Technological process of making flat spring steel for automobile

A process method and flat steel technology, applied in the direction of manufacturing converters, etc., can solve the problems of poor quality of spring flat steel, less than 90% blanking rate of ingots, poor blanking and sizing ratio, etc. The effect of high rate, omission of blanking process, and stable liquid level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

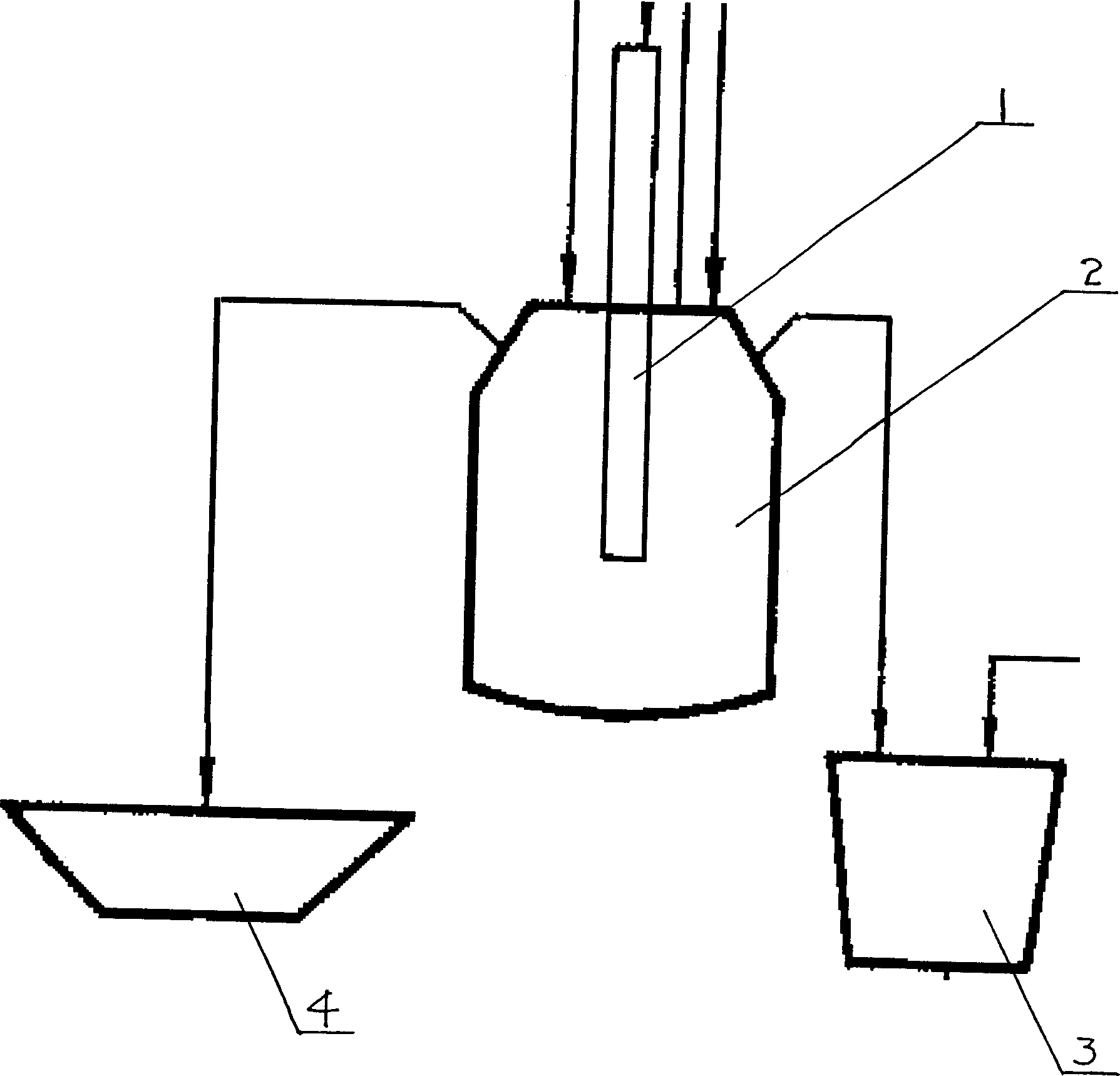

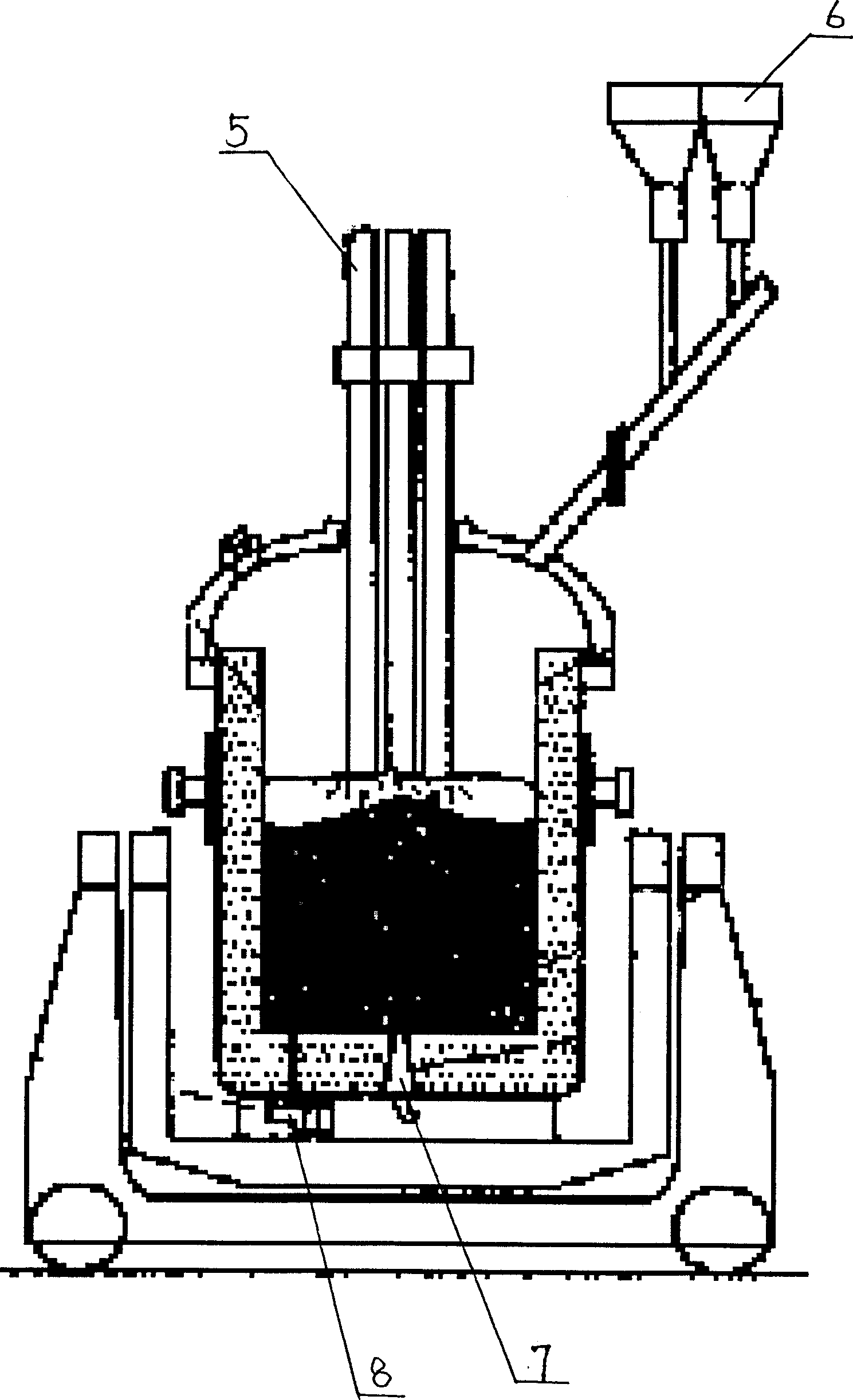

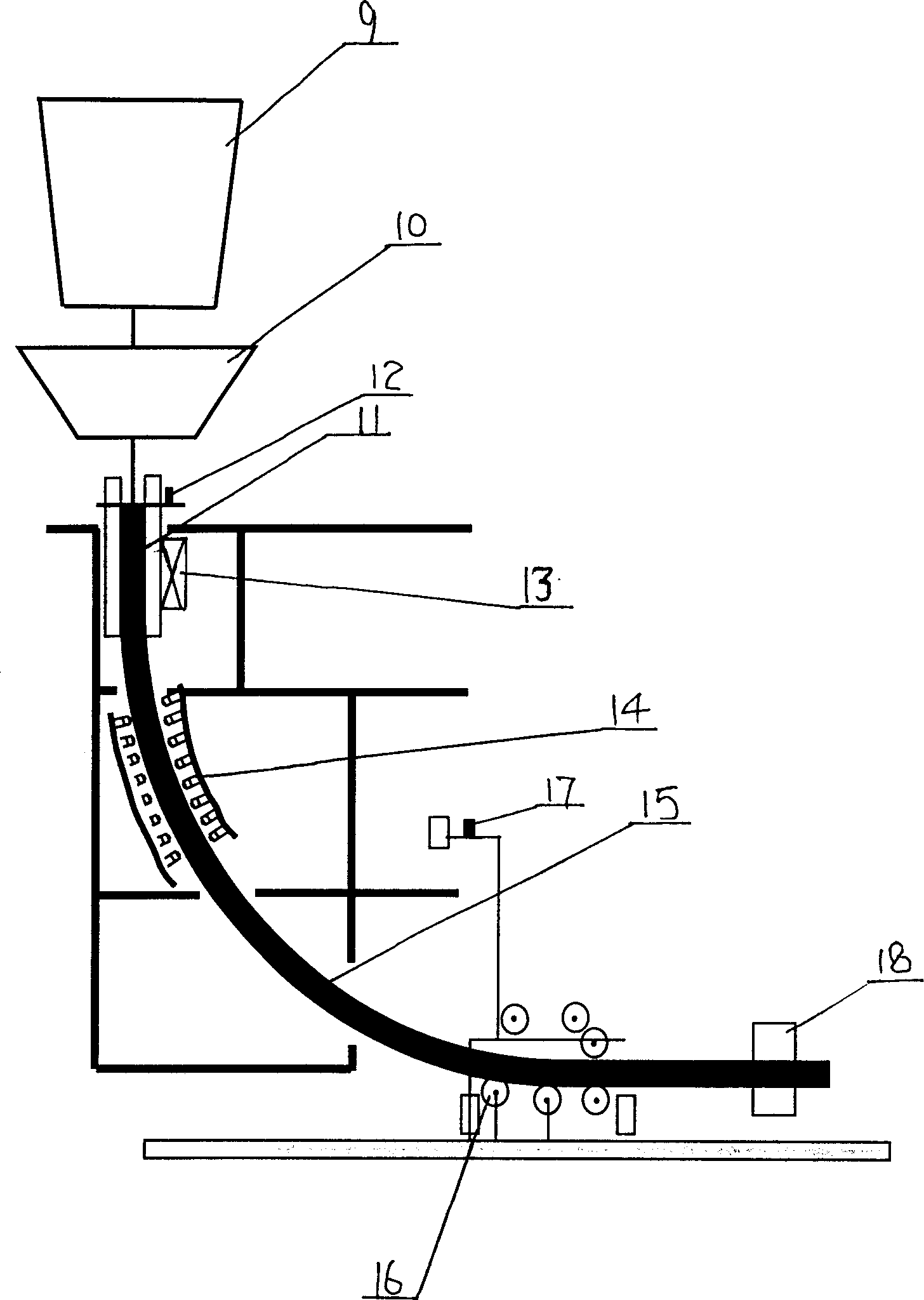

[0031] see figure 1 , figure 2 and image 3 , the grade of the smelted spring flat steel is 60Si 2 Mn is made by converter smelting process.

[0032] Described spring flat steel adopts converter smelting process to carry out as follows:

[0033] Charging process → blowing process → deoxidation and alloying → continuous casting billet → rolling into flat steel;

[0034] (1), the main raw material of described charging operation is molten iron 85-90%, steel scrap 10-15%;

[0035] (2), the described blowing process adopts the carbon drawing method, and the carbon drawing method is to calculate the required oxygen amount according to the initial carbon content of the charged molten iron and the target carbon content of the steel made, and then according to the required oxygen content Quantity control of oxygen supply time. At the same time, through reasonable control of process gun position, decarburization speed and slag oxidation, impurities such as P and S are quickly re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com