Oil smoke purifier power supply capable of effectively reducing oil stain influence

A technology of oil fume purifier and power supply, which is applied in the direction of circuits, electrical components, and parts of connecting devices, etc. It can solve the problems of oil stains attached to the surface, affecting the working effect of the high-voltage power supply of the oil fume purifier, and the processing effect becomes poor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

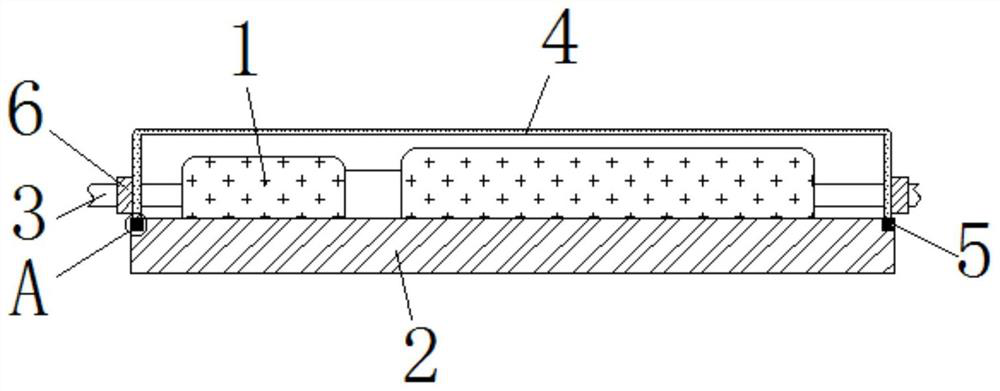

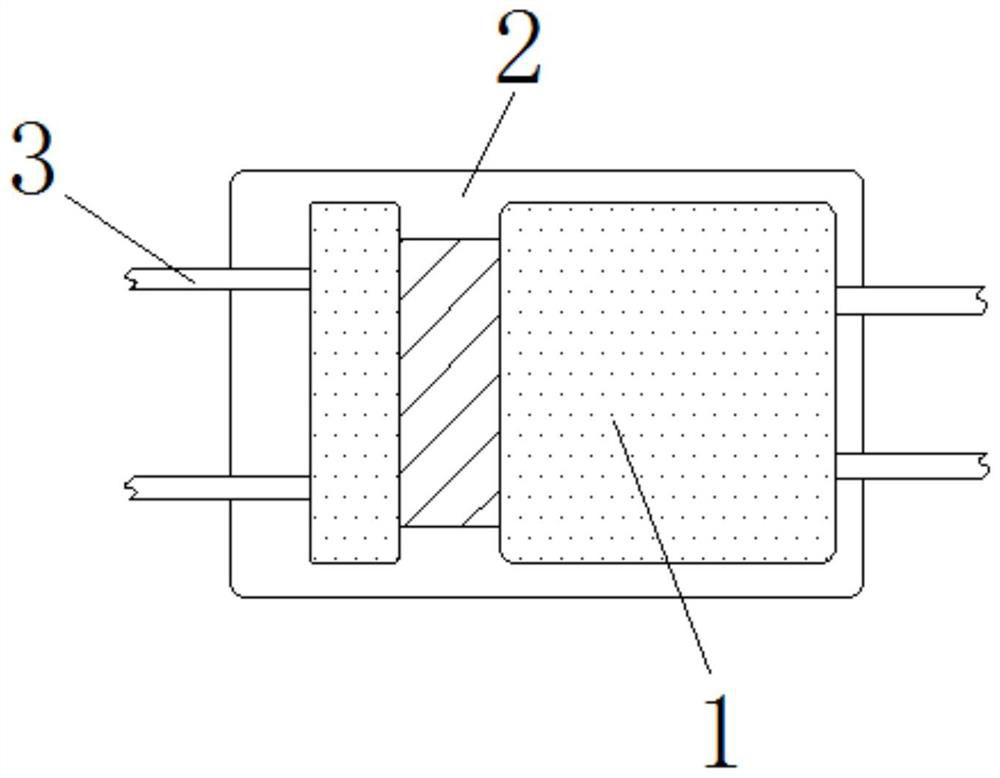

[0027] Such as Figure 1-5 As shown, the present invention provides a lampblack purifier power supply that can effectively reduce the influence of oil stains, including: power supply body 1, installation base 2, external wiring 3, protective cover 4, quick docking mechanism 5, alignment column 501, alignment slot 502, built-in slot 503, movable block 504, return spring 505, clamping block 506, clamping slot 507, line body retaining mechanism 6, alignment block 601, first guide groove 602, first guide block 603, fixed line Block 604, first connector 605, movable rod 606, second connector 607, second guide block 608, second guide groove 609, return spring 610, isolation cooling mechanism 7, water inlet 701, flow channel 702, partition The flow plate 703 and the water outlet 704, the bottom end of the power supply body 1 is equipped with an installation base 2, and the outside of the power supply body 1 is provided with an external wire 3, and a protective cover 4 is installed be...

Embodiment 2

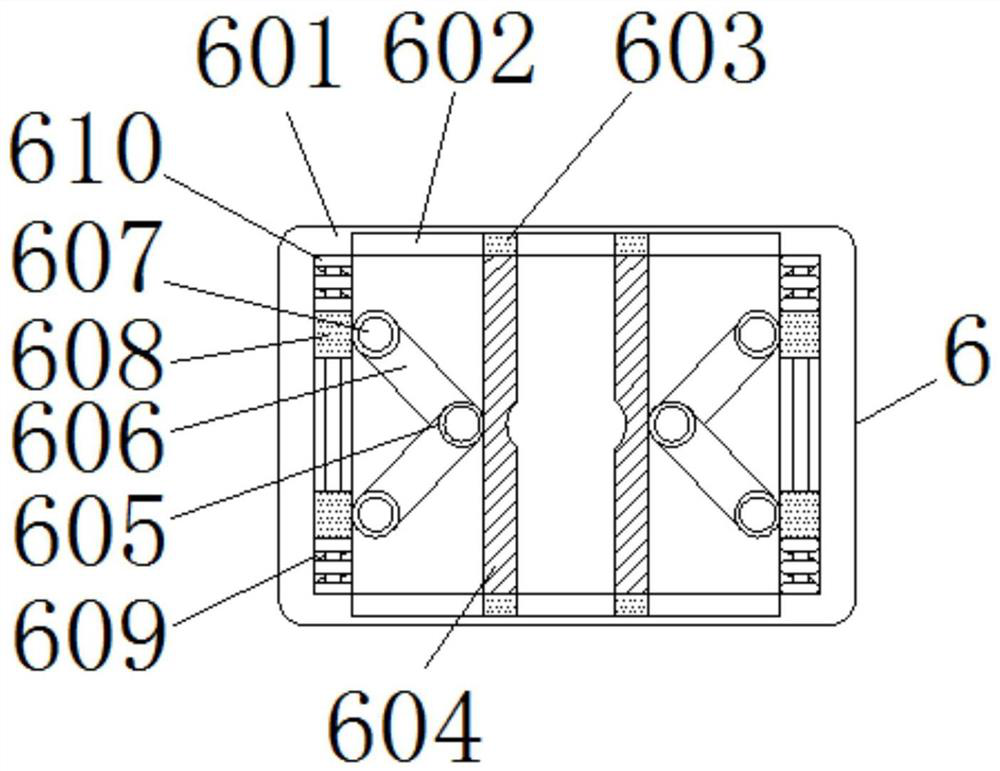

[0033] Such as figure 2 As shown, this embodiment provides a lampblack purifier power supply that can effectively reduce the influence of oil stains. The difference from Embodiment 1 is that the wire body retaining mechanism 6 includes a wiring block 601 inside, and the inside of the wiring block 601 A first guide groove 602 is opened, the inside of the first guide groove 602 is connected with a first guide block 603, and the outer side of the first guide block 603 is installed with a fixing block 604, and the outside of the fixing block 604 is connected with a first connecting piece 605, and the outside of the first connecting piece 605 is equipped with a movable rod 606, the outside of the movable rod 606 is connected with a second connecting piece 607, and the outside of the second connecting piece 607 is equipped with a second guide block 608, the second guide block 608 A second guide groove 609 is provided on the outside, and a return spring 610 is installed between the ...

Embodiment 3

[0040] Such as Figure 4 As shown, this embodiment provides a lampblack purifier power supply that can effectively reduce the influence of oil stains. The difference from Embodiment 2 is that the isolation and cooling mechanism 7 includes a water inlet 701 inside, and the right end surface of the water inlet 701 is installed with a flow Channel 702 , a flow partition 703 is arranged inside the flow channel 702 , and a water outlet 704 is installed on the right end surface of the flow channel 702 .

[0041] Preferably, in one of the preferred technical solutions of this embodiment, the outlet of the water inlet 701 is connected to the inlet of the flow channel 702 , and the outlet of the flow channel 702 is connected to the inlet of the water outlet 704 .

[0042] Preferably, in one of the preferred technical solutions of this embodiment, the cross-sectional area of the flow divider 703 is smaller than the cross-sectional area of the flow channel 702, and the central axis o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com