Internally-cooling electric conductor special for rotor of generator

A generator rotor and internal cooling technology, applied in cooling/ventilation devices, electromechanical devices, shape/style/structure of winding conductors, etc., can solve problems such as the influence of generator power, achieve sufficient and uniform cooling, low power requirements, The effect of power increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

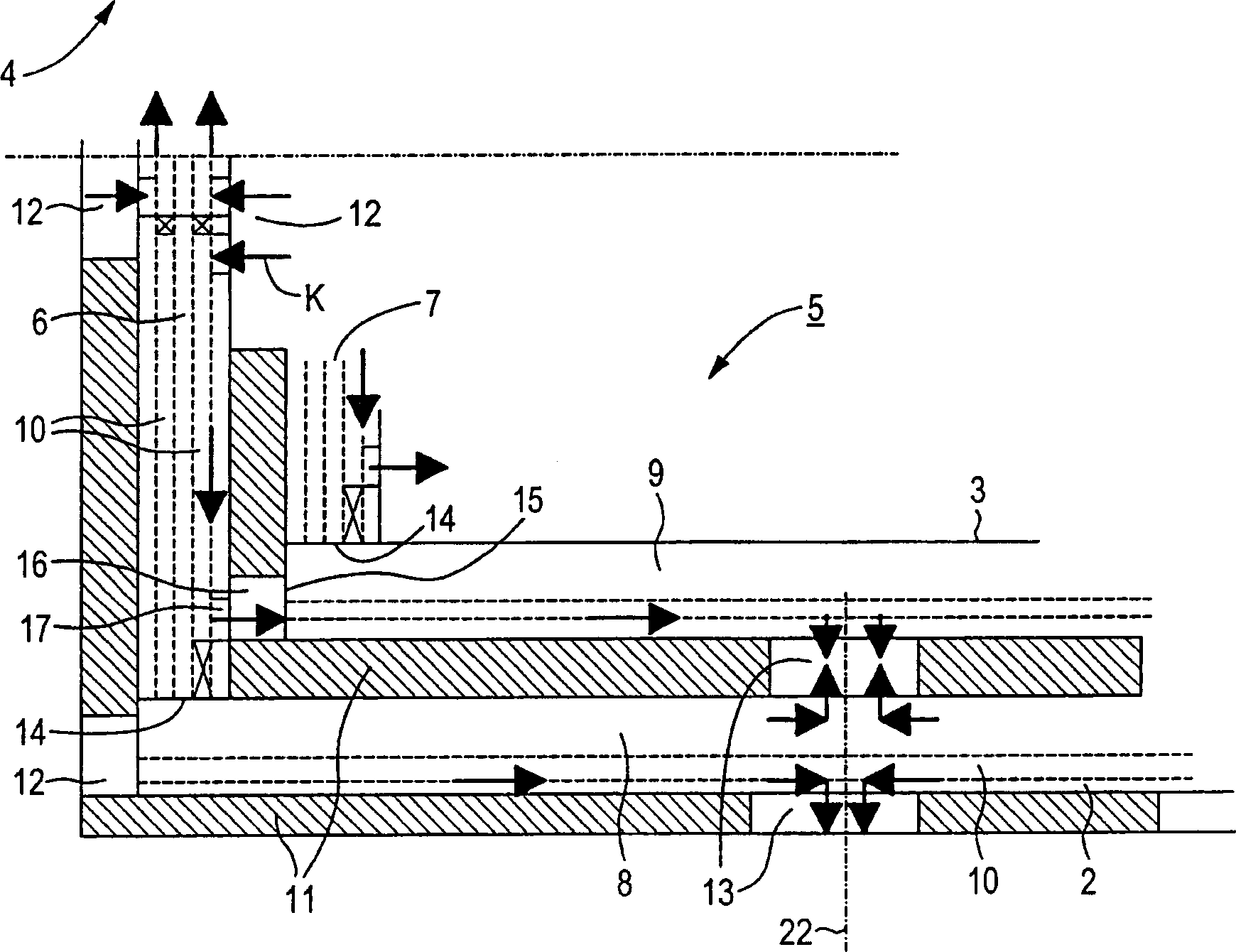

[0022] 1 shows a detail of a generator rotor 1 cooled by a cooling fluid K, with axially extending conductors 2, 3 in the region of the rotor body 4, and comprising longitudinal conductors 6, 7 in the region of the end windings 5, With transverse conductors 8 , 9 extending transversely thereto. Several conductors 2, 3 are stacked radially and form windings G and H, respectively. The windings G, H shown in detail by way of example are the outermost windings of the windings provided on the generator rotor 1, each winding being indicated by A to H from the inside to the outside, the length of each winding increasing from A to G.

[0023] figure 2 Shown in is a detail view of the end winding 5 with longitudinal conductors 6 , 7 and transverse conductors 8 , 9 . In this case, as a starting point in FIG. 1 , the longitudinal conductors 6 , 7 are arranged to the left of the transverse conductors 8 , 9 . Each conductor part 6 to 9 comprises in each case two cooling ducts 10 . Betw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com