Graphene cleaning and transferring method

A transfer method, graphene technology, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve problems such as surface impurity residue, reduce impurities, avoid solution immersion, and improve electrical performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A kind of graphene clean transfer method that preferred embodiment of the present invention provides, comprises the following steps:

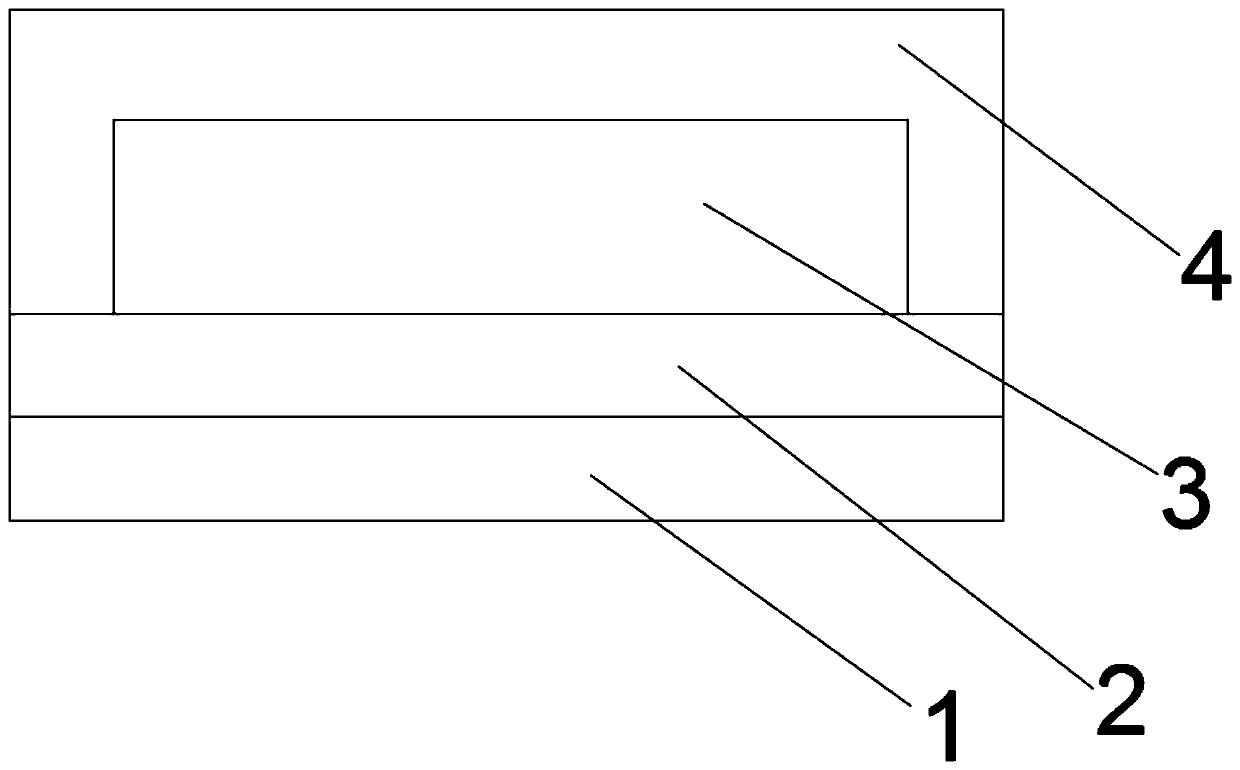

[0030] S1. Build tape / target substrate / graphene / metal structure: transfer graphene grown on metal copper foil (graphene / copper foil) to target substrate SiO 2 / Si as an example, such as figure 1 As shown, the clean target substrate was edge-sealed on a piece of graphene / copper slightly larger than the target substrate with thermal release tape to avoid the solution entering between the graphene and the target substrate during subsequent processing;

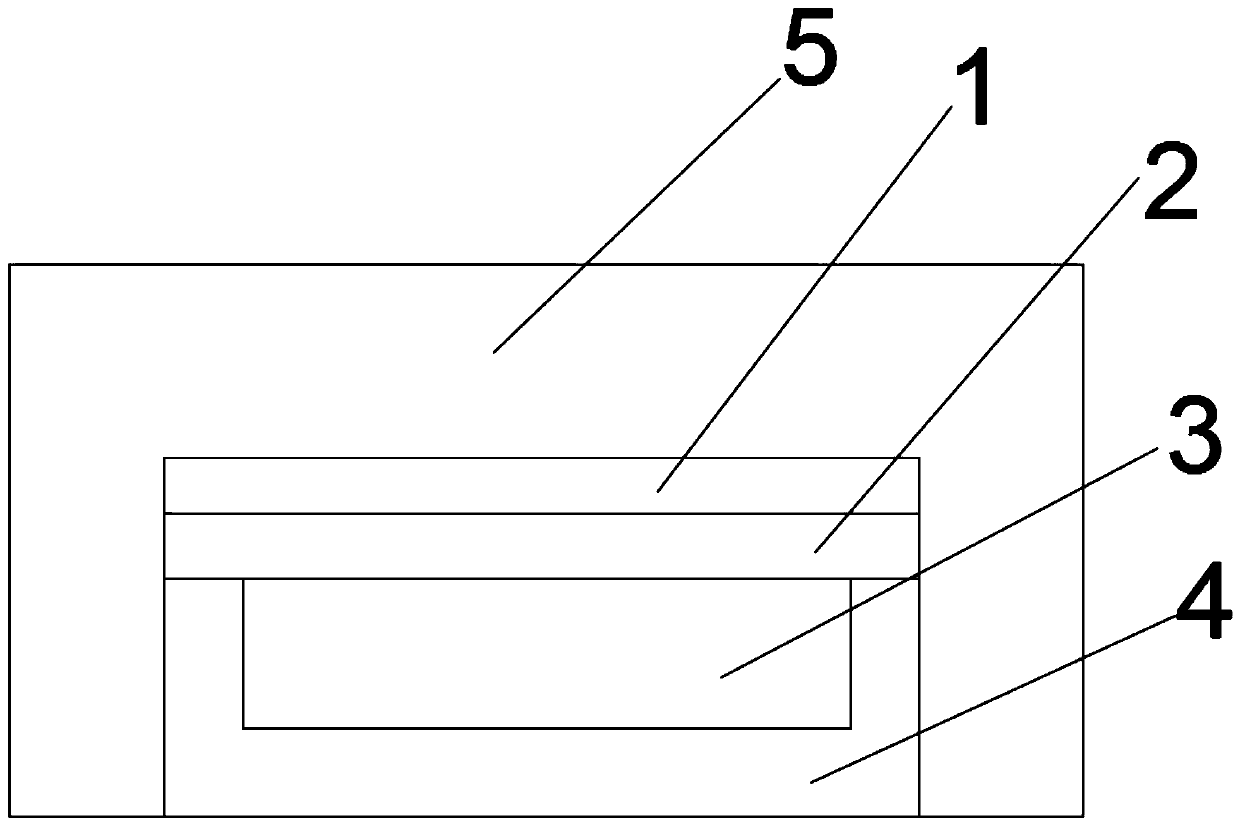

[0031] S2. Etching: press the tape / silicon wafer / graphene / copper foil structure figure 2 In the manner shown, metal copper is etched in 1mol / L ferric chloride mixed with 5% hydrochloric acid in the etching solution to form a graphene / silicon wafer / tape structure;

[0032] S3. Cleaning: After the etching is completed, remove the graphene / silicon wafer / tape structure from the etching soluti...

Embodiment 2

[0036] A kind of graphene clean transfer method that preferred embodiment of the present invention provides, comprises the following steps:

[0037] S1. Build tape / target substrate / graphene / metal structure: transfer graphene grown on metal copper foil (graphene / copper foil) to target substrate SiO 2 / Si as an example, such as figure 1 As shown, the clean target substrate is sealed on a piece of graphene / copper slightly larger than the target substrate with an insulating tape edge, so as to avoid the solution entering between the graphene and the target substrate during subsequent processing;

[0038] S2. Etching: press the tape / silicon wafer / graphene / copper foil structure figure 2 In the way shown, metal copper is etched in a 0.3mol / L ammonium persulfate solution to form a graphene / silicon wafer / tape structure;

[0039] S3. Cleaning: After the etching is completed, remove the graphene / silicon wafer / tape structure from the etching solution, and then rinse it in deionized wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com