Wet type cleaning process monitoring apparatus and monitoring method

A monitoring equipment and cleaning technology, applied in the field of monitoring equipment and its monitoring, can solve the problems affecting the company's market competitiveness and share, reducing production capacity, increasing the cost of manufacturing materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to have a further cognition and understanding of the features, purposes and functions of the present invention, a detailed description is given below with reference to the accompanying drawings.

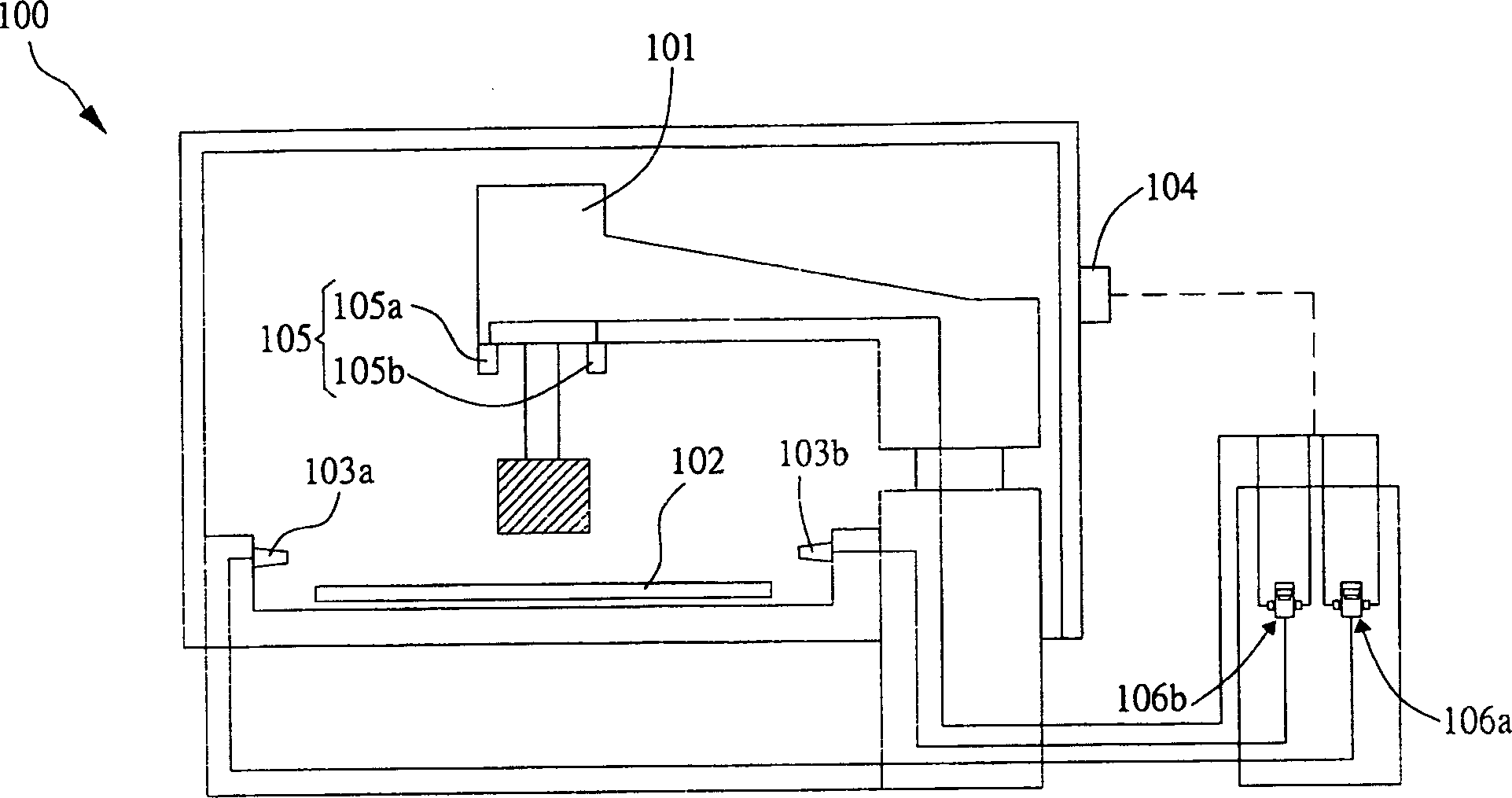

[0036] Such as figure 1 As shown, it is a schematic diagram of a preferred embodiment of the monitoring equipment for the wet cleaning process of the present invention. The wet cleaning equipment 100 is to provide a fluid (not shown) in a cleaning process (usually shown here) to an object to be cleaned. The object referred to is the surface of the wafer 102), and the monitoring device of the present invention is mainly applied in the wet cleaning device 100 having at least one cleaning brush arm 101 and fluid supply units 103a, 103b, and when the cleaning brush arm 101 cleans Wafer 102, the fluid supply unit 103a, 103b also provides fluid on the wafer 102 at the same time, and the monitoring equipment at least includes: an arm position sensor 105 is connected to the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com