Diversion non-woven composite material synthesis device

A technology of composite materials and synthetic devices, applied in the field of composite diversion nets, can solve problems such as manual separation, achieve the effects of improving product quality, ensuring stable and continuous work, and improving the pressing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

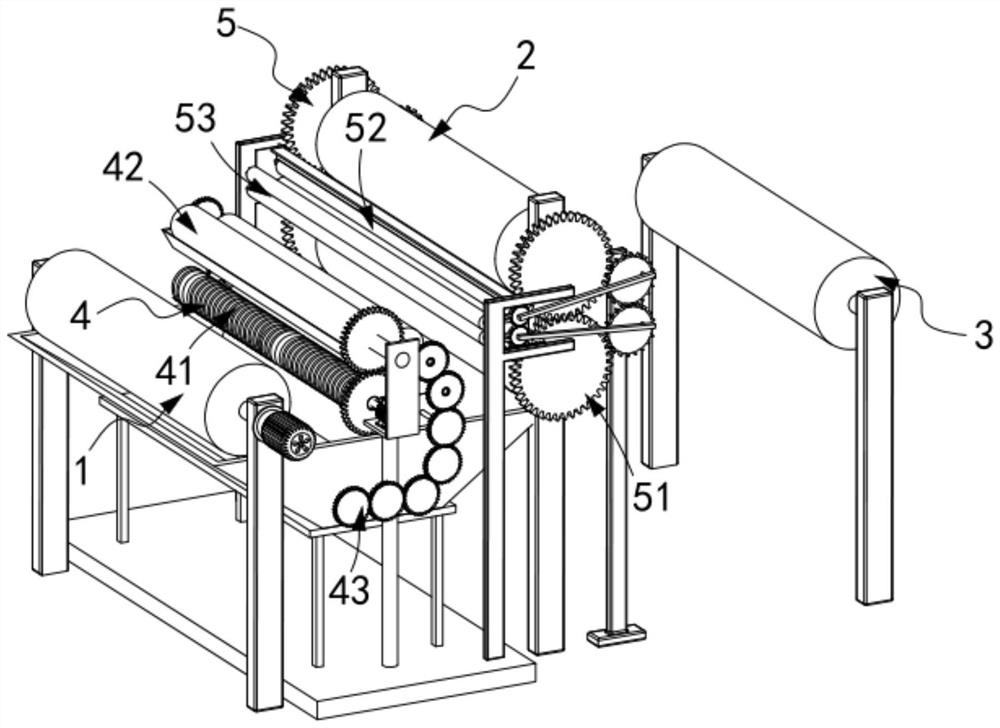

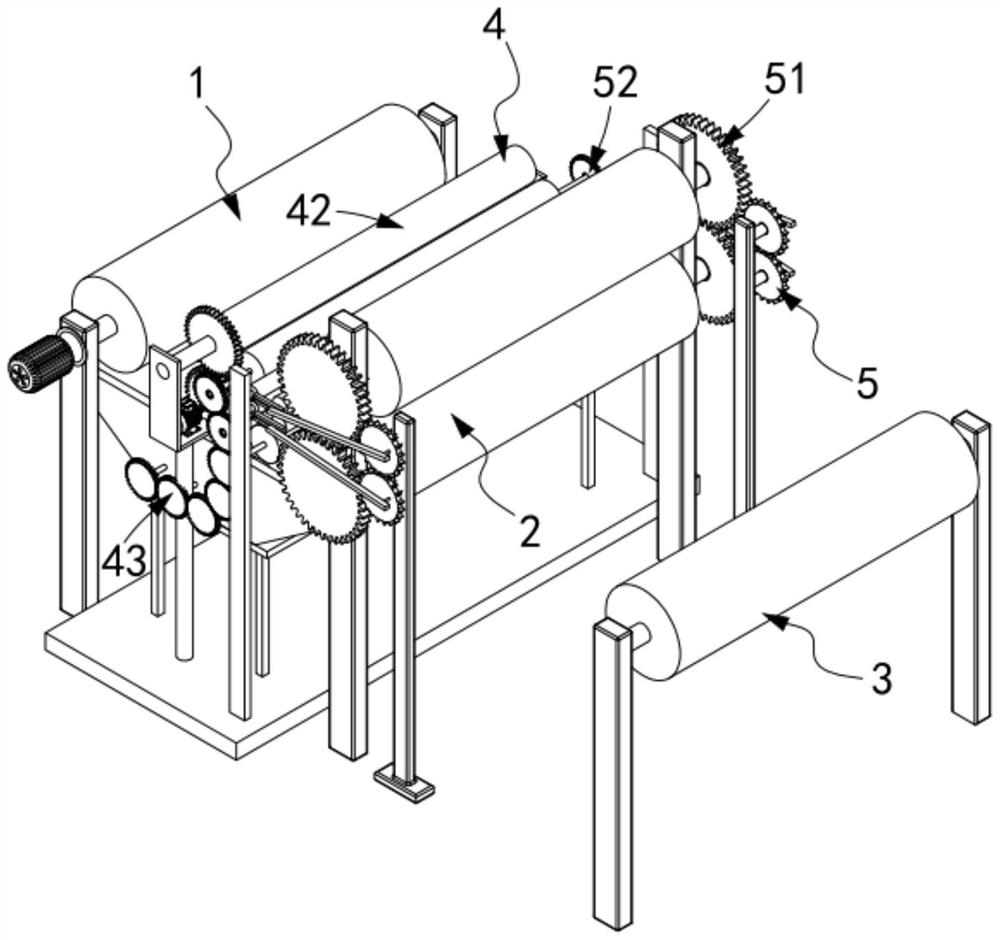

[0059] Such as figure 1 , figure 2 As shown, a diversion nonwoven composite material synthesis device includes a rubber transfer roller part 1, a pressing roller part 2 and a winding roller part 3, and also includes:

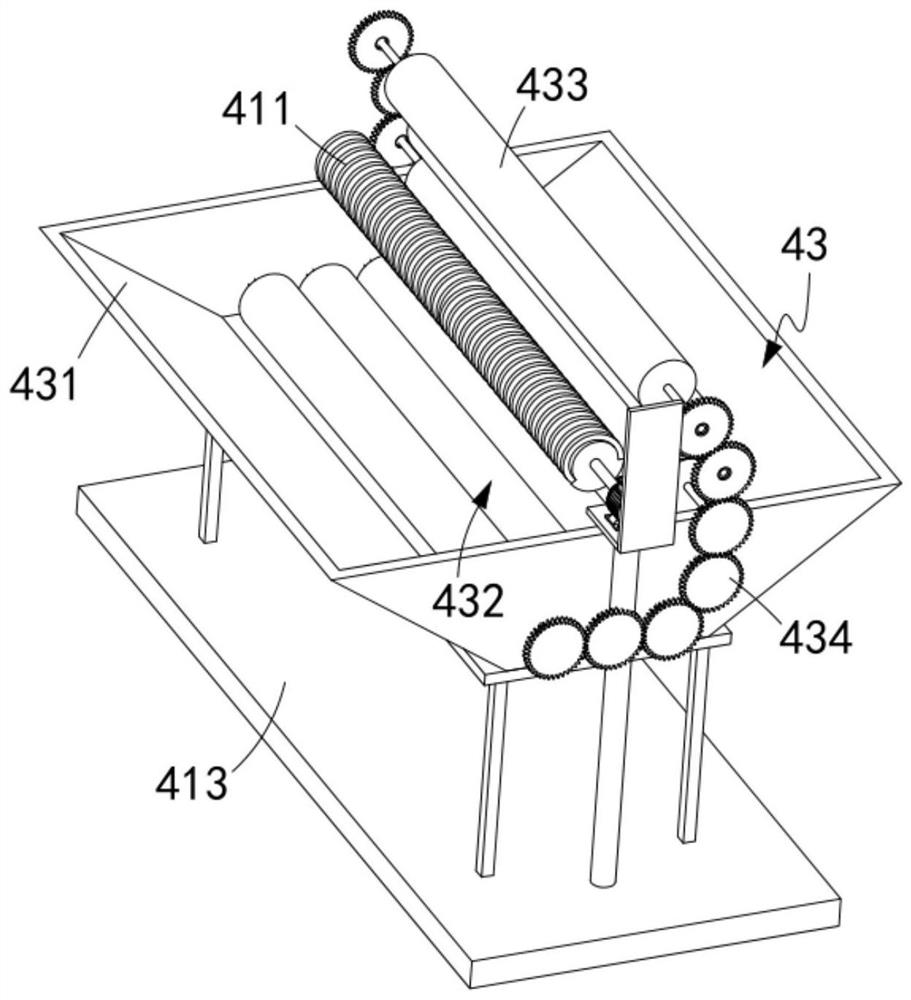

[0060] The first glue leveling mechanism 4, the first glue leveling mechanism 4 includes a scraper assembly 41 located between the glue transfer roller part 1 and the pressure roller part 2 and positioned below the flow guide net 10, located on the flow guide net 10 And between the porous isolation film 20 and the gluing assembly 42 arranged directly above the scraper assembly 41 and arranged between the scraper assembly 41 and the gluing assembly 42 in the vertical direction and used to scrape the material The waste glue on the assembly 41 is transferred to the glue transfer assembly 43 on the gluing assembly 42; and

[0061] The second glue equalizing mechanism 5, the second glue equalizing mechanism 5 includes a speed change assembly 51 synchronously drive...

Embodiment 2

[0097] Such as Figure 13 As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. The difference between this embodiment two and embodiment one is:

[0098] further, such as Figure 13 As shown, the gluing assembly 53 includes a second mounting frame 531 and a gluing roller 532 rotatably arranged on the second mounting frame 531 , and the gluing roller 532 is vertically along the second mounting frame 531 There are two sets of rubber-coated rollers 532 arranged in the upper direction in contact with the lower surface of the perforated isolation film 20 and the rubber-coated rollers 532 located in the lower part are arranged in contact with the upper surface of the flow guiding net 10 .

[0099] When the traditional pressure roller part 2 performs pressing work,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com