Built-in vortex combustion device and combustion system for disposing RDF through cement decomposing furnace

A kind of combustion device, built-in technology, applied in the direction of burning fuel in molten state, fluidized bed combustion equipment, combustion type, etc., can solve the problems of large fluctuations in calorific value and ash content, high cost, slow combustion speed, etc., to achieve effective Conducive to the operation of the system, improve the scope of application, and improve the effect of disposal volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solutions of the present invention will be described in detail below in combination with specific implementation methods and accompanying drawings.

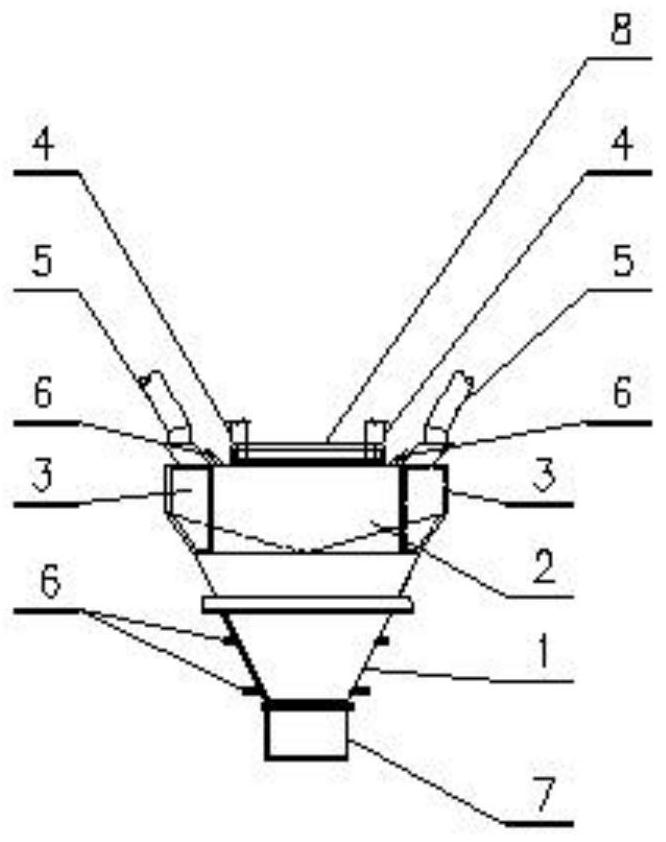

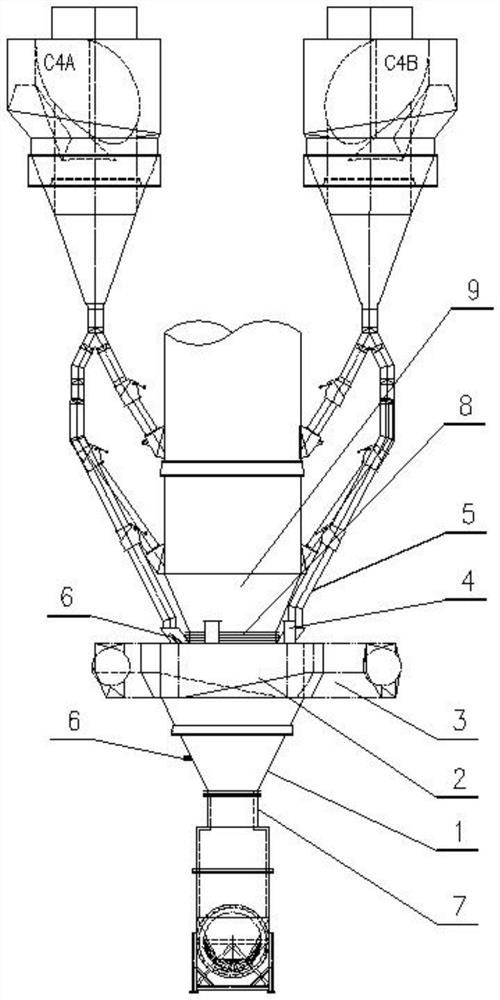

[0018] The calciner substitute fuel RDF completes drying, gasification and primary combustion in the built-in vortex combustion device of the present invention, and partially or completely replaces the fuel coal of the cement calciner. Such as figure 1 As shown, the built-in vortex combustion device of the present invention includes a first cylinder 1 and a second cylinder 2 , and the second cylinder 2 is connected above the first cylinder 1 and communicated with the first cylinder 1 . The outer shells of the first cylinder 1 and the second cylinder 2 are made of steel plates, and the inner linings are made of fire-resistant and heat-insulating materials, so as to improve the overall firmness and high-temperature resistance of the device. The second barrel 2 adopts a cylindrical structure with a volute, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com