A device for cleaning the surface of optical components by ion wind and electrostatic coupling

A technology of optical components and electrostatic coupling, applied in the direction of external electrostatic separators, cleaning methods and appliances, chemical instruments and methods, etc., can solve the problems of space pollution particles, etc., and achieve high safety, strong cleaning power, convenient collection and cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

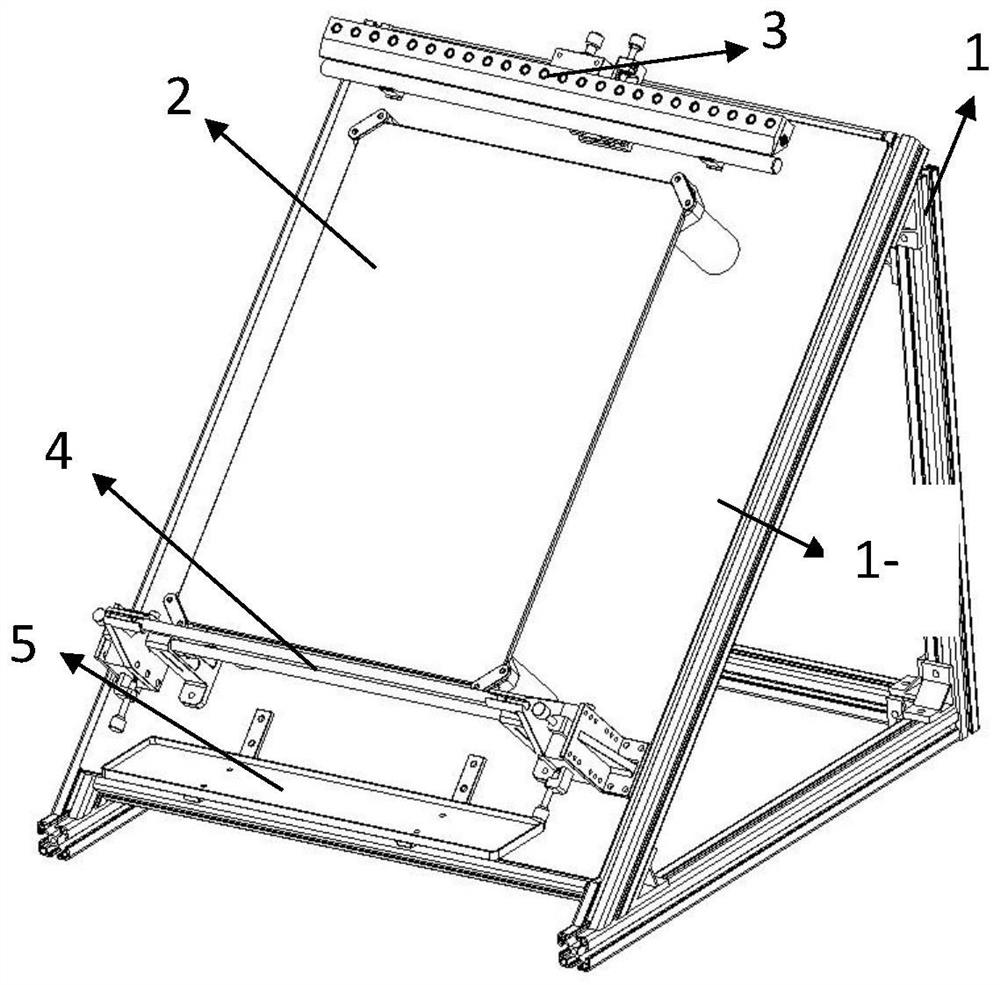

[0019] Specific implementation mode 1: This implementation mode records a device for cleaning the surface of optical components by ion wind and electrostatic coupling, such as figure 1 As shown, the device includes a fixed bracket 1, an optical element 2 (a smooth mirror or other optical elements), an ion wind system 3, an electrostatic adsorption system 4 and a particle pollutant storage box 5;

[0020] Described fixed support 1 is a triangular prism placed horizontally, and the slope on fixed support 1 front side is working surface 1-1, and the included angle of described working surface 1-1 and horizontal plane is 45 °, on working surface 1-1 ( The base plate is fixed by bolts), and the ion wind system 3, the electrostatic adsorption system 4 and the particle pollutant storage box 5 are fixed on the base plate from top to bottom (by bolts);

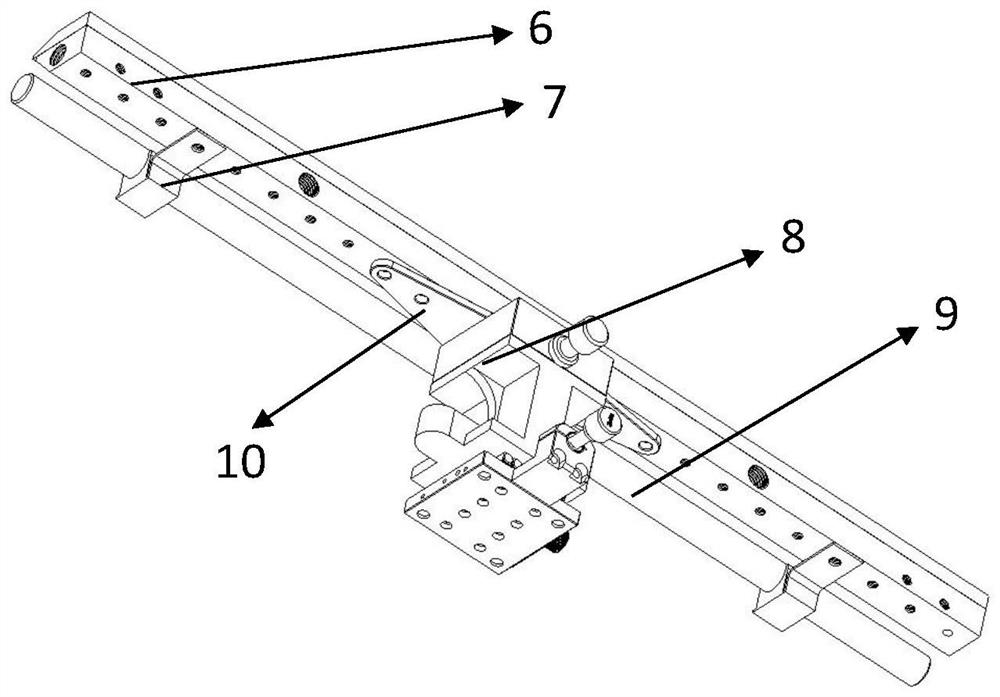

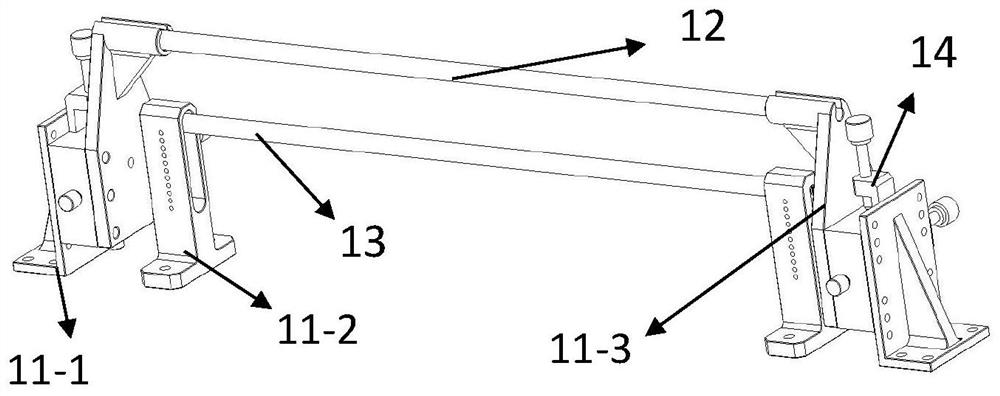

[0021] Such as figure 2 As shown, the ion wind system 3 includes an air knife 6, an ion rod support 7, a three-degree-of-freedom co...

specific Embodiment approach 2

[0025] Specific embodiment two: a kind of ion wind and electrostatic coupling described in specific embodiment one realize the device that optical element surface cleans, and the width of described air knife 6 and ion bar 9 is 610mm, and the diameter of described ion bar 9 The length and height of the ion wind system 3 are 132mm and 145mm respectively, the length is along the direction perpendicular to the working surface and the width, and the height is the direction perpendicular to the working surface 1-1.

specific Embodiment approach 3

[0026] Specific embodiment three: a kind of ion wind and electrostatic coupling described in specific embodiment one realizes the device that optical element surface cleans, and described ion bar support 7 and air knife 6 are connected by bolt, and ion bar support 7 has elastic force, when After the ion rod 9 is stuck into the ion rod bracket 7, it will generate elastic force due to deformation, so as to ensure that it will not slip. The air knife 6 is fixed on the three-degree-of-freedom combined translation platform through the four bolt holes provided on the connecting piece 10. 8, there are three M6 countersunk bolts on the connecting piece 10 to ensure the fixing of the connecting piece 10 and the three-degree-of-freedom combined translation stage 8.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com