Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about How to "Controllable operation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

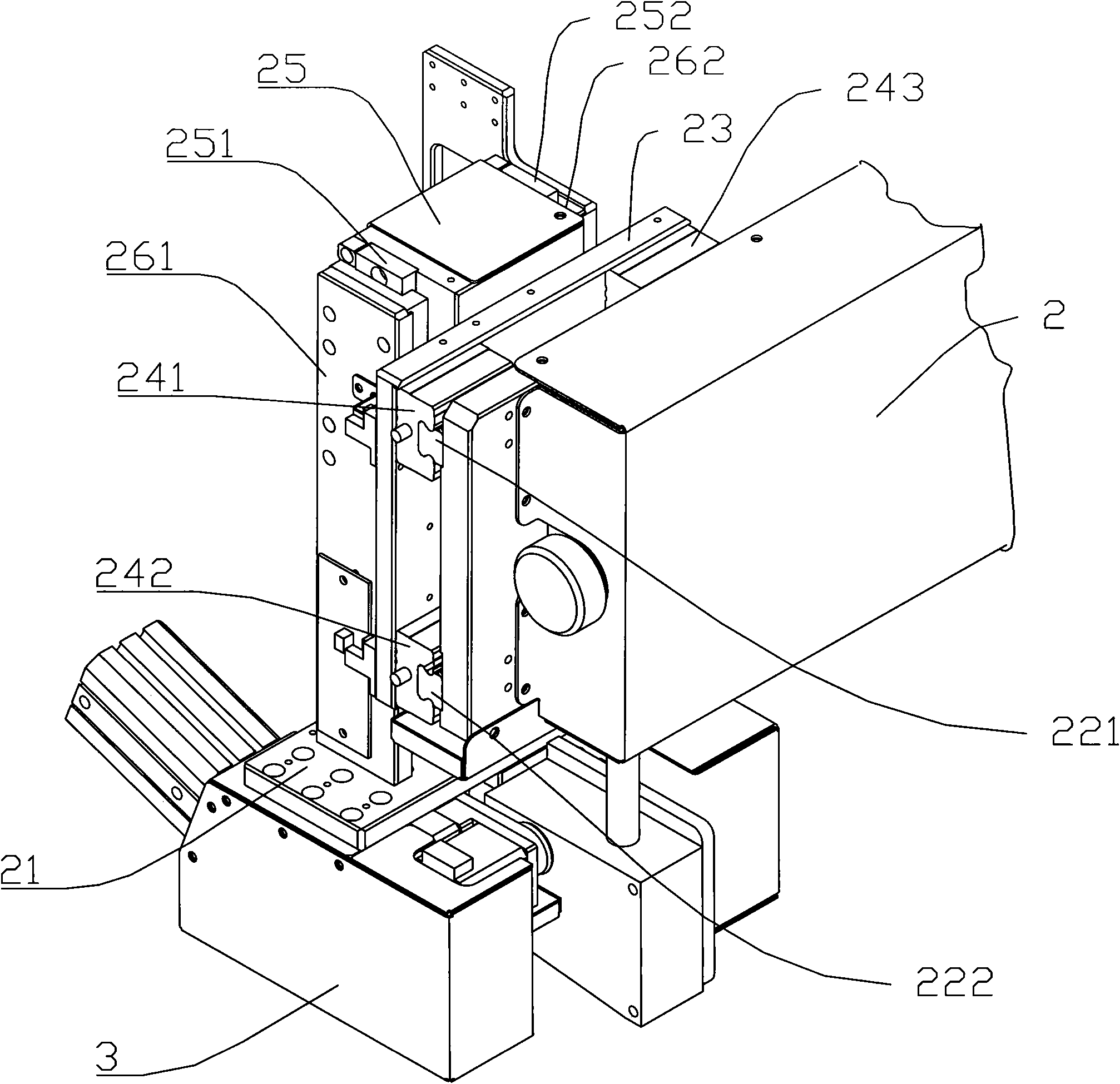

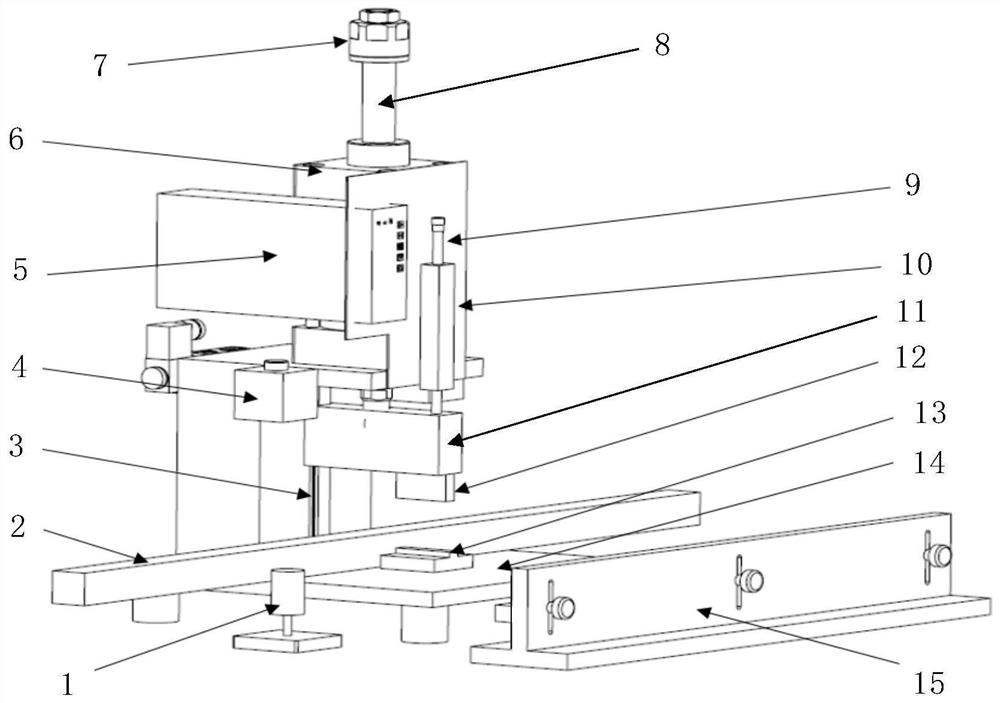

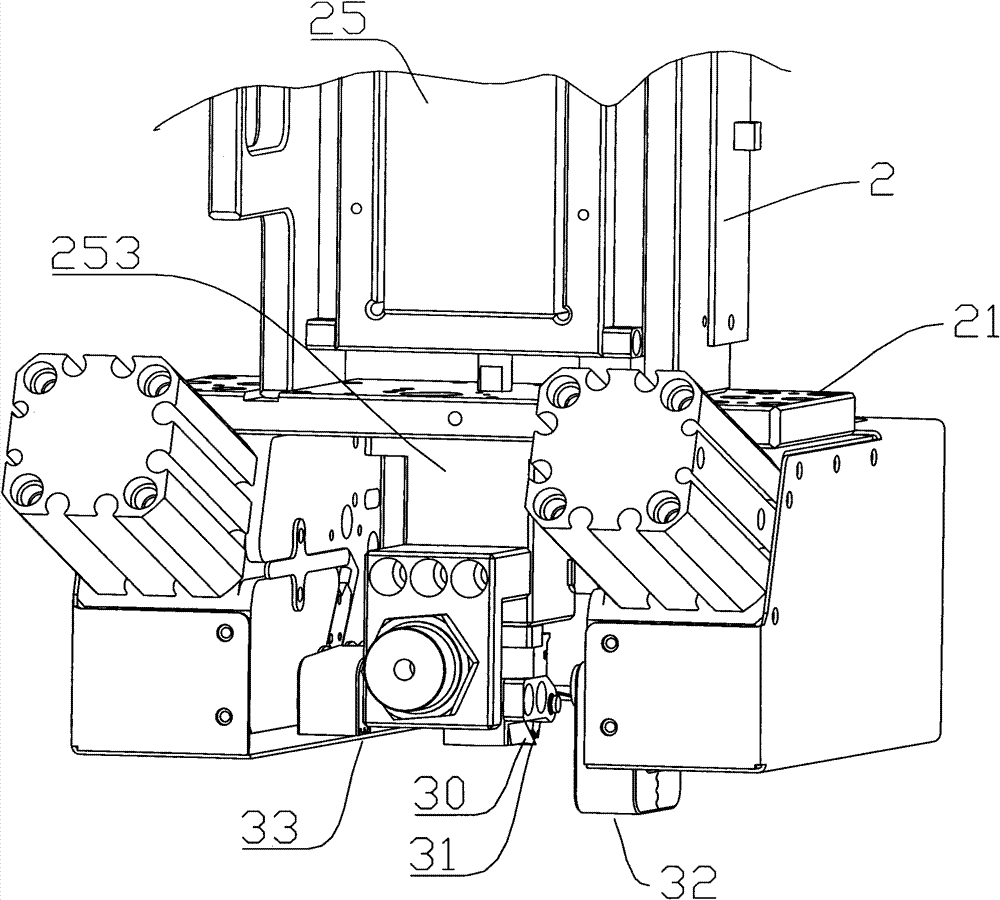

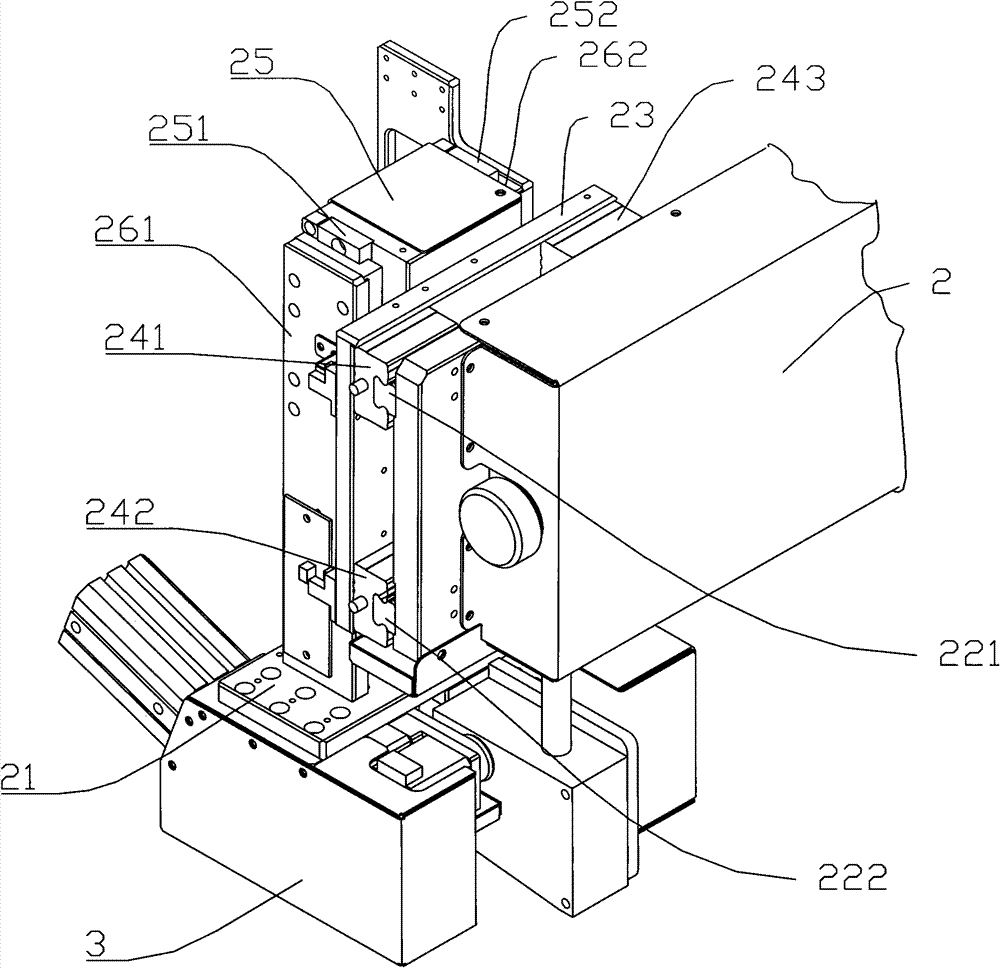

Dyestripping method, dyestripping device and dyestripping equipment

ActiveCN102064087AReduce usageEnsure safetySemiconductor/solid-state device manufacturingEngineering physicsMaterials science

The invention discloses a dyestripping method. The dyestripping method is characterized in that film edges are separated from a substrate attached with the film edges; and a first fixture is used to clamp the film edges, and the first fixture is moved to gradually separate the film from the substrate attached with the film until the film and the substrate attached with the film are completely separated. The invention provides a novel dyestripping method which is as follows: a mechanical device is used for dyestripping in no need of using consumption materials such as tapes or films and the like, thereby reducing the use of consumable articles and effectively reducing the cost; and a dyestripping device can be recycled, thereby saving the cost of dyestripping. In the dyestripping device, dyestripping operation is simple and practicable, the success rate is high, the film on a wafer can be safely torn, thus the phenomenon that the tape can not be adhered with the film so that the film can not be torn is not occur; in the process of dyestripping, the operation of parts in the dyestripping device is easy to control, the precision is easy to handle, and the wafer can not be touched by the dyestripping device, thereby effectively avoiding the wafer is damaged and ensuring the safety of the wafer; and the dyestripping process is safe and reliable.

Owner:上海技美科技股份有限公司

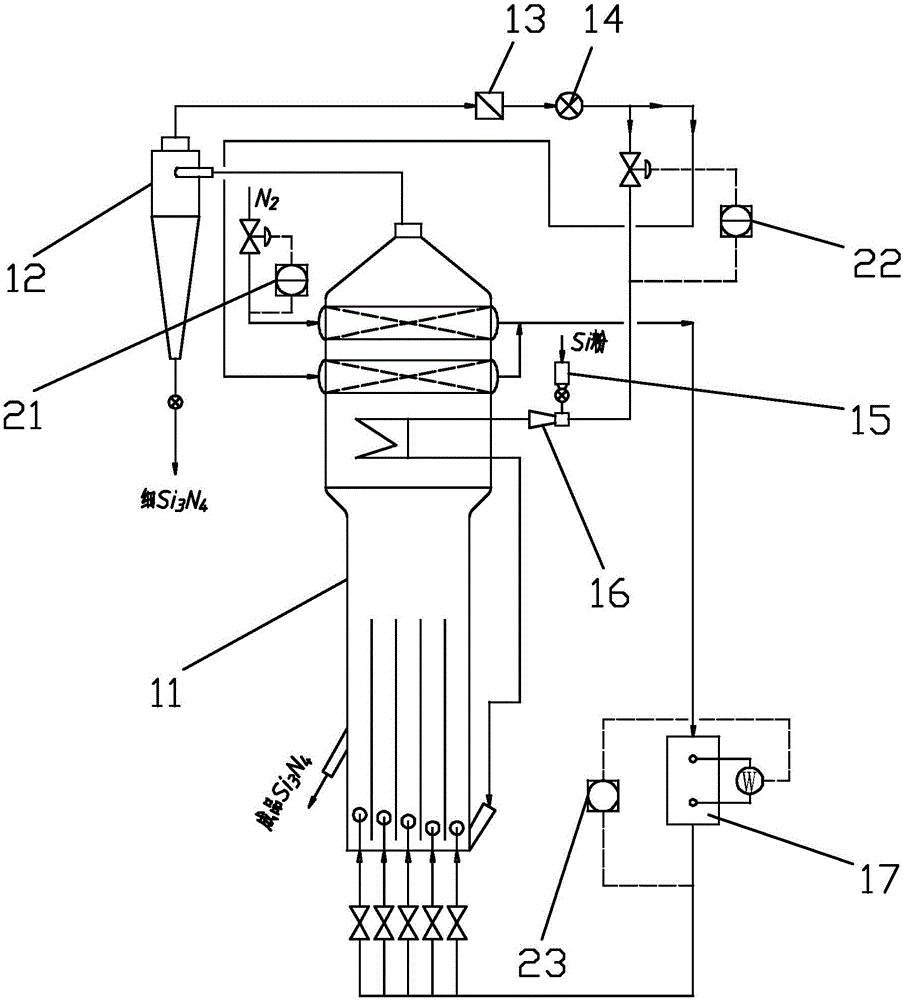

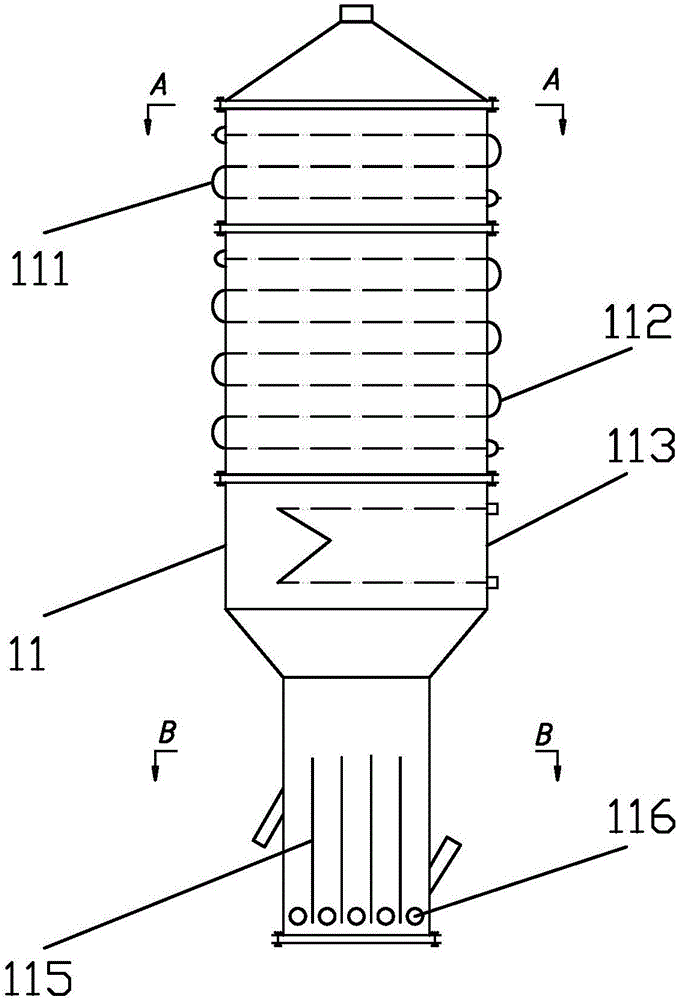

System for synthesizing silicon nitride by fluidized bed reactor

The invention relates to a system for synthesizing silicon nitride by a fluidized bed reactor. The system comprises the fluidized bed reactor, a nitrogen supply unit and a silicon powder supply unit, the fluidized bed reactor comprises a shell, a lower cavity of the shell is used for performing nitridation reaction for nitrogen and silicon powder under the fluidization condition, an air supply opening and a material supply opening are formed in the shell wall of the bottom of the shell, the nitrogen supply unit comprises a heating device for heating the nitrogen, an air outlet of the heating device is connected with the air supply opening, the silicon powder supply unit comprises a feeding barrel and a Venturi charging device, the feeding barrel is used for containing the silicon powder, a discharging port of the feeding barrel is connected with a powder inlet of the Venturi charging device, a discharging port of the Venturi charging device is connected with the material supply opening, and a discharging port in the top of the shell is connected with a cyclone separator for recovering synthesized silicon nitride. According to the system, the silicon powder and the nitrogen react under the fluidization condition, the synthesized Si3N4 cannot aggregate and cake, and continuous production of the Si3N4 can be achieved.

Owner:HEFEI UNIV

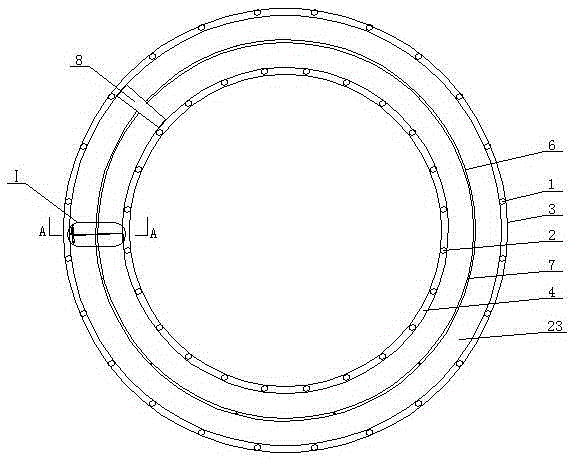

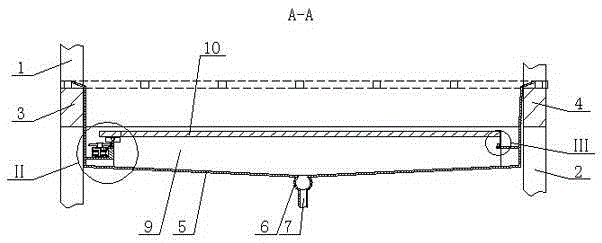

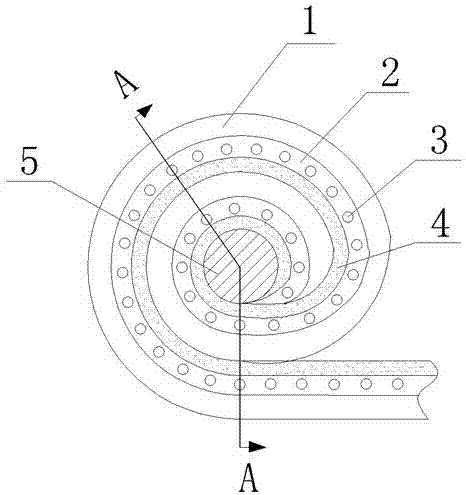

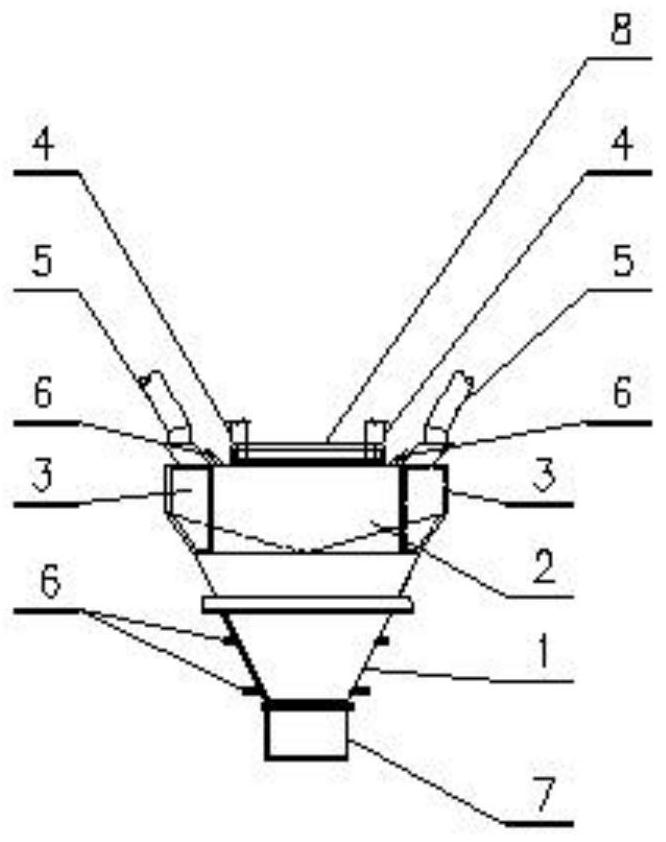

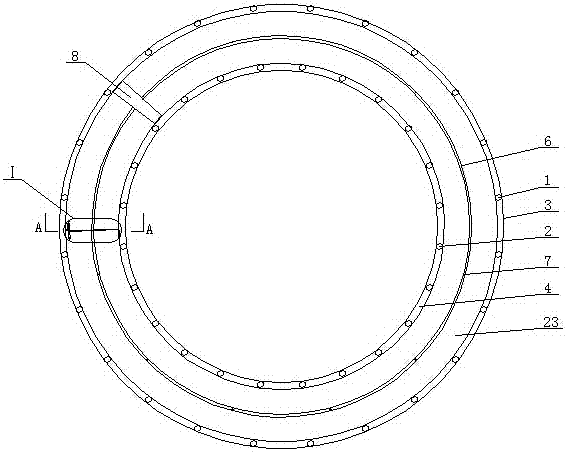

Livestock and poultry breeding solid-liquid separation excrement cleaning device

The invention provides a livestock and poultry breeding solid-liquid separation excrement cleaning device. The livestock and poultry breeding solid-liquid separation excrement cleaning device comprises an annular excrement collecting box; an excrement scraping plate is installed in the annular excrement collecting box; the excrement scraping plate is directly connected with a power driving mechanism or is connected with the power driving mechanism through a connecting piece; the excrement scraping plate is driven by the power driving mechanism to rotate around the annular excrement collecting box; the bottom plate of the annular excrement collecting box is an inclined plate; the lowest point of the inclined plate is located at the middle of the bottom plate; an urine discharging opening is formed at the middle of the bottom plate; and a solid excrement outlet is formed at the bottom plate of the annular excrement collecting box. According to the livestock and poultry breeding solid-liquid separation excrement cleaning device of the invention, after excrement falls into the annular excrement collecting box, solid-liquid separation of the excrement can be realized; solid excrement and liquid excrement are separately collected through different pipelines; the solid excrement is directly treated and is packaged; and the liquid can be adopted as secondary water after being purified; and therefore, excrement treatment procedures can be decreased, and treatment cost can be decreased, and underground space can be greatly saved. The livestock and poultry breeding solid-liquid separation excrement cleaning device of the invention is reasonable in integral design. The driving mechanism is arranged on the excrement scraping plate. The livestock and poultry breeding solid-liquid separation excrement cleaning device is especially suitable for annular comprehensive cultivation buildings and can realize fast and convenient solid-liquid separation treatment.

Owner:姜伟

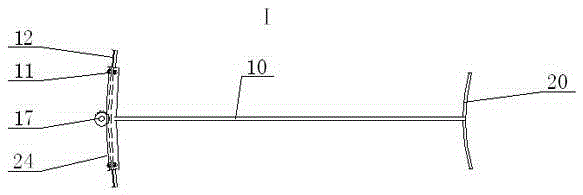

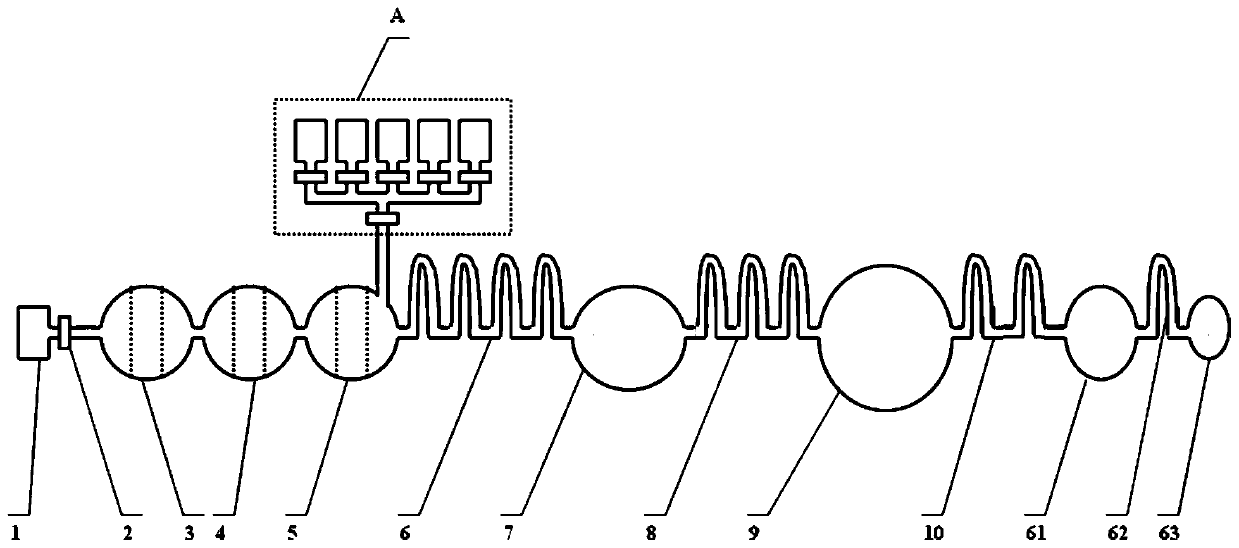

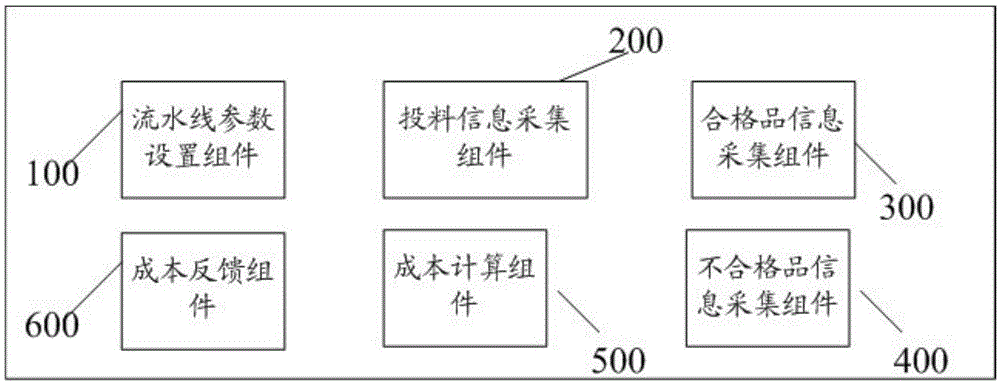

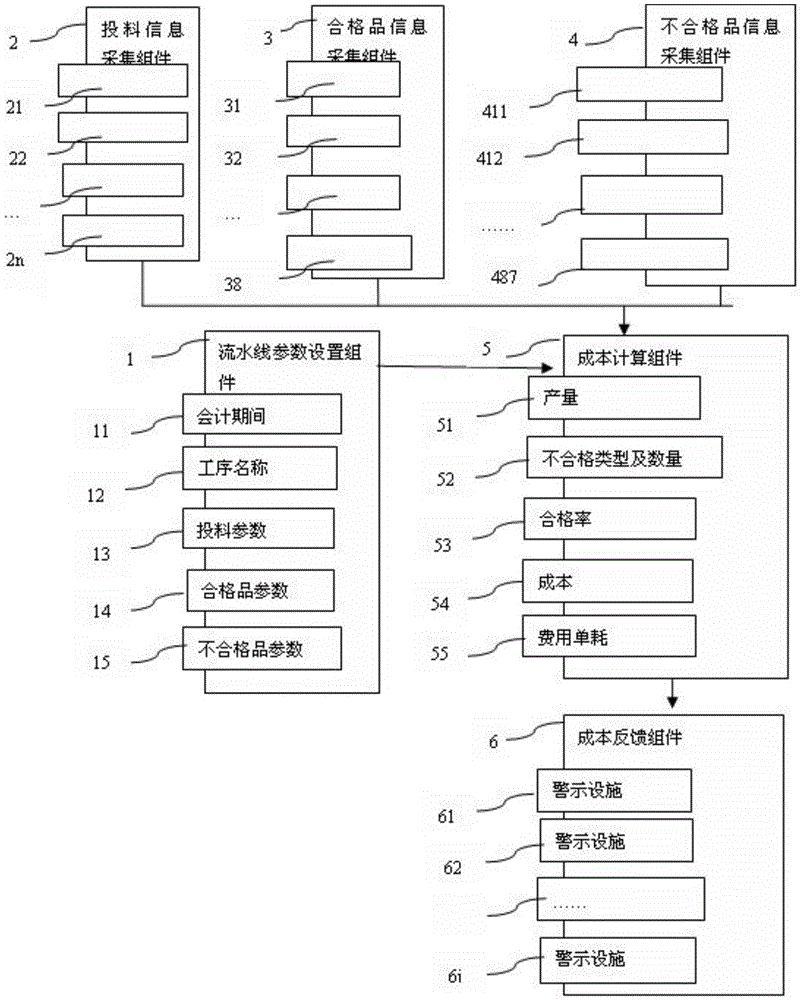

Assembly line production cost real-time monitoring device and assembly line production cost diagnostic method

InactiveCN103645720AReal-time discovery and resolution of production cost anomaliesControllable operationTotal factory controlProgramme total factory controlData displayAssembly line

The invention provides an assembly line production cost real-time monitoring device and an assembly line production cost diagnostic method. The assembly line production cost real-time monitoring device comprises an assembly line parameter setting assembly, a feeding information collecting assembly, a qualified product collecting assembly, a defective product information collecting assembly, a cost computing assembly and a cost feedback assembly. The assembly line production cost diagnostic method comprises that an assembly line parameter setting assembly is set according to operational parameters of a plurality of assembly lines in an industry; the feeding information collecting assembly, the qualified product collecting assembly and the defective product information collecting assembly collect related data and send to the cost computing assembly; the cost computing assembly is triggered to perform cost computing at a cost computing trigger time point and sends a cost computing result to the cost feedback assembly; the cost feedback assembly performs warning on caution items and data display according to the computing result of the cost computing assembly.

Owner:SHANGHAI DIANJI UNIV

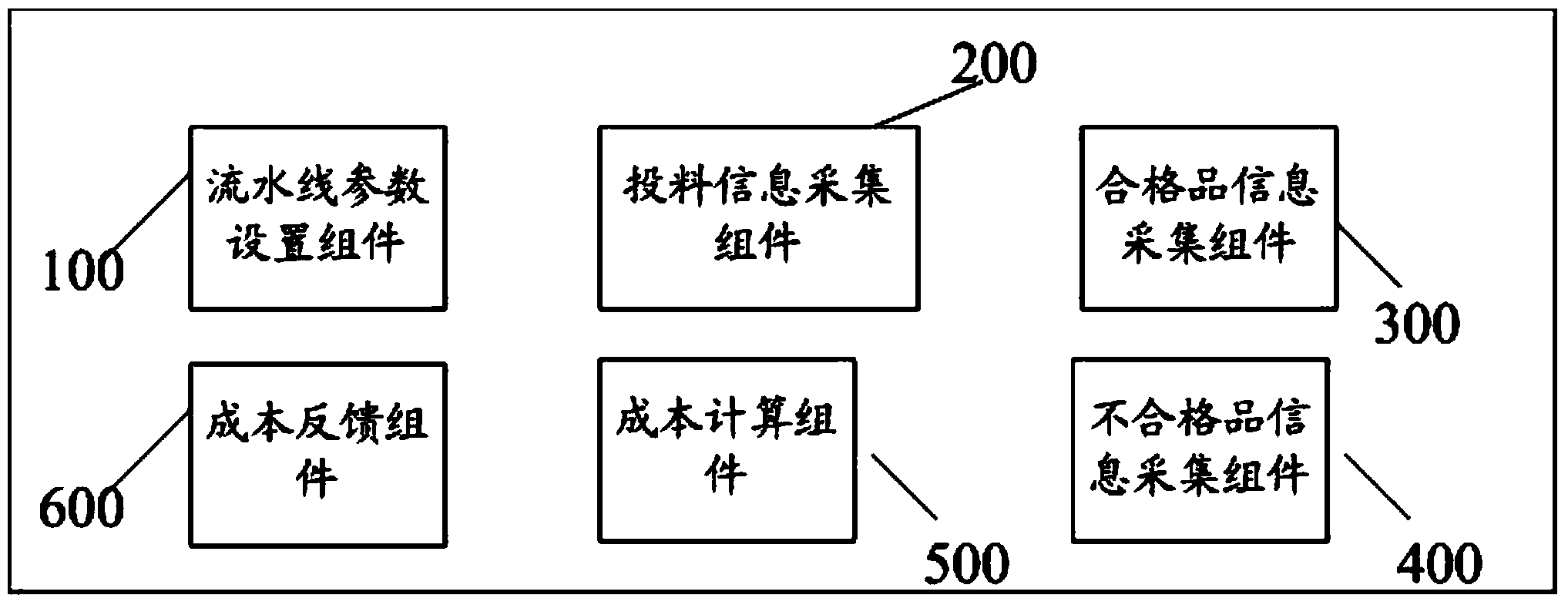

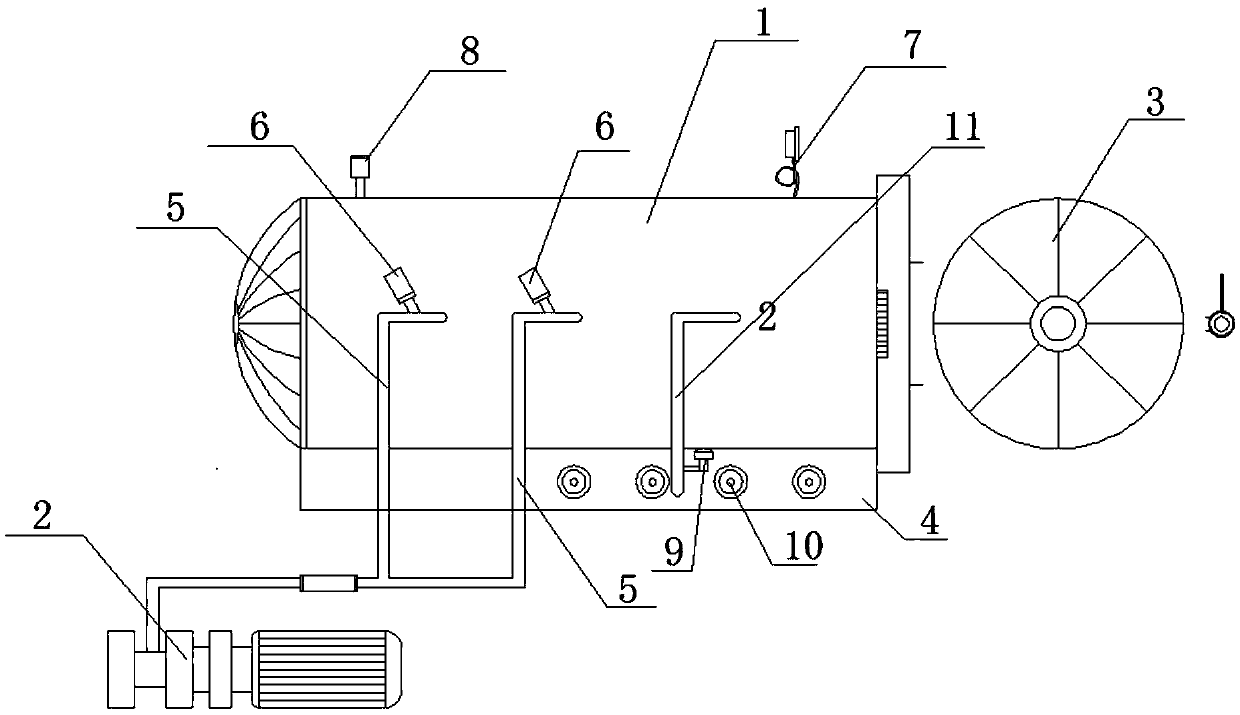

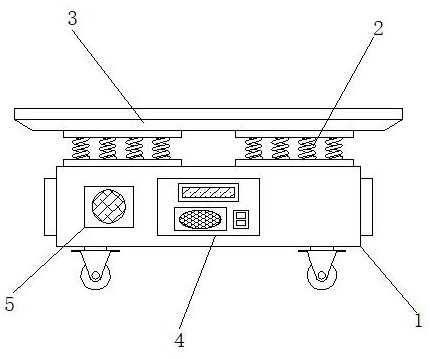

Vacuum type yarn steaming forming equipment and application method thereof

ActiveCN104278455ALow boiling pointEvenly distributed moistureTextile treatment machine arrangementsLiquid/gas/vapor yarns/filaments treatmentYarnThermal insulation

The invention discloses vacuum type yarn steaming forming equipment which mainly comprises a box, a water ring vacuum pump, a box door and a water tank. A water level meter and a heating pipe are arranged in the water tank. A water inlet pipe and a water outlet pipe are arranged on the lateral wall of the box. A suction pipe is arranged in the box. A filter cover is disposed on the suction pipe. A pressure gauge and a surface temperature meter are further disposed on the surface of the top end of the box. The invention further provides an application method of the vacuum type yarn steaming forming equipment. The method includes: sequentially performing preheating, vacuumizing, heating, standing thermal insulation, secondary vacuumizing, heating and thermal insulation on the box. The vacuum type yarn steaming forming equipment has the advantages that the equipment is simple in structure, low in manufacturing cost, low in energy consumption, high in controllability and good in thermal insulation performance, water inlet amount, humidity and temperature change can be well adjusted, mildew and off-shade of the yarn processed by the equipment are avoided, yarn damage is avoided, condensing spots are avoided, processing time is short, yarn weight loss is compensated, and yarn quality is improved.

Owner:JIANGSU JINDA TEXTILE IND

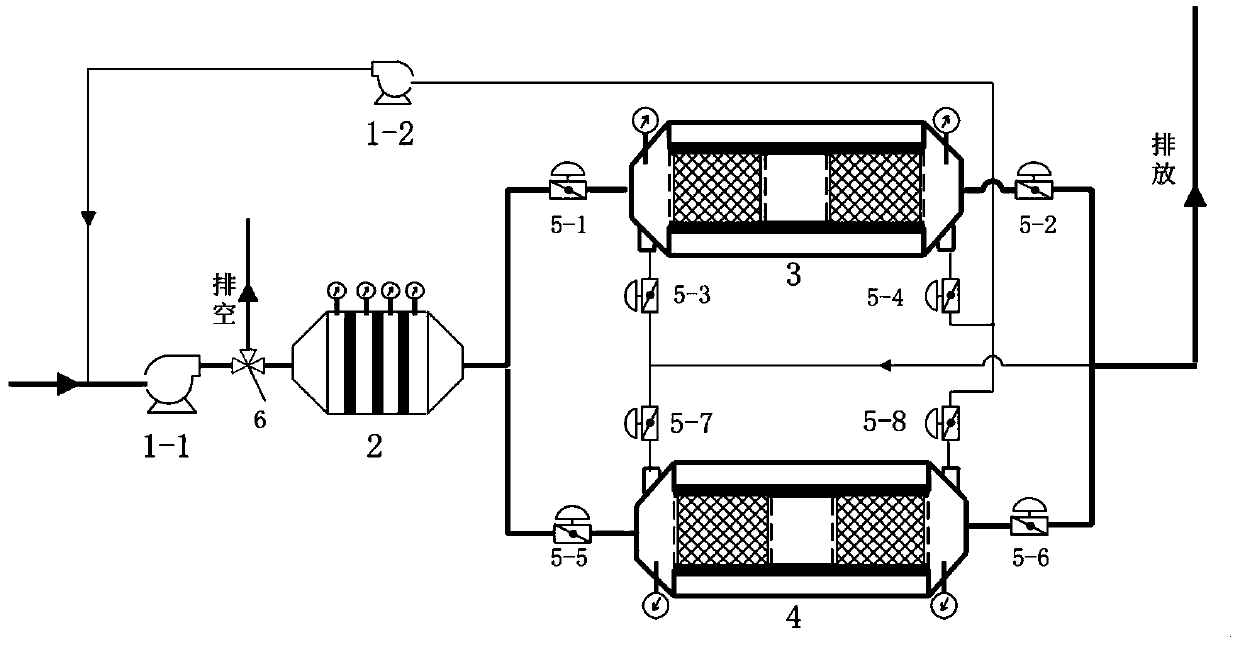

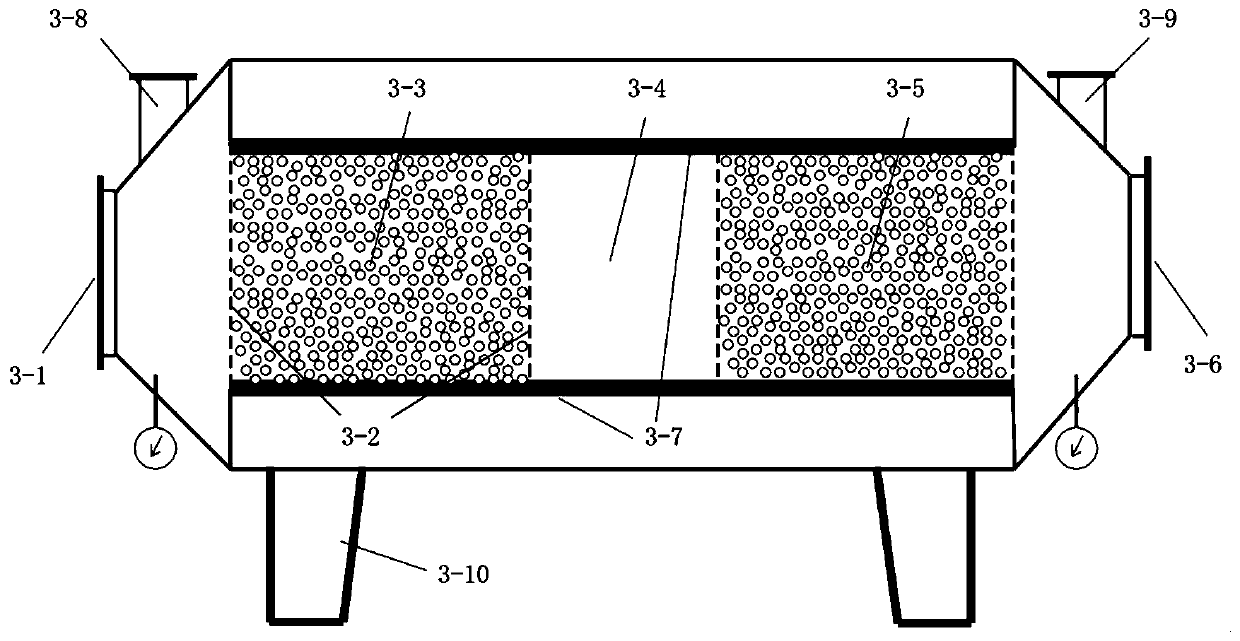

VOCs adsorption-plasma catalytic regeneration device and treatment system and process

ActiveCN111467885AImprove adsorption capacityFast adsorption rateGas treatmentDispersed particle filtrationMolecular sievePtru catalyst

Aiming at the defects of high equipment investment, high operation cost, large occupied area and the like in an ultralow-concentration and large-air-volume organic waste gas mainstream treatment process, the invention discloses a VOCs adsorption-plasma catalytic regeneration device and a treatment system and process. The adsorption-plasma catalytic regeneration device comprises a gas tank, a plasma discharge unit and an adsorption / catalyst unit. The plasma discharge unit comprises a plasma pulse power supply and a flat discharge structure. The adsorption / catalyst unit is arranged between the discharge electrodes and adopts a three-section design, namely a high-efficiency adsorption catalysis section, a buffer section and a medium-efficiency adsorption catalysis section. The high-efficiencyadsorption catalysis section is filled with a noble metal modified molecular sieve; the buffer section is hollow; and the medium-efficiency adsorption catalytic section is filled with a common metal-loaded molecular sieve. The whole device realizes the integration of adsorption, desorption and treatment units, and simplifies the treatment system. The whole process is controlled by a PLC, 24-hourcontinuous and stable operation is achieved, and VOCs are efficiently removed.

Owner:ZHEJIANG UNIV OF TECH

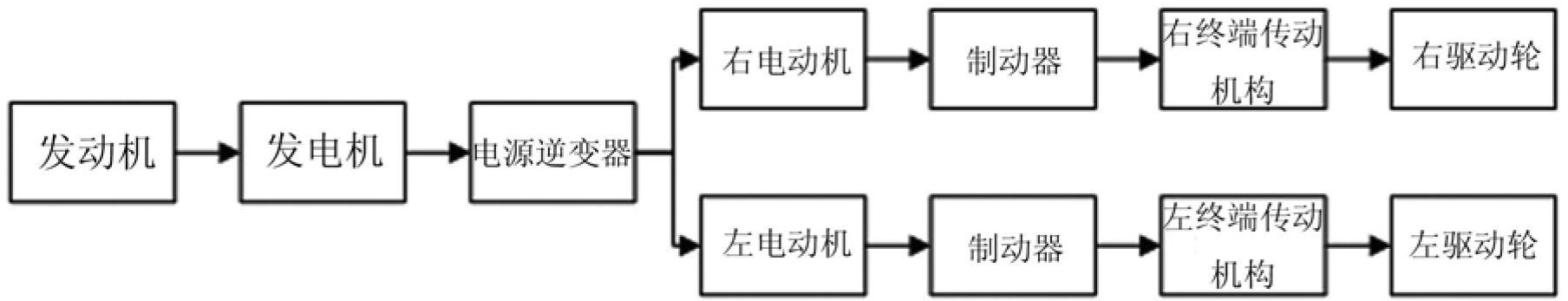

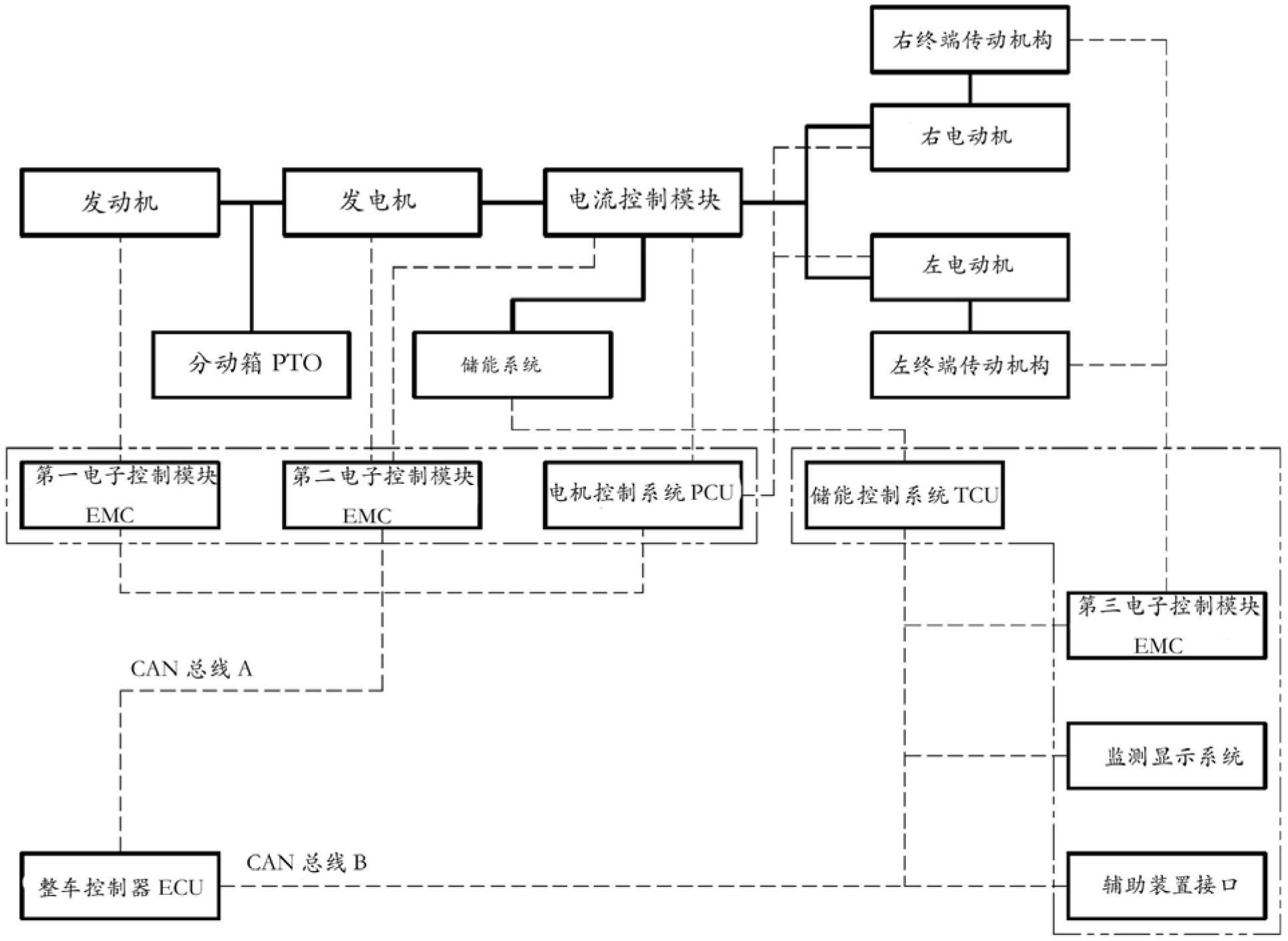

Hybrid power driving device of bulldozer and bulldozer

InactiveCN102642461AReduce weightQuick responseHybrid vehiclesGas pressure propulsion mountingDynamoSprocket

The invention discloses a hybrid power driving device of a bulldozer, which comprises an engine, a generator, a current control module and an electrical motor, wherein an output shaft of the engine is connected with a power distribution device, an output shaft of the power distribution device is connected with the generator, alternating current generated by the generator is converted by the current control module and then drives the electrical motor, and the electrical motor drives a drive sprocket and an apron wheel. The driving device is steady and reliable in transmission and low in noise and oil consumption, has high transmission efficiency, can respond to changes of loads quickly, and can achieve stepless speed change. The invention also discloses the bulldozer with the driving device.

Owner:SHANTUI CONSTR MASCH CO LTD

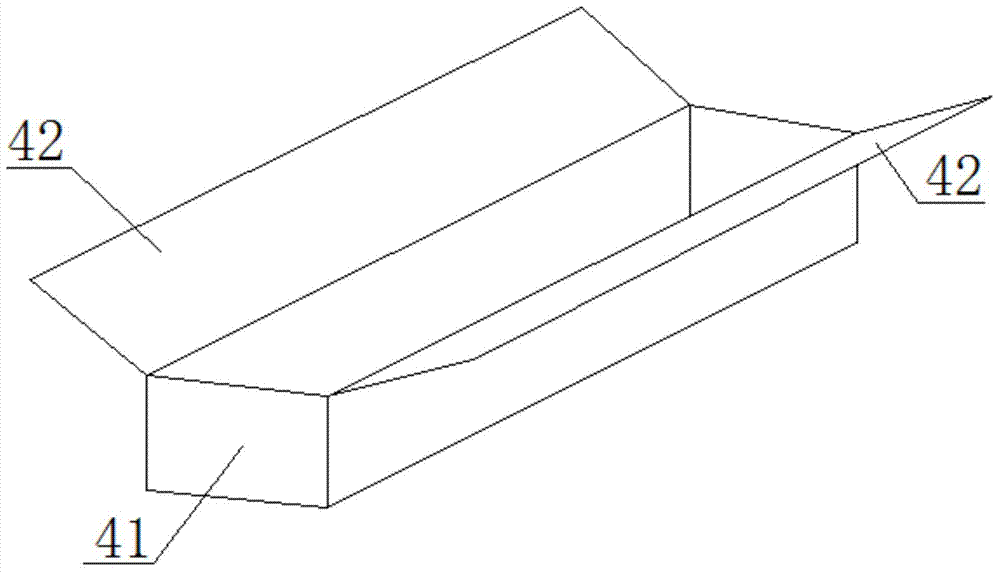

Plasma combustion-supporting Swiss roll combustor

InactiveCN105180183AReduce pollutionSolving the problem of smooth ignition and maintaining combustionIncinerator apparatusCombustion chamberPorous medium

The invention provides a plasma combustion-supporting Swiss roll combustor and belongs to the technical field of low-heating-value gas utilization. The combustor comprises a combustion chamber and a spiral plate type channel. The combustor specifically comprises a combustor shell, a flow guide plate, a porous medium, a gas inflow channel, a gas outflow channel, a discharge device, an ozone addition opening, a thermometer hole, an ignition hole, an observation hole, a metal high-voltage electrode plate, an electrode leading-out wire and an exhaust chimney. The combustor is round or square. The upper end and the lower end of the combustor are sealed through sealing plates. The gas inflow channel and the gas outflow channel are formed in the two ends of the spiral plate type channel. The porous medium is located in the center of the combustion chamber. The inner wall of the combustion chamber is coated with a heat-resisting material. The combustion chamber is wrapped by a heat insulating material. The discharge device and the flow guide plate are located in an inlet of the combustion chamber. The ozone addition opening is formed in the outermost ring of the spiral plate type channel. According to the combustor, the plasma discharge device or an ozone generator and the porous medium material are combined, and the purposes of reducing energy consumption, eliminating poison and the like can be achieved.

Owner:UNIV OF SCI & TECH BEIJING

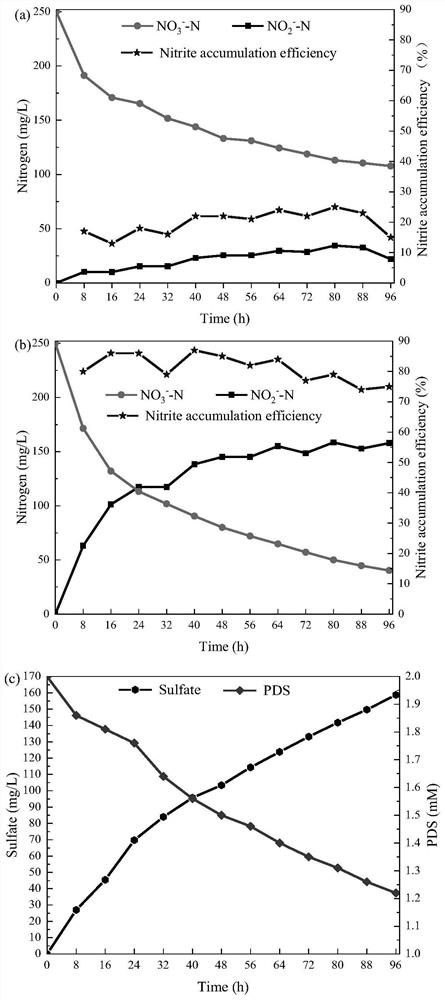

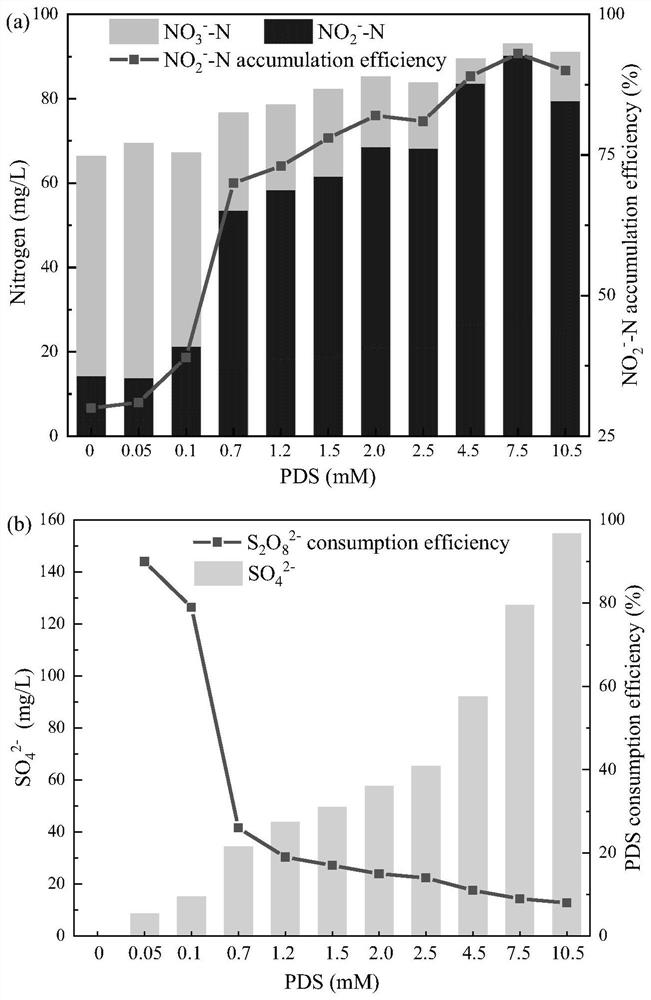

Method for improving nitrite accumulation in short-cut denitrification process

ActiveCN113511731APromote reductionInhibition decreasedWater treatment parameter controlWater treatment compoundsActivated sludgeNitrate salts

The invention provides a method for improving nitrite accumulation in a short-cut denitrification process, and belongs to the technical field of wastewater treatment. The method comprises the following steps: S1, inoculating denitrification activated sludge into an anaerobic reactor, and adding 0.05-15 mmol of an oxidizing agent into each gram of denitrification activated sludge; and S2, feeding water into the anaerobic reactor to form a reaction mixed solution, and starting the anaerobic reactor to carry out denitrification reaction. According to the invention, by adding the specific oxidant, the reduction of nitrate is selectively promoted, and the further reduction of nitrite can be inhibited, so that the accumulation of nitrite is accelerated by increasing the generation amount of nitrite and reducing the consumption amount of nitrite, and the short-time, efficient and stable accumulation of nitrite is realized.

Owner:DONGGUAN UNIV OF TECH

Garbage container

InactiveCN108750454AEasy to go outEasy to cleanWaste collection and transferRefuse receptaclesGear wheelRotating disc

The invention discloses a garbage container which comprises a bracket, wherein a shaking device is arranged on one side of the bracket; one end of the shaking device sequentially penetrates through the bracket and a first bearing, and is fixedly connected with the surface of a first gear on the side, far away from the shaking device, of the bracket; second gears are meshed with the first gear; a first rotating shaft is fixedly connected onto one side surface of each second gear; and a second bearing is movably connected with the end, far away from the corresponding second gear, of each first rotating shaft and connected to the surface of the bracket in a clamping manner. The garbage container has the beneficial effects that through the arrangement of the shaking device, the first gear andthe second gears, garbage can be more conveniently taken out; through the arrangement of a control device, the running of a motor and that of an electric telescopic rod can be more easily controlled;and through the arrangement of the motor and a rotating disc, garbage remaining on the inner wall of the garbage container can be further cleared, the previous space of the garbage container can be restored, and the garbage storage capacity can be improved.

Owner:施英

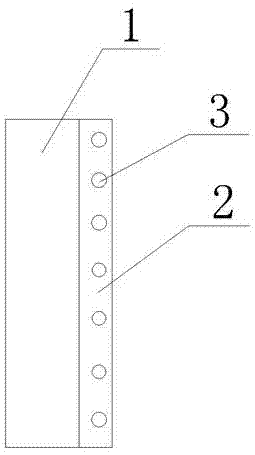

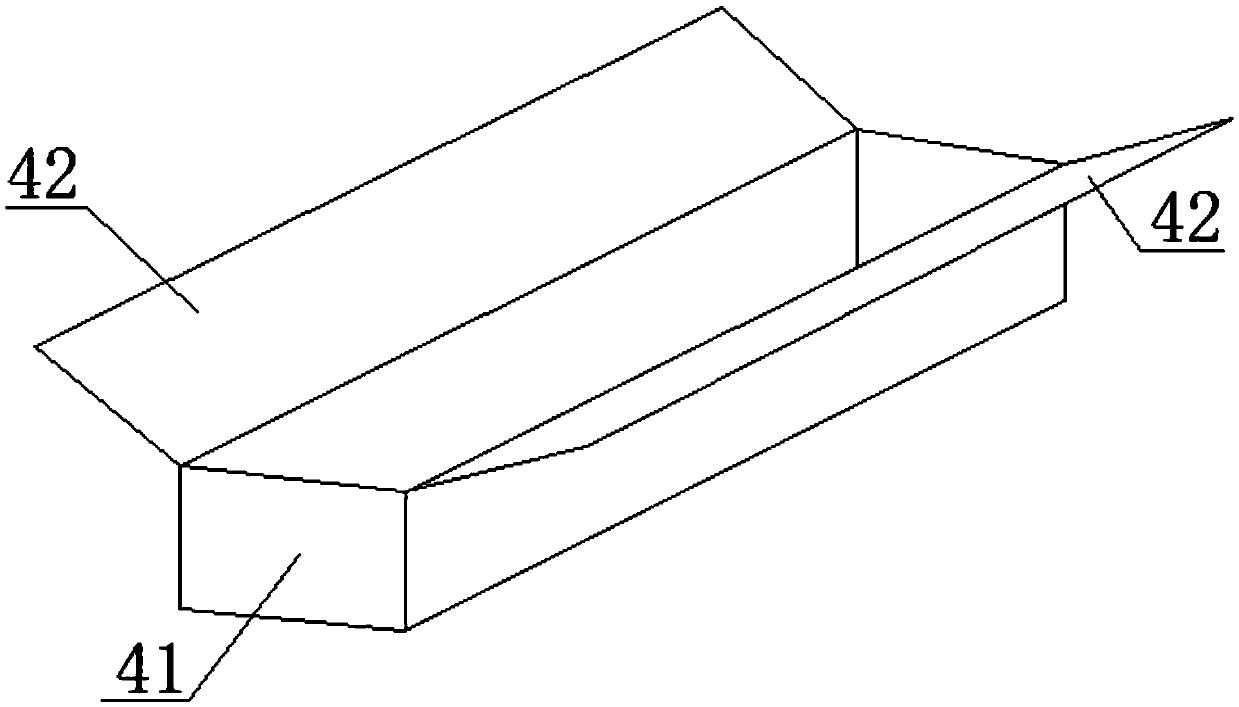

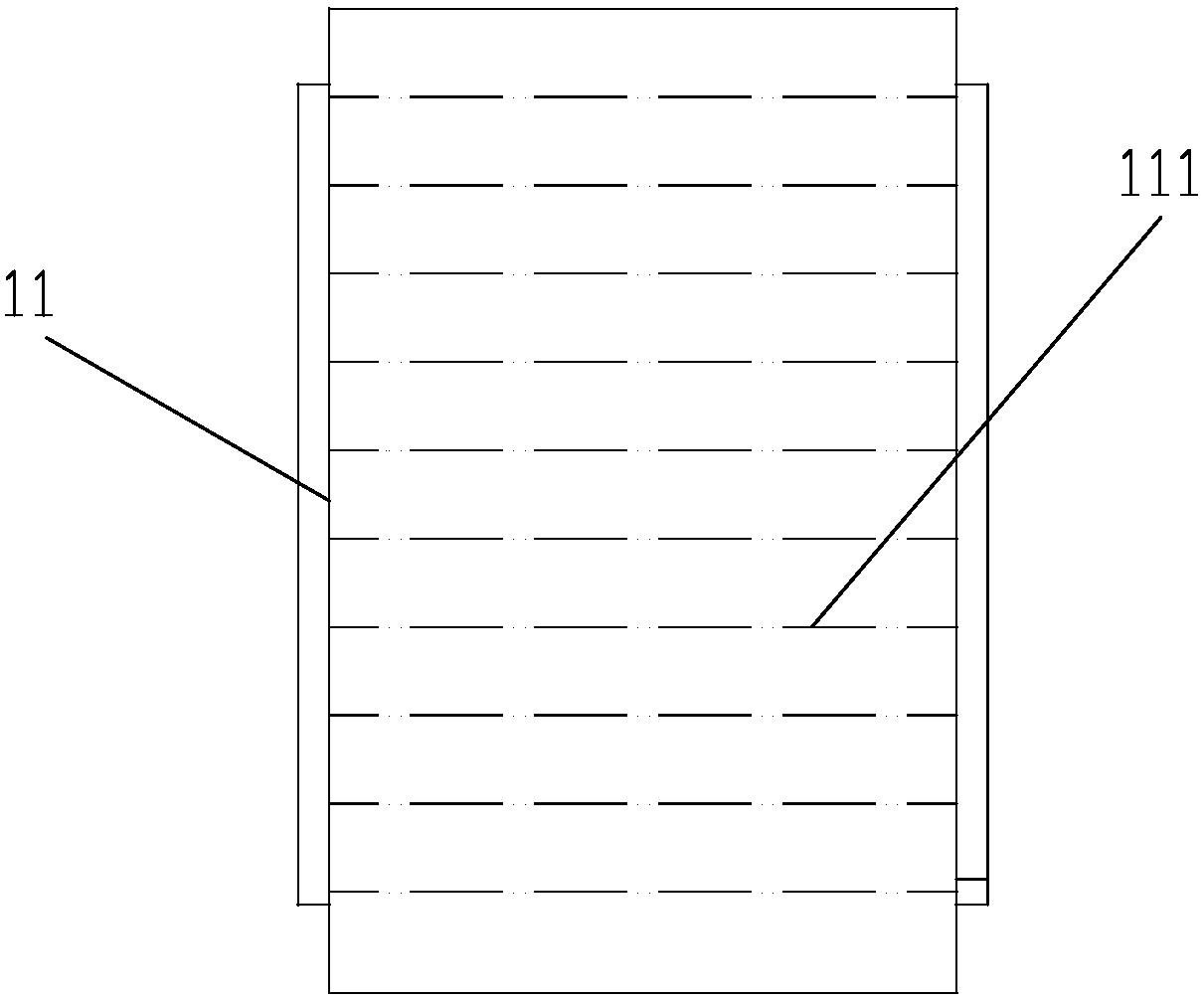

Device and method for curing and flattening glue-free soft plate material

The invention discloses and provides a device for curing and flattening a glue-free soft plate material, which has the advantages of simple structure, reduction in production cost and superior flatness of a manufactured product, and provides a method for curing and flattening a glue-free soft plate material by applying the device. The device comprises a rewinding machine and a metal heat-conducting plate (1), wherein steel belts (2) are arranged at the two ends of the lower surface of the metal heat-conducting plate (1), and are provided with fine holes (3); in a production process, a soft plate material (4) is attached to the upper surface of the metal heat-conducting plate (1); the metal heat-conducting plate (1) and the soft plate material (4) are tightly coiled on a steel pipe (5) of the rewinding machine for curing; and in a curing process, the soft plate material (4) is always attached to the metal heat-conducting plate (1), and is limited from moving through the metal heat-conducting plate (1), so that flatness is achieved. The device is applied in the field of material flattening.

Owner:江西优钛新材料科技有限公司

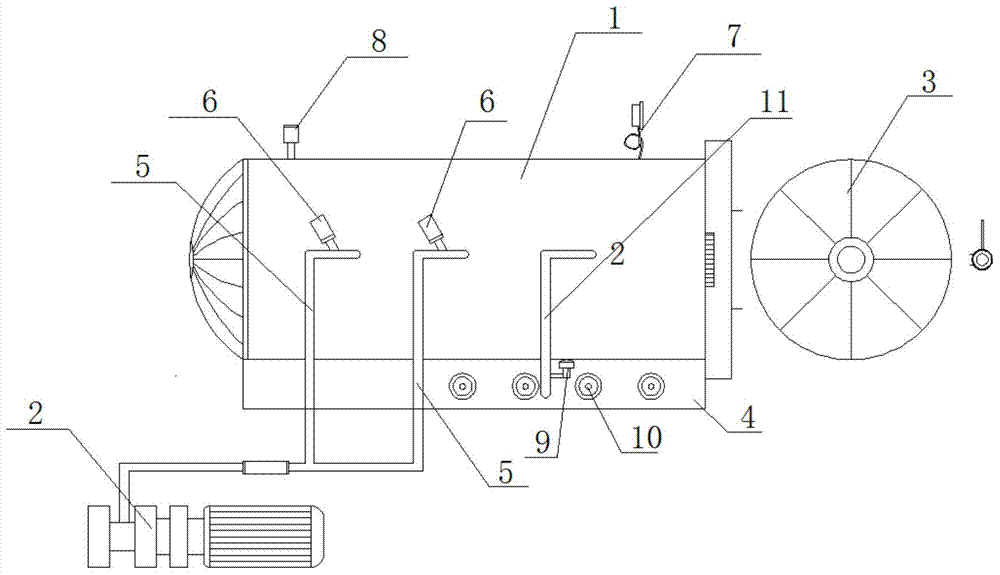

Integrated equipment for concentrating and conditioning river and lake bottom mud

PendingCN112608001ALow costControllable operationSludge treatment by de-watering/drying/thickeningElectric machinerySewage

The invention discloses integrated equipment for concentrating and conditioning river and lake bottom mud, and relates to the technical field of sewage and sludge treatment. The integrated equipment comprises a steel structure pool body and a mixing and conditioning mechanism arranged in the steel structure pool body, the mixing and conditioning mechanism comprises a guide cylinder and a stirring assembly, and the guide cylinder is installed above the pool bottom of the steel structure pool body through a fixing piece; the stirring assembly comprises a stirring motor and a stirring impeller arranged on an output shaft of the stirring motor, the stirring motor is fixed to the steel structure pool body above the guide cylinder, and the stirring impeller is located in the guide cylinder; and the steel structure pool body is connected with a sludge outlet pipe, a sludge inlet pipe, a water outlet pipe and a dosing pipe, the sludge outlet pipe communicates with the bottom or the lower part of the steel structure pool body, the water outlet pipe communicates with the upper part or the top of the steel structure pool body above the guide cylinder, and one end of the dosing pipe communicates with the inner cavity of the guide cylinder. According to the invention, the concentration efficiency is high, the investment is not high, the occupied area of equipment is small, and the concentration and conditioning can be carried out together under the condition of controlling the cost.

Owner:POWERCHINA CHENGDU ENG

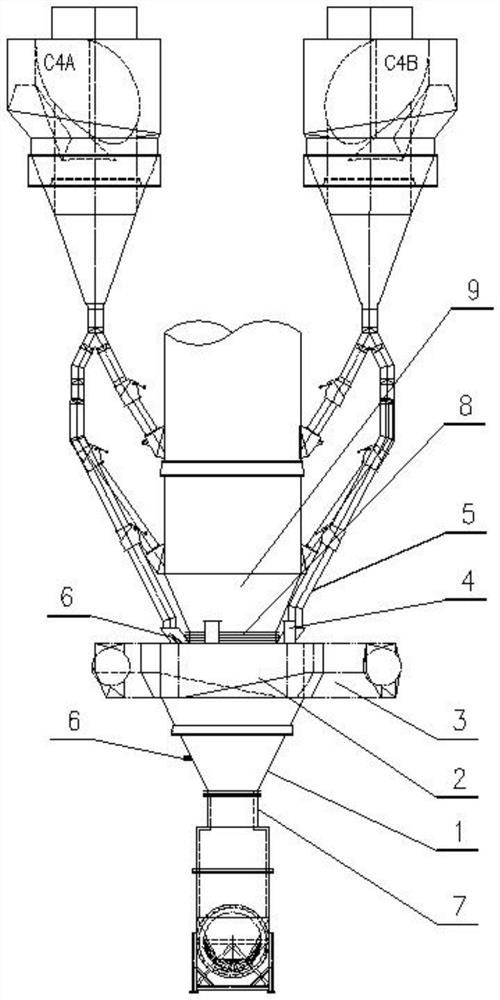

A cross-flow coal blending pyrolysis method and pyrolysis device

ActiveCN112625720BSolve the problem of pyrolysisImprove qualityDirect heating destructive distillationLiquid hydrocarbon mixture productionThermodynamicsProcess engineering

The invention discloses a cross-flow mixed coal pyrolysis method and a pyrolysis device, adopting a longitudinal multi-layer gas distribution and multi-layer gas collection structure, combining gas-solid two-phase cross-flow and counter-flow, and realizing uniform heat exchange and primary dust reduction at the same time , for the dusty and oily high-temperature gas produced by pyrolysis, make it contact with the medium-temperature material in the dry distillation transition section for heat exchange to achieve the purpose of secondary dust removal, and condense a part of the heavy tar, which is brought into the dry distillation section by dry coal for secondary Secondary pyrolysis, the gas precipitated by the pyrolysis device has the characteristics of moderate temperature, low dust content and high light oil content, which significantly reduces the workload and equipment investment of the gas purification system, and improves the quality of gas and tar products.

Owner:BEIJING GUODIAN FUTONG SCI & TECH DEV

Application method of vacuum steaming and setting equipment

ActiveCN104278455BEvenly distributed moisturePlay a role in heat preservationTextile treatment machine arrangementsLiquid/gas/vapor yarns/filaments treatmentYarnThermal insulation

The invention discloses vacuum type yarn steaming forming equipment which mainly comprises a box, a water ring vacuum pump, a box door and a water tank. A water level meter and a heating pipe are arranged in the water tank. A water inlet pipe and a water outlet pipe are arranged on the lateral wall of the box. A suction pipe is arranged in the box. A filter cover is disposed on the suction pipe. A pressure gauge and a surface temperature meter are further disposed on the surface of the top end of the box. The invention further provides an application method of the vacuum type yarn steaming forming equipment. The method includes: sequentially performing preheating, vacuumizing, heating, standing thermal insulation, secondary vacuumizing, heating and thermal insulation on the box. The vacuum type yarn steaming forming equipment has the advantages that the equipment is simple in structure, low in manufacturing cost, low in energy consumption, high in controllability and good in thermal insulation performance, water inlet amount, humidity and temperature change can be well adjusted, mildew and off-shade of the yarn processed by the equipment are avoided, yarn damage is avoided, condensing spots are avoided, processing time is short, yarn weight loss is compensated, and yarn quality is improved.

Owner:JIANGSU JINDA TEXTILE IND

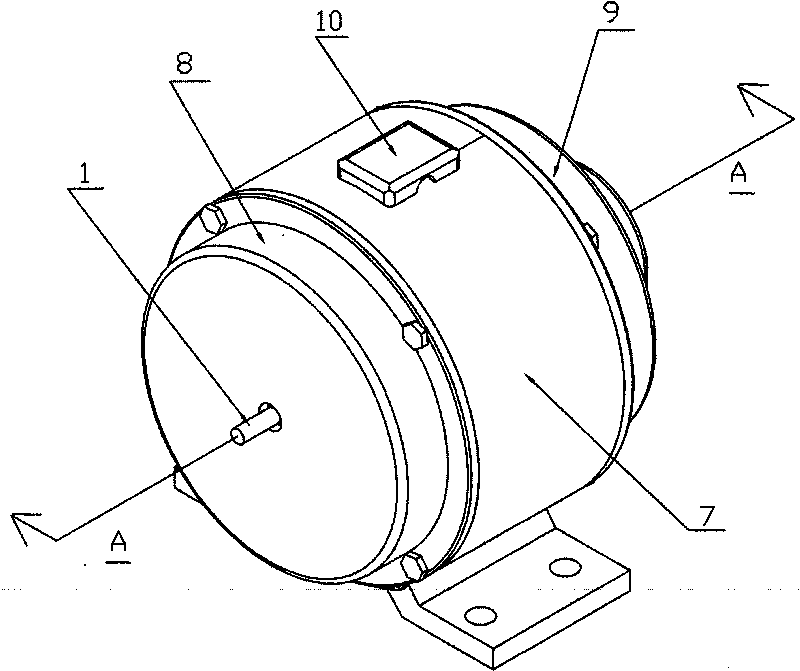

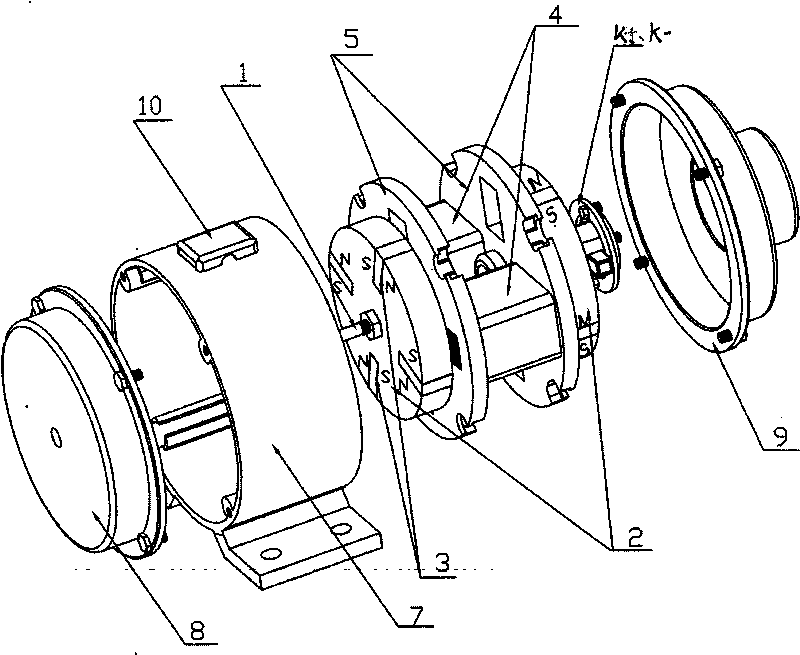

Self-inductance DC (Direct Current) magnetic-dynamic method and device

The invention relates to a self-induction DC magnetic-dynamic method and device. The method is characterized in that more than two attracted permanent magnet blocks are evenly arranged around a rotor support along a rotation shaft; the south and north poles of the attracted permanent magnet blocks are located on the tangents of the circumferences and the directions of the magnetic poles of all attracted permanent magnet blocks are the same; more than one electromagnet is evenly arranged along the direction of the circumference of the side surface of the rotor support; the directions of the magnetic poles of the electromagnets are parallel to the axes of the rotation shaft; the positive power input ends of the electromagnets are connected with the negative pole of a diode; and the positive pole of the diode and the negative power input ends of the electromagnets are connected with a power storage unit or a power consumption unit. Compared with the prior art, the invention has the advantages of simple structure, easy control of operation, high use ratio of electric energy, and large kinetic energy converted from permanent magnetic energy.

Owner:邓金茂

Method for removing nitrite ions

InactiveCN101948388BDoes not affect product qualityNo follow-upOrganic chemistryOrganic compound preparationNitrite ionNitrate

The invention belongs to the technical field of environment protection, particularly relating to a method for removing nitrite ions. The method comprises the following steps: adding nitrified crude containing the nitrite ions into water to be fully stirred, or adding waste water containing the nitrite ions into water to be fully stirred; measuring the content of nitrous acid and nitric acid in an aqueous phase layer or waste water; and adding sulfamic acid into the aqueous phase layer or the waste water to cause the molar ratio of total amount of nitrous acid and nitric acid to sulfamic acid to be 1:1-1.5, wherein stirring time is at least 0.5 hour. The method breaks the nitrite ions generated by nitrification, neutralization and washing with sulfonamides so as to solve the technical problems that the original neutralization-urea washing-rinsing technology has high nitrite ion content in nitrate and can not reach the requirements of products, and waste water amount generated by multiple washing is large, is easy to pollute environment and the like.

Owner:ZHEJIANG KANGFENG CHEM

Built-in vortex combustion device and combustion system for disposing RDF through cement decomposing furnace

PendingCN114484423APromote combustionIncrease temperatureFluidized bed combustionApparatus for fluidised bed combustionCombustion systemThermodynamics

The invention discloses a built-in vortex combustion device and a combustion system for disposing RDF through a cement decomposing furnace. The built-in vortex combustion device comprises a first barrel and a second barrel, and the second barrel is connected to the upper portion of the first barrel and communicates with the first barrel; the second barrel is of a cylindrical structure with a volute, and a plurality of tertiary air inlets are evenly distributed in the rotary cutting line of the volute. A plurality of RDF feeding ports are formed in the top surface of the second barrel; and a preheated raw material feeding opening is formed in the top surface of the second barrel body and is positioned on the outer side of the tertiary air inlet. The RDF can be in a suspended state in the vortex combustion device, the combustion speed is far higher than stacking combustion, the vortex combustion device is arranged to be of a built-in structure, and tertiary air does not need to be introduced independently.

Owner:SINOMA INT ENG

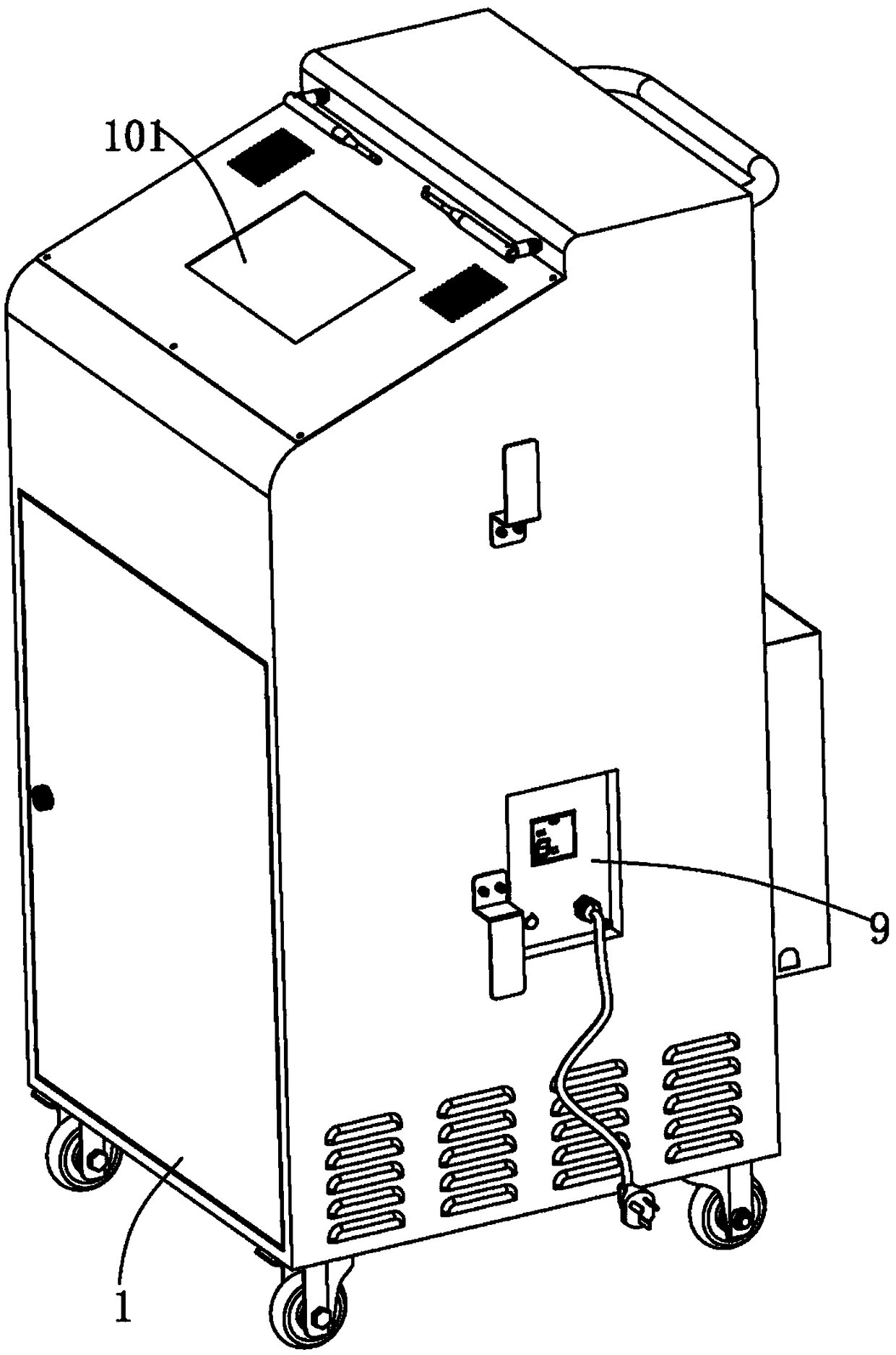

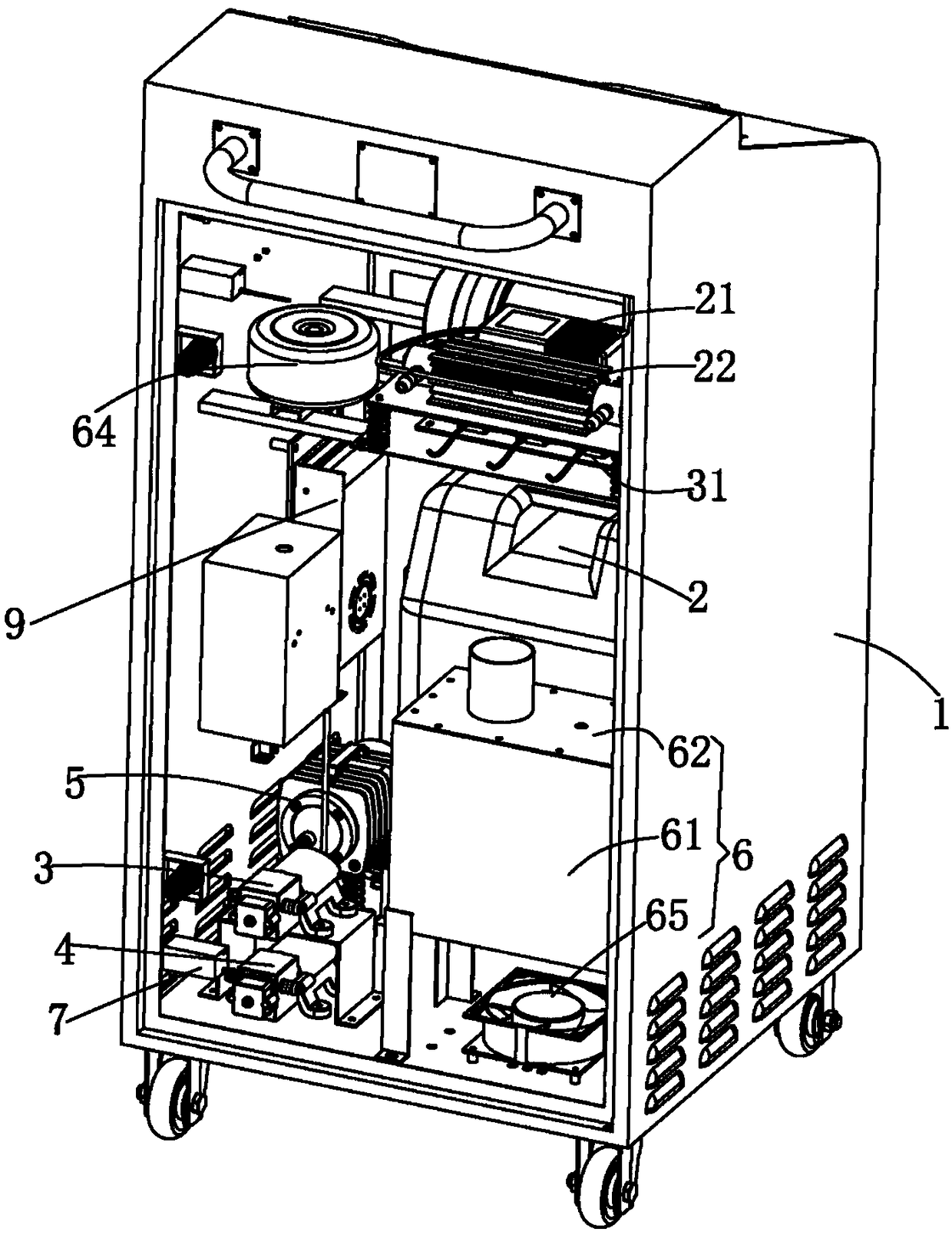

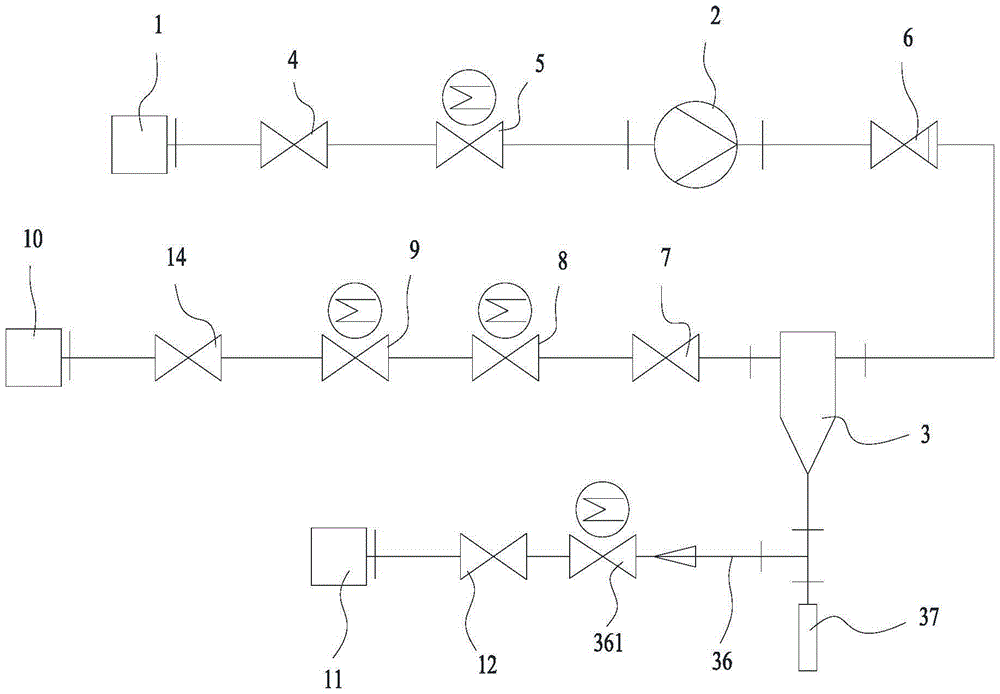

Automobile indoor environment comprehensive treatment equipment and control method

PendingCN108859676ARealize fully automatic comprehensive managementControllable operationAir-treating devicesGaseous substancesLiquid storage tankAutomobile air conditioning

The invention discloses automobile indoor environment comprehensive treatment equipment and a control method. The treatment equipment comprises an equipment cabinet, a control unit used for controlling equipment to work, an ozone unit used for generating ozone and conveying the ozone to a treatment liquid mixing unit, an anion unit used for generating anion air and conveying the anion air to the treatment liquid mixing unit, and the treatment liquid mixing unit comprising a liquid storing tank, a recycling pump, a filling pump, an inflating pump and an atomizing assembly, wherein the liquid storage tank is used for storing treatment liquid; the recycling pump is used for pumping the treatment liquid / residual liquid in an atomizing box to the liquid storing tank; the filling pump is used for pumping the treatment liquid in the liquid storing tank to the atomizing box and cooperating with the recycling pump to complete the stirring for the treatment liquid; the inflating pump is used forblowing ozone and anions to the atomizing box; the atomizing assembly can atomize the treatment liquid, mix the atomized treatment liquid, the ozone and the anions into sterilization gas, and conveythe sterilization gas to an air pipe communicated with the inside of the automobile chamber and / or an automobile air conditioning system.

Owner:广东车安达股份有限公司

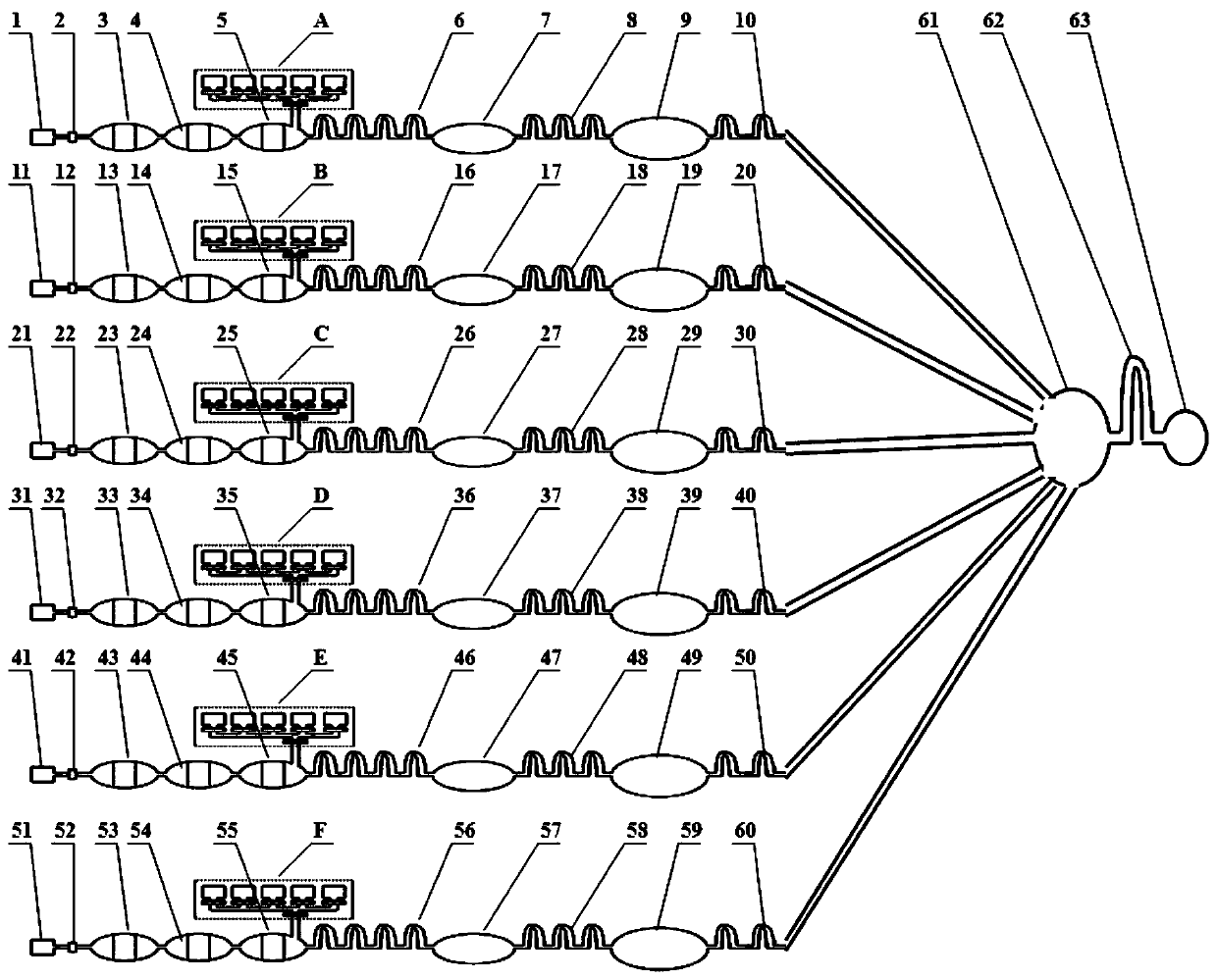

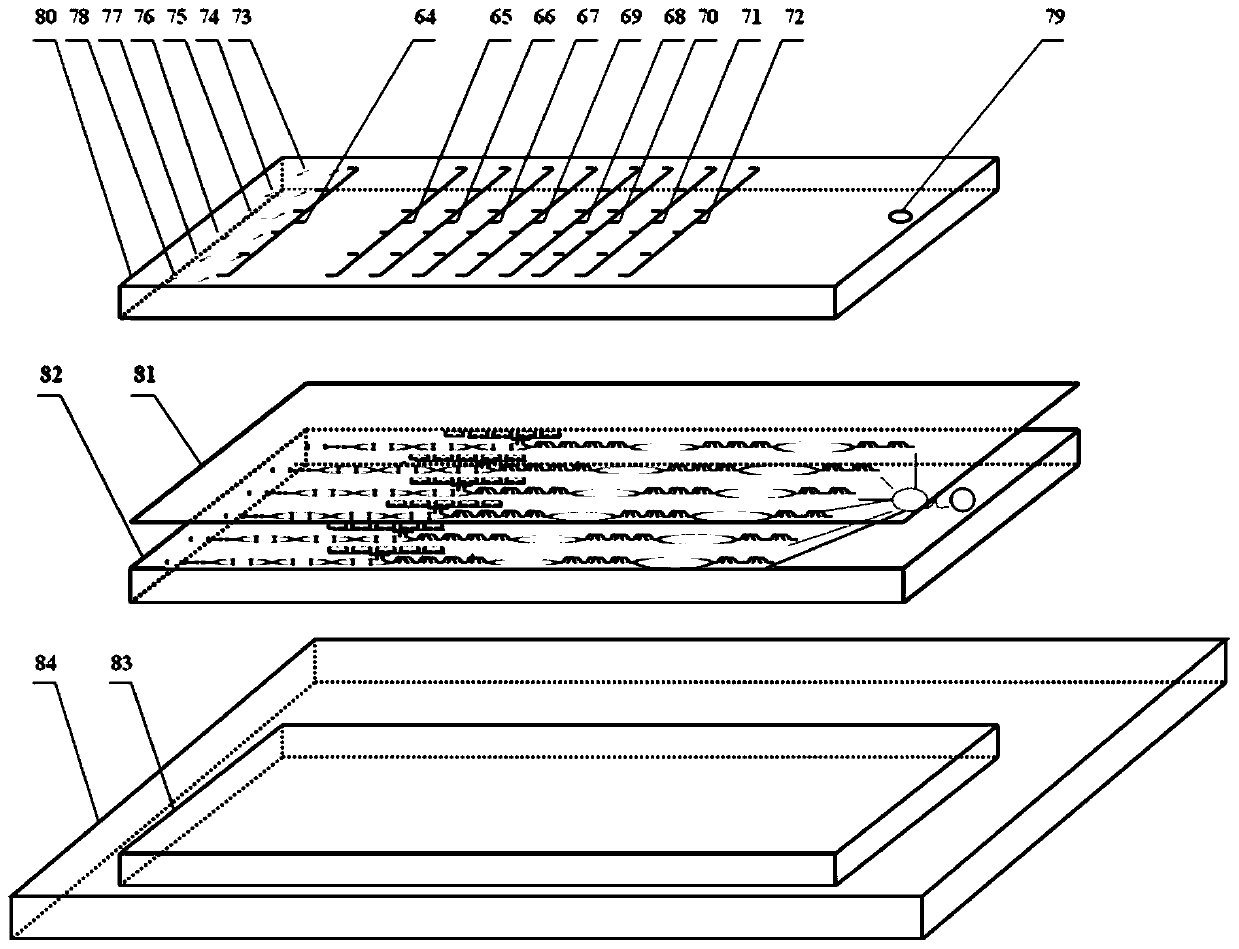

A microfluidic chip for detecting blood-related proteins in Alzheimer's disease associated with depression, its preparation method and application

InactiveCN108745426BEasy to handleNo interferenceLaboratory glasswaresBiological testingDiseaseWhite blood cell

The invention discloses a microfluidic chip for detecting blood related proteins of Alzheimer's disease accompanied by depression and a preparation method and application thereof. The microfluidic chip aims at the deficiencies of existing detection methods, and the microfluidic chip comprises a white blood cell filter pool, a red blood cell filter pool and a platelet filter pool. The microfluidicchip can be used to directly test a blood sample without the need of blood centrifuging to obtain serum for detection. In addition, by setting an independent microfluidic detection unit, detected related proteins do not interfere with each other. At the same time, a magnetic control valve is arranged in the chip, and the synchronization and automation of the detection can be realized by controlling a switch of an electromagnetic conversion instrument. The microfluidic chip has the advantages such as simple sample processing, short detection time, low price, controllable operation, and automatic detection.

Owner:QIQIHAR MEDICAL UNIVERSITY

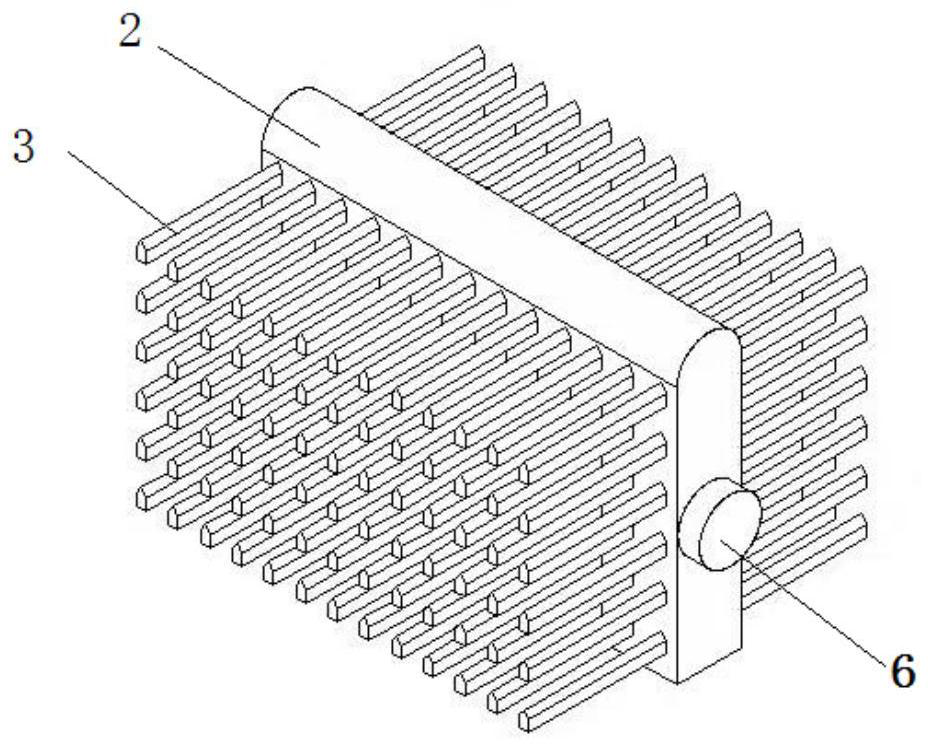

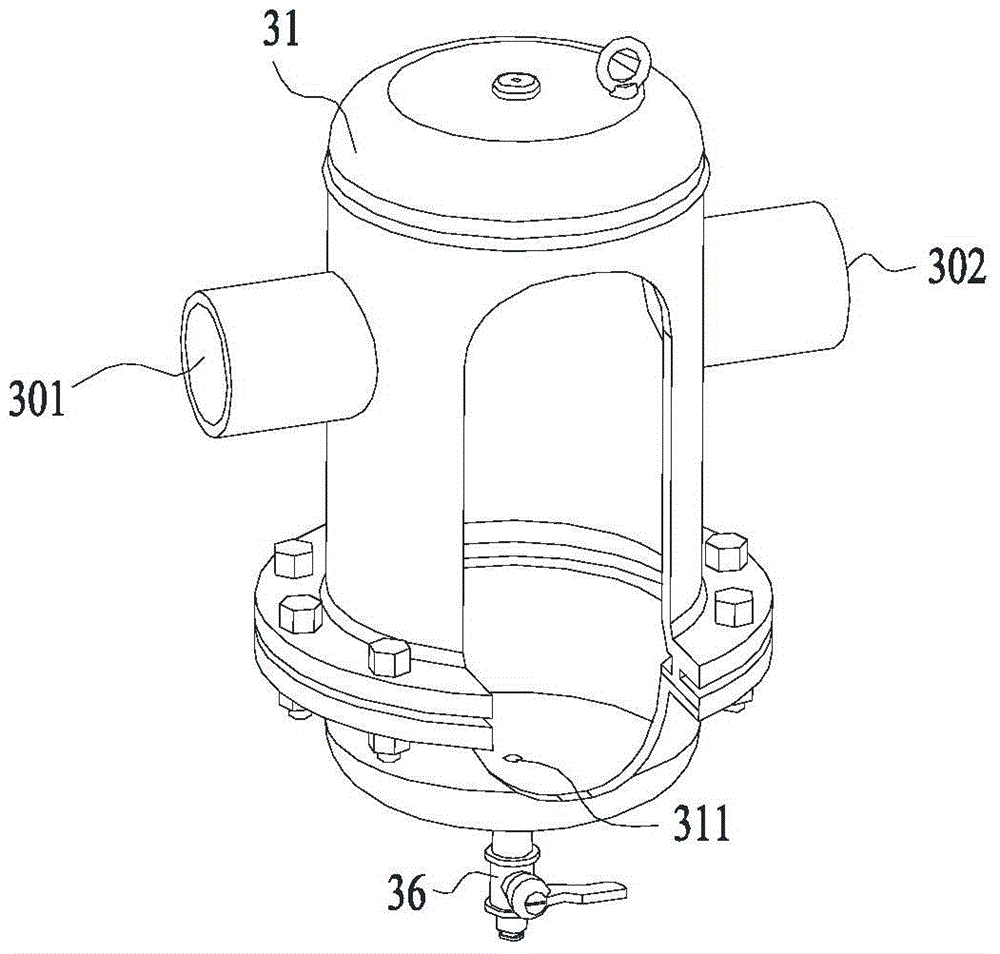

Circulating water filter

InactiveCN104785008BControllable operationEfficient filtering effectMoving filtering element filtersCouplingWater filter

The invention discloses a circulating water filter. The circulating water filter comprises a first quick coupling, a water pump, a filter and a second quick coupling, which are connected in sequence through a pipeline, wherein the filter comprises a relatively closed shell, a cylinder which is pivoted in the shell and a plurality of spiral strips which are spirally coiled on the cylinder; a filter inlet and a filter outlet are formed in the side wall of the shell; the filter inlet and the filter outlet are coaxial; the filter inlet is communicated with the water pump; the filter outlet is communicated with the second quick coupling; a drain outlet which is connected with a drain pipe is formed in the bottom wall of the shell; a first electromagnetic valve is arranged on the drain pipe; a conductometer which is used for detecting the conductivity of the water in the shell is arranged on the side wall of the shell on one side of the drain outlet; the conductometer is in communication connection with the first electromagnetic valve. The circulating water filter is easy to maintain and strong in filter capability.

Owner:广州蓝水环境设备科技有限公司

A connector crimping device

ActiveCN110391570BImprove consistencySemi-automaticCoupling device connectionsLine/current collector detailsEngineeringRetaining Pin

The invention discloses a connector crimping device, comprising: a pressing mechanism, which provides a pressing force within a set stroke, and the pressing mechanism is provided with a pressing moving part; The thickness is set to the corresponding stroke of the pressing mechanism; the crimping mechanism includes an upper crimping needle block and a lower fixing seat, the lower end of the upper crimping needle block is provided with a pressing needle, and the upper crimping needle block It is arranged at the lower end of the press-down moving part, and is used for driving the press-down moving part to pass through the fixing pin on the connector of the board card positioned on the lower fixing seat below the pressing pin Make a crimp. The invention can well meet the requirements of the same equipment for crimping connectors of various specifications, and at the same time can realize semi-automatic and controllable operation, and has very high consistency and traceability.

Owner:SHANGHAI NCATEST TECH CO LTD

A solid-liquid separation and manure cleaning device for livestock and poultry breeding

The invention provides a livestock and poultry breeding solid-liquid separation excrement cleaning device. The livestock and poultry breeding solid-liquid separation excrement cleaning device comprises an annular excrement collecting box; an excrement scraping plate is installed in the annular excrement collecting box; the excrement scraping plate is directly connected with a power driving mechanism or is connected with the power driving mechanism through a connecting piece; the excrement scraping plate is driven by the power driving mechanism to rotate around the annular excrement collecting box; the bottom plate of the annular excrement collecting box is an inclined plate; the lowest point of the inclined plate is located at the middle of the bottom plate; an urine discharging opening is formed at the middle of the bottom plate; and a solid excrement outlet is formed at the bottom plate of the annular excrement collecting box. According to the livestock and poultry breeding solid-liquid separation excrement cleaning device of the invention, after excrement falls into the annular excrement collecting box, solid-liquid separation of the excrement can be realized; solid excrement and liquid excrement are separately collected through different pipelines; the solid excrement is directly treated and is packaged; and the liquid can be adopted as secondary water after being purified; and therefore, excrement treatment procedures can be decreased, and treatment cost can be decreased, and underground space can be greatly saved. The livestock and poultry breeding solid-liquid separation excrement cleaning device of the invention is reasonable in integral design. The driving mechanism is arranged on the excrement scraping plate. The livestock and poultry breeding solid-liquid separation excrement cleaning device is especially suitable for annular comprehensive cultivation buildings and can realize fast and convenient solid-liquid separation treatment.

Owner:姜伟

Cargo carrying robot and carrying method thereof

InactiveCN113715056AAvoid damageImprove the safety of useManipulatorControl engineeringStructural engineering

The invention discloses a cargo carrying robot and a carrying method thereof, and belongs to the technical field of carrying device. The cargo carrying robot comprises a cargo carrying robot body, a damping mechanism is installed on the surface of the top of the cargo carrying robot body and composed of a bottom plate, damping springs and a top plate, and a bracket is installed on the surface of the top of the damping mechanism; and warning mechanisms are installed in the middles of the peripheral surfaces of the outer wall of the cargo carrying robot body, each warning mechanism is composed of a protection box, a storage battery, an LED warning lamp, a buzzer and a switch, and a smoke alarm is installed at one side of the surface of the outer wall of the cargo carrying robot body. According to the cargo carrying robot, damage to the cargo carrying robot body caused by impact force of cargos on the bracket can be relieved through the damping mechanism, then the use safety of the cargo carrying robot body is improved, and the functionality and safety of the cargo carrying robot body during use can be improved through the warning mechanisms and the smoke alarm.

Owner:江苏力宝达机器人有限公司

Device and method for curing and flattening glue-free soft plate material

The invention discloses and provides a device for curing and flattening a glue-free soft plate material, which has the advantages of simple structure, reduction in production cost and superior flatness of a manufactured product, and provides a method for curing and flattening a glue-free soft plate material by applying the device. The device comprises a rewinding machine and a metal heat-conducting plate (1), wherein steel belts (2) are arranged at the two ends of the lower surface of the metal heat-conducting plate (1), and are provided with fine holes (3); in a production process, a soft plate material (4) is attached to the upper surface of the metal heat-conducting plate (1); the metal heat-conducting plate (1) and the soft plate material (4) are tightly coiled on a steel pipe (5) of the rewinding machine for curing; and in a curing process, the soft plate material (4) is always attached to the metal heat-conducting plate (1), and is limited from moving through the metal heat-conducting plate (1), so that flatness is achieved. The device is applied in the field of material flattening.

Owner:江西优钛新材料科技有限公司

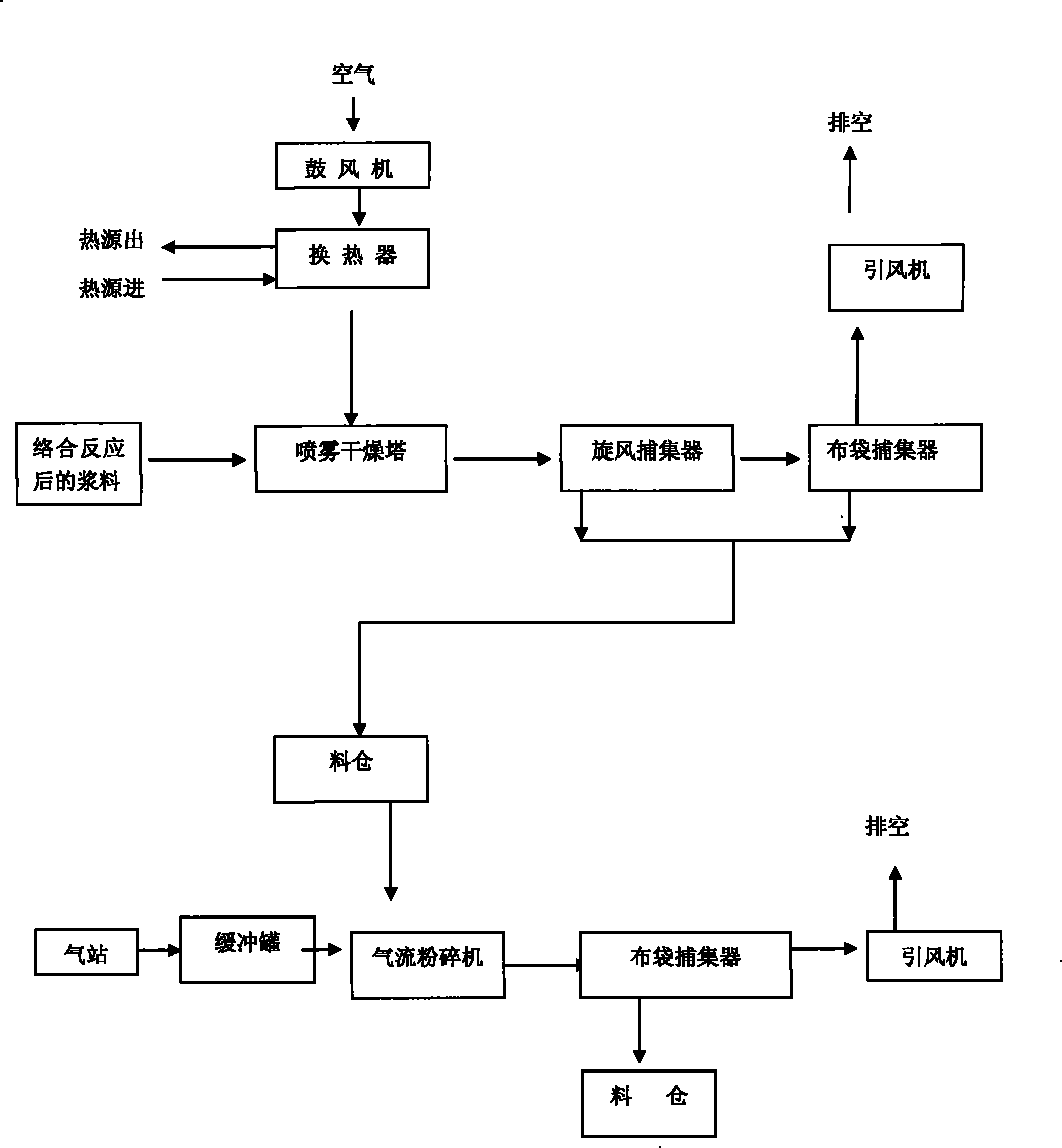

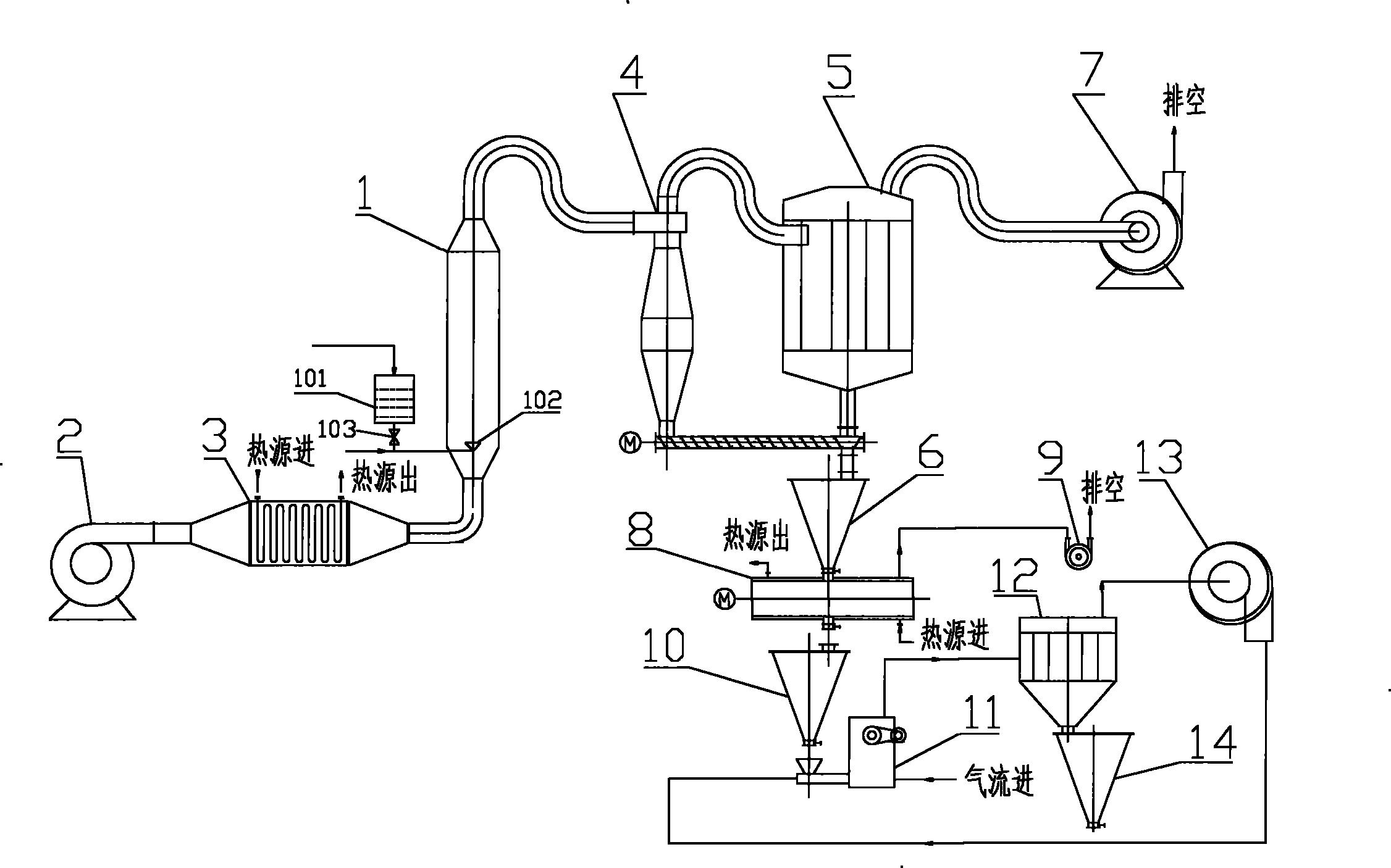

Method and device for drying complex mancozeb

ActiveCN101543681BGuaranteed uptimeControllable operationBiocideDrying using combination processesPulp and paper industryTower

The invention discloses a method and a device for drying complex mancozeb. The method for drying complex mancozeb mainly adopts a two-stage drying and closed recirculation air stream pulverization process. Sizing agent undergone complex reaction is atomized after entering an atomizing and drying tower and exchanges thermal mass with hot air; dried sizing agent is collected by a cyclone receiver and a first cloth bag collector, the collected dried sizing agent is temporarily stored after being transferred to a transitional storage bin; the temporarily-stored dried sizing agent is dried after entering a vacuum dried so as to remove sizing agent crystallizing water under high vacuum so that sizing agent with the water content of less than 1 weight percent is obtained; the sizing agent entersa dried sizing agent storage bin; the dried sizing agent in the dried sizing agent storage bin uniformly enters an airflow mill to be milled to obtain complex mancozeb wettable powder, and dried air is led to the inlet of the airflow mill and mixed with the dried sizing agent from the dried sizing agent storage bin for reuse. The invention has the advantages of high complex mancozeb yield, low energy consumption, stable complex mancozeb quality and free from ambient air influence in the sizing agent milling process.

Owner:利民化学有限责任公司

Assembly line production cost real-time monitoring device and assembly line production cost diagnosis method

InactiveCN103645720BReal-time discovery and resolution of production cost anomaliesControllable operationTotal factory controlProgramme total factory controlData displayAssembly line

The invention provides an assembly line production cost real-time monitoring device and an assembly line production cost diagnostic method. The assembly line production cost real-time monitoring device comprises an assembly line parameter setting assembly, a feeding information collecting assembly, a qualified product collecting assembly, a defective product information collecting assembly, a cost computing assembly and a cost feedback assembly. The assembly line production cost diagnostic method comprises that an assembly line parameter setting assembly is set according to operational parameters of a plurality of assembly lines in an industry; the feeding information collecting assembly, the qualified product collecting assembly and the defective product information collecting assembly collect related data and send to the cost computing assembly; the cost computing assembly is triggered to perform cost computing at a cost computing trigger time point and sends a cost computing result to the cost feedback assembly; the cost feedback assembly performs warning on caution items and data display according to the computing result of the cost computing assembly.

Owner:SHANGHAI DIANJI UNIV

A Method to Quickly Stop Underpickling Defects

Owner:TANGSHAN IRON & STEEL GROUP +1

A kind of volatile organic compound treatment system and process

ActiveCN111467885BImprove processing efficiencyImprove adsorption capacityGas treatmentDispersed particle filtrationMolecular sievePtru catalyst

For ultra-low concentration, the mainstream treatment process of organic waste gas with large air volume has disadvantages such as high equipment investment, high operating cost, and large land occupation. The invention discloses a VOCs adsorption-plasma catalytic regeneration device, a treatment system and a process. The adsorption-plasma catalytic regeneration device includes a gas tank, a plasma discharge unit and an adsorption / catalyst unit. The plasma discharge unit includes a plasma pulse power supply and a flat plate discharge structure. The adsorption / catalyst unit is placed between the discharge electrodes and adopts a three-stage design, namely, a high-efficiency adsorption catalytic section, a buffer section, and a medium-efficiency adsorption catalytic section. The high-efficiency adsorption catalysis section is filled with molecular sieves modified by precious metals; the buffer section is hollow; the medium-efficiency adsorption catalysis section is filled with ordinary metal-loaded molecular sieves. The whole device realizes the integration of adsorption, desorption and treatment units, which simplifies the treatment system. The whole process is controlled by PLC to achieve continuous and stable operation for 24 hours and efficiently remove VOCs.

Owner:ZHEJIANG UNIV OF TECH

Dyestripping method, dyestripping device and dyestripping equipment

ActiveCN102064087BReduce usageEnsure safetySemiconductor/solid-state device manufacturingEngineeringElectrical and Electronics engineering

The invention discloses a dyestripping method. The dyestripping method is characterized in that film edges are separated from a substrate attached with the film edges; and a first fixture is used to clamp the film edges, and the first fixture is moved to gradually separate the film from the substrate attached with the film until the film and the substrate attached with the film are completely separated. The invention provides a novel dyestripping method which is as follows: a mechanical device is used for dyestripping in no need of using consumption materials such as tapes or films and the like, thereby reducing the use of consumable articles and effectively reducing the cost; and a dyestripping device can be recycled, thereby saving the cost of dyestripping. In the dyestripping device, dyestripping operation is simple and practicable, the success rate is high, the film on a wafer can be safely torn, thus the phenomenon that the tape can not be adhered with the film so that the film can not be torn is not occur; in the process of dyestripping, the operation of parts in the dyestripping device is easy to control, the precision is easy to handle, and the wafer can not be touched by the dyestripping device, thereby effectively avoiding the wafer is damaged and ensuring the safety of the wafer; and the dyestripping process is safe and reliable.

Owner:上海技美科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com