Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

57results about How to "Cool evenly and fully" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

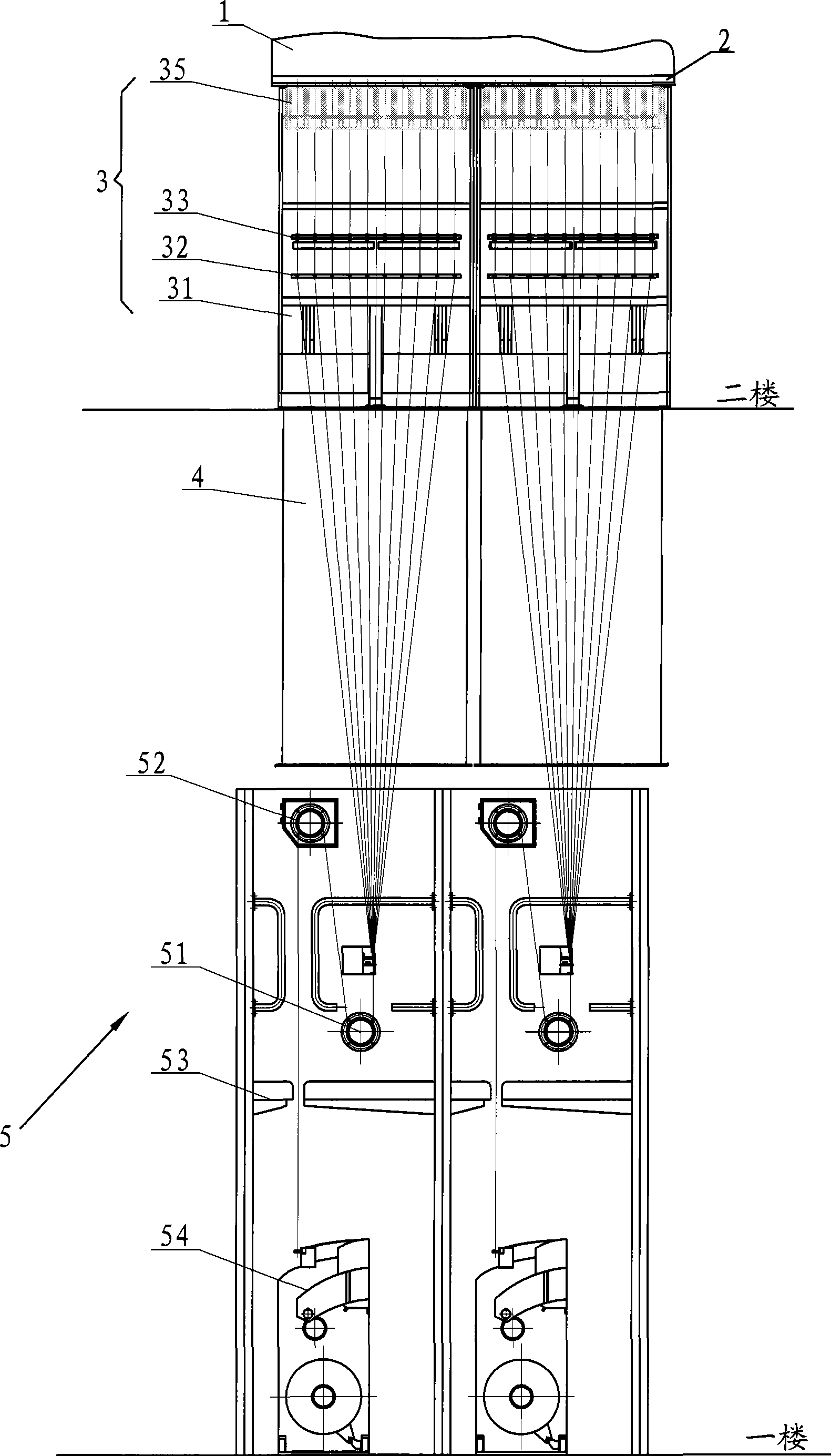

Spinning equipment for producing porous fine denier polyester POY

ActiveCN101487144ACool evenly and fullyGuaranteed uptimeArtificial thread manufacturing machinesMelt spinning methodsWinding machinePolyester

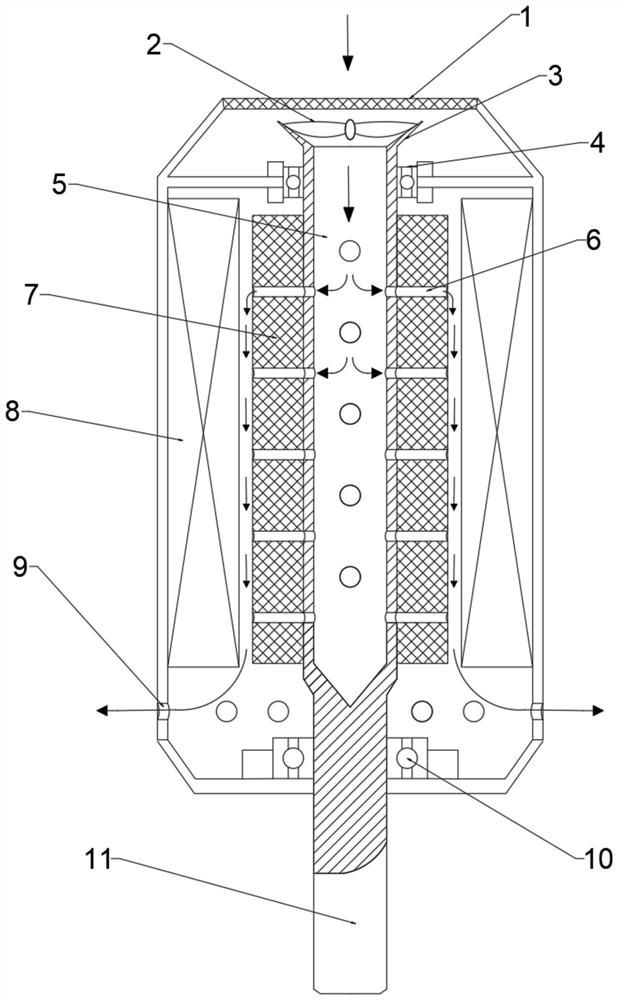

The invention relates to spinning equipment used for producing porous fine POY yarn, comprising a spinning box, a no-wind area, a blowing device, a passage and a winding machine, all of which are arranged sequentially from top to bottom, wherein, the blowing device is a sealed circular blowing device; when at the working state, the cooled wind cools the yarn beams which enter the blowing device in the circular direction for shaping; the wind quantity of a closed ring is reduced by more than 60% compared with the quantity of the side wind; the energy consumption of the circular blowing air conditioner is saved by 70% and the cooling stability thereof is greatly improved; furthermore, the circular blowing air conditioner is not disturbed by the external environment; the spinning equipment is beneficial to improving the production speed, further improves the production efficiency and improves the quality of the fine yarn product.

Owner:JIANGSU SHENJIU CHEM FIBER CO LTD

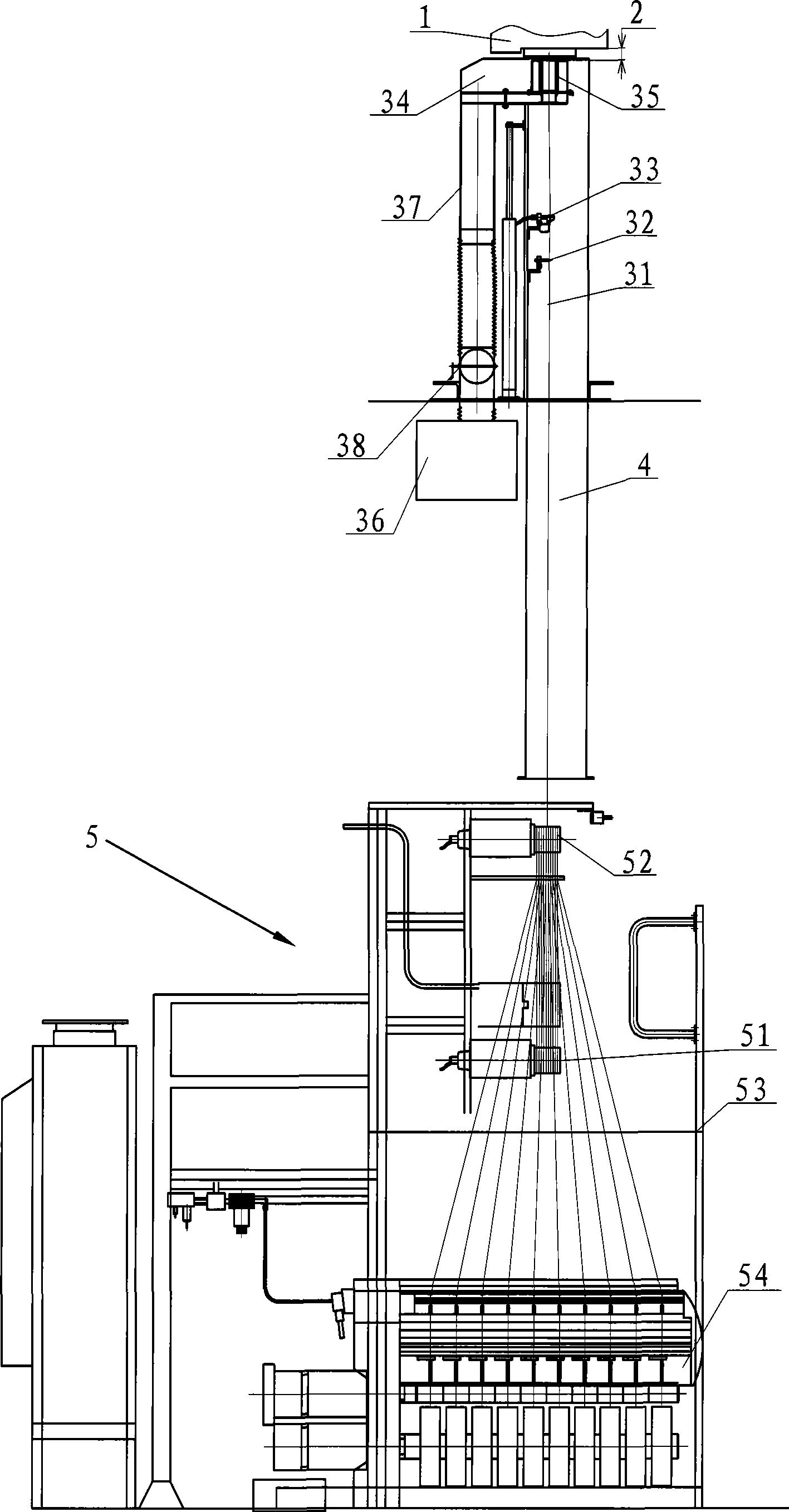

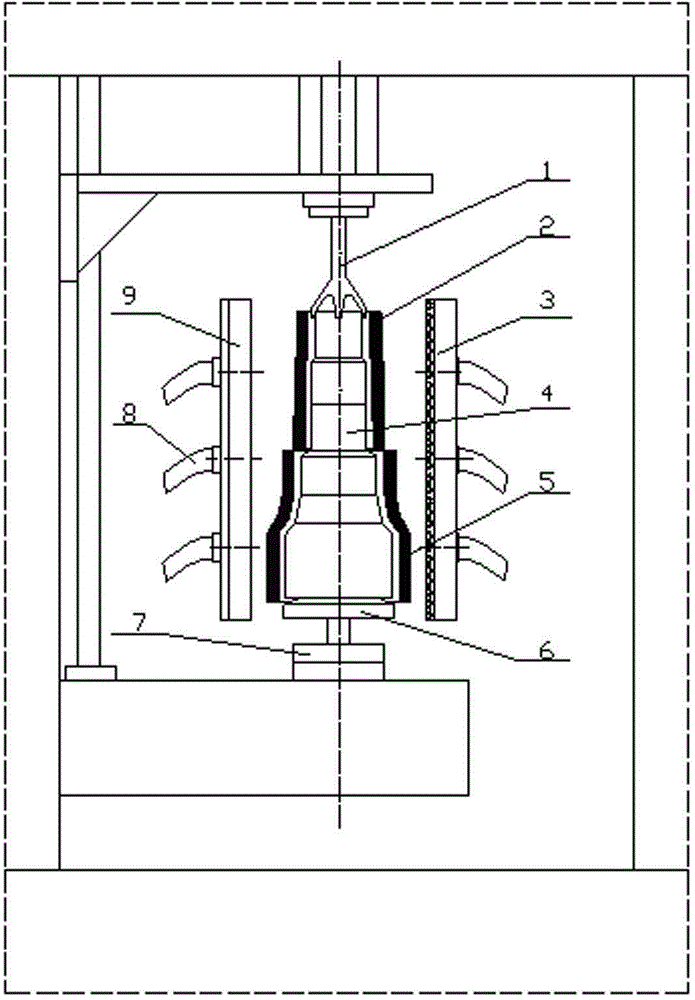

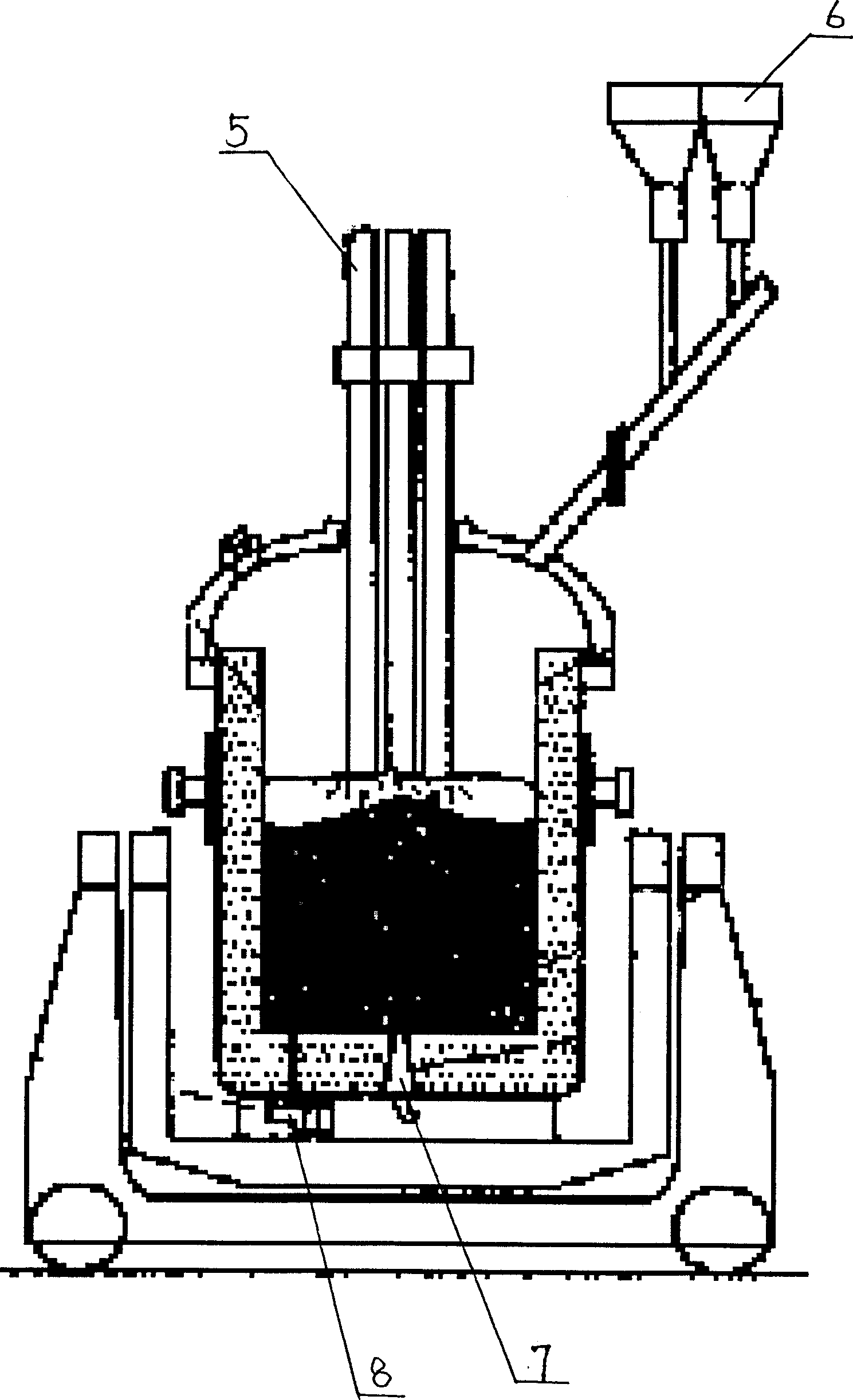

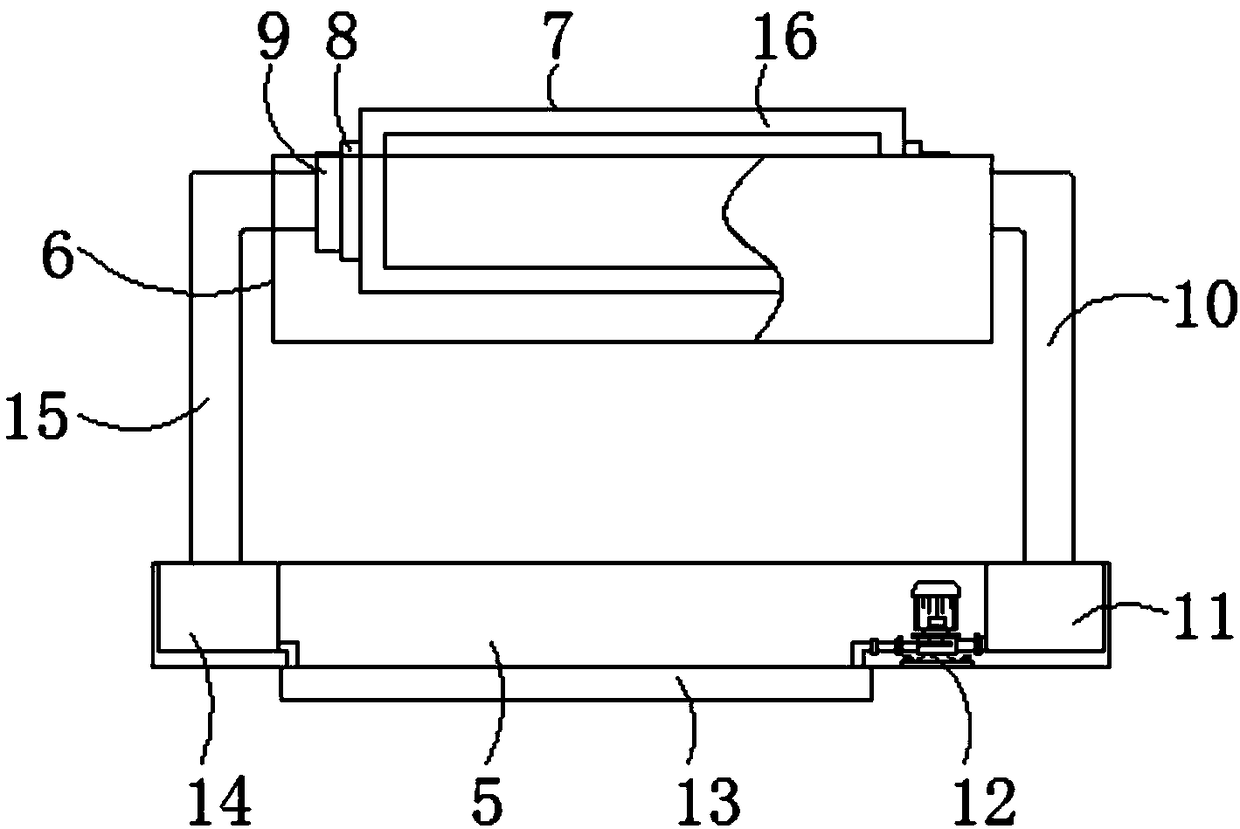

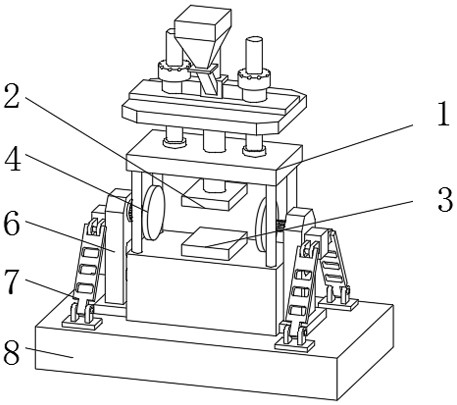

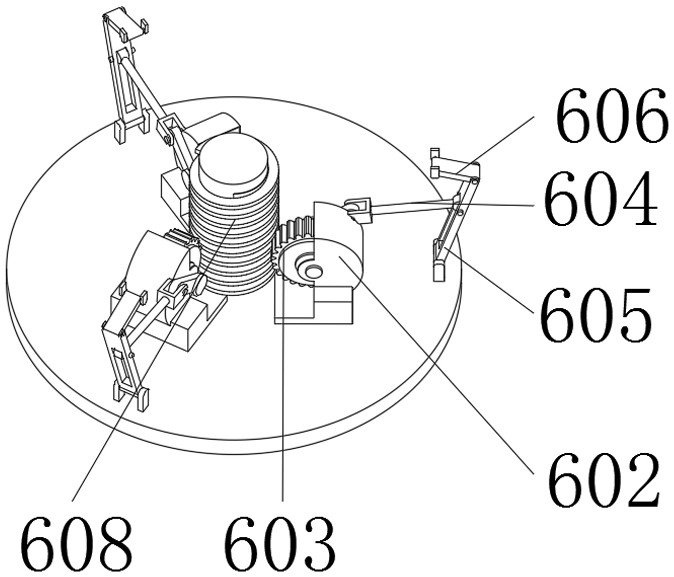

Novel quenching technology applied to vehicular hollow variable cross-section spindle nose and use equipment of novel quenching technology

InactiveCN104611538AAccelerateReduce energy consumptionFurnace typesHeat treatment furnacesHardnessMachine tool

The invention provides a novel quenching technology applied to a vehicular hollow variable cross-section spindle nose, which adopts a technical process of charging, induction heating, spray cooling, blanking, quenching hardness detection, tempering, cooling, hardness detection and mechanical property analysis. Equipment used by the quenching technology is characterized in that a turntable is arranged on a machine tool station, a locating disc is arranged on the turntable, a workpiece is placed on the locating disc, an induction coil is arranged at the periphery of the workpiece, water spray plates with a plurality of water inlet pipes are arranged at the periphery of the induction coil, and an upper centre having a clamp action is arranged at the upper part of the workpiece. The technology is energy-saving, efficient, environment-friendly and easy to control, easily achieves automatic heat treatment, can allow the vehicular spindle nose to obtain good comprehensive mechanical properties after heat treatment and ensures that products of all batches and all workpieces can keep relatively high consistency.

Owner:南阳市红阳锻造有限公司

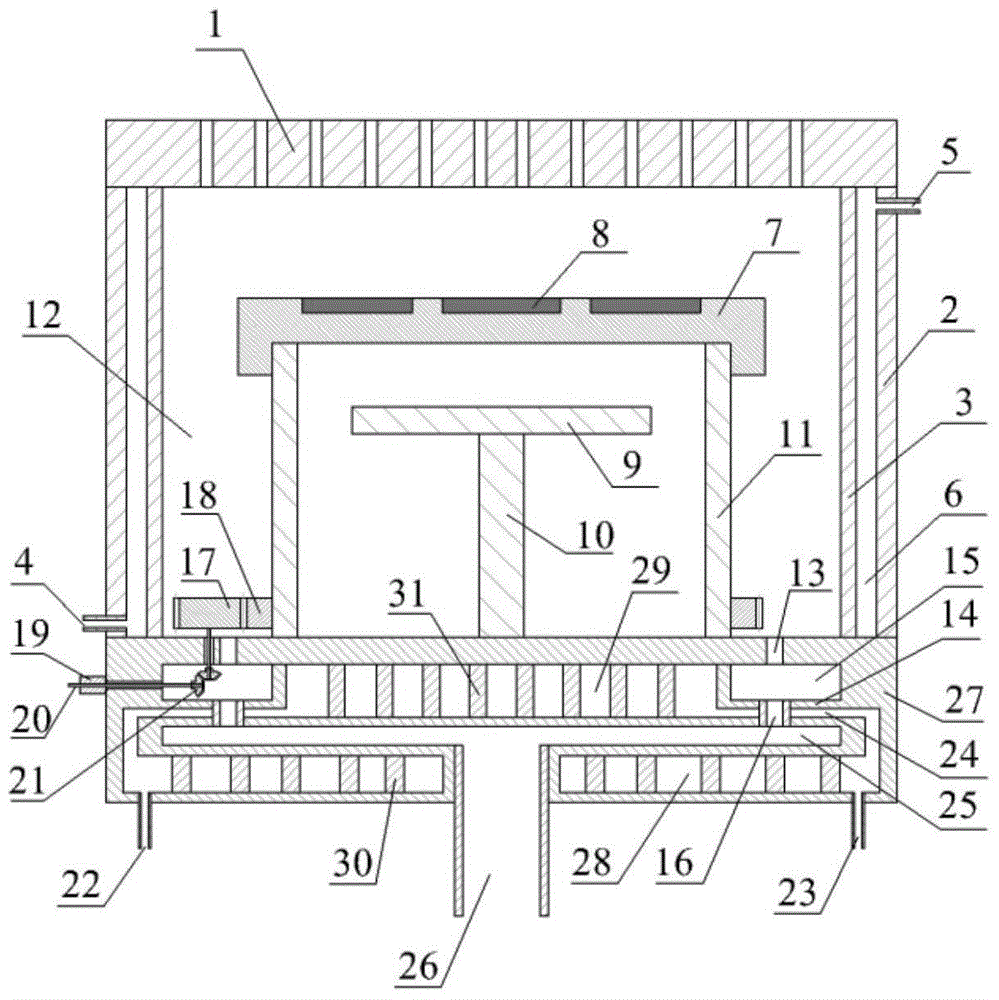

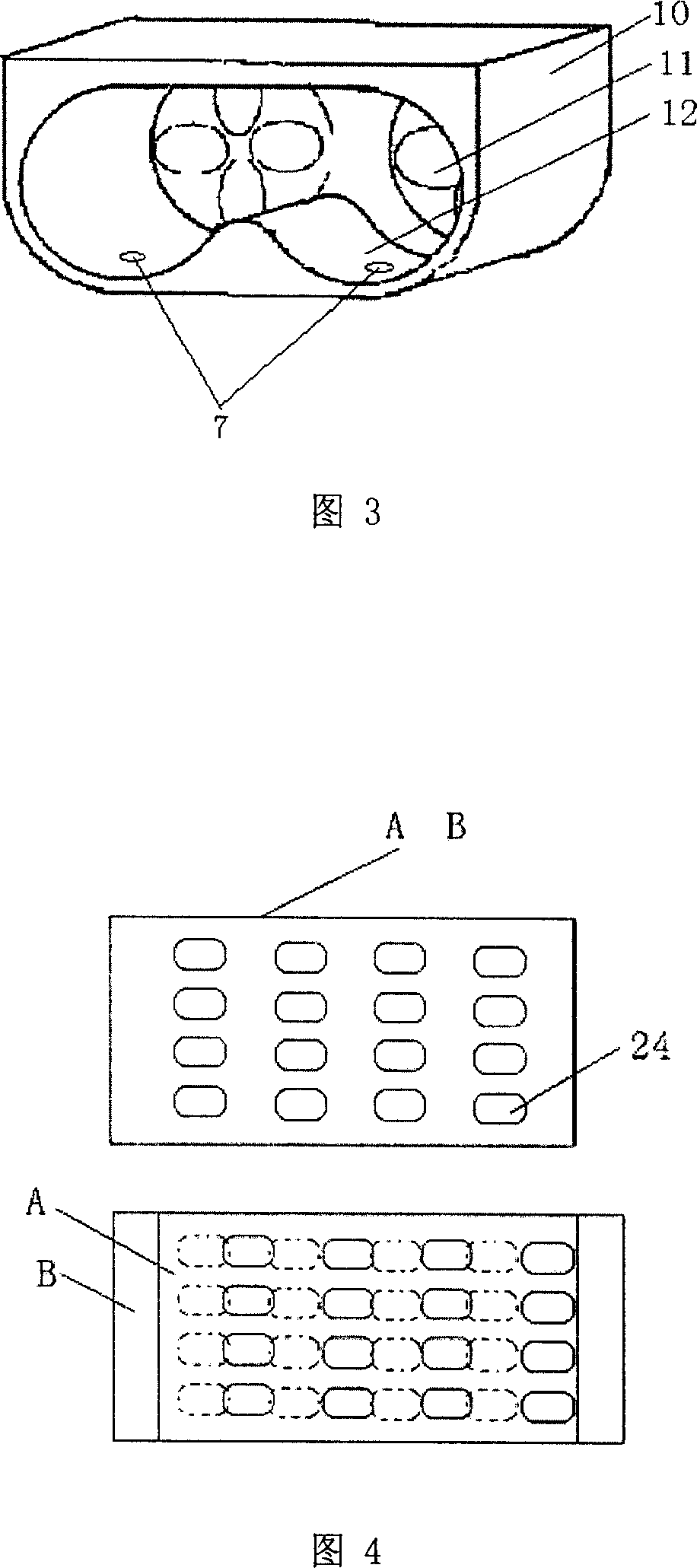

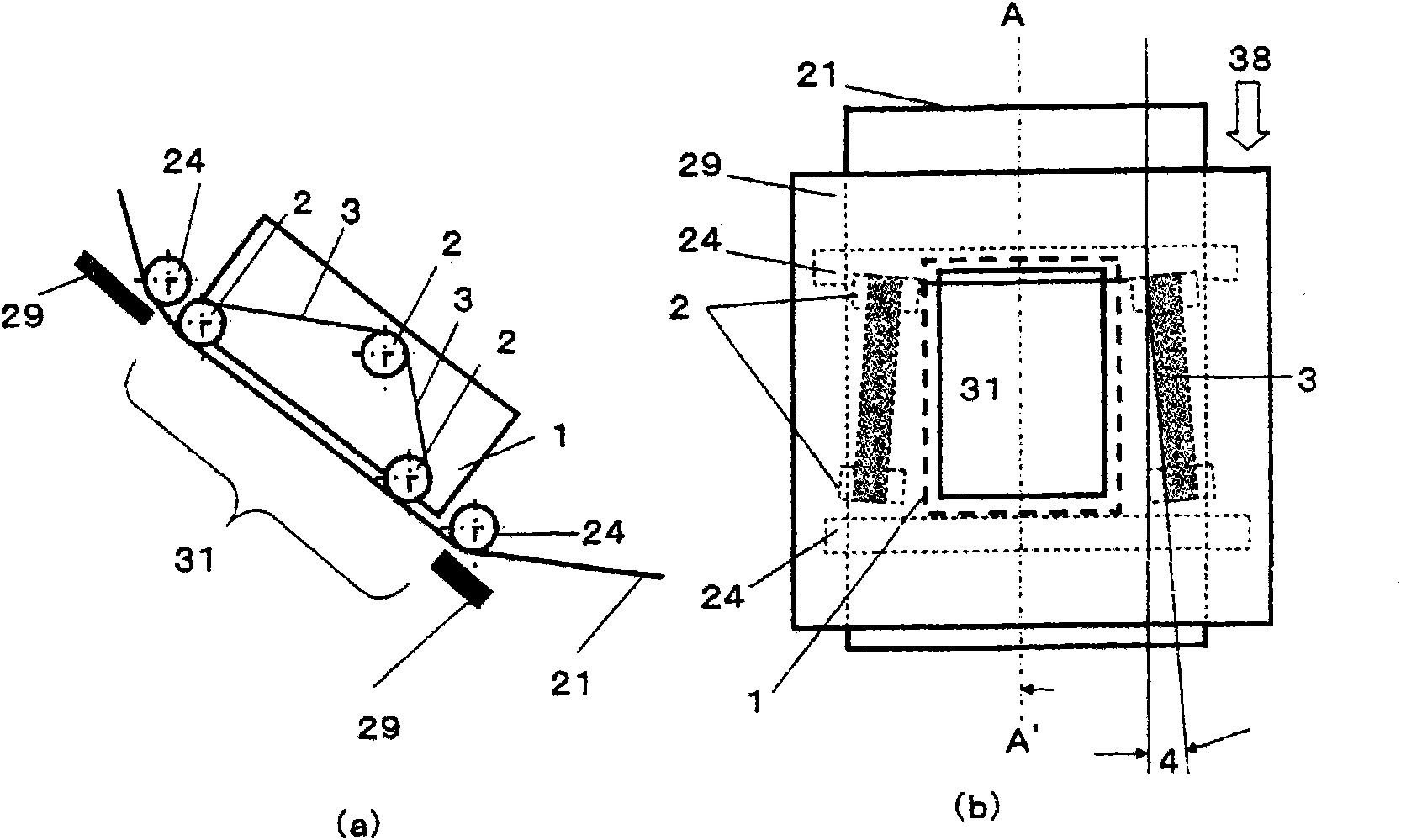

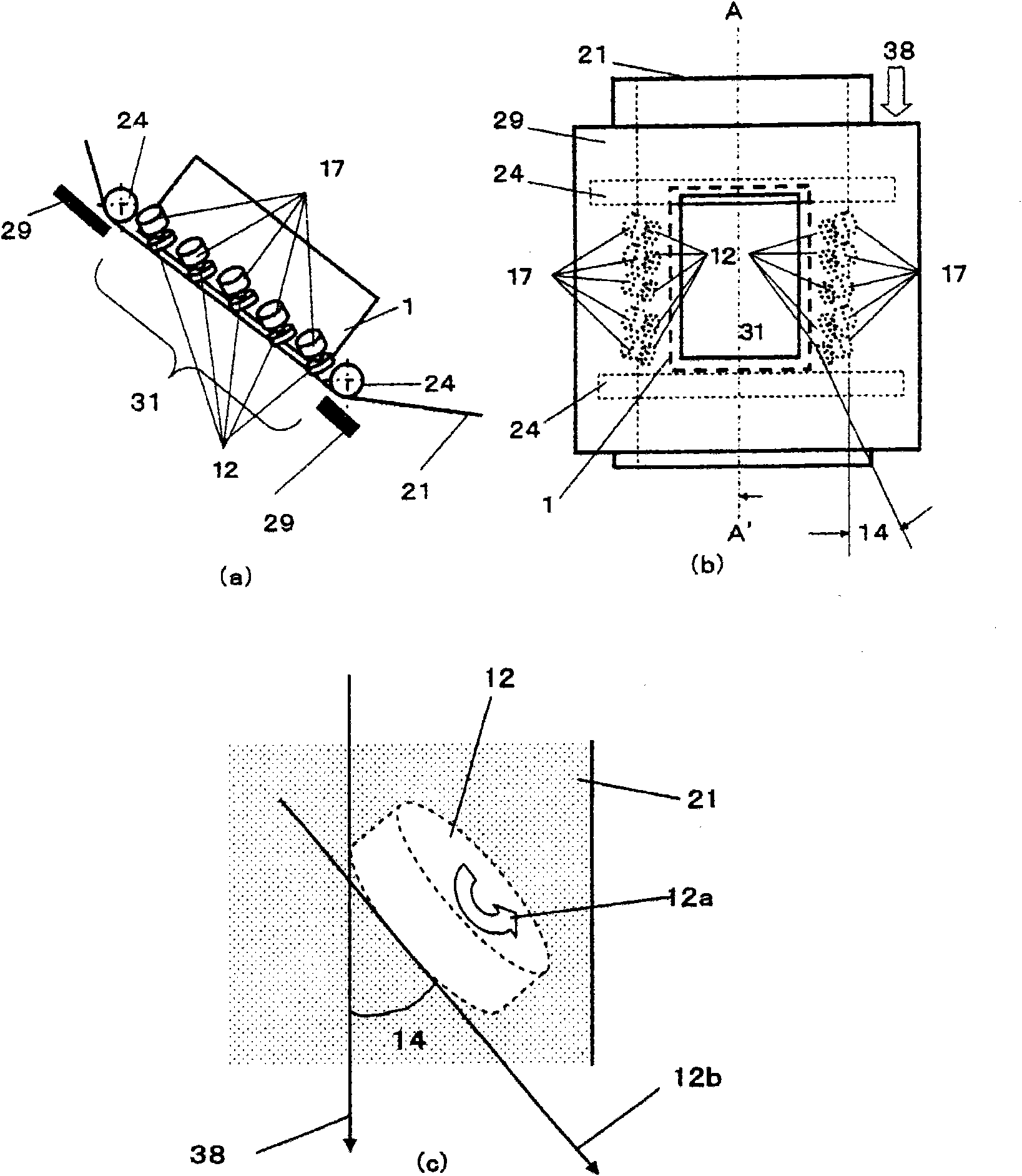

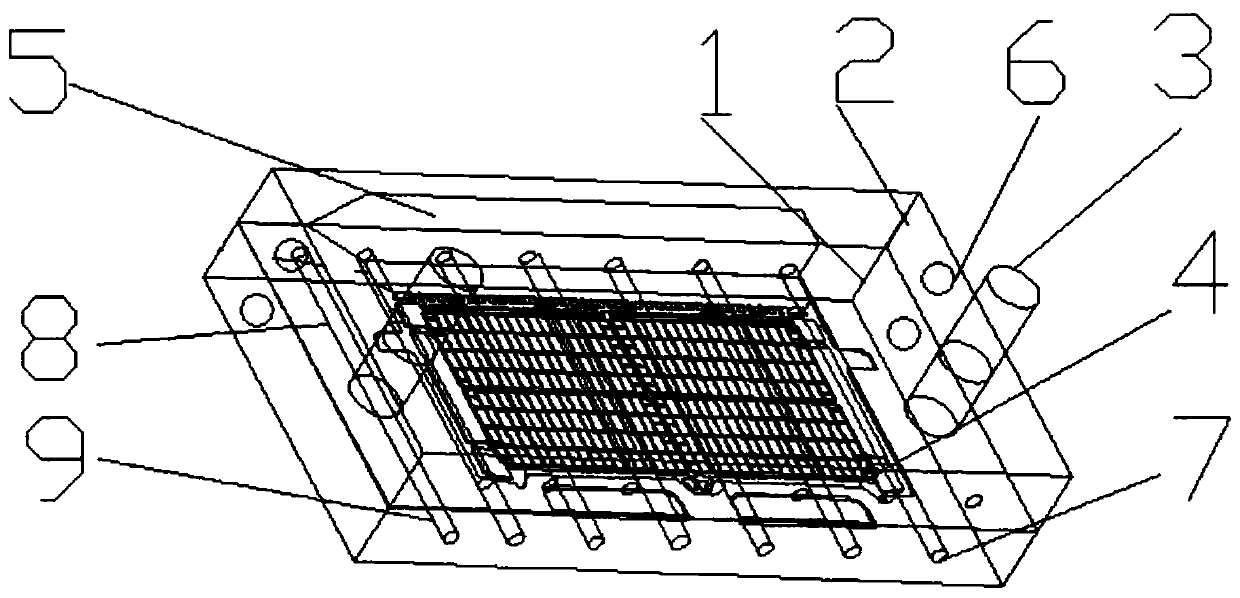

Rectangle plane magnetron sputtering cathode

InactiveCN101250687AIncrease widthAvoid discharge phenomenonVacuum evaporation coatingSputtering coatingSputteringEngineering

The invention relates to a rectangular plane magnetically controlled sputtering cathode, which is provided with a target, a cathode component and a shielding case which is arranged on the periphery of the cathode component, wherein a magnetic circuit mechanism is fixedly arranged on a target seat and is located inside a cathode body, the target is fixedly arranged on the lower portion of the target seat, and the cathode is characterized in that a magnetic conductive plate is arranged on the periphery of the cathode component and located on the inner side and the outer side of the shielding case in a whole circumference mode. The cathode of the invention can effectively increase the stability of a sputtering process and can increase the availability ratio of the target.

Owner:HEFEI UNIV OF TECH

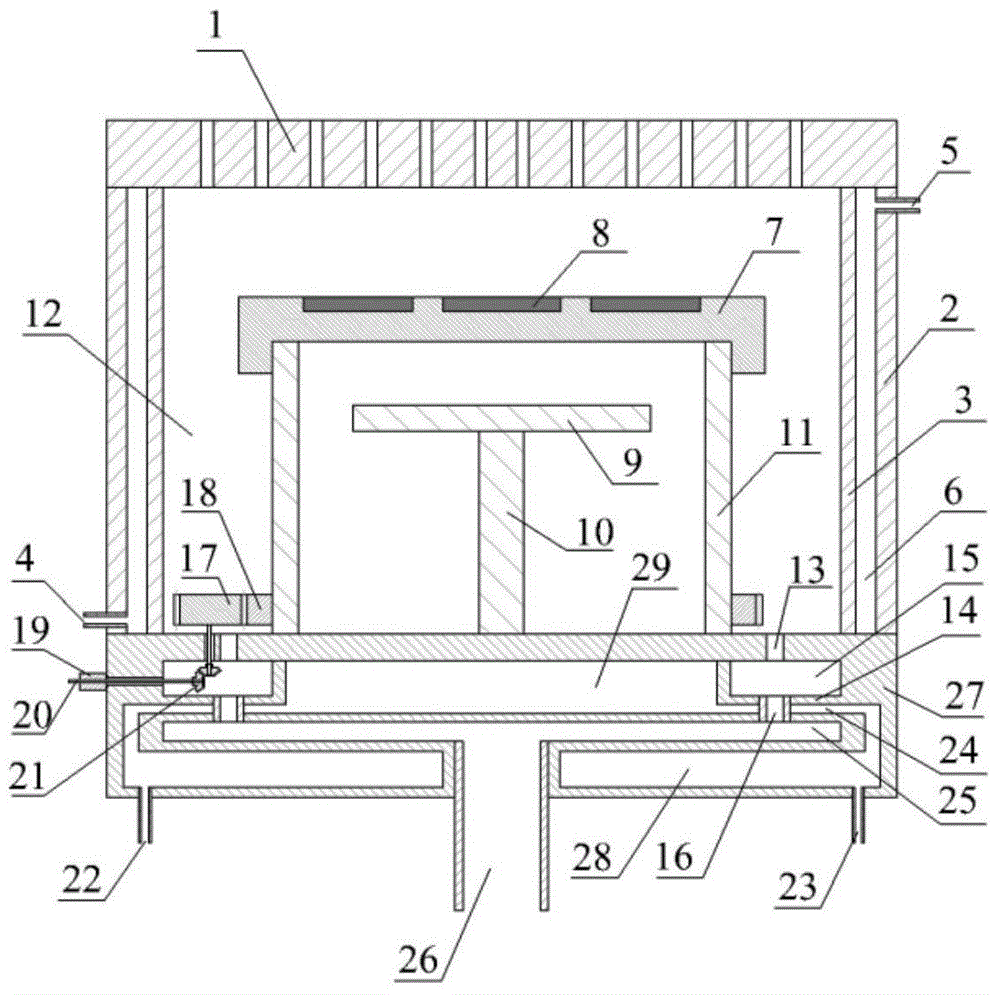

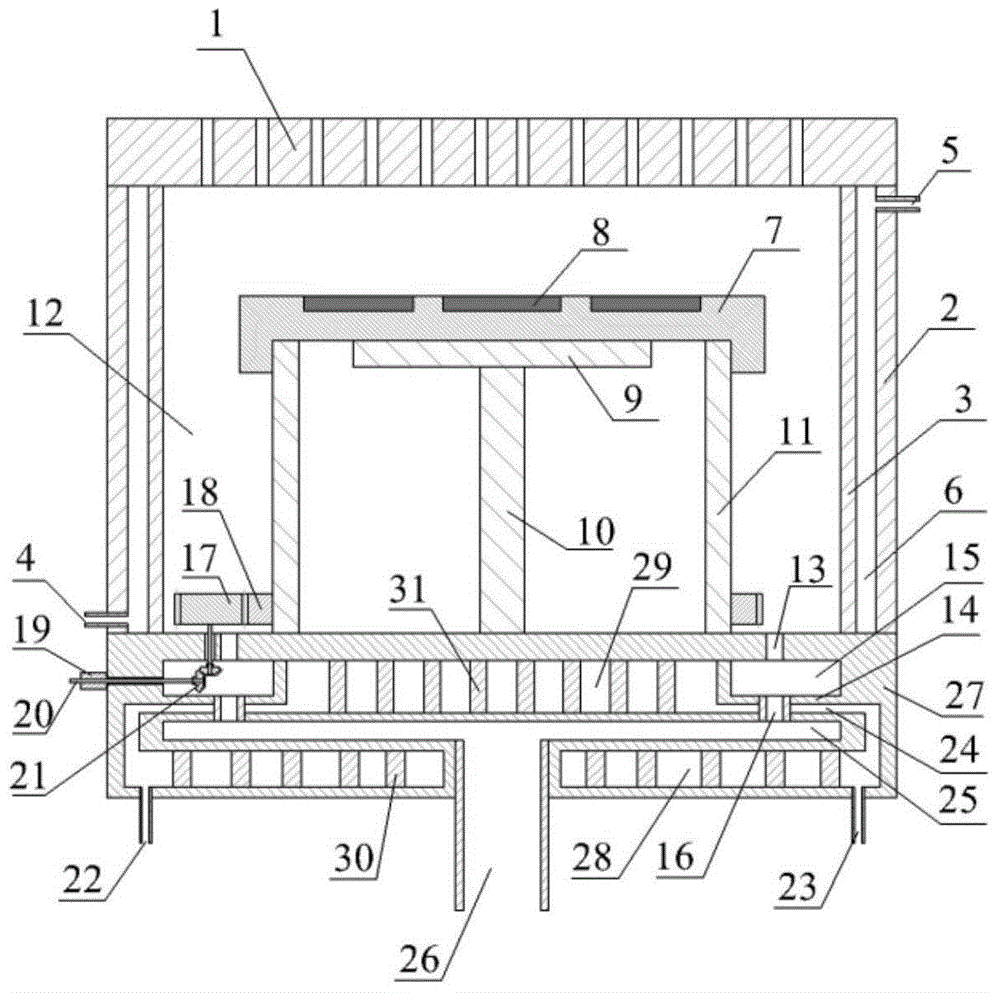

Symmetrical vapor deposition equipment reaction cavity

ActiveCN104862667AEasy to cleanReduce depositionChemical vapor deposition coatingCooling chamberProduct gas

The invention discloses a symmetrical vapor deposition equipment reaction cavity. The reaction cavity mainly comprises a gas input body, a heater, a slide carrying disc, a slide carrying disc support, a reaction cavity housing, a heater, a heater support, a reaction gas channel, a cavity pedestal and a tail gas outlet. The reaction cavity is characterized in that the tail gas outlet is arranged at the center of the cavity pedestal, a gas chamber is arranged in the middle of the cavity pedestal and a cooling chamber is arranged around the gas chamber. The tail gas outlet is arranged at the center of the cavity pedestal so that gas inlet and outlet symmetrical distribution is realized and uniformity of gas flowing distribution in the reaction cavity is guaranteed and improved. Tail gas goes through the gas chamber of the cavity pedestal and cooling surfaces of the gas chamber of the cavity pedestal cool the reaction tail gas so that the reaction tail gas is uniformly cooled, precipitates are reduced and tail gas treatment system damage caused by a high reaction tail gas temperature is avoided.

Owner:甘志银

Technological process of making flat spring steel for automobile

The flat spring steel for automobile is produced via converter smelting process. Compared with available technology, the present invention has the following advantages and positive effects: utilizing molten iron with less harmful elements as material to result in high flat spring steel quality; higher finished product rate and lower power consumption to result in lower cost than production in electric furnace; casting molten steel into small square billet to omit the billet cutting step and lower cost; and high size precision of the continuously cast small square billet to ensure high size precision of flat spring steel.

Owner:青岛钢铁控股集团有限责任公司

Icebox without temperature tunable clapboard, and having snapchill cabinet and air return port turnable to open /close positiones, and control method

ActiveCN101093124AReduce long line loopsShorten the loopLighting and heating apparatusDomestic refrigeratorsEngineeringCold store

This invention relates to a refrigerator with a rapid cold chamber and return intakes capable of opening or closing without baffles and a control method, in which the refrigerator includes a shell, an inner tank and an insulated shell between the two with an insulating layer, a safe is set in the refrigerator closed by an insulating door, the temperature of the safe is tested by a sensor, concretely speaking, a rapid cold chamber is included with up and down return intakes, when needing cold alcohol quickly, one puts the bottle into a barrel inside of an outtake to close the lower return intake and cold air is blown from the fan to directly cool the bottle quickly so as to satisfy needs of users.

Owner:HAIER GRP CORP +1

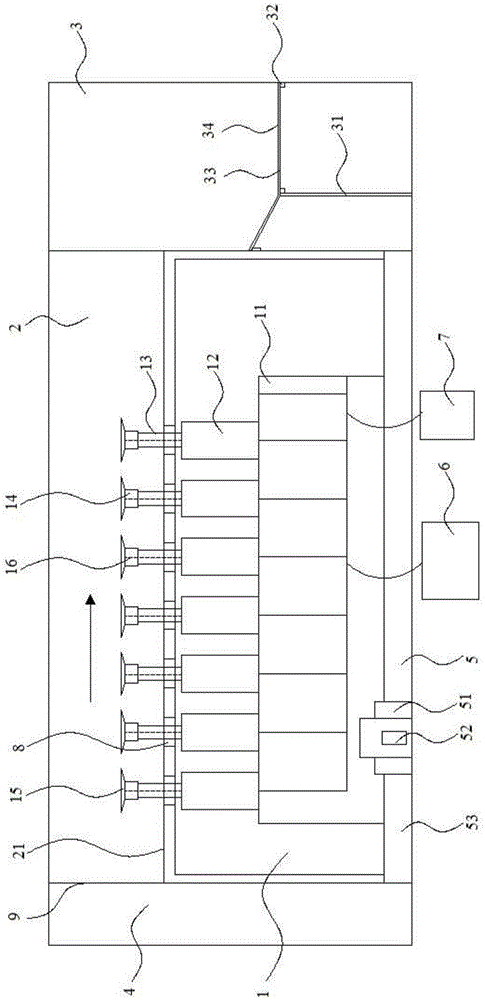

Cooling device of chemical fiber

InactiveCN108425155AImprove cooling effectCool evenly and fullyMelt spinning methodsFiberCooling efficiency

The invention discloses a cooling device of chemical fiber. The cooling device comprises a fan box, a fan is fixedly connected to the interior of the fan box through bolts, air feeding pipes are welded to the outer wall of one side of the fan box, air outlet pipes are fixedly connected to the tops of the air feeding pipes through bolts, a first condensing box is installed at the bottom of the fanbox, a first cooling box is installed at the upper portion, close to the fan box, at the top of the first condensing box, and an outer cylinder is installed inside the first cooling box. By means of the cooling device of the chemical fiber, on one hand, the problem that the cooling efficiency is low due to series flow of cooling water is solved, and the cooling efficiency of the chemical fiber isimproved; on the other hand, through the rotary outer cylinder, the friction between the chemical fiber and the outer cylinder can be effectively reduced, the chemical fiber is prevented from being damaged due to friction, and the integrity of the structure of the chemical fiber is guaranteed; through a second cooling box and a second condensing box, cooling above the chemical fiber can be cooled,and the cooling uniformity and sufficiency of the chemical fiber are guaranteed while the cooling efficiency of the chemical fiber is improved.

Owner:CHANGXING BAOFU WEAVING

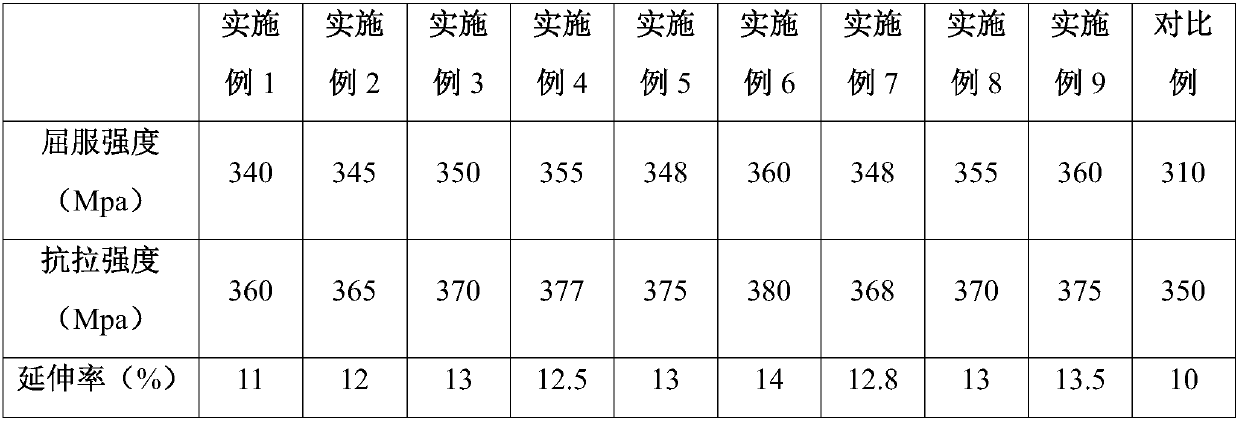

Technique for improving performance of aluminum alloy control arm for automobile

The invention belongs to the technical field of aluminum alloy techniques, and relates to a technique for improving the performance of an aluminum alloy control arm for an automobile. Alloy elements of an aluminum alloy cast ingot include 1.15%-1.25% of Si, 0.18-0.25% of Fe, no more than 0.1% of Cu, 0.8%-0.9% of Mn, 0.9%-1.0% of Mg, 0.1%-0.2% of Cr, no more than 0.05% of Ni, no more than 0.05% ofZn, 0.03%-0.08% of Ti, no more than 0.03% of each of other elements, wherein the total content of other elements is no more than 0.1%. According to the technique for improving the performance of the aluminum alloy control arm for the automobile, a 75MN horizontal extruder is adopted, the section of the 75MN horizontal extruder is approximately in a T shape, the heating temperature of a mold is 450-500 DEG C, the heating temperature of an extrusion cylinder is 420-460 DEG C, the heating temperature for the cast ingot is 480-510 DEG C, the extrusion speed is 1-3 m / min, and the extrusion ratio is14.7; and a water mist cooling method is adopted, the microstructure of a profile is free of coarse grains after solid solution heat treatment (at the temperature of 545+ / -5 DEG C for 2h), and the performance of the profile meets agreement standards through aging heat treatment after solid solution heat treatment.

Owner:CHINA ZHONGWANG

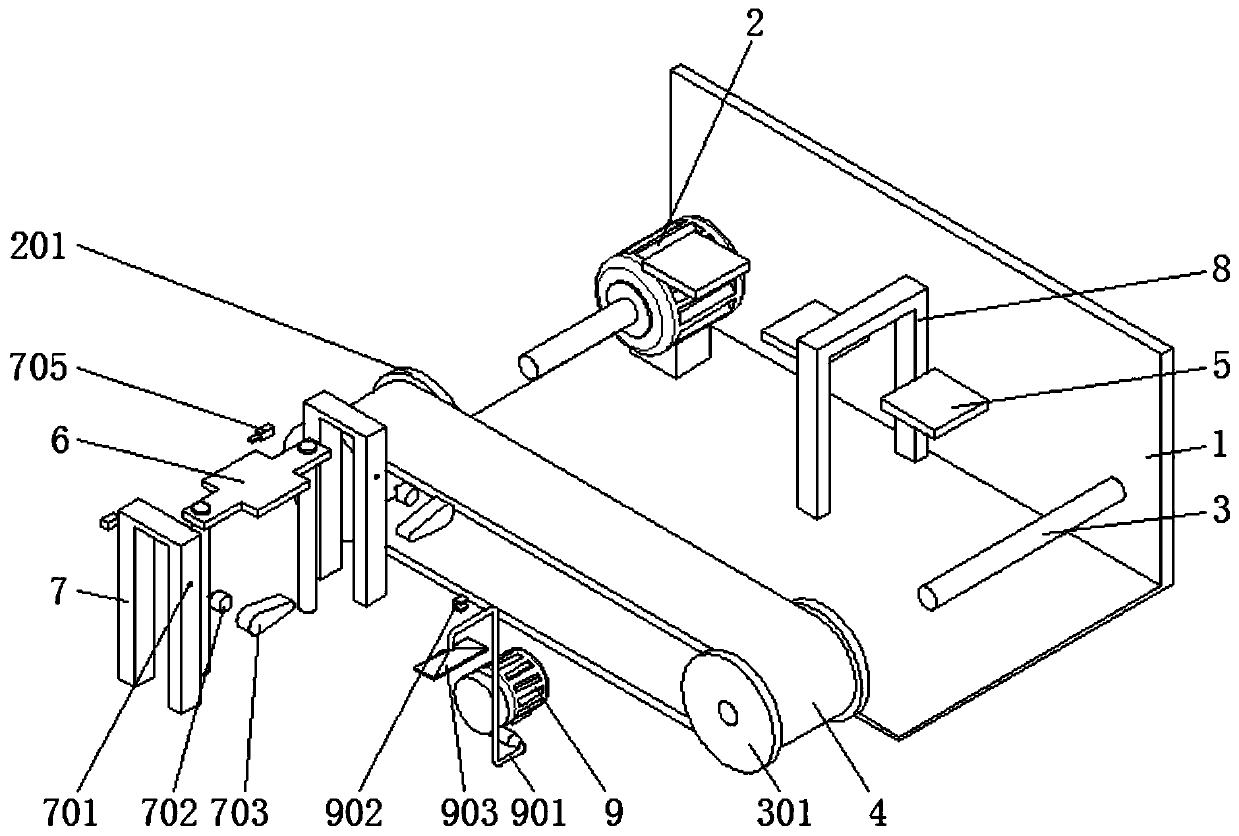

Intelligent dispensing machine for automatic production

ActiveCN109821703AFacilitate automated productionWill not cause stickingLiquid surface applicatorsCoatingsDrive shaftAssembly line

The invention relates to the technical field of dispensing machines, and discloses an intelligent dispensing machine for automatic production. The intelligent dispensing machine comprises a casing, acircuit board and a dispensing mechanism, wherein the casing is composed of a bottom plate and a back side plate, the dispensing mechanism is composed of a sliding post and a dispensing device, a driving motor is fixedly installed on the left side of the top surface of the bottom plate of the casing, a driving roller fixedly sleeves an output shaft of the driving motor, and a driven shaft is fixedly installed on the right side of the front surface of the back side plate of the casing. According to the intelligent dispensing machine for automatic production, the circuit board is fed by a conveying belt, the circuit board makes contact with a piezoelectric plate on the left side surface of a stop block and generates extrusion, a telescopic rod on the left side of the circuit board is controlled to protrude so as to position the circuit board, the circuit board is dispensed by the dispensing mechanism, and the motor is rotated so as to drive the stop block to rotate after dispensing is completed, so that the circuit board can move forward under the action of the conveying belt, the dispensing machine is combined with an assembly line, and the automatic production is realized.

Owner:DONGGUAN BABU ELECTRONICS TECH

Production method of PLA colored silk fiber

InactiveCN110184663APrevent high temperature hydrolysisUniform and stable colorArtificial filament heat treatmentMelt spinning methodsWinding machineMasterbatch

The invention relates to a production method of a PLA colored silk fiber. The production method comprises the following steps: providing a polylactic acid raw material and a polylactic acid color master batch, drying the provided polylactic acid raw material and the polylactic acid color master batch, proportionally mixing the dried polylactic acid raw material and the polylactic acid color masterbatch to form a mixed raw material, conveying the mixed raw material to a spinning assembly through a screw extruder, carrying out melting compression on the polylactic acid raw material through thescrew extruder to form a mixed raw material in a molten state, and spraying color silk tows from the mixed raw material in the molten state through the spinning assembly; making the color silk tows sequentially pass through a lateral air blowing device, an oil feeding device and a channel; drawing the tows drawn from the channel through a drawing assembly; after the drawn tows enter a main interlacer and network points, feeding the drawn tow into a winding machine to be wound into a silk cake. The production method is beneficial to the effective popularization of the PLA colored silk fiber.

Owner:BEIJING CHONGLEE MACHINERY ENG

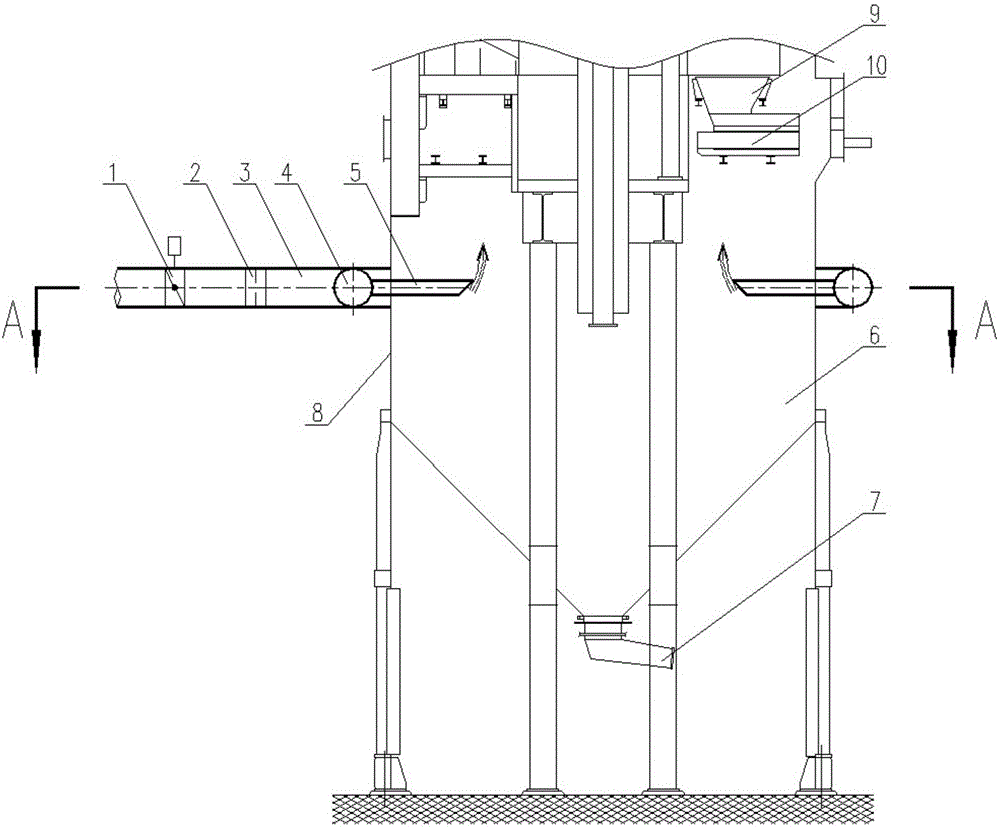

Passive residual heat removal system for high-temperature heat pipe reactor

ActiveCN110767332AImprove natural circulationAchieve compactNuclear energy generationCooling arrangementNuclear powerProcess engineering

The invention relates to a passive residual heat removal system for a high-temperature heat pipe reactor, and belongs to the technical field of nuclear power station safety systems. The system comprises a passive residual heat removal heat exchanger, high-temperature heat pipes, a transverse partition plate and ascending channels, wherein the passive residual heat removal heat exchanger is a cylindrical heat exchanger, is arranged inside a pressure vessel and at the upper part of a reactor core, and can be arranged at the upper part or the lower part of a main heat exchanger, the plurality ofhigh-temperature heat pipes are arranged inside the passive residual heat removal heat exchanger, the transverse partition plate divides the inside of the passive residual heat removal heat exchangerinto an upper layer and a lower layer, and the ascending channels are connected with the top of the passive residual heat removal heat exchanger. The system realizes passive residual heat removal of the high-temperature heat pipe reactor, the high-temperature heat pipes are used as heat transfer pipes of the passive residual heat removal heat exchanger, the reactor core decay heat is brought intothe environment by means of two-phase natural circulation in the high-temperature heat pipes and natural circulation of a working medium in the passive residual heat removal heat exchanger under the accident condition, and thereby the long-term cooling of a reactor is realized.

Owner:HARBIN ENG UNIV

Production method of PLA (polylactic acid) differential shrinkage composite fiber

InactiveCN110055644AAvoid quenchingExcellent hand feelSpinnerette packsArtificial filament heat treatmentYarnPolylactic acid

The invention relates to a production method of a PLA (polylactic acid) differential shrinkage composite fiber. The production method comprises: drying a polylactic acid material; melt-compressing thedried polylactic acid material in a screw extruder, feeding the melt-compressed polylactic acid material into a spinning component, ejecting a melt jet strand via the spinning component, wherein themelt jet strand includes an FDY (fully drawn yarn) part strand and a POY (pre-oriented yarn) part strand independent of each other, cooling the two strands with a side blowing device, an oiling deviceand a passage, drafting the DFY part strand via two pairs of hot roller units to ensure finish quality of the FDY part strand, feeding the FDY part strand drafted by the two pairs of hot roller unitsand the POY part strand drafted via two guide discs into a main interlacer, interlacing, combining, connecting, and winding with a winder to obtain spinning cake. The production method helps effectively popularize the PLA differential shrinkage composite fiber.

Owner:BEIJING CHONGLEE MACHINERY ENG

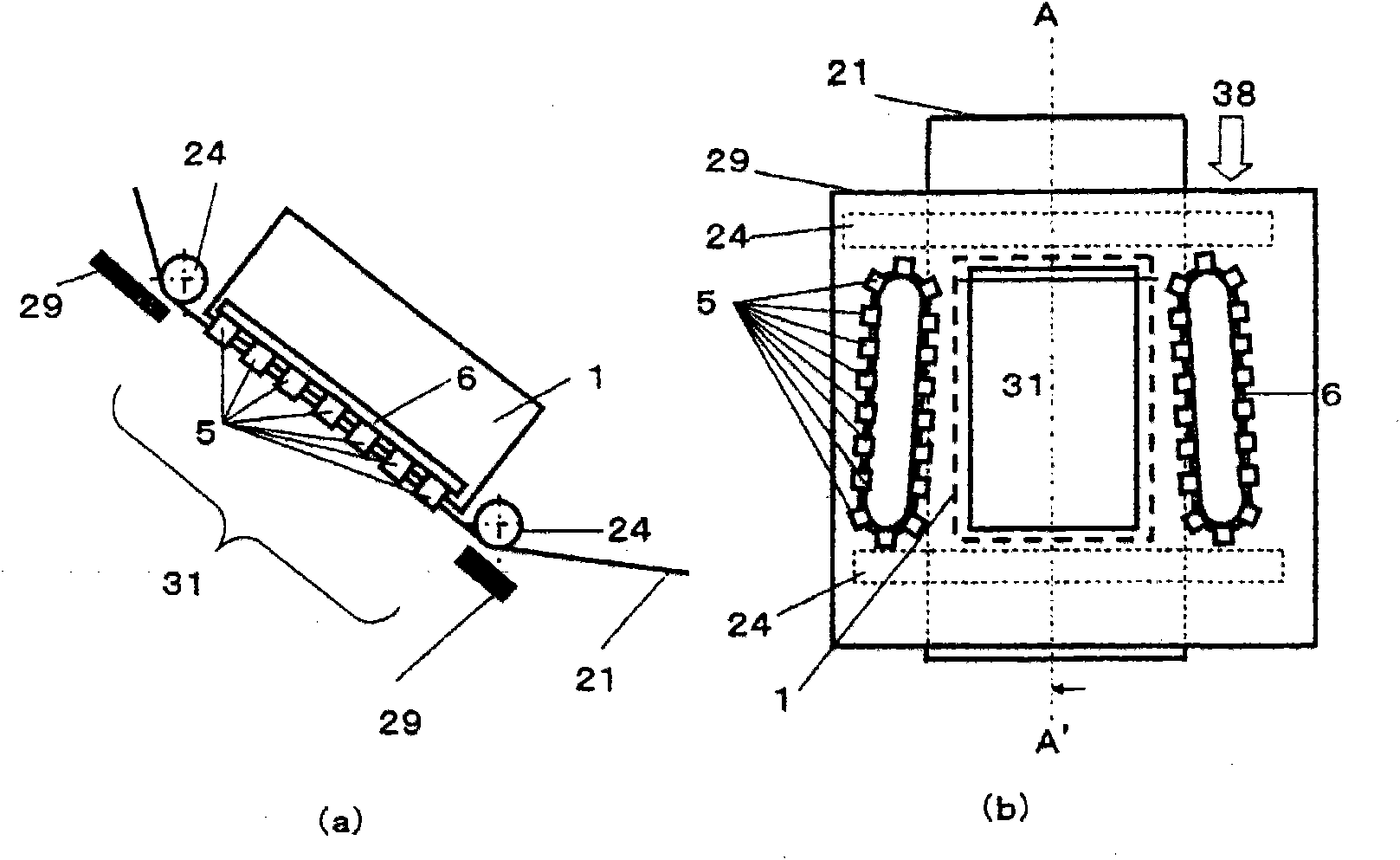

Thin film forming apparatus and forming method for thin film

InactiveCN101849033AForm realizationAvoid deflectionVacuum evaporation coatingSputtering coatingThin membraneComposite material

Owner:PANASONIC CORP

Glass machining system for filtering grinding liquid and adjusting absorption intensity

The invention discloses a glass machining system for filtering grinding liquid and adjusting absorption intensity, and belongs to the technical field of glass machining equipment. The glass machining system comprises a glass fixing device, a grinding liquid cooling box, a grinding liquid filter box, a grinding liquid cooling box and a grinding liquid circulating system; a baseplate is arranged below the grinding liquid cooling box; multiple upper through holes are formed in the baseplate; a support rod is arranged at the bottom end of the grinding liquid filter box, and is provided with a support piece; the support piece is provided with a second filter screen and a first filter screen; the glass fixing device is also connected with an operating terminal; the glass fixing device includes a fixed base, an air compressor, a cylinder, a piston and a rubber sucker; the grinding liquid circulating system includes a water pump, a cooling system and a circulating water pipe; and multiple rubber rings are arranged between the glass fixing device and the grinding liquid cooling box. The glass machining system not only can protect glass, but also can adjust the glass absorption intensity, can effectively recover glass chips for recycling, and improves the glass cooling effect.

Owner:YUNNAN YINENG GLASS TECH CO LTD

Lime cooling device for sleeve kiln

The invention discloses a lime cooling device for a sleeve kiln. Mainly aiming at the problem that a lime product cannot be uniformly cooled by a sleeve kiln in the prior art, a lime cooling device for the sleeve kiln, which can be used for uniformly cooling the lime product, is provided. The lime cooling device comprises an annular pipe, wherein the annular pipe surrounds a kiln body; the inner side of the annular pipe is uniformly provided with a plurality of air outlet ports along the axial direction; the kiln body is provided, corresponding to the air outlet ports, with a plurality of through holes; a plurality of branch pipes are arranged in the through holes in a penetration manner; the outer walls of the branch pipes are in seal fit with the side walls of the through holes; all the branch pipes and lime hoppers in the kiln body are arranged in a one-to-one correspondence manner; cretins ends of the branch pipes are communicated with the air outlet ports of the annular pipe, while the other ends of the branch pipes are arranged just under lower ports of the corresponding lime hoppers; the annular pipe is provided with an air inlet port; the air inlet port is communicated with an air inlet pipeline. By using the lime cooling device, the segregation and the short circuit of a cooling gas can be avoided; the lime product can be uniformly cooled.

Owner:HUATIAN ENG & TECH CORP MCC

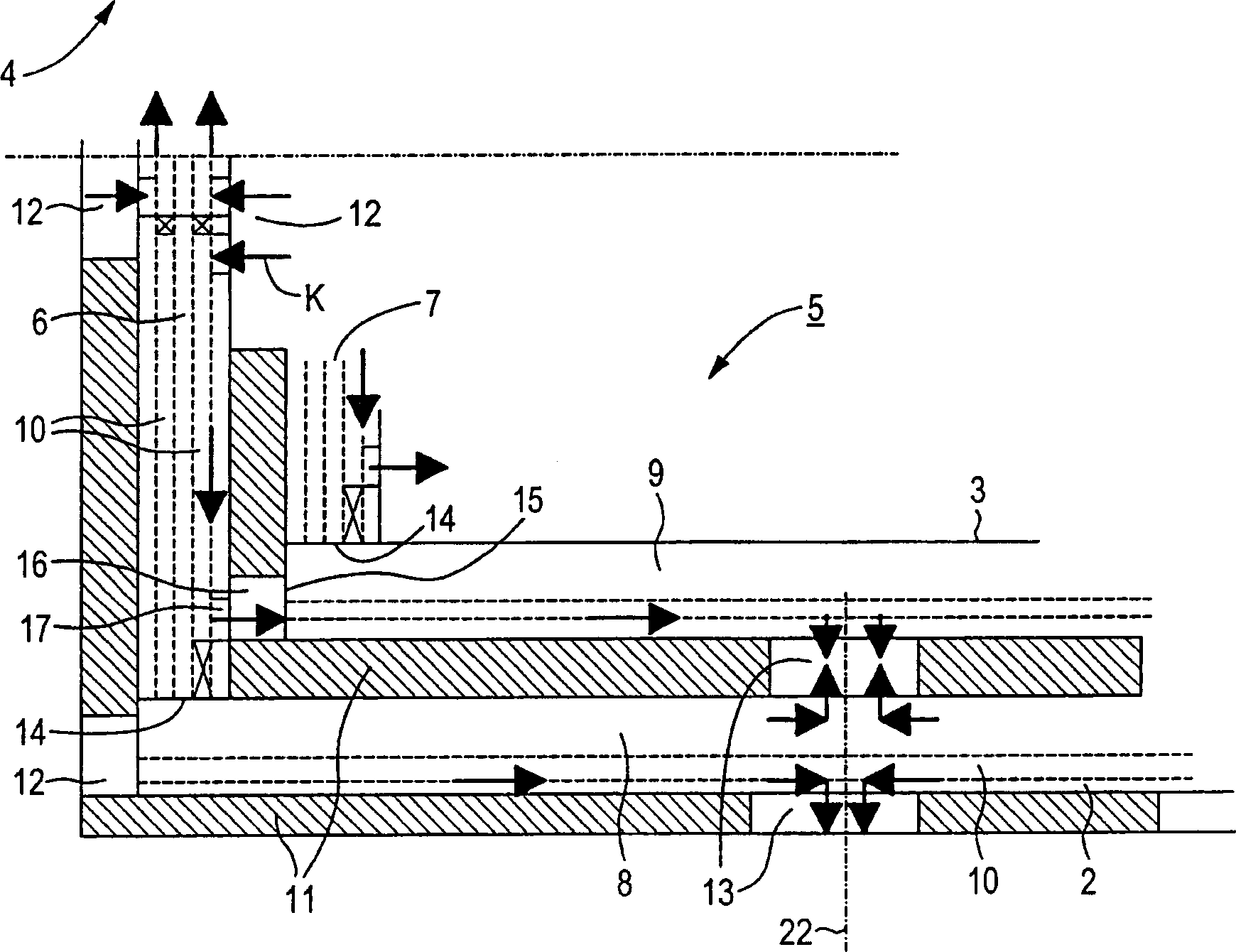

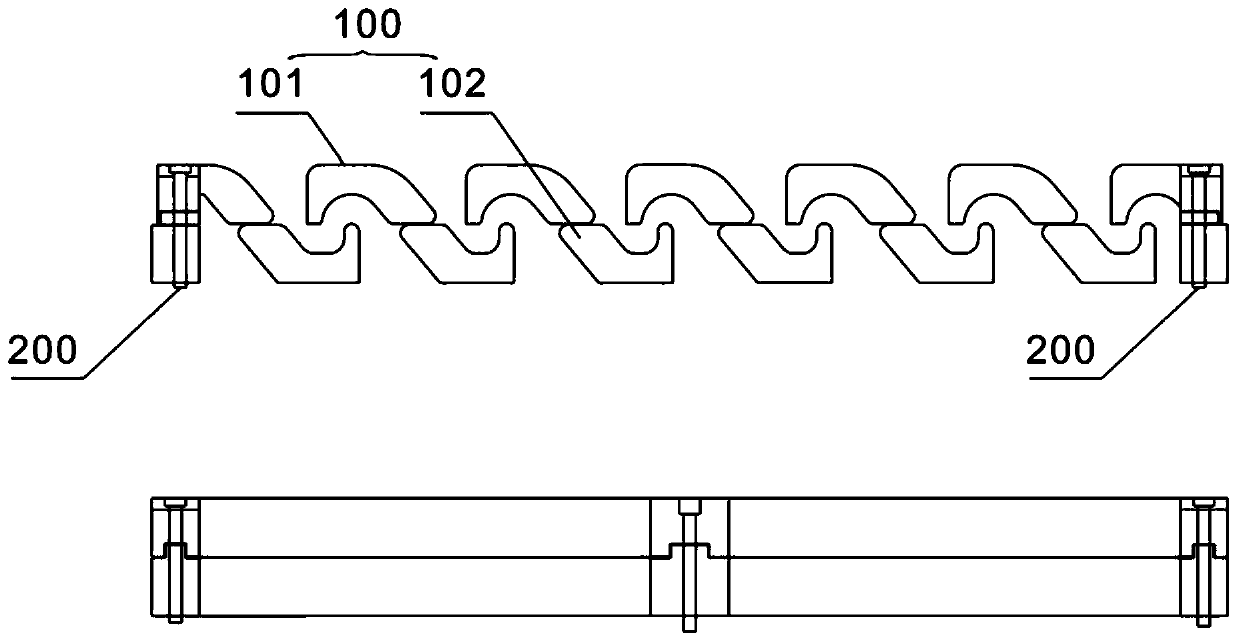

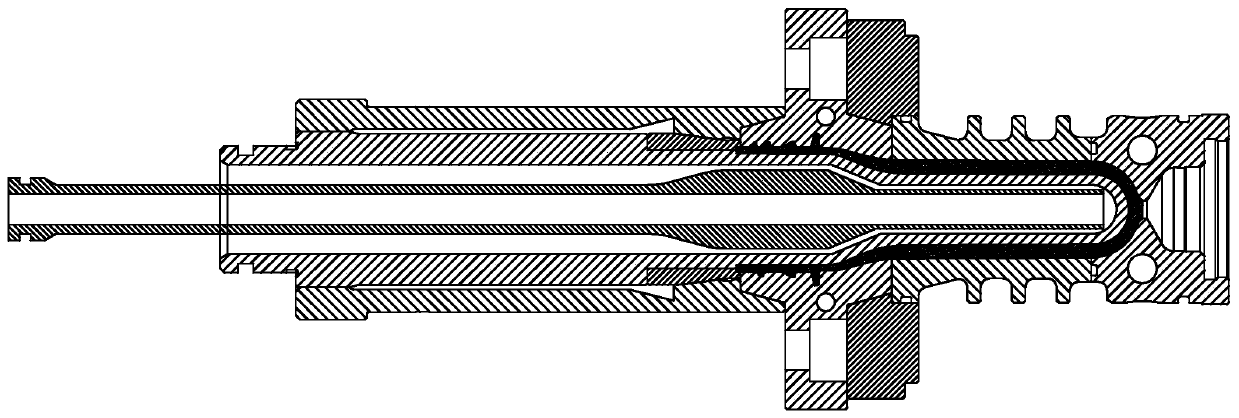

Internally-cooling electric conductor special for rotor of generator

InactiveCN1405950ACool evenly and fullyIncrease powerCooling/ventillation arrangementWindings conductor shape/form/constructionElectrical conductorEngineering

A number of internally cooled conductors in each case comprise a longitudinal conductor and a transverse conductor connected to it, the longitudinal conductors and the transverse conductors being respectively arranged at least approximately parallel and a small distance apart. Advantageous cooling in terms of fluid mechanics is achieved by a cooling duct of a longitudinal conductor of one conductor being connected to a cooling duct of a transverse conductor of an adjacent conductor.

Owner:SIEMENS AG

Circulating cooling device capable of preventing plastic particle sticking

The invention discloses a circulating cooling device capable of preventing plastic particle sticking. An inner casing is arranged in a material cylinder. A material guide passage passes through the interior of the inner casing from top to bottom. The outer side wall of the inner casing is fixedly connected to the inner side wall of the material cylinder through a connection rod. The top and bottomof the inner casing and the top and the bottom of the material cylinder form gaps. A rotating shaft is vertically disposed in the material guide passage. Two ends of the rotating shaft are rotatinglyconnected to the top and bottom of the material cylinder. A circulating water passage passes through the interior of the rotating shaft along the center line. The rotating shaft is sleeved by a driven gear. An output shaft of a driving motor is provided with a driving gear. The driving gear is meshed with the driven gear. The rotating shaft is provided with a spiral blade. The top and bottom of the rotating shaft are respectively provided with rotary joints. Through movement of the spiral blade, the spiral blade drives the plastic particles to continuously flip and rise so that the adhesion between the plastic particles is prevented and the circulation movement of the plastic particles is promoted. The plastic particles can be fully and uniformly cooled.

Owner:苏州市丽苏塑胶科技有限公司

Lead-acid storage battery gravity casting grid mold

The invention relates to a lead-acid storage battery gravity casting grid mold. Due to the fact that the temperature of the gravity casting plate grid mold is not uniform, the fluidity of lead liquidin the mold can be reduced, the casting performance can only be improved through adopting a method for increasing the temperature in the production process, or in order to solve the problem of grid casting, the design weight of a grid is generally increased, so that the burning loss in the production process is increased, the alloy performance is reduced, the energy is wasted, and the lead dust pollution is caused. The invention relates to the lead-acid storage battery gravity casting grid mold, wherein one end of a guide column is fixed at the top of a fixed mold, the fixed mold and a movablemold are connected as a matching whole through the guide column and a through hole in a matched mode, and the fixed mold are attached with the movable mold, so that a lower mold cavity and a upper mold cavity form a plate grid mold cavity; the upper ends of the fixed mold and the movable mold are provided with gates, and the gates communicate with the plate grid mold cavity; and superconducting pipe holes are formed in the lower ends of the fixed mold and the movable mold, and superconducting materials are filled in the superconducting pipe holes. The lead-acid storage battery gravity castinggrid mold has the advantages that the temperature in the casting process can be kept uniform, rapid forming is realized, and the cooling time can be greatly shortened.

Owner:JIANGXI XINWEI POWER ENERGY TECH

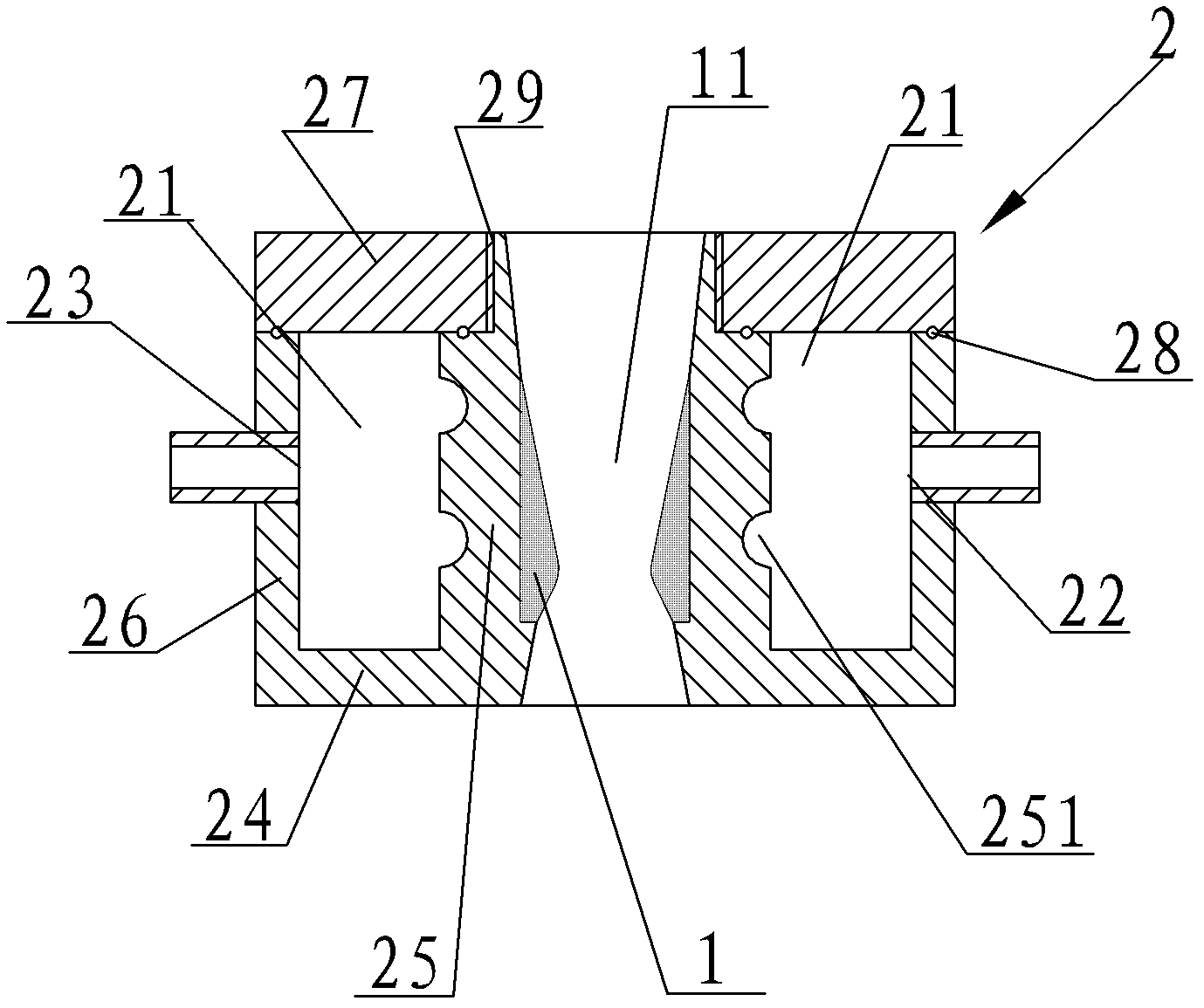

Water-cooled stranding device used in the stranding production of cable conductive cores

ActiveCN102280212ACool evenly and fullyExtended service lifeCable/conductor manufactureWater cyclingElectric cables

The invention relates to a water-cooled stranding device used in a cable-conductive-core strand production. The device comprise: a mold body which has a stranding hole; a mole base which is fixed and arranged coaxially on a periphery of the mold body; a water supply system. The mole base is provided with a cyclic space which surrounds the mold body. A water inlet and a water outlet are symmetrically arranged on an outer wall of the mole base, wherein the water inlet and the water outlet are connected with the cyclic space. The water supply system comprise: a water tank; an inlet pipe which isconnected with the water inlet; an outlet pipe which is connected with the water outlet; a water pump which is arranged in the water tank and used to pump water into the cyclic space so as to form a water cycle of the cyclic space and the water tank. By using the stranding device, product qualities can be improved and the water can be recycled so that production costs can be substantially reduced.

Owner:JIANGSU GANGTONG CABLE

Follow-up spray cooling structure of piston of drilling pump

ActiveCN110159526AImprove cooling effectAvoid large splashesPositive displacement pump componentsLiquid fuel engine componentsEngineeringMechanical engineering

The invention provides a follow-up spray cooling structure of a piston of a drilling pump. The follow-up spray cooling structure comprises a piston rod, wherein one end of the piston rod is coaxiallyconnected with the middle pull rod, the other end of the piston rod is coaxially connected with a piston assembly, and the piston assembly can do piston motion in a matched cylinder sleeve; a coolingliquid flow channel is formed in the piston rod, one end of the cooling liquid flow channel is formed in the outer wall of the piston rod, an assembly flow channel is formed in the piston assembly from the outer circumference face inwards, and the other end of the cooling liquid flow channel of the piston rod is communicated with the assembly flow channel. The follow-up spray cooling structure ofthe piston of the drilling pump solves the problem that the cooling efficiency is poor due to a large amount of cooling liquid splashing in an existing cooling structure.

Owner:BAOJI PETROLEUM MASCH CO LTD +2

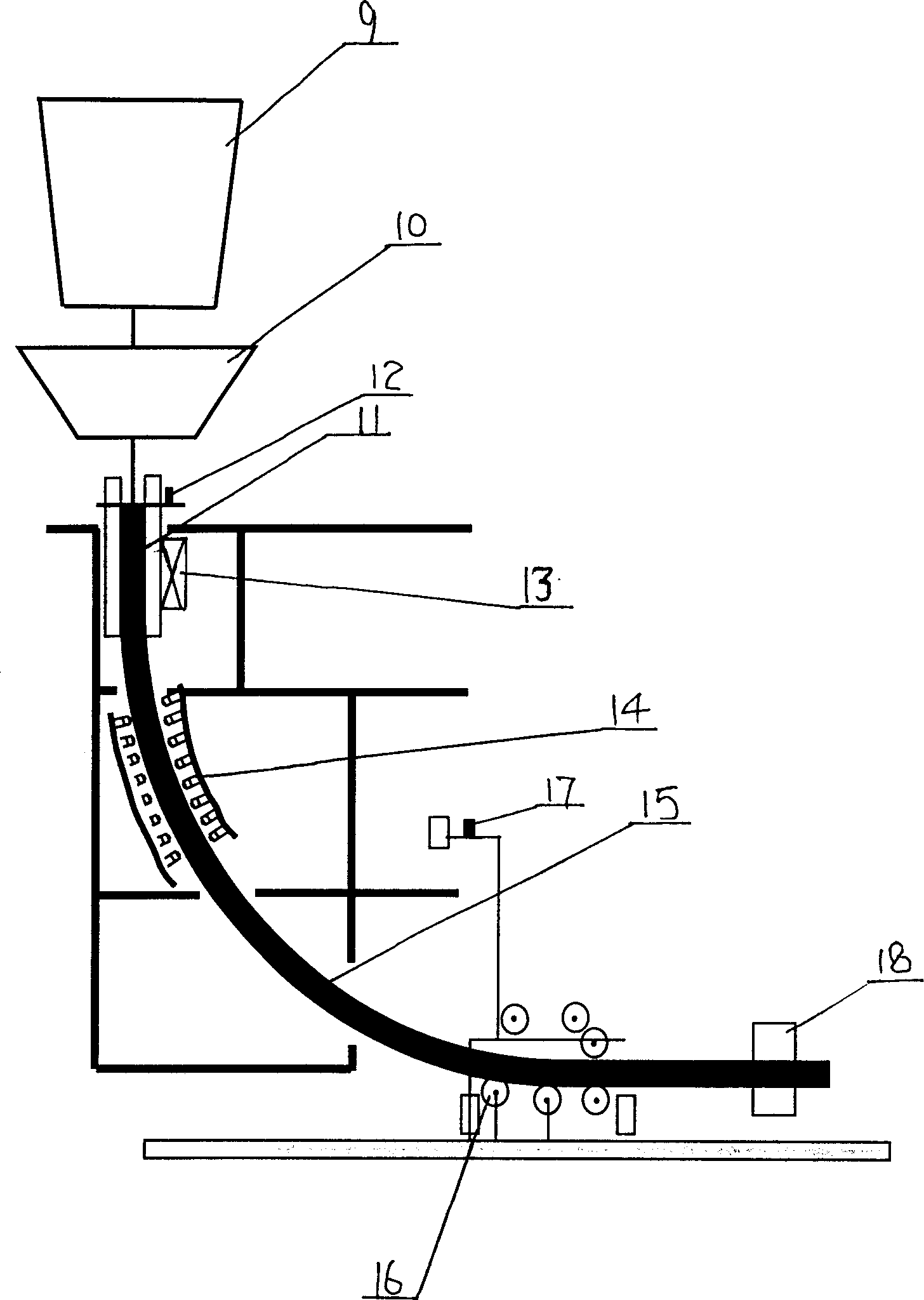

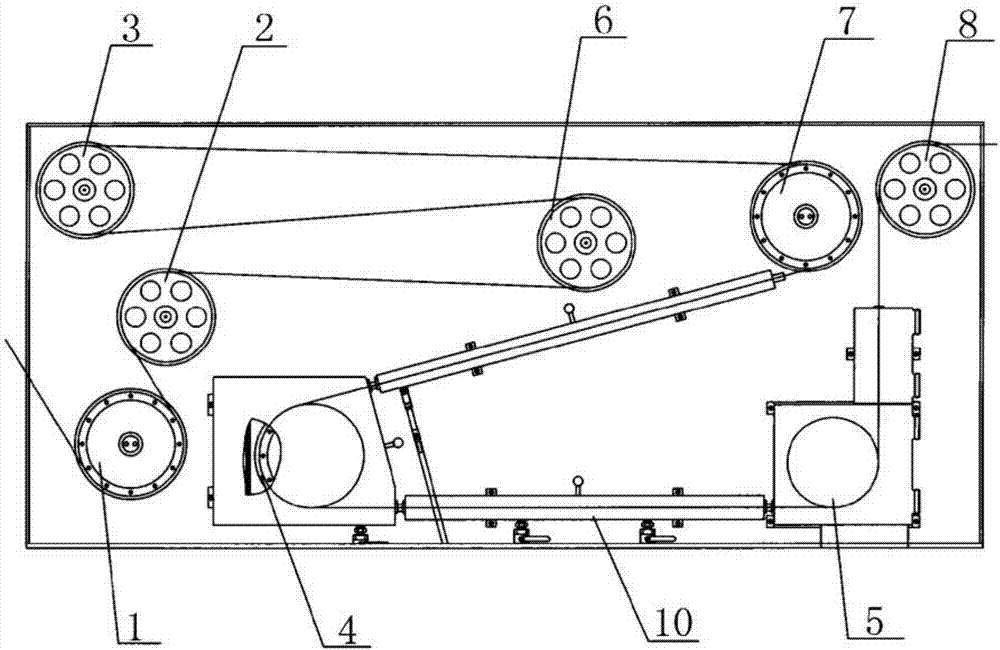

Novel material large-diameter annealing machine

InactiveCN107385161ACool evenly and fullyIncrease contact lengthFurnace typesCoatingsPlate heat exchangerAir cooling system

The invention discloses a large-diameter annealing machine for novel materials, which comprises a pre-annealing wheel, a guide wheel 1, a guide wheel 2, a guide wheel 3, an upper annealing wheel, a lower annealing wheel, a constant speed wheel and a wire rod leading out Guide wheel four, wherein, the pre-annealing wheel to the upper annealing wheel is the preheating section, the annealing section is between the upper annealing wheel and the lower annealing wheel, and the cooling section is between the lower annealing wheel and the guide wheel four. It is as follows: the cooling tank in the cooling section is placed horizontally, and the cooling liquid circulation system in the cooling section is provided with a plate heat exchanger, and the number of carbon brushes on the carbon brush wheel used in the large-diameter annealing machine is eight Group. An air cooling system is arranged on the carbon brush wheel. The length of the preheating section is 9800-10000 mm. The length of the cooling section is 2225-2435 mm. The diameters of the upper annealing wheel and the lower annealing wheel are φ440˜φ460 mm.

Owner:JIANGSU SUFENG MECHANICAL DEV CO LTD

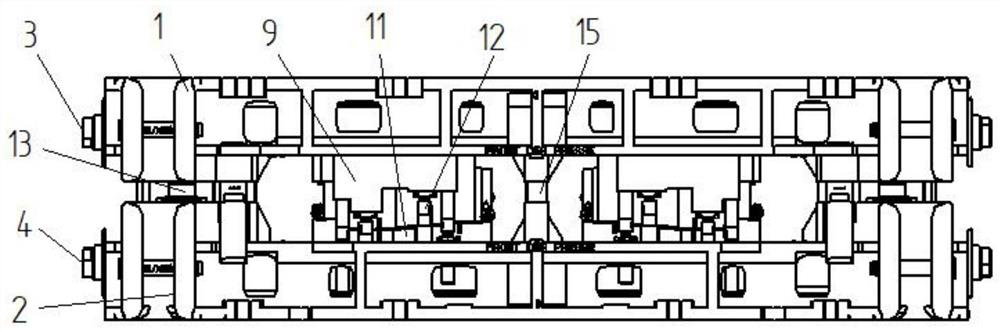

Cross-flow air cooling rotor and high-speed motor

InactiveCN111884379AImprove cooling efficiencyGood energy saving effectMagnetic circuit rotating partsCooling/ventillation arrangementPermanent magnet rotorElectric machine

The present invention relates to a cross-flow air cooling rotor and a high-speed motor. The high-speed motor comprises a shell, a hollow shaft, a permanent magnet rotor and a stator, the interior of the hollow shaft is hollow, the two ends of the hollow shaft are supported and arranged in the shell through bearings respectively, one end of the hollow shaft is open, and the other end of the hollowshaft is fixedly connected with an output shaft of the high-speed motor. The permanent magnet rotor sleeves the hollow shaft, the permanent magnet rotor and the stator fixed to the inner side of the shell are coaxially installed, the permanent magnet rotor is further provided with a plurality of cooling air centrifugal tubes which are communicated in the radial direction, and a gap is reserved between the permanent magnet rotor and the stator. Compared with the prior art, the problems of poor cooling effect and non-uniform cooling of an air heat dissipation system of the high-speed motor are solved, and the high-speed motor can be cooled by adopting an open-circuit hybrid ventilation cooling system.

Owner:SHANGHAI RES INST OF CHEM IND +1

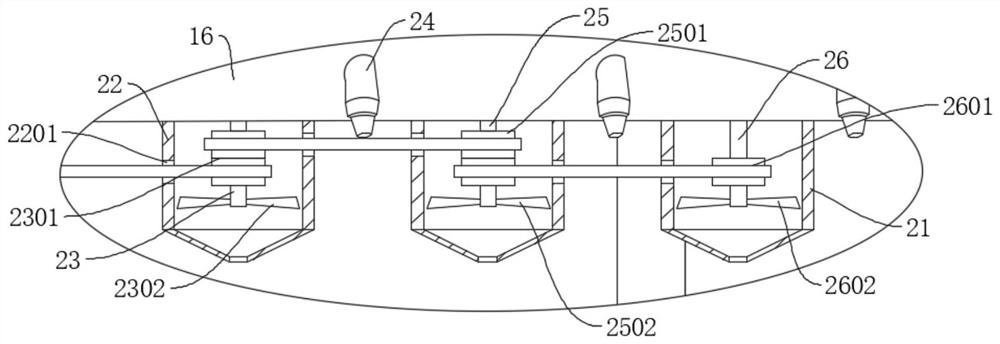

Inflation box fixed grate bed of grate cooler

PendingCN108759487AEliminate the "red river" phenomenonRapid cooling fully and evenlyHandling discharged materialPorosityFailure rate

The invention discloses a partition combined inflation box fixed grate bed of a cement clinker grate cooler. The inflation box fixed grate bed comprises a combined inflation box; the combined inflation box consists of at least two combined modules; the combined modules comprise air chambers, and grate plates arranged on the air chambers; each air chamber of each combined module is divided into multiple subareas communicating with a fan; each air chamber of each combined module at the end part of a feed end is divided into at least two subareas transversely arranged; and each air chamber of each rest non-end combined module is divided into at least three subareas transversely arranged. The fixed grate bed has the characteristics of compact structure assembly, low failure rate, high heat recovery efficiency and convenience to maintain; each air chamber of each combined module of the fixed grate bed is divided into multiple subareas; and aiming at different material layer thicknesses anddifferent material layer porosities, corresponding reasonable air volumes and air pressures are set.

Owner:邓建新

Multi-water-channel hot stamping die

PendingCN112338065APrecise temperature controlCool evenlyShaping toolsQuenching devicesHot stampingThermodynamics

The invention provides a multi-water-channel hot stamping die. The multi-water-channel hot stamping die comprises an upper die base, upper die inserts, a lower die base and lower die inserts. The upper die base and the lower die base are each provided with a main water channel, a plurality of cavities are formed in each main water channel, the cavities are communicated through water passing openings, the caliber of each water passing opening is far smaller than the size of the corresponding cavity, cooling media in the water channels and the cavities in a stable state can be changed into a turbulent flow state, and the cooling efficiency is improved. Meanwhile, the multiple cavities are arranged in a non-single straight line in the main water channels, water retaining blocks are placed insome water passing openings of the cavities, multiple cooling areas can be formed, the multiple inserts are correspondingly arranged in the multiple cooling areas, simultaneous cooling of the multipleinserts can be achieved, water supply cooling can be conducted on only one insert, The cooling water flow of the main water channels is controlled in a targeted mode, unnecessary cooling circulationis reduced, the main water channels and all parts of the inserts are accurately controlled to be evenly cooled, a hot stamping part is fully and evenly cooled, and the problems that the mechanical property of the hot stamping part is unstable and the deformation amount is large are solved.

Owner:HUNAN SUNRISE AUTOMOBILE MOULD & DIE CO LTD +2

Mold rapid cooling device and using method thereof

The invention discloses a rapid mold cooling device and a using method thereof, and belongs to the technical field of mold cooling. The rapid mold cooling device comprises a base; a mold base is fixedly connected to the outer wall of the base; a lower mold is fixedly connected to the outer wall of the top of the mold base; a supporting rod is fixedly connected to the outer wall of the base; a topbase is fixedly connected to the end, away from the base, of the supporting rod; an air cylinder is arranged on the top base, and an output end of the air cylinder is fixedly connected with an upper mold; a stabilizing plate is slidably connected to the base; a piston cylinder is fixedly connected to the stabilizing plate; a second water inlet pipe and a second water outlet pipe are arranged on the piston cylinder; one-way valves are arranged on the second water inlet pipe and the second water outlet pipe; and a piston plate is slidably connected into the piston cylinder, and a piston rod is fixedly connected to the outer wall of the piston plate. The rapid mold cooling device provided by the invention is good in cooling effect, high in cooling speed and high in model yield, economic benefits are increased, cooling can be fully and evenly conducted, and the use performance of a casting mold is greatly improved.

Owner:深圳利朋技术研发有限公司

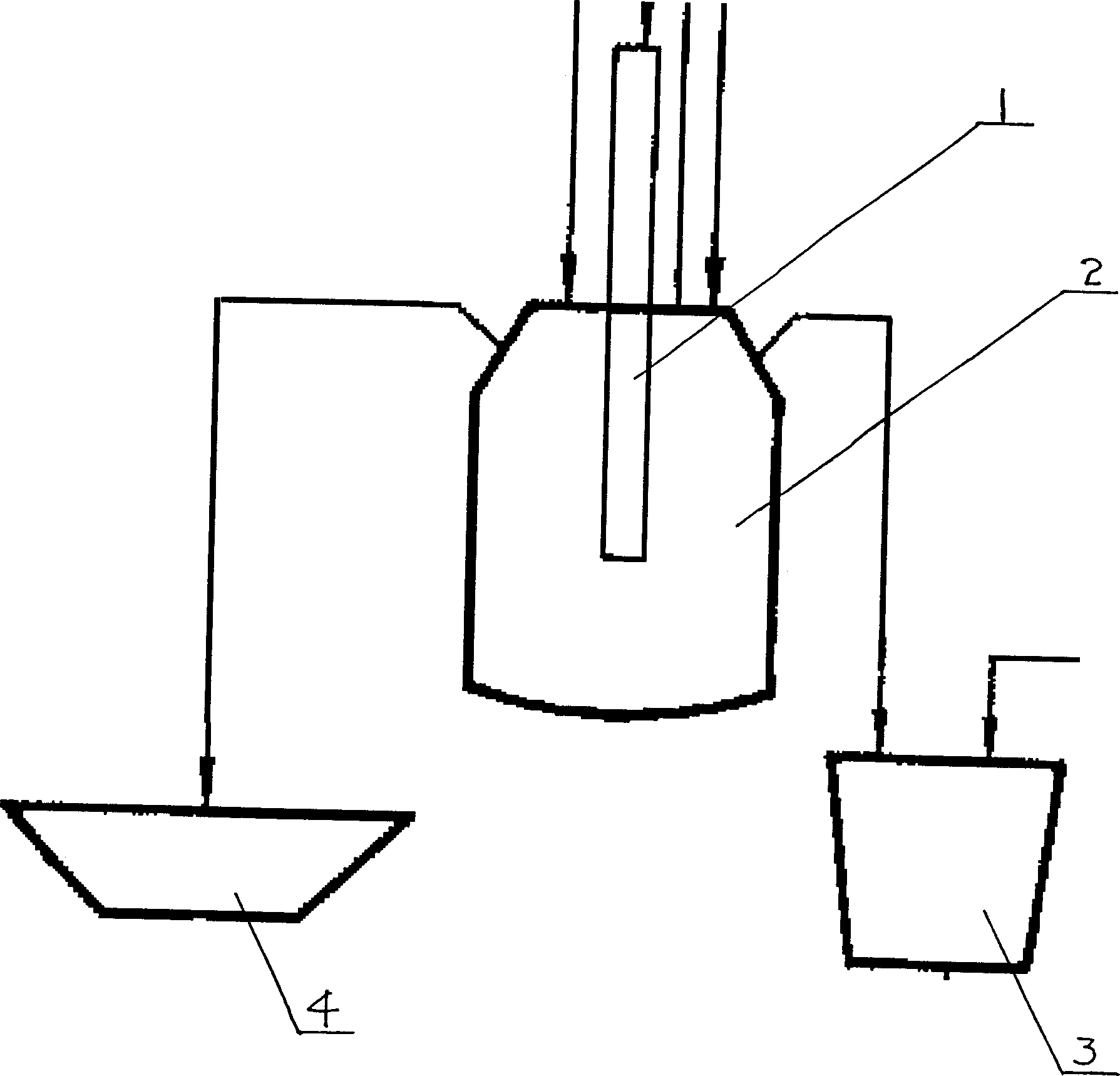

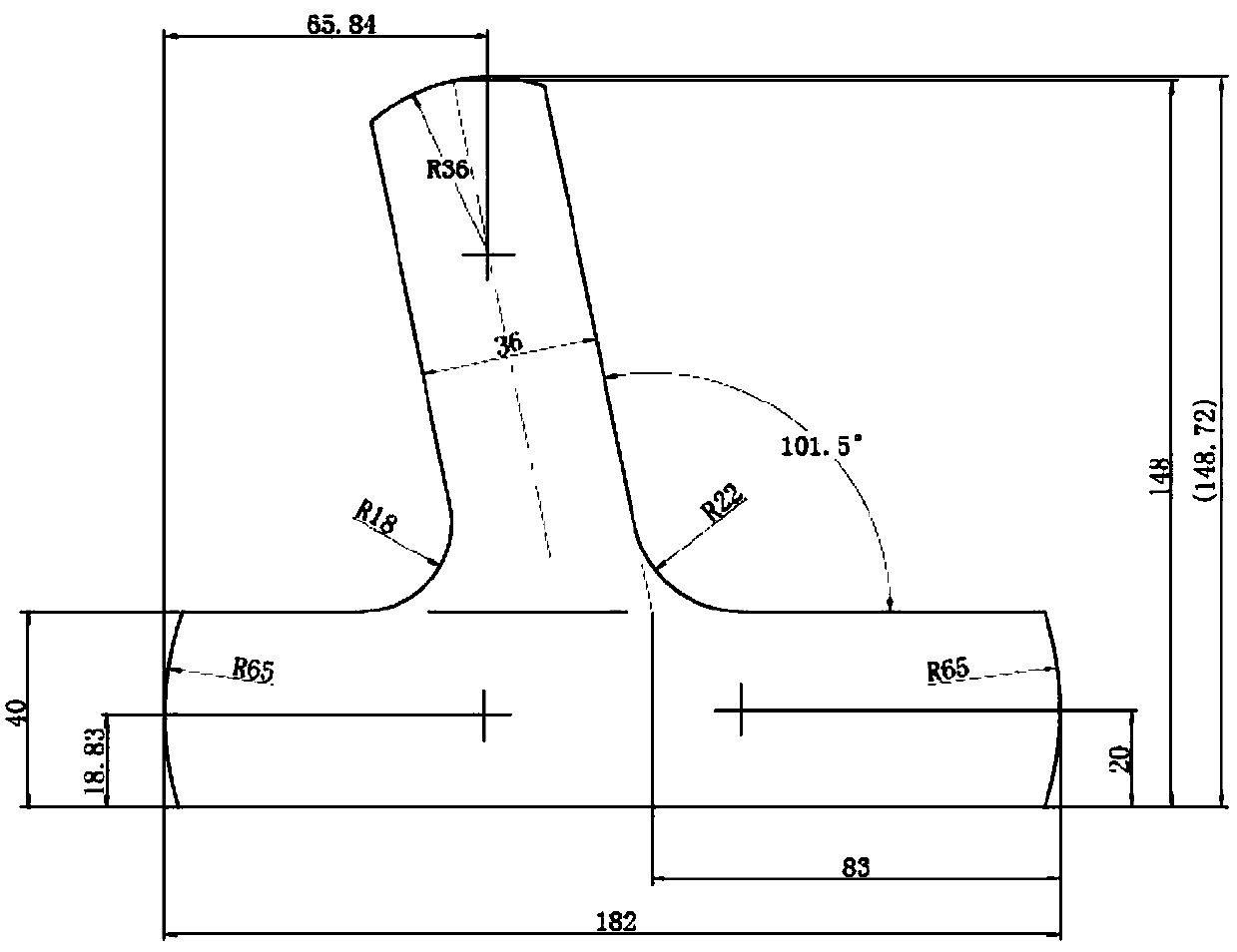

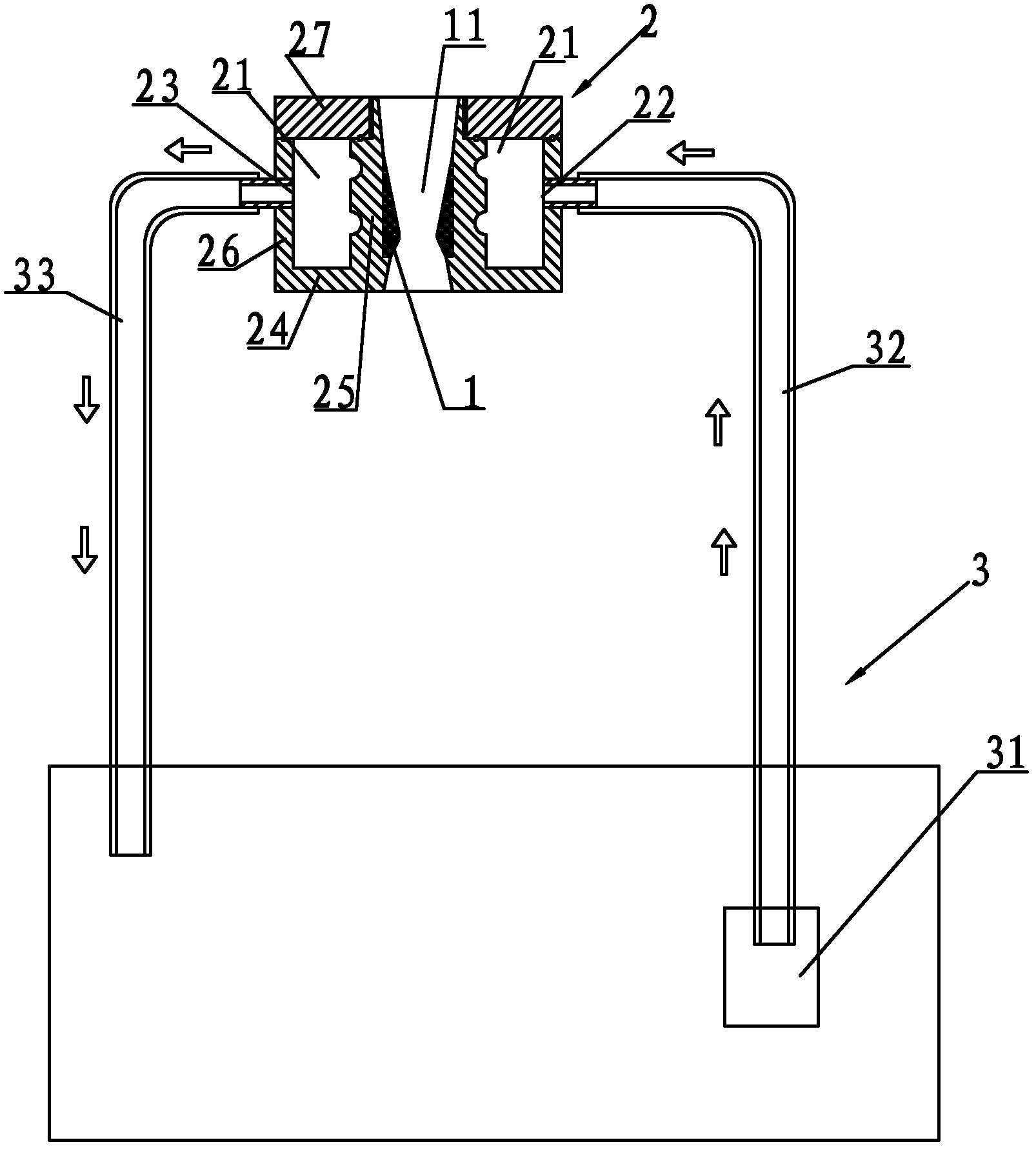

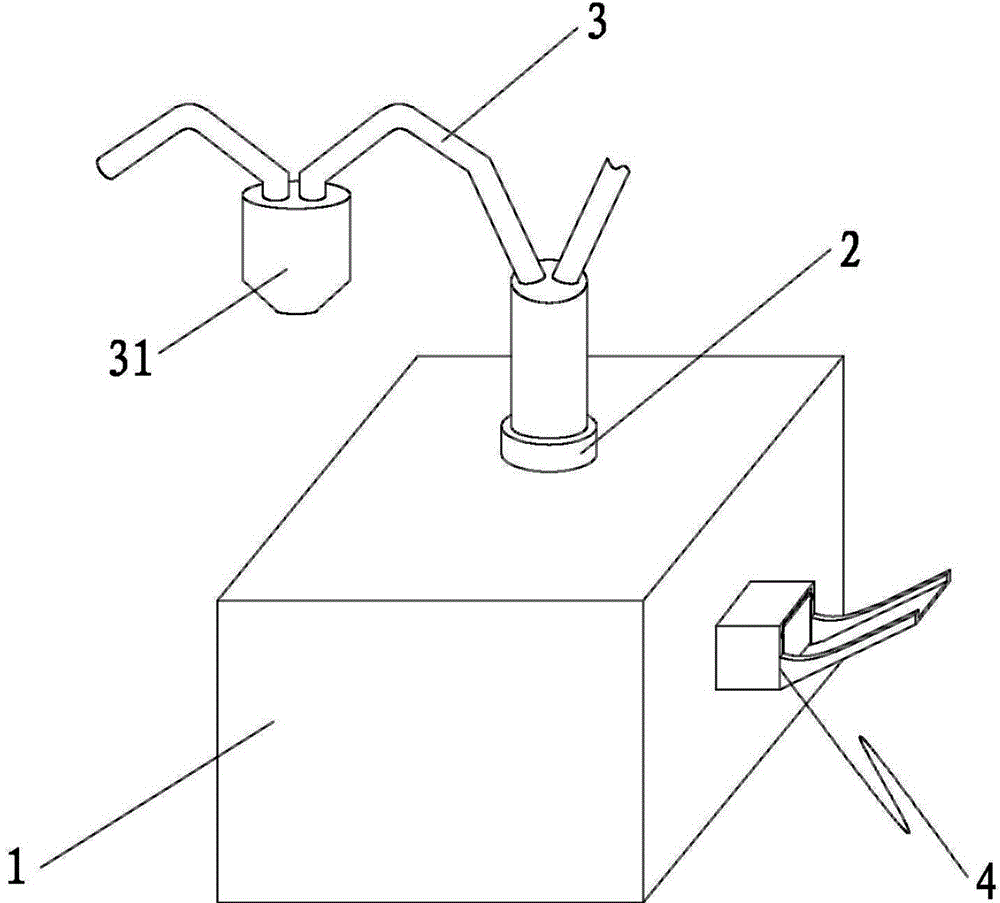

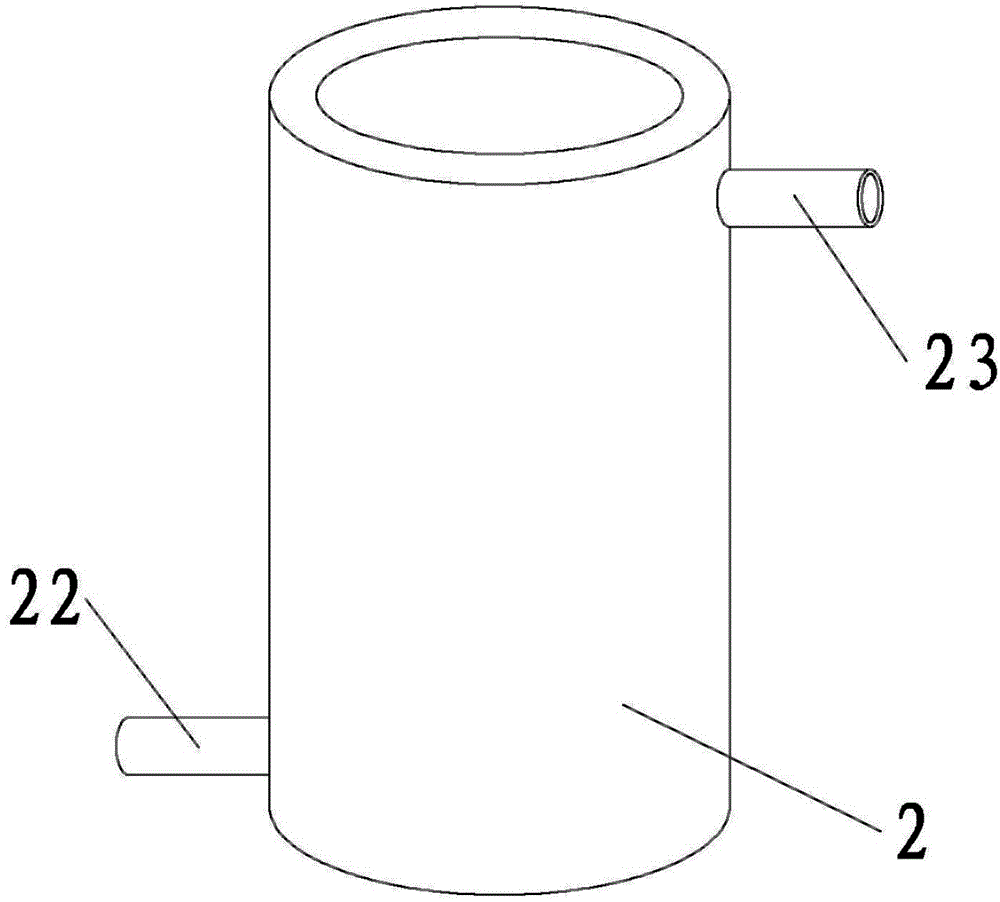

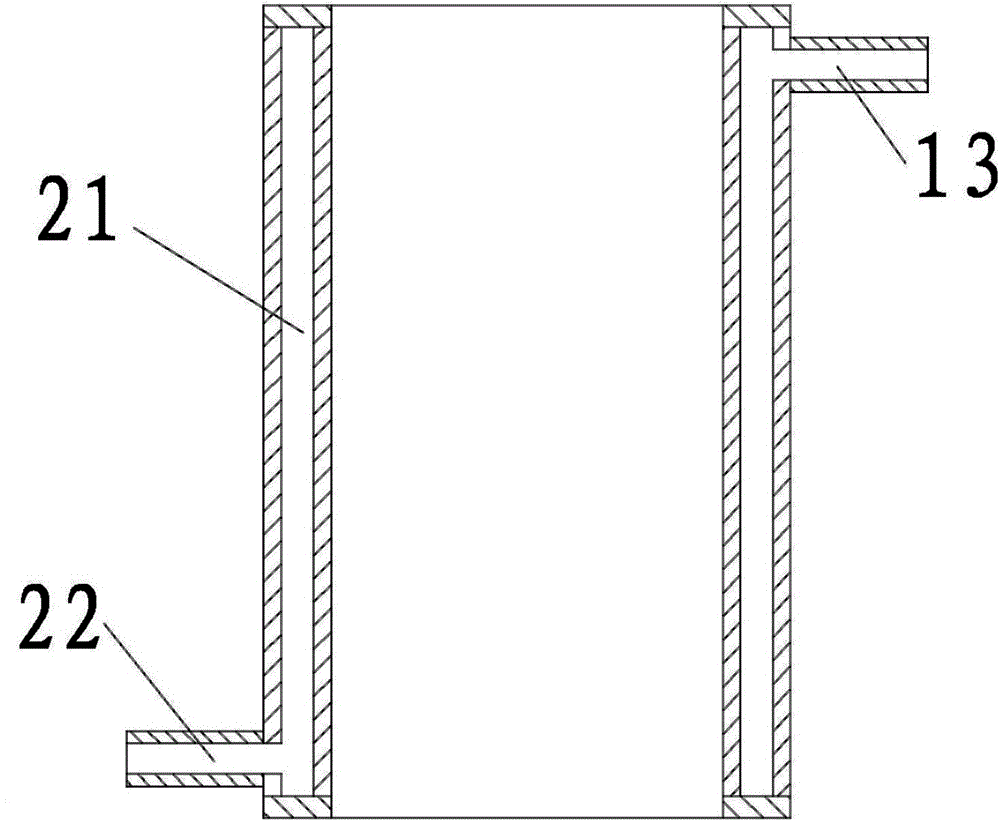

Antimony powder production system

The invention discloses an antimony powder production system which comprises a smelting furnace (1), an upper water-cooling time delay unit (2) and an antimony powder transferring pipeline (3). The water-cooling time delay unit (2) is arranged on an antimony powder outlet of the smelting furnace (1), and the antimony powder transferring pipeline (3) is connected with the upper water-cooling time delay unit (2). The cross section of a powder outlet of the upper water-cooling time delay unit (2) is oval, and a condensate water layer (21) is arranged in the peripheral wall of the upper water-cooling time delay unit (2). The antimony powder transferring pipeline (3) is composed of multiple bent pipes, and a conical hopper (31) is arranged at the connecting position of the lower ends of every two bent pipes. Through arranging the upper water-cooling time delay unit of which the cross section is oval, antimony powder is discharged from the smelting furnace and passes through the upper water-cooling time delay unit, distances between the antimony powder in the center and water grooves in the peripheral wall of the upper water-cooling time delay unit are equal, the distances between the antimony powder which passes through the whole outlet and the water grooves in the peripheral wall of the upper water-cooling time delay unit are small in difference, and therefore cooling is more sufficient and evener when the antimony powder is discharged from the furnace.

Owner:贵州华星冶金有限公司

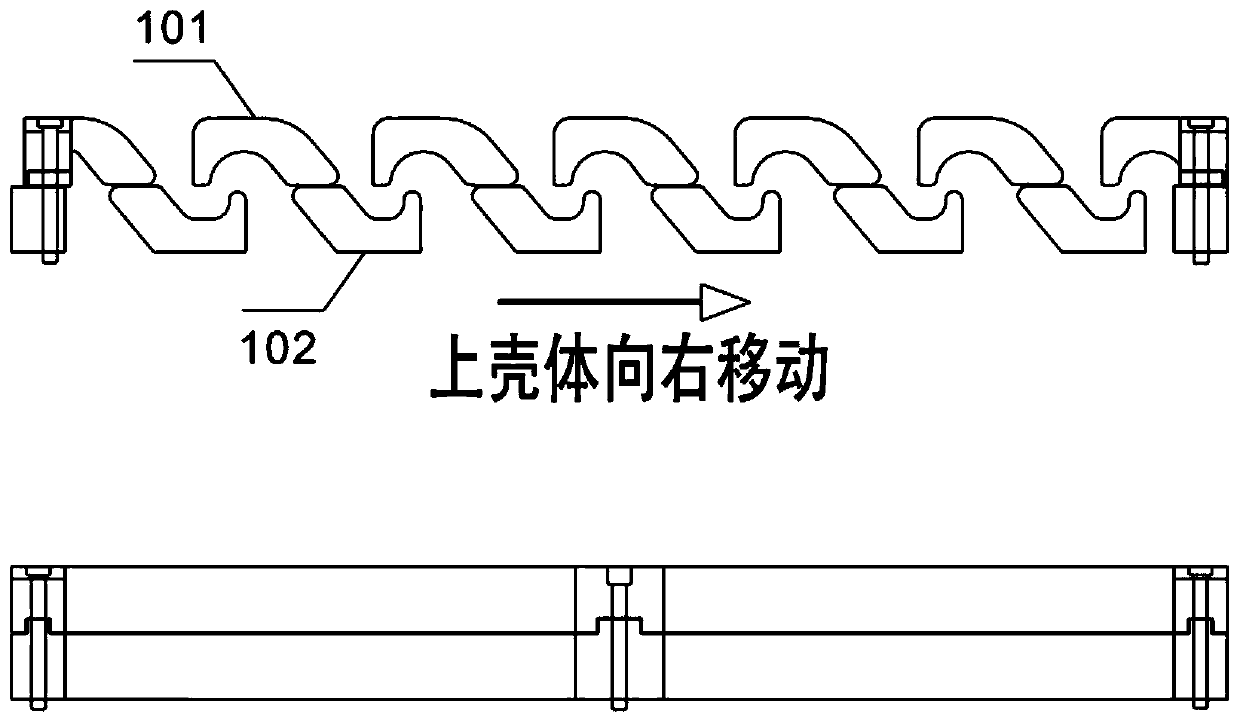

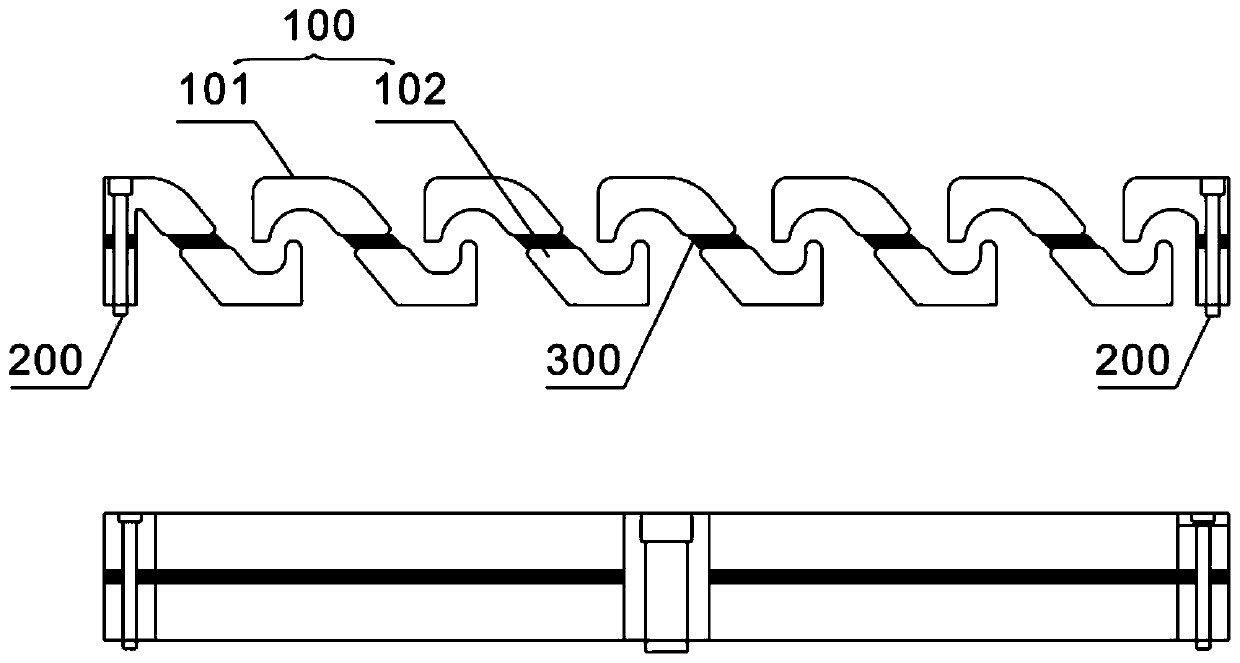

Gratecooler grate plate capable of adjusting width of grate seam

InactiveCN110332810AImprove cooling efficiencyEnsure adequate and even coolingHandling discharged materialL-shellEngineering

The invention discloses a grate cooler grate plate capable of adjusting width of a grate seam. The grate plate comprises a grate plate body and a connector. The grate plate body comprises an upper shell and a lower shell; positioning holes are formed in the upper shell and the lower shell, the quantity of the positioning holes in at least one of the upper shell and the lower shell is greater thanor equal to 2, and the upper shell and the lower shell are matched with each other and are connected according to different positioning holes to form change of relative positions so as to adjust the width of the grate seam; and the connector is fixed to the opposite positioning holes in the upper shell and the lower shell to connect the upper shell and the lower shell integrally. By adopting the grate plate disclosed by the invention, the grate plate needs not to be replaced integrally. When agrate cooler is stopped, the width of the grate seam of the grate plate is adjusted timely to achievethe optimum cooling blast capacity and the cooling pressure so as to improve the material cooling efficiency, so that clinker is fully and uniformly cooled, and the clinker temperature of a cooler isfurther reduced.

Owner:NANJING KISEN INT ENG

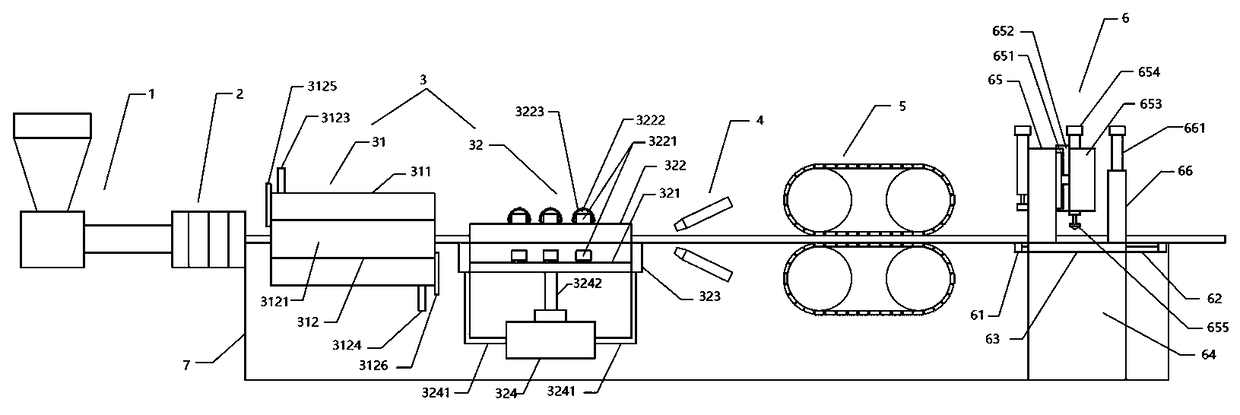

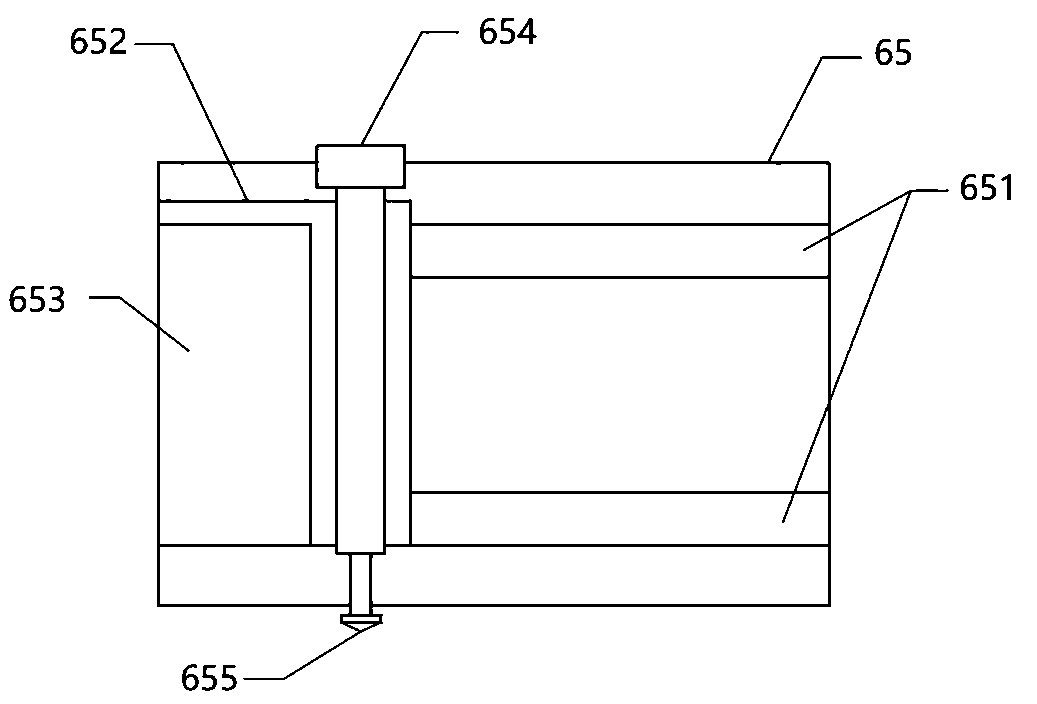

Production line of integrated wallboard

PendingCN109454847ACompact structureEasy to useDomestic articlesMetal working apparatusProduction lineAir knife

The invention discloses a production line of an integrated wallboard. The production line of the integrated wallboard comprises an extruding machine, a forming mold, a conveying frame, an air knife and a traction machine, wherein the forming mold is connected to the extruding machine, and the air knife and the traction machine are connected to the conveying frame. The production line of the integrated wallboard is characterized by further comprising a cooling mechanism and a cutting mechanism which are both connected to the conveying frame, wherein the cooling mechanism, the air knife, the traction machine and the cutting mechanism are sequentially arranged, and the cooling mechanism comprises a dry type cooling device and a wet type cooling device which are sequentially arranged. According to the production line of the integrated wallboard, the structure is compact, the use is convenient, after the wallboard is extruded, the wallboard is primarily shaped through dry type cooling and wet type cooling, so that cooling is sufficient and uniform, the surface is flat without hollowing phenomena, cutting is efficient, fast and convenient, the notch is flat without roughness phenomena, and the whole production line is high in automation degree, good in product forming and worthy of popularization and use.

Owner:福州启辰阳光建材有限公司

Cooling spraying device of injection molding machine and using method thereof

The invention discloses a cooling spraying device of an injection molding machine and a using method thereof, and belongs to the technical field of injection molding machines. The cooling spraying device of the injection molding machine comprises the injection molding machine, and the interior of the injection molding machine is movably connected with an upper mold. According to the cooling spraying device of the injection molding machine and the using method thereof, supporting rods are arranged, in each angle adjusting mechanism, a power device works to drive first gears to rotate through a screw rod, each first gear drive the corresponding supporting rod on one side of the first gear to rotate in the rotating process, the supporting rods are connected with movable rods, so that the supporting rods move to push or pull the movable rods, the movable rods are movably connected with a holding table, the three supporting rods push and pull the three movable rods, so that a bearing disc connected to the tops of the movable rods rotates at multiple angles, and the bearing disc rotates at multiple angles to drive a corresponding cooling fan to synchronously rotate at multiple angles; and in this way, products are fully and uniformly cooled in the production process of the injection molding machine, and the final production quality of the products is improved.

Owner:无锡安森源通讯科技有限公司

Bottle billet forming part assembly with die cavity extending into die lip for matching and bottle billet die thereof

The invention discloses a bottle billet forming part assembly with a die cavity extending into a die lip for matching. The bottle billet forming part assembly comprises a die cavity, a die lip, a diecore and a die cavity fastener, wherein the die cavity fastener is positioned between the die cavity and the die lip; a die lip cooling water channel is arranged in the die lip; a flange is arranged at the end part of the die cavity; a matching hole site is formed in the end part of the die lip and is connected with the outer side wall of the flange in a sleeving manner; a matching end face between the flange and the matching hole site forms a billet body parting surface; and the billet body parting surface is arranged on a billet body neck forming area. The invention further discloses a bottle billet die with the die cavity extending into the die lip for matching. The bottle billet die comprises the bottle billet forming part assembly and a die cavity bottom; the die cavity bottom is mounted at the end, far away from the die lip, of the die cavity; a billet bottom cavity for forming the bottle billet bottom is formed in the die cavity bottom; a die cavity bottom cooling water channelis formed in the die cavity bottom; and the die cavity bottom cooling water channel surrounds the periphery of the billet bottom cavity.

Owner:GUANG DONG XING LIAN PRECISE MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com