Water-cooled stranding device used in the stranding production of cable conductive cores

A conductive wire core, water-cooled technology, applied in the direction of cable/conductor manufacturing, circuits, electrical components, etc., can solve the problems of easily damaged molds, unsafe, flammable alcohol, etc., to reduce production costs, prolong service life, The effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing, preferred specific embodiment of the present invention is described:

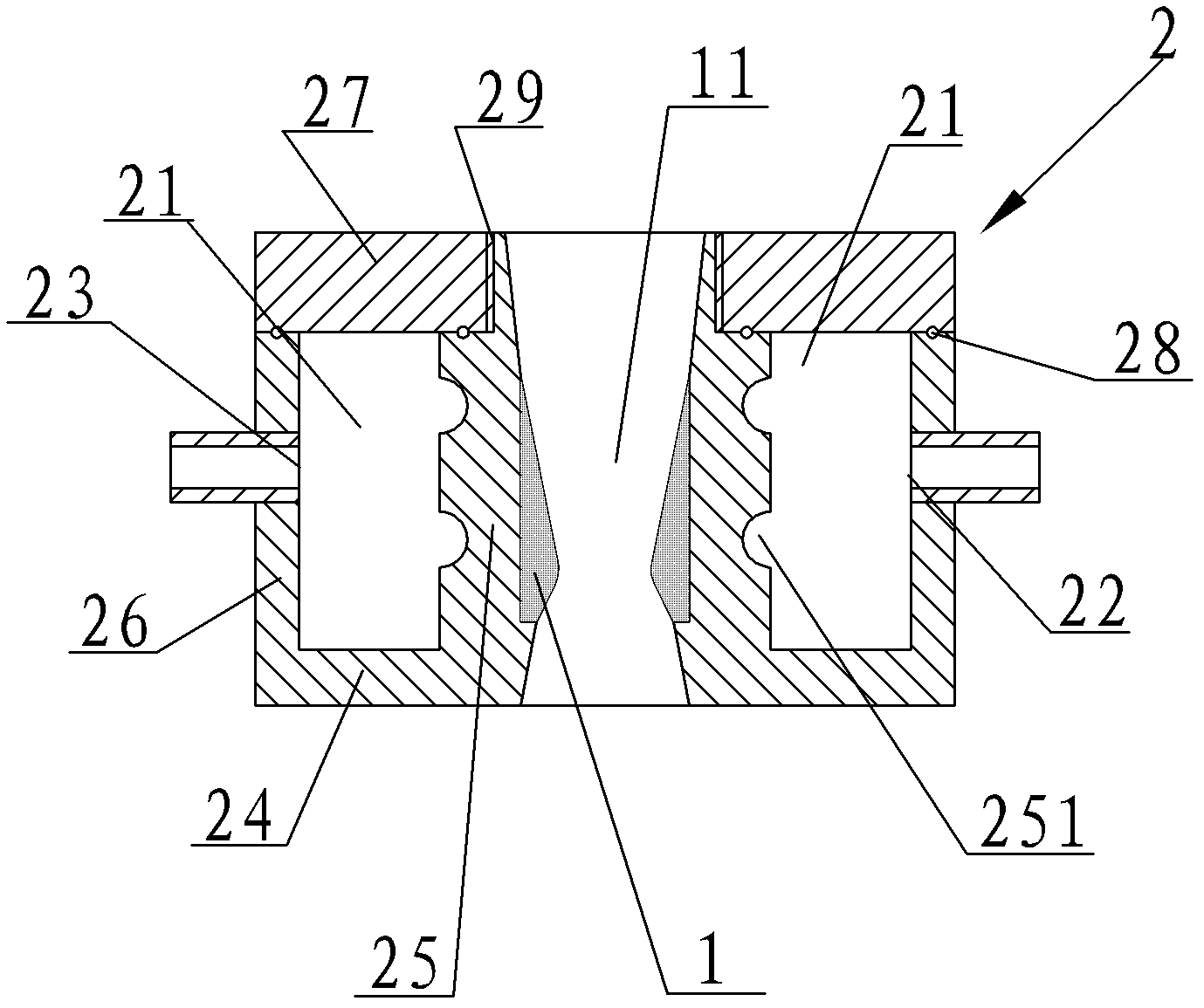

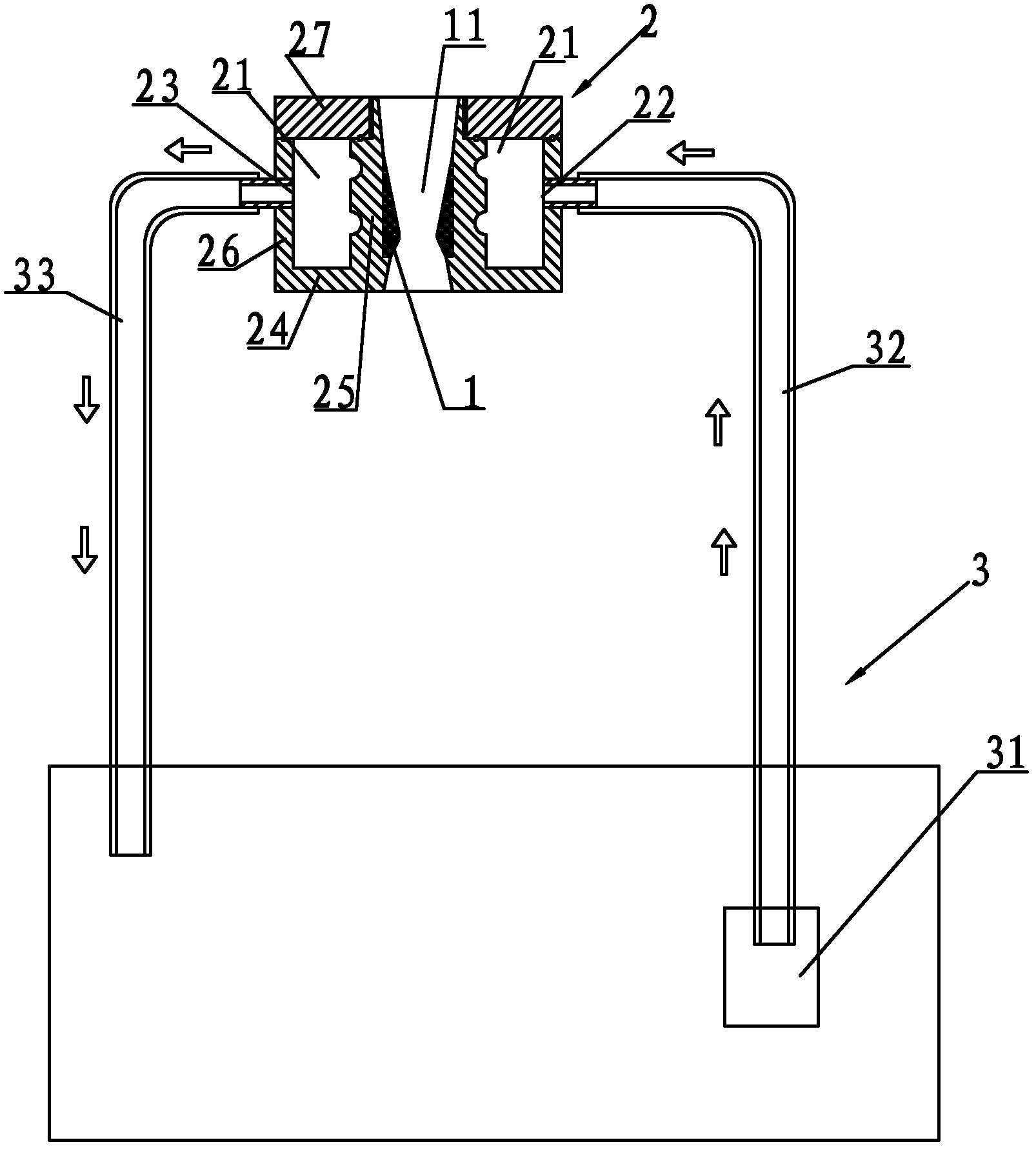

[0024] like figure 1 The shown water-cooled stranding device is used in the stranding production of electric cable conductive cores, and mainly consists of a mold body 1 formed with stranding holes 11, a mold seat 2 fixed and coaxially arranged on the outer periphery of the mold body 1, The water supply system consists of 3 components, and the structure of each part will be described below:

[0025] The mold base 2 is composed of a base 24 with a central hole, an inner mold wall 25 and an outer mold wall 26 extending upward along the inner and outer rings of the base 24, and a mold wall connected between the inner mold wall 25 and the outer mold wall 26. The mold cover 27 is composed of the mold cover 27 and the base 24 which are respectively sealed with the inner mold wall 25 and the outer mold wall 26, and the inner mold wall 25, the inner mold wall ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com