Preparation method of titanium alloy dental implant surface composite coating

A dental implant and surface composite technology, which is applied in coatings, prostheses, medical science, etc., can solve the problems of being unable to clean up impurities on the surface of titanium alloy dental implants, unable to dry and dry, and not having the function of immersion and rinsing. , to improve long-term stability and service performance, improve implant effect, and improve osseointegration performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with accompanying drawing:

[0035] In the picture:

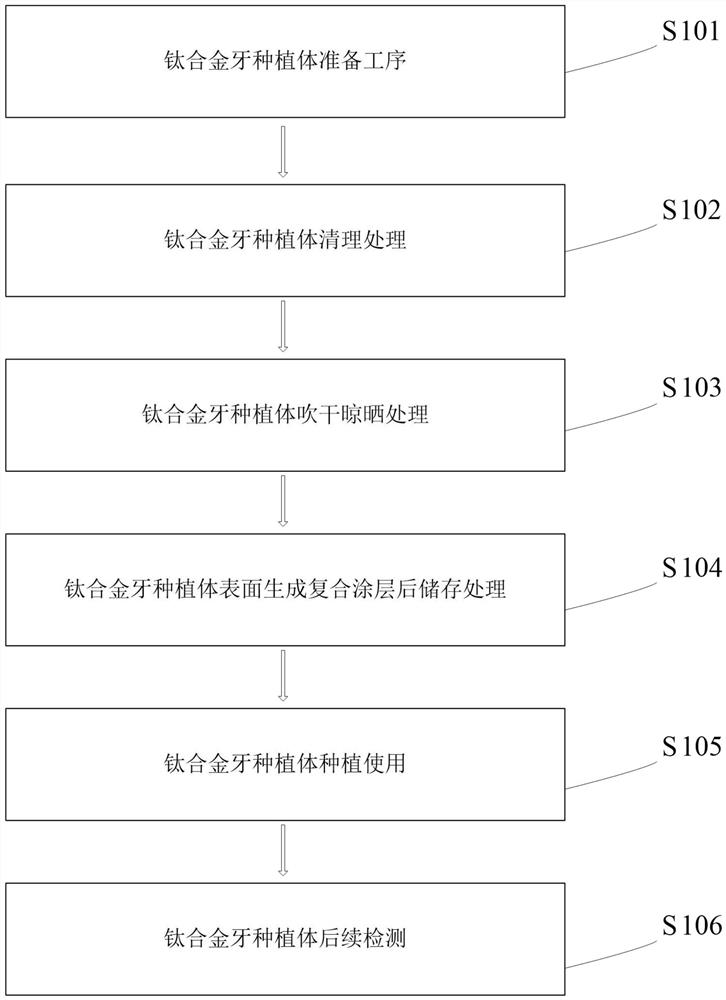

[0036] as attached figure 1 shown

[0037] A preparation method of a titanium alloy dental implant surface composite coating specifically comprises the following steps:

[0038] S101: Titanium alloy dental implant preparation process, visually inspect the processed titanium alloy dental implant to ensure the integrity of the titanium alloy dental implant surface, and at the same time ensure the smoothness of the titanium alloy dental implant surface, and polish it with sandpaper Remove impurities and burrs on the surface of the titanium alloy dental implant, then perform preliminary cleaning and polishing with a brush, immerse in water for cleaning once, dry it, perform sandblasting, and prepare for the second cleaning after sandblasting;

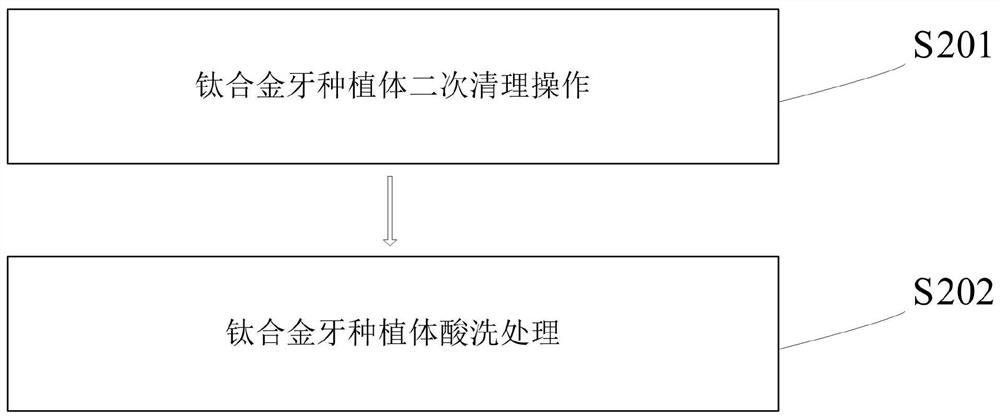

[0039] S102: Titanium alloy dental implant cleaning treatment, combined with attachment figure 2 As shown...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com