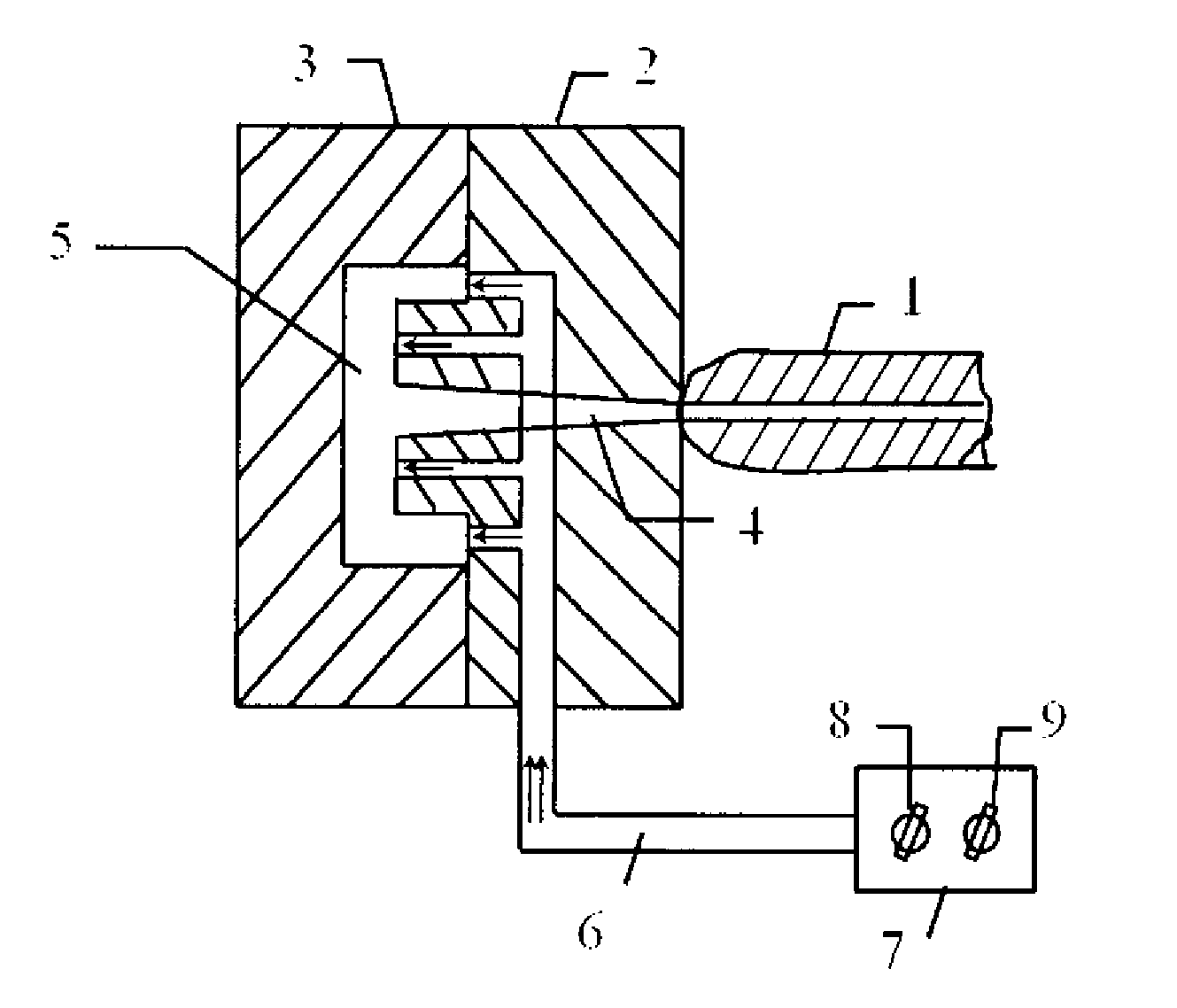

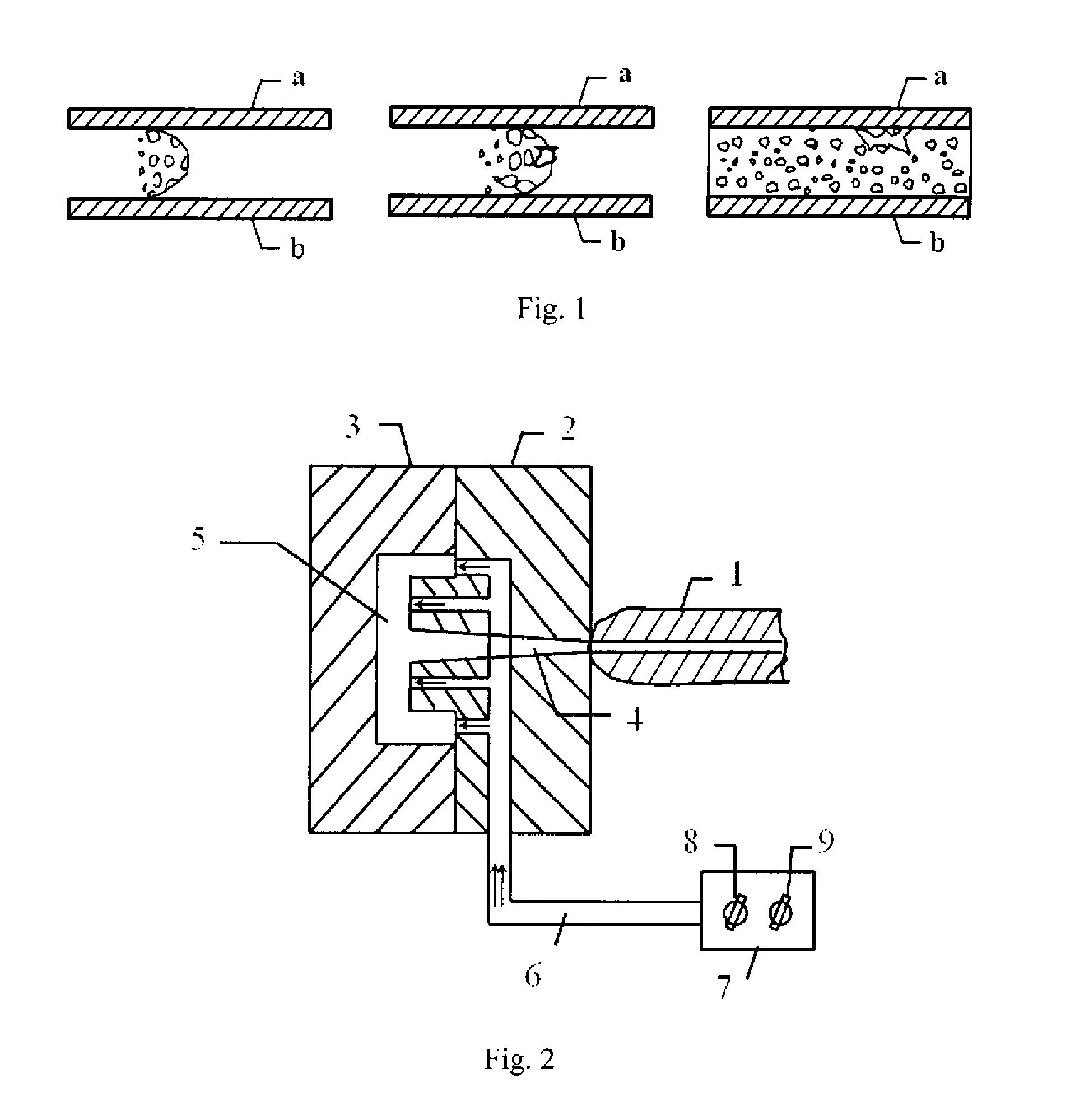

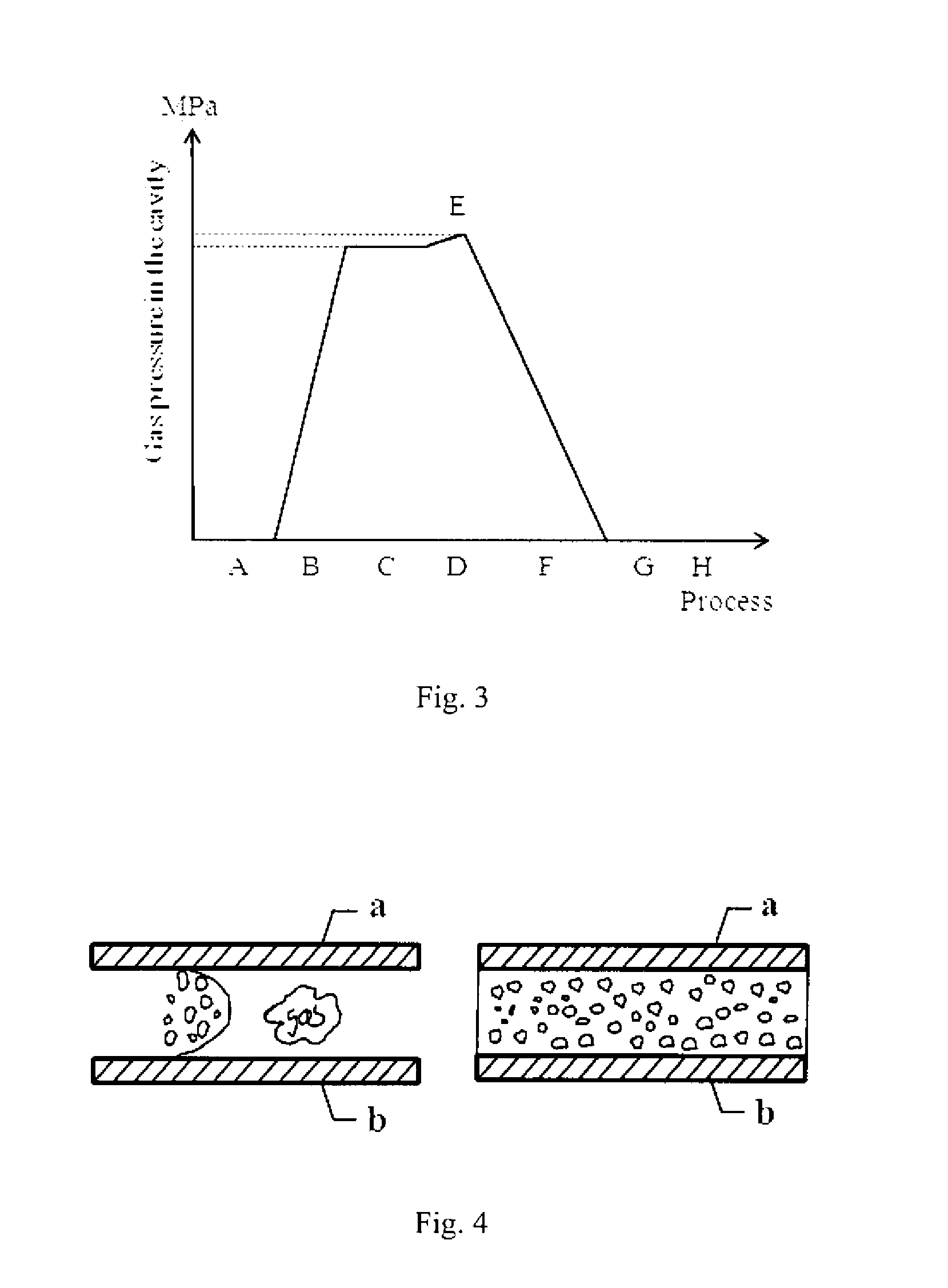

Method Of Improving The Appearance Of Injection Molding And Foaming Product

A method of improving the appearance of foaming injection molding product includes closing the moving mold and the fixed mold and setting a clamping force on the closed mold, wherein a mold cavity is formed between the moving mold and the fixed mold. The method proceeds by inflating the mold cavity with high pressure and high temperature gas until the air pressure in the mold cavity reaches 2-25 MPa and the temperature of the high pressure and high temperature gas is between 60-200° C., then injecting molten resin that contains foaming agent into the mold cavity while continuously inflating high pressure and high temperature gas. After injection completed, stopping inflating high pressure and high temperature gas and simultaneously releasing pressure, wherein the step of releasing pressure includes the step of opening the mold.

Owner:YANFENG AUTOMOTIVE TRIM SYST CO LTD

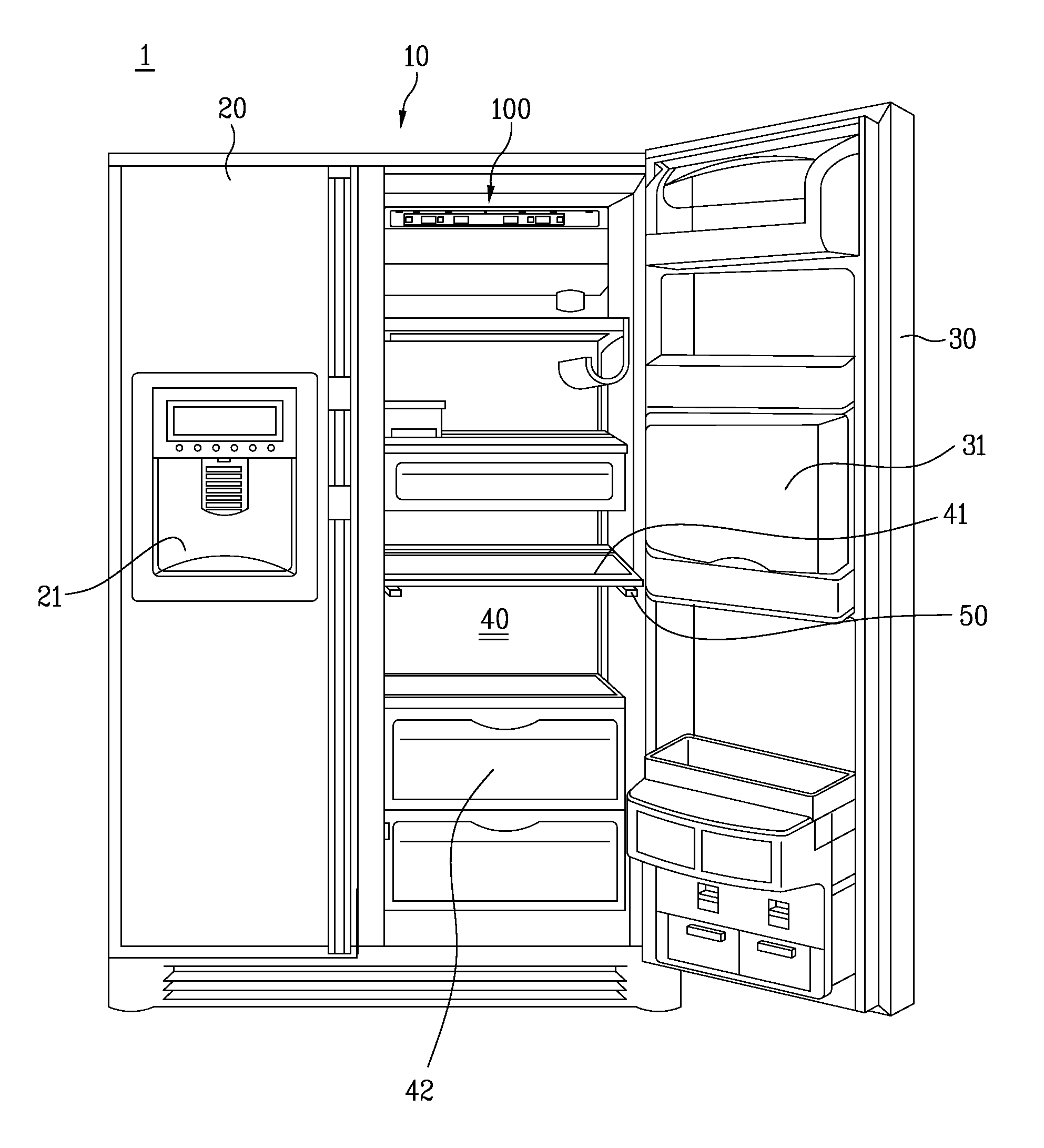

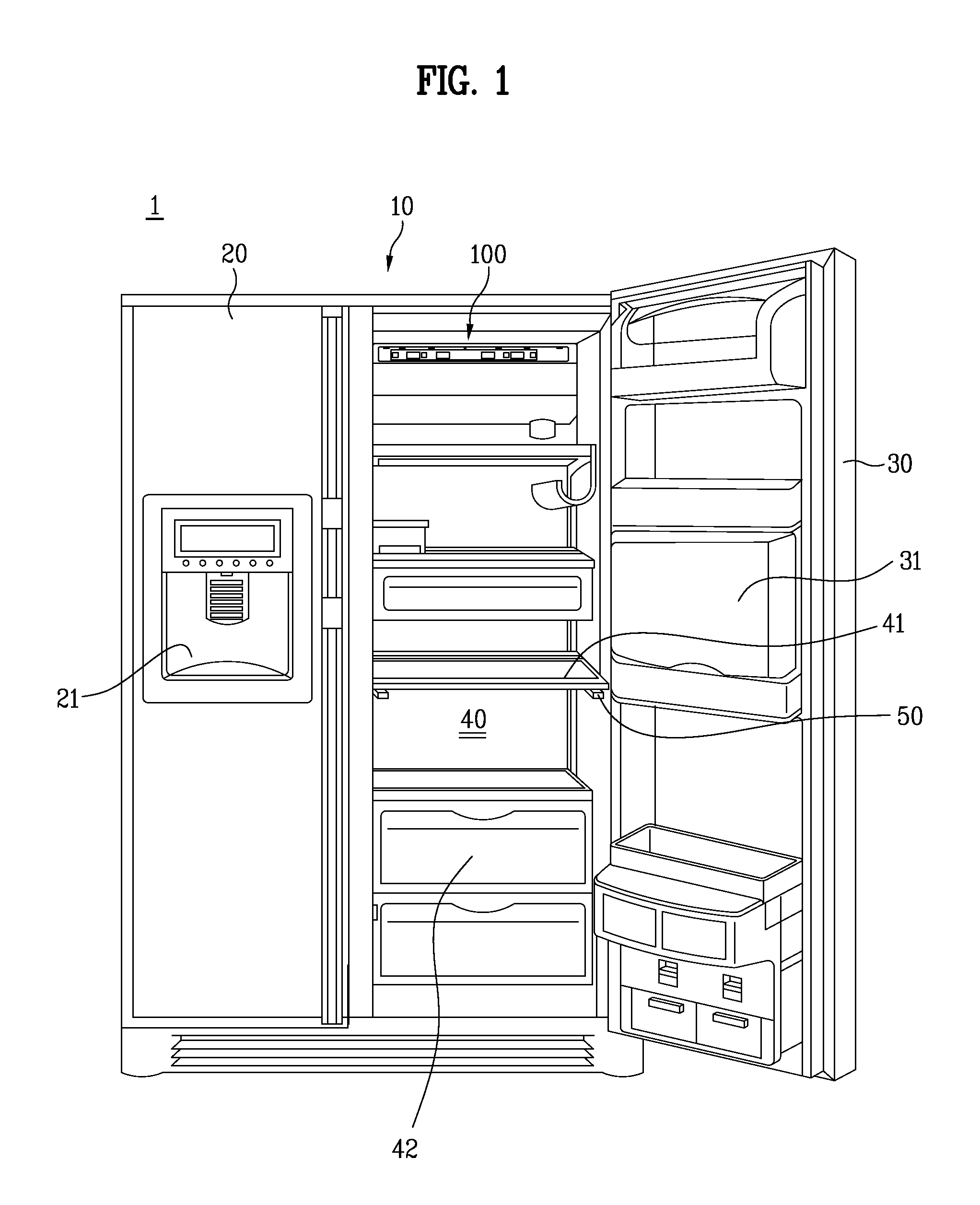

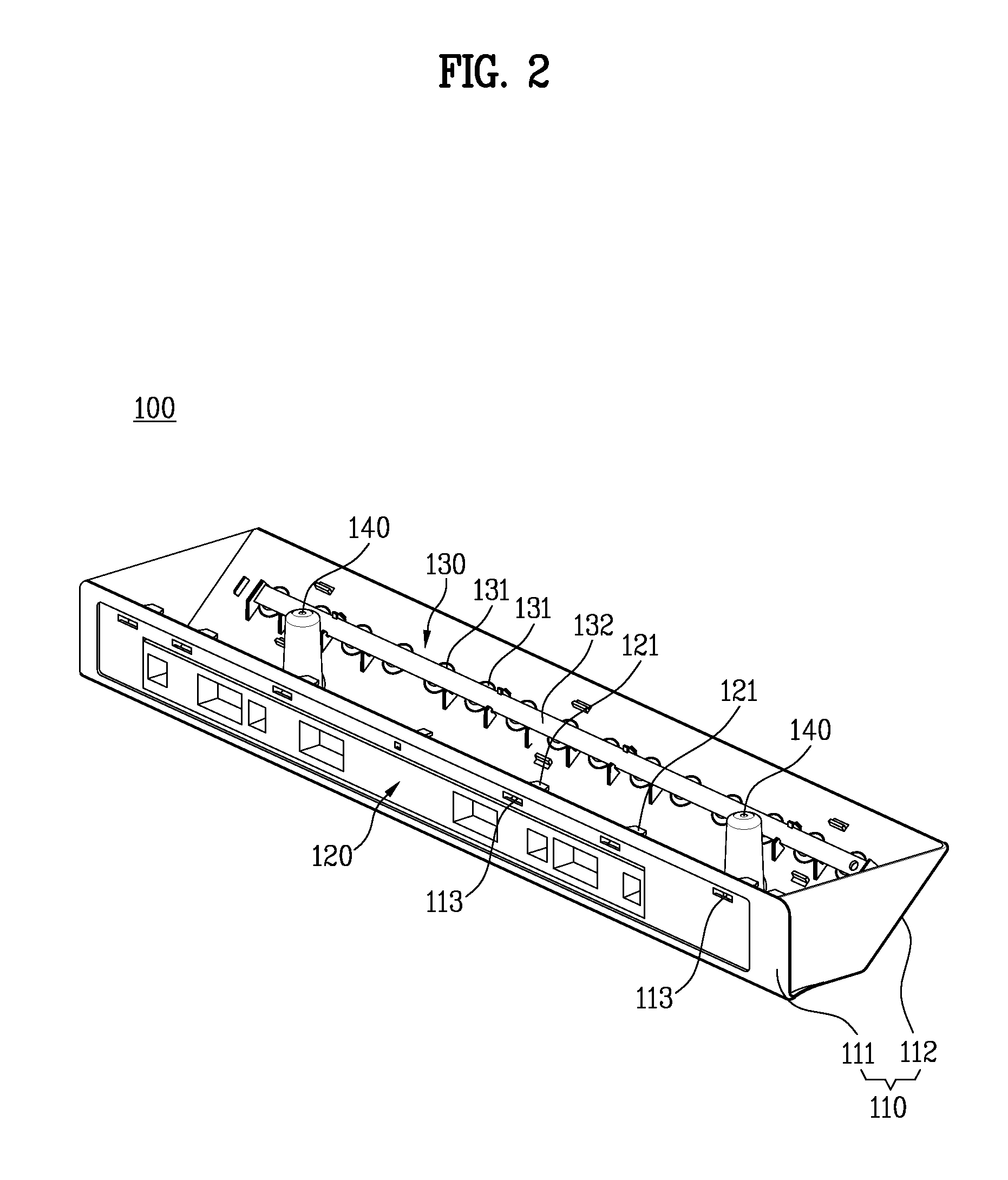

Refrigerator

ActiveUS20120014090A1High quality appearanceFurnace componentsLighting elementsEffect lightEngineering

Owner:LG ELECTRONICS INC

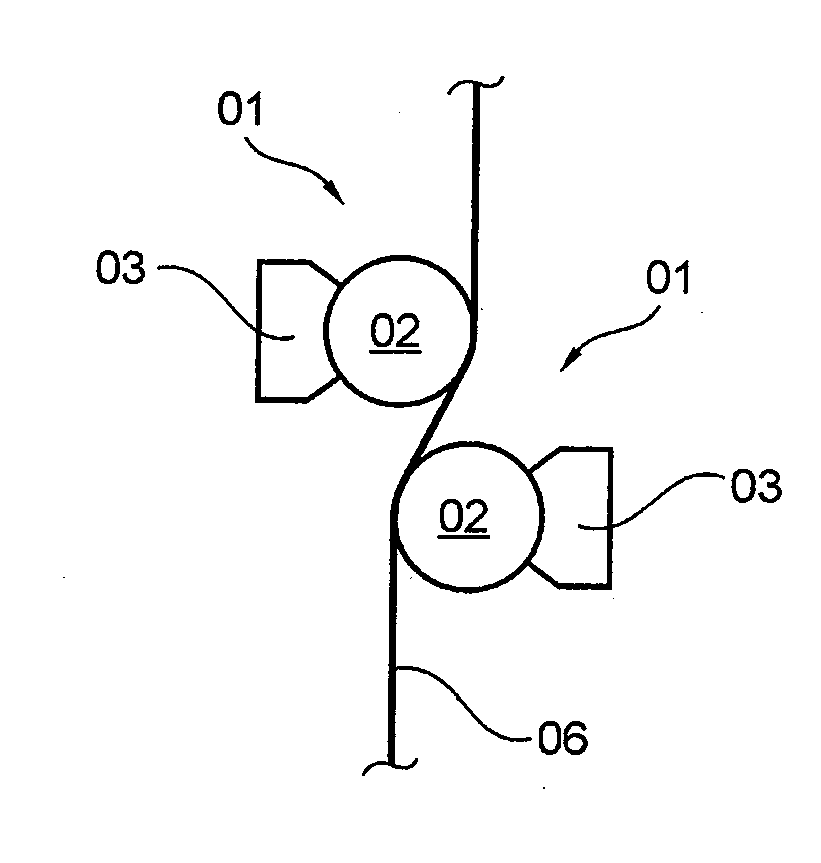

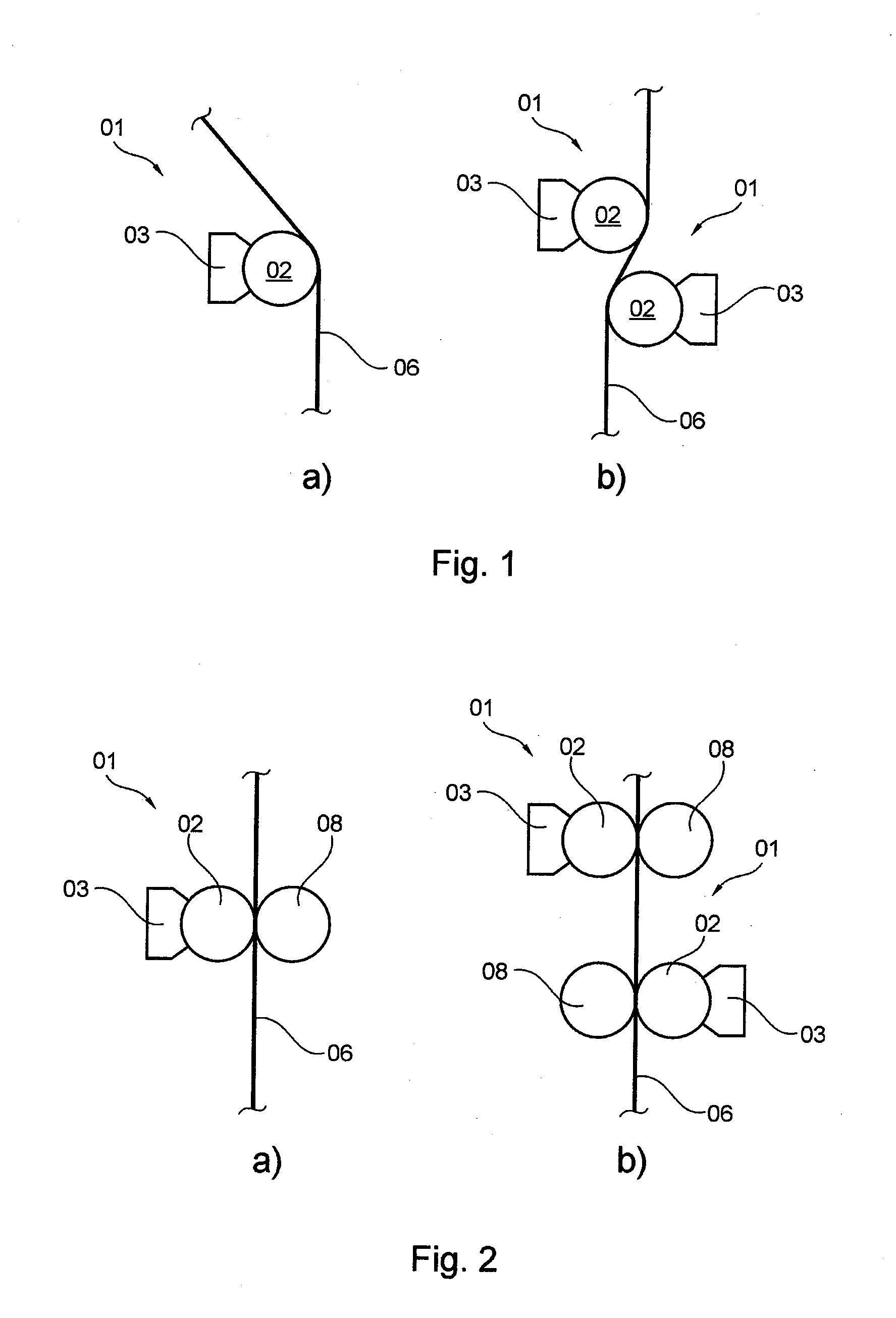

Roller rotary offset printing press having at least one coating unit with a chamber blade and an anilox roller

InactiveUS20120118183A1High quality appearanceIncrease contrastCylinder pressesPlaten pressesWater basedEngineering

A roller rotary offset printing press has at least one coating unit and at least one printing unit. The coating unit comprises at least one coating unit and at least one printing unit. The coating unit comprises at least one chamber blade having a water-based coating and at least one anilox roller. The coating unit is arranged along a transport path of a print stock downstream of the at least one printing unit of the roller rotary offset printing press. At least one pair of two rollers is arranged that together form a coating gap. At least one roller of the at least one pair is in contact with the at least one anilox roller. The conveyed volume, at least on one part of the shell surface of the at least one anilox roller, is filled by an amount of coating, the mass of which, based on this part of the shell surface of the at least one anilox roller, minus a water portion, equals, on average, a maximum of 4 g / m2. A blanket having several layers can be placed or is placed on at least one roller of the coating unit.

Owner:KOENIG & BAUER AG

Propylene-based block copolymer

ActiveUS20160137831A1Improve appearance defectHigh intrinsic viscosityCoatingsPropeneIntrinsic viscosity

An object of the present invention is to prevent an occurrence of flow-mark molding defects to improve an appearance of molded articles, and as a means for achieving the object, a propylene-based block copolymer is used as an appearance improver, the copolymer comprising 80 to 60% by weight of crystalline propylene polymer portion which has an intrinsic viscosity [η]p of 0.90 dL / g or less and 20 to 40% by weight of propylene / ethylene random copolymer portion which has an ethylene content of 35 to 50% by weight and an intrinsic viscosity [η]c of 7.0 dL / g or higher ([η]c / [η]p being 7.5 to 30), in which the propylene-based block copolymer has a MFR of 10 to 50 g / 10 min.

Owner:JAPAN POLYPROPYLENE CORP

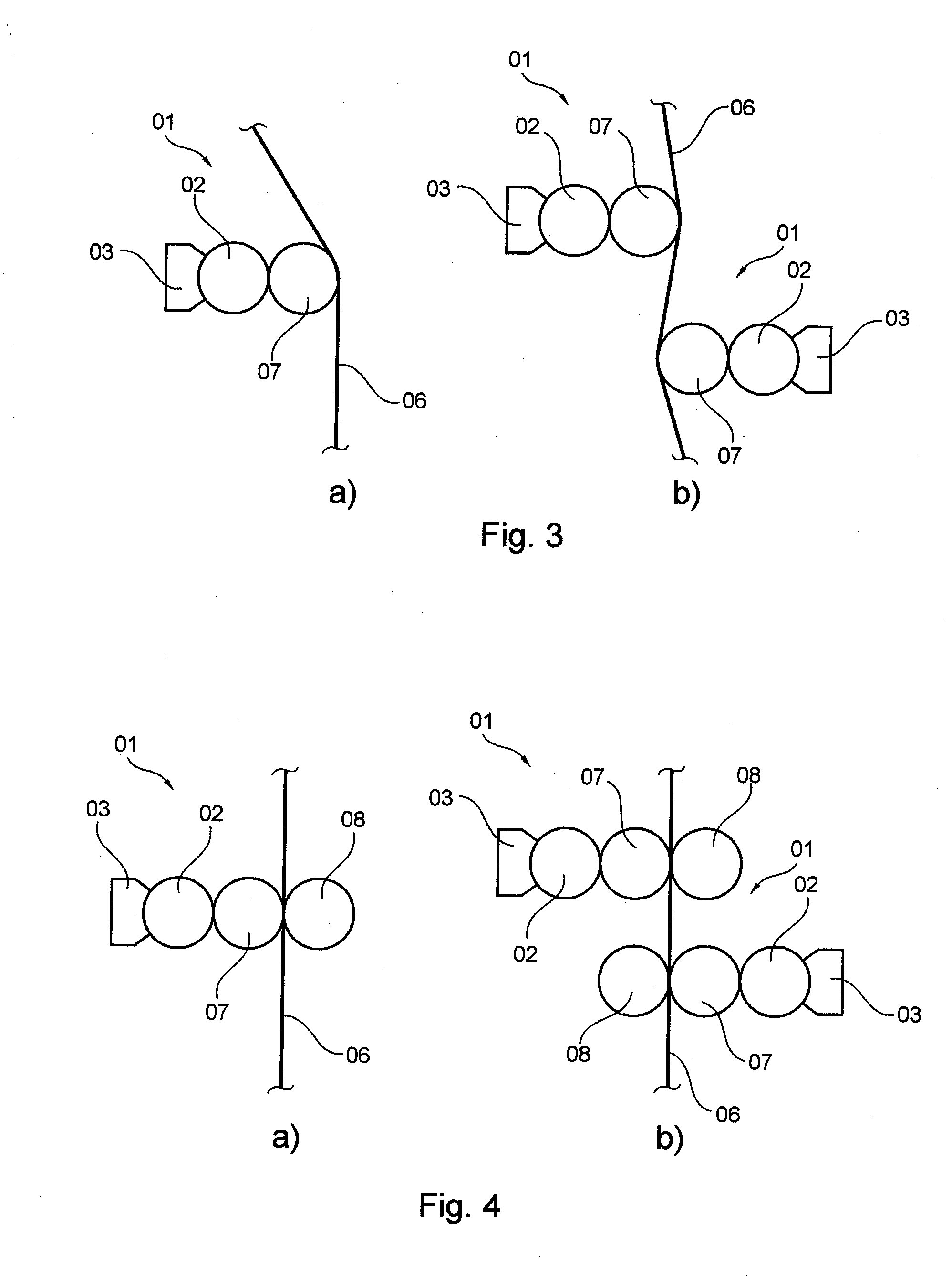

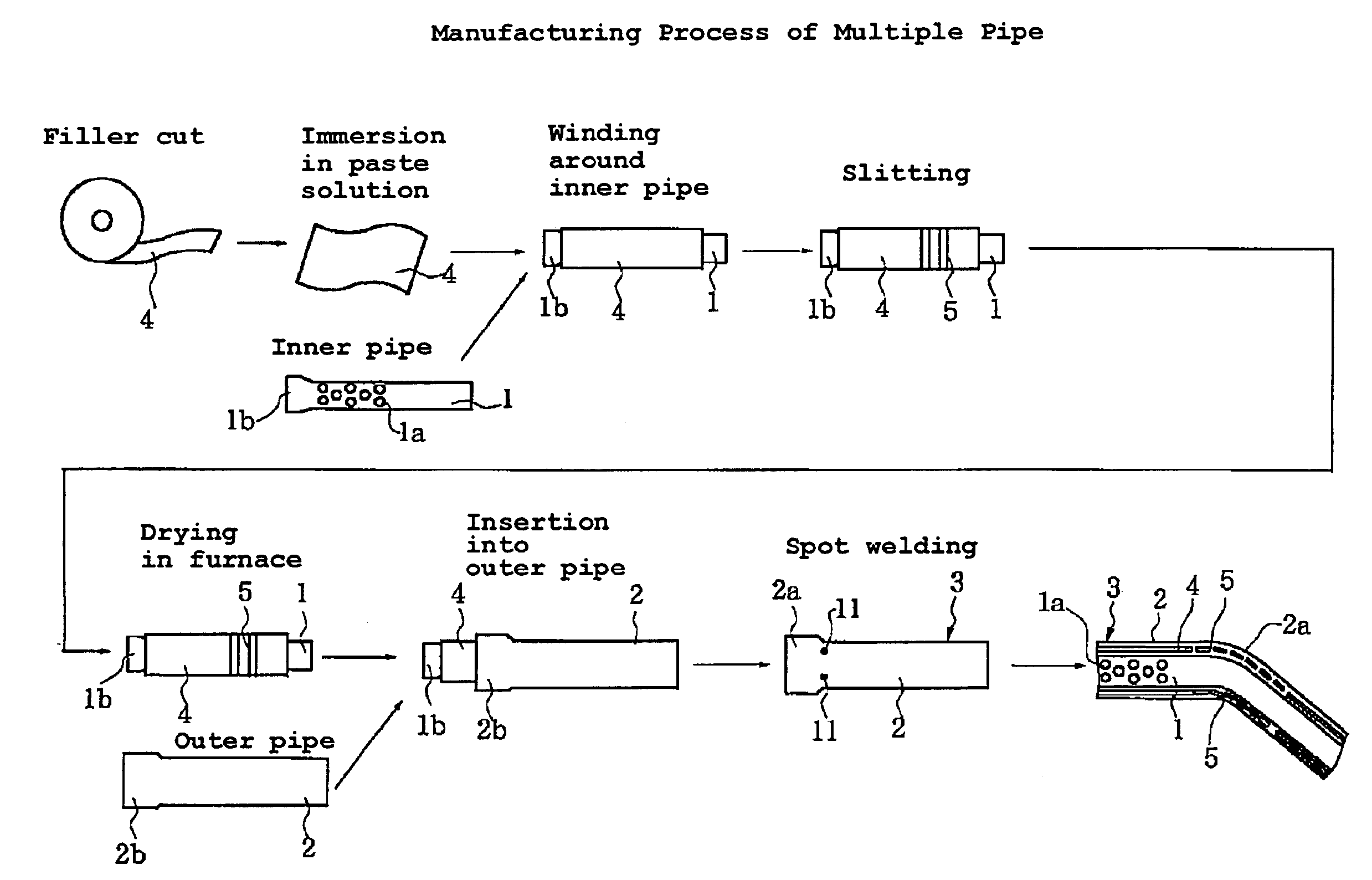

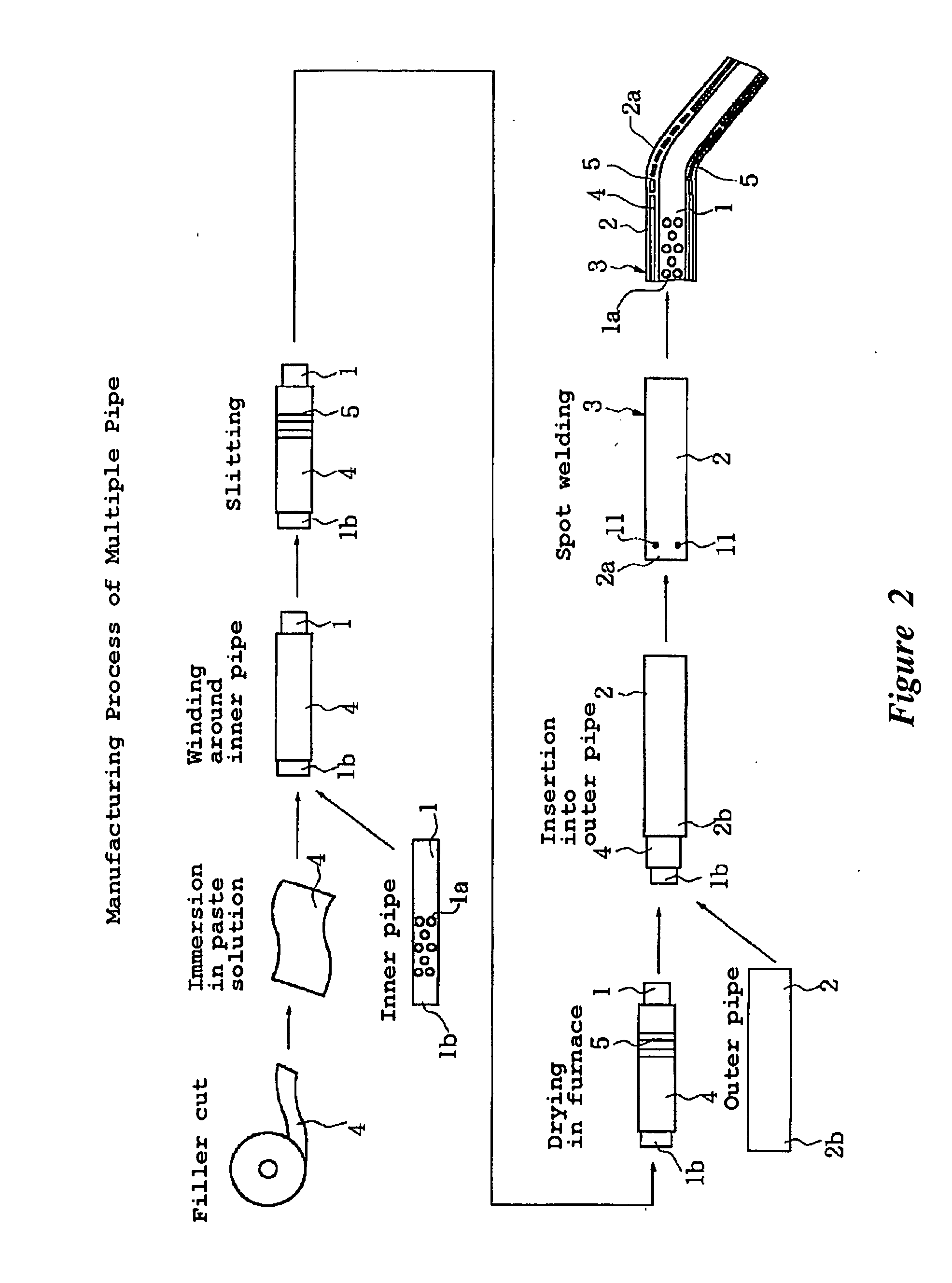

Multiple pipe, method of manufacturing the multiple pipe and device for manufacturing multiple pipe

InactiveUS20060108017A1High quality appearanceReduce manufacturing costExhaust apparatusSilencing apparatusFiberEngineering

The multiple pipe component is a pipe made up of at least an inner pipe and an outer pipe in which a fibrous filler is positioned between the outer pipe and the at least one inner pipe in a region that will be bent. The filler is formed with slits spaced at given pitches. Holes are provided in the inner pipe on at least one of the downstream side and the upstream side of the inner pipe in the bending region while holes are not disposed in the bending region.

Owner:YAMAHA MOTOR CO LTD

Method for manufacturing fiber-reinforced composite material

ActiveUS20180186134A1Nice appearanceHigh quality appearanceSynthetic resin layered productsThree dimensional shapeFiber-reinforced composite

A method for producing a fiber-reinforced composite material is provided. By satisfying particular conditions, this method is capable of suppressing the problem of poor appearance caused by the release film in the production of the fiber-reinforced composite material having a three-dimensional shape by heat-press molding to enable production of the fiber-reinforced composite material having a high quality appearance in high cycle.A method for manufacturing a fiber-reinforced composite material wherein a fiber-reinforced substrate containing a reinforcing fiber (A) and a thermosetting resin (B) is sandwiched between release films (C) to constitute a layered material, and the layered material is pressed in a mold heated to molding temperature to thereby cure the thermosetting resin (B), whereinthe method satisfies the following (i), (ii), and (iii) or (i), (ii), and (iv):(i) the fiber-reinforced composite material has at least 1 bent part,(ii) the molding temperature is 130 to 180° C., and pressure application time is 0.5 to 20 minutes,(iii) the release film (C) has a thermal contraction rate satisfying the following expressions (1) and (2):0<Ta≤20 expression (1), and1≤Ta−Tb≤20 expression (2),Ta: the thermal contraction rate (%) of the release film (C) measured by using a thermomechanical analyzer at the temperature the same as the molding temperatureTb: the thermal contraction rate (%) of the release film (C) measured by using a thermomechanical analyzer at a temperature 30° C. lower than the molding temperature, and(iv) hardness of the fiber-reinforced substrate and the hardness of the release film (C) measured by using a durometer corresponding to JIS-K-7215, type A satisfy the following expressions (3) and (4):0.8≤Hrc / Hrf≤1.2 expression (3),1<Hhc / Hhf≤1.5 expression (4),Hrc: hardness of the release film (C) at 30° C.,Hrf: hardness of the fiber-reinforced substrate at 30° C.,Hhc: hardness of the release film (C) at the molding temperature,Hhf: hardness of the fiber-reinforced substrate at the molding temperature.

Owner:TORAY IND INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com