Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

40results about How to "Ensure surface cleanliness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

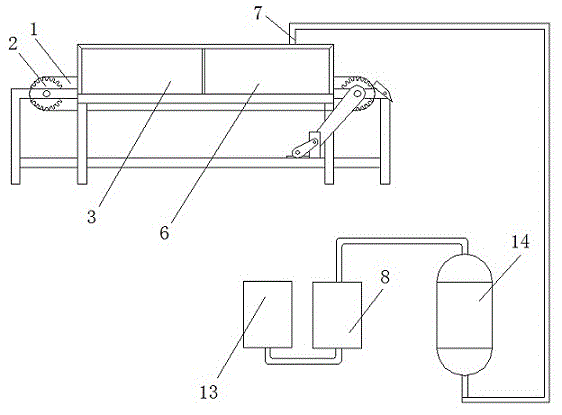

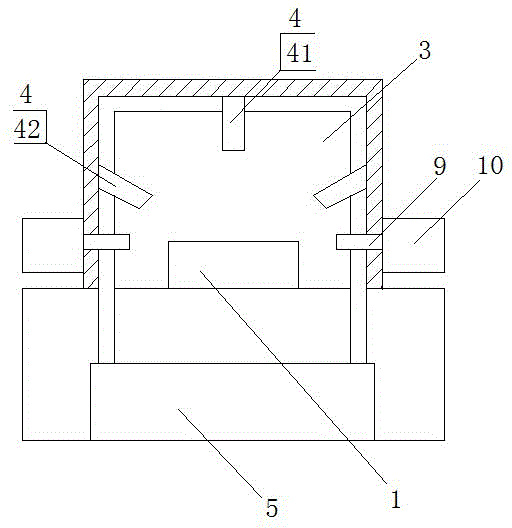

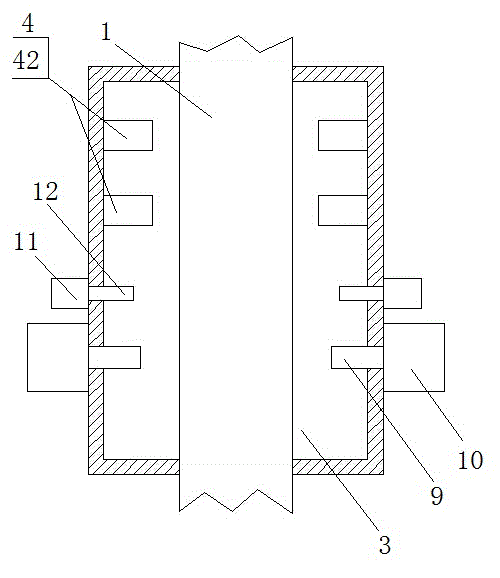

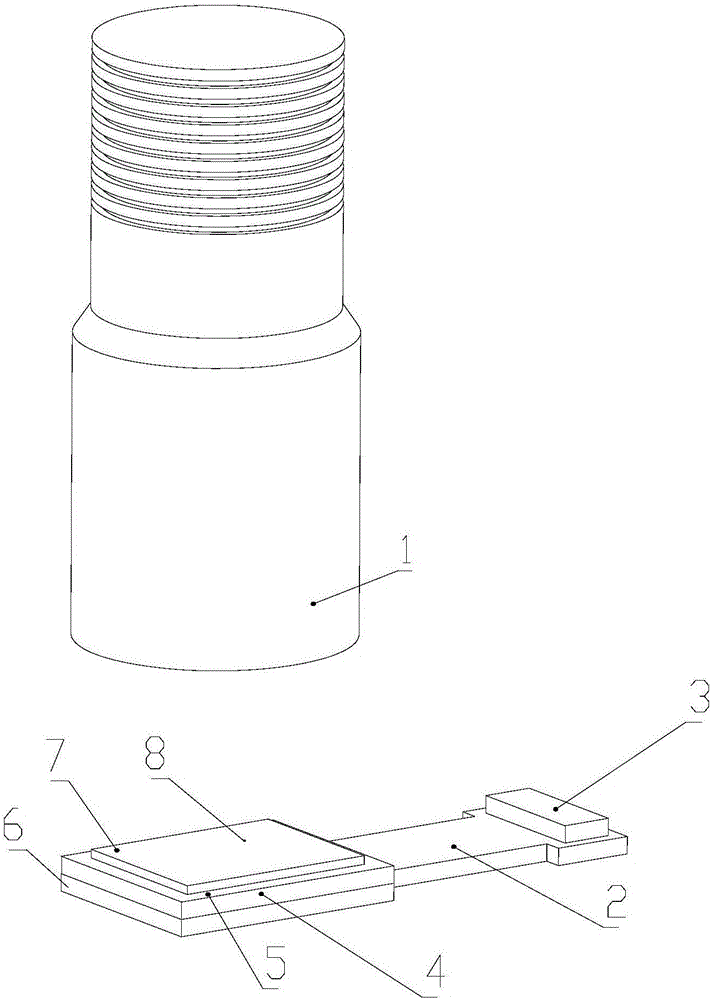

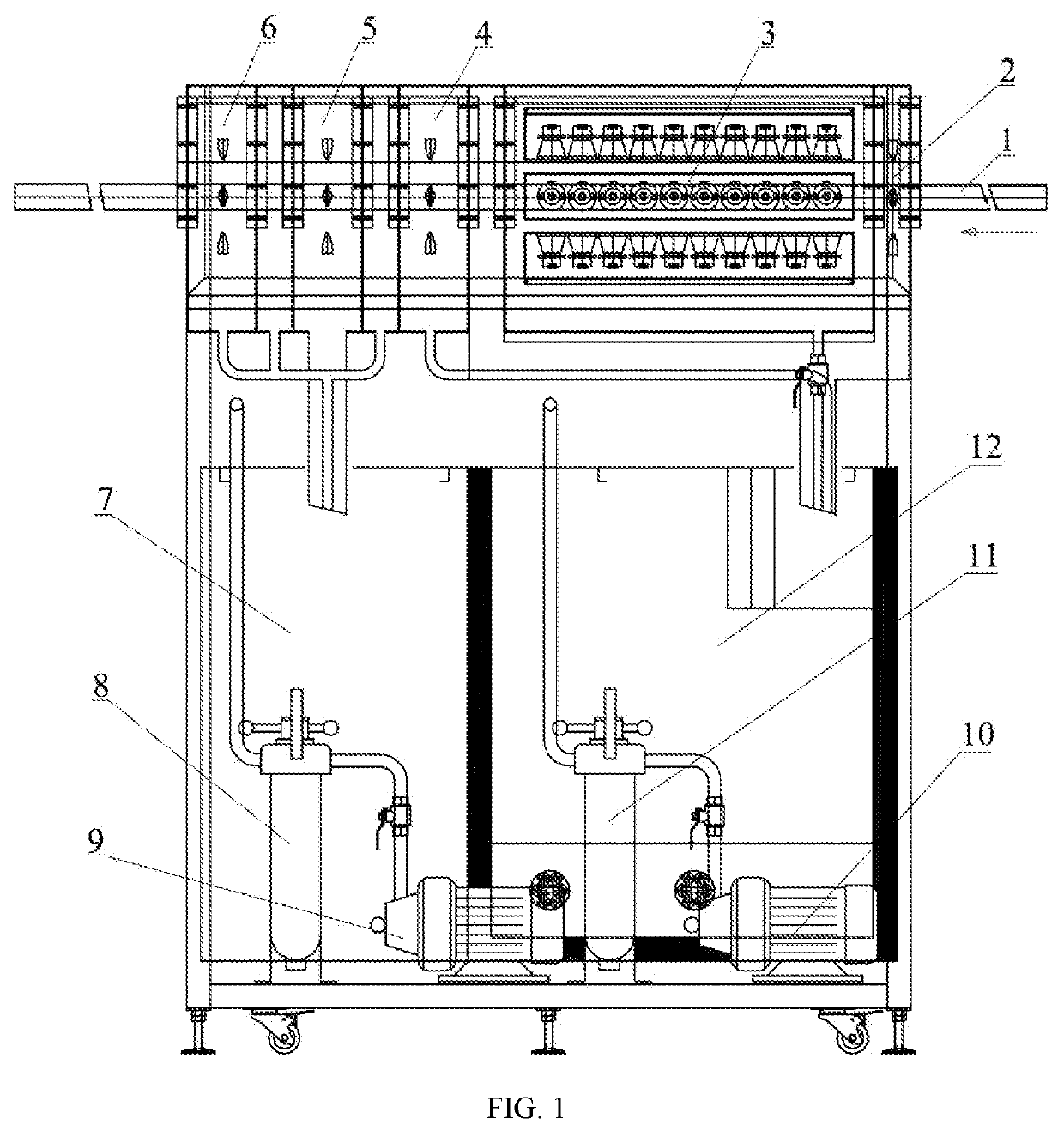

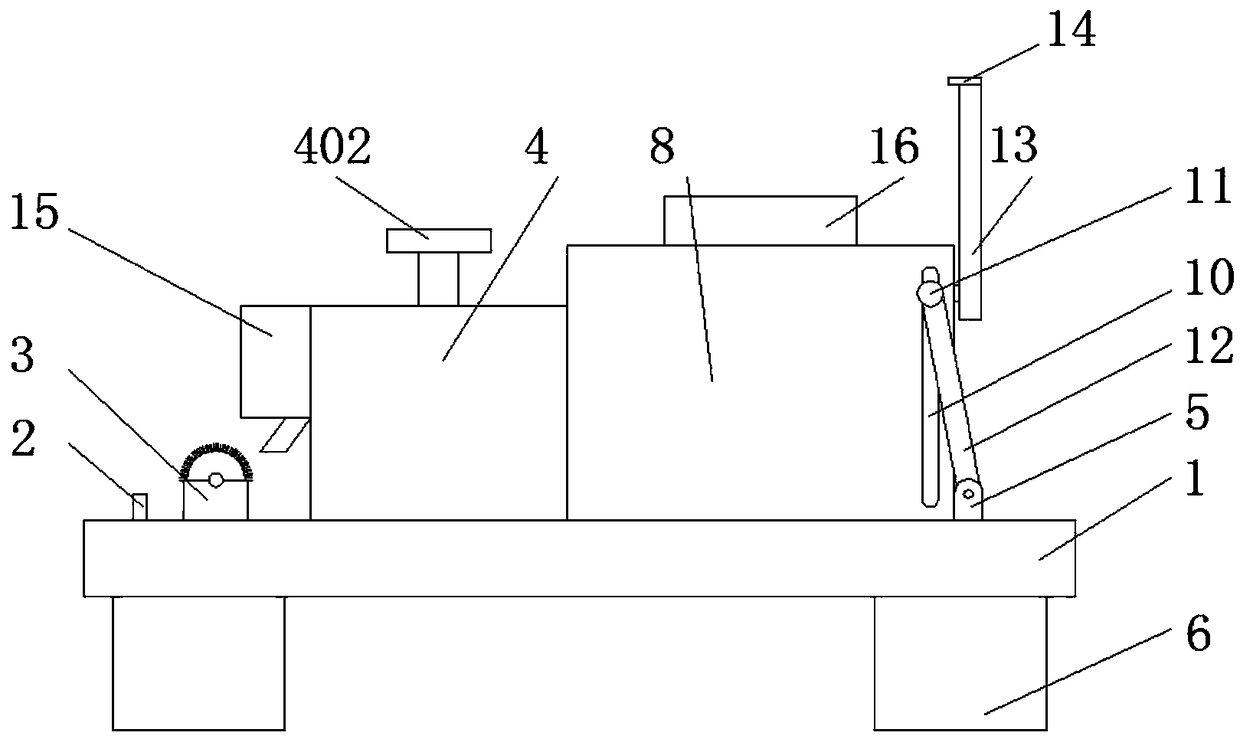

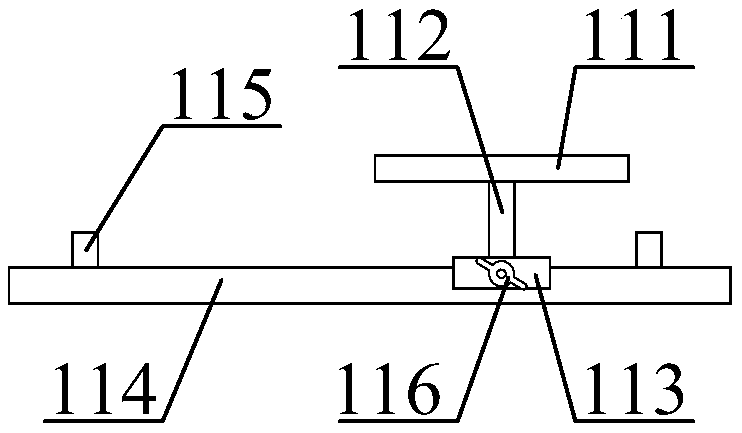

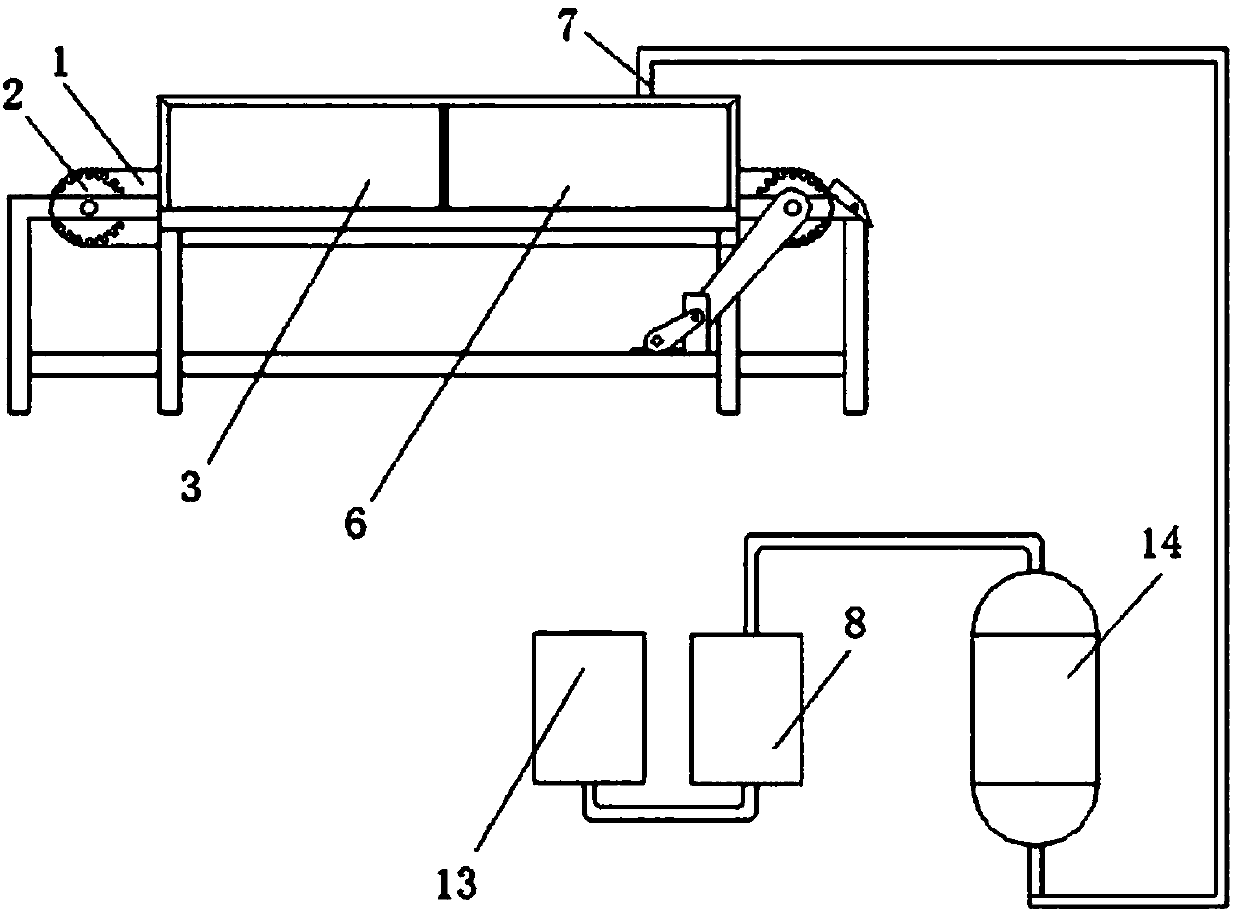

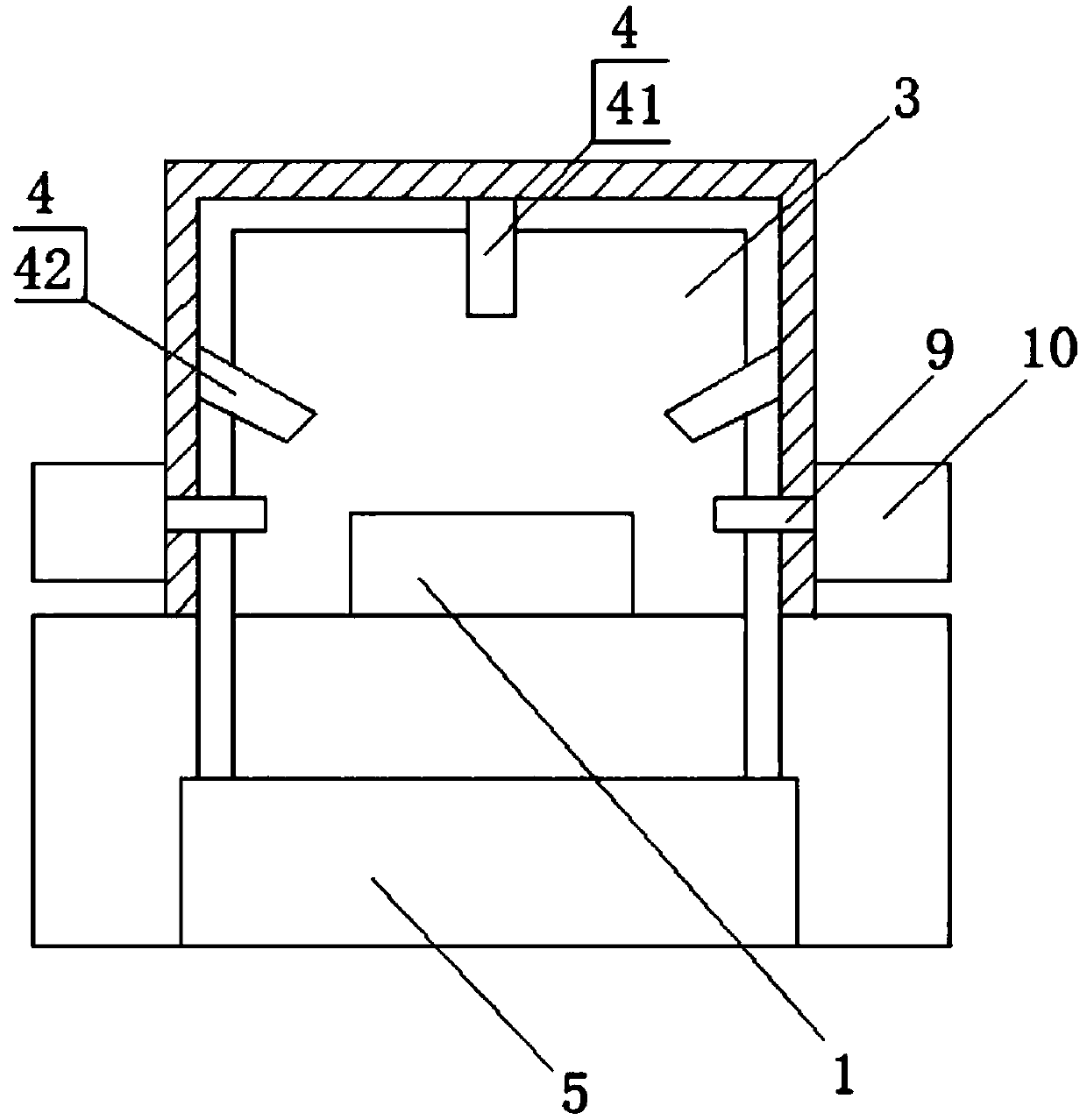

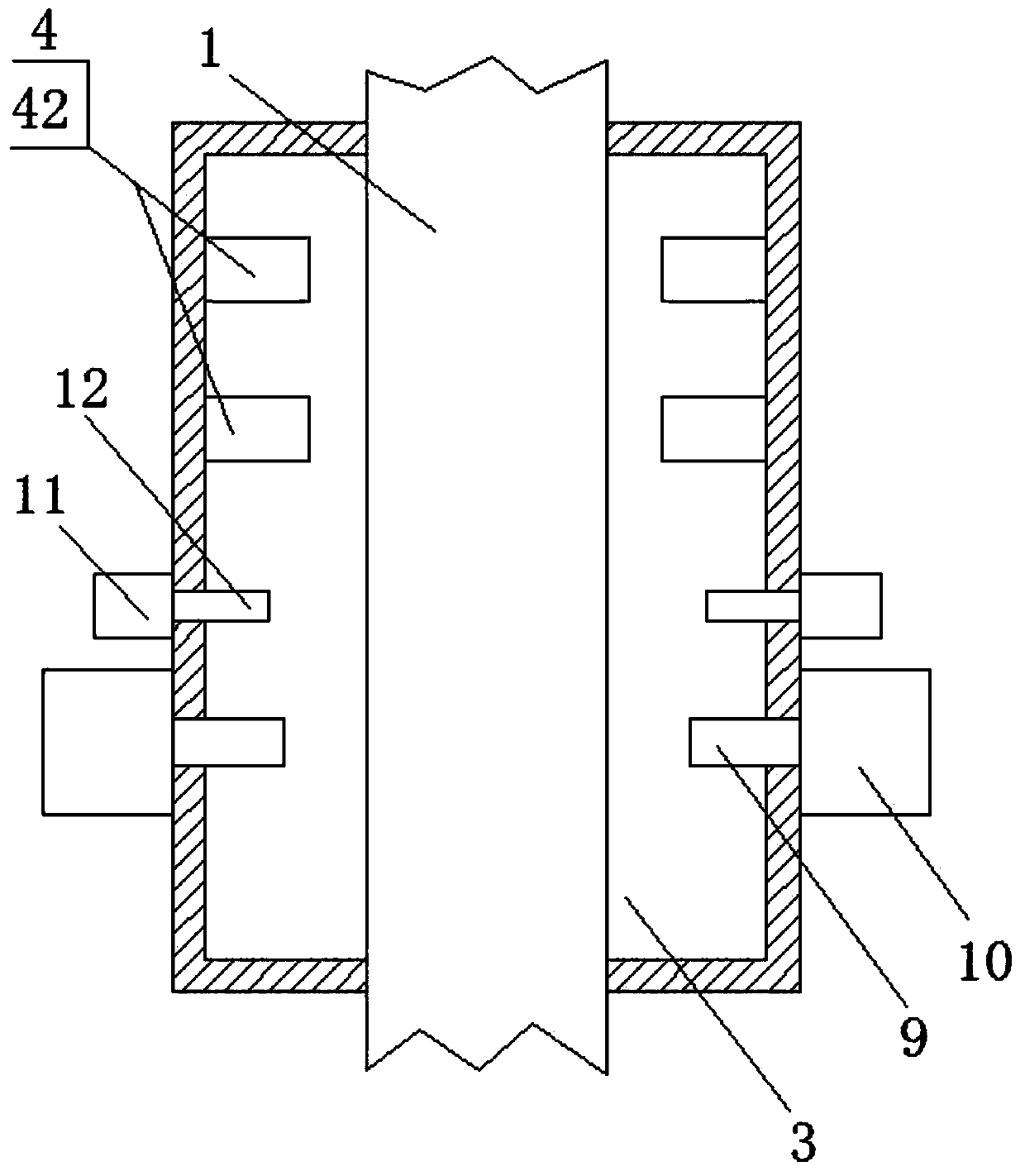

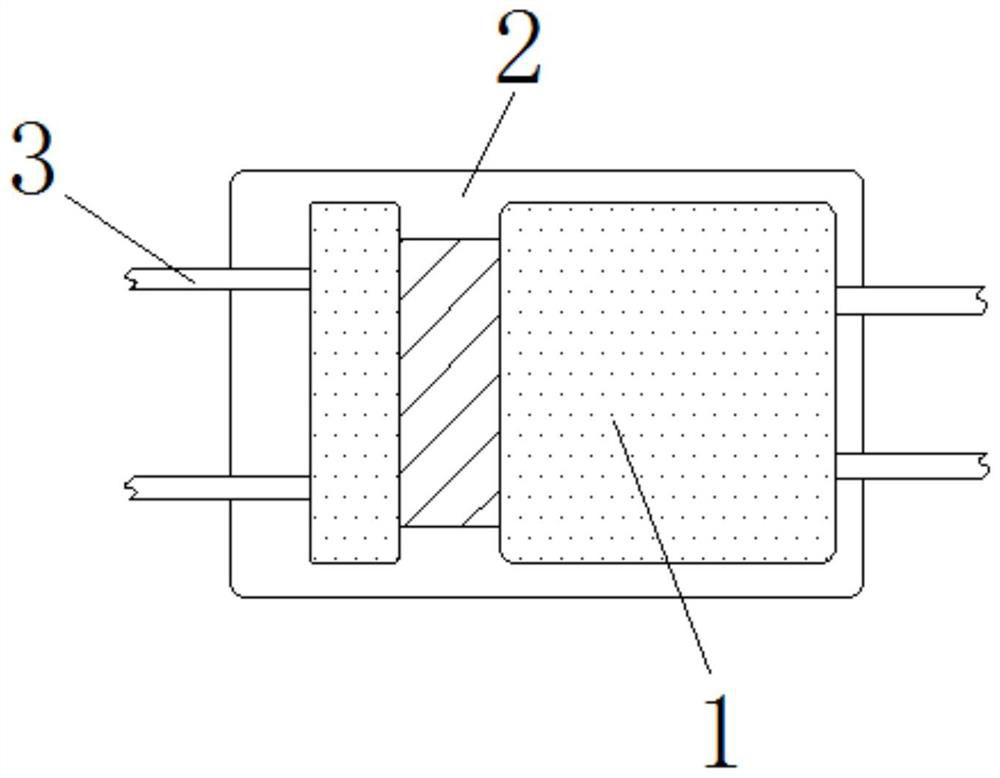

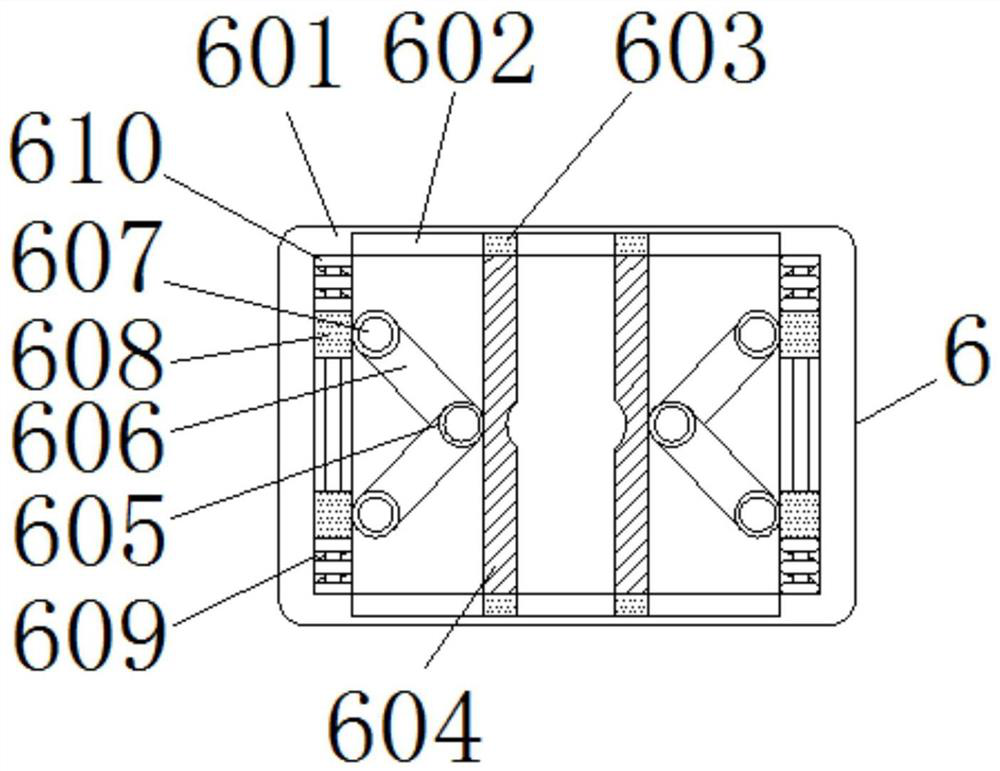

Cleaning and drying integrated device for mechanical part

InactiveCN104550090AClean evenly and thoroughlyEnsure surface cleanlinessDrying gas arrangementsCleaning using liquidsEngineeringAir heater

The invention discloses a cleaning and drying integrated device for a mechanical part. The cleaning and drying integrated device comprises a conveying device, a cleaning device and a drying device, wherein the conveying device comprises a conveying belt driven by chain wheels arranged in the conveying belt; the cleaning device comprises a cleaning chamber in which cleaning spraying heads are arranged; the cleaning spraying heads are communicated to a cleaning liquid tank arranged outside the cleaning chamber; the drying device comprises a drying chamber in which a drying spraying opening is formed; the drying spraying opening is communicated to an air heater arranged outside the drying chamber; the conveying belt passes through the inner parts of the cleaning chamber and the drying chamber in sequence. According to the cleaning and drying integrated device disclosed by the invention, by multiple cleaning working procedures, the mechanical part can be uniformly and thoroughly cleaned after being processed, so that the surface cleanness of the mechanical part is guaranteed.

Owner:JIANGSU HONGBAO FORGING

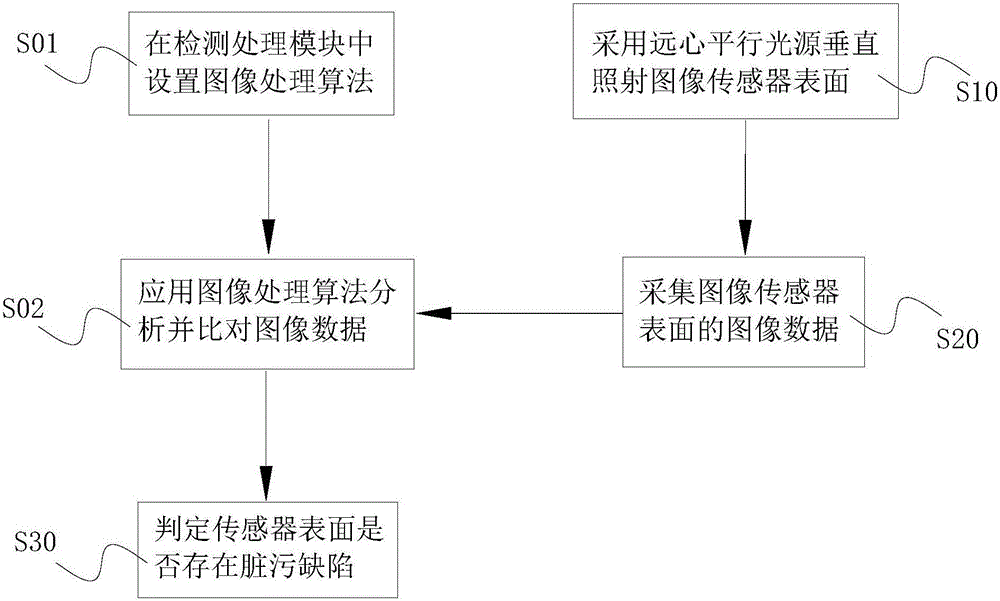

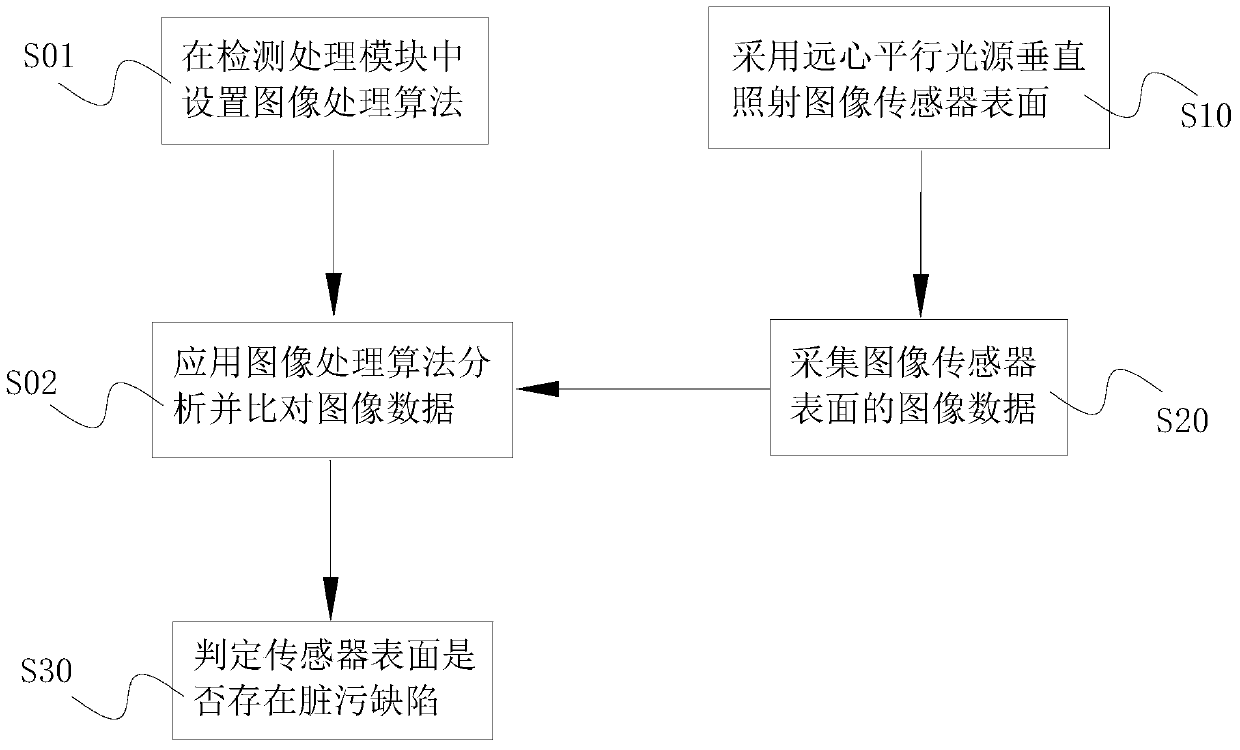

Method for detecting surface dirt defect of image sensor

ActiveCN106226270AEnsure surface cleanlinessReduce missed detectionScattering properties measurementsLuminescenceImaging data

The invention provides a method for detecting a surface dirt defect of an image sensor. The method comprises the following steps: step S10, irradiating the surface of the image sensor through a telecentric collimated light source; step S20, starting an image sensor, performing imaging to the surface of the image sensor, and collecting the surface of the image sensor and forming image data of surface dirt defect particles; and step S30, obtaining a detection result about whether a surface dirt defect exists on the surface of the image sensor according to the image data. According to the method, the problem of missed detection that is prone to happen when an image sensor is subjected to surface dirt defect detection through a uniform luminescence light source in the prior art is solved.

Owner:深圳睿晟自动化技术有限公司

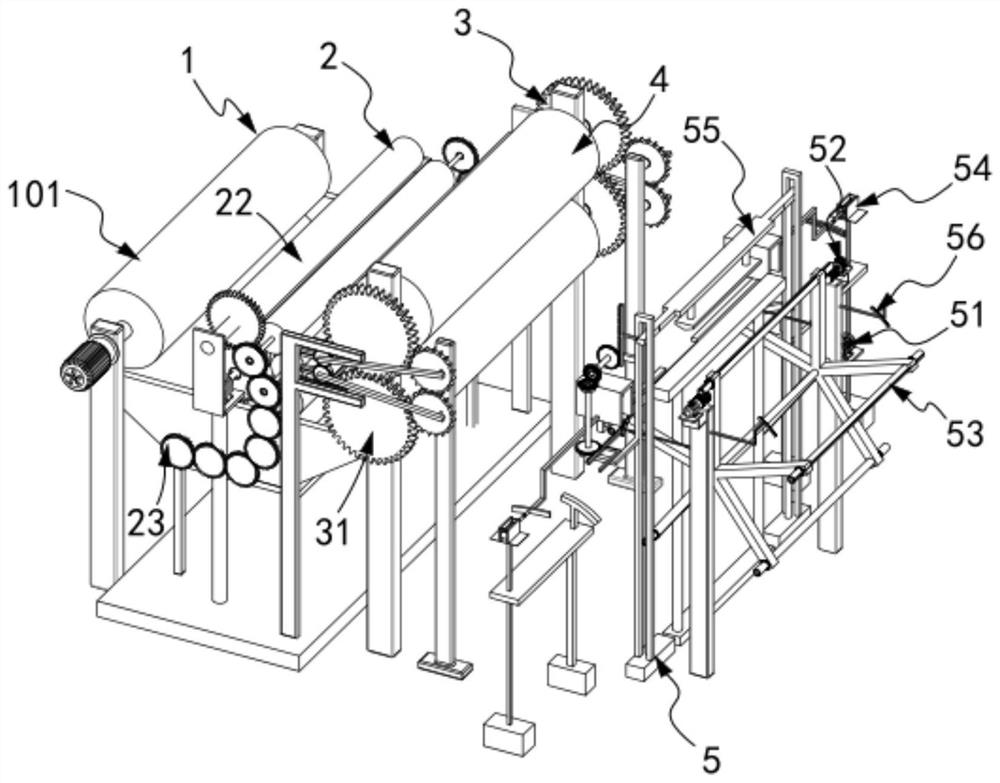

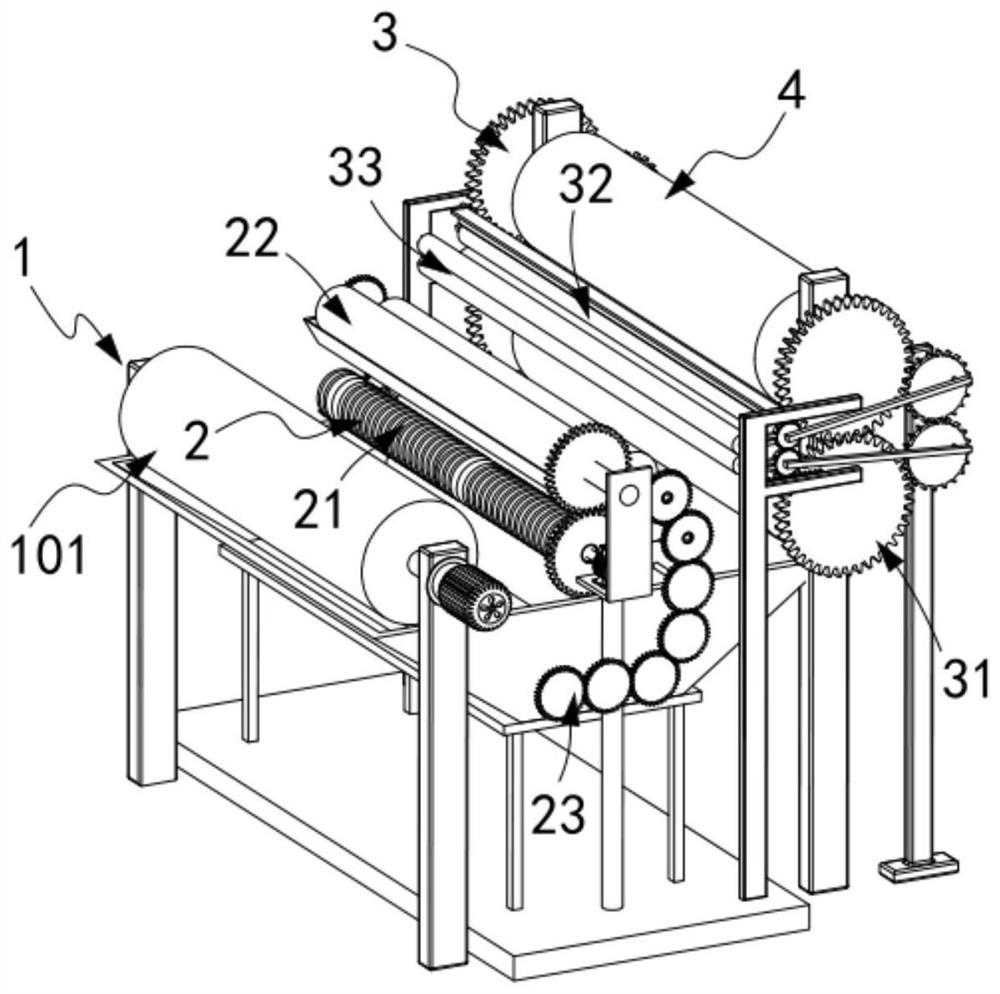

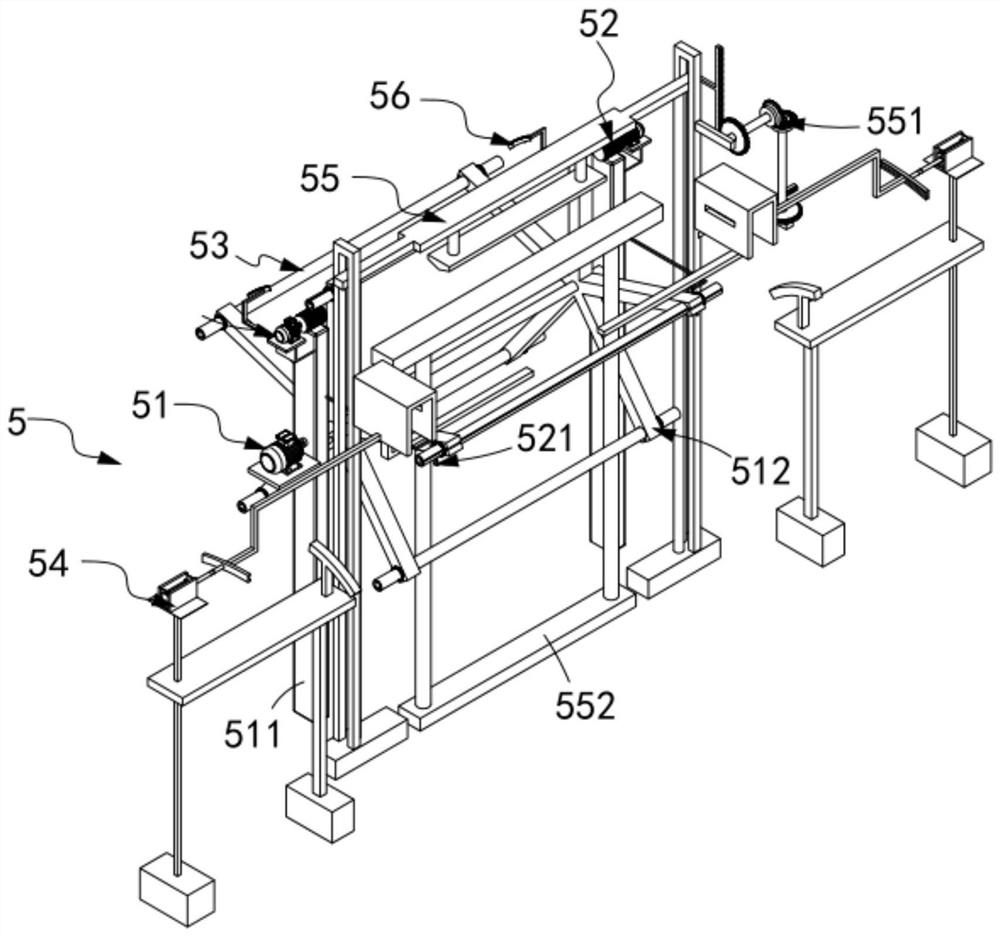

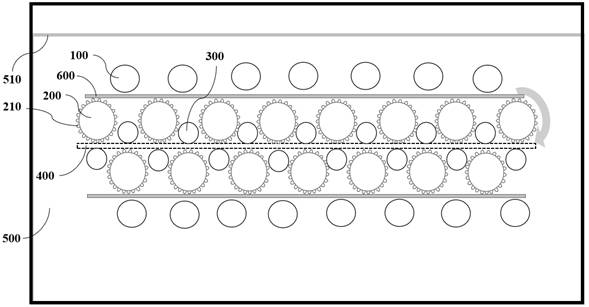

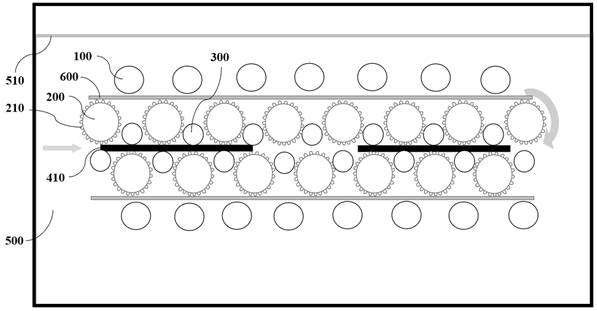

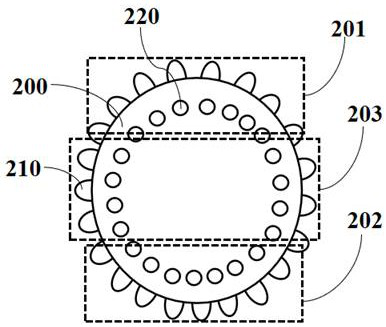

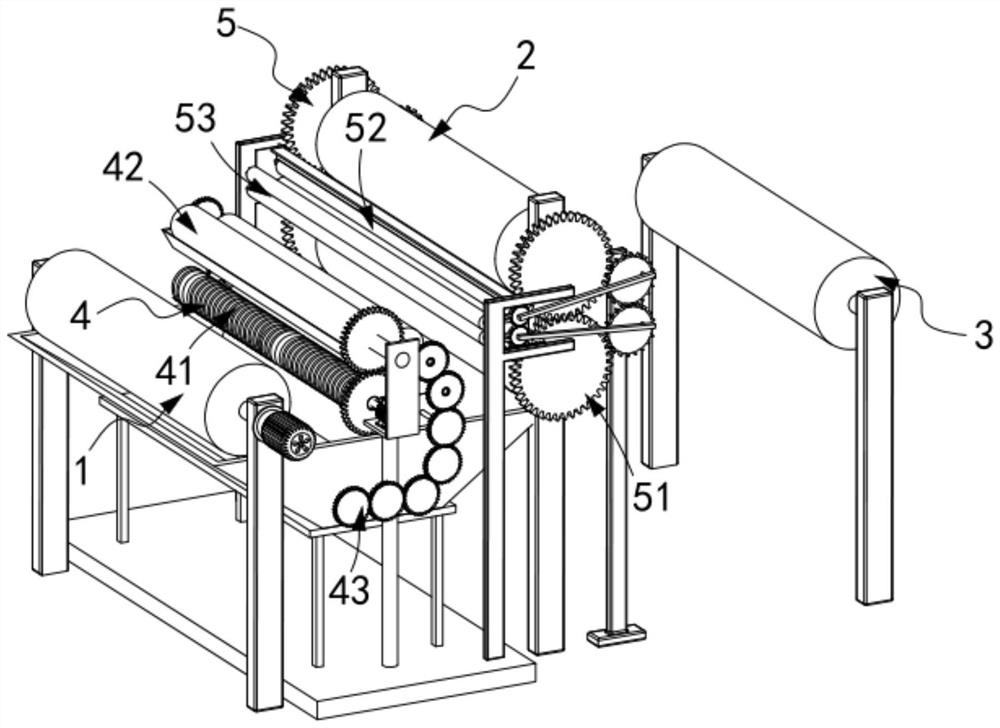

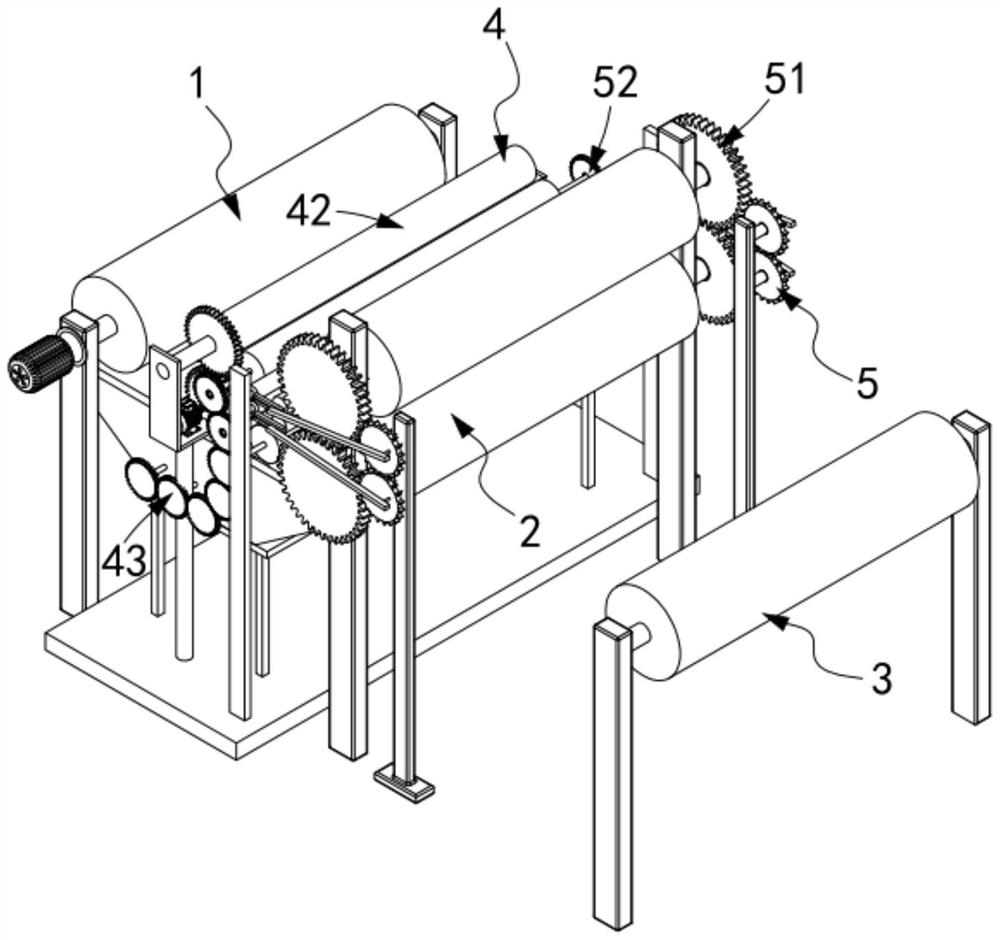

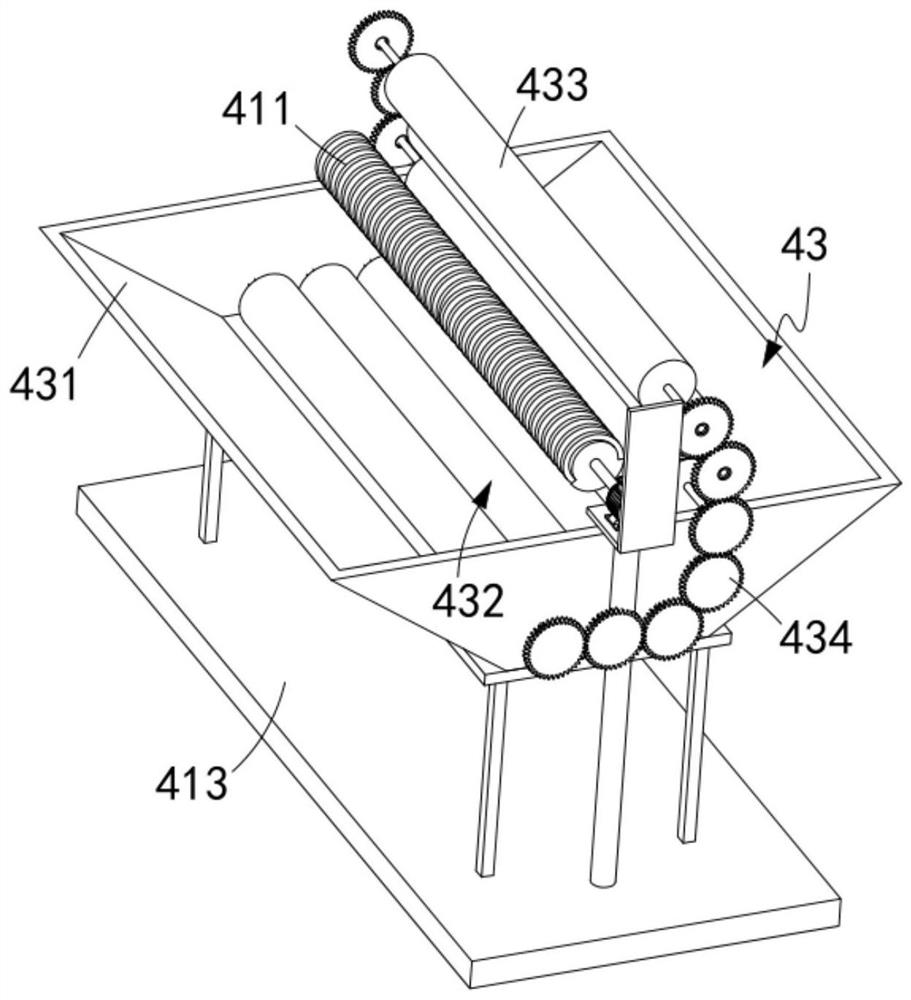

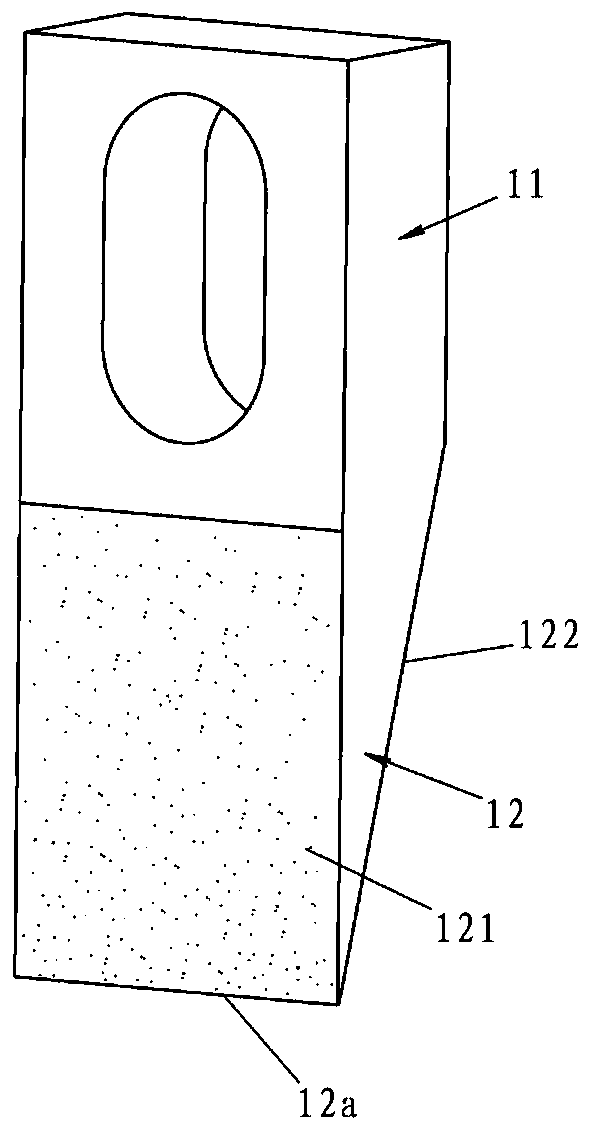

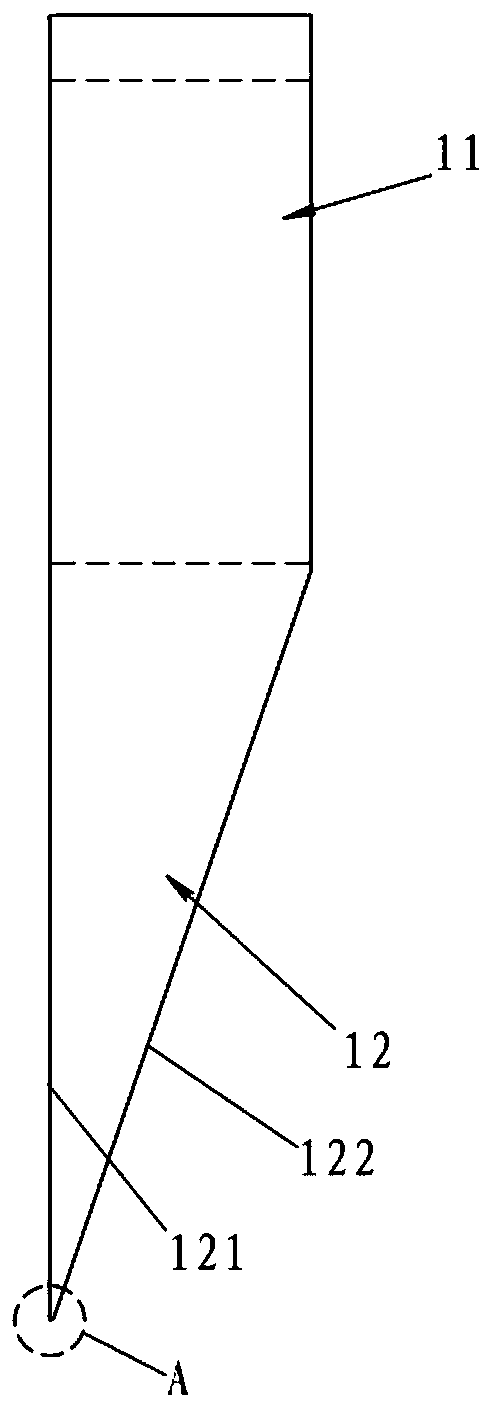

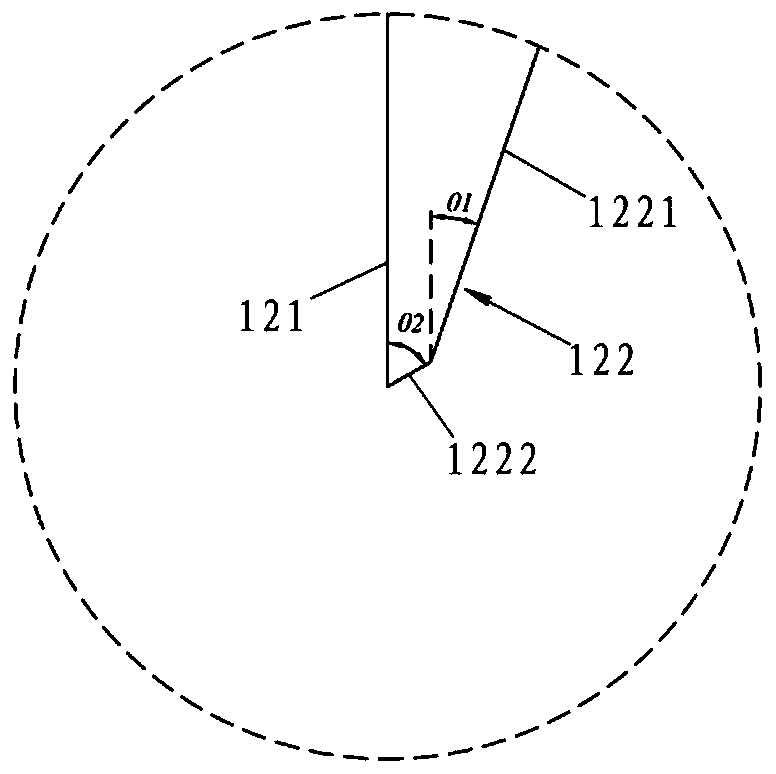

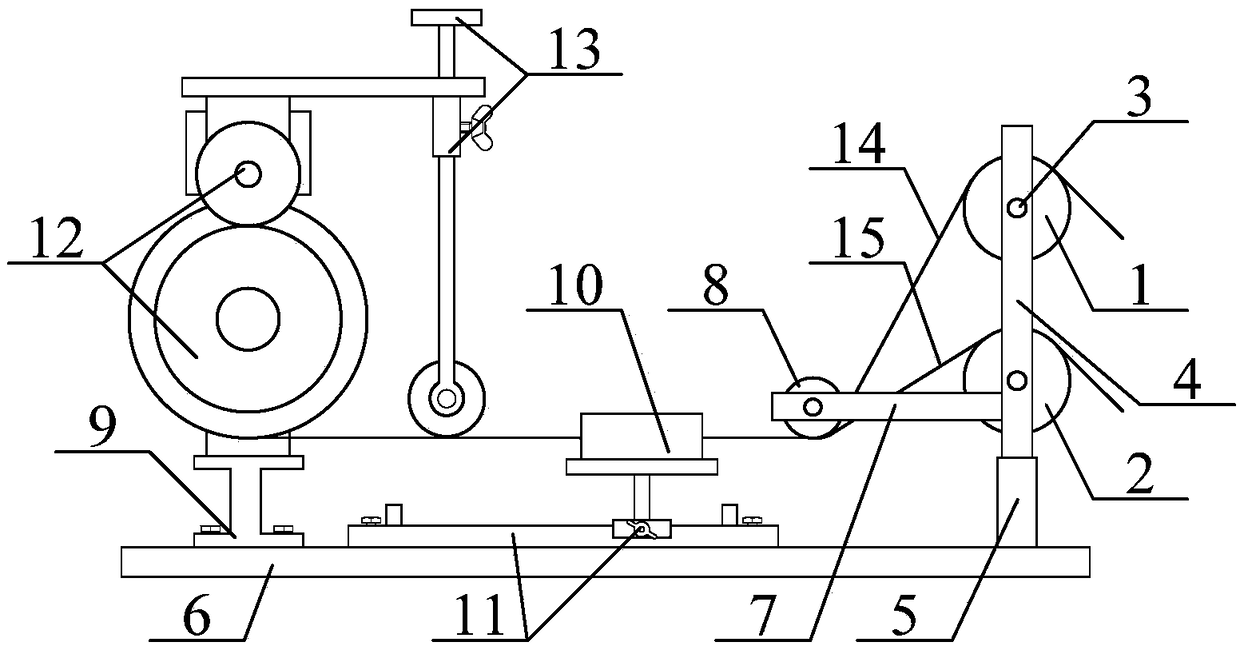

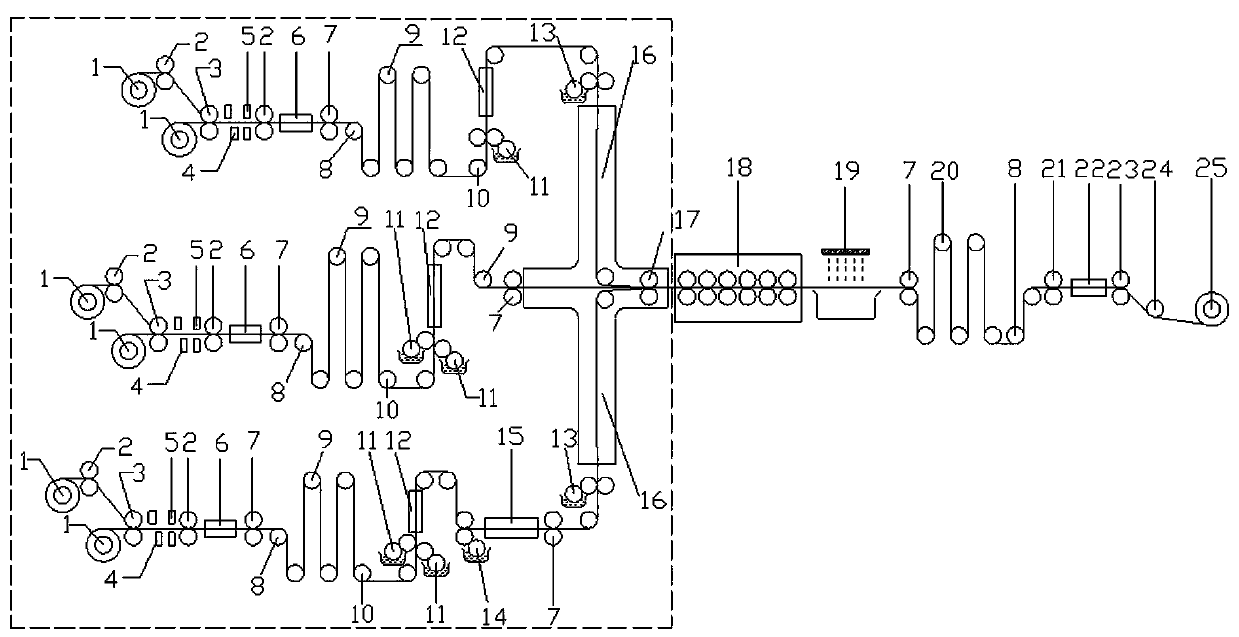

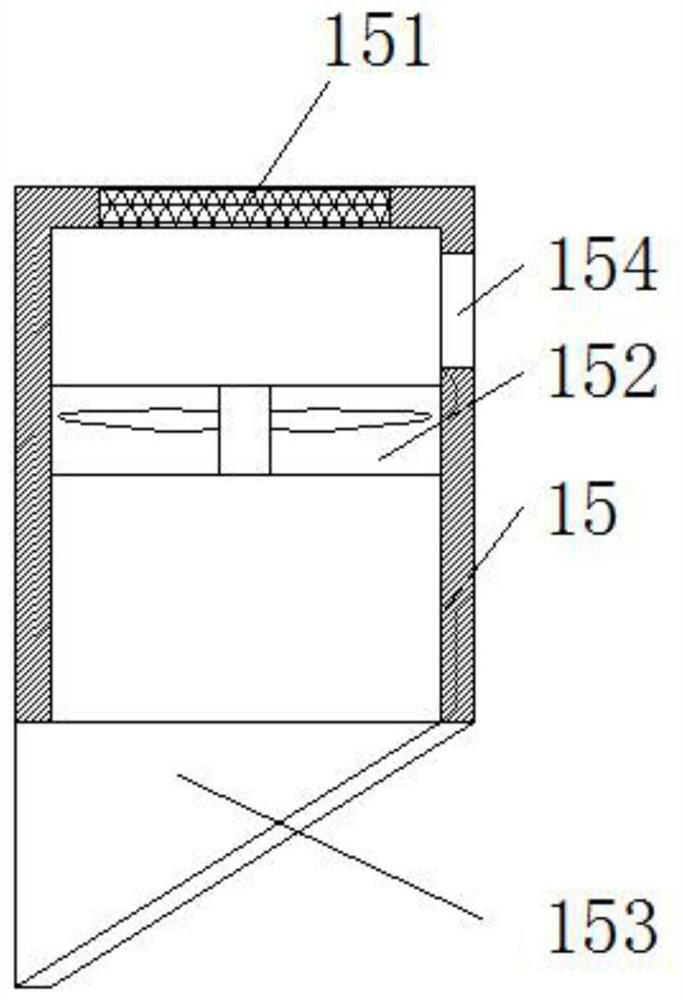

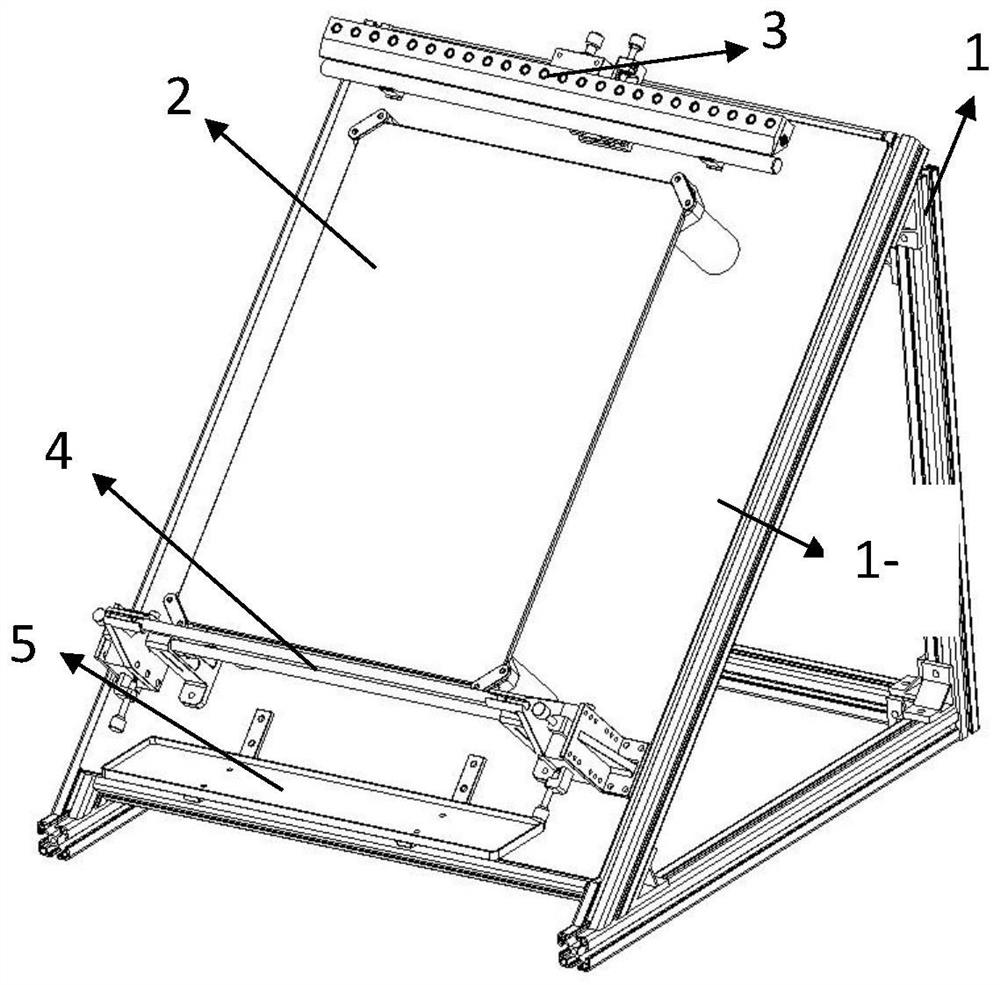

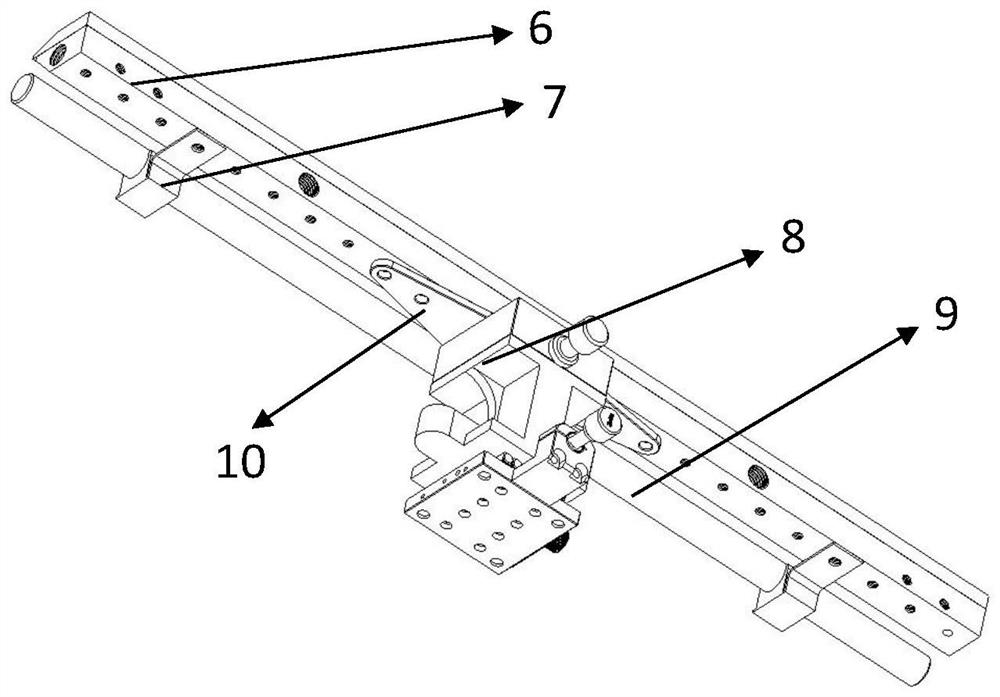

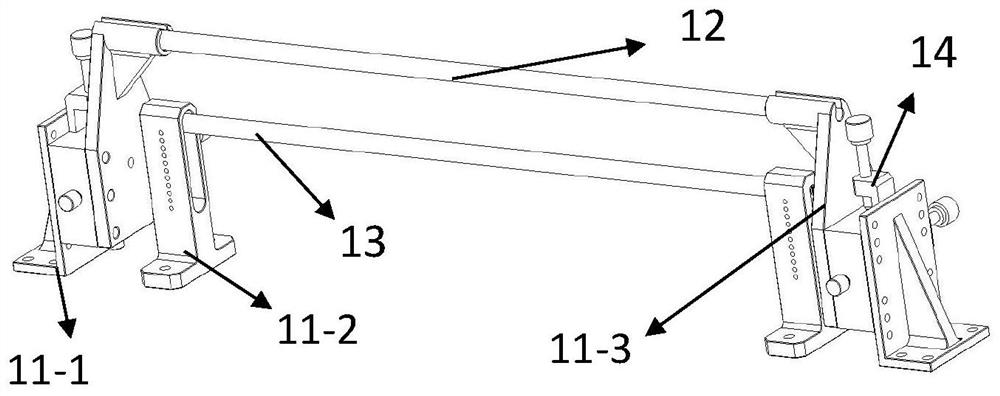

Flow guide net punching isolating film composite material structure production system

InactiveCN111674051AGuaranteed continuous winding workEffective bondingDirt cleaningCleaning using toolsPunchingIndustrial engineering

The invention relates to a flow guide net punching isolating film composite material structure production system. The system comprises a gluing mechanism, a synthesis mechanism and a film rolling mechanism, wherein the gluing mechanism comprises a glue coating mechanism, a first glue homogenizing mechanism and a second glue homogenizing mechanism, the second glue homogenizing mechanism comprises aspeed change assembly, a stretching assembly and a glue coating assembly, the synthesis mechanism is located behind the gluing mechanism and used for pressing a flow guide net subjected to gluing work and a porous isolating film, and the film rolling mechanism comprises a switching mechanism, a driving mechanism, a winding roll element rotationally arranged on a circulating assembly, two windingmechanisms symmetrically arranged on the two sides of the winding roll element, a cutting mechanism used for cutting a composite flow guide net and a glue sealing mechanism used for carrying out automatic finishing work on the tail of the cut composite flow guide net on the winding roll element. According to the system, the technical problems that when the porous isolating film and the flow guidenet work in a composite mode, production work is discontinuous, finished products need to be packaged and output after winding work is completed through shutdown, and the efficiency is low are solved.

Owner:潘利斌

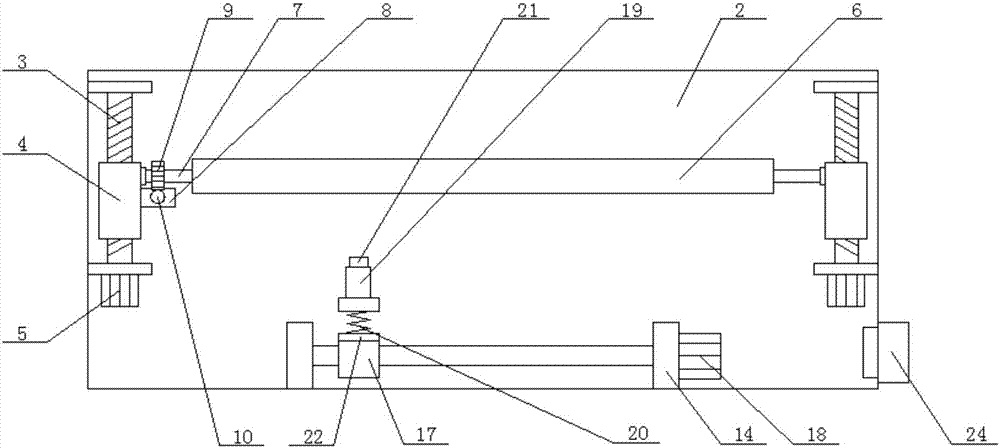

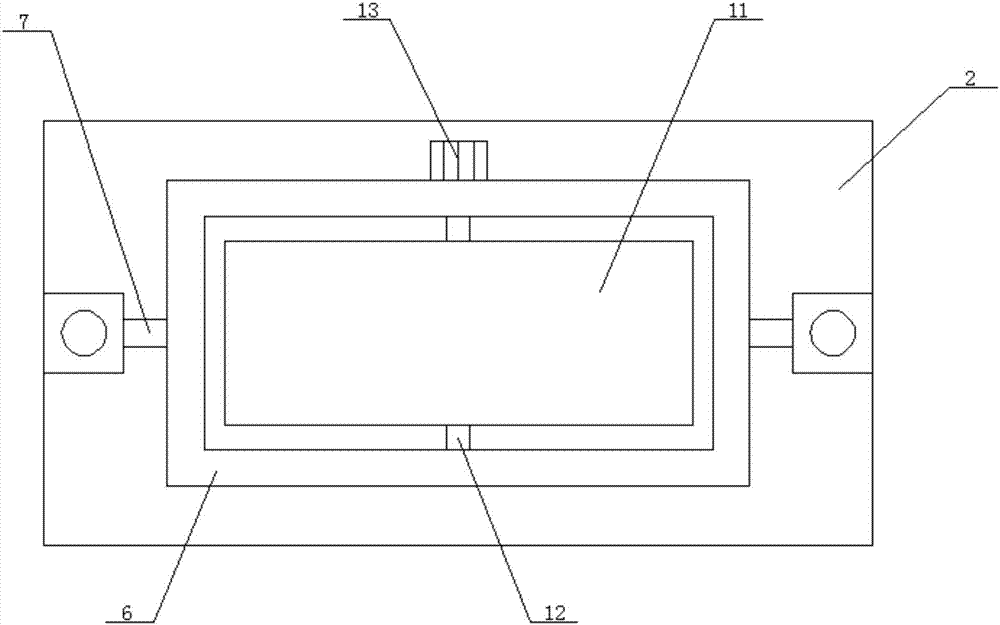

Solar car

InactiveCN107472036AIngenious designImprove power generation efficiencyPhotovoltaic supportsVehicular energy storageAutomotive engineeringEngineering

The invention relates to a solar car which comprises a car body, a top shell and a solar energy mechanism, wherein the solar energy mechanism comprises lifting and lowering assemblies, a first rotation assembly and a second rotation assembly; the lifting and lowering assemblies comprise first lead screws, displacement blocks and first motors; the first rotation assembly comprises a support frame, first rotation shafts and a driving unit; the driving unit comprises a second motor, a worm wheel and a worm screw; and the second rotation assembly comprises a solar panel, second rotation shafts and a third motor. By virtue of the particular first rotation assembly, the solar car can enable the solar panel to be inverted to face upwards with the bottom surface in circumstances without lights or some special circumstances, so as to protect the solar panel. The first rotation assembly, the second rotation assembly and a light sensor are used in a cooperative manner to adjust the angle of the solar panel according to an illumination angle so as to improve the power generation efficiency. In addition, a particular cleaning mechanism can keep the surface of the solar panel clean, thereby ensuring the power generation efficiency.

Owner:NANJING WEILI INNOVATIVE ENERGY TECH CO LTD

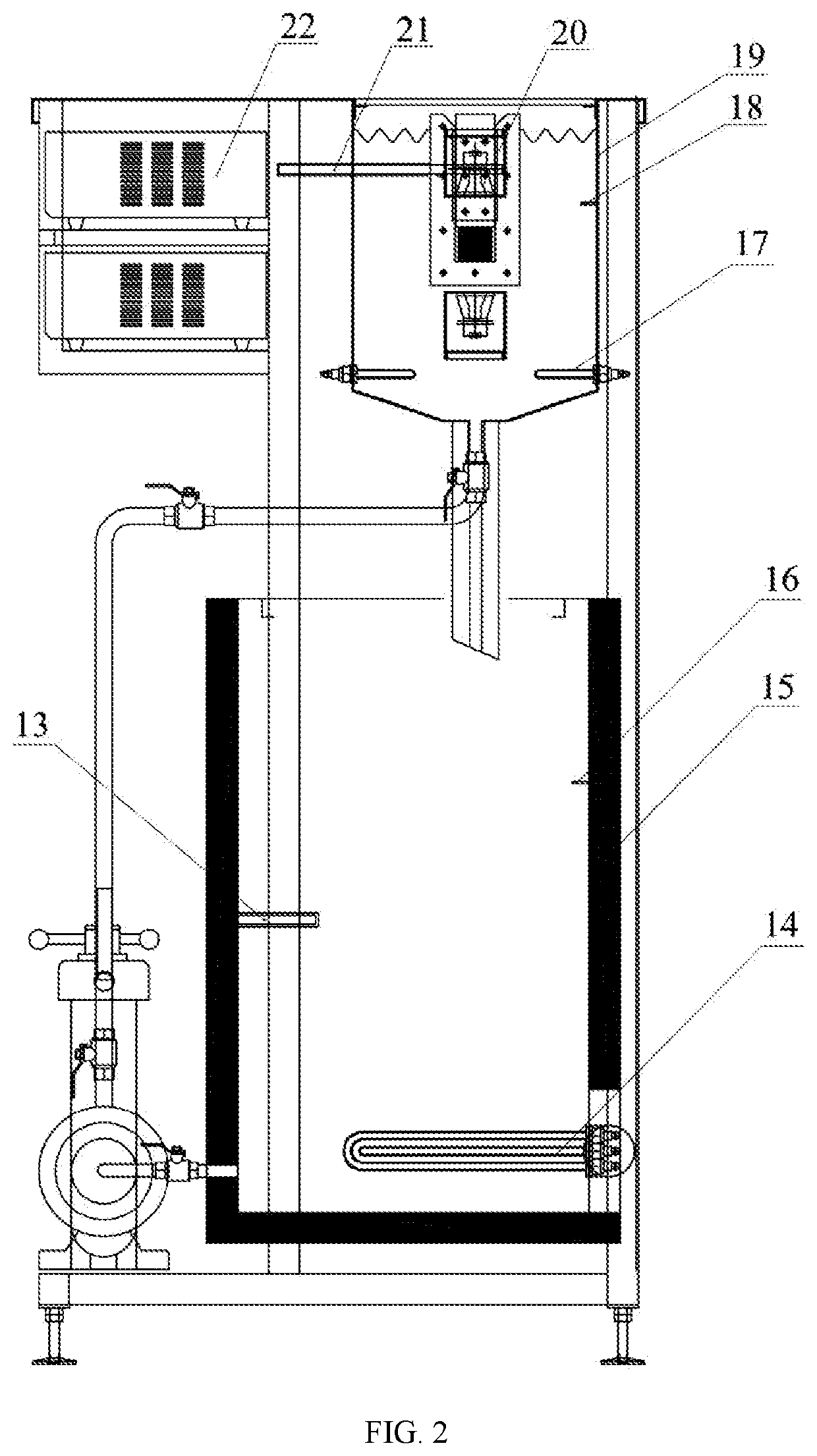

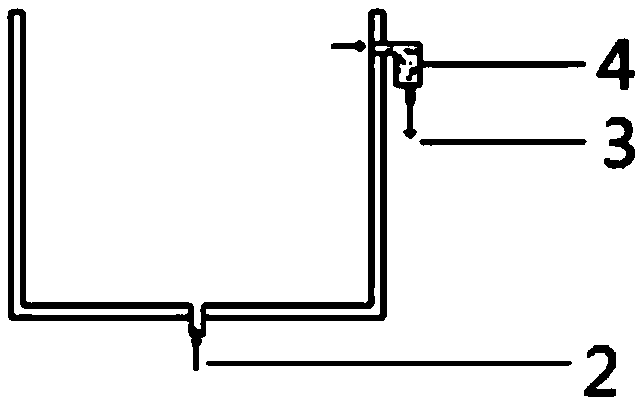

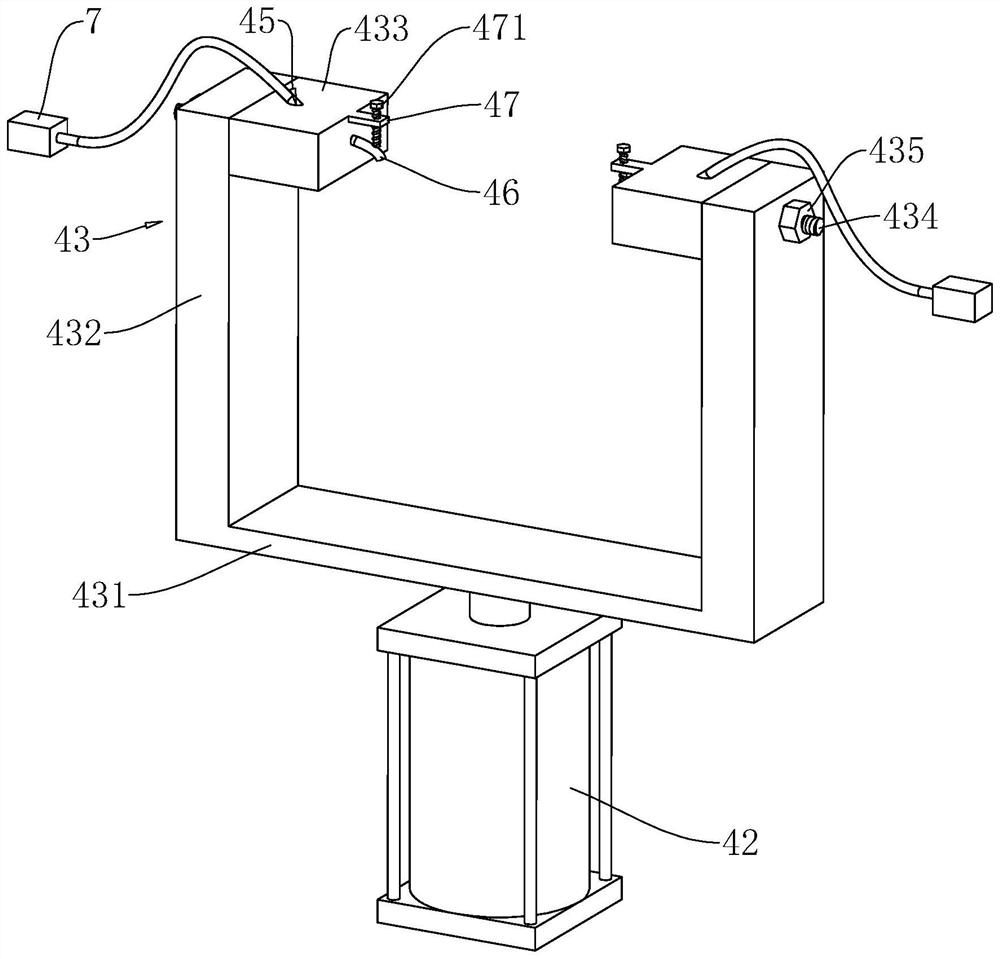

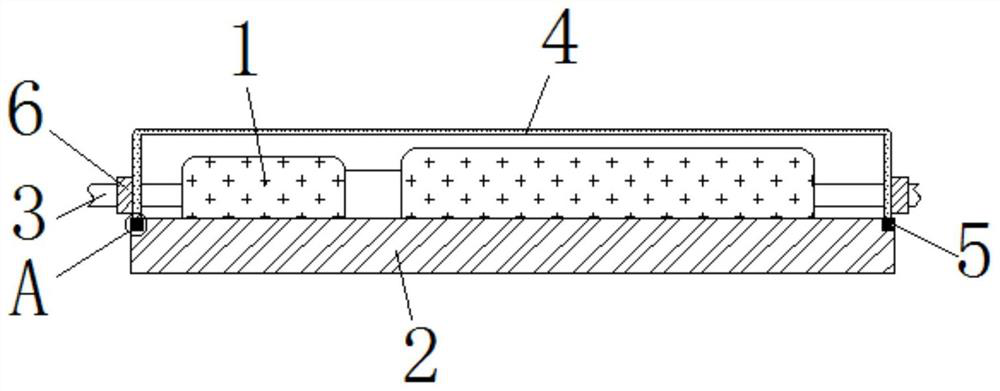

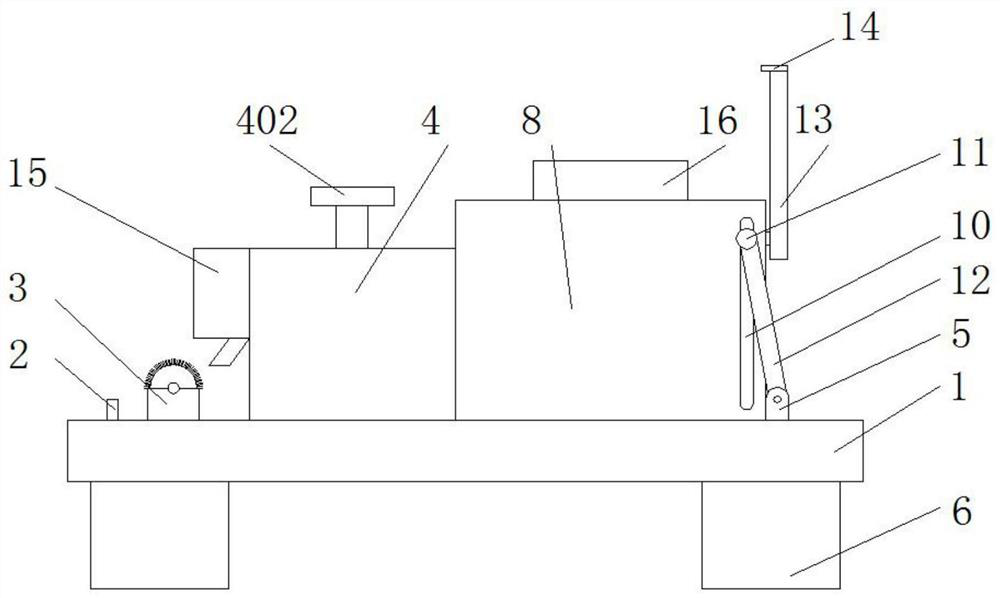

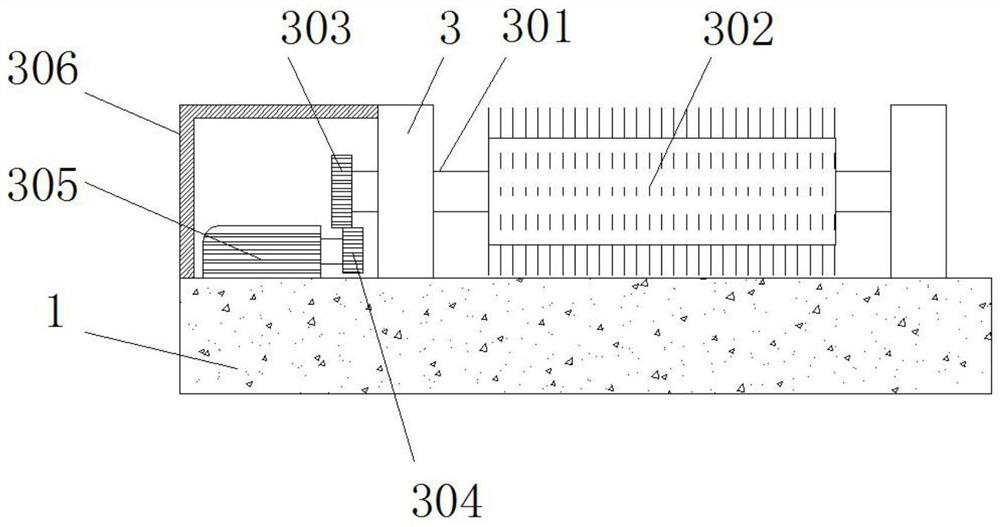

Feed-through ultrasonic cleaning system for winding of large-sized superconducting coils

ActiveUS20190366392A1Ensure cleanlinessQuality improvementDrying solid materials with heatDrying gas arrangementsSuperconducting CoilsAutomatic control

A feed-through ultrasonic cleaning system for winding of a large-sized superconducting coil, including a sealed chamber system, a main ultrasonic cleaning system, a deionized water spraying system, a compressed air blow-drying system, an automatic control system. During the winding of an armored superconducting coil, a superconducting conductor which is fed at a constant speed successively passes through a sealed chamber, an ultrasonic cleaning chamber, a first compressed air blow-drying chamber, a deionized water spray chamber, and a second compressed air blow-drying chamber in the ultrasonic cleaning system. By integrating mechanical dynamic sealing, ultrasonic cleaning and automatic control, the present invention meets a special requirement of removing oil and completely cleaning the conductor during the winding of large-sized superconducting coils.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Cleaning method for quartz glass swing pieces

InactiveCN109013526AEnsure surface cleanlinessImprove coating adhesionDrying gas arrangementsCleaning using liquidsChemistryAcid washing

The invention discloses a cleaning method for quartz glass swing pieces. The quartz glass swing pieces are positioned in a cleaning basket for acid washing, rinsing, ultrasonic cleaning and slow-pulldrying in sequence. In the cleaning method for the quartz glass swing pieces, surface attached matters can be effectively removed through hydrofluoric acid dilute solution; then, the surface cleannessis further guaranteed through rinsing and three-stage ultrasonic cleaning; and finally, the slow-pull drying is performed in pure water, and the surface tension of the water and the wind shearing ofhot wind are used for guaranteeing no water, so that the subsequent film plating adhesion of the quartz glass swing pieces is improved. More swing pieces are once cleaned, and are automatically cleaned and dried to prevent the damage of flexible beams of the swing pieces caused by manual cleaning.

Owner:CHINA BUILDING MATERIALS ACAD

Preparation method of high anti-corrosion coating on surface of sintered Nd-Fe-B magnet

InactiveCN108364780AImprove anti-aging propertiesExtend corrosion resistance timeMagnetic materialsPermanent magnet manufacturePorosityAging resistance

The invention discloses a preparation method of a high anti-corrosion coating on the surface of a sintered Nd-Fe-B magnet. The method comprises the steps that a machined and shaped Nd-Fe-B magnet is preprocessed, the preprocessed Nd-Fe-B product is soaked with a pre-processing solution, and the pre-processing solution is prepared by mixing distilled water, a coating agent and an accelerator; priming coating of a ZnAl coating solution is performed on the surface of the soaked Nd-Fe-B magnet, and the Nd-Fe-B magnet with the ZnAl coating obtained after priming coating is obtained; top coating ofa Al-enriched coating solution is performed on the surface of the Nd-Fe-B magnet obtained after priming coating, and the high anti-corrosion Nd-Fe-B magnet is obtained. Due to two times of coating processing, the porosity between the magnet and a corrosive medium is effectively lowered, the binding force between the coating and the magnet is improved, and the sintered Nd-Fe-B magnet has the good corrosion resistance. Due to the ZnAl coating obtained after priming coating, the quantity of a medium entering the deeper layer of the coating is greatly reduced, and therefore the high temperature and high pressure resistance and the ageing resistance of the magnet are greatly improved.

Owner:EARTH PANDA ADVANCE MAGNETIC MATERIAL

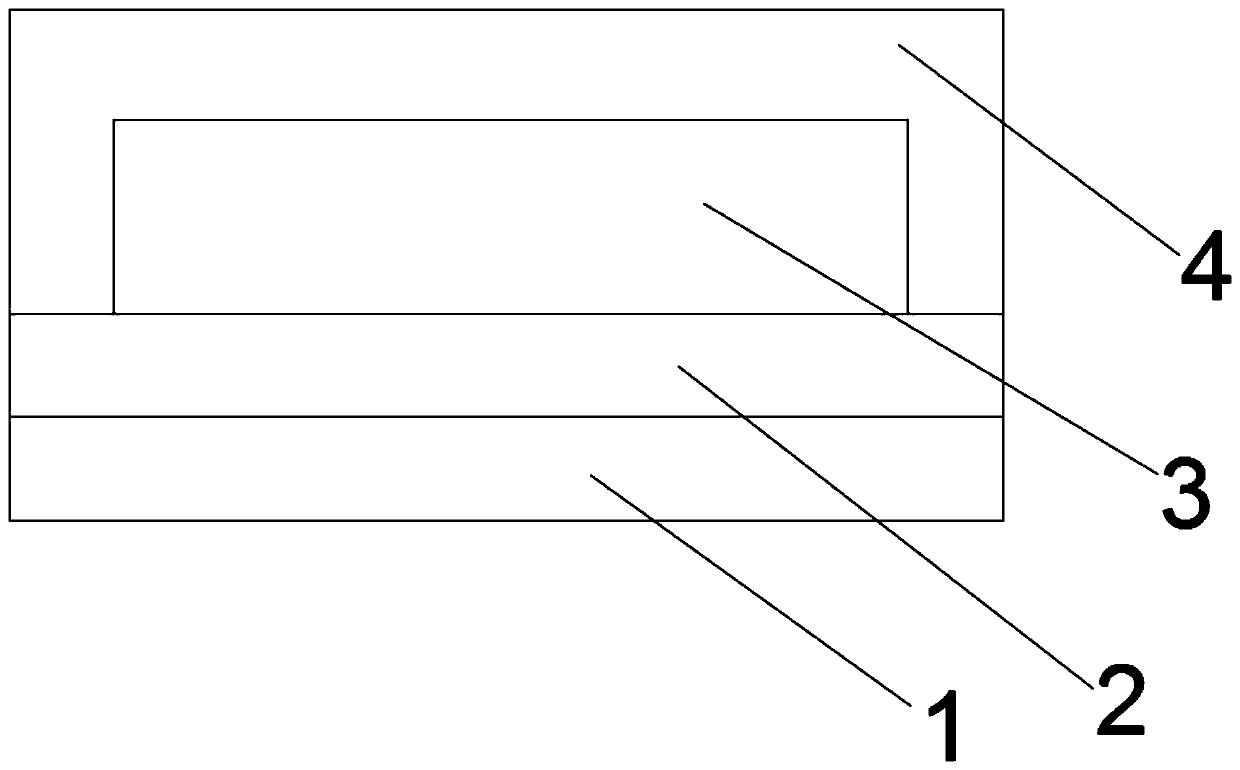

Method for manufacturing mask

InactiveCN108272148AGuaranteed flatnessGuaranteed fitGarment special featuresProtective garmentThermostatNonwoven fabric

The invention discloses a method for manufacturing a mask. The method comprises the following steps of S1, material selection, wherein a non-woven fabric with a certain length is selected as the outerside, a melt-blown fabric is selected as the upper layer of the non-woven fabric, a bamboo fiber spinning layer is used on a layer of the melt-blown fabric, and the bamboo fiber spinning layer, the melt-blown fabric and the non-woven fabric are placed on the selected fabrics from top to bottom; S2, raw material forming at constant temperature,wherein the selected raw materials pass through a thermostat forming machine in a flat laying manner. Compared with the prior art, the method has the advantages that in the process of making the disposable mask, the surface smoothness and the fit degreeof the disposable mask can be effectively ensured, and under existing process conditions, the shaping effect of the disposable mask can be achieved, so that the use effect of the disposable mask is improved, high-efficiency and pollution-free effects in the process of packaging the disposable mask are achieved, the quality and safety of the disposable mask are improved, the surface cleanliness anddrying effect of the mask can be effectively ensured, the production process is advanced, the influence of an enterprise can be effectively improved, and a great popularization value is achieved.

Owner:爱而康医疗(浙江)有限公司

Production method for continuous functional composite material

ActiveCN107571593AImprove surface qualityHigh bonding strengthLamination ancillary operationsPretreated surfacesThermal insulationPipe insulation

The invention provides a production method for a continuous functional composite material. The invention mainly aims to deeply improve and optimize a present production technology and produce two-layer and three-layer functional composite materials with higher applicability and higher bonding property. The product produced according to the method is capable of continuously and stably working at -20 DEG C to 100 DEG C; the product has multiple functions, such as vibration reduction, noise reduction, sound insulation, heat insulation and magnetism resistance; the product is a novel environment-friendly functional composite material and has wide application prospect.

Owner:嘉峪关天源新材料有限责任公司

Dust remover of bamboo piece longitudinal cutting machine

InactiveCN105150307AEasy to clean laterAvoid flying toCane mechanical workingBark-zones/chip/dust/waste removalPhysical healthSurface cleaning

The invention discloses a dust remover of a bamboo piece longitudinal cutting machine. The dust remover comprises a dust hood arranged above a workbench surface and a horn-shaped collector arranged below a conveyor belt above the workbench surface, wherein a first dust remover is arranged on at least one side surface of the dust hood, a second dust remover is further arranged on one side surface of the horn-shaped collector, and both the first dust remover and the second dust remover are automatic dust suction devices. The dust remover is simple in structure and convenient to disassemble, respectively processes bamboo scraps in the cutting, transporting and remaining stages of the bamboo pieces, ensures high automatic cleaning degree in the whole process of longitudinally cutting the bamboo pieces, prevents cutting waste materials from flying about, ensures the surface cleaning degree of a processing site and improves the physical health of processing workers.

Owner:ANHUI HONGYU BAMBOO IND TECH

Graphene cleaning and transferring method

InactiveCN109879277AEnsure surface cleanlinessDoes not degrade electrical performanceCarbon compoundsGrapheneImpurity

The invention discloses a graphene cleaning and transferring method. The graphene cleaning and transferring method includes the following steps: S1, a glue / target substrate / graphene / metal structure isbuilt; S2, etching is conducted to form a graphene / target substrate / glue structure; S3, rinsing is conducted; and S4, drying is conducted. In order to solve the problem of surface residual impuritiesin graphene transferring, the transferring method easy to operate and suitable for various substrates is provided, through the transferring method, the clean graphene surface can be obtained.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Pretreatment Process for Magnesium Alloy Wheel

InactiveUS20150284869A1Ensure surface cleanlinessAnodisationElectrolysis componentsChromium freeCooking & baking

A pretreatment process for a magnesium alloy wheel is provided. The process flow is as follows: washing with hot water; degreasing; washing with hot water; acid washing for surface adjustment; washing with water; washing with pure water; performing chromium-free conversion treatment; washing with pure water; washing with pure water; sealing film; washing with pure water; baking; and spraying (electrophoresis). The process of the present invention can improve corrosion resistance of magnesium alloys and adhesion of surface coating thereof, realizing durable use of the surface of the magnesium alloy wheel. An immersion type treatment is adopted in the pretreatment, and therefore the process time is short, and the formed film is uniform and has good compactness. Application standard for corrosion-resistance of wheels can be reached by combining the pretreatment process with spraying and electrophoresis.

Owner:CITIC DICASTAL

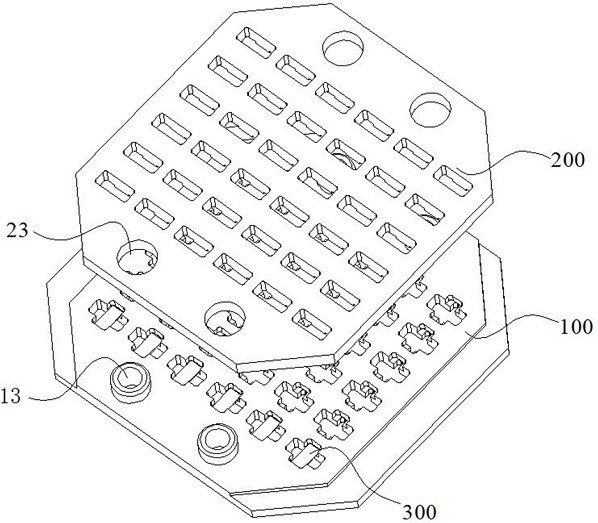

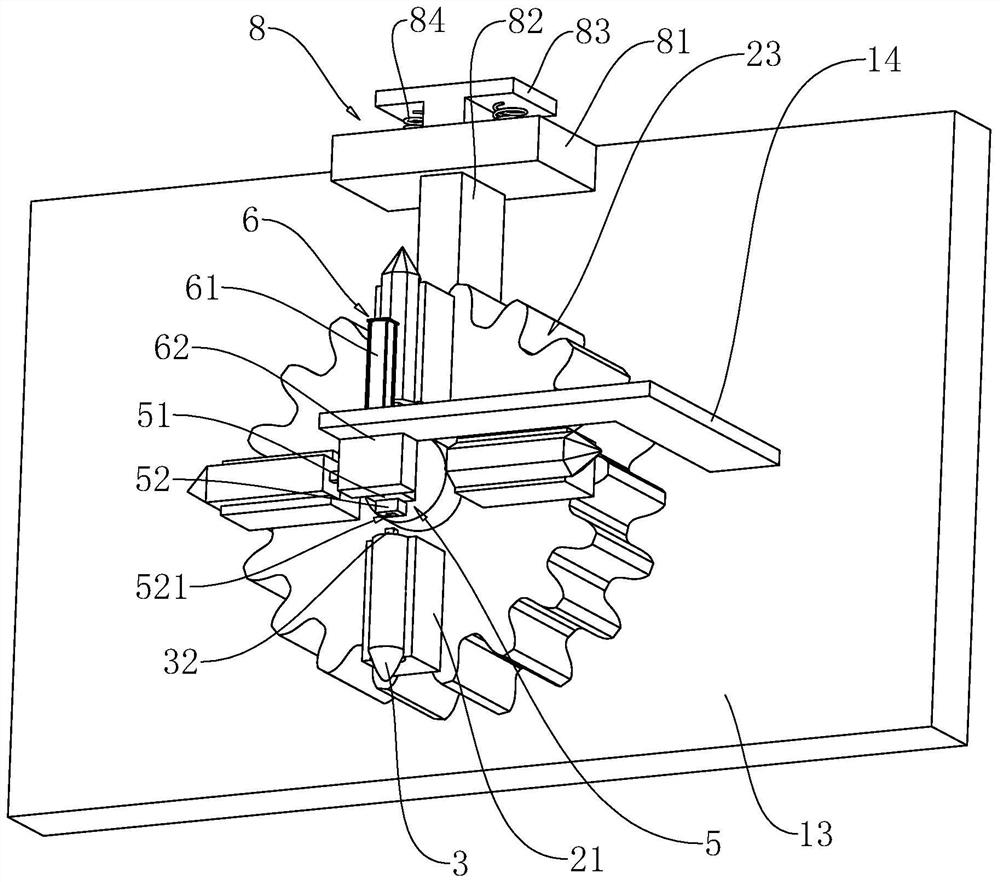

Manufacturing method and manufacturing device of electronic component

ActiveCN114574922AWith electroplatingFunctionalElectrolysis componentsFinal product manufactureElectrical batteryDevice material

The invention discloses a manufacturing method and a manufacturing device of an electronic component, and belongs to the technical field of photovoltaic device manufacturing. The method comprises the following steps of: putting the semiconductor device into a cathode area and driving the semiconductor device to move in the cathode area, switching on a wire plating roller and driving the wire plating roller to rotate, so that a conductive part in the circumferential direction of the outer side of the wire plating roller is plated with a metal wire on the surface of the semiconductor device along the movement direction; the conductive part comprises a wire plating area and a deplating area; an anode is arranged on the outer side of the deplating area and is electrically connected with the positive pole of the power supply through a conductive part of the deplating area; a cathode area capable of placing a semiconductor device is arranged on the outer side of the wire plating area, and the semiconductor device is electrically connected with the negative electrode of the power supply through a conductive part of the wire plating area. The surface wire plating efficiency of the semiconductor device can be improved, the uniformity of a metal layer on the surface of the semiconductor device such as a silicon wafer or a battery piece is improved, and the production efficiency of an electronic element is improved.

Owner:SUZHOU MAXWELL TECH CO LTD

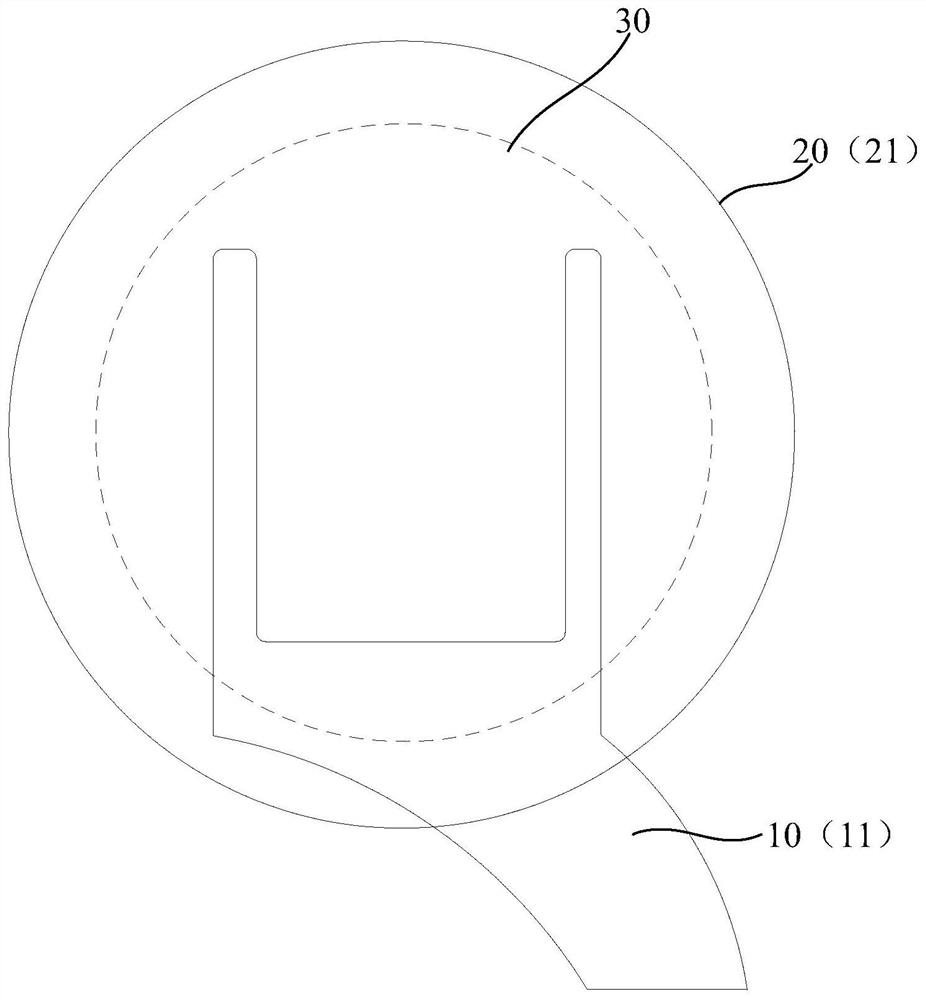

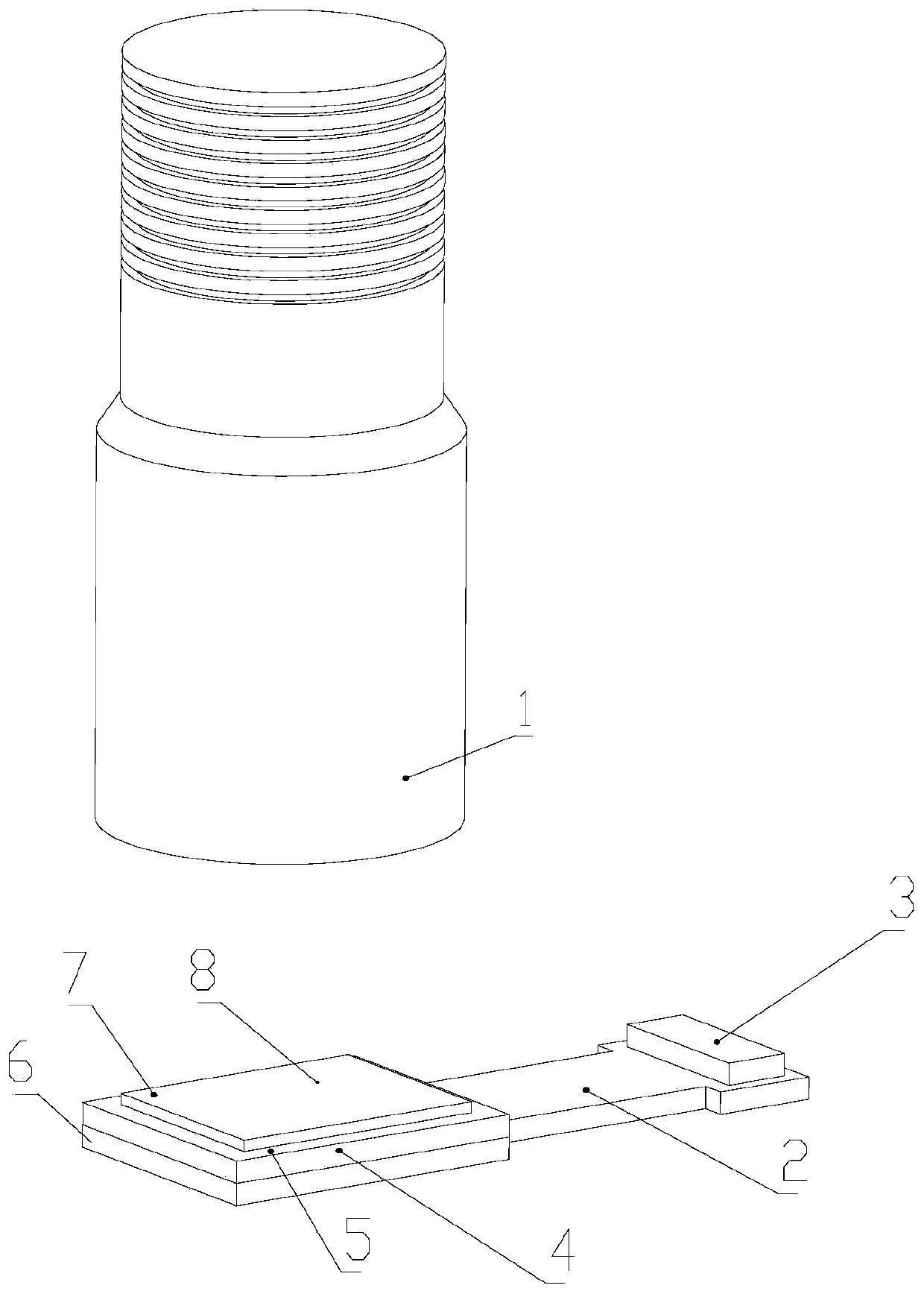

Cleaning tool and cleaning method for semiconductor wafer

ActiveCN114378085AFully cleanedEasy to separate and storeSemiconductor/solid-state device manufacturingFlexible article cleaningWaferingEngineering

The invention provides a cleaning tool and a cleaning method for a semiconductor wafer. The cleaning tool for the semiconductor wafer comprises a first clamping plate and a second clamping plate, a plurality of first through holes are formed in the first clamping plate, and a sinking groove is formed in one side of each first through hole; the sinking groove is formed in the first surface of the first clamping plate, the opening end of the sinking groove is formed in the hole wall of the first through hole, and the sinking groove and the first through hole form a communicating structure; a plurality of second through holes are formed in the second clamping plate, a protrusion is arranged on one side of each second through hole, and the protrusions are arranged on the first surface of the second clamping plate; the multiple first through holes are opposite to the multiple second through holes in a one-to-one mode, one end of the protrusion is located in the sinking groove, and a containing space is defined in the communicating structure based on the end face of the protrusion and the groove bottom of the sinking groove. According to the semiconductor wafer cleaning device, the semiconductor wafers can be conveniently separated and stored, the semiconductor wafers are prevented from being stacked in the cleaning process, the semiconductor wafers can be fully cleaned, the semiconductor wafers are prevented from being broken, damaged or stacked in the cleaning process, and therefore the good cleaning effect is achieved.

Owner:BEIJING CHENJING ELECTRONICS

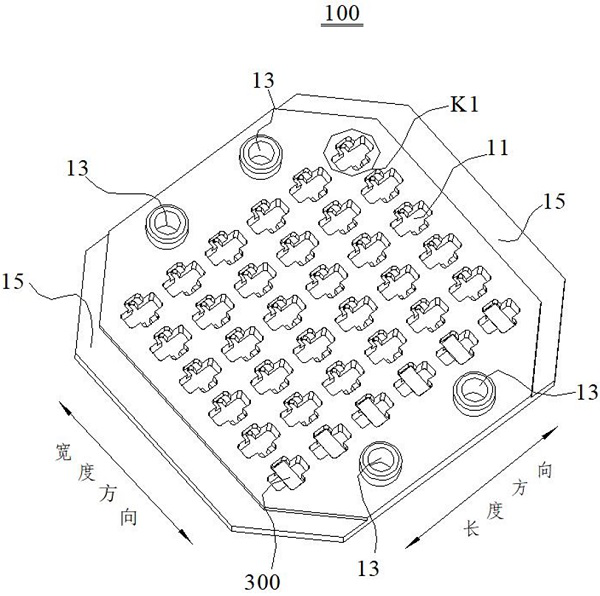

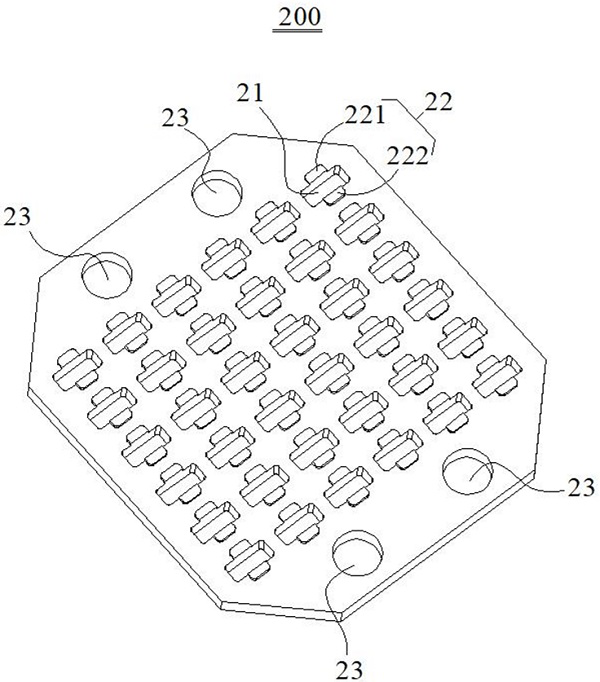

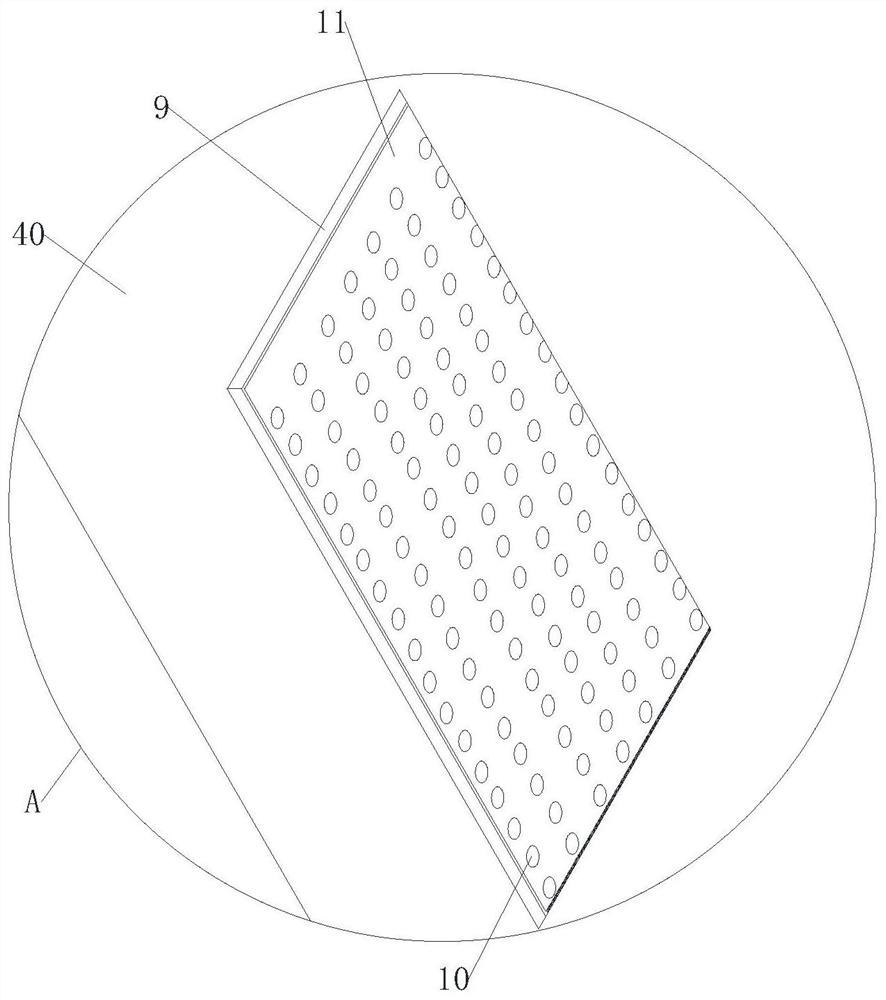

Diversion non-woven composite material synthesis device

InactiveCN111634009AEffective bondingWill not cause mutual stickingDirt cleaningCleaning using toolsMaterial synthesisAdhesive glue

The invention relates to a diversion non-woven composite material synthesis device. The device comprises a glue transfer roller, a pressure roller and a winding roller, and further comprises a first glue leveling mechanism and a second glue leveling mechanism, wherein the first glue leveling mechanism comprises a scraping assembly, a glue feeding assembly and a glue transfer assembly; the second glue leveling mechanism comprises a variable speed assembly, a stretching assembly and a glue coating assembly; when composite operation of the pressure roller is carried out by the stretching assembly, glue is extruded onto the stretching assembly, then the extruded glue is transferred to the glue coating assembly through the stretching assembly, and the glue is transferred to the upper surface ofa diversion net and the lower surface of a perforated isolation film through the driving glue coating assembly. According to the device, the technical problems that when the composite operation is carried out between the diversion net and the perforated isolation film, water-based glue on a glue roller will flow out from gaps of the diversion net to the non-composite surface of the diversion net,then the non-composite surface of the diversion net and the perforated isolation film in contact with each other may be bonded together during winding operation, and manual separation is required inlater use are solved.

Owner:潘利斌

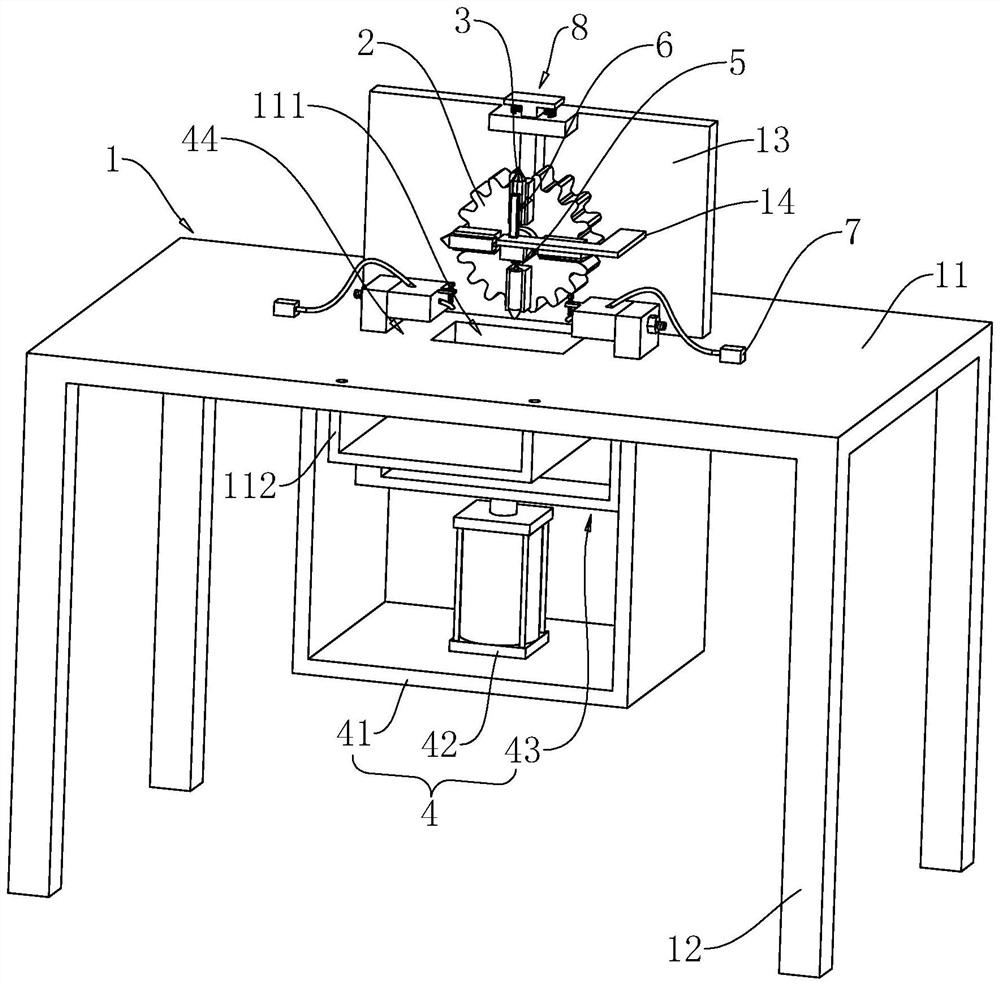

Sole drilling equipment

The invention relates to the technical field of shoe material processing equipment, and discloses sole drilling equipment which comprises a rack, a rotating disc rotationally arranged on the rack, a plurality of drill bits detachably connected to the rotating disc and a positioning assembly used for fixing a to-be-processed sole, and the multiple drill bits are different in shape and distributed in the circumferential direction along the central axis of the rotating disc; a support is arranged on the machine frame, a rotating assembly and a lifting assembly used for driving the rotating assembly to vertically move are connected to the support, the rotating assembly comprises a rotating motor and a rotating block arranged on an output shaft of the rotating motor, and a non-circular inserting groove is formed in the bottom face of the rotating block. Inserting blocks with the same shape as the inserting grooves are fixed to the sides, close to the central axis of the rotary disc, of the drill bits, and the inserting blocks on the drill bits can sequentially move to the positions under the inserting grooves along with the rotary disc and are embedded into the inserting grooves. The drilling device has the effect that the drilling requirements of various shapes can be met.

Owner:夏书妍

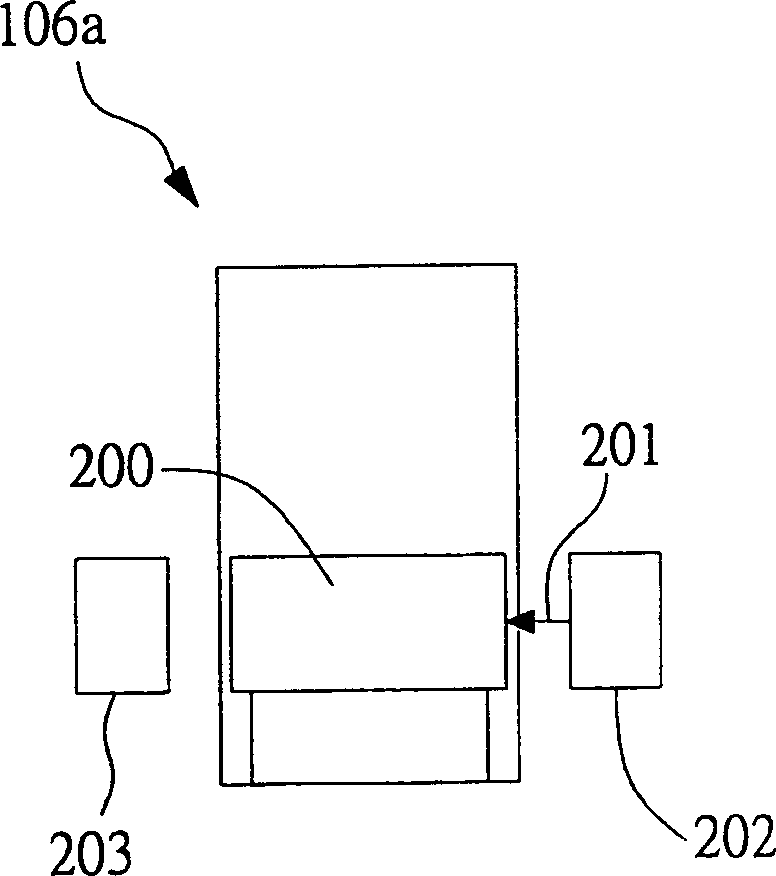

Wafer processing device, wafer conveying assembly and working method thereof

InactiveCN113206032APrevent oxidationAvoid pollutionSemiconductor/solid-state device manufacturingCleaning using gasesParticulatesWafer

The invention relates to a wafer processing device, a wafer conveying assembly and a working method thereof. The wafer conveying assembly comprises a moving mechanism and a purging structure. The moving mechanism comprises a tray. The tray can drive the wafer to move into the process chamber or move out of the process chamber. The purging mechanism is provided with a purging surface, and the purging area of the purging surface can completely cover the wafer placed on the tray. And when the tray of the moving mechanism drives the wafer to be positioned outside the process chamber, the purging mechanism is arranged right above the tray at an interval, so that the purging surface and the wafer on the tray are arranged in a face-to-face manner. In the process that the protective gas directly faces the wafer and purges the whole outer surface of the wafer, the pollution phenomenon that oxidation or particulate matter adheres to the surface of the wafer can be well avoided, it can be avoided that when the moving mechanism carries the wafer to move into the process cavity, water vapor is brought into the process cavity synchronously, and the surface cleanliness of the wafer can be guaranteed; and the surface of the wafer can be prevented from being oxidized, and the product quality is improved.

Owner:CHANGXIN MEMORY TECH INC

Rust-proof durable digital printer

ActiveCN109397900AEnsure surface cleanlinessGuaranteed effectOther printing apparatusEngineeringPrinting ink

The invention discloses a rust-proof durable digital printer. The rust-proof durable digital printer comprises a board body; a limiting block, a supporting frame, a fixing tank and a first hinge baseare fixed to the top of the board body; supporting legs are fixed to the bottom of the board body; a track groove is formed in the top of the board body; a movable tank is arranged on the top of the board body; movable wheels are movably installed at the bottom of the movable tank; the bottoms of the movable wheels make contact with the groove bottoms of the track groove; a movable groove is formed in the side face of the movable tank; a movable rod penetrates through the movable groove; a mounting tank is fixed to the outer side of the fixing tank; and a first air bellow, a transfer tank anda second air bellow are fixed to the top of the movable tank. Impurity removal is conducted on objects before printing, drying and curing of printing ink on the surface of the printed objects are accelerated, the height of the body is convenient to adjusted and the body is prevented from rusting, so that the digital printer is convenient to use, the protection function is achieved, and durabilityof the digital printer is improved.

Owner:GUANGZHOU NUOCAI DIGITAL PROD CO LTD

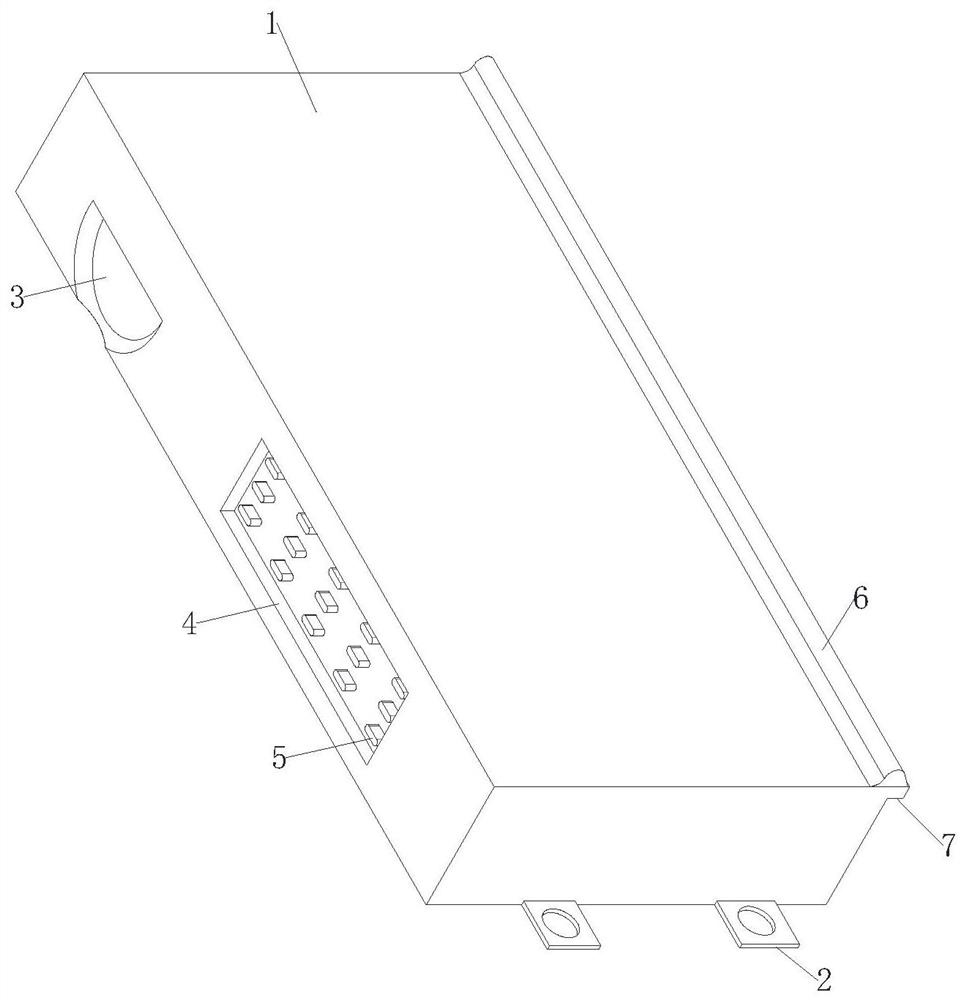

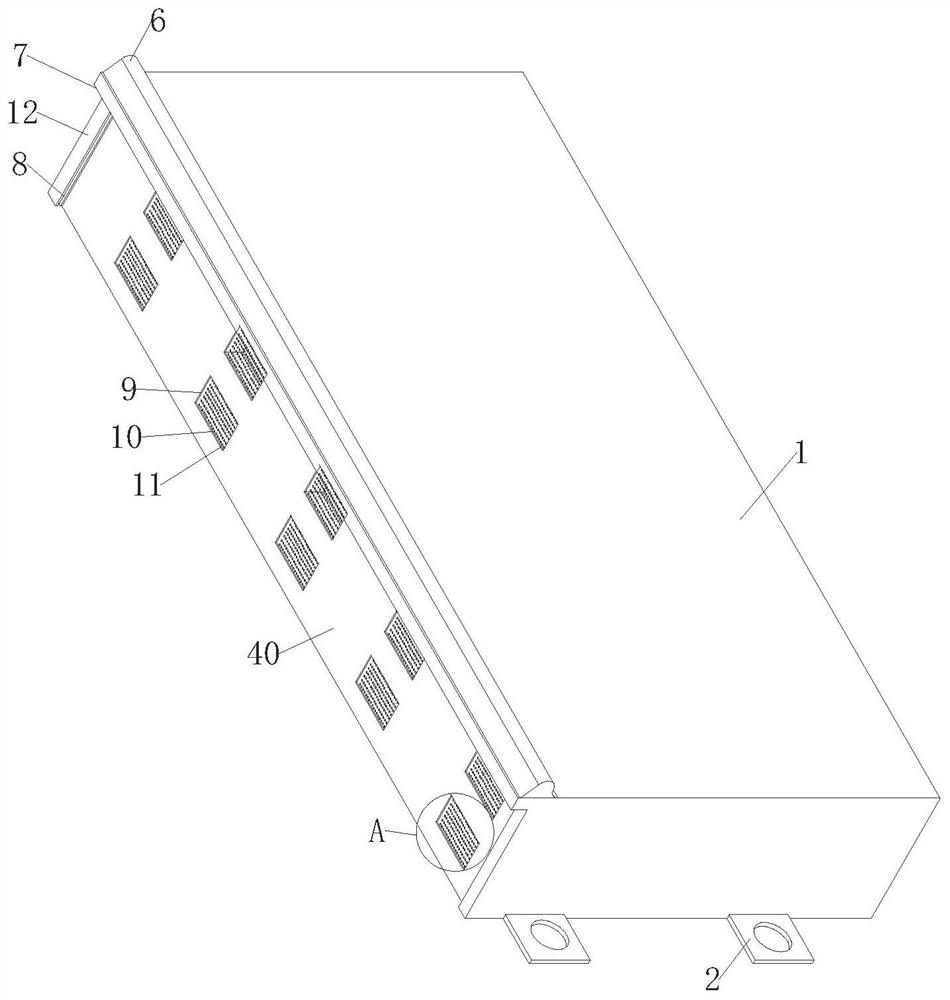

Intelligent dust removal type communication equipment for new energy automobile

InactiveCN112291953AEasy to installImprove installation firmnessCasings with display/control unitsCoupling device detailsNew energyDust control

The invention provides intelligent dust removal type communication equipment for a new energy automobile, and relates to the technical field of new energy automobiles. The intelligent dust removal type communication equipment comprises a communication box fixedly installed at the bottom of an automobile, the communication box is arranged to be in a square block shape, and fixing bottom feet are symmetrically arranged on the two side walls of the square-block-shaped communication box; the communication box is fixedly installed at the bottom of an automobile through fixing bottom feet on the twosides. A rolling box is arranged at the top end of a dust blocking awning, a flexible panel in front of a connecting panel is contained in the rolling box, the flexible panel is rolled upwards, a connecting wire can be conveniently and rapidly communicated with a connecting notch in the connecting panel, and side rib plates are symmetrically arranged on the left side and the right side of the connecting panel; slideways standing at the bottom end of the dust blocking awning are symmetrically formed in the inner side walls of the side rib plates on the two sides so that the flexible panel canstretch out downwards along the slideways when stretching out downwards, the contact distance between the flexible panel and the connecting panel can be better controlled, and the cleaning and brushing effect of the first cleaning and brushing bristles on the surface of the flexible panel on the surface of the connecting panel can be improved.

Owner:磐安纵横信息科技有限公司

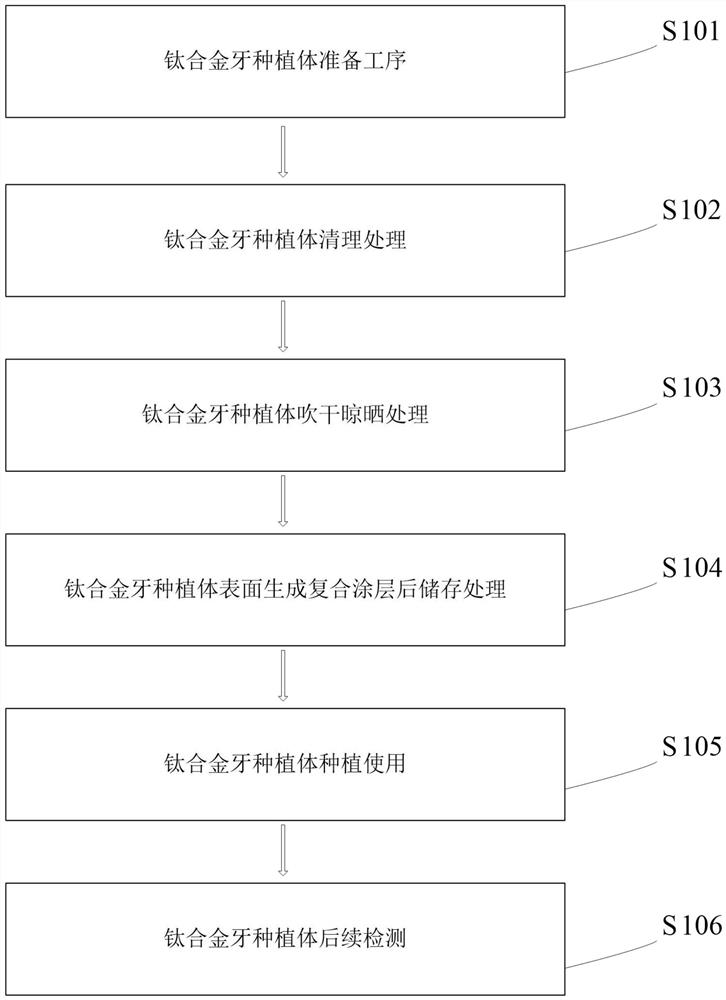

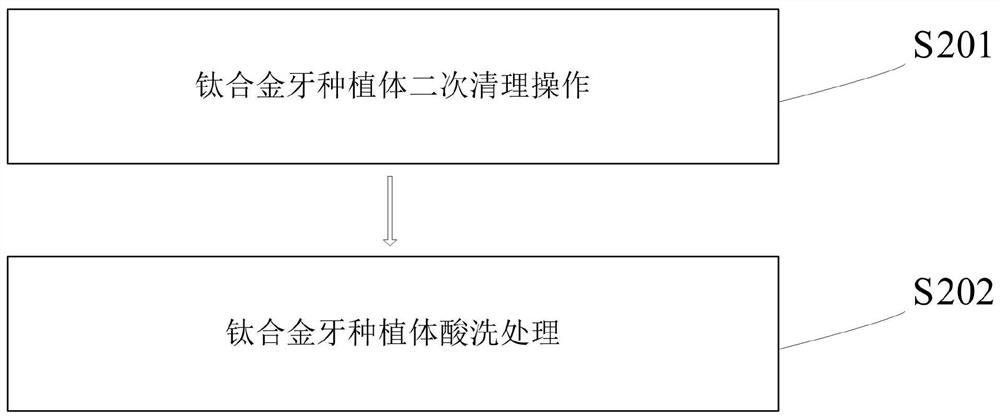

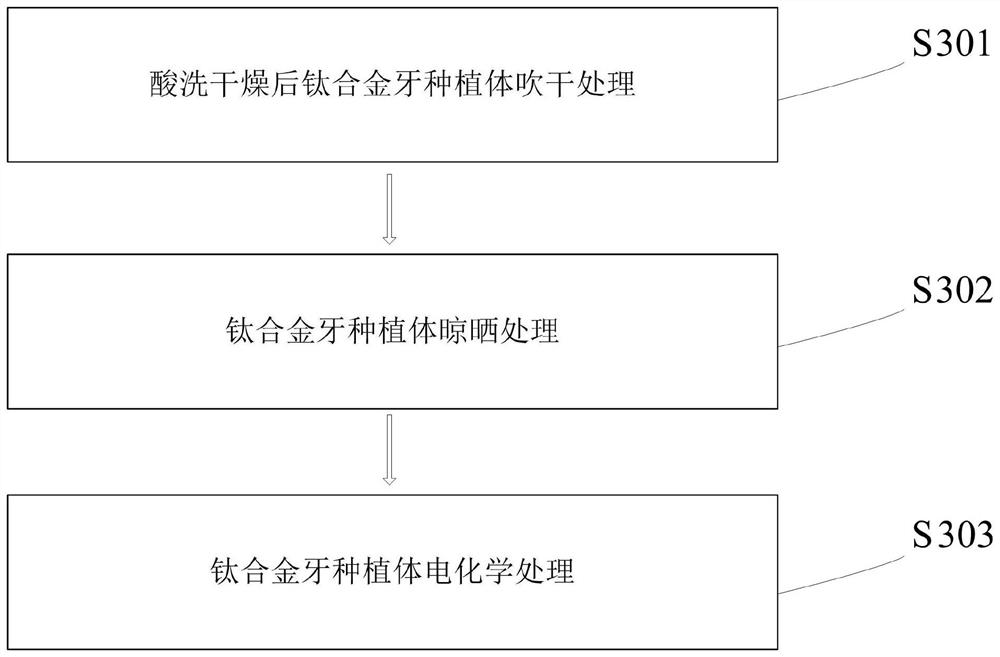

Preparation method of titanium alloy dental implant surface composite coating

InactiveCN112843331AEnsure surface cleanlinessEasy to useTissue regenerationCoatingsMetallurgyTitanium alloy

The invention provides a preparation method of a titanium alloy dental implant surface composite coating, and belongs to the field of surface modification of oral titanium alloy dental implants. The preparation method of the titanium alloy dental implant surface composite coating comprises the specific steps of titanium alloy dental implant preparation, titanium alloy dental implant cleaning treatment, titanium alloy dental implant blow-drying and airing treatment, storage treatment after a composite coating is generated on the surface of the titanium alloy dental implant, titanium alloy dental implant implanting and using, and titanium alloy dental implant subsequent detection. The method is mature in process and simple to operate, the process of cleaning the surface of the titanium alloy dental implant for many times is added to ensure the cleanliness of the surface of the titanium alloy dental implant and further ensure the adhesiveness of the coating, meanwhile, the use effect of the titanium alloy dental implant is ensured through the clear transportation and use process, unnecessary damage can be avoided, the utilization rate of the titanium alloy dental implant is guaranteed, the implanting effect is improved, and the implanting rate is guaranteed.

Owner:SHANDONG MAIER DENTAL MATERIALS CO LTD

Shearing blade for plastic lens pouring gate

PendingCN110587670AImprove image qualityEliminate reflectionOptical articlesMetal working apparatusRough surfaceImaging quality

The invention relates to a shearing blade for a plastic lens pouring gate. The shearing blade comprises a positioning portion and a shearing portion connected with the positioning portion; in the thickness direction of a shearing blade body, a first surface and a second surface are arranged oppositely on the shearing portion; in the direction away from the positioning portion, the thickness of theshearing portion gradually decreases, and the first surface and the second surface intersect at the farthest end to form a knife-edge structure; and the first surface is a rough surface. The first surface of the shearing portion is arranged as the rough surface, so that when a plastic lens is sheared by the shearing blade, the first surface can be used for directly processing the shearing surfaceon the plastic lens into the rough surface; and the reflection effect of a traditional smooth shearing surface on light is eliminated, so that the shearing surface formed by using the shearing bladehas a good suppression effect on the formation of stray light, and the shearing blade is beneficial to improving the imaging quality of the lens.

Owner:ZHEJIANG SUNNY OPTICAL CO LTD

Multifunctional fancy yarn stranding device

PendingCN109322025AGuaranteed length requirementGuaranteed stock requirementsFibre cleaning/openingYarnYarnCanis lupus familiaris

The invention discloses a multifunctional fancy yarn stranding device. The multifunctional fancy yarn stranding device comprises a first winding disc, a second winding disc, fixing shafts, a supporting base, a connecting base, a base, a fixed wheel base, a yarn pressing wheel, an I-type supporting frame, a false twister, a stranding length adjustable mobile rail structure, a stranded fancy yarn collecting wheel structure, an adjustable fancy yarn surface dust clearing wheel structure, decorative yarn and core yarn, and the first winding disc and the second winding disc are installed in the middles of the upper side and the lower side inside the supporting base through the fixing shafts respectively. By arranging an installing base, a supporting pillar, an inverted-U-shaped sliding block, alinear slide rail, a stop dog and an adjusting bolt, the position of the inverted-U-shaped sliding block on the upper portion of the outer wall of the linear slide rail is slidingly and easily adjusted according to the requirement of stranding length to change the position of the false twister and guarantee the length position to meet the requirement of stranding.

Owner:JIANGSU XINFANG TEXTILE GROUP

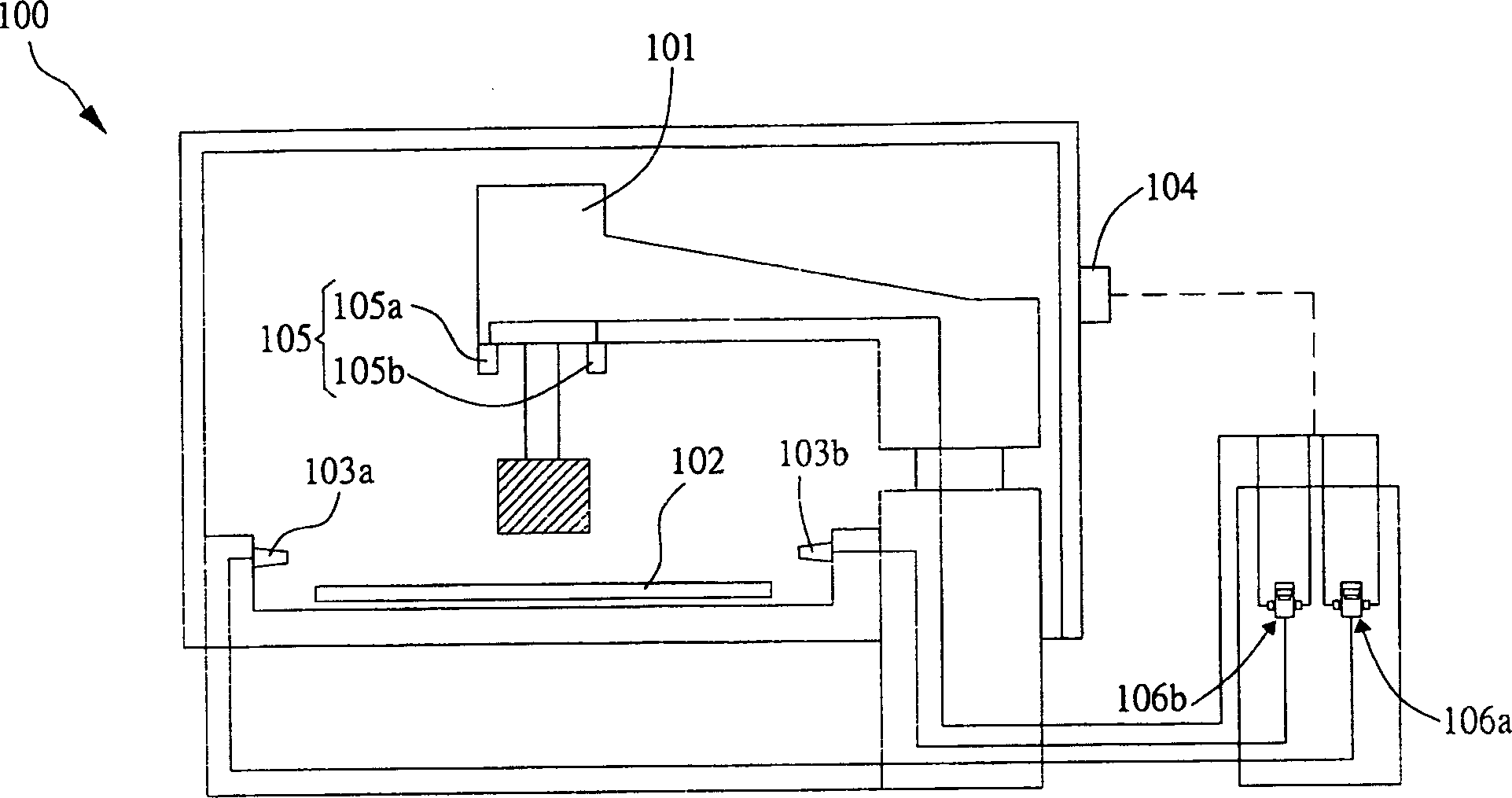

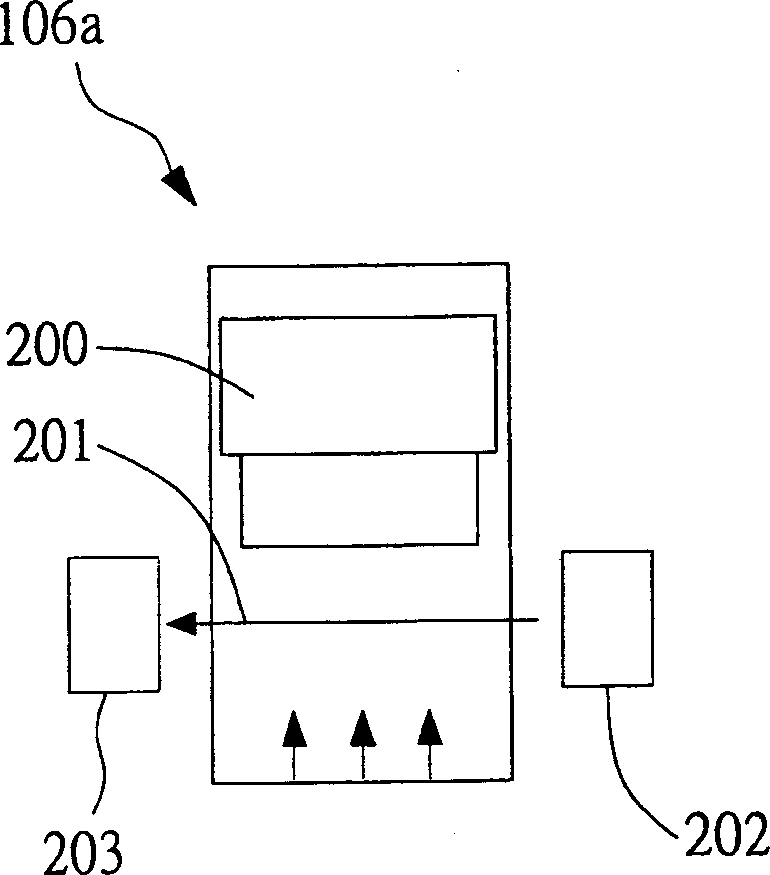

Wet type cleaning process monitoring apparatus and monitoring method

InactiveCN1770420AMonitoring statusEffective Monitoring StatusSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingEngineeringTransistor

This invention relates to one clearing process monitoring device with one clearing arm and one fluid part. When the arm cleans the transistor, the flow provides one fluid part on transistor. The monitor device at least comprises the following parts: arm position sensor connected to arm when the sensor is started; at least one flow sensor unit connected to flow unit to monitor flow providing unit when started. The flow sensor unit at least comprises the following: emission end, receiving end and floating parts, wherein, the receiving end responds to eradiation end to receive signals. The floating element is located between emission end and receiving end. The floating part alters position. The float element makes the receiving end receive the signals from emission end.

Owner:POWERCHIP SEMICON CORP

Method for Detecting Dirty Defects on Image Sensor Surfaces

ActiveCN106226270BEnsure surface cleanlinessReduce missed detectionScattering properties measurementsLuminescenceImaging data

The invention provides a method for detecting a surface dirt defect of an image sensor. The method comprises the following steps: step S10, irradiating the surface of the image sensor through a telecentric collimated light source; step S20, starting an image sensor, performing imaging to the surface of the image sensor, and collecting the surface of the image sensor and forming image data of surface dirt defect particles; and step S30, obtaining a detection result about whether a surface dirt defect exists on the surface of the image sensor according to the image data. According to the method, the problem of missed detection that is prone to happen when an image sensor is subjected to surface dirt defect detection through a uniform luminescence light source in the prior art is solved.

Owner:深圳睿晟自动化技术有限公司

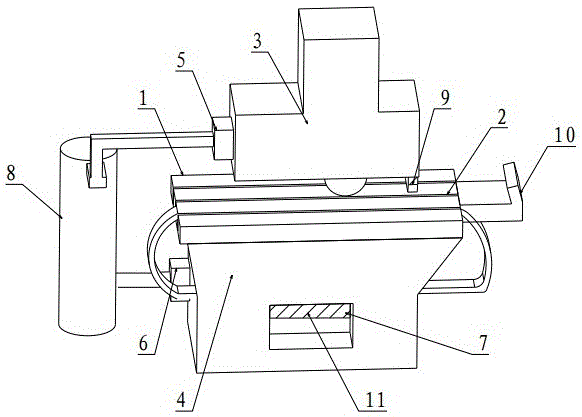

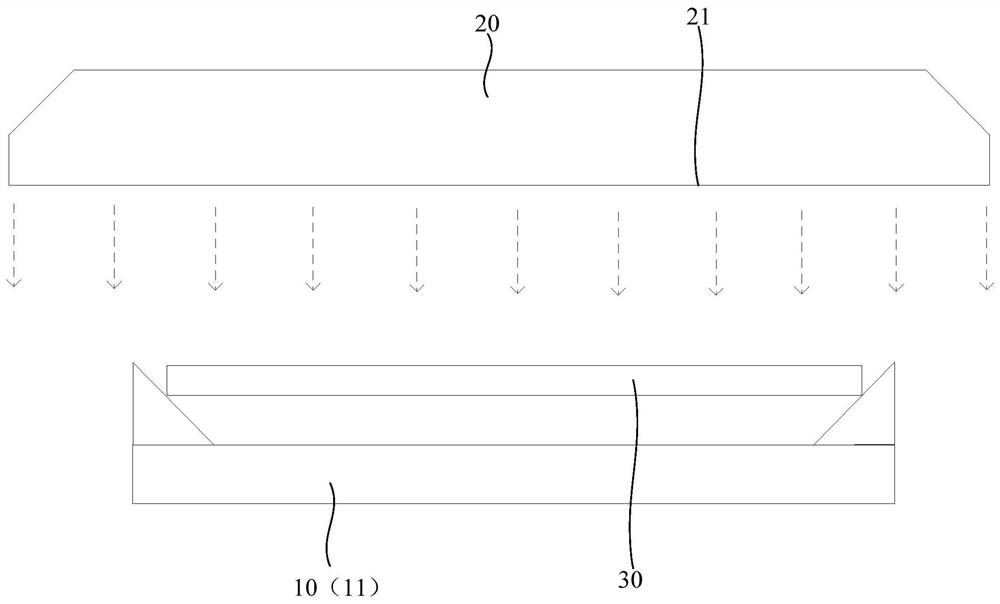

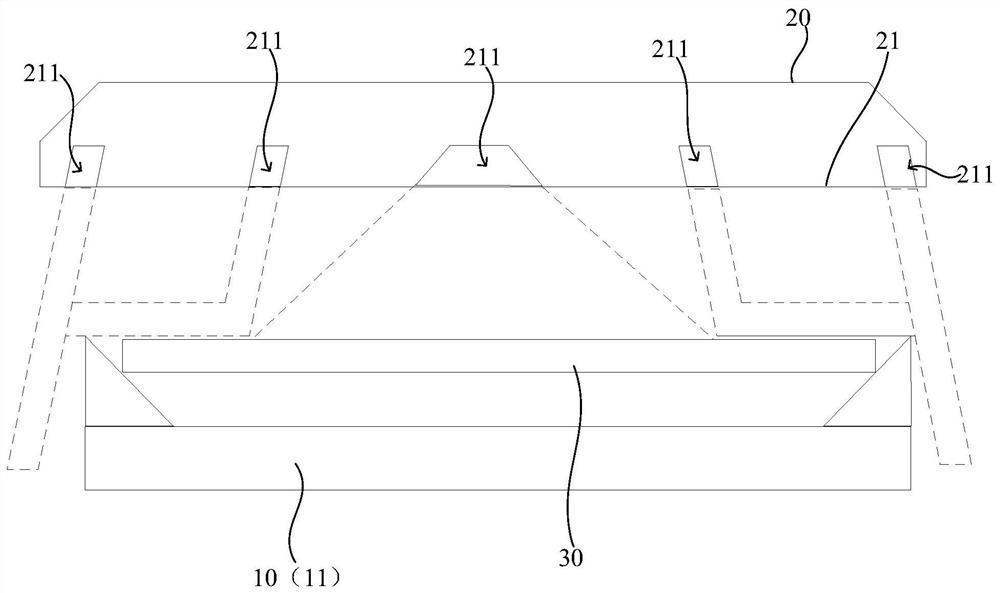

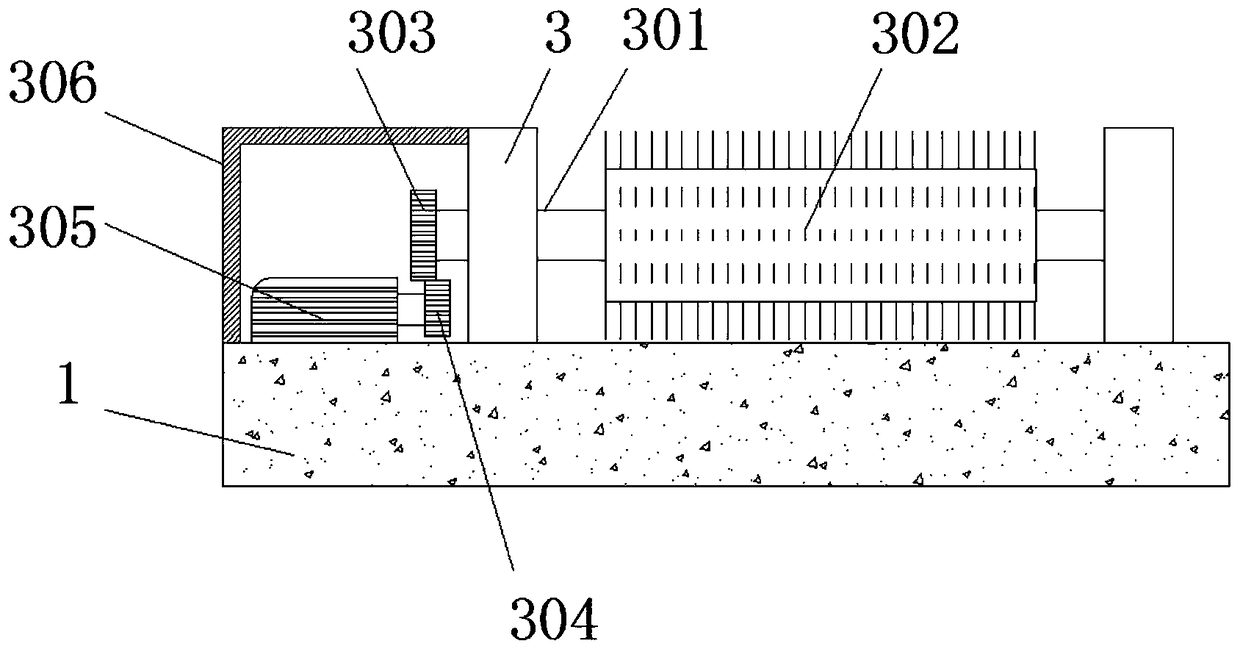

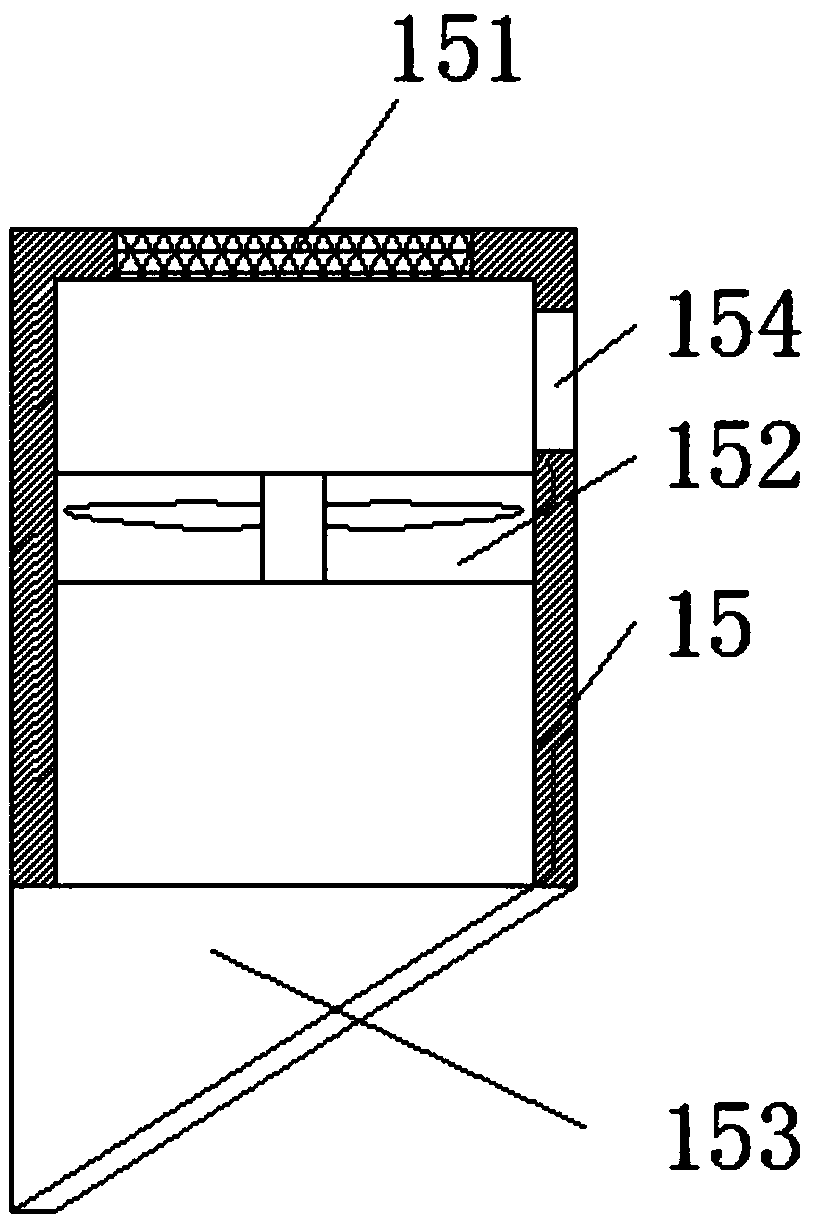

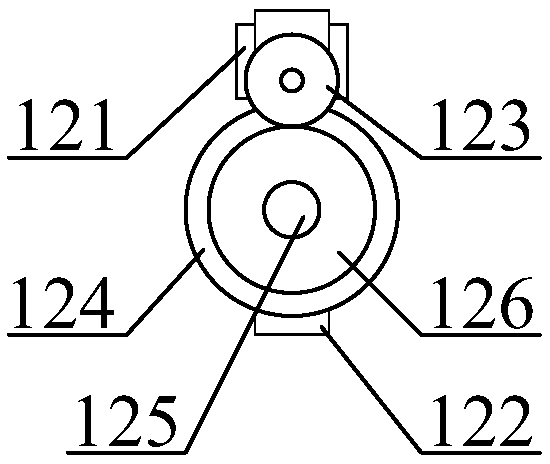

Cleaning and drying integration device for mechanical parts

InactiveCN110270537AClean evenly and thoroughlyEnsure surface cleanlinessDrying gas arrangementsCleaning using liquidsEngineeringLiquid tank

The invention discloses a cleaning and drying integration device for mechanical parts. The cleaning and drying integration device comprises a conveying device body, a cleaning device body and a drying device body, wherein the conveying device body comprises a conveying belt which is driven by a chain wheel arranged in the conveying belt; the cleaning device body comprises a cleaning chamber; a cleaning spray head is arranged in the cleaning chamber and communicates with a cleaning liquid tank arranged outside the cleaning chamber; the drying device body comprises a drying chamber; a drying nozzle is arranged in the drying chamber and communicates with an air heater arranged outside the drying chamber; and the conveying belt sequentially passes through the inside of the cleaning chamber and the inside of the drying chamber. According to the cleaning and drying integration device for the mechanical parts, the mechanical parts can be uniformly and thoroughly cleaned after being processed through multiple cleaning processes, so that the surface cleanliness of the mechanical parts is guaranteed.

Owner:长兴恒腾机械设备有限公司

A kind of production method of continuous functional composite material

ActiveCN107571593BImprove surface qualityHigh bonding strengthLamination ancillary operationsLaminationThermal insulationNoise reduction

Owner:嘉峪关天源新材料有限责任公司

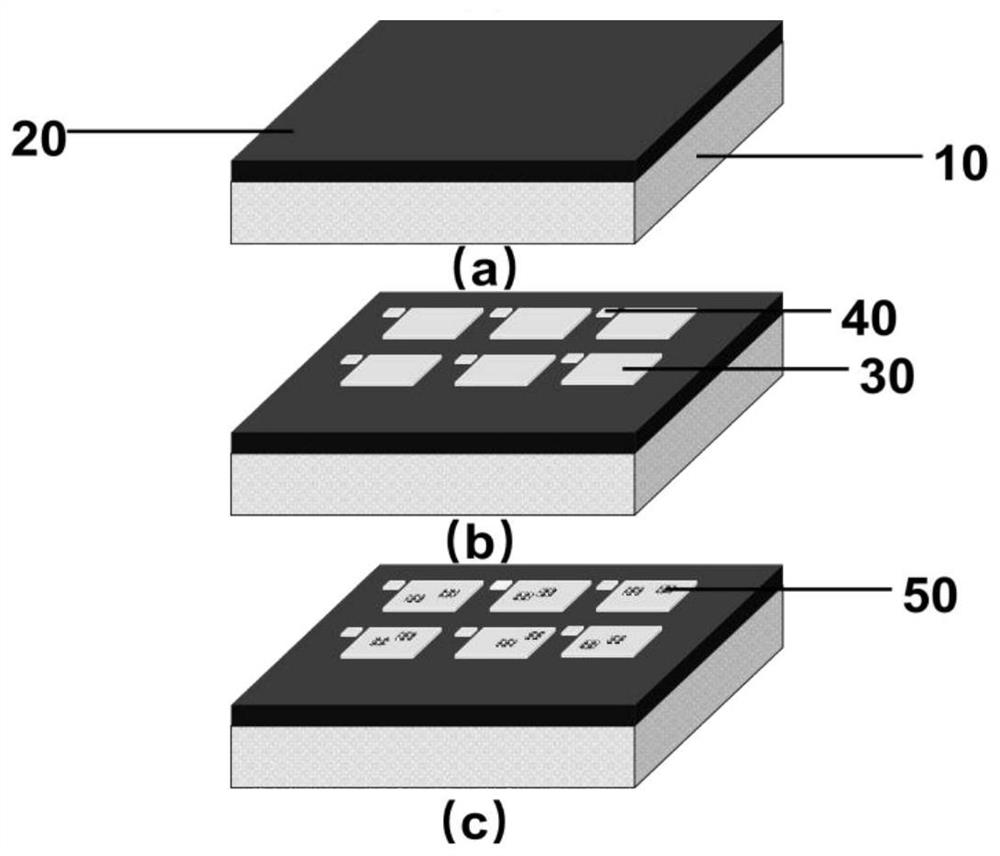

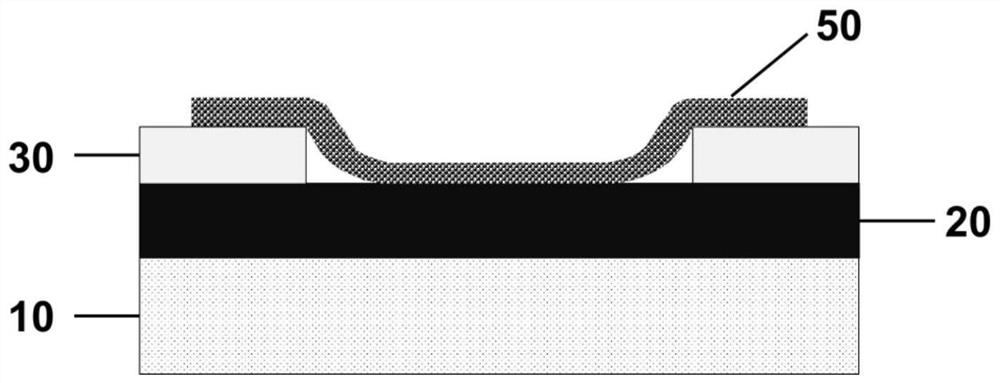

Preparation method of device based on two-dimensional material

InactiveCN111681964AEasy to manufactureWill not remainSemiconductor/solid-state device detailsSolid-state devicesCapacitanceField effect

The invention belongs to the technical field of two-dimensional materials, and particularly relates to a preparation method of a device based on a two-dimensional material. According to the invention,the method comprises the steps: employing a mark plate containing a labyrinth type source-drain electrode pattern for forming a mark and a labyrinth type source-drain electrode on a target substratein one step, and then transferring the two-dimensional material to the target substrate, so a device based on the two-dimensional material can be prepared simply and efficiently, and the method is suitable for preparing devices of any substrate; the device comprises a field effect transistor, a resistor, a capacitor and the like.

Owner:FUDAN UNIV

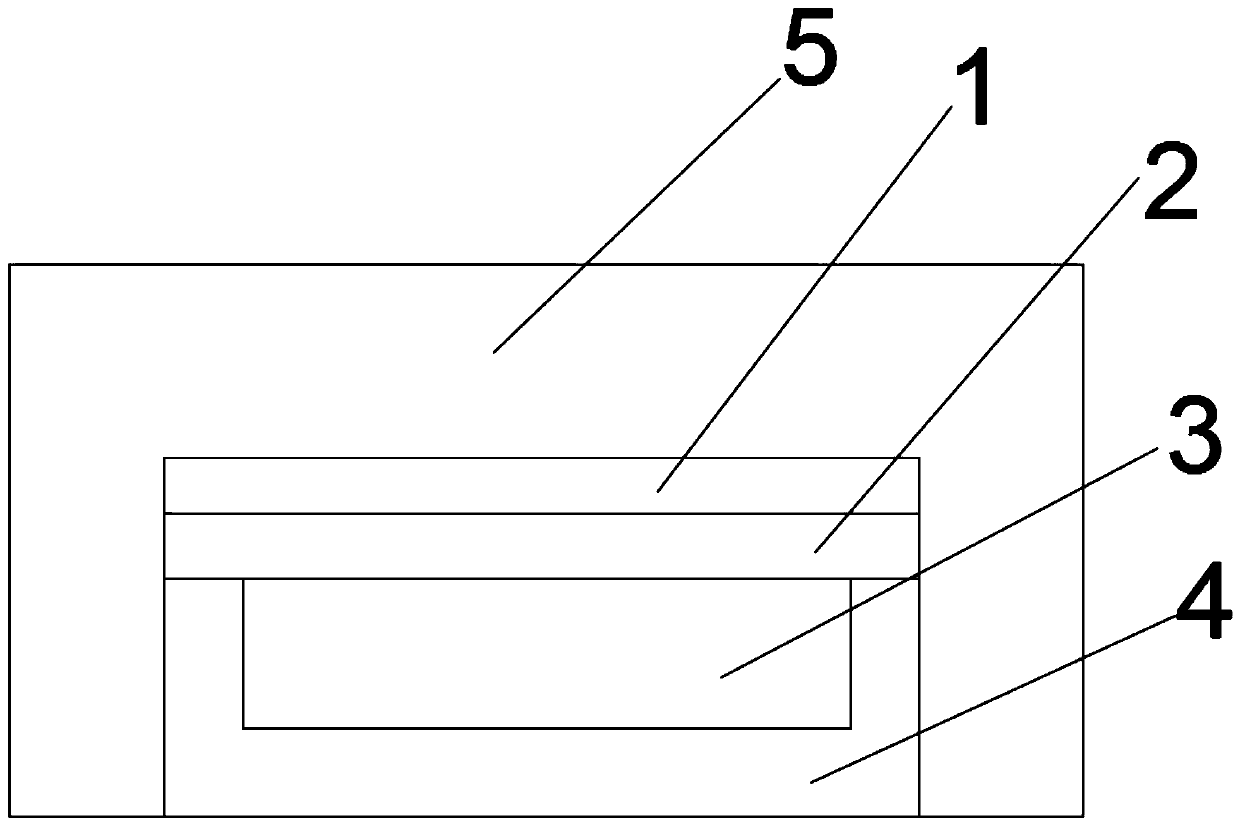

Oil smoke purifier power supply capable of effectively reducing oil stain influence

InactiveCN112333946AEnsure surface cleanlinessEasy to clean and replaceCoupling device detailsCasings/cabinets/drawers detailsProcess engineeringMechanical engineering

The invention discloses an oil smoke purifier power supply capable of effectively reducing oil stain influence, which comprises a power supply body; wherein a mounting base is mounted at the bottom end of the power supply body, an external connecting wire is arranged outside the power supply body, and a protective cover is mounted between the power supply body and the external connecting wire, anda quick butt joint mechanism is connected between the protective cover and the mounting base. According to the scheme, the protective cover is installed outside the power source of the lampblack purifier, oil stains outside the power source can be effectively isolated through the protective cover, and therefore the influence of the oil stains on the power source is effectively reduced, the protective cover is fixed to the base through the alignment column, and the alignment groove and the clamping groove are formed in the base in advance; and the alignment columns are effectively inserted andthen clamped through the clamping blocks, so that the position of the protective cover is quickly fixed, a user can conveniently mount and dismount the protective cover, the protective cover is conveniently replaced and cleaned, and therefore, the surface cleanliness of the lampblack purifier power supply is effectively guaranteed.

Owner:天长市兴龙电子有限公司

A rust-proof and durable digital printer

ActiveCN109397900BEnsure surface cleanlinessGuaranteed effectOther printing apparatusComputer printingPrinting ink

The invention discloses a rust-proof durable digital printer. The rust-proof durable digital printer comprises a board body; a limiting block, a supporting frame, a fixing tank and a first hinge baseare fixed to the top of the board body; supporting legs are fixed to the bottom of the board body; a track groove is formed in the top of the board body; a movable tank is arranged on the top of the board body; movable wheels are movably installed at the bottom of the movable tank; the bottoms of the movable wheels make contact with the groove bottoms of the track groove; a movable groove is formed in the side face of the movable tank; a movable rod penetrates through the movable groove; a mounting tank is fixed to the outer side of the fixing tank; and a first air bellow, a transfer tank anda second air bellow are fixed to the top of the movable tank. Impurity removal is conducted on objects before printing, drying and curing of printing ink on the surface of the printed objects are accelerated, the height of the body is convenient to adjusted and the body is prevented from rusting, so that the digital printer is convenient to use, the protection function is achieved, and durabilityof the digital printer is improved.

Owner:GUANGZHOU NUOCAI DIGITAL PROD CO LTD

A device for cleaning the surface of optical components by ion wind and electrostatic coupling

ActiveCN111229727BImprove securityEnsure safetyElectrode carrying meansElectrostatic cleaningIon windSurface cleaning

The invention relates to a device for cleaning the surface of an optical element by ion wind and electrostatic coupling, which belongs to the field of clean technology. The purpose is to solve how to clean the surface of optical components in an environment that cannot be reached manually, including fixed brackets, optical components, ion wind system, electrostatic adsorption system and particle pollutant storage box; the ion wind system consists of air knife, Composed of ion rods, ion rod brackets, fixed brackets, connecting pieces, and three-degree-of-freedom combined translation stages, the electrostatic adsorption system consists of rod-shaped electrodes, electrode fixing supports, manual translation tables, and fixed brackets. The box support frame is connected with the working surface. The included angle between the particle pollutant storage box and the storage box support frame is 135°. The structure of the present invention is very compact, the optical element is fixed on the bottom plate through the fixed bracket, the mass production is high, the cost is low, the ion wind blowing is adopted, the high-voltage adsorption effect is good, and it has the characteristics of leakage protection performance and high safety factor.

Owner:HARBIN INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com