Manufacturing method and manufacturing device of electronic component

A technology of electronic components and manufacturing methods, which is applied in the field of photovoltaic device manufacturing, can solve problems such as metal plating residue and uniformity reduction of metal layers, and achieve the effects of improving uniformity, improving uniformity, and improving plating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

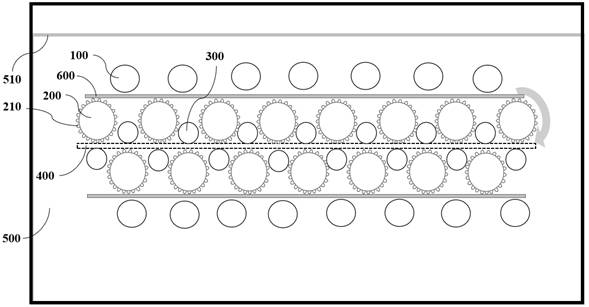

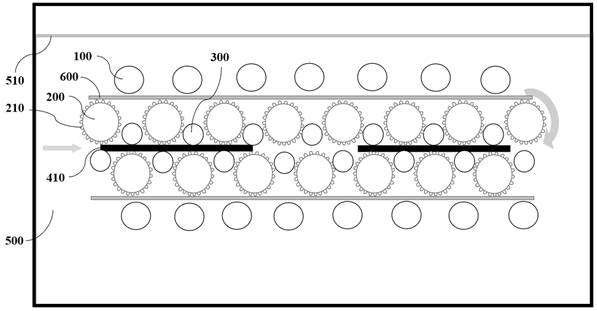

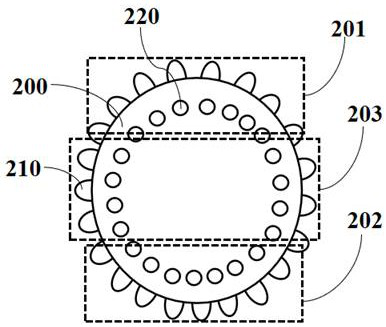

Image

Examples

Embodiment 1

[0048] Perform the surface of the silicon wafer surface of the electroplating, select 25 points evenly, and get the uniformity value of the test results calculation, record it in Table 1.

[0049] Table 1. Different embodiments The uniformity of the surface plating of the silicon wafer surface

Embodiment 2

[0050] Perform uniform testing of the surface of the silicon wafer completed by electroplating, and record the test results in Table 1.

Embodiment 3

[0052] Perform uniform testing of the surface of the silicon wafer completed by electroplating, and record the test results in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| velocity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com